Spare tire cover plate production method, and composite tool with heating function

A production method and the technology of the spare tire cover, which are applied in the production method of the spare tire cover and the field of composite tooling, can solve the problems of low initial adhesion, low heating efficiency, inconvenient operation of surface materials, etc., and achieve improved initial adhesion, Avoid the effect of glue opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

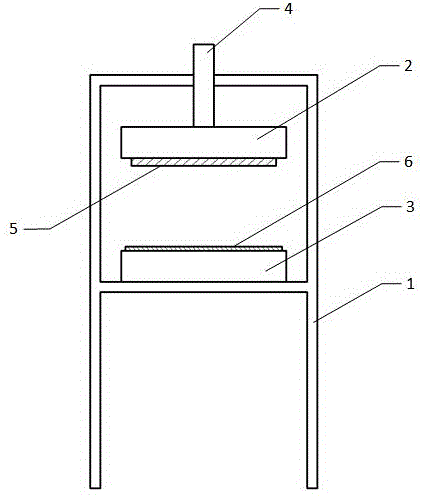

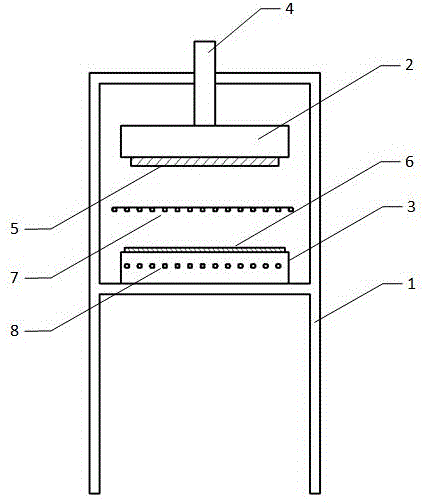

[0019] Such as figure 2 As shown, the composite tooling of the present invention includes a frame 1, an upper mold 2, and a lower mold 3. The upper mold 2 is installed on the frame 1 through a lifting device 4, and the lower mold 3 is directly installed on the frame 1. Between the upper mold 2 and the lower mold 3, a radiation heating device 7 that can enter and exit the frame is also provided, and the lower mold 3 is also provided with a cooling water pipe 8, which can be connected to cooling water.

[0020] In the fabric compounding process of the Great Wall CH071 spare tire cover, the surface material 6 sprayed with hot melt adhesive is prepared first, and the surface material 6 is laid on the lower mold 3 of the tooling, and the base plate 5 is installed on the upper mold 2 . The radiation heating device 7 enters between the upper and lower molds, heats the surface material 6 on the lower mold 3, softens and melts the hot melt adhesive, and then withdraws the radiation he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com