Patents

Literature

1228 results about "Radiation heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat can be transmitted through empty space by thermal radiation often called infrared radiation. This is a type electromagnetic radiation . No mass is exchanged and no medium is required in the process of radiation. Examples of radiation is the heat from the sun, or heat released from the filament of a light bulb.

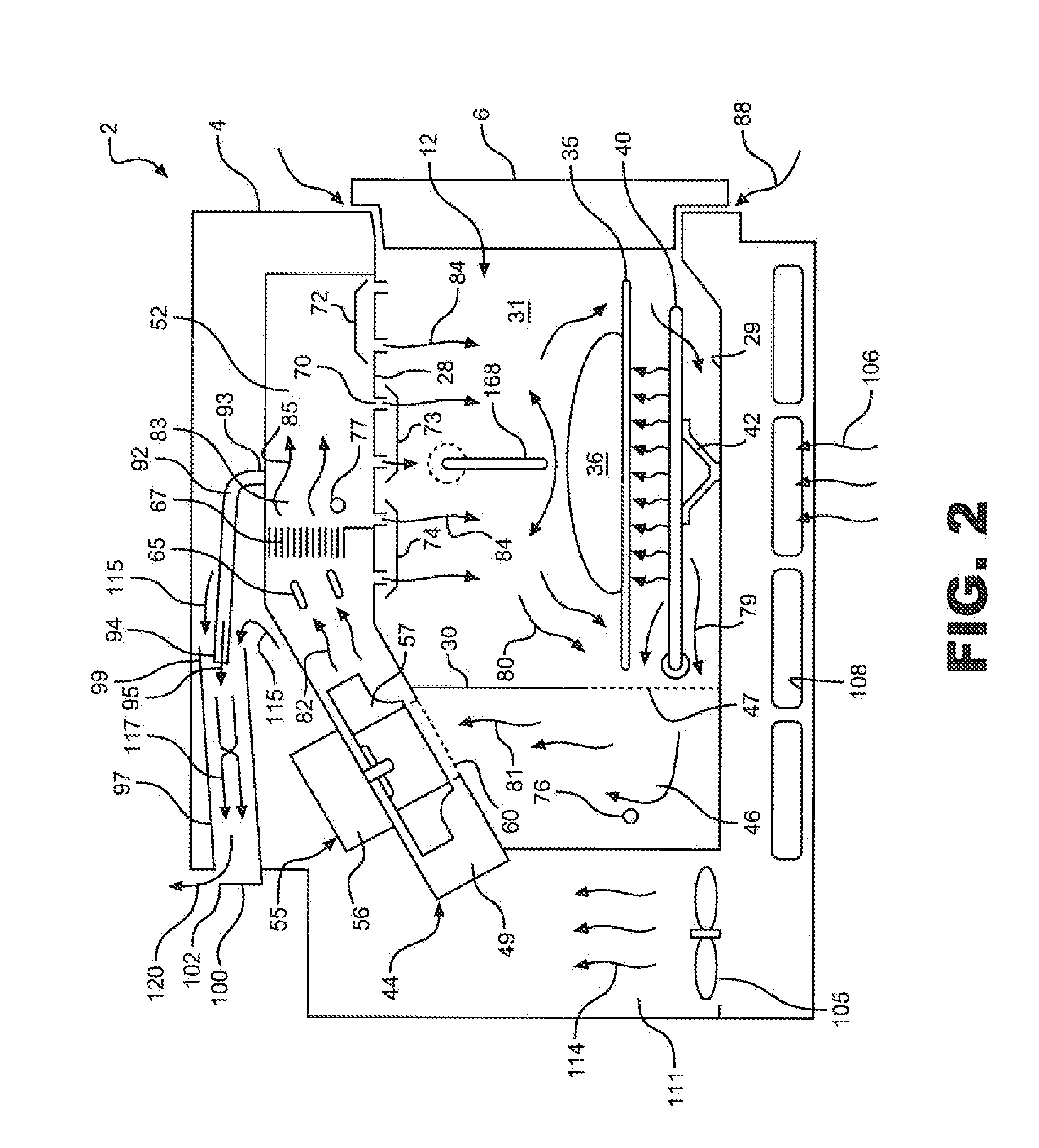

Increased tool utilization/reduction in mwbc for UV curing chamber

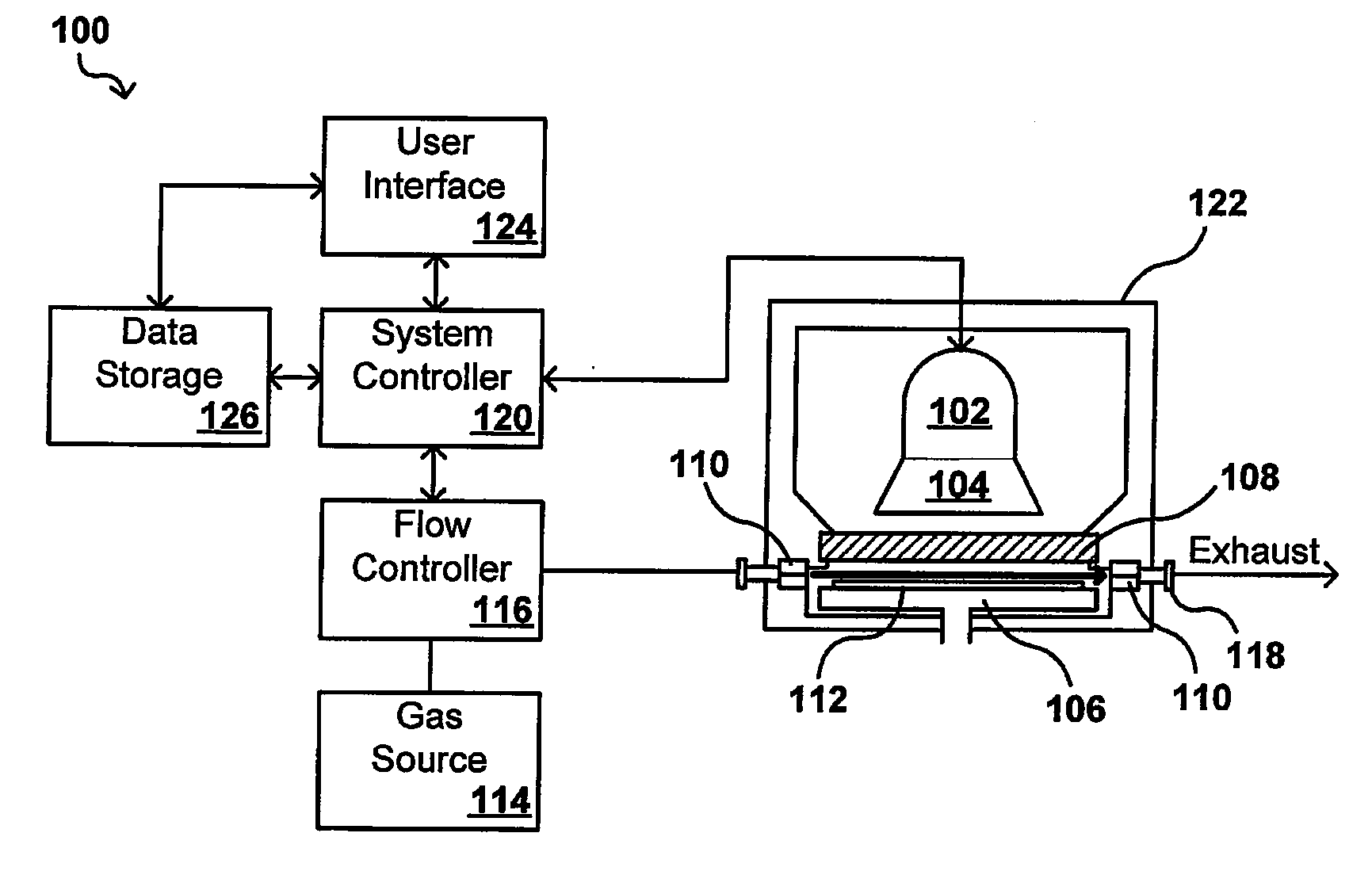

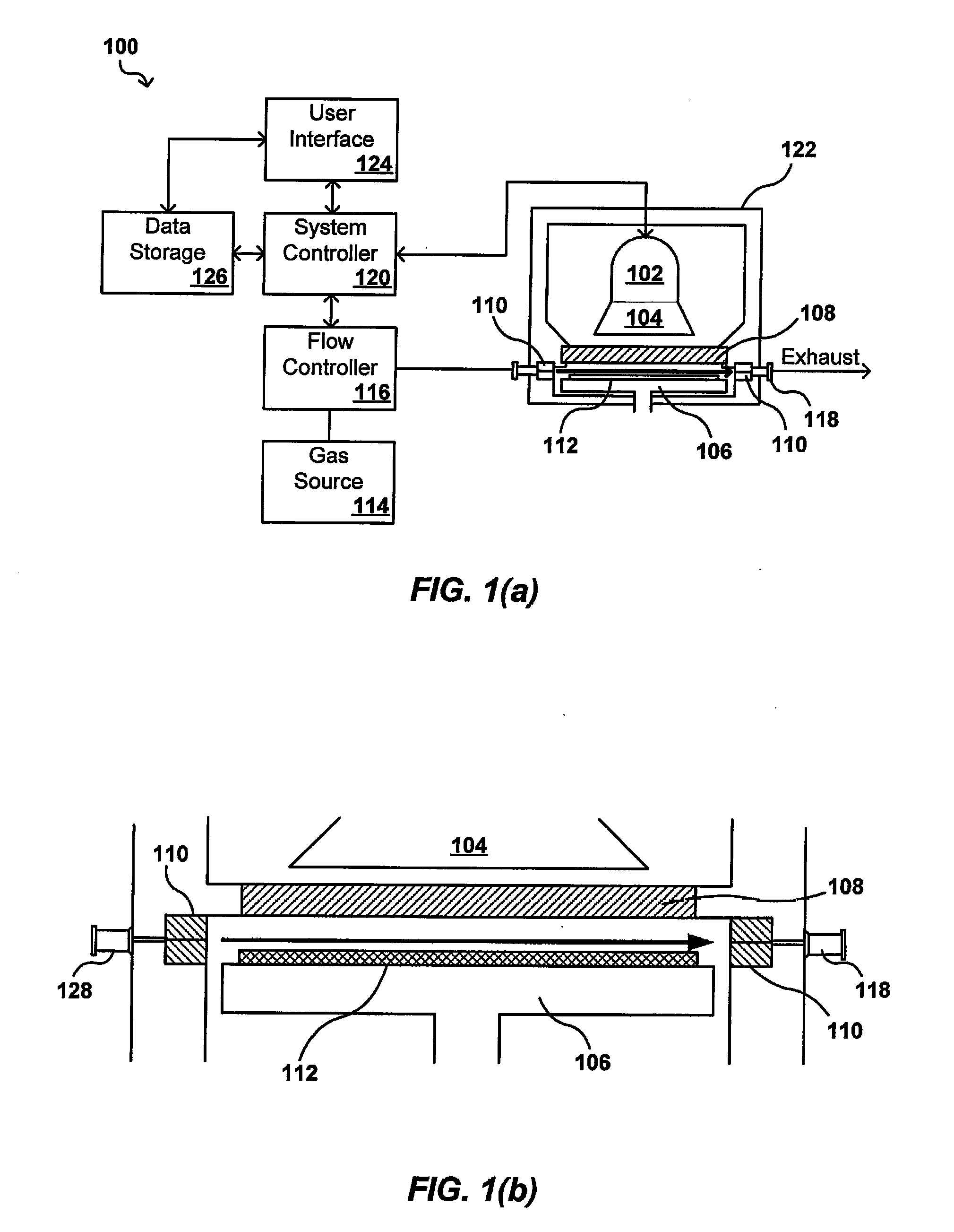

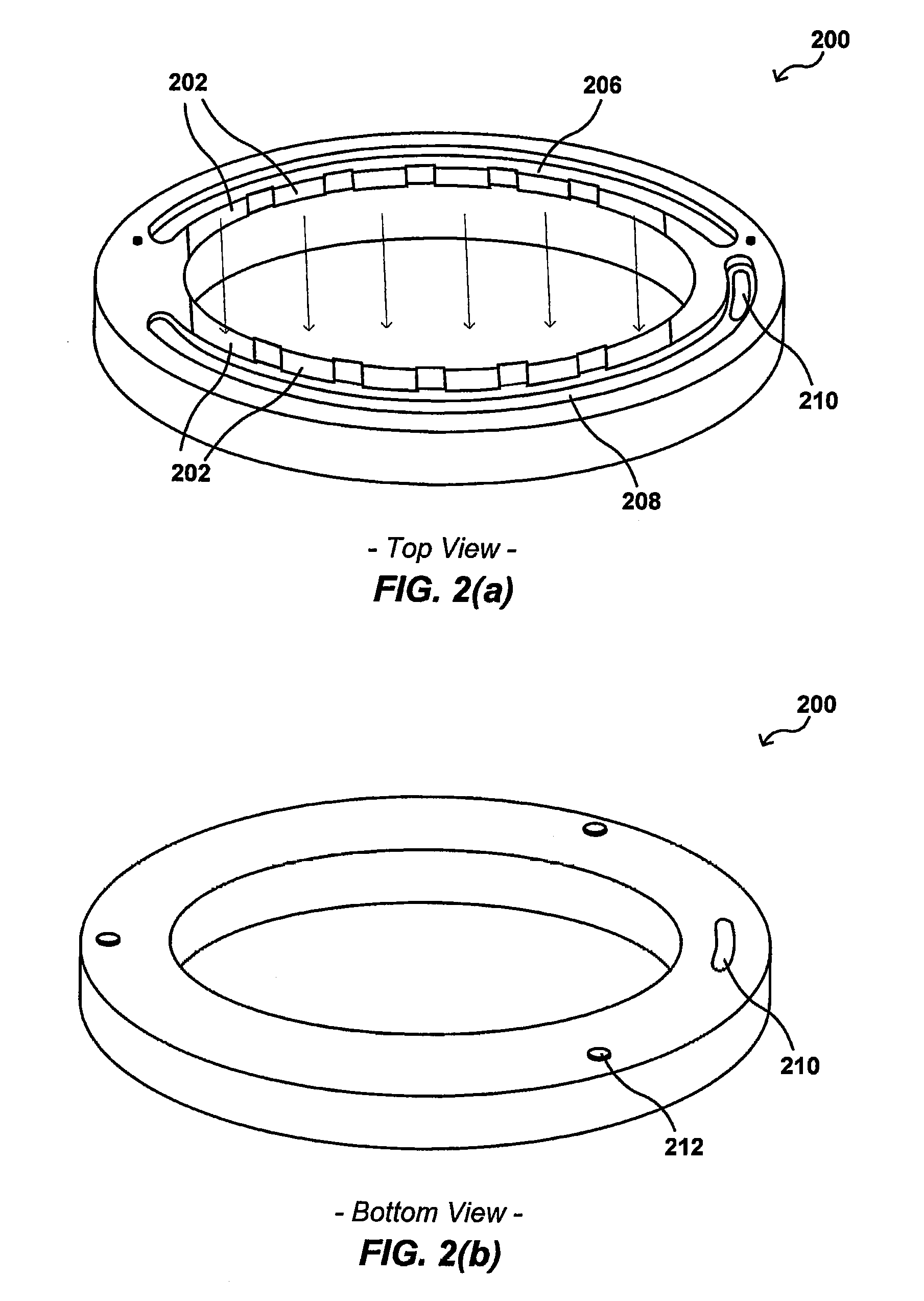

ActiveUS20070298362A1Avoid collectingHigh emissivitySemiconductor/solid-state device manufacturingCharge manipulationUV curingInjection port

A pump liner is used to direct a laminar flow of purge gas across a workpiece to remove contaminants or species outgassed or otherwise produced by the workpiece during processing. The pump liner can take the form of a ring having a plurality of injection ports, such as slits of a variety of shapes and / or sizes, opposite a plurality of receiving ports in order to provide the laminar flow. The flow of purge gas is sufficient to carry a contaminant or outgassed species from the processing chamber in order to prevent the collection of the contaminants on components of the chamber. The pump liner can be heated, via conduction and irradiation from a radiation source, for example, in order to prevent the condensation of species on the liner. The pump liner also can be anodized or otherwise processed in order to increase the emissivity of the liner.

Owner:APPLIED MATERIALS INC

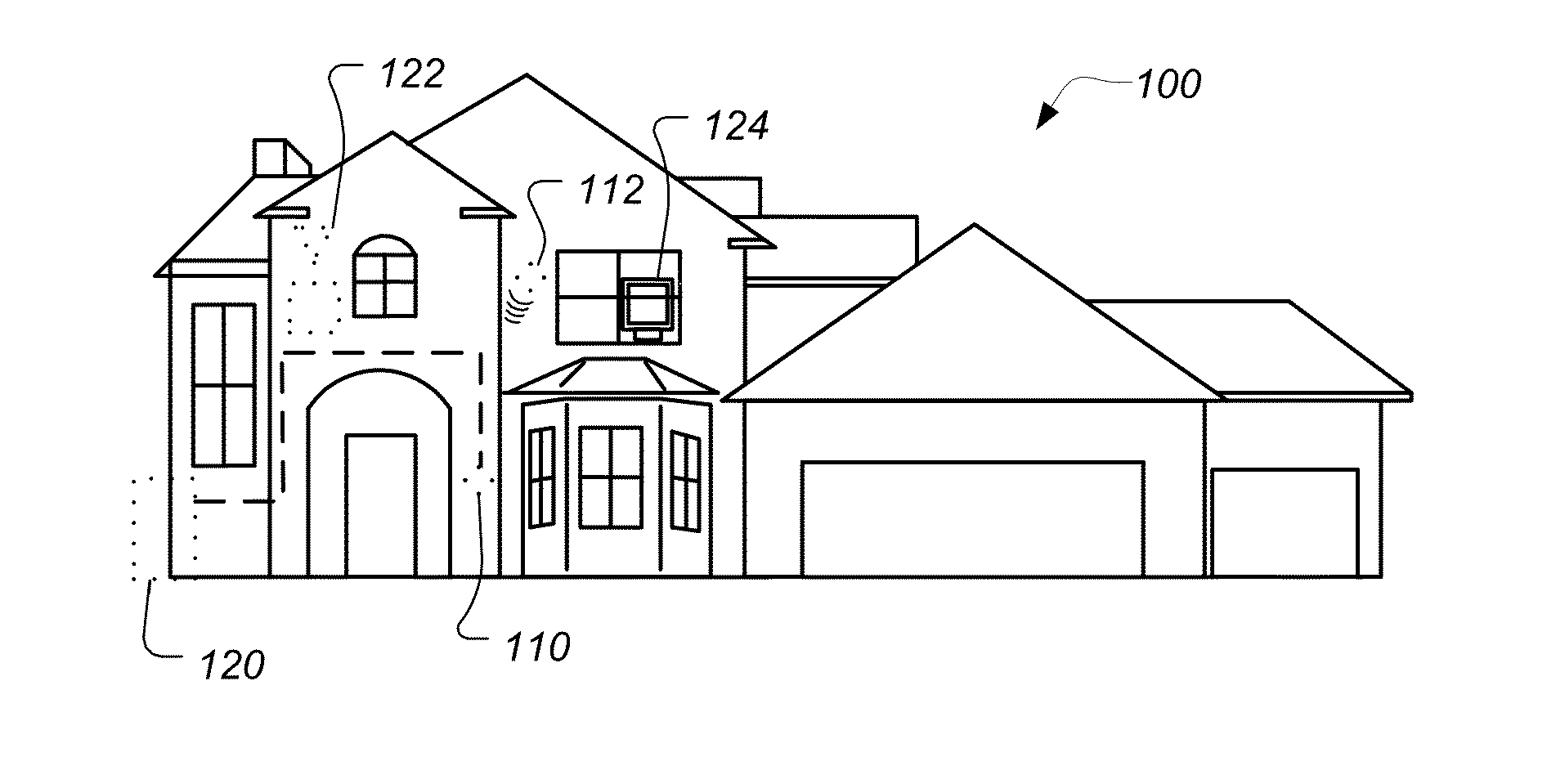

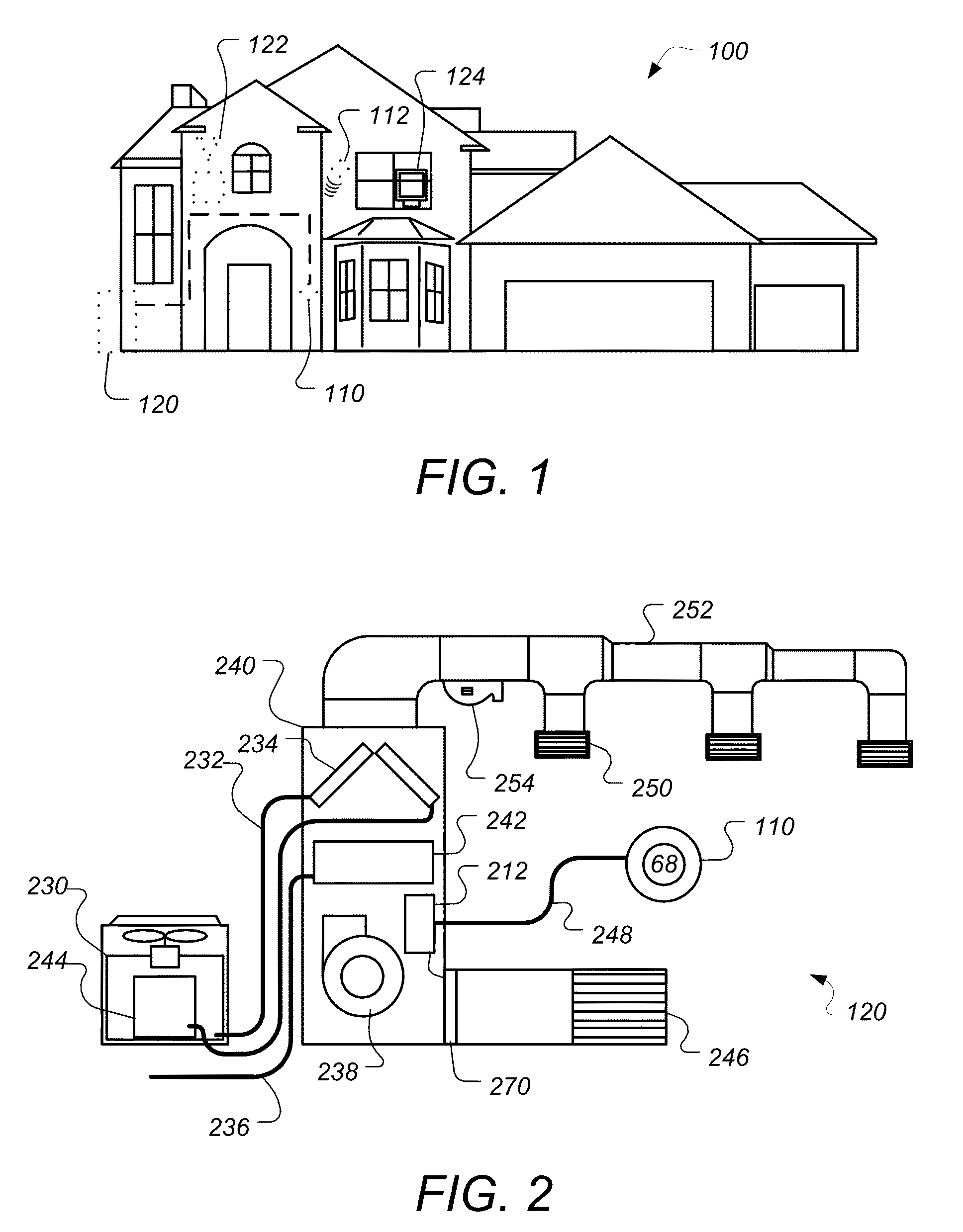

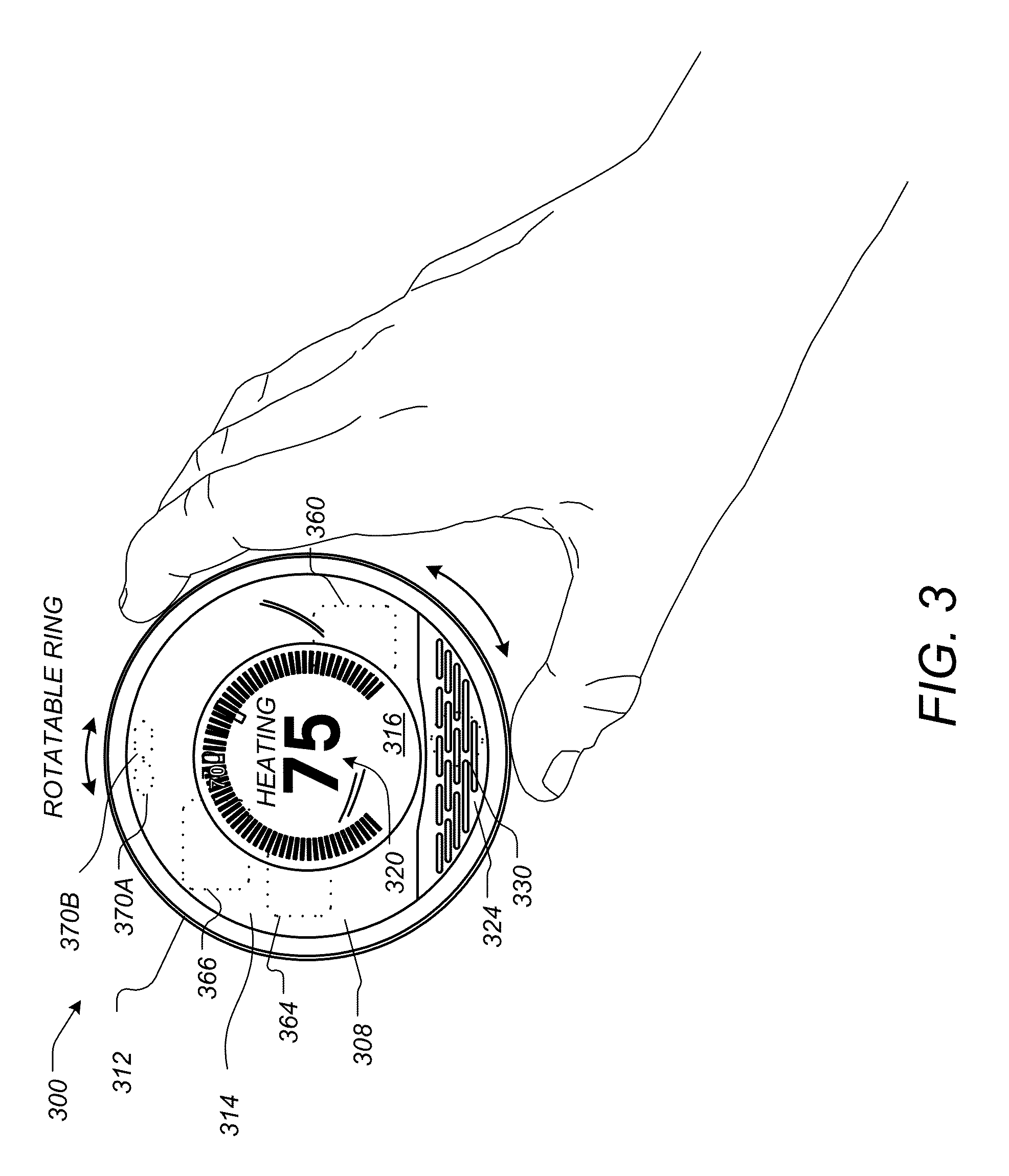

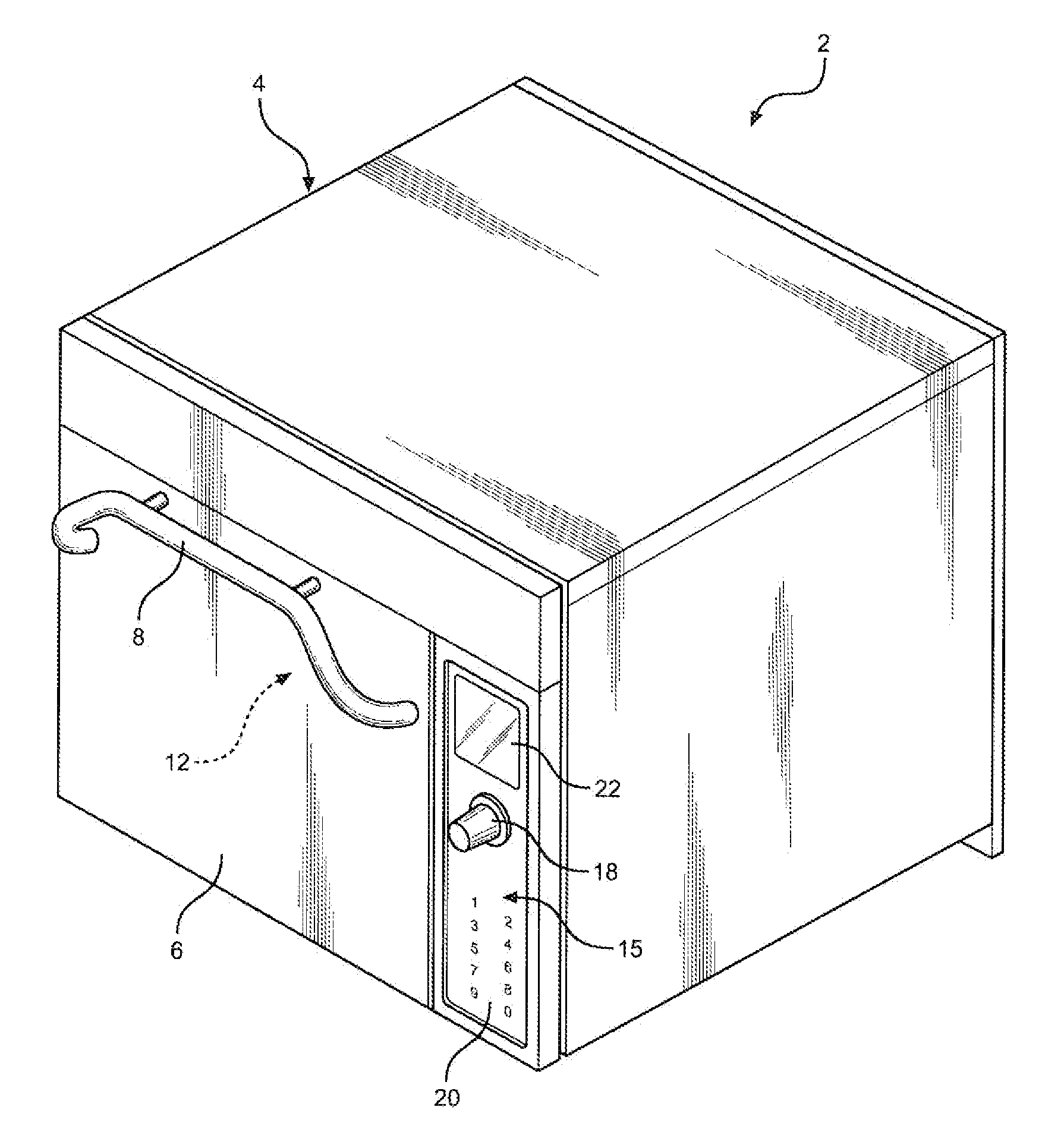

Radiant heating controls and methods for an environmental control system

ActiveUS8600561B1Function increaseIncrease valueMechanical apparatusStatic/dynamic balance measurementPrediction algorithmsOptimal control

Embodiments of the invention describe thermostats that use model predictive controls and related methods. A method of controlling a thermostat using a model predictive control may involve determining a parameterized model. The parameterized model may be used to predicted ambient temperature values for an enclosure. A set of radiant heating system control strategies may be selected for evaluation to determine an optimal control strategy from the set of control strategies. To determine the optimal control strategy, a predictive algorithm may be executed, in which each control strategy is applied to the parameterized model to predict an ambient temperature trajectory and each ambient temperature trajectory is processed in view of a predetermined assessment function. Processing the ambient temperature trajectory in this manner may involve minimizing a cost value associated with the ambient temperature trajectory. The radiant heating system may subsequently be controlled according to the selected optimal control strategy.

Owner:GOOGLE LLC

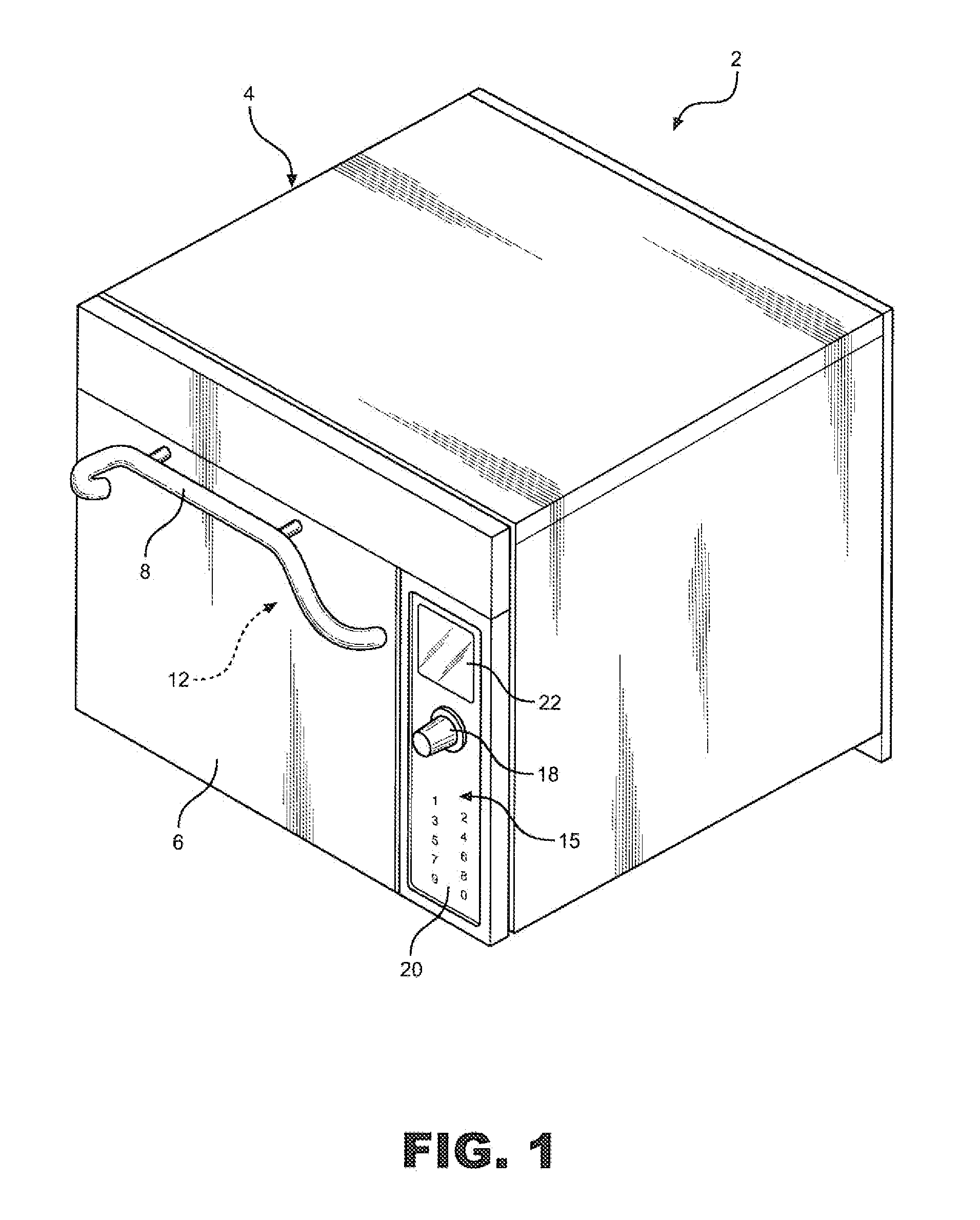

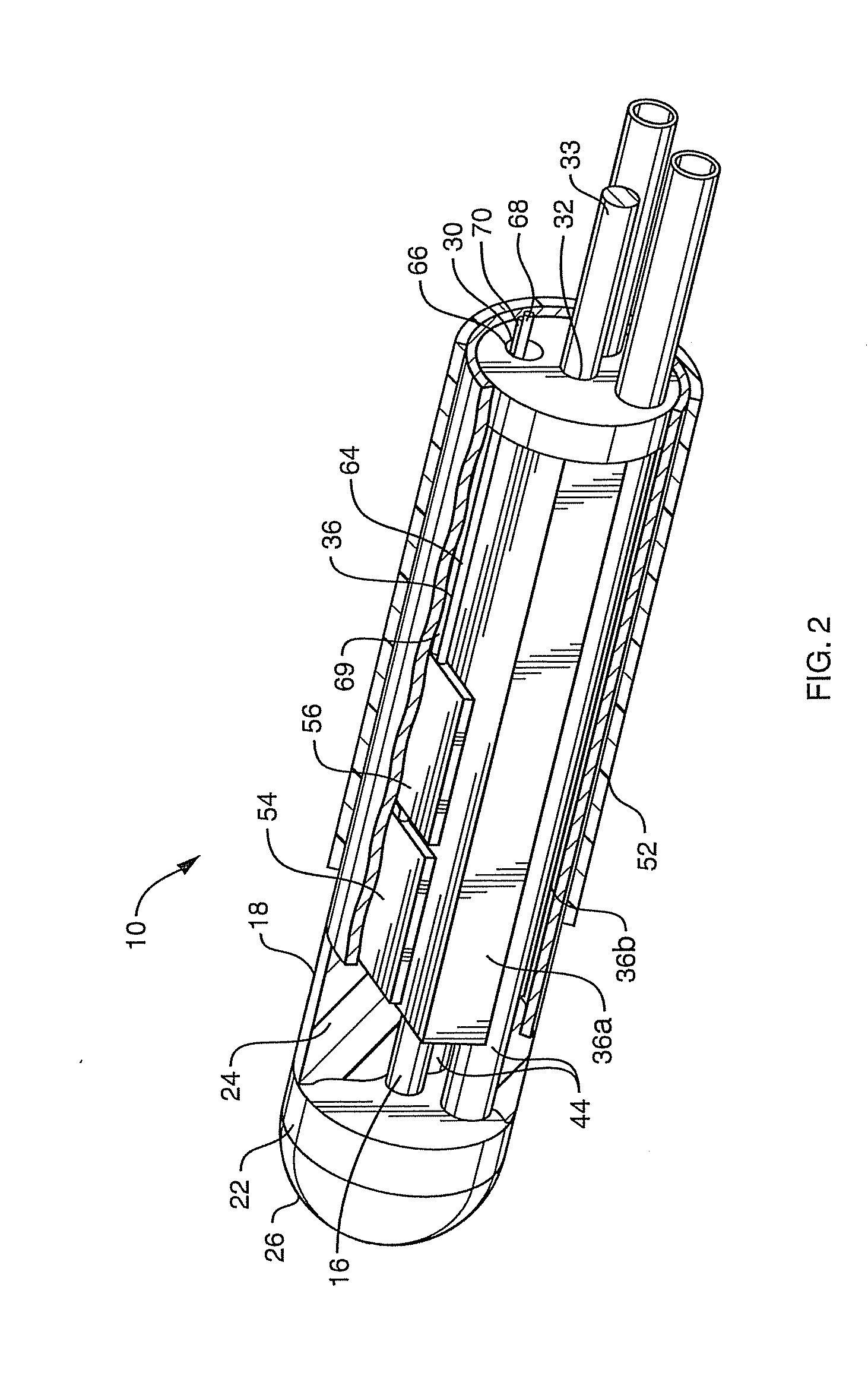

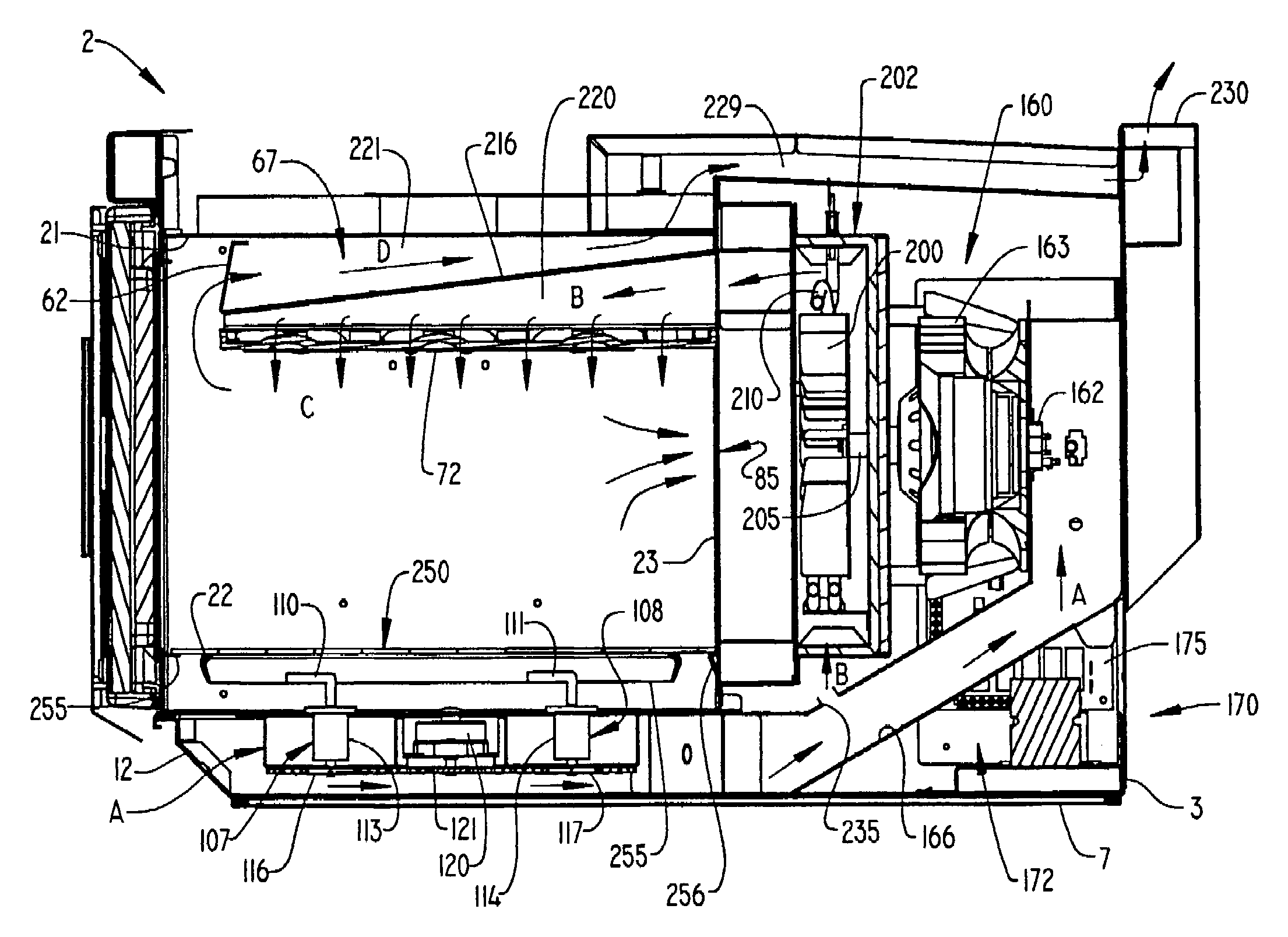

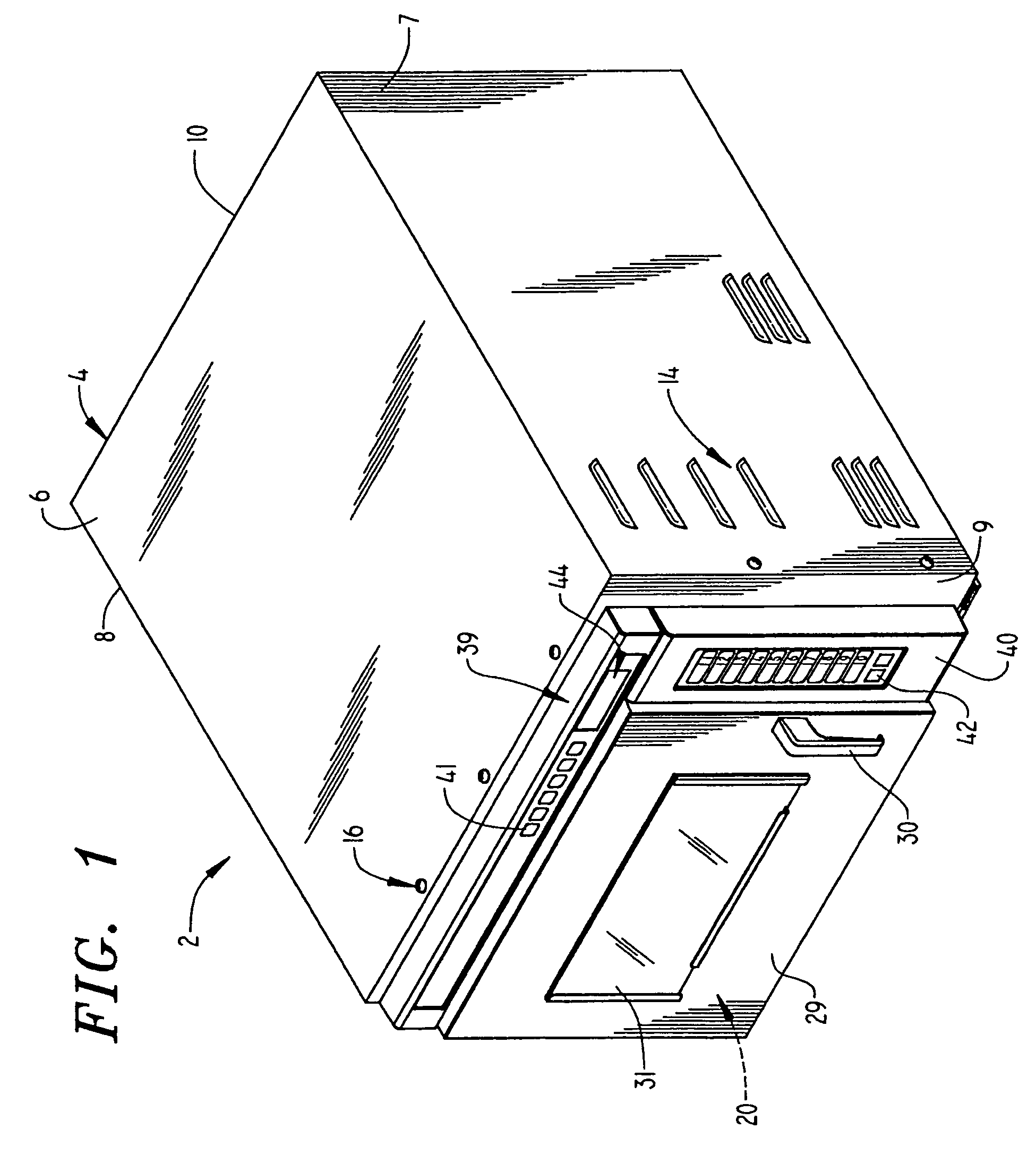

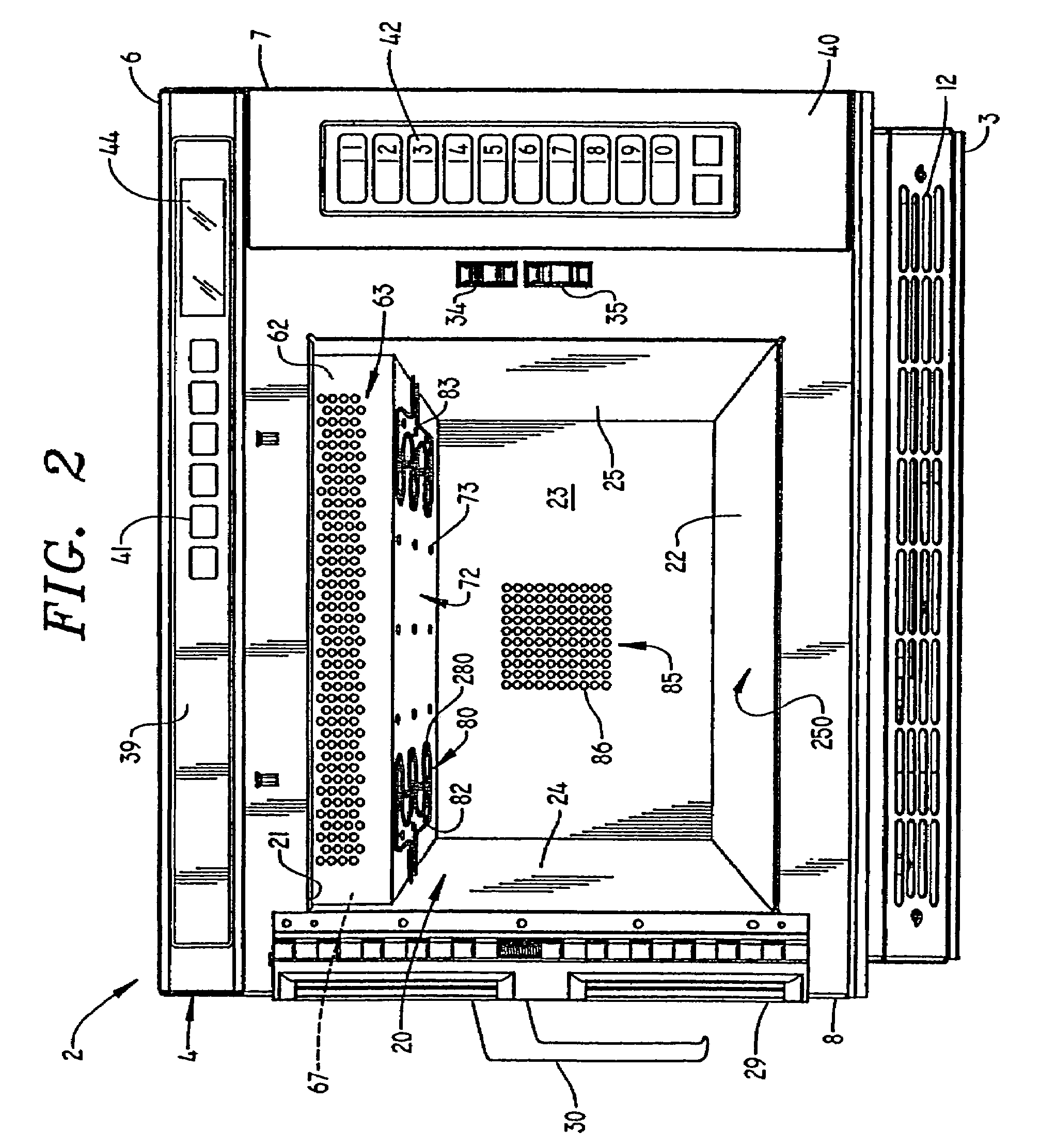

Temperature Control for Cooking Appliance Including Combination Heating System

A combination cooking appliance controls a radiant heating element provided in an oven cavity and a convection heating element provided in an air plenum with a regulating system which receives signals from multiple temperature sensors. More specifically, the appliance includes a first temperature sensor provided in an air return plenum portion for controlling the radiant heating element and a second temperature sensor arranged in a discharge air plenum portion, preferably downstream of a catalyst, for controlling the convection heating element. The heating elements are independently controlled based on the sensed temperatures to establish a desired oven cavity temperature, while accommodating for temperature fluctuations due to the incoming fresh air stream.

Owner:ACP

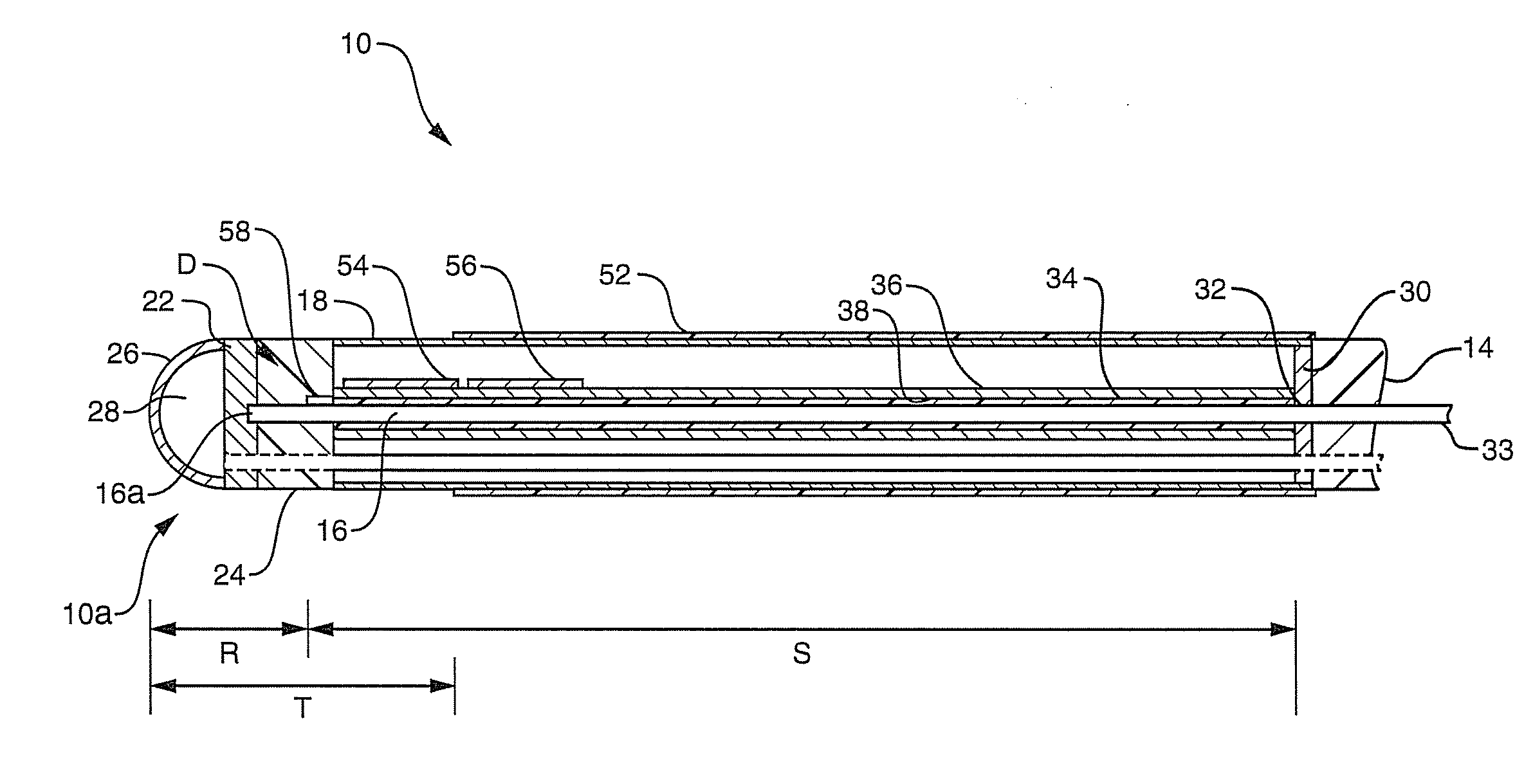

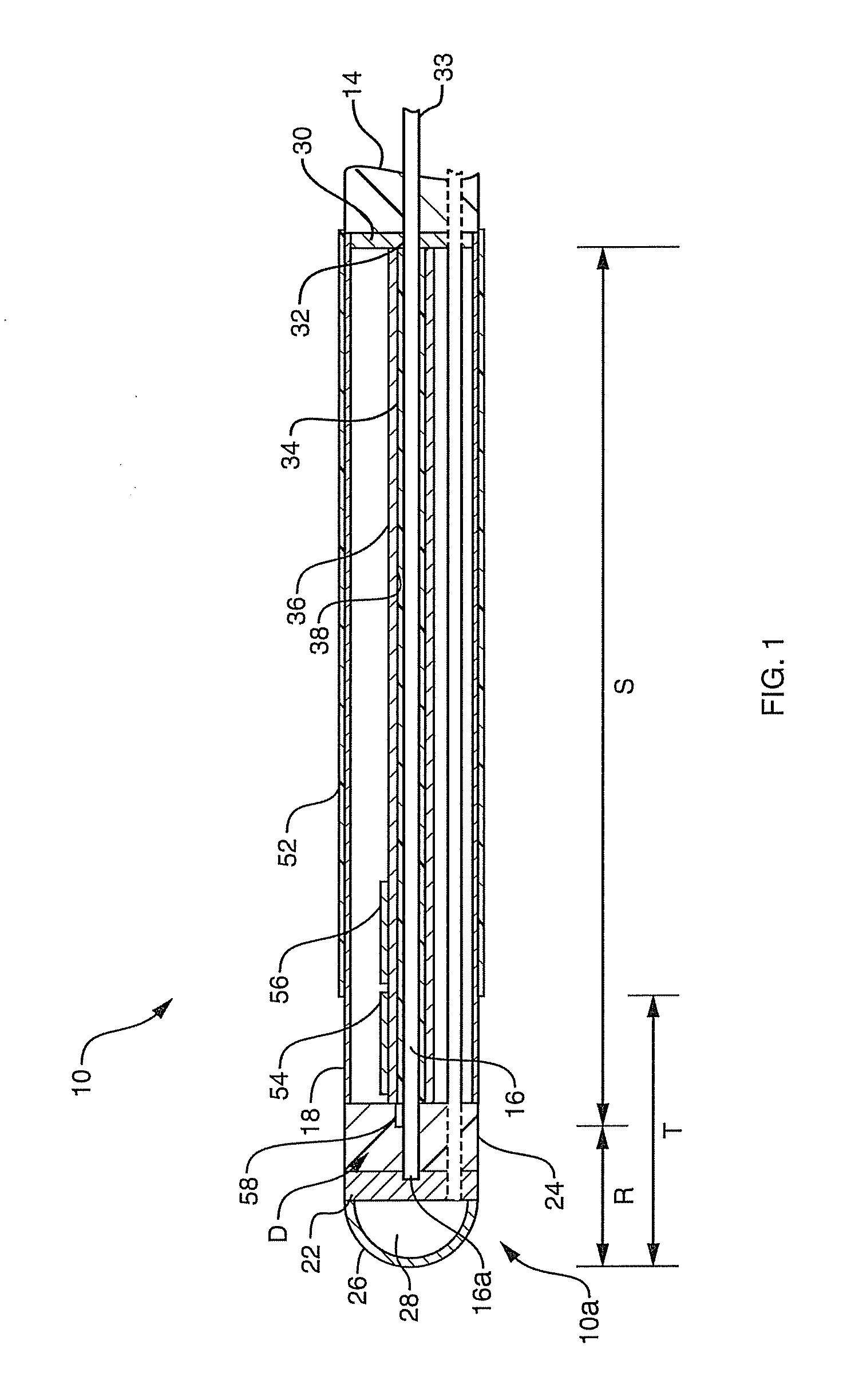

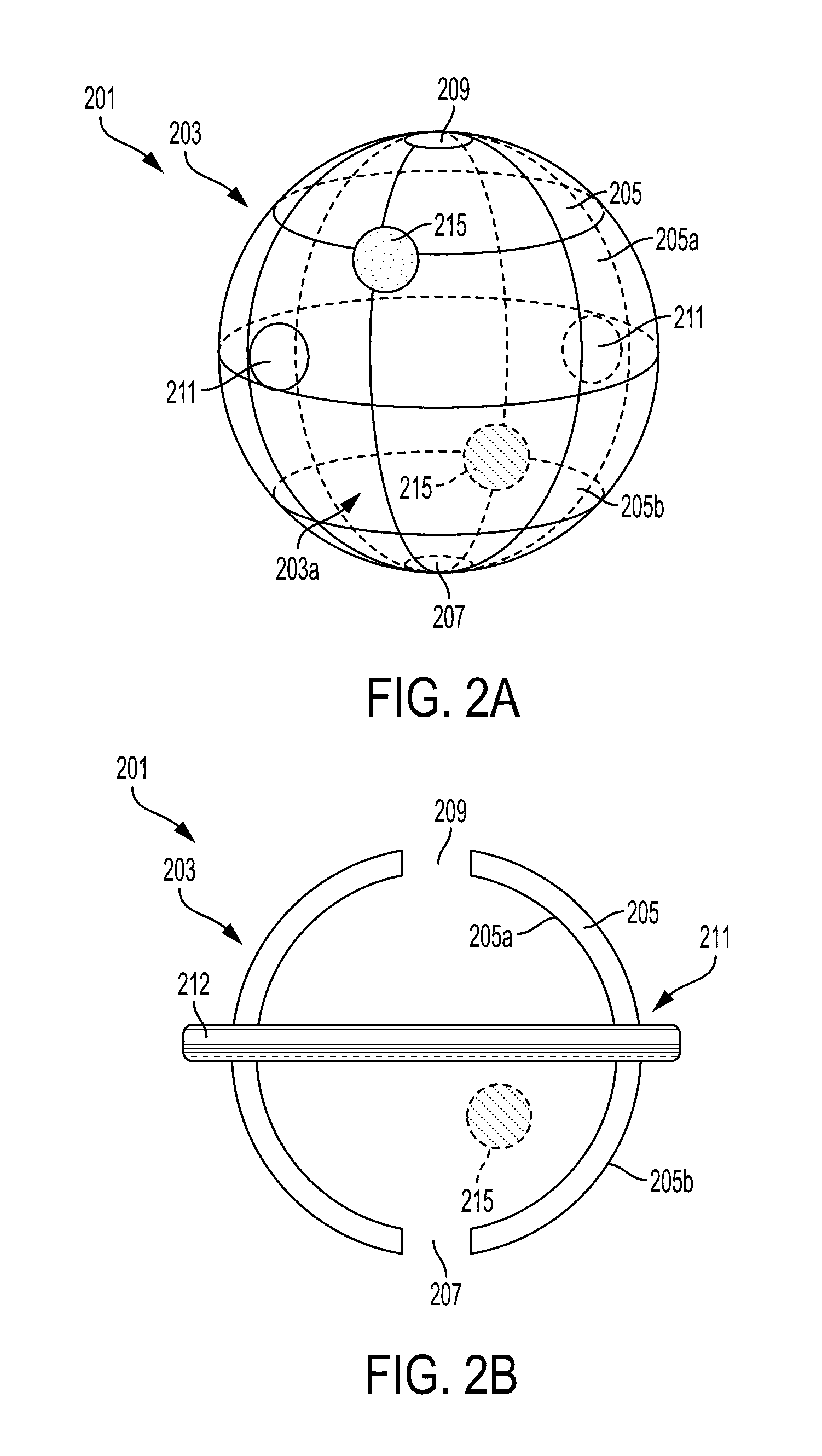

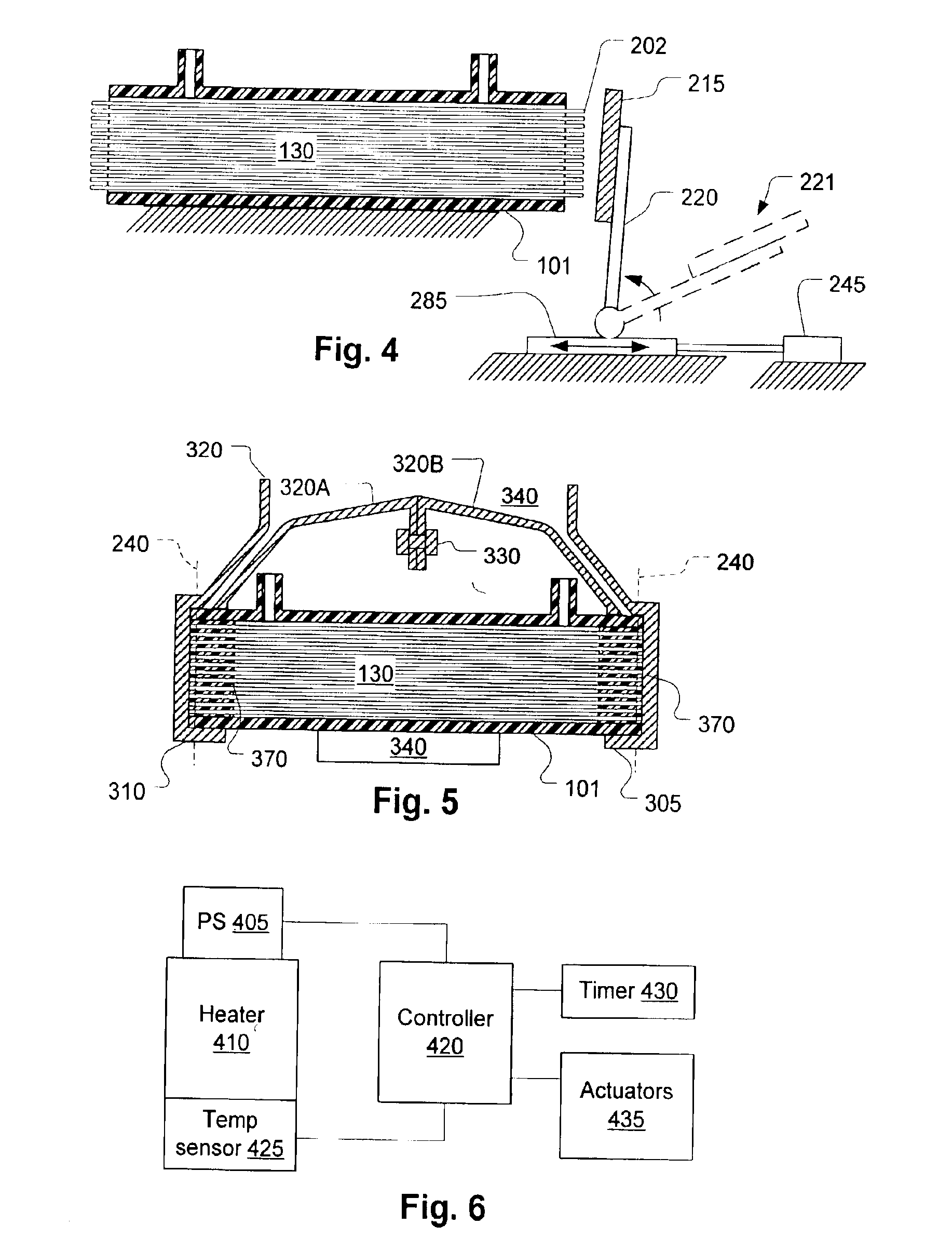

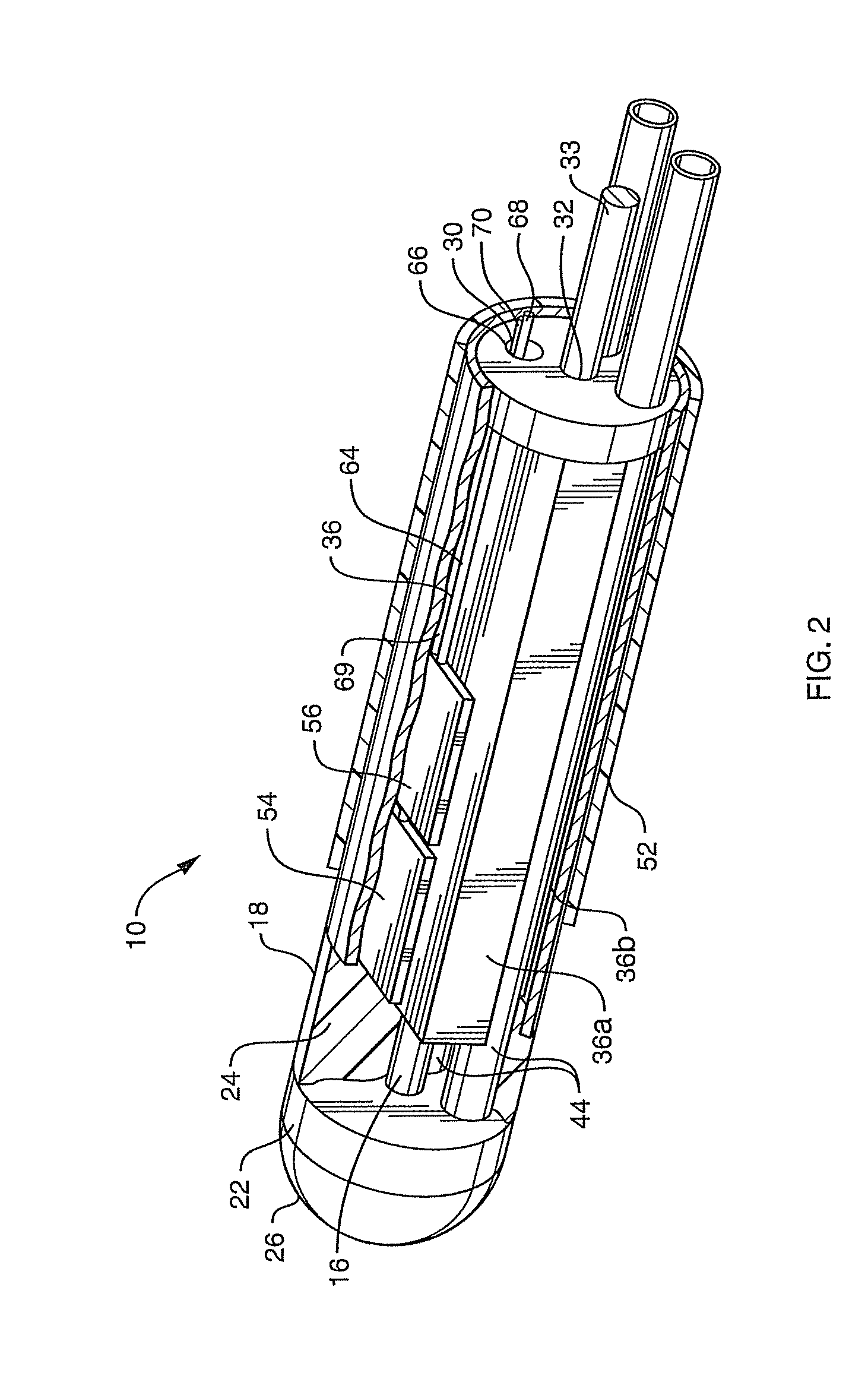

Radiometric heating/sensing probe

ActiveUS20100076424A1Easy and less-expensiveLow costElectrotherapyDiagnostic recording/measuringDual frequencyRadiometer

A radiometric heating / sensing probe for radiating electromagnetic waves of a first frequency capable of heating tissue and detecting electromagnetic waves of a second frequency emitted by the tissue indicating tissue temperature. The probe includes a dual frequency antenna, a signal transmitting path to the antenna and a signal receiving path from the antenna to a radiometer. A diplexer connected between those paths inside the probe includes a quarter wave stub in the form of a shorted slab line-type transmission line in the signal transmitting path. The entire probe package is only about 0.4 in. long and 0.08 in. in diameter so that it can be used in many minimally invasive applications.

Owner:CORAL SAND BEACH LLC

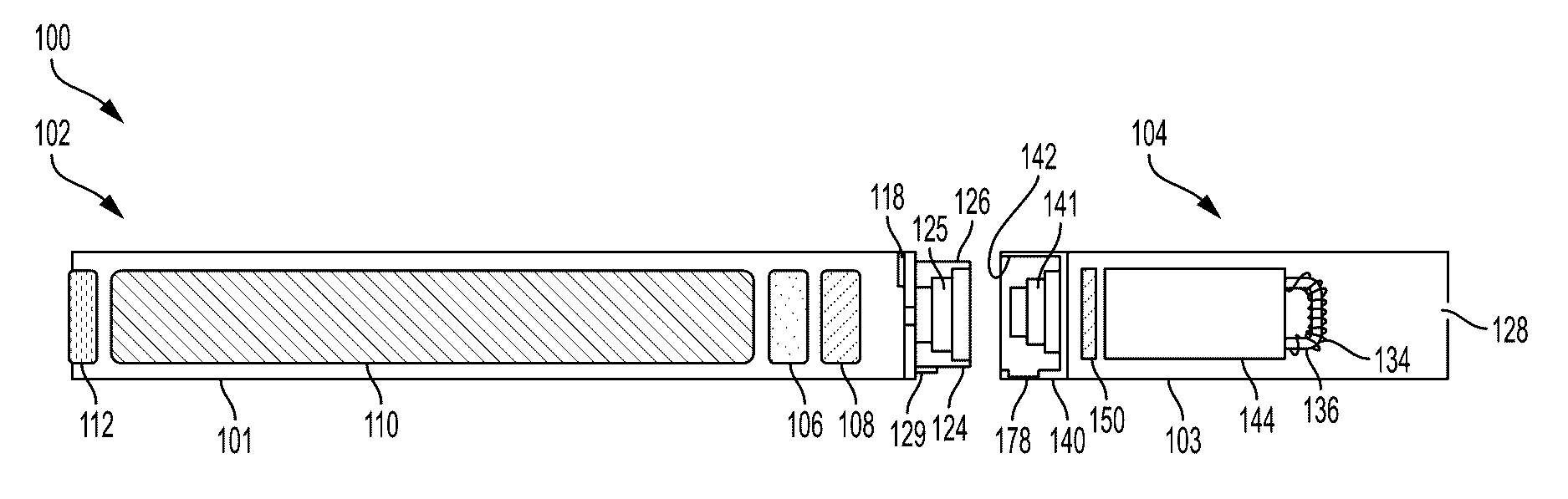

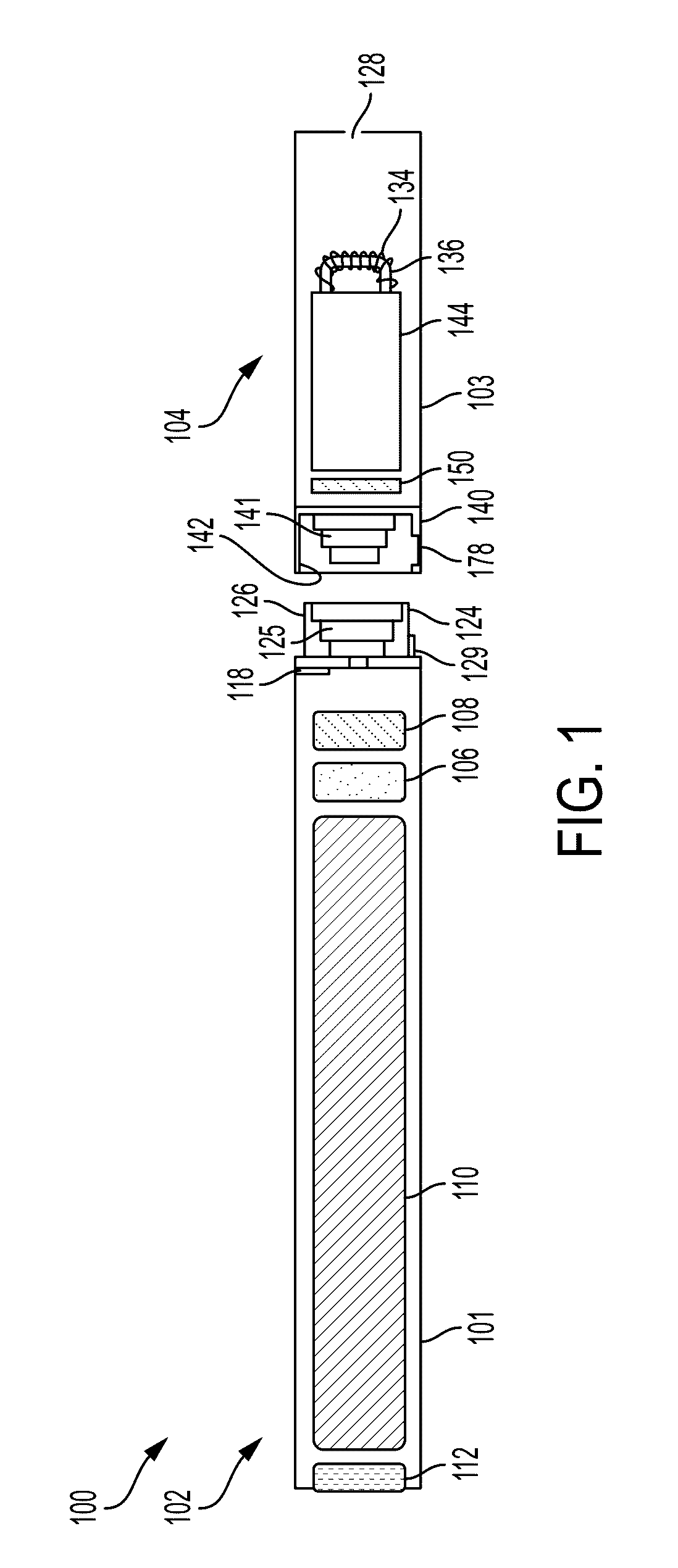

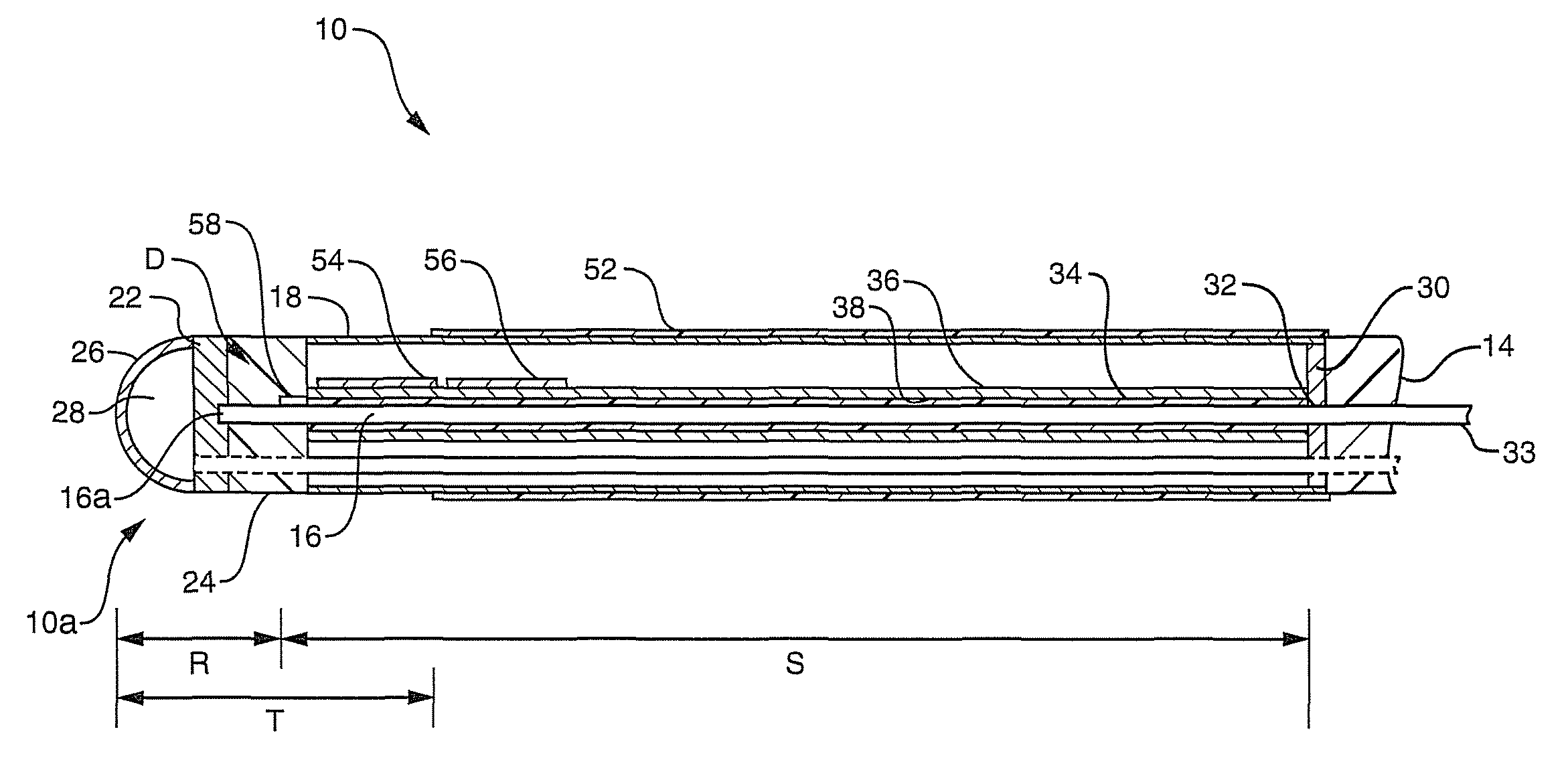

Aerosol delivery device with radiant heating

ActiveUS20170020193A1Increase heatExtended service lifeRespiratorsOhmic-resistance waterproof/air-tight sealsBlack bodyVaporization

The present disclosure relates to aerosol delivery devices, methods of forming such devices, and elements of such devices. In some embodiments, the present disclosure provides devices configured for vaporization of an aerosol precursor composition through radiant heating. The radiant heat source may be a laser diode or further element suitable for providing electromagnetic radiation, and heating may be carried out within an optional chamber, which can be a radiation-trapping chamber. In some embodiments, an interior of such chamber may be configured as a black body or as a white body.

Owner:RAI STRATEGIC HLDG INC

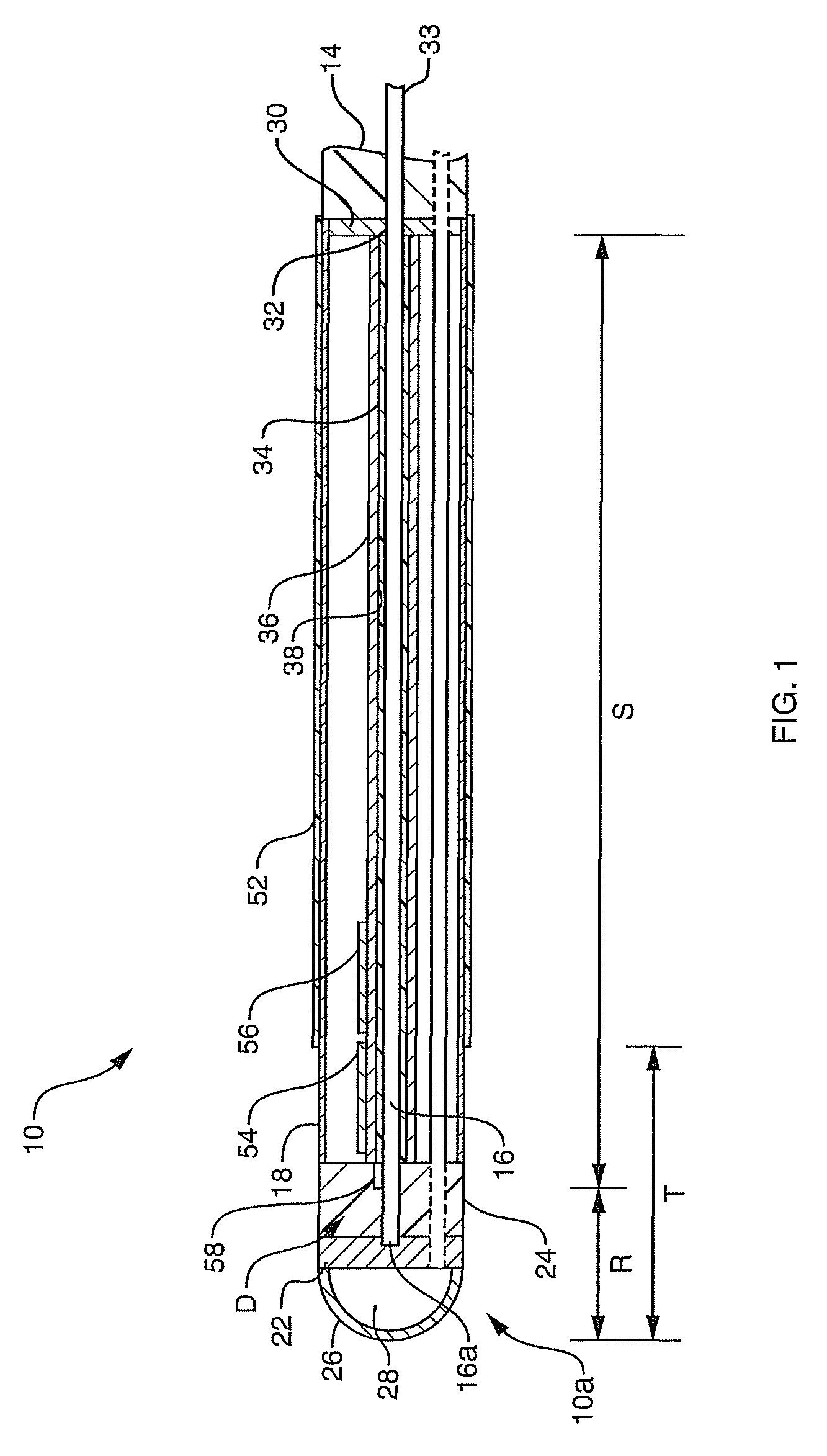

Method and apparatus for manufacturing filters

InactiveUS6872346B2Speed productionShort amount of timeSemi-permeable membranesTailstocks/centresEngineeringMechanical engineering

A problem in the manufacture of filters using tubular membrane bundles is keeping potting material from flowing into the openings at the ends of the tubes. A preferred embodiment of a method for manufacturing a tubular membrane filter employs a non-contact heat source such as radiant heating to melt the tips of the tubular membranes. This prevents the migration of potting material into the tubes when the potting material is flowed into the ends of tube bundles during the manufacturing process for a filter.

Owner:NXSTAGE MEDICAL

Radiometric heating/sensing probe

ActiveUS8515554B2Simpler and less-expensiveAccurate and reliable operating parameterElectrotherapyDiagnostic recording/measuringDual frequencyRadiometer

Owner:CORAL SAND BEACH LLC

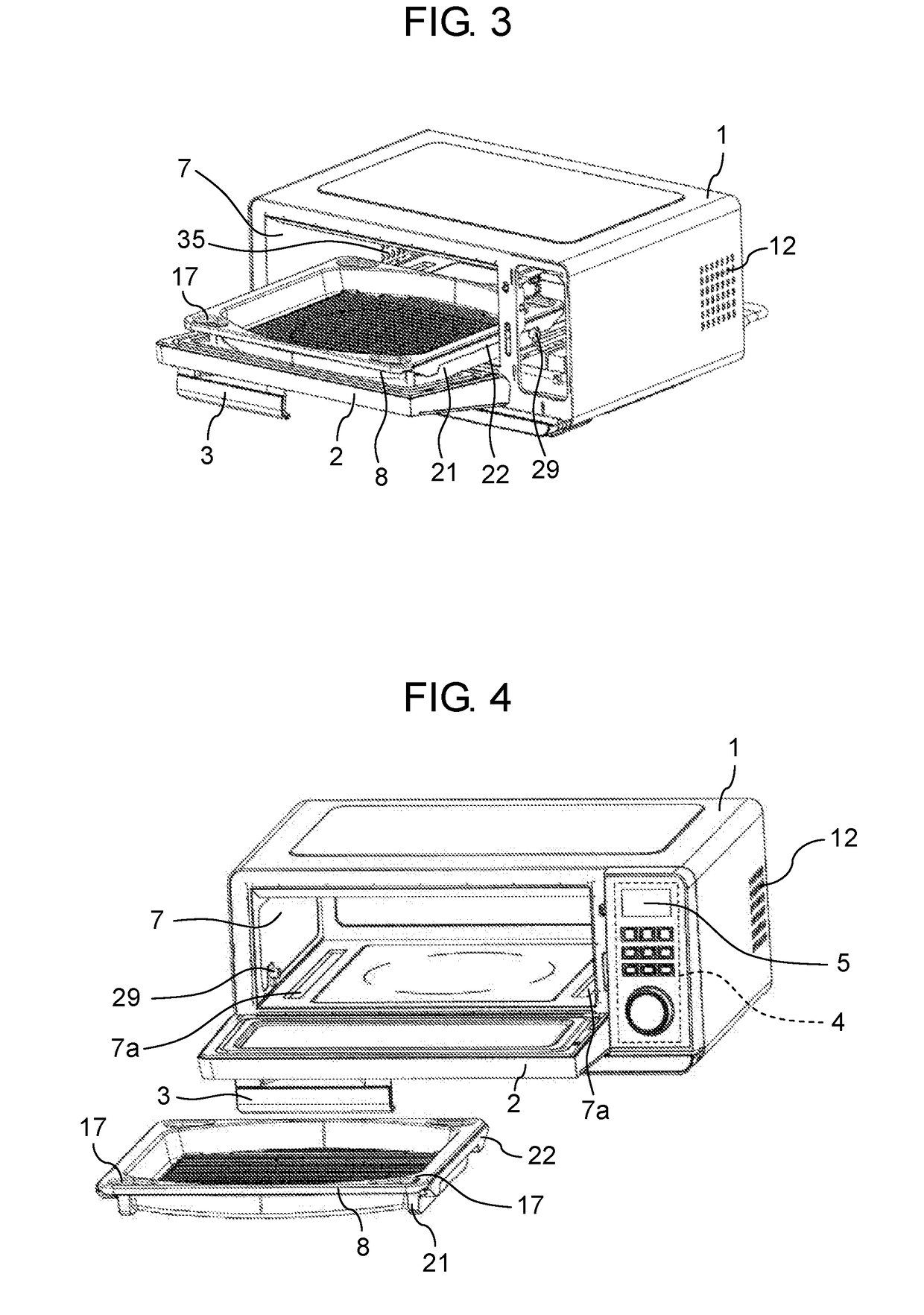

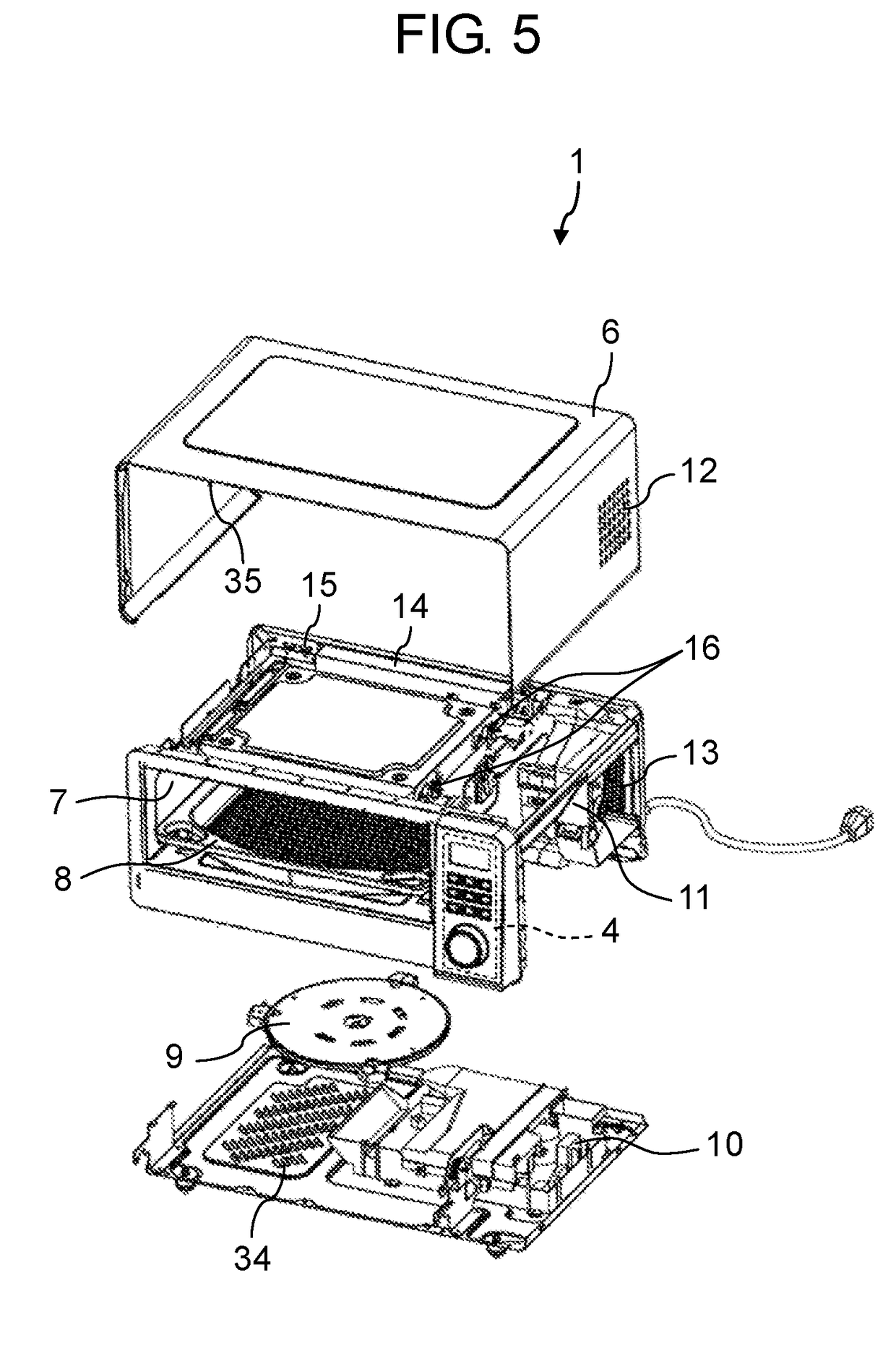

Cooking appliance including combination heating system

A cooking appliance includes a heating system capable of combining radiant, convection, microwave and conduction heating techniques to perform a cooking operation. The cooking appliance includes a cooking chamber and a bifurcated air plenum having an angled divider that defines a tapered air delivery portion and a tapered exhaust portion. The tapered air delivery portion actually guides a convective air flow through an air emitter plate positioned at a top of the cooking chamber. The air emitter plate includes a recessed, serpentine-like channel having a plurality of openings that lead to the air delivery portion. A radiant heating element is nested within the recessed channel. The cooking appliance further includes a convection fan, as well as a magnetron having a rotatable antenna positioned below the cooking chamber and a conductive plate upon which food to be cooked is supported.

Owner:AGA FOODSERVICE GROUP +1

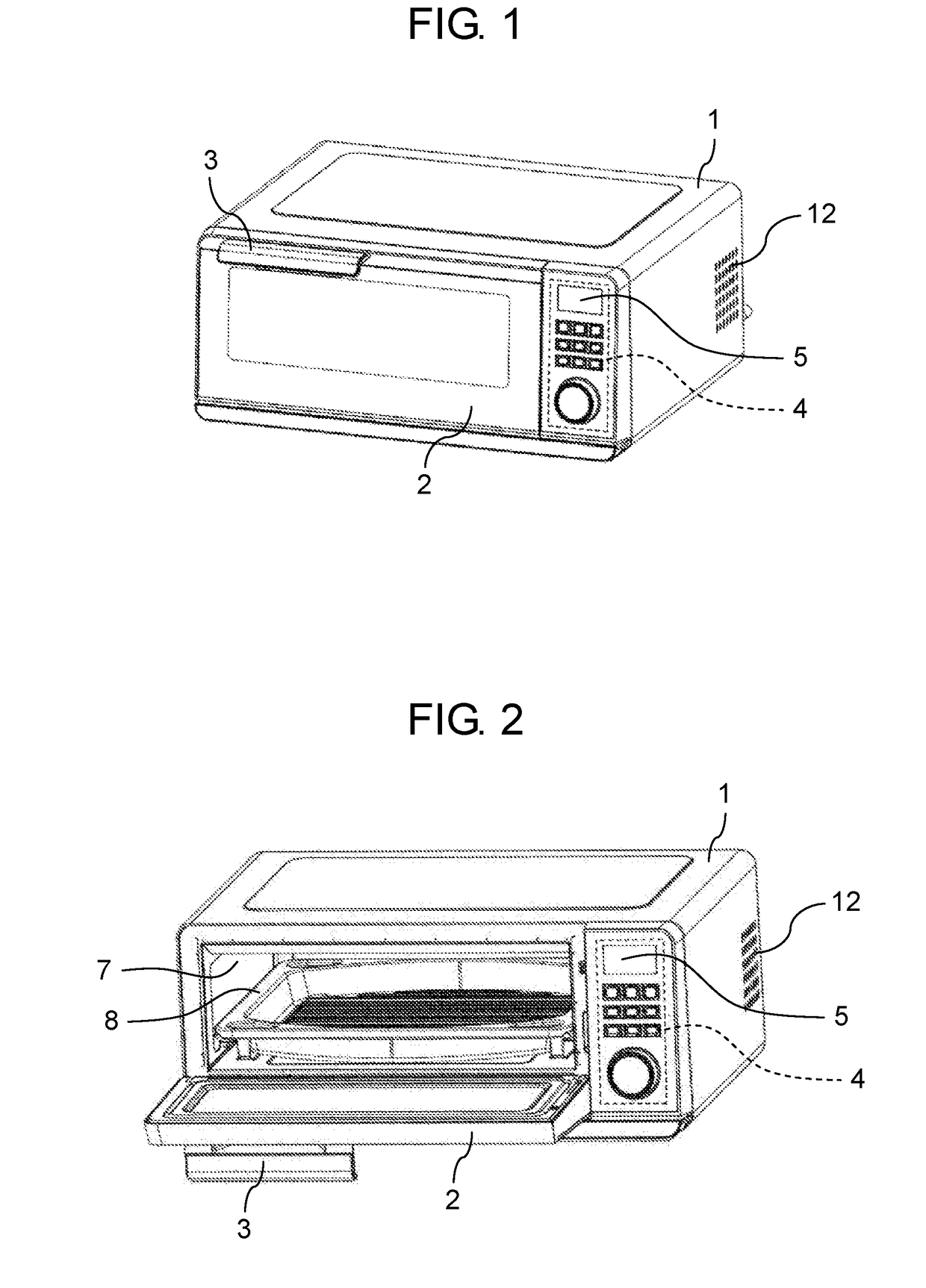

Induction heating cooker and grill tray

Provided is an induction heating cooker which can be carried to a desired position on a cooking table to conduct grill cooking using induction heating and radiation heating and includes a grill tray (8) that is placed inside a heating chamber (7) and includes an engaging section that is used for removing the grill tray (8) from the heating chamber (7) and inserting the grill tray (8) into the heating chamber (7). The grill tray (8) is configured as being placeable on a cooking table. Grill cooking is conducted using an upper heating unit which is provided above the heating chamber (7) and heats a food item inside the heating chamber (7) by radiation and a lower heating unit which is provided below the heating chamber and heats the grill tray by induction.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

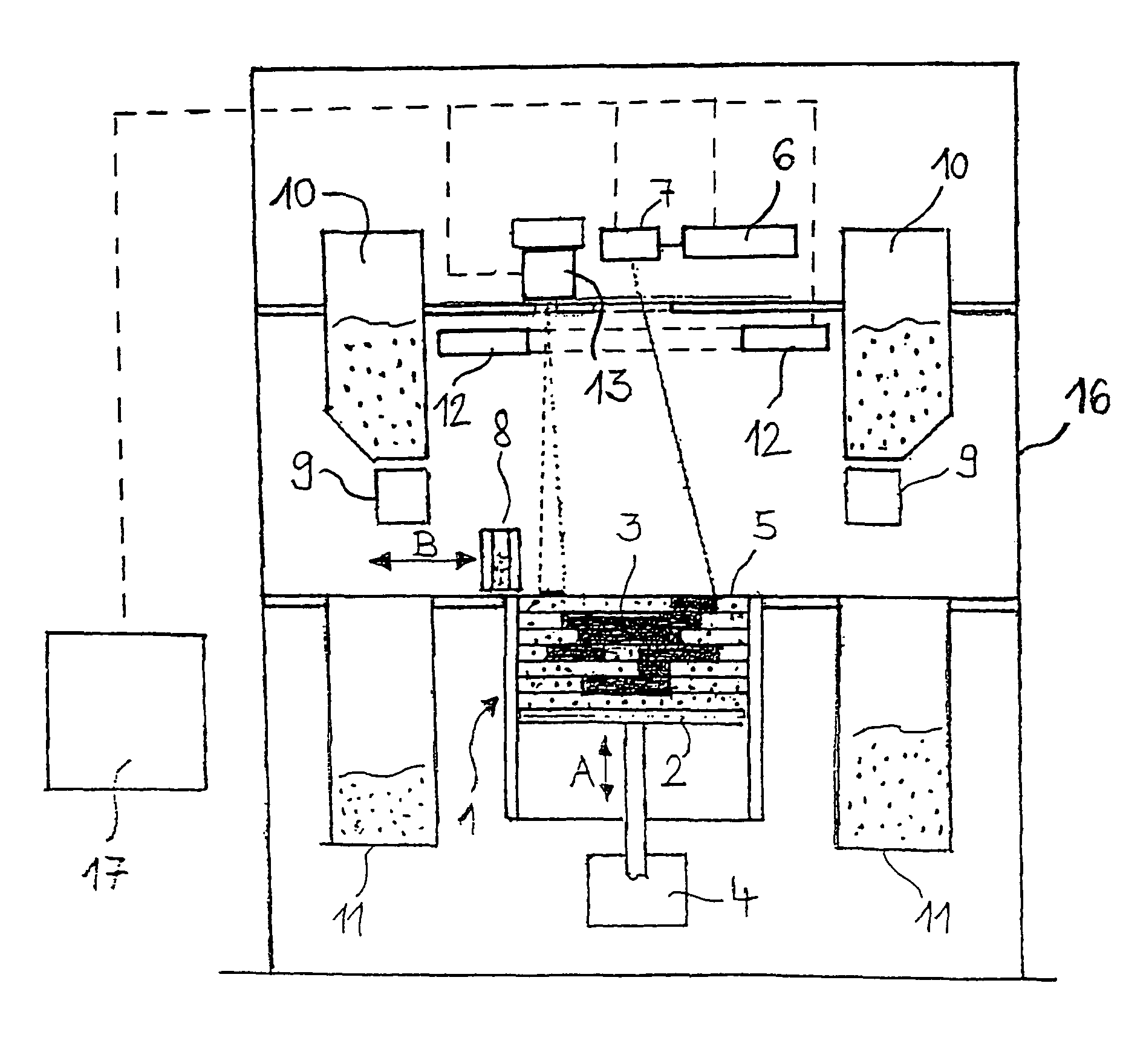

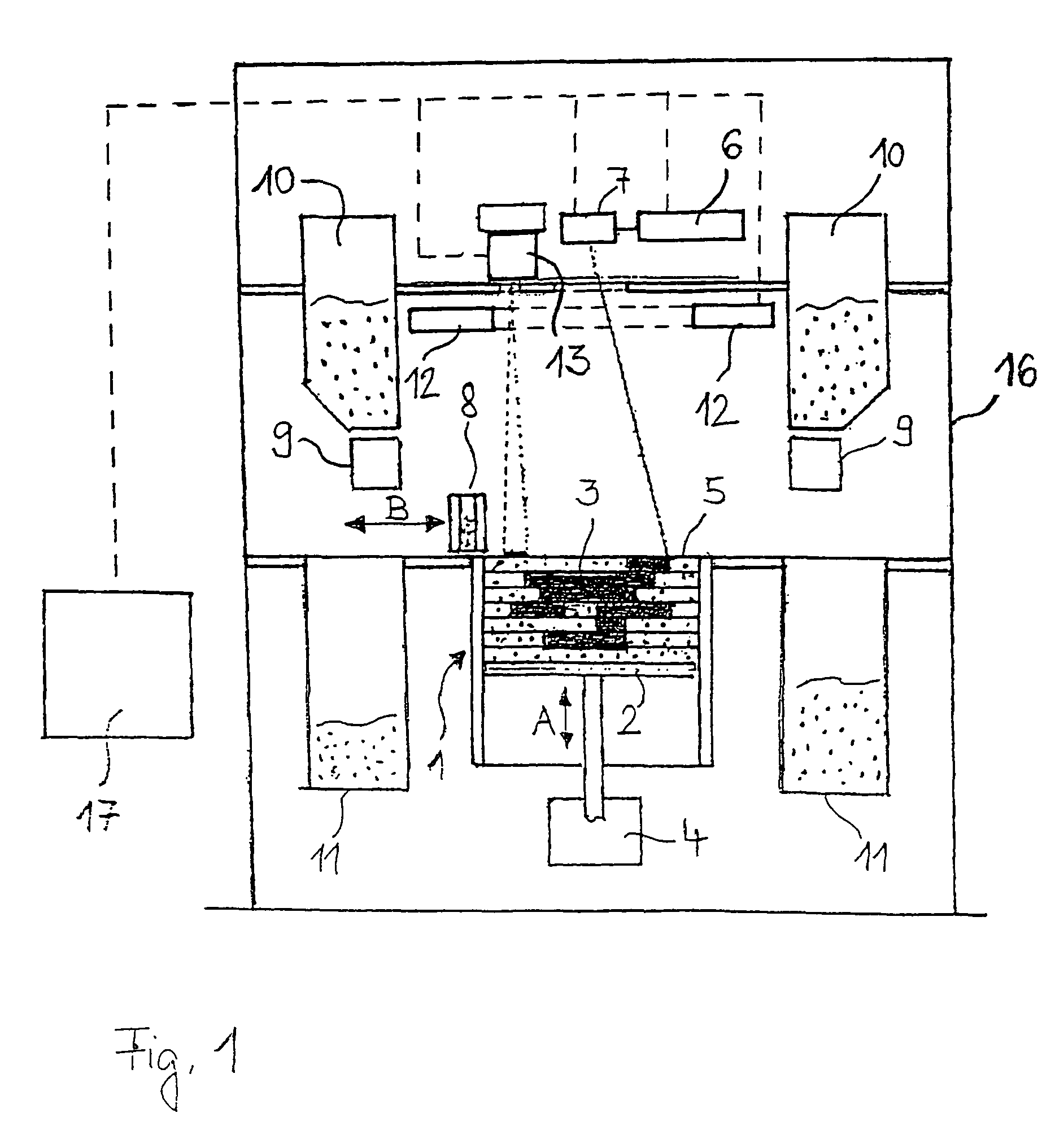

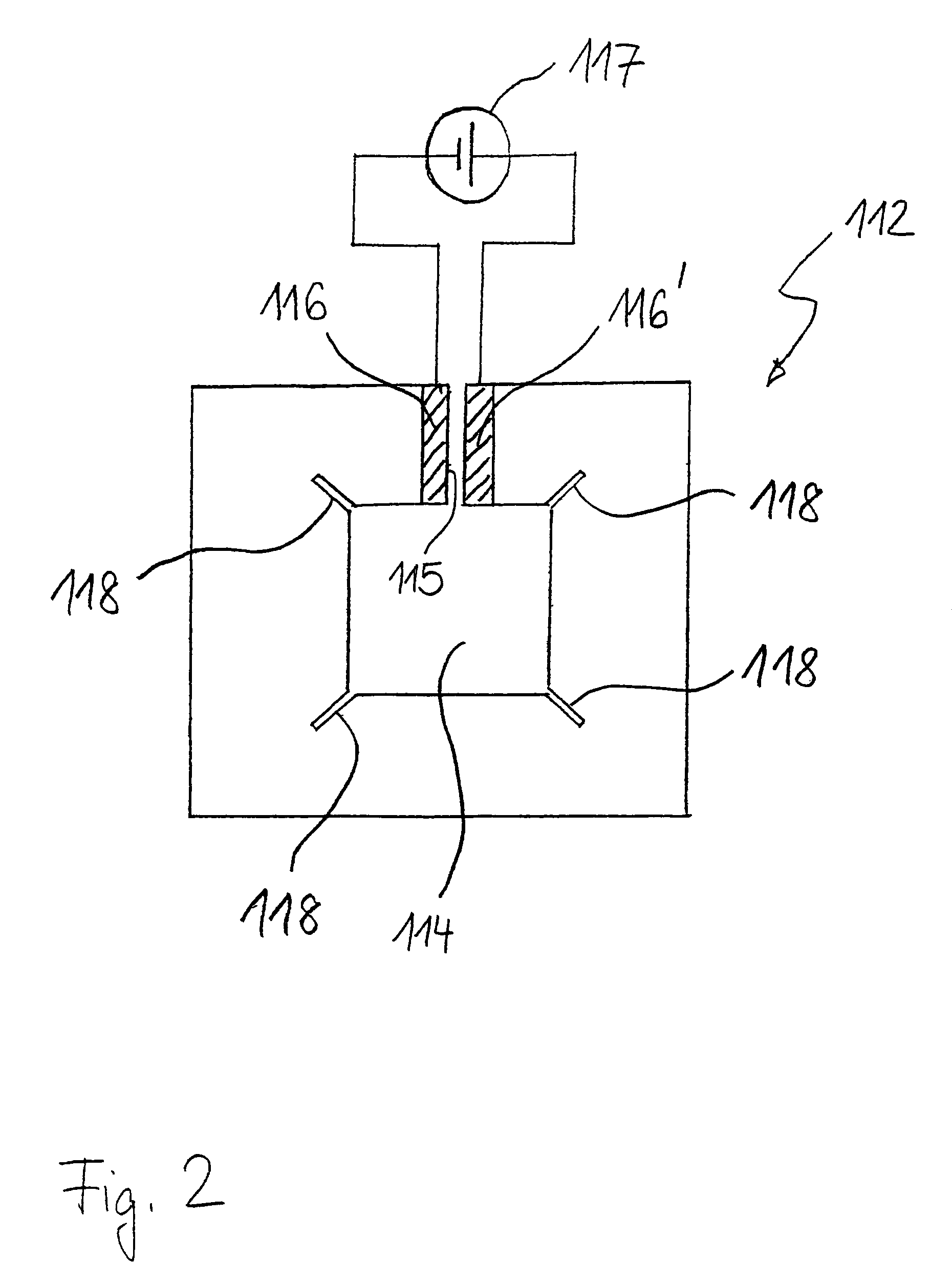

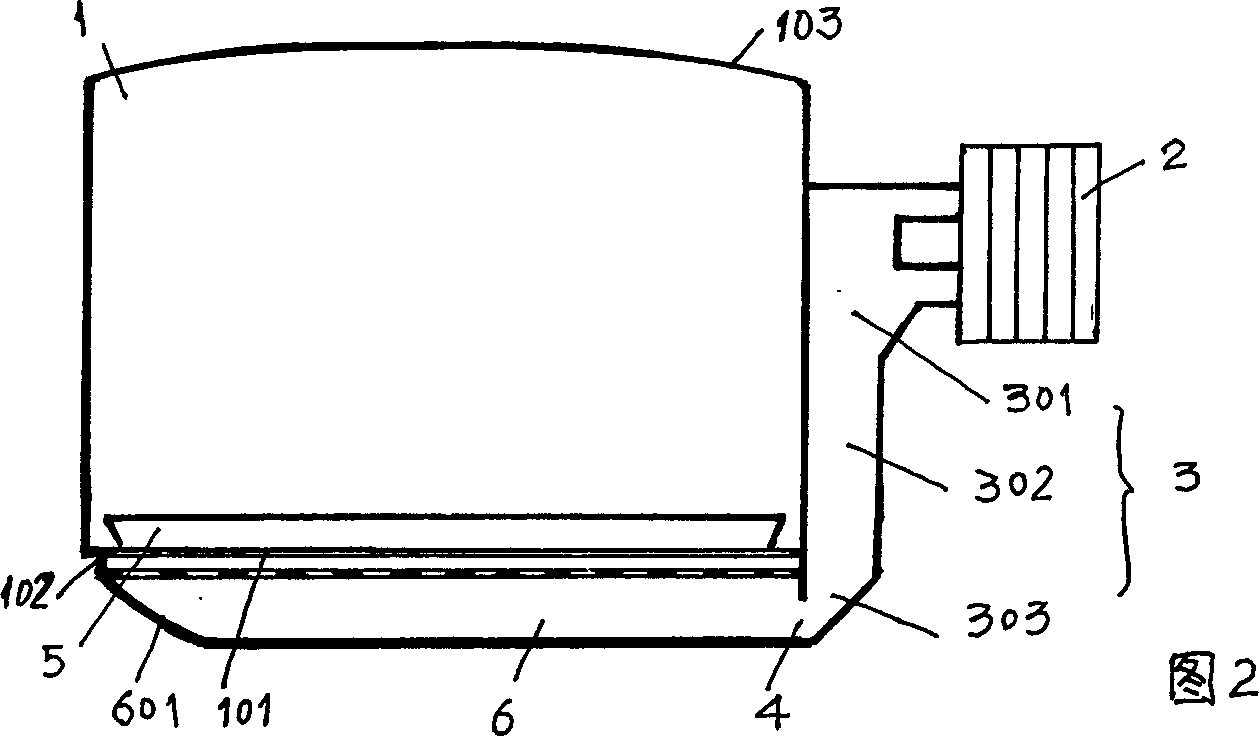

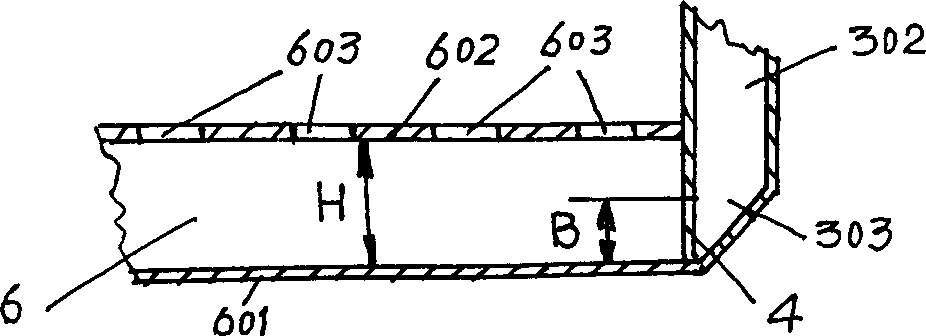

Radiant heater for heating the building material in a laser sintering device

InactiveUS8073315B2Reduce the temperatureThermal inertiaDomestic stoves or rangesDrying solid materials with heatRadiant heaterMetallurgy

A radiant heating for heating the building material in a laser sintering device and a laser sintering device having such a radiant heating are described. The radiant heating has a sheet-like heat radiating element (113, 213, 313), which is characterized in that it is made of a material, that has a low thermal inertia with a thermal diffusivity of preferably more than 1.5·10−4 m2 / s and preferably has a thickness of 2 mm or less.

Owner:EOS ELECTRO OPTICAL SYST

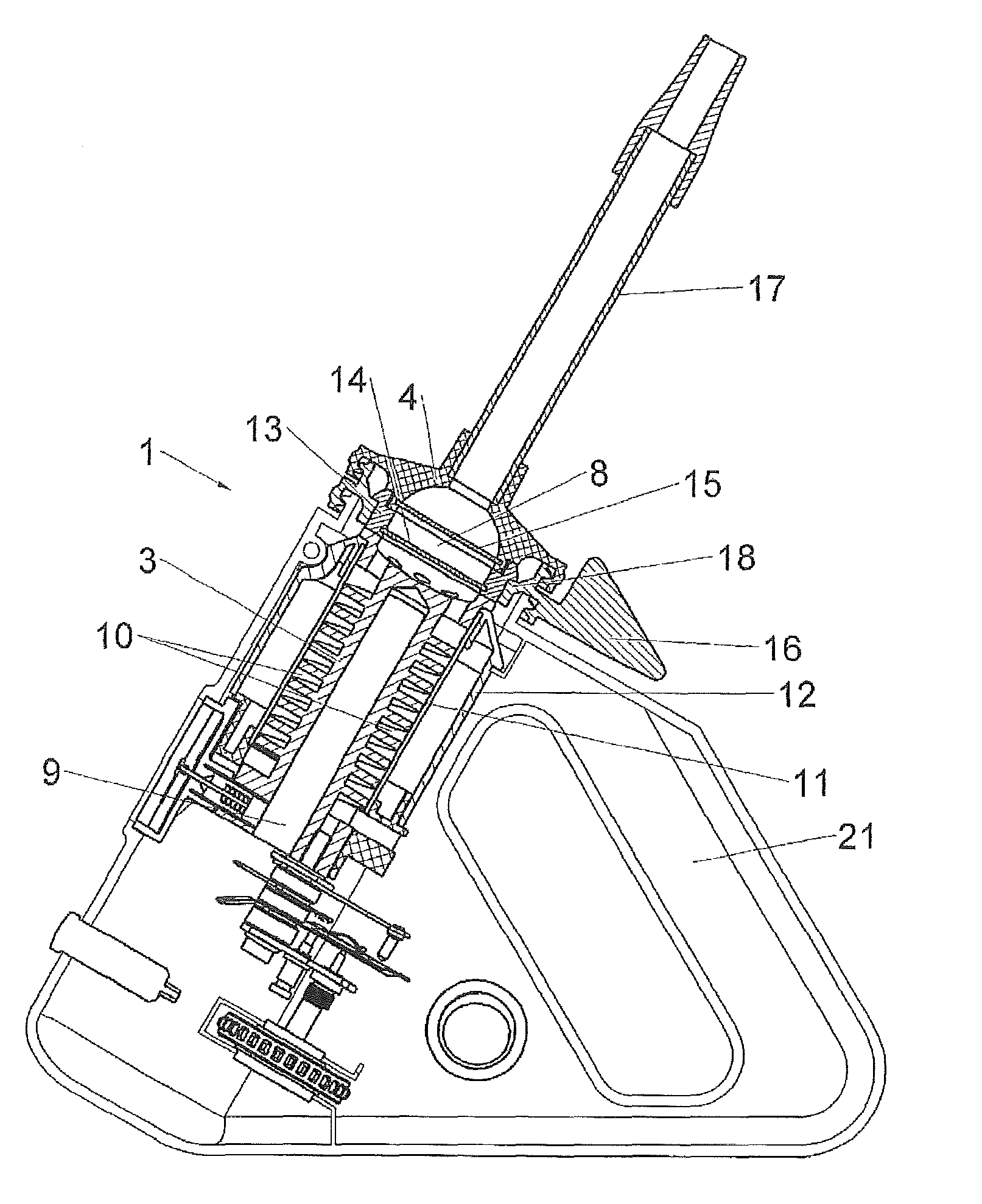

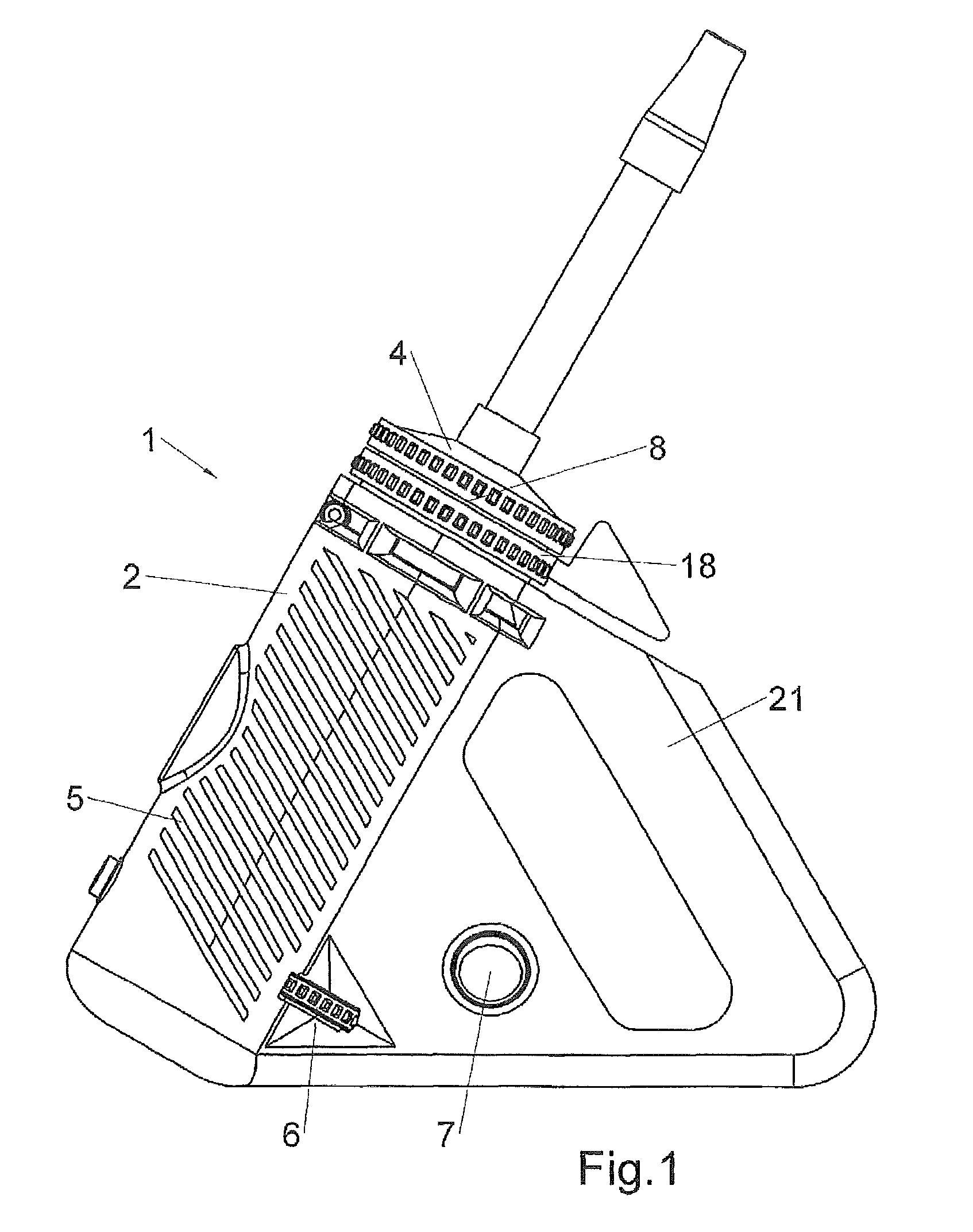

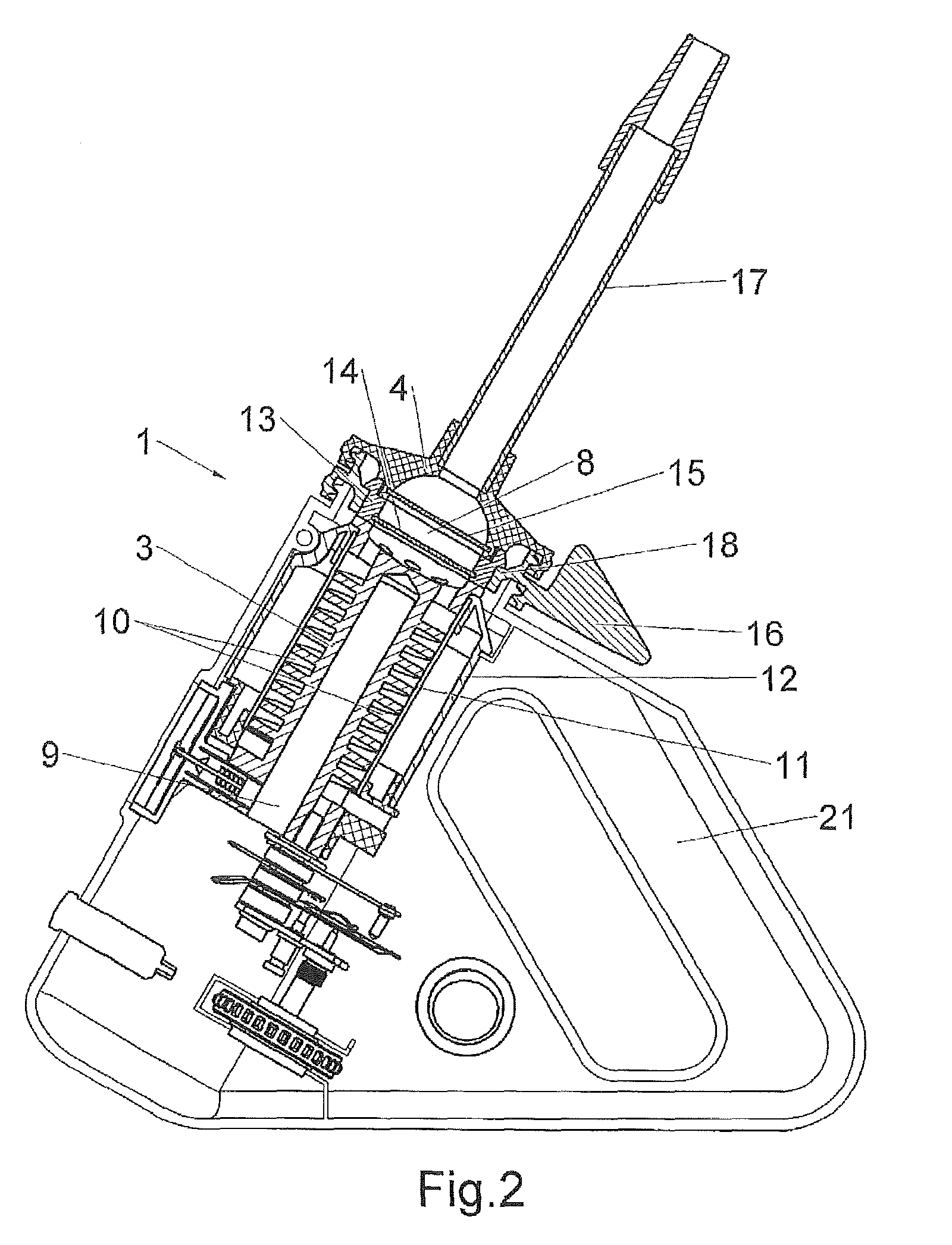

Vaporizer with combined air and radiation heating

A hot air extraction vaporizer that is provided with a heat exchanger, a filling chamber for accommodating a substance generating an aerosol when subjected to heat, and a vaporizer outlet for inhaling the aerosol / air mixture. The heat exchanger is in a thermally conductive connection with the filling chamber that when heated up subjects the substance to radiant heat. The heat exchanger is provided with at least one airflow channel generating a hot airflow. The filling chamber comprises at least one of airflow passages and a mesh allowing the hot airflow to pass through the filling chamber and the substance provided therein.

Owner:STORZ & BICKEL GMBH

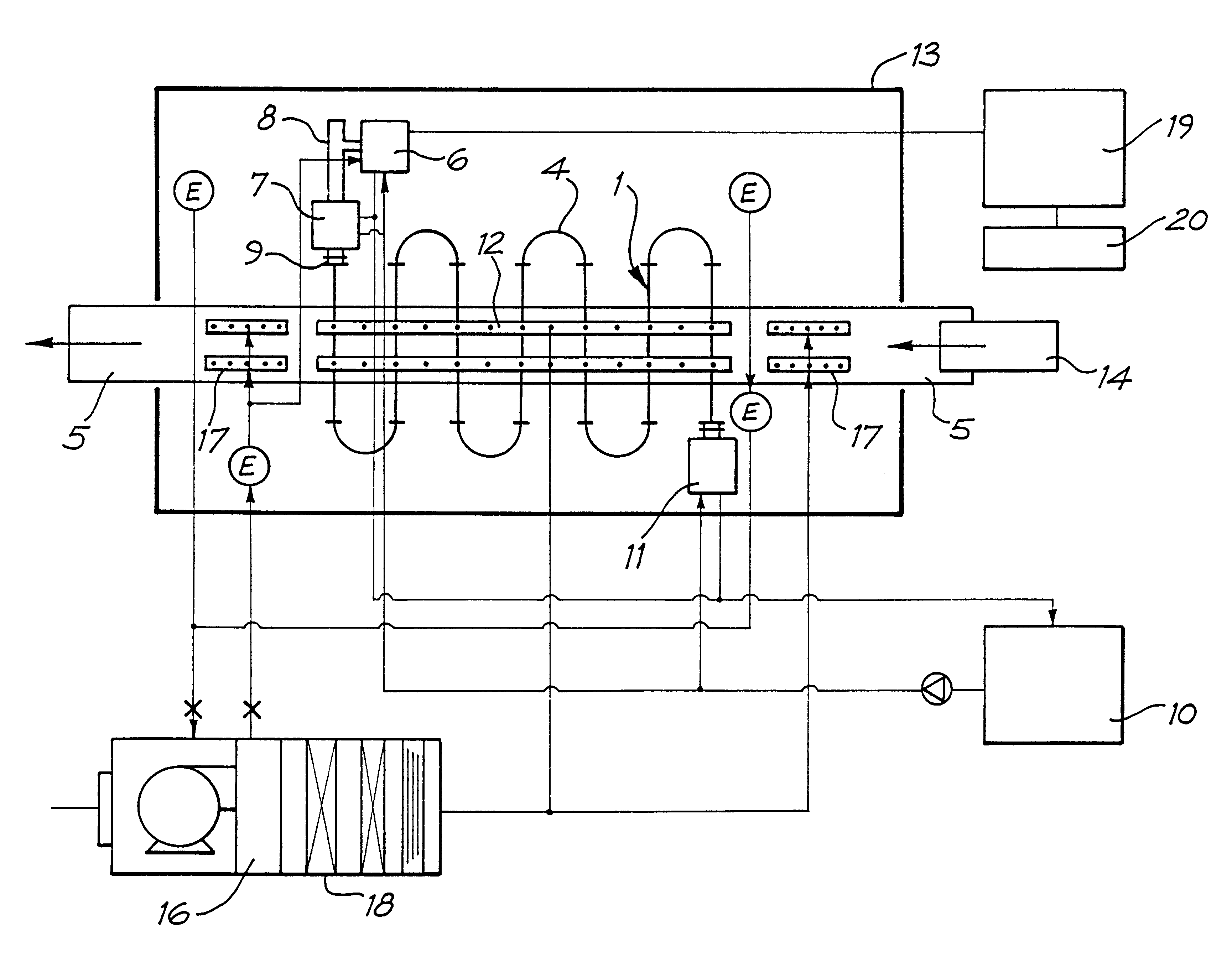

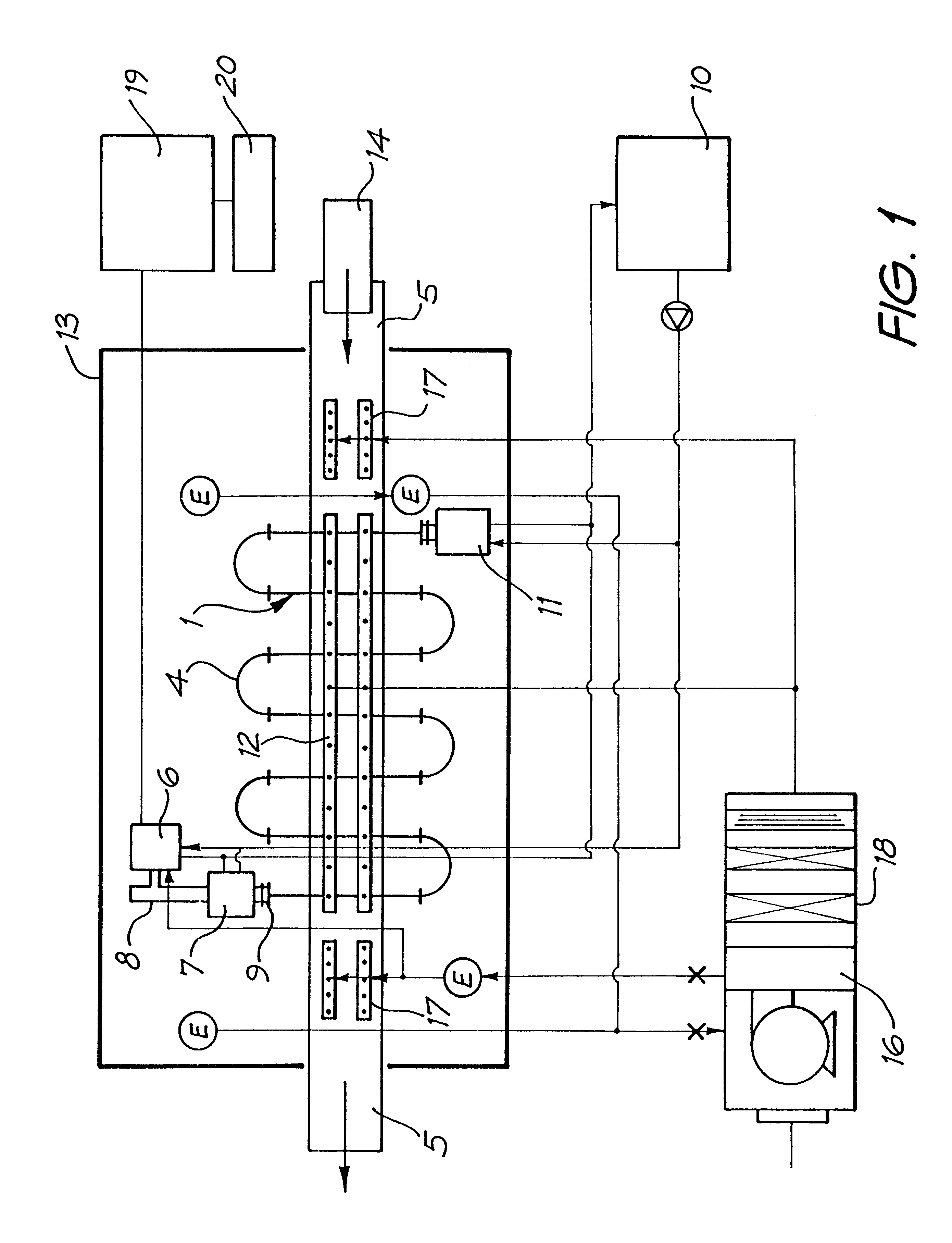

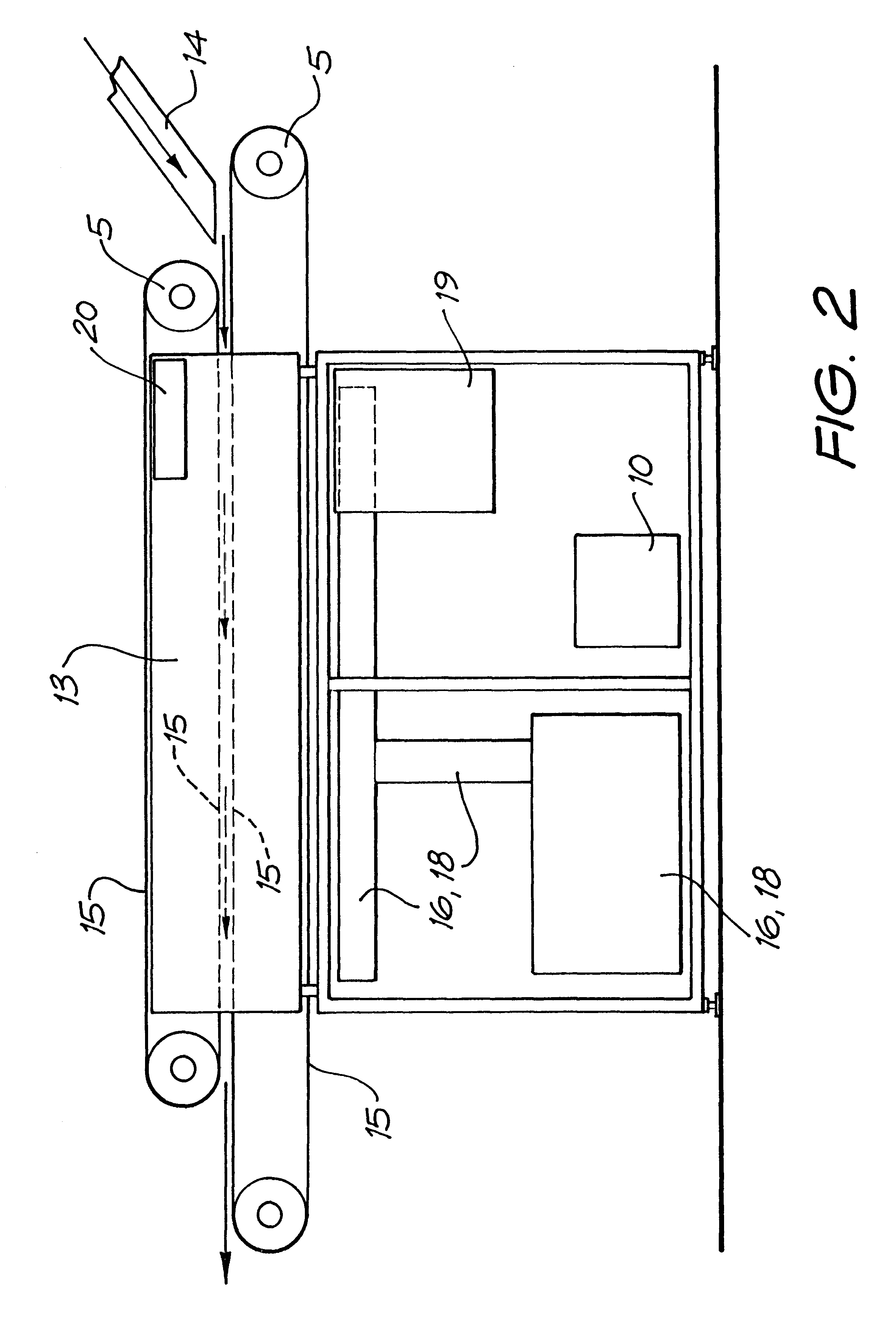

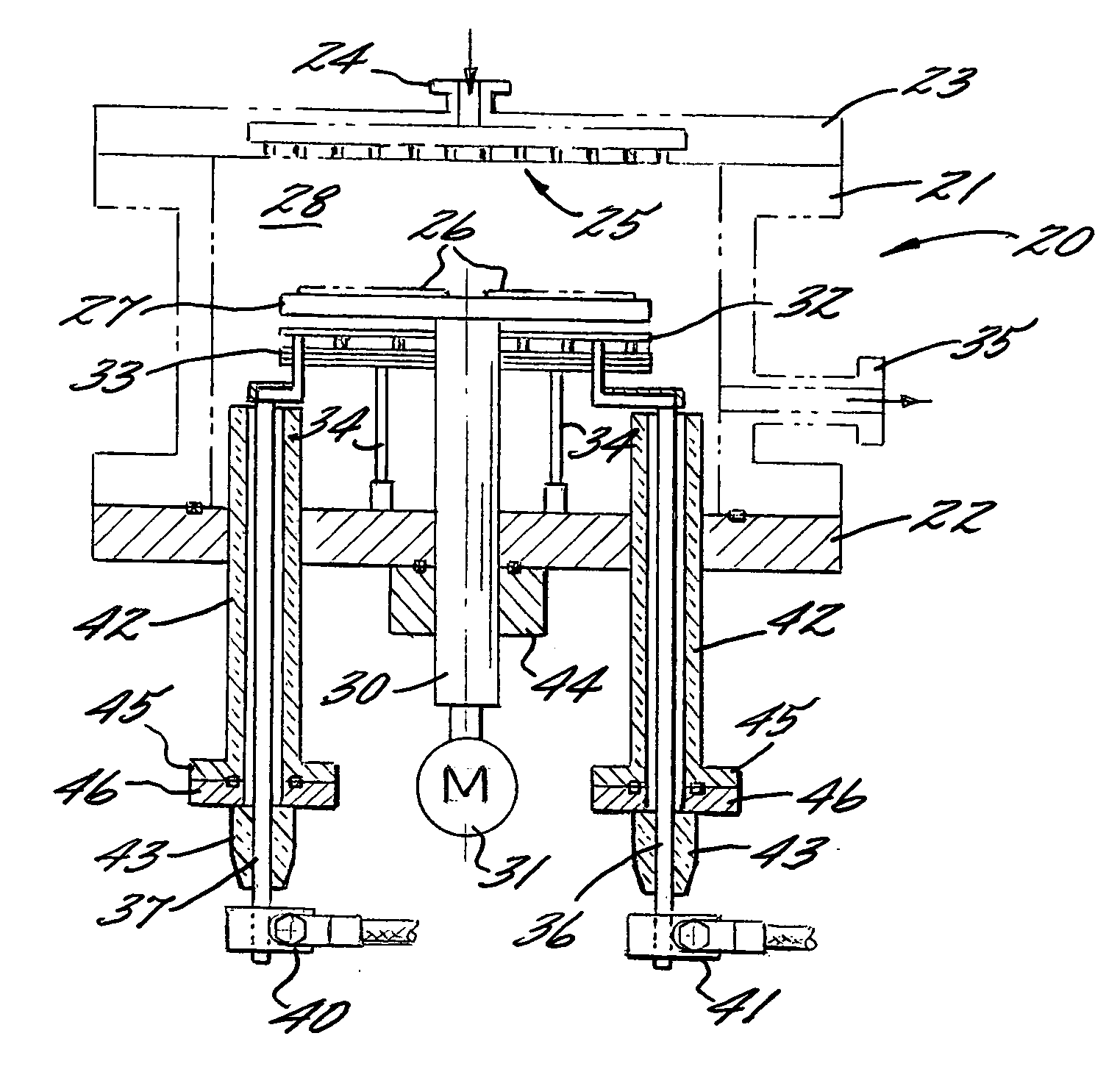

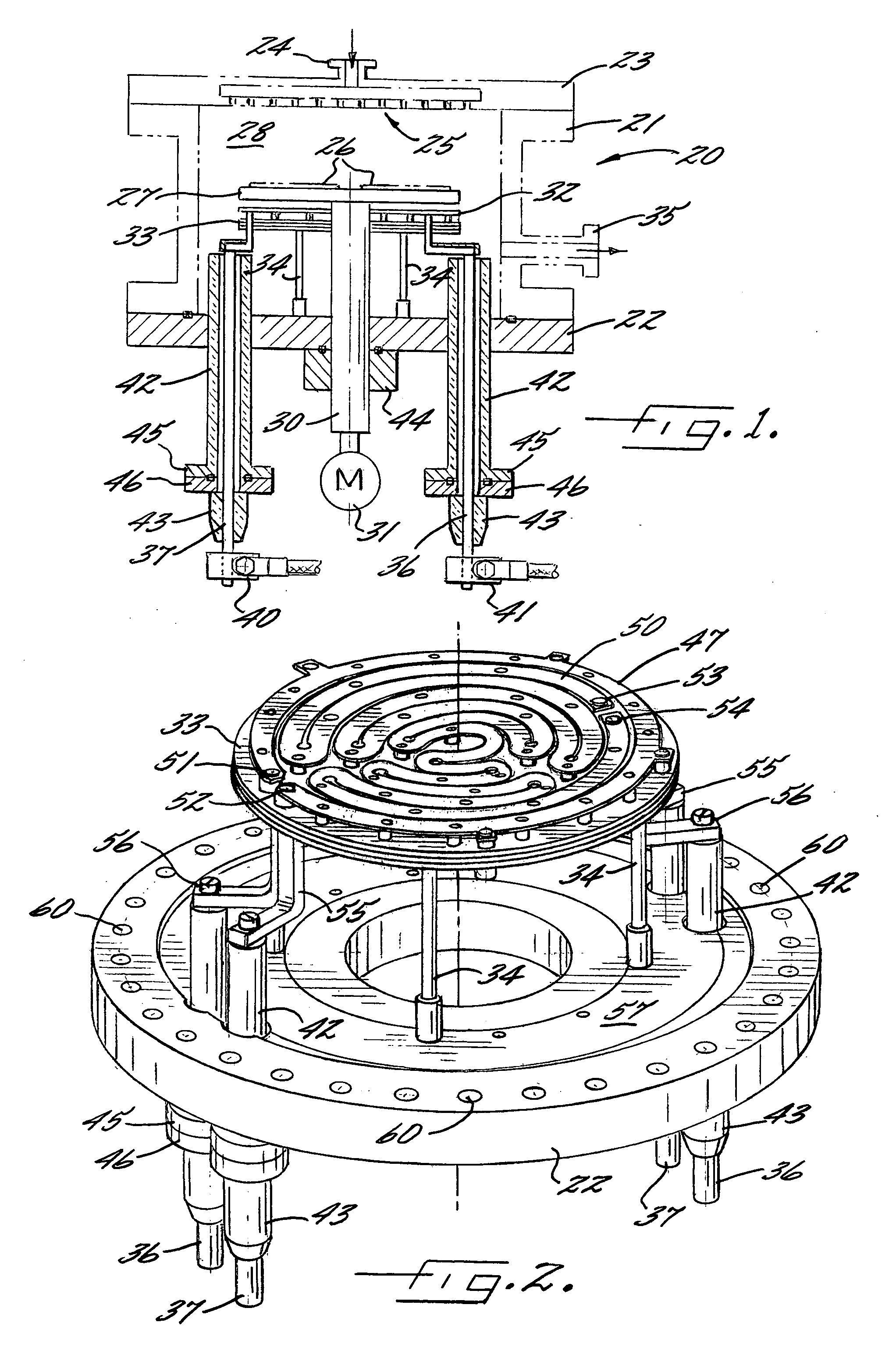

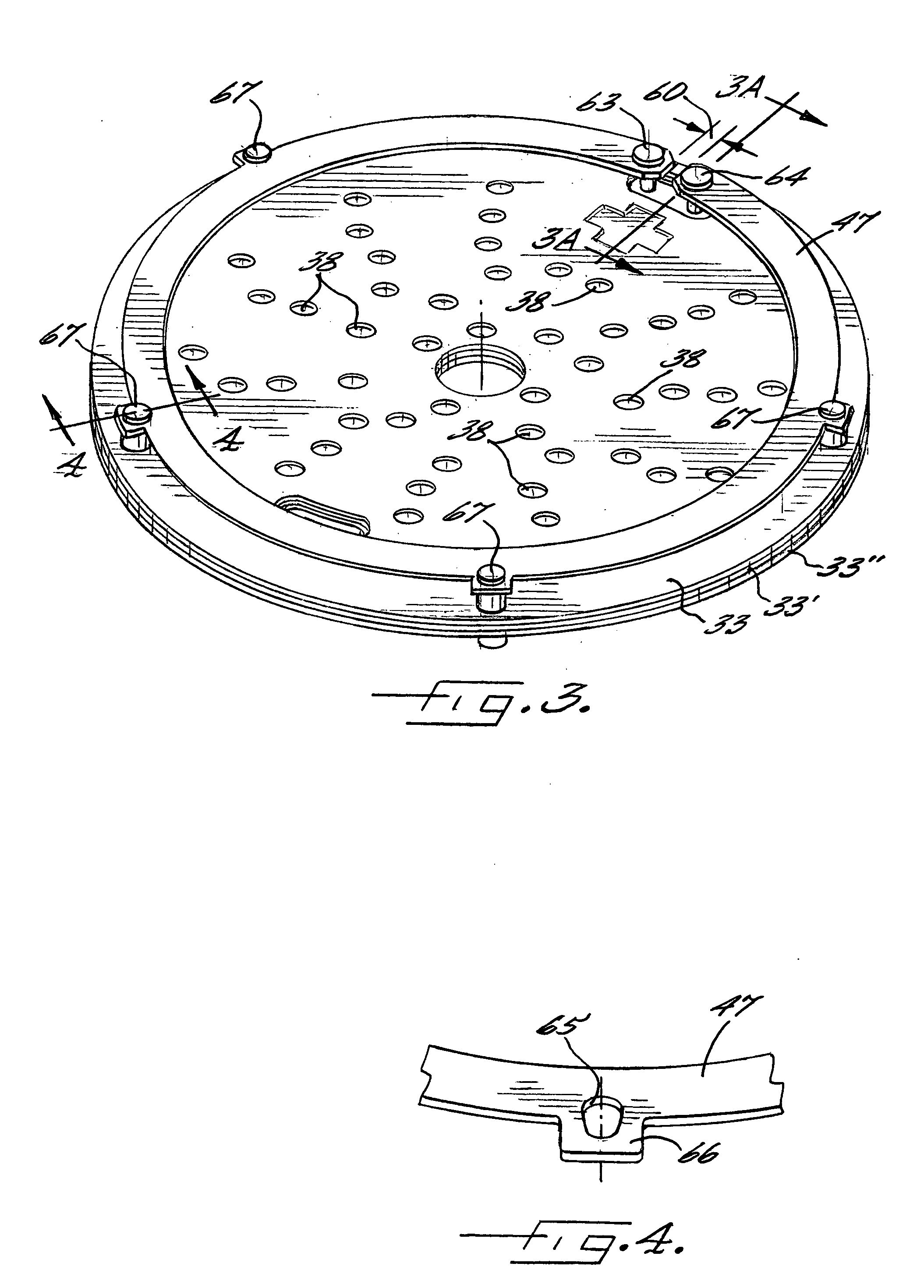

Method and apparatus for microwave processing of planar materials

InactiveUS6546646B1Remove moistureEliminate warpingMilk preparationDough treatmentVaporizationEngineering

A process and apparatus for removing moisture from a material, without spoiling the processed product, through the implementation of microwave irradiation heating, drying, dehydration, curing, disinfection, pasteurization, sterilization or vaporization or any combination thereof. The process and apparatus provide for a controlled processing of planar material, a combination of materials organic or inorganic, in natural or processed form, in sheet leaf, granular, prepared or transportable planar form.

Owner:SUSTAINABLE WORLD TECH

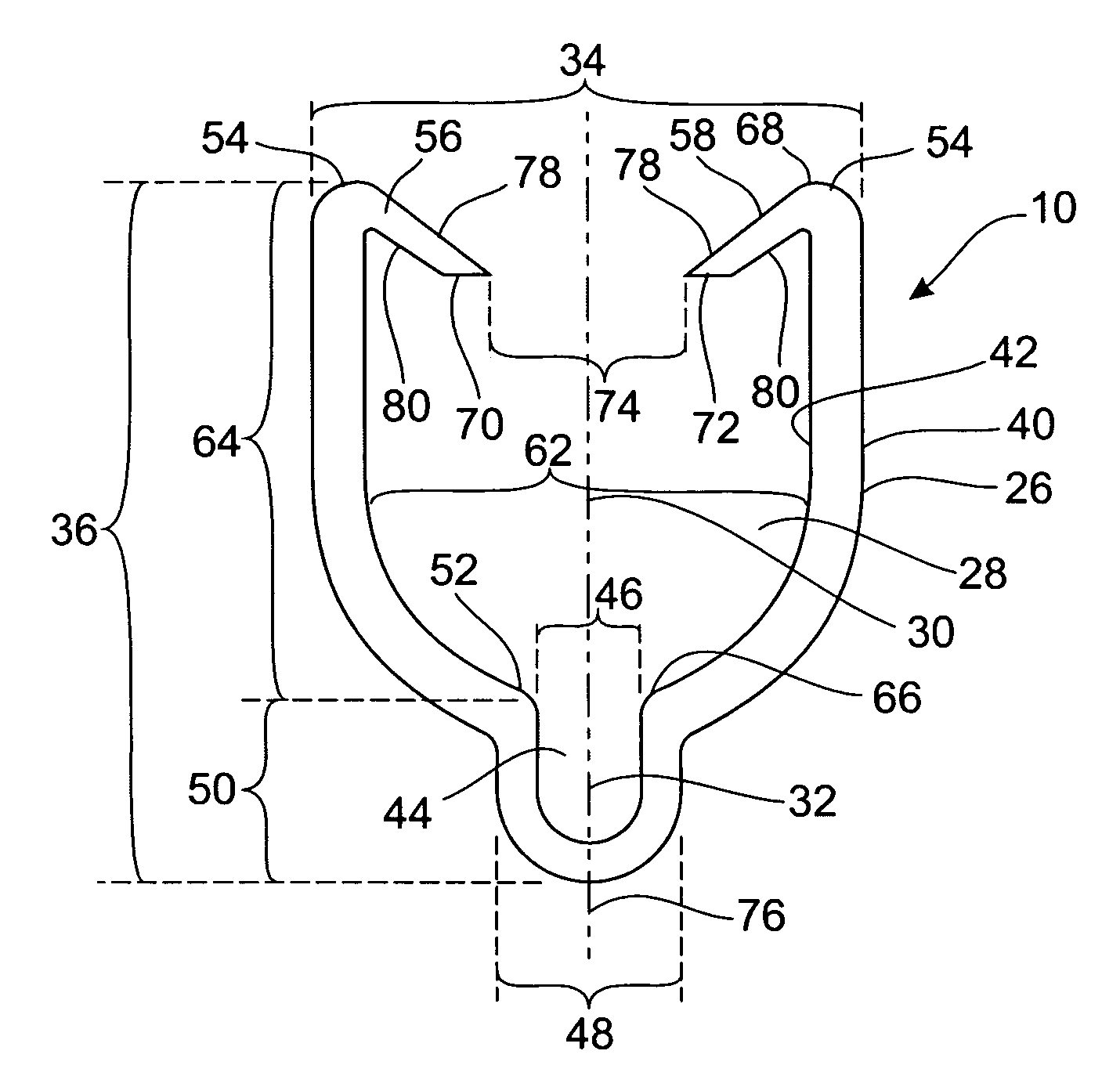

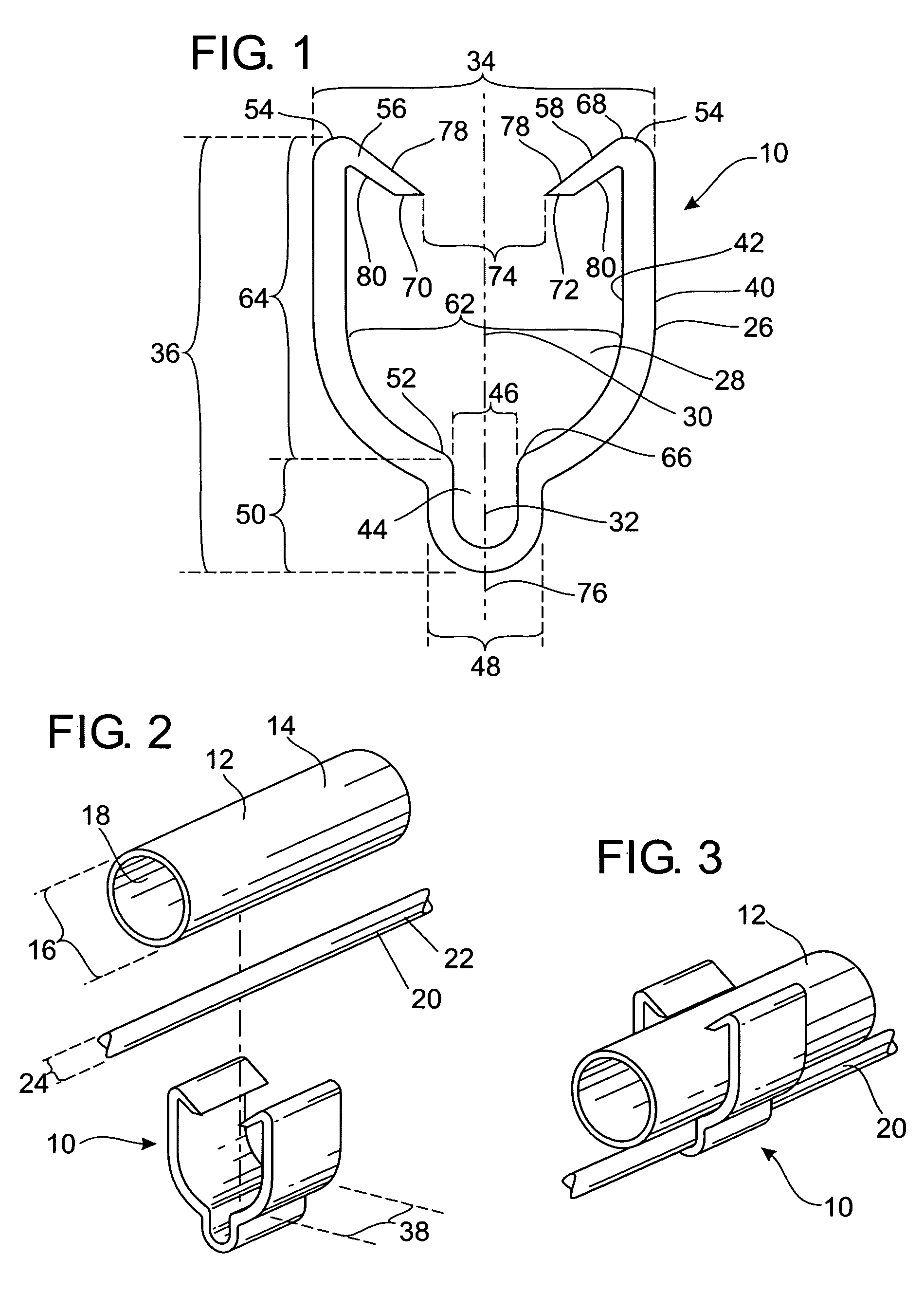

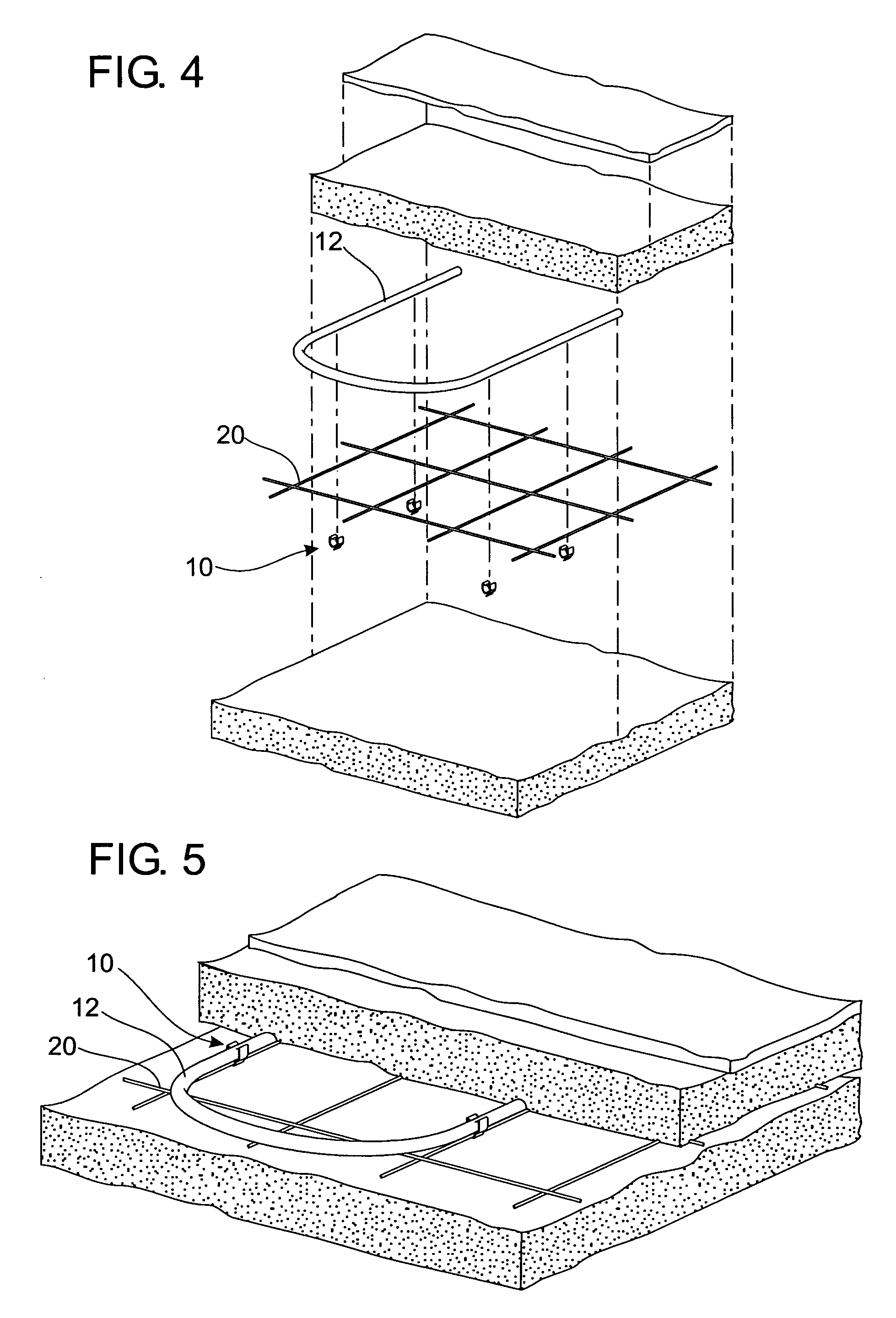

Radiant floor heating and cooling system clip

ActiveUS6969832B1Durable and reliable constructionLower sales pricePipe supportsLighting and heating apparatusMain channelEngineering

A radiant heating and cooling system clip for positioning a tube and construction support wire with one hand comprising an interior having a main channel for positioning a tube with a narrowing second channel within said main channel for positioning a wire.

Owner:MEYER ENTERPRISES

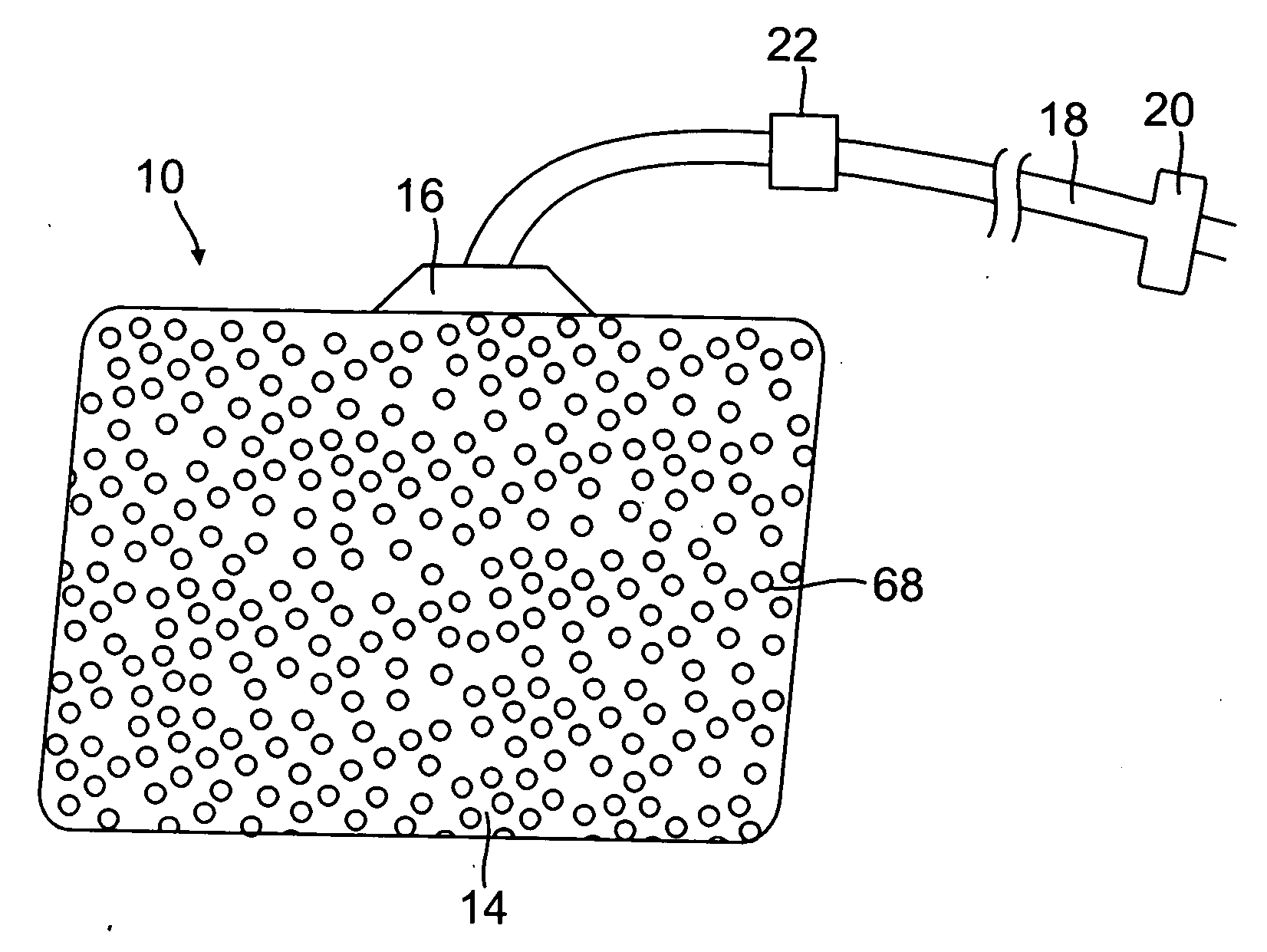

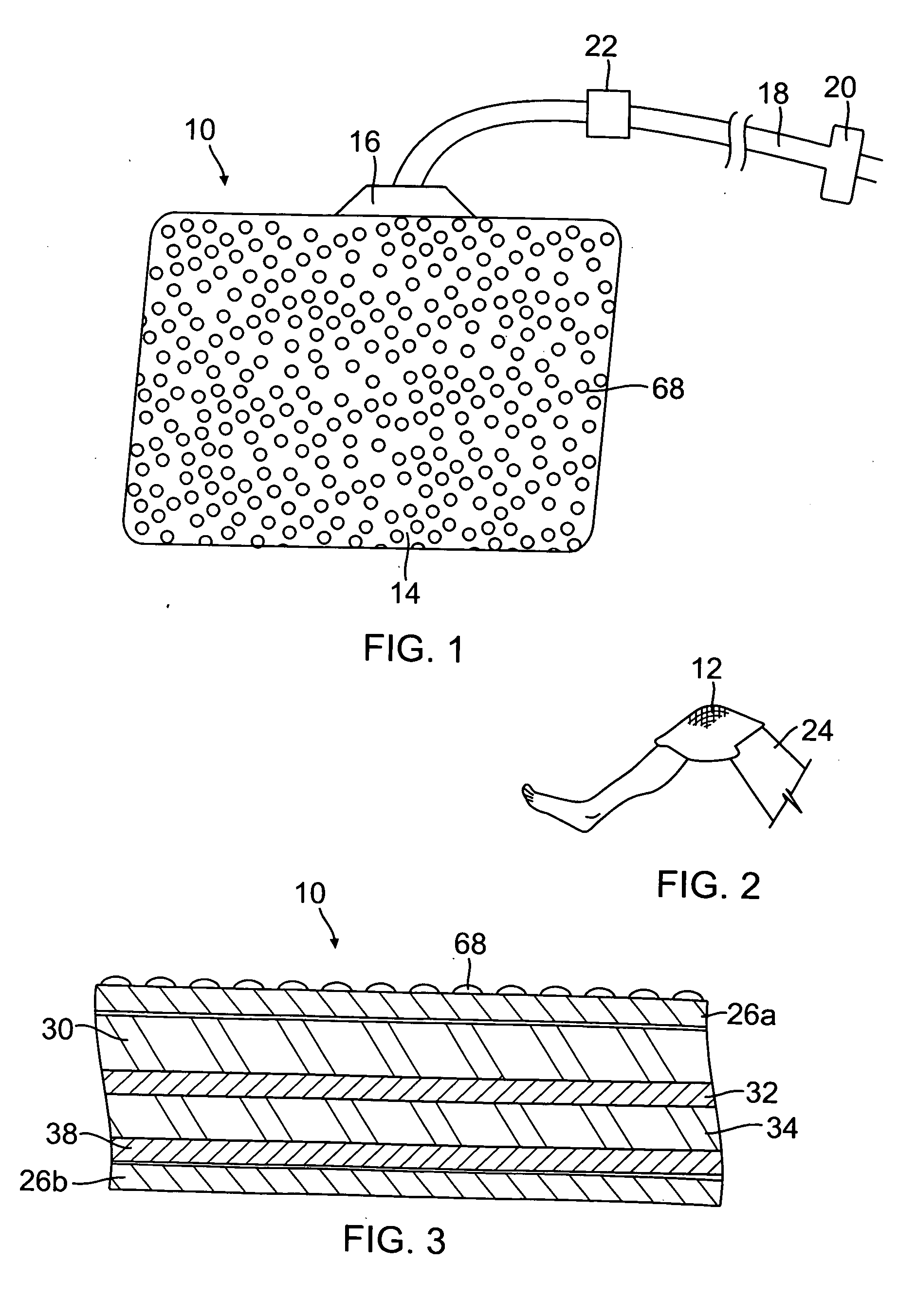

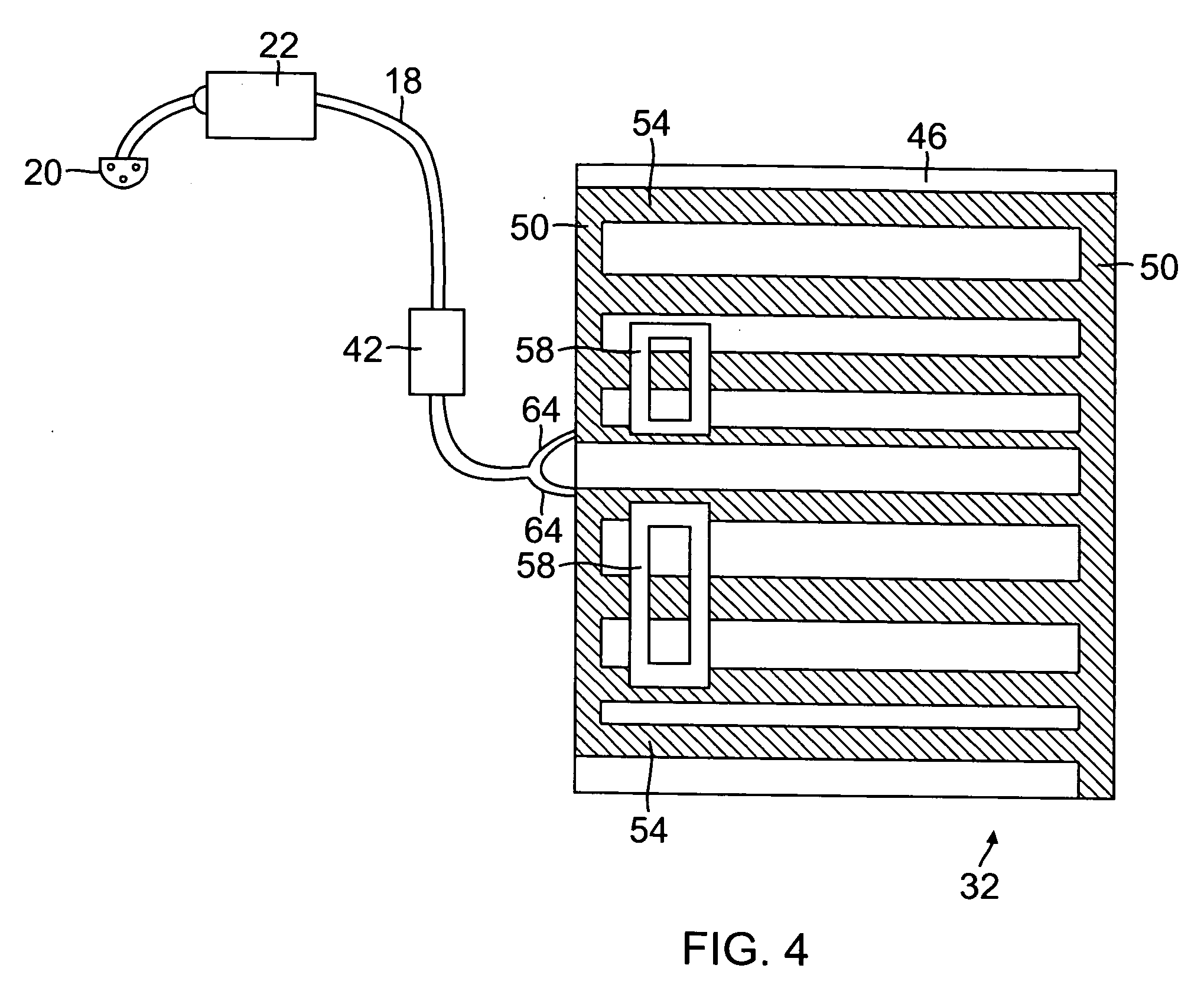

Radiant heating apparatus and method for therapeutic heating

The present invention provides a method and apparatus for heating via infrared radiation. The invention may incorporate a heating pad, safe to the touch, for therapeutic treatment. A heating pad according to the present invention may comprise of layers, such as a heat generation layer, electrically insulating layers, radiation permeable layers, with a sealed cover enclosing the entire pad. This invention is especially useful for heat therapy when a heat pad is applied to the skin of a human or an animal.

Owner:GANDER NICHOLAS M +1

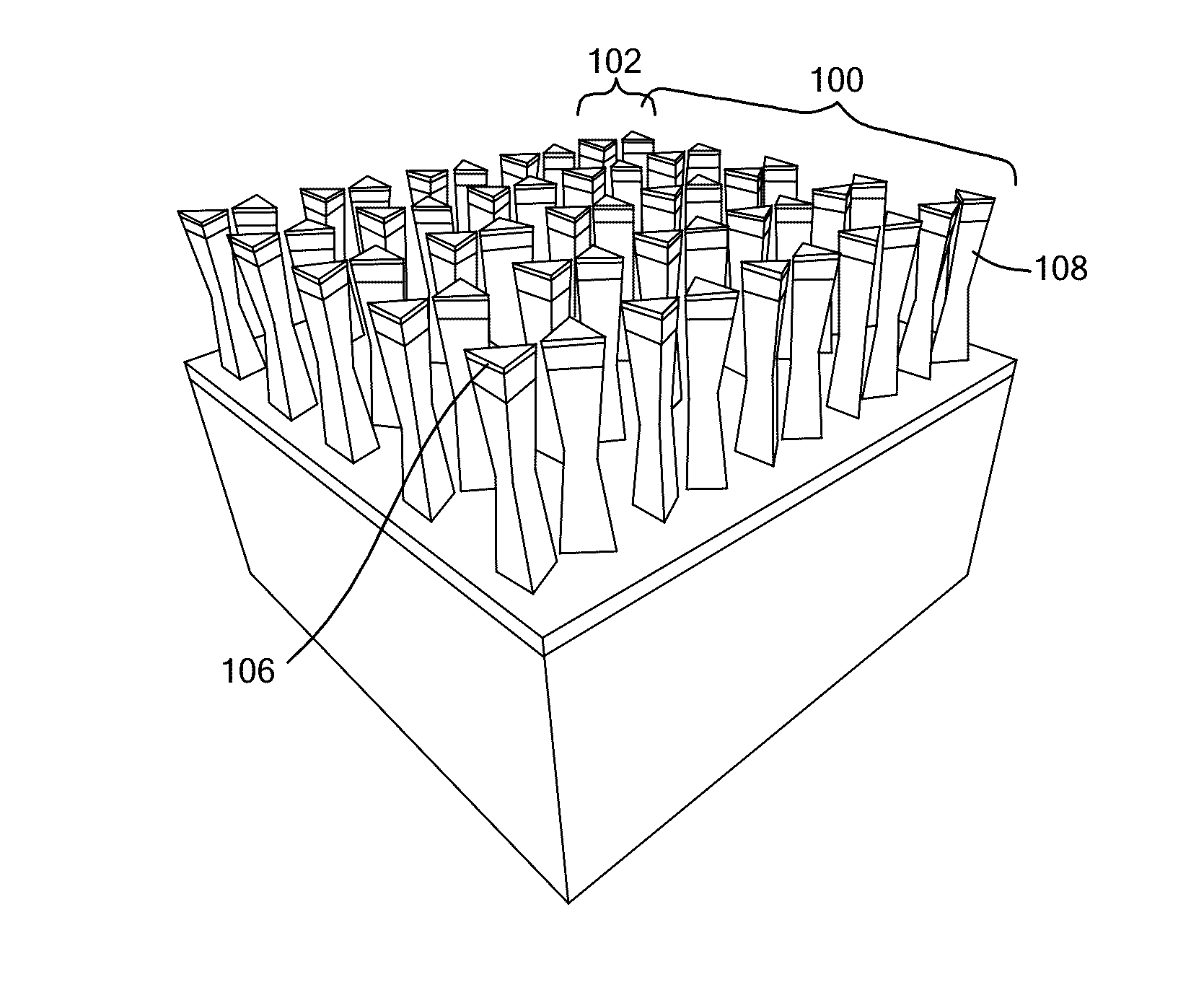

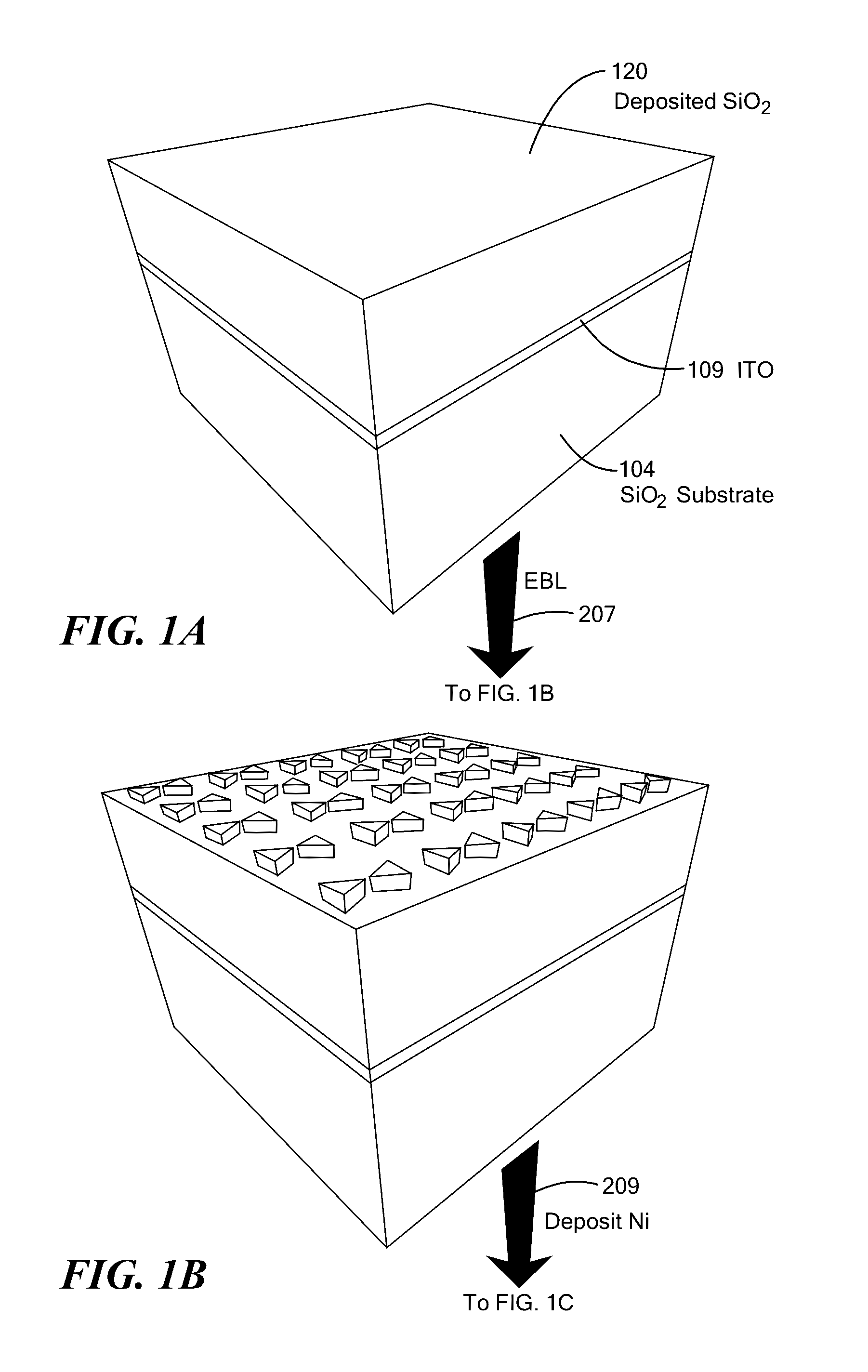

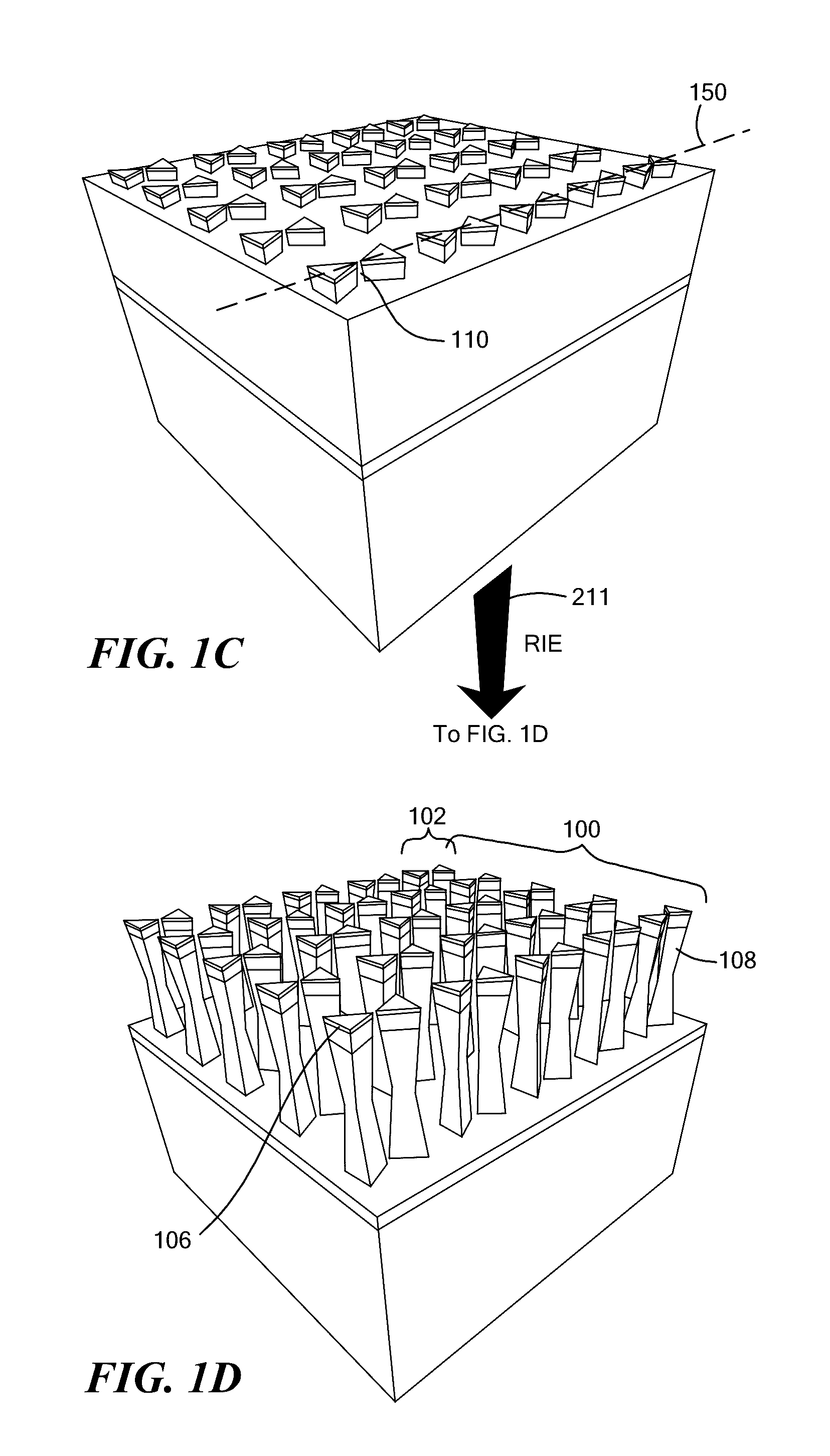

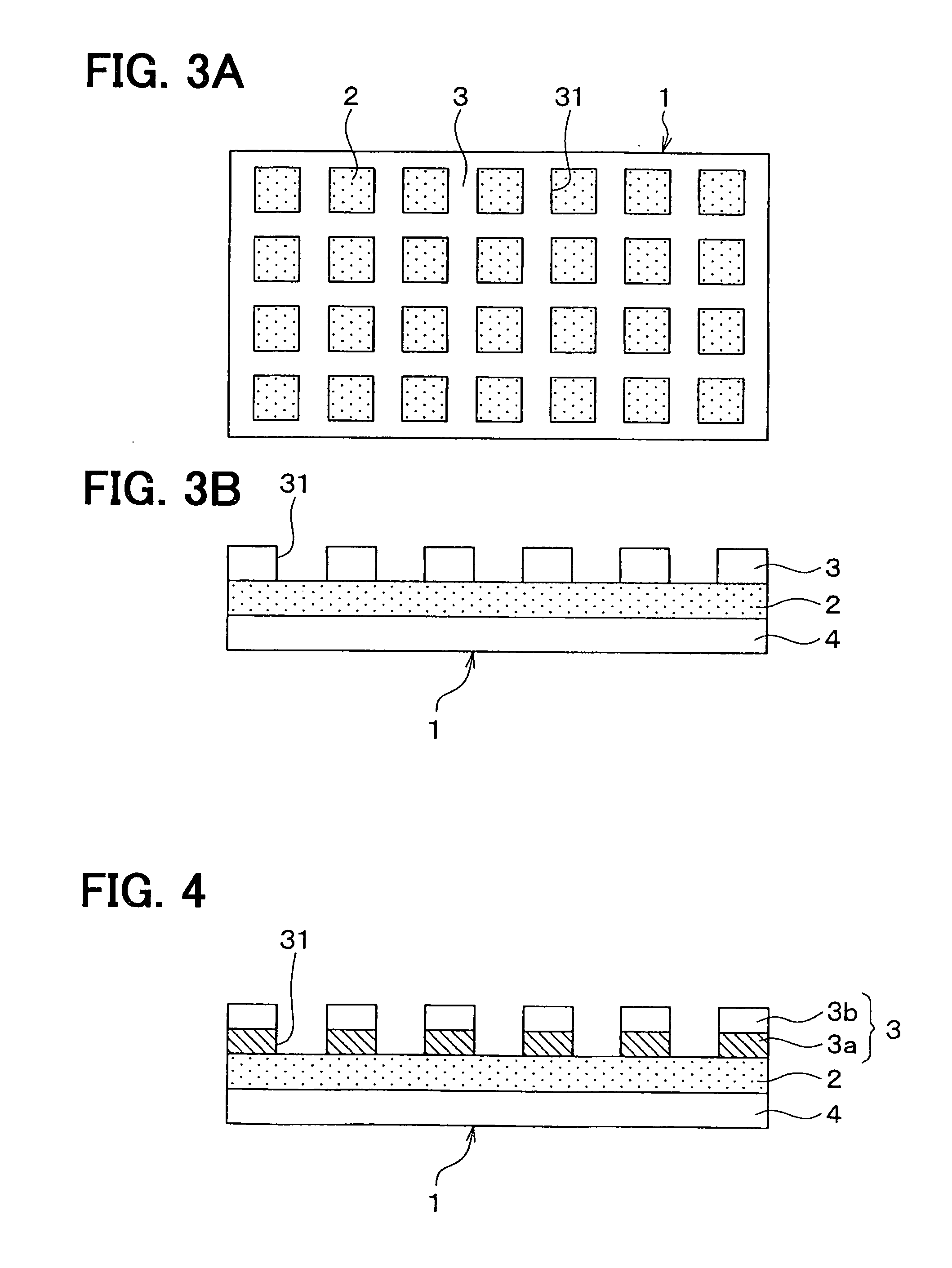

Bowtie Nanoantennas and Methods of Using the Same

A pillar-nanoantenna array structure is fabricated with a substrate to which pairs of pillars are coupled, where the pillars are characterized either by a thermal conductance less than 0.1 μW / deg or by transparency and a height exceeding thickness by at least a factor of two. Metallic caps atop a neighboring pair of pillars are separated by no more than 50 nm. An image-capture structure may be formed by modifying reflectance of a portion of the structure by heating of the portion by electromagnetic radiation. The array may be plastically deformed by raster scanning an electron beam across the array, exciting plasmon modes in the conducting particles thereby inducing a gradient force between neighboring conducting particles, and deforming neighboring pillars in such a manner as to vary the spacing separating neighboring conducting particles. A technique of plasmon-assisted etching provides for fabricating specified planar pattern of metal outside a cleanroom environment.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

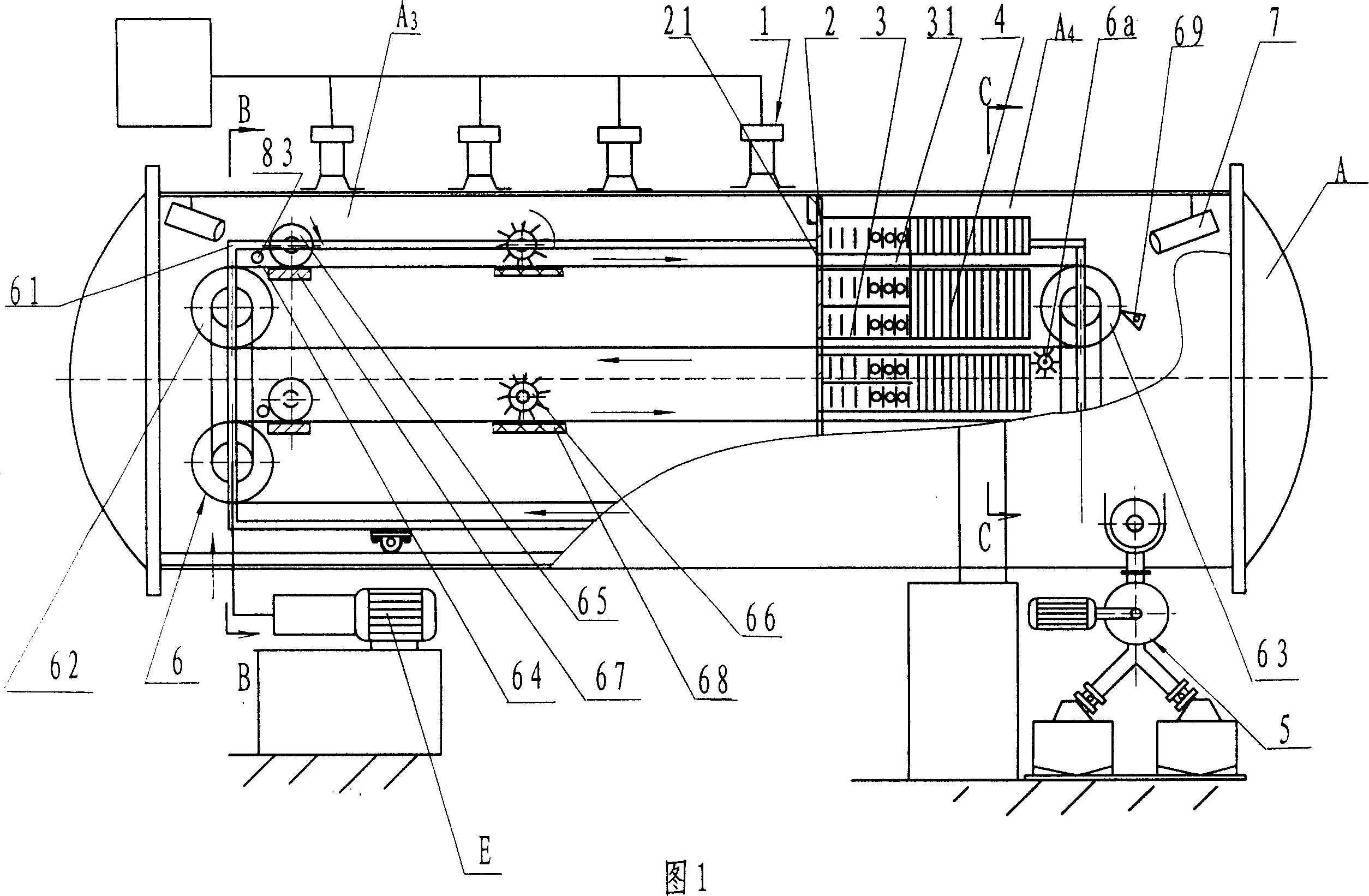

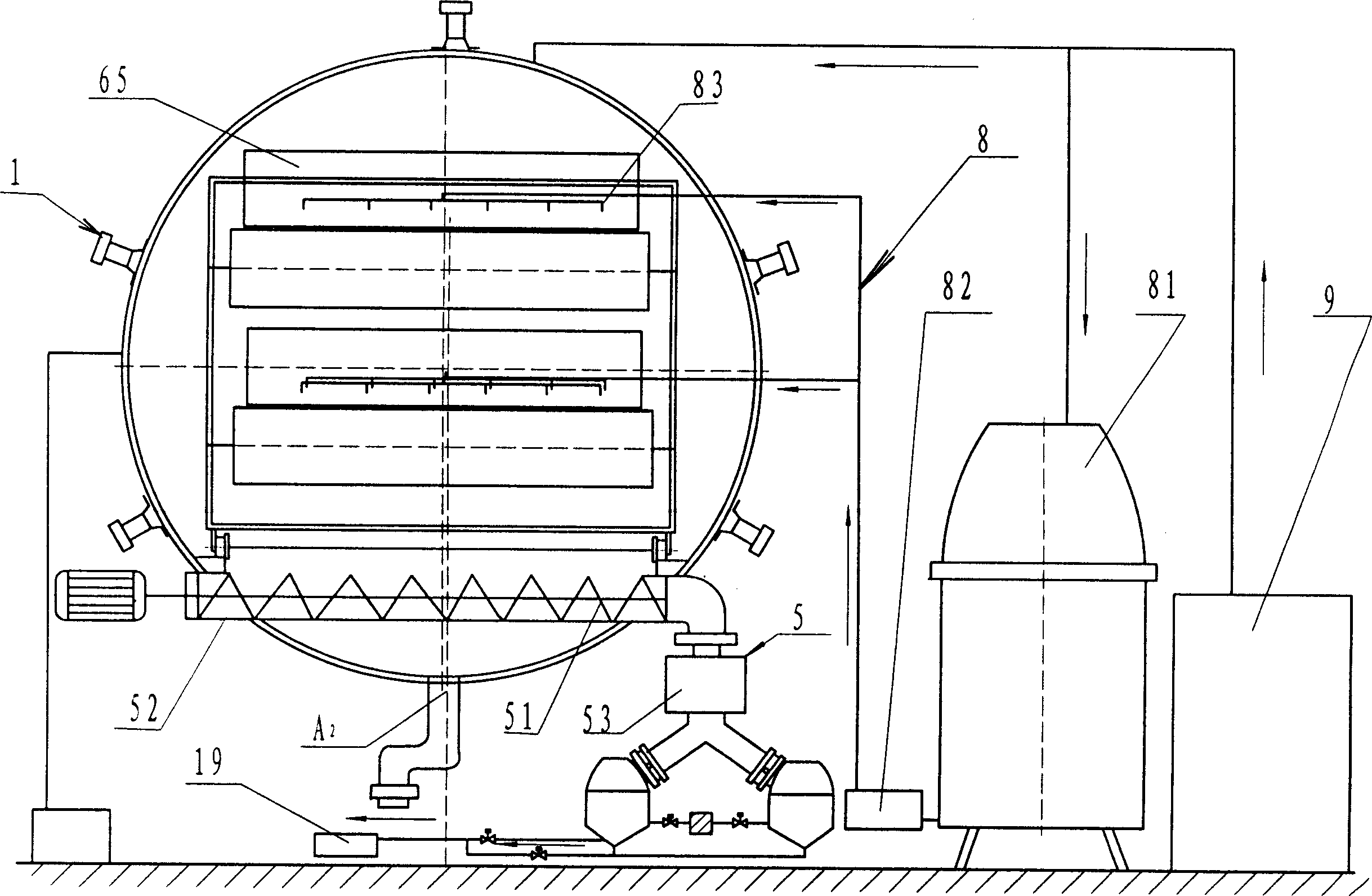

Microwave vacuum continuous drier with two drying chambers and method using the same

InactiveCN1908560ADehydration fastHeating evenlyDrying solid materials with heatHearth type furnacesEngineeringMicrowave irradiation

The present invention mainly relates to the structure of a microwave drier, especially a structure of a microwave vacuum drier. A microwave vacuum continuous drier with two drying chambers, includes a tank (A), a hoisting system (8), a vacuum system (9), wherein a delivery device (6) is disposed in the tank (A), and a discharging device (5) below the delivery device (6), characterized by including a microwave vacuum drying chamber (A3) in the tank (A), a microwave heater system (1) on the wall of the tank (A) of the microwave vacuum drying chamber (A3), a separating plate (2) on one side of the microwave vacuum drying chamber (A3) to form a vacuum cooling solidifying chamber (A4). The driving belt (64) of the delivery device (6) traverses the window (21) arranged on the separating plate (2). On one end of the tank (A) is arranged with the microwave vacuum drying chamber (A3) and on the other end is the vacuum cooling solidifying chamber (A4). The separating plate (2) separates the two chambers to make the temperature have the obvious gradient. The invention adopts the way of microwave radiation heating, utilizing the characters of microwave high efficiency, easy to control, antisepsis, sterilization, fast heating, even heating, fast dehydration, preserving to reduce the power waster and advance the efficiency.

Owner:TIANSHUI HUAYUAN PHARMA EQUIP TECH

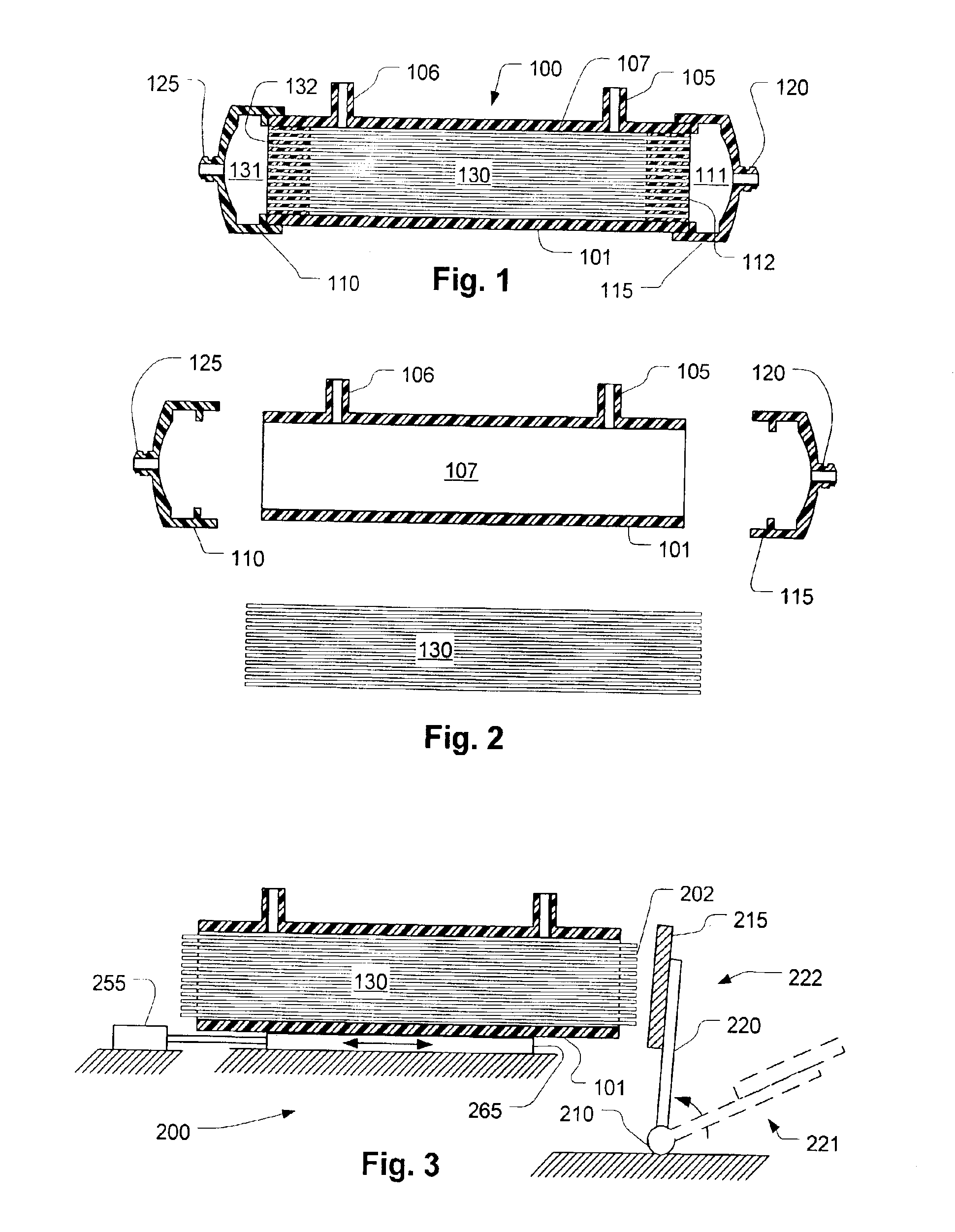

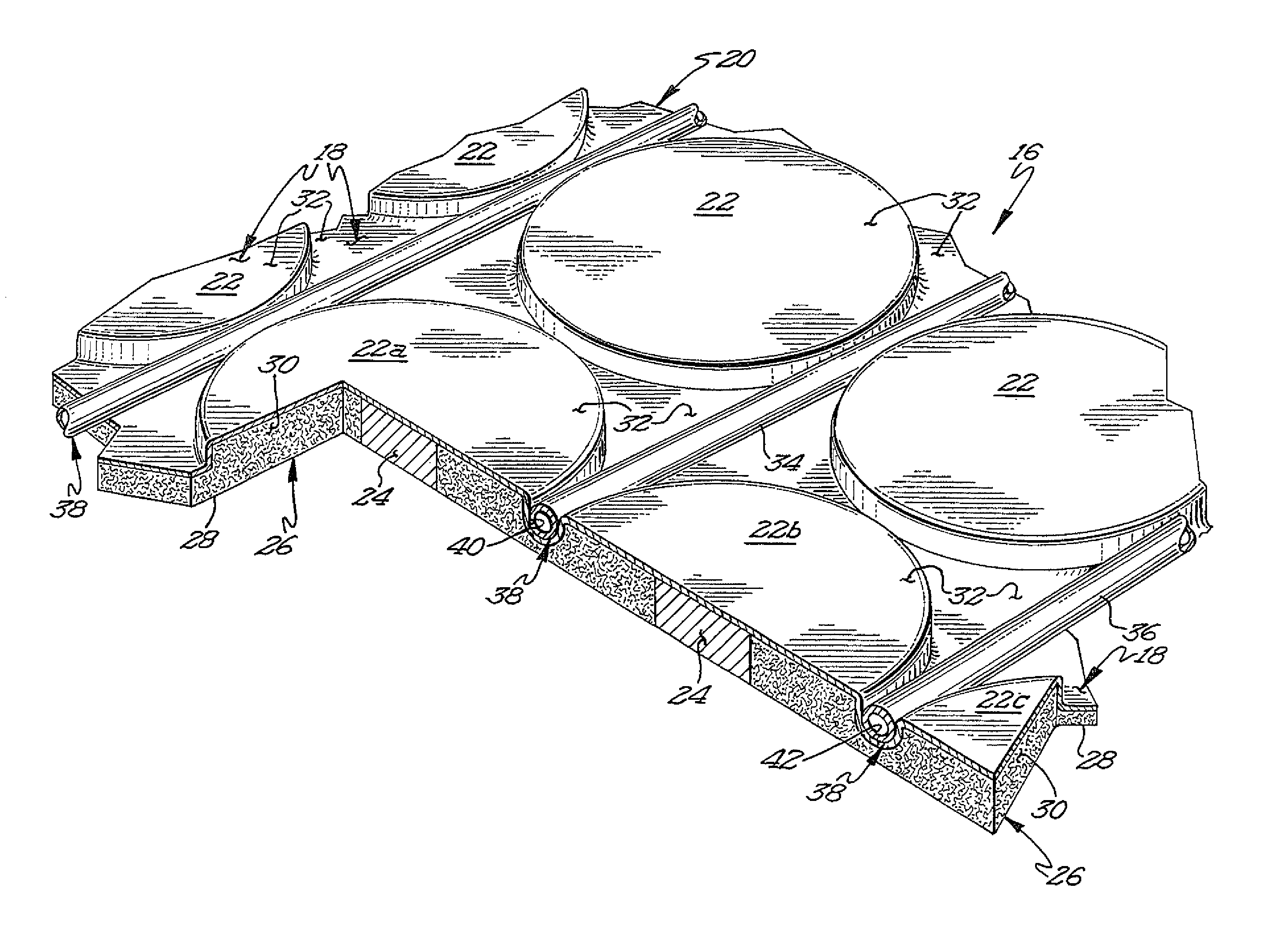

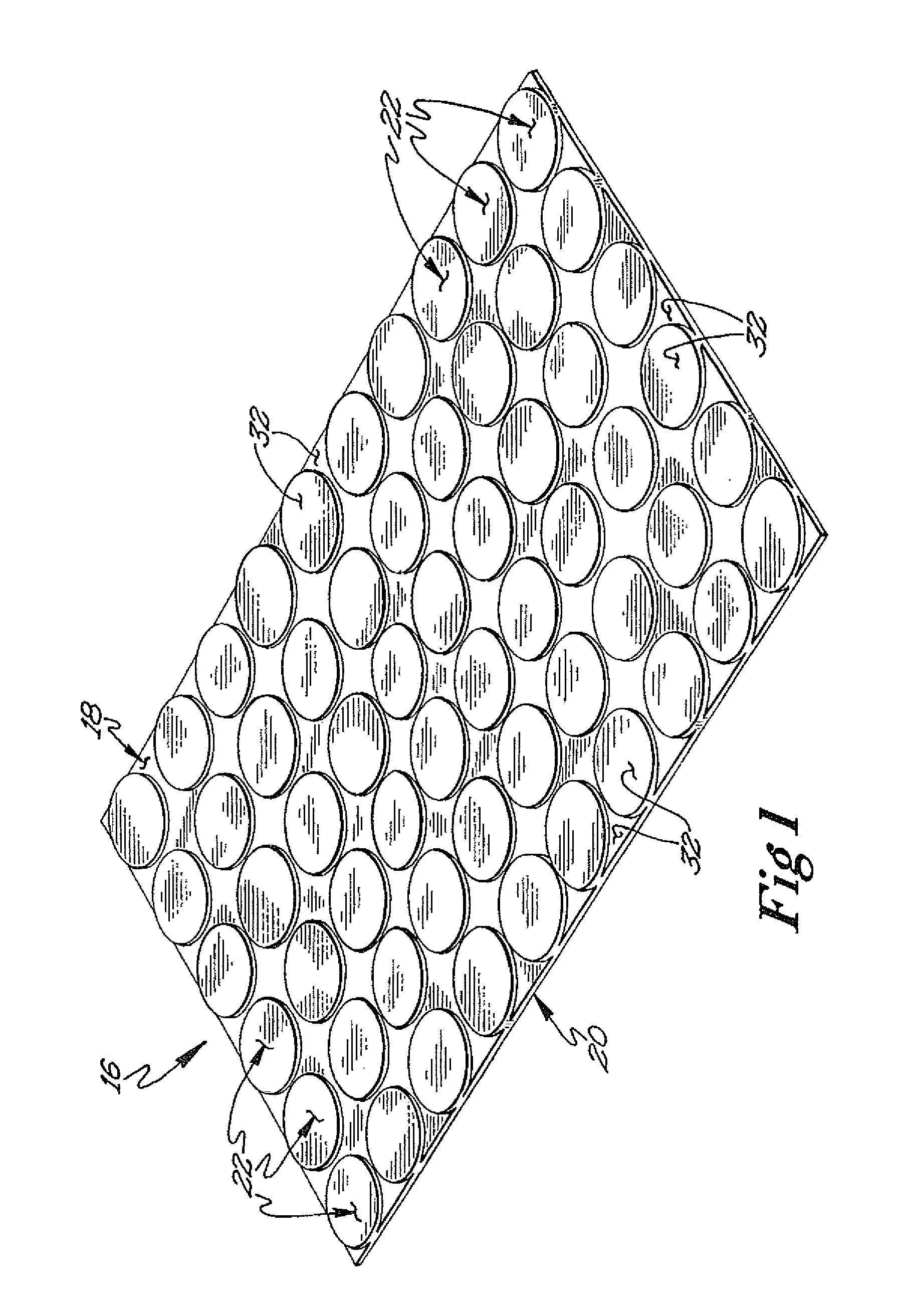

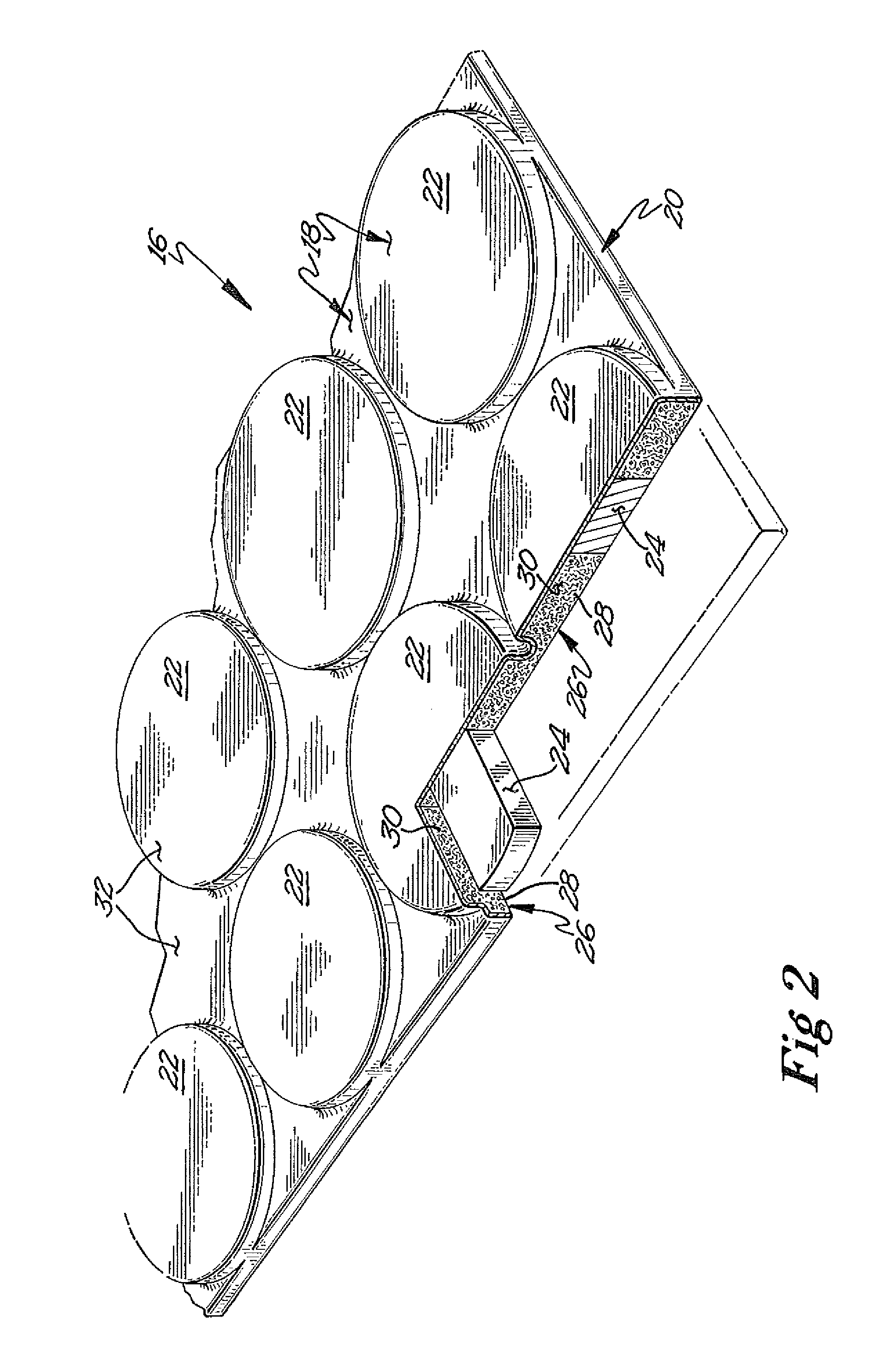

Apparatus with multi-directional radiation emitters for printing a dye image onto a three dimensional object

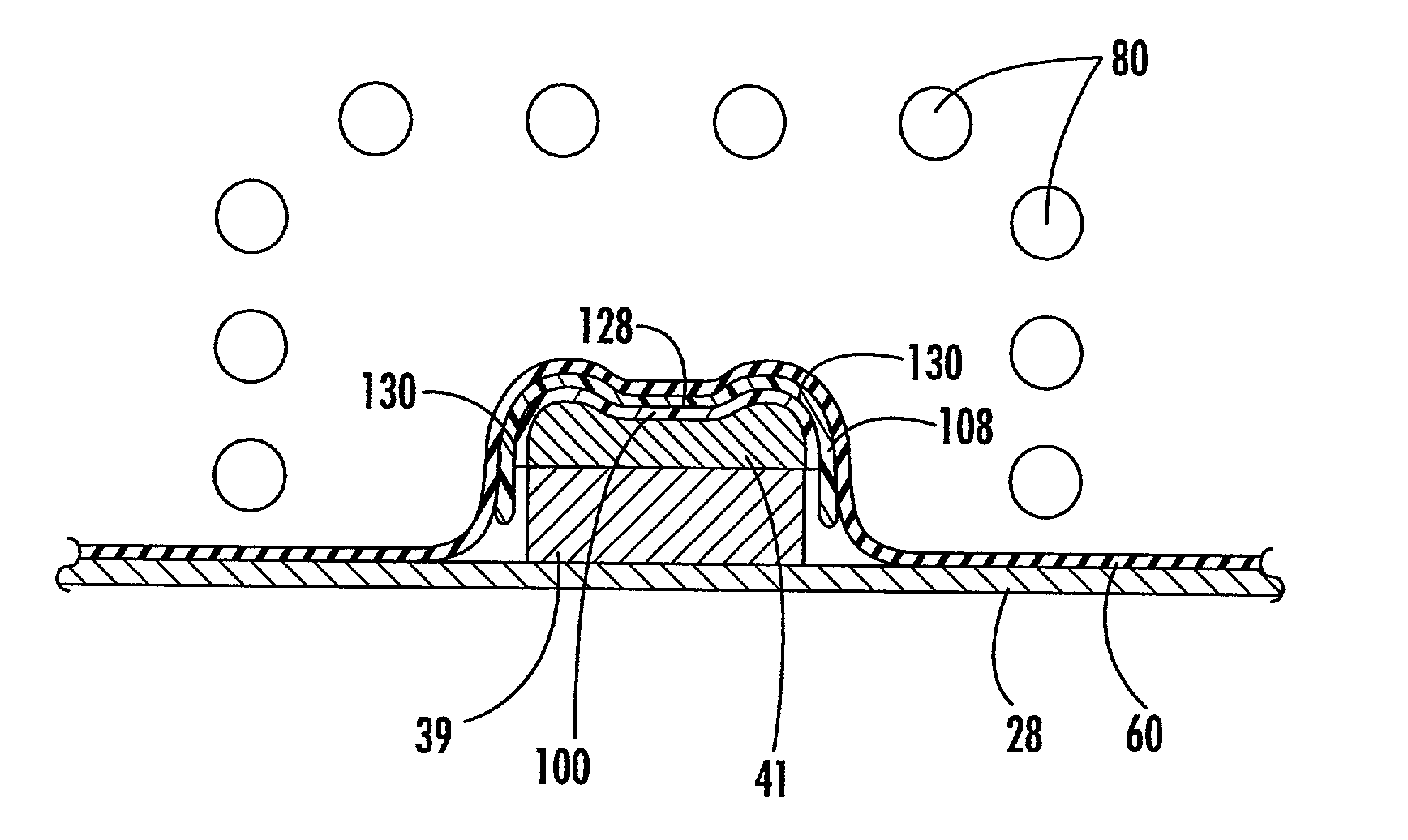

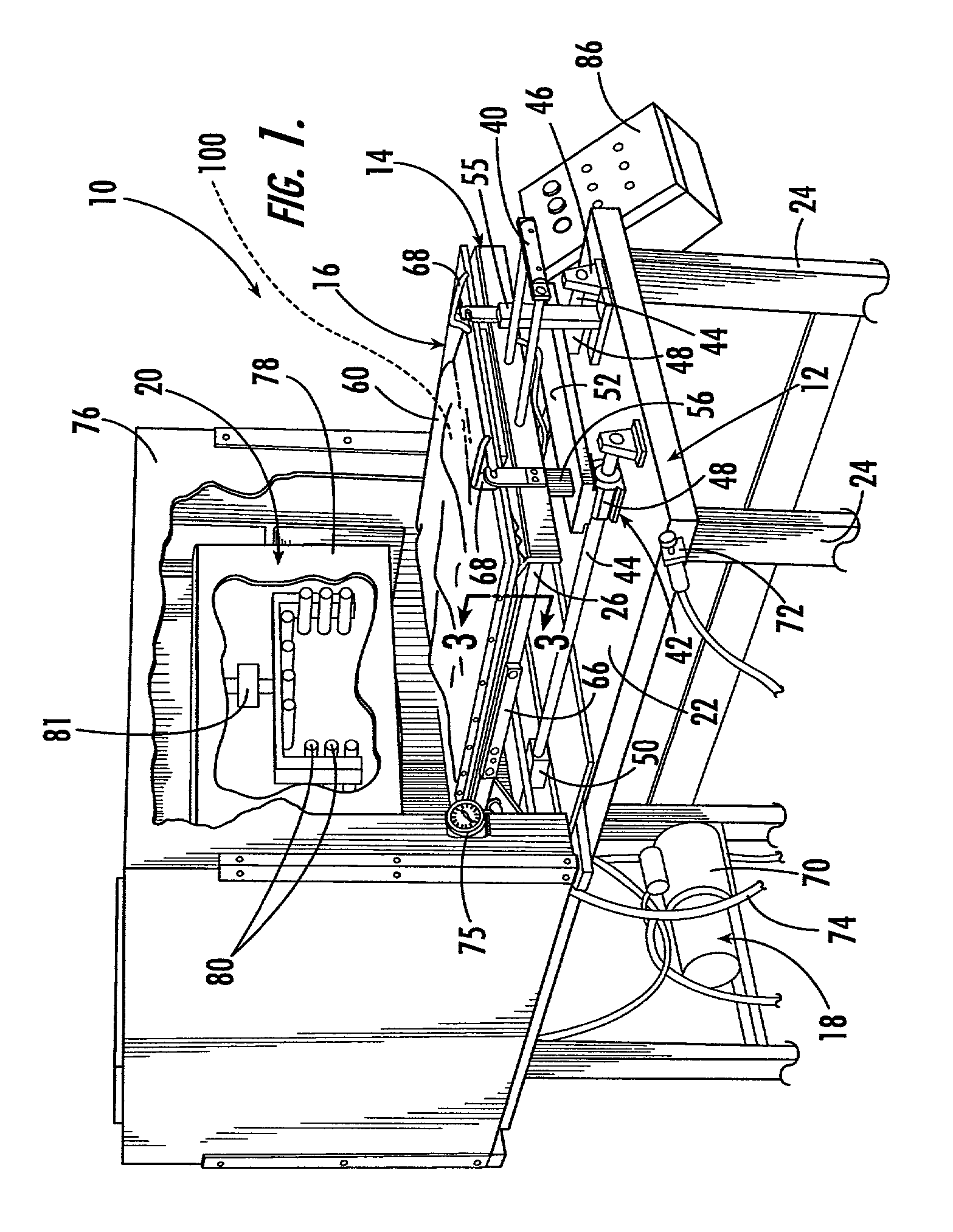

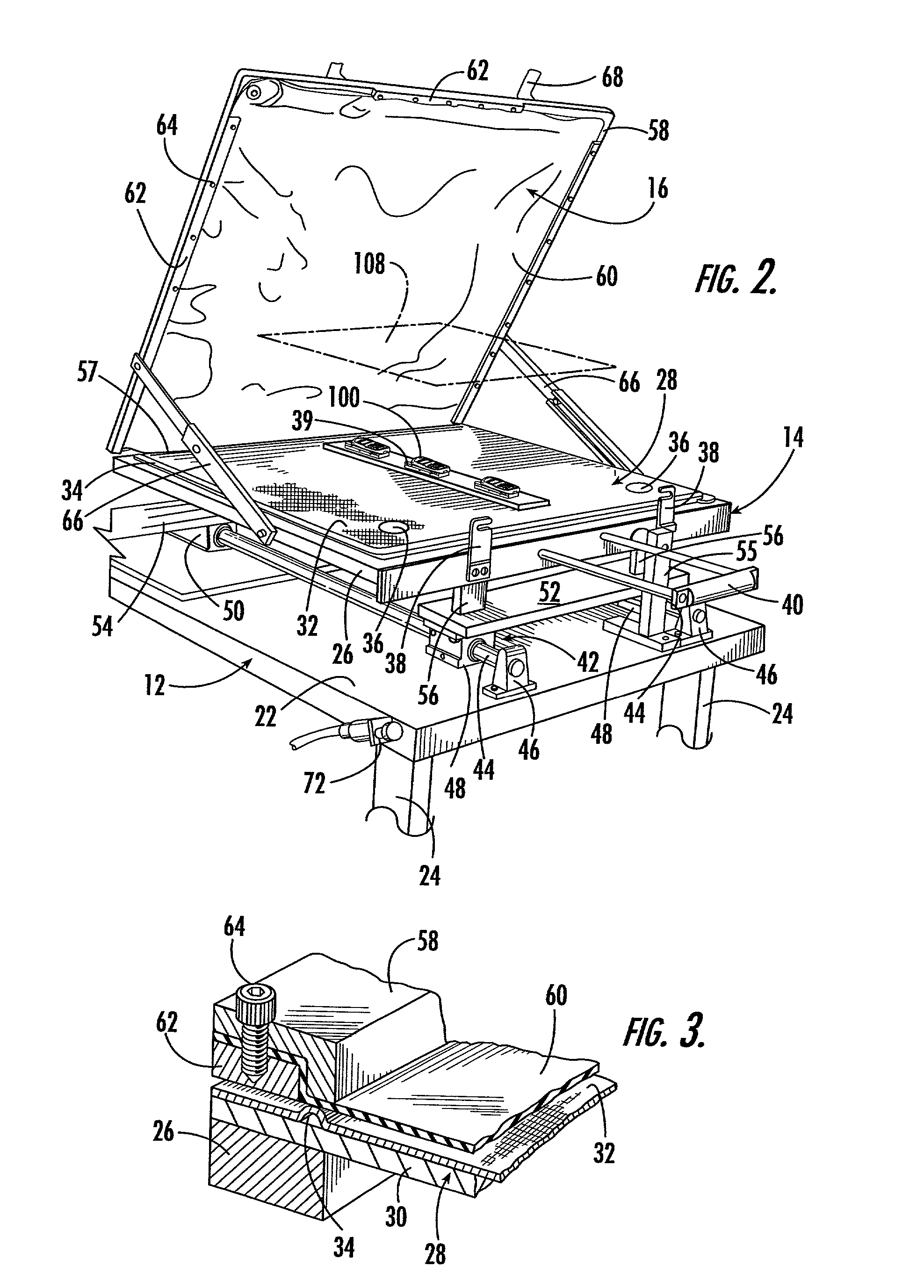

InactiveUS7137426B2Improve heating efficiencyEfficient transferTransfer printingDigitally marking record carriersEngineeringMirror image

The present invention provides an apparatus and method for applying preselected dye images to three dimensional objects, having plastic outer surfaces, utilizing flexible carrier sheets bearing dyes in the mirror images of the preselected images, where the sheets are overlaid in registration with the objects and maintained in pressurized engagement therewith while the sheets and the objects are heated. The present invention includes a bed for receiving at least one three-dimensional object member thereon with a flexible dye bearing carrier sheet placed in registration on the object and a resiliently flexible membrane, which is positionable over the sheet on the member. A vacuum assembly of the apparatus is operable to evacuate the area between the membrane and the bed in order to draw the membrane into pressurized engagement with the flexible sheet on the member thereby drawing the flexible sheet around the various surfaces of the three dimensional object. Radiant heating elements are operable both to preheat the carrier sheet, improving its flexibility and to heat the membrane after the vacuum assembly has been actuated, whereby the dye on the sheet is applied to the surfaces of the object to produce the preselected image thereon.

Owner:KII TEKU INC

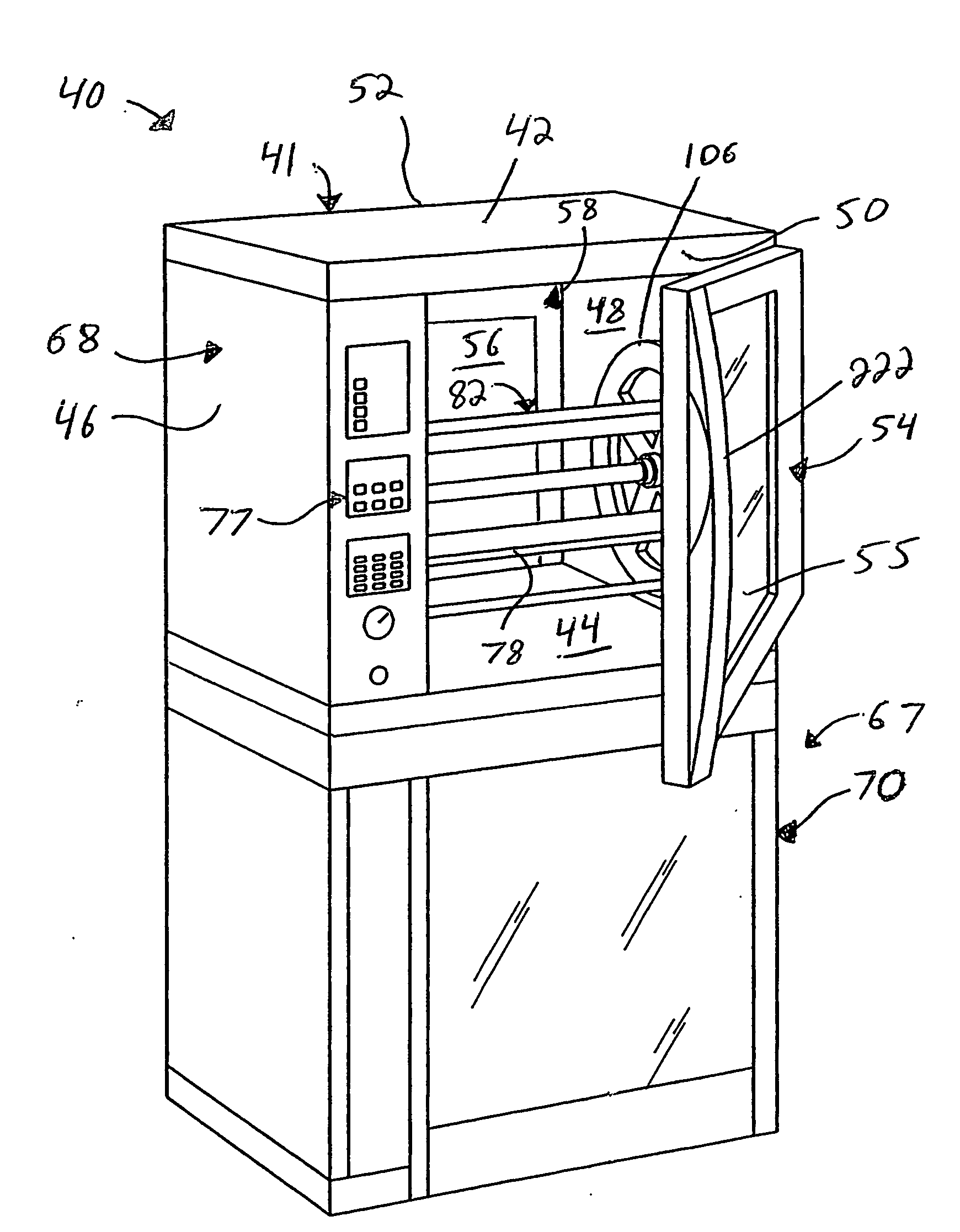

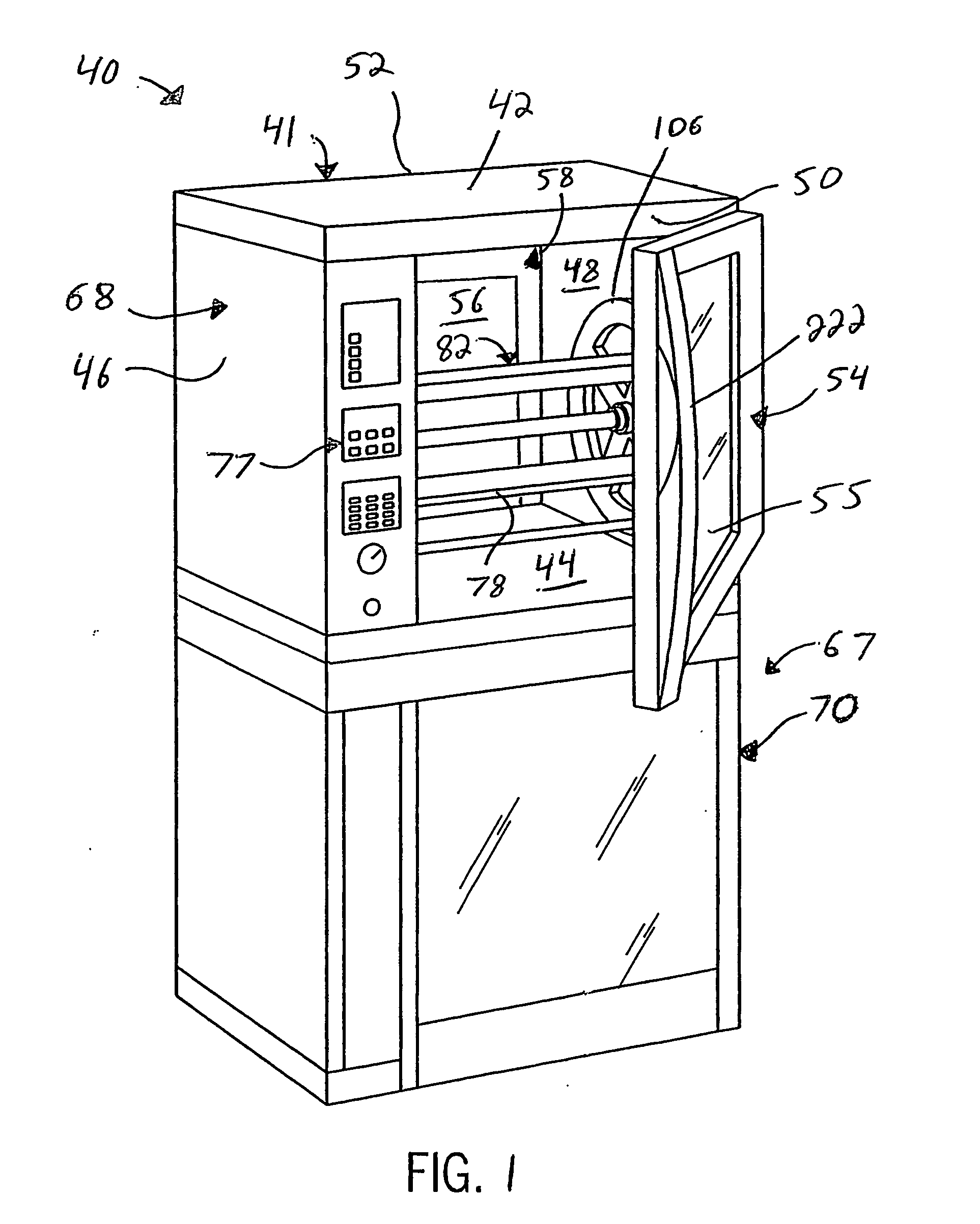

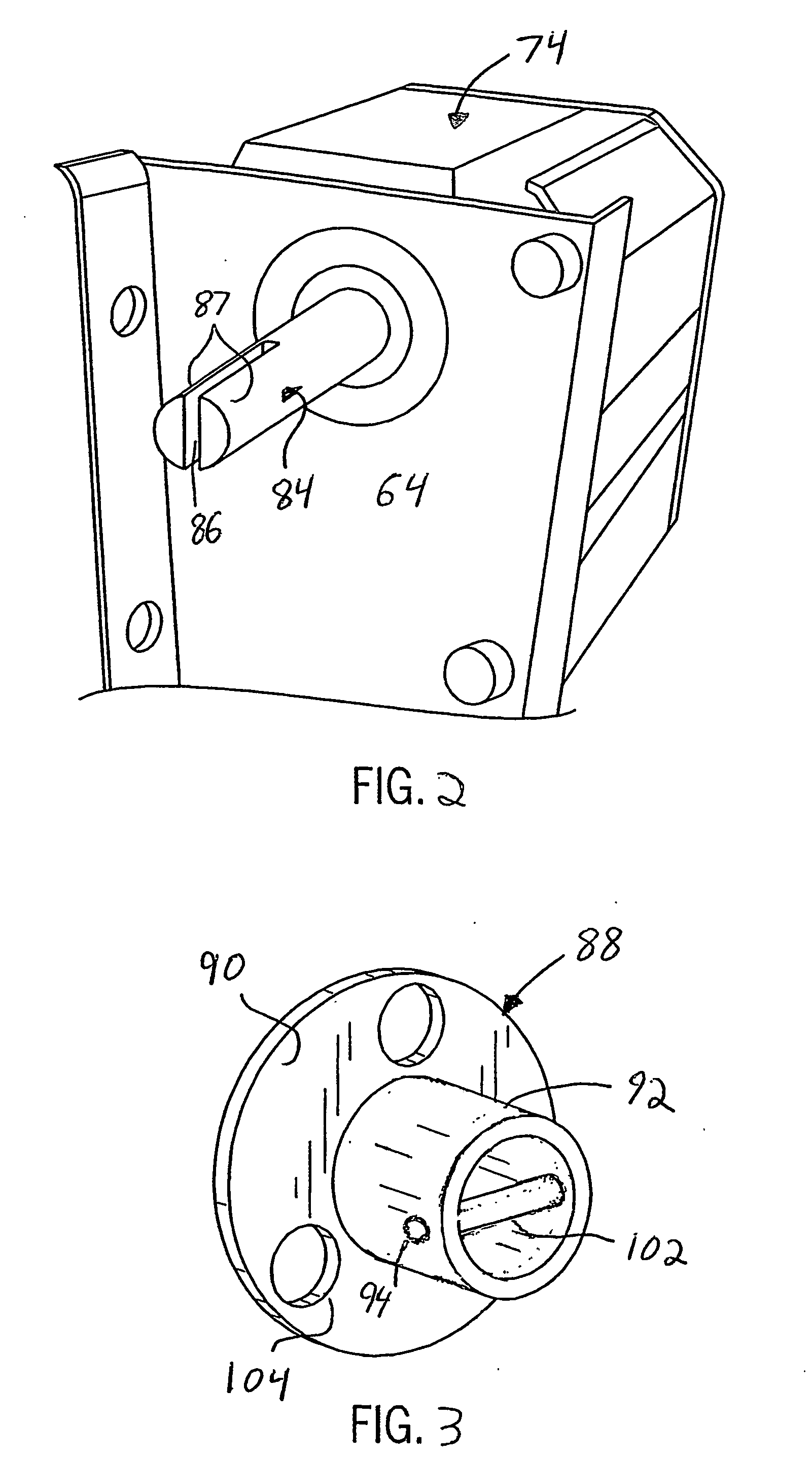

Rotisserie oven and hood

A rotisserie oven is provided having a radiating heating system in combination with a convection heating system to prepare raw meat and poultry food product inside of a cooking chamber. A spit assembly carries the food product, and includes components that are detachable to assist in cleaning. The oven further includes a steam cleaning assembly that is integrated with the convection heating system that assists in grease removal from the components inside the cooking chamber. A humidity removal system regulates the moisture level inside of the cooking chamber during food preparation. A rotisserie oven is provided of the type that includes a cooking chamber having at least one open end closed by a movable door assembly. A radiating heating system is disposed in the cooking chamber and receives electricity to produce radiating heat to cook food carried by a rotating spit assembly. A hood assembly is supported by the cooking chamber, and defines a filtration chamber that receives incoming grease-laden air from the cooking chamber and houses at least one filtration member drawing the incoming air therethrough towards a hood outlet. The hood assembly and cooking chamber move together as the rotisserie oven travels from one location to another.

Owner:SWANK PHILIP D +5

Radiant heating and cooling panel

InactiveUS8288689B1Easy to useFacilitate placement of the thermal control componentIncandescent ignitionBaking ovenAdhesiveEngineering

A panel for radiant heating and cooling includes a moisture impermeable shell with protrusions extended from a base. Channels between adjacent protrusions frictionally retain a thermal control component such as flexible tubing or an electrical heating element. The protrusions define chambers open at the bottom of the shell. An anchor in each chamber is secured to the top wall and extends downwardly beyond the base. A thermally conductive film is applied to the top surface of the shell. An insulative layer extends downwardly from inside the shell and beyond the base, surrounding the anchors while leaving bottom surfaces of the anchors exposed. The anchors are secured to a floor or substrate by an adhesive to integrally mount the panel. The anchors can receive and frictionally retain axially driven fasteners such as nails and staples, facilitating the attachment of a flooring overlayer integrally with respect to the substrate through the panel.

Owner:ADELMAN DEAN W

Restricted radiated heating assembly for high temperature processing

ActiveUS20060130763A1Reduce the differenceIncreasing lifetimeSemiconductor/solid-state device manufacturingFrom chemically reactive gasesProduction rateElectrical resistance and conductance

A vapor deposition reactor and associated method are disclosed that increase the lifetime and productivity of a filament-based resistive-heated vapor deposition system. The reactor and method provide for heating the filament while permitting the filament to move as it expands under the effect of increasing temperature while limiting the expanding movement of the filament to an amount that prevents the expanding movement of the filament from creating undesired contact with any portions of the reactor.

Owner:CREE INC

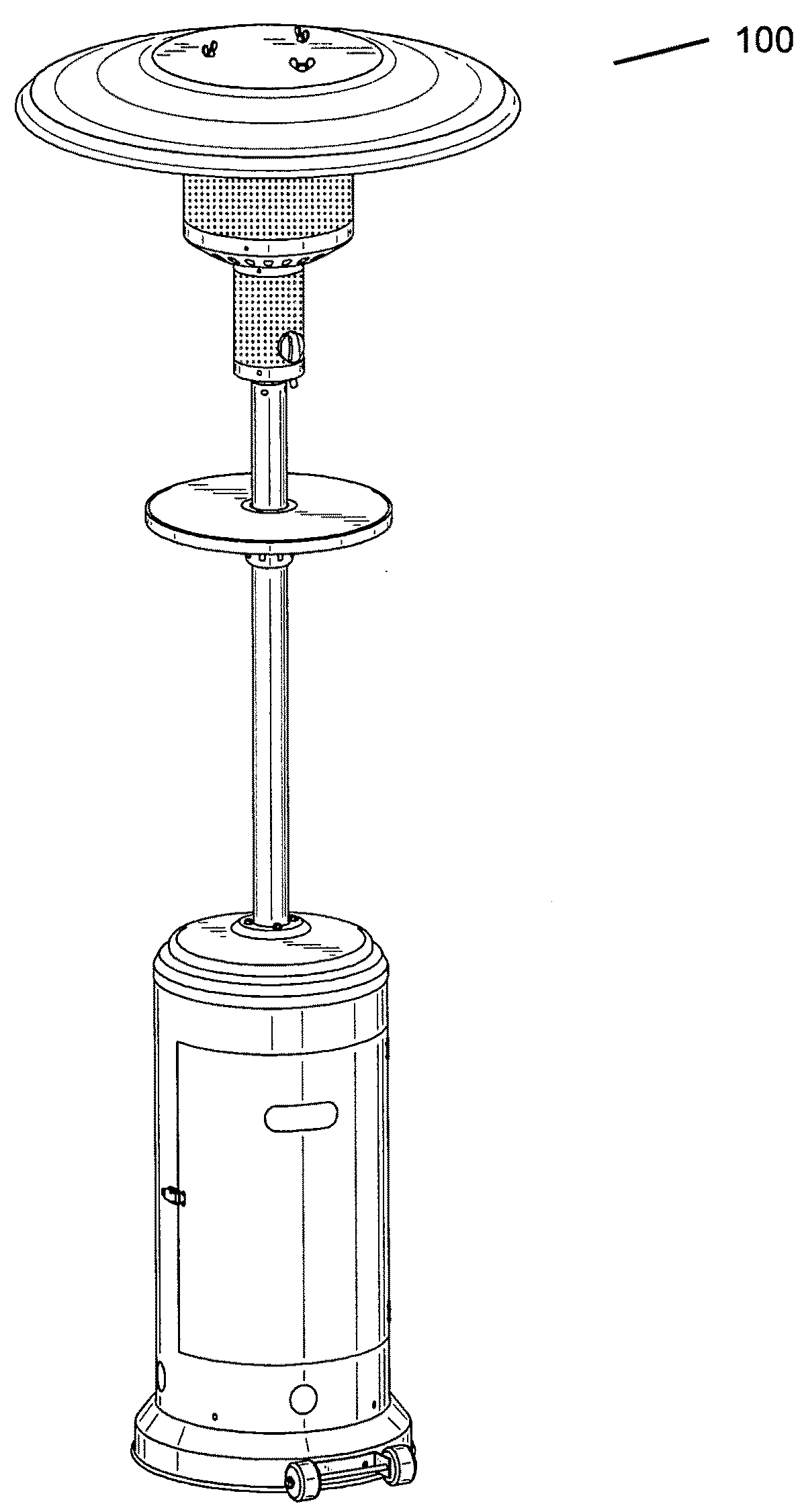

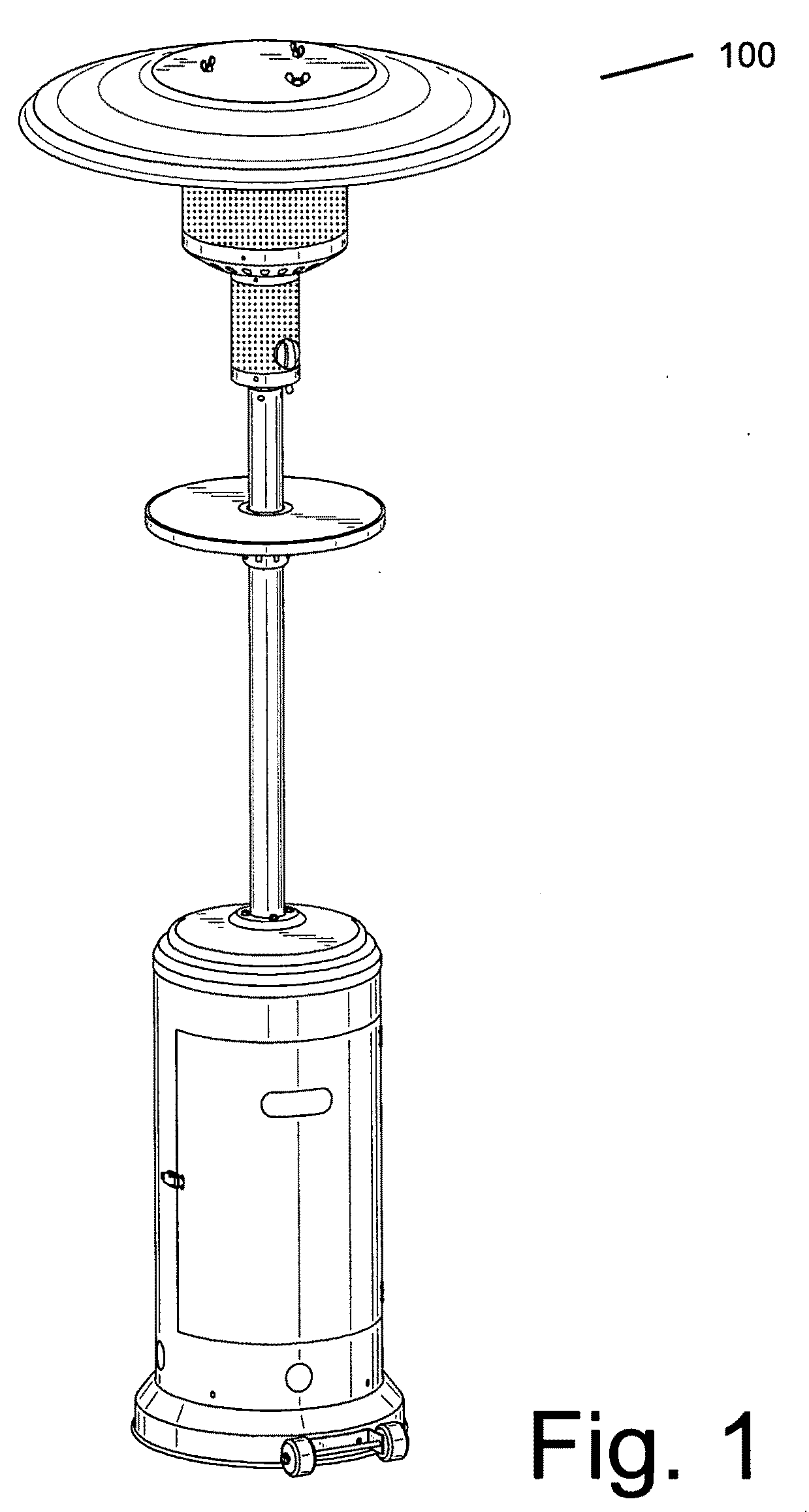

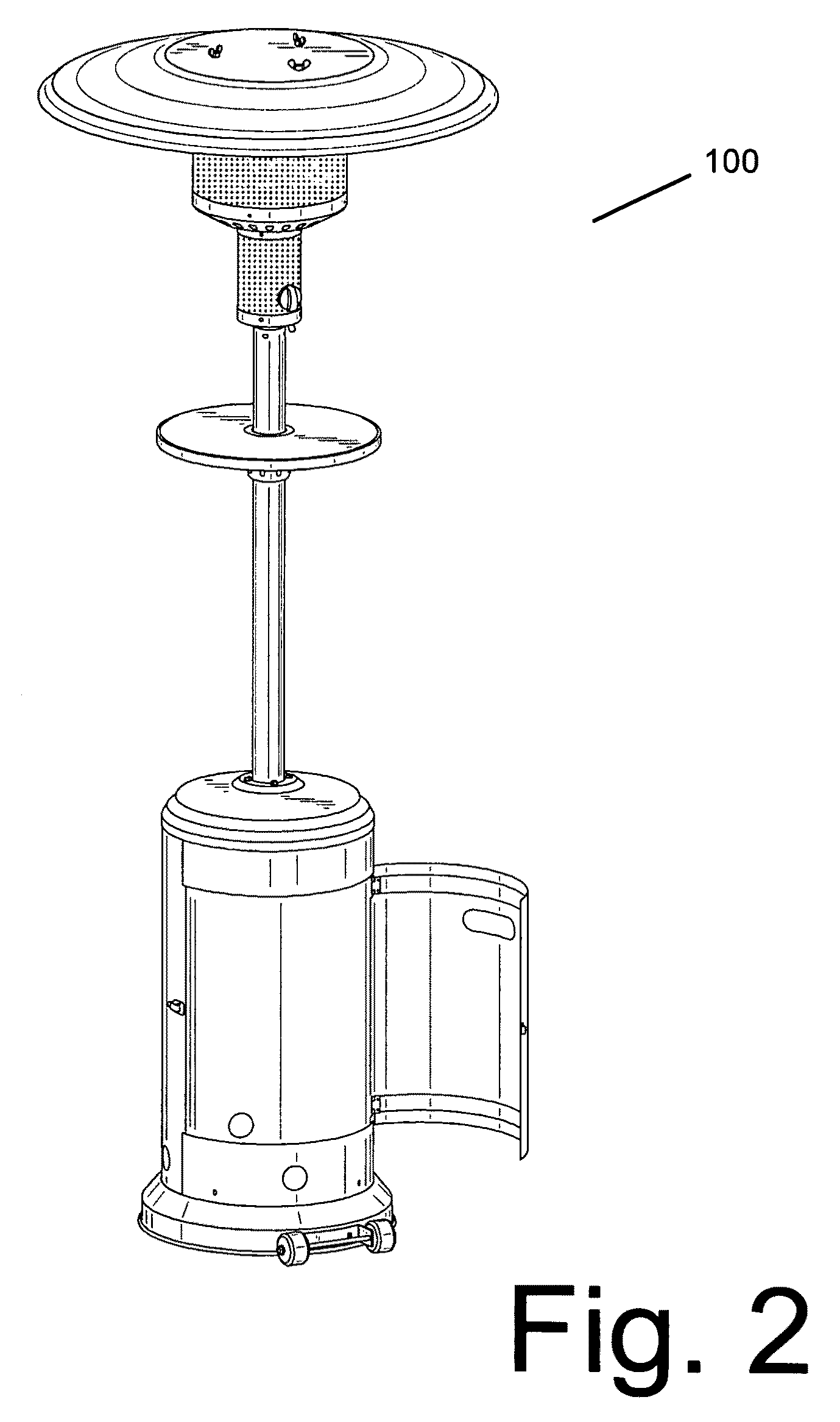

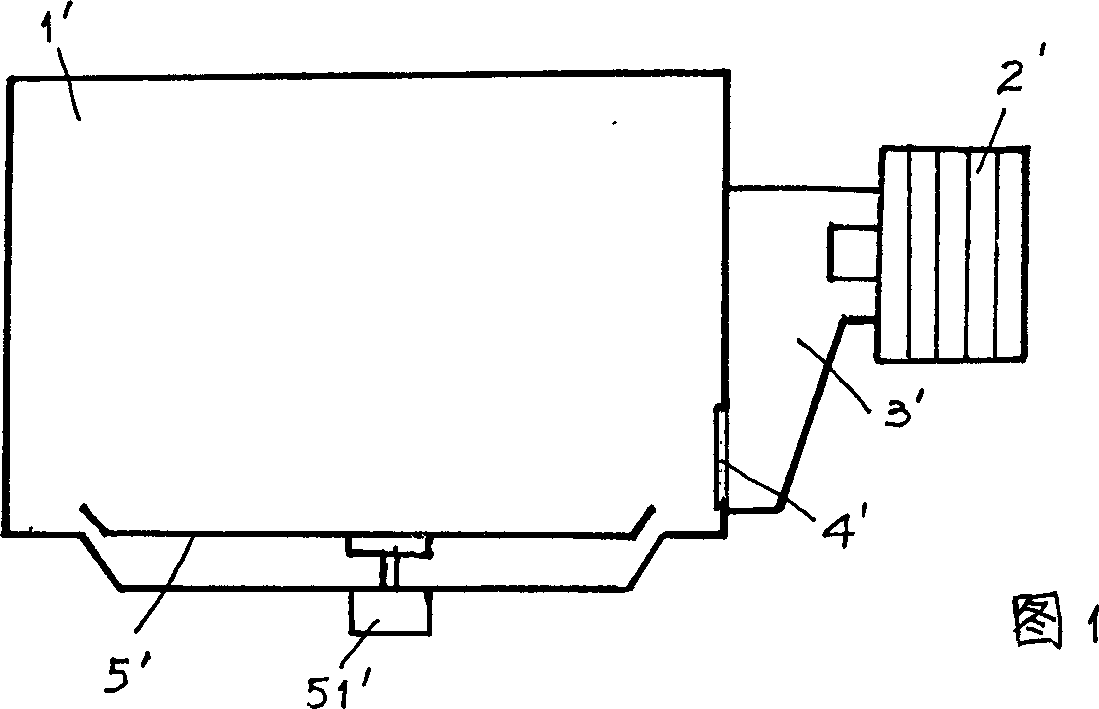

All around radiation heating apparatus

InactiveUS20100065047A1Prevent unintended tippingLower center of gravityDomestic stoves or rangesGaseous fuel burnerLiquid propaneEngineering

The present invention provides a safer all-around radiation heating assembly than similar traditional heaters. As typical with traditional heaters, a shroud is used to surroundably cover a portable liquid propane tank. To replace the portable liquid propane tank, the shroud must be continuously raised to a predetermined height while a service person accesses the propane tank. There is a danger that if and when the shroud drops, a spark could be created resulting in igniting highly flammable escaped propane gas. The present invention overcomes dangers associated with the traditional heaters by eliminating the spark creation danger and by introducing a ventilation system to allow any leaked propane gas to escape away from the heater.

Owner:CHANGZHOU GARDENSUN FURNACE

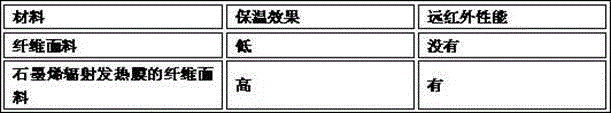

Graphene radiation heating film and preparation method and application thereof

The invention relates to a graphene radiation heating film and the preparation method and application thereof. The graphene radiation heating film is formed by coating graphene sizing agent on a surface of fiber fabric; the graphene sizing agent is formed by mixing the following components in part by weight: 3 to 5 parts of graphene powder, 1 to 3 parts of far-infrared cast charge and 4 to 6 parts of bonding diluent; the preparation method comprises the following steps: weighting graphene powder of 3 to 5 parts by weight, far-infrared cast charge of 1 to 3 parts by weight and bonding diluent of 4 to 6 parts by weight, after mixing the graphene powder with far-infrared cast charge, stirring the mixture uniformly firstly, then adding bonding diluent and mixing, so as to form sizing agent; coating the sizing agent on the surface of the fiber fabric to form a film, and after the film is dried in the air or dried by baking, the graphene radiation heating film is formed. During use, the graphene radiation heating film emits heating by radiation under the effect of external temperature.

Owner:南京天脉健康科技发展有限公司

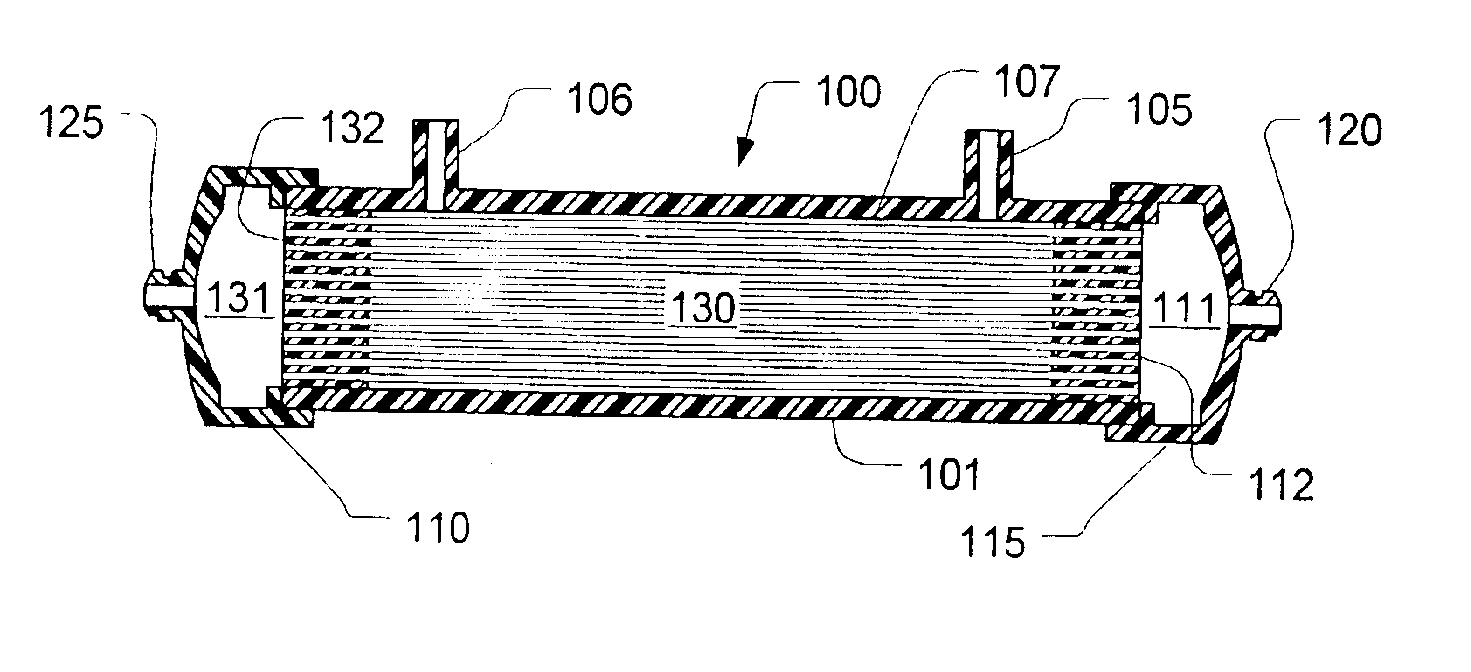

Low-temperature baking smoking set

PendingCN109846093AHeating evenlyStrong penetrating powerTobacco devicesCoatingsComputer moduleEngineering

The invention relates to the field of smoking sets, and provides a low-temperature baking smoking set. The smoking set comprises a heating substrate, a far infrared coating, a first conductive module,a second conductive module and a power supply unit, wherein the heating substrate is in a hollow shape, a heating bin used for containing smoking substances is formed in the heating substrate; the far infrared coating is coated on the outer side of the heating substrate; the first conductive module is arranged outside the heating substrate and is in contact with the far infrared coating; the second conductive module is arranged outside the heating substrate and is in contact with the far infrared coating; at least one part of the far infrared coating is positioned between the first conductivemodule and the second conductive module; the power supply unit is electrically connected with the first conductive module and second conductive module, so that far infrared light generated by at least one part of the far infrared coating after power up passes through the heating substrate to carry out radiation heating on the smoking substances in the heating bin. Due to stronger penetrability ofthe far infrared light, the far infrared light can penetrate the peripheral smoking substances and enter the inner part, so that the smoking substances are uniformly heated.

Owner:上海合元深蓝科技有限公司

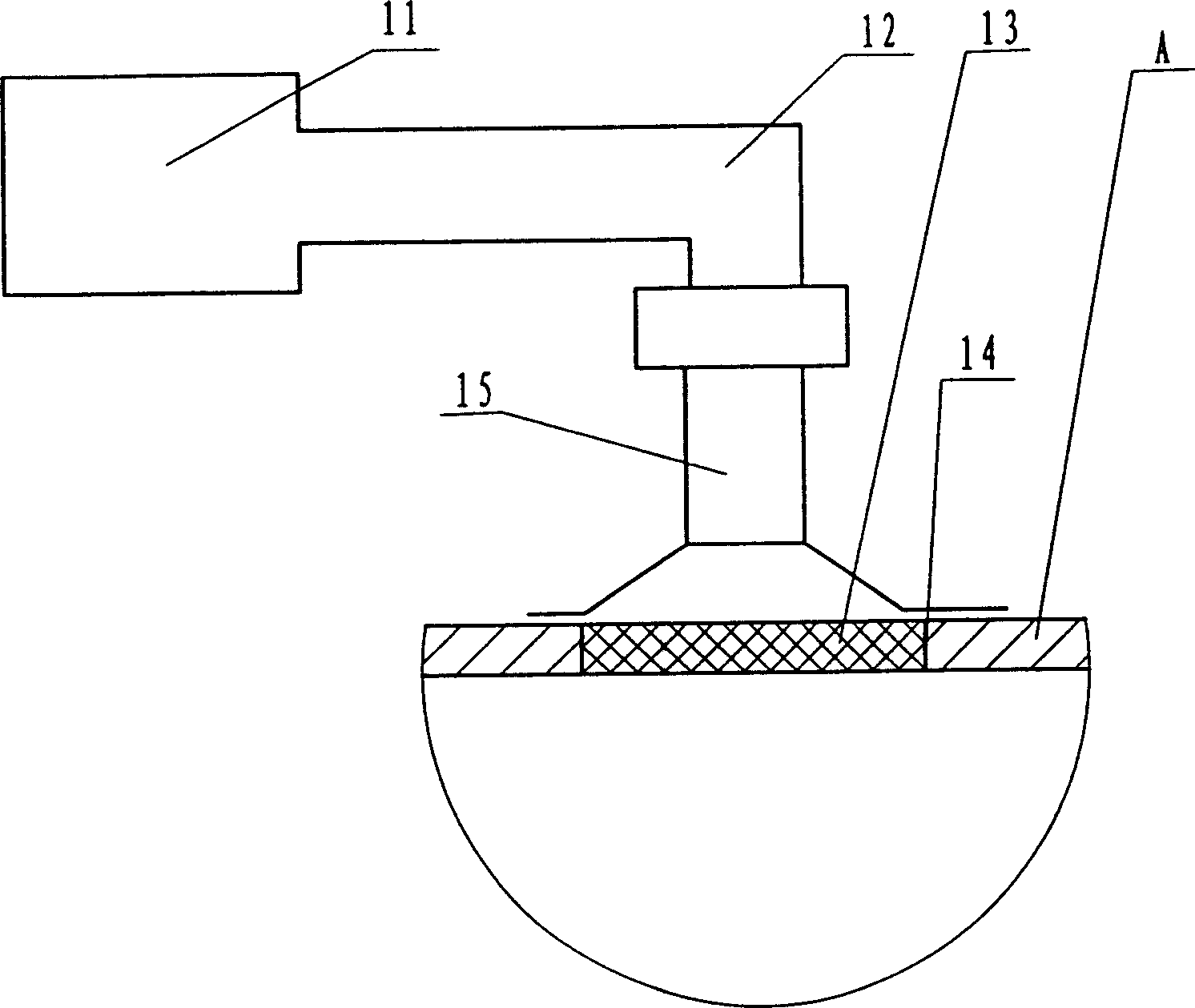

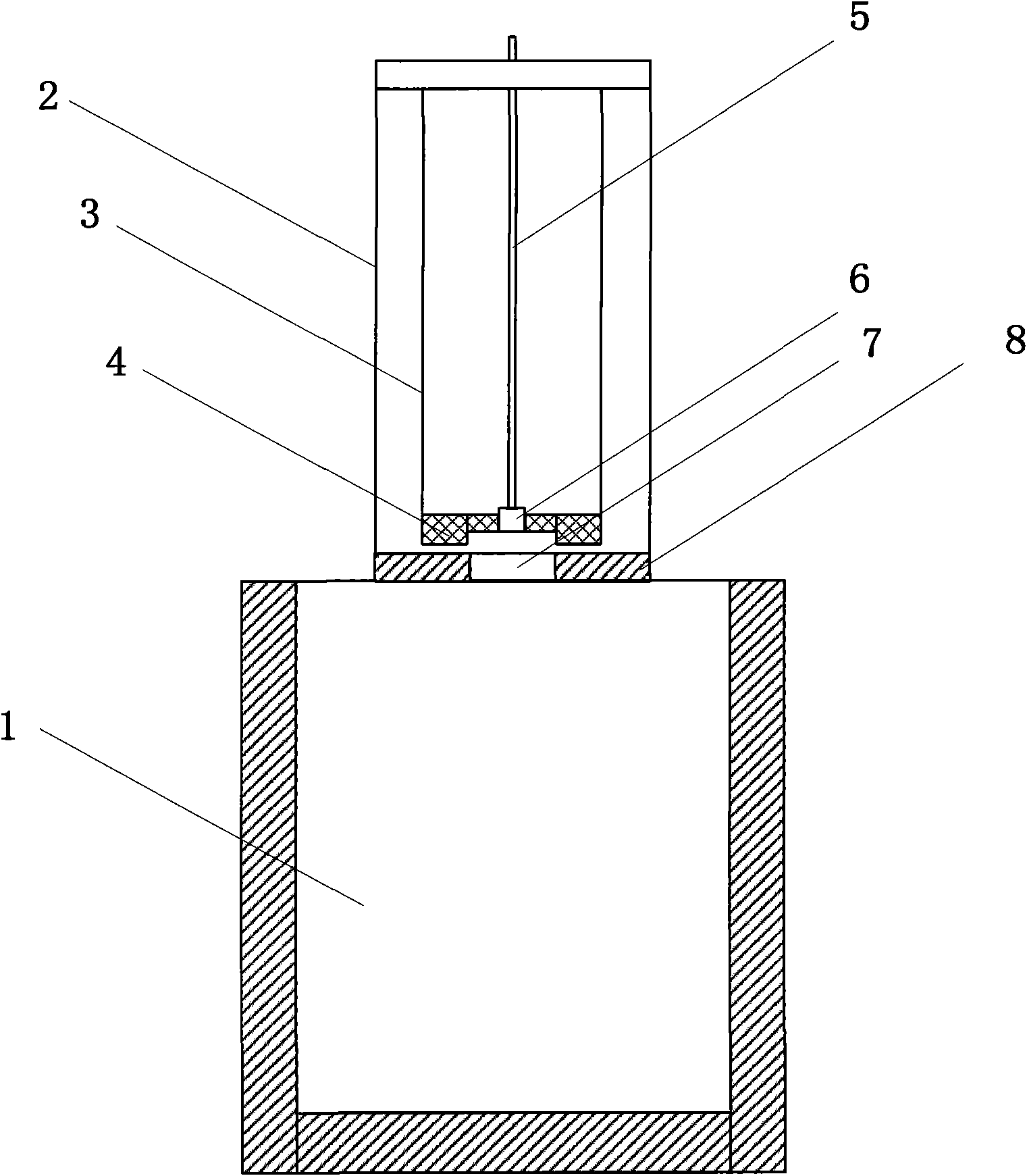

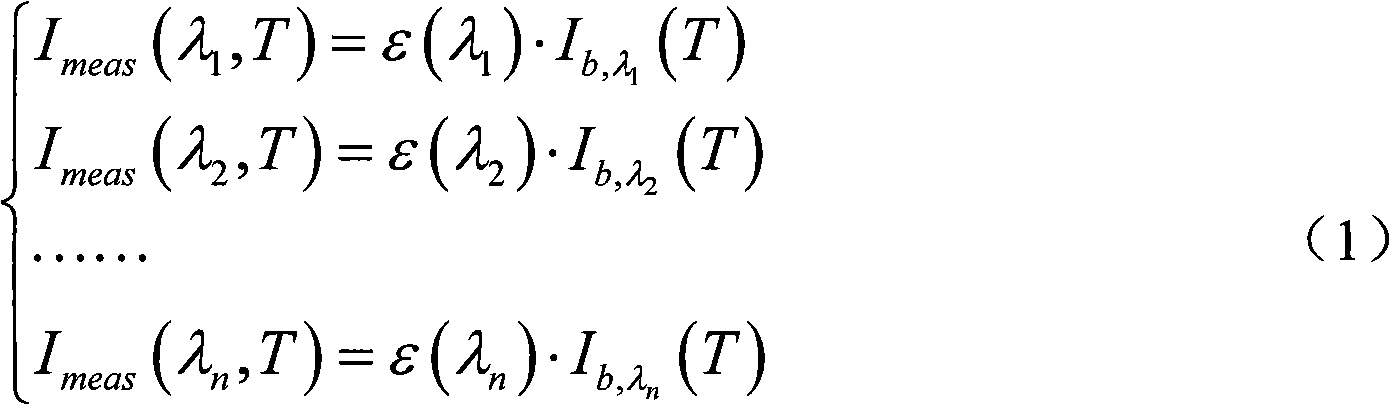

System for measuring normal spectral emissivity of high-temperature material

ActiveCN102042993ASimple designLess interference with radiometric measurementsSpectrum investigationMaterial thermal analysisData acquisitionEngineering

The invention discloses a system for measuring the normal spectral emissivity of a high-temperature material, comprising a vacuum heating unit, a water cooling sleeve unit, an optical fiber sensor measurement unit and a data acquisition and analysis unit, wherein a test sample is arranged on the upper part of the vacuum heating unit, and the vacuum heating unit performs radiant heating on the lower surface of the test sample; the water cooling sleeve unit is sleeved on the upper part of the test sample, and the upper surface of the test sample is placed in a constant-temperature cold environment; the optical fiber sensor measurement unit is arranged above the test sample to measure the normal spectral radiant intensity of the upper surface of the test sample; and the data acquisition and analysis unit is connected with the optical fiber sensor measurement unit and is used for calculating the normal spectral emissivity through a multi-spectrum inversion algorithm according to the measured normal spectral radiant intensity. The invention realizes material normal spectral emissivity measurement in a spectrum range of 0.4-1.7mum and a temperature range of 600-1,500 DEG C without on-line radiometric calibration, is accurate and reliable to realize the technology, and overcomes limitations on high price, complicated structure, high difficulty in technical implementation and other applications of the conventional spectral emissivity device.

Owner:TSINGHUA UNIV +1

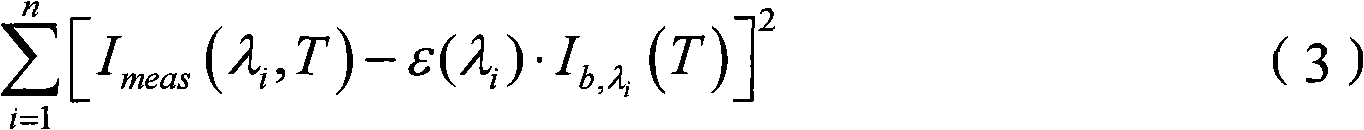

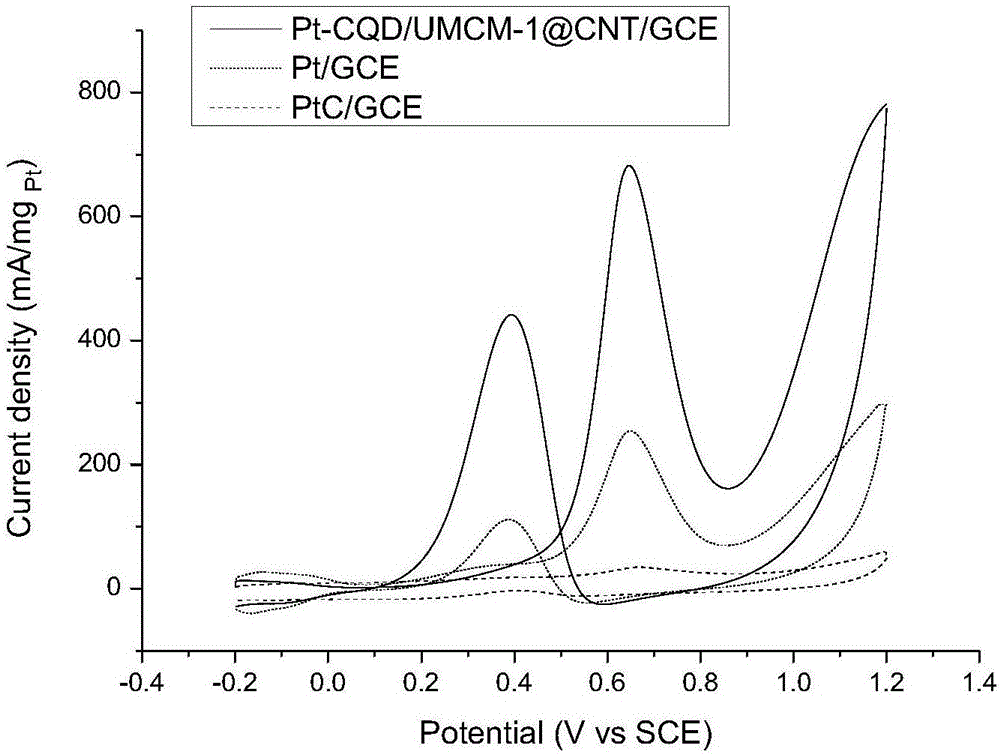

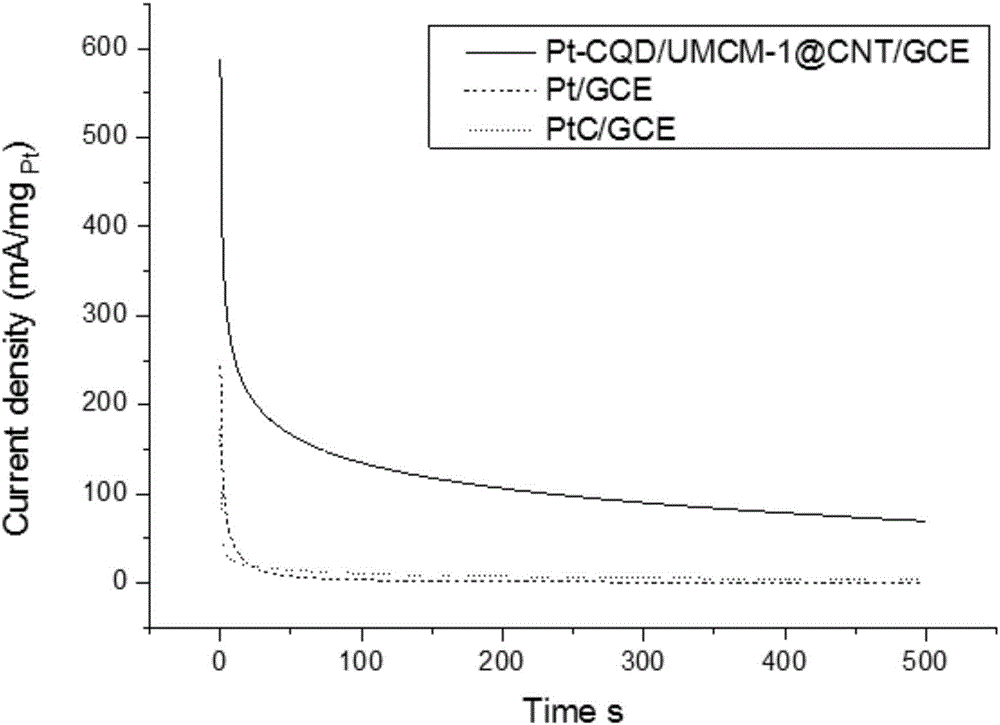

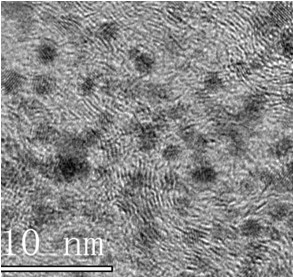

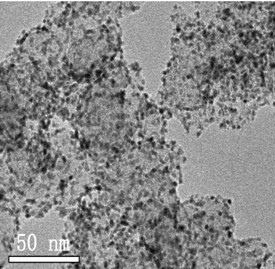

Preparation of carbon nanotube material embedded with quantum-dot modified metal organic framework

The invention provides preparation of a carbon nanotube material embedded with a quantum-dot modified metal organic framework. The preparation comprises the following steps of firstly, adding a certain amount of powder quantum dots to a formed metal organic framework precursor solvent so that the quantum dots of which the diameters are matched with the sizes of pore passages are embedded into the pore passages of the formed metal organic framework; secondly, uniformly mixing the obtained quantum-dot modified metal organic framework and melamine powder, and performing high-temperature processing to obtain a composite material (QD / UMCM-1@CNT) in a carbon nanotube embedded with the quantum-dot modified metal organic framework; and finally, enabling Pt to be loaded on a surface of the composite material carbon nanotube (Pt / QD / UMCM-1@CNT) by microwave radiation heating to be used as a positive electrode catalyst of a methanol fuel cell. Compared with a traditional hydrothermal method for synthesis of the carbon nanotube, the quantum-dot modified metal organic framework obtained by high-temperature processing is embedded into the composite material in the carbon nanotube, the structural aspects such as the length and the diameter of the carbon nanotube are more consistent, and a catalyst substrate with a unified structure is easier to form.

Owner:QINGDAO UNIV

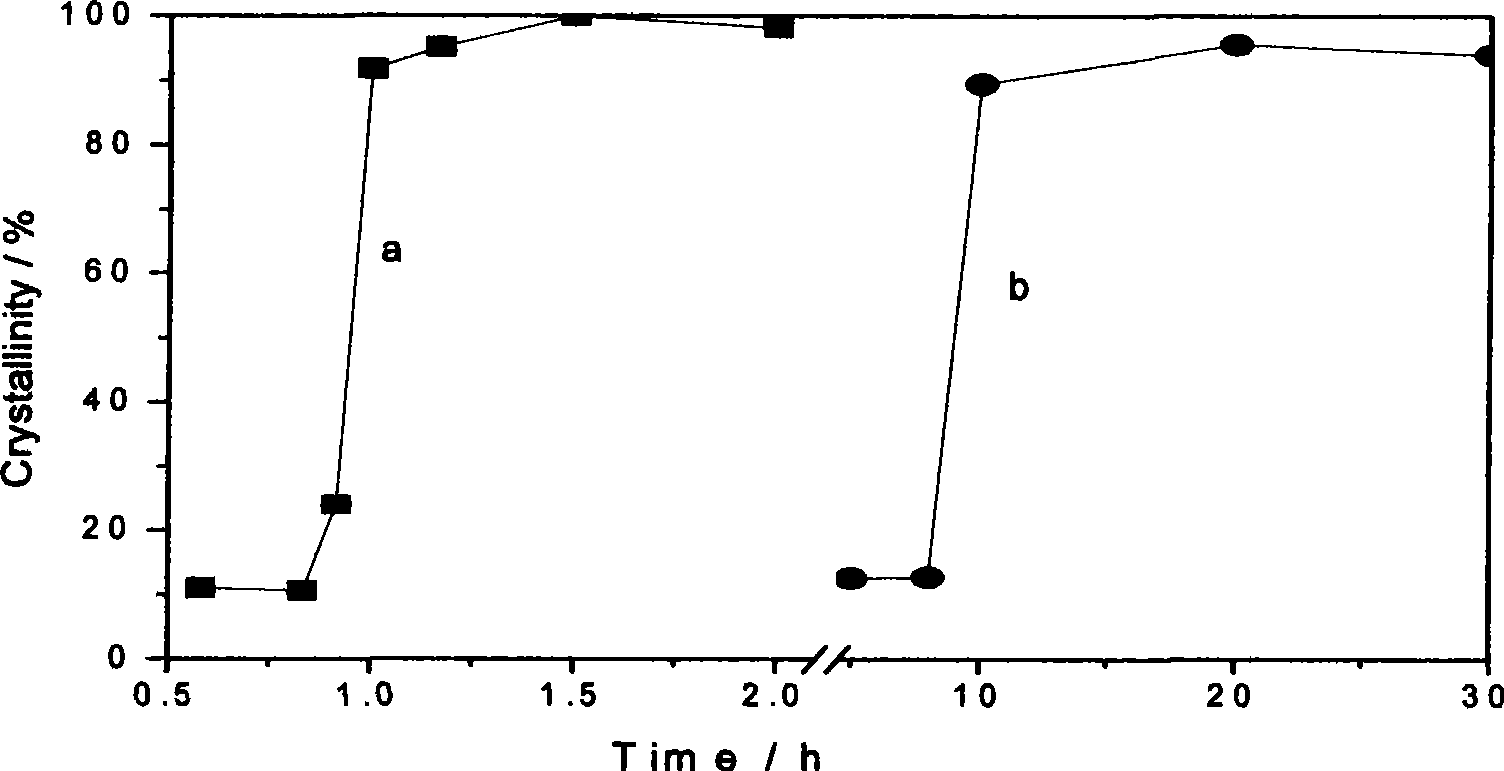

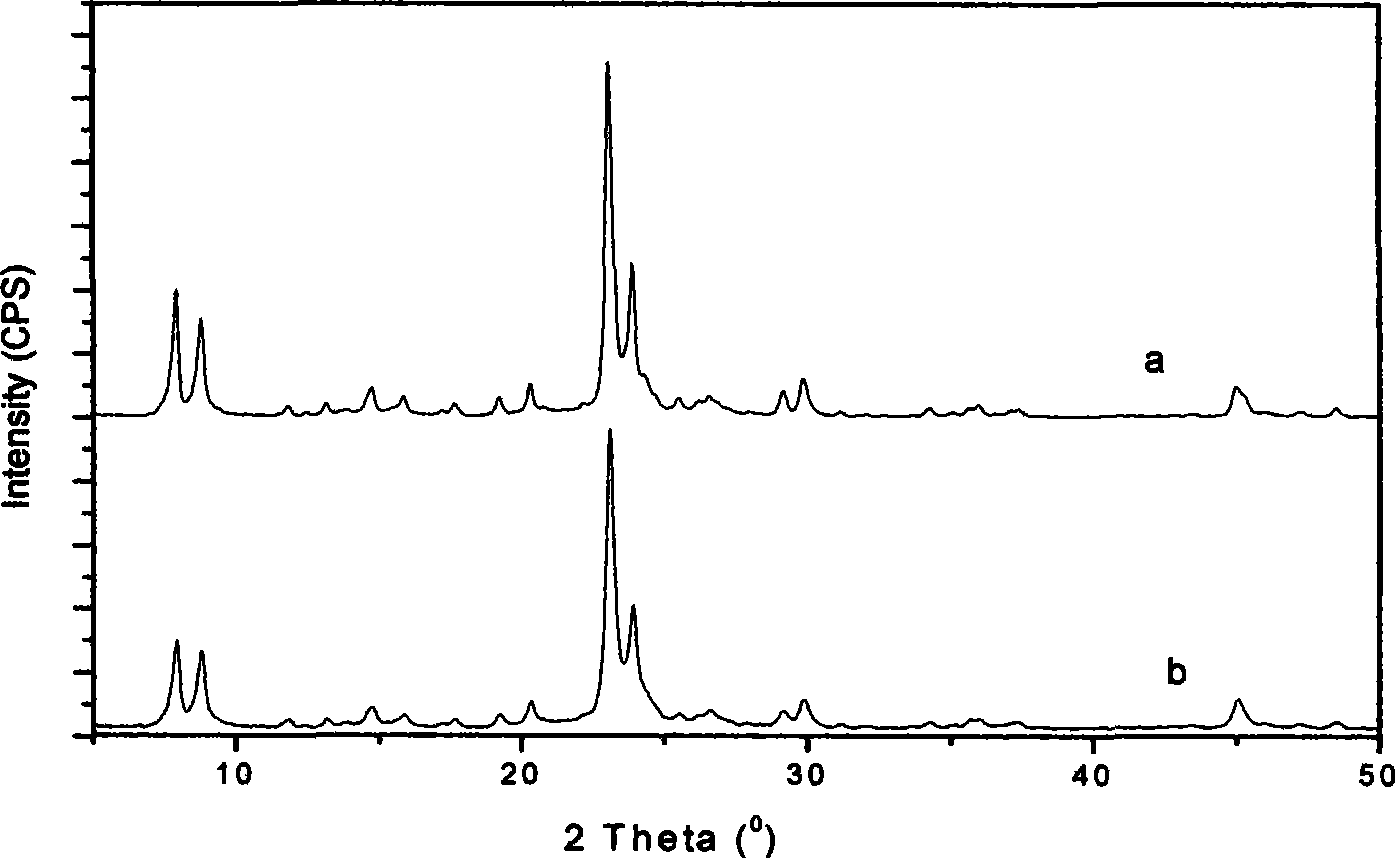

Microwave synthesis process for ZSM-11 molecular sieve

InactiveCN101531376AIncrease growth rateHigh crystallinityPentasil aluminosilicate zeoliteCrystallinityCrystal growth rate

The invention relates to a microwave synthesis process for a ZSM-11 molecular sieve. The process uses aluminum source, alkali source, silicon source, tetrabutylammonium bromide and de-ionized water as the raw materials and adopts the heating mode of microwave radiation. The reaction mixture is crystallized for 1 to 8 hours under microwave radiation and self-generated pressure at 130 to 180 DEG C, solid is separated from the mother liquid, and then the product is washed by the de-ionized water until the pH value is 8 to 9, thus obtaining the raw powder of the ZSM-11 molecular sieve. The microwave synthesis process for the ZSM-11 molecular sieve has the advantages of replacing traditional water heating by microwave radiation heating and obtaining the ZSM-11 molecular sieve with the advantages of high crystallinity, pure crystal phase and controllable and wide range of grain size, and the process accelerates the nucleation rate and crystal growth speed obviously and shortens the crystallization time greatly by pre-placing crystal seeds.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

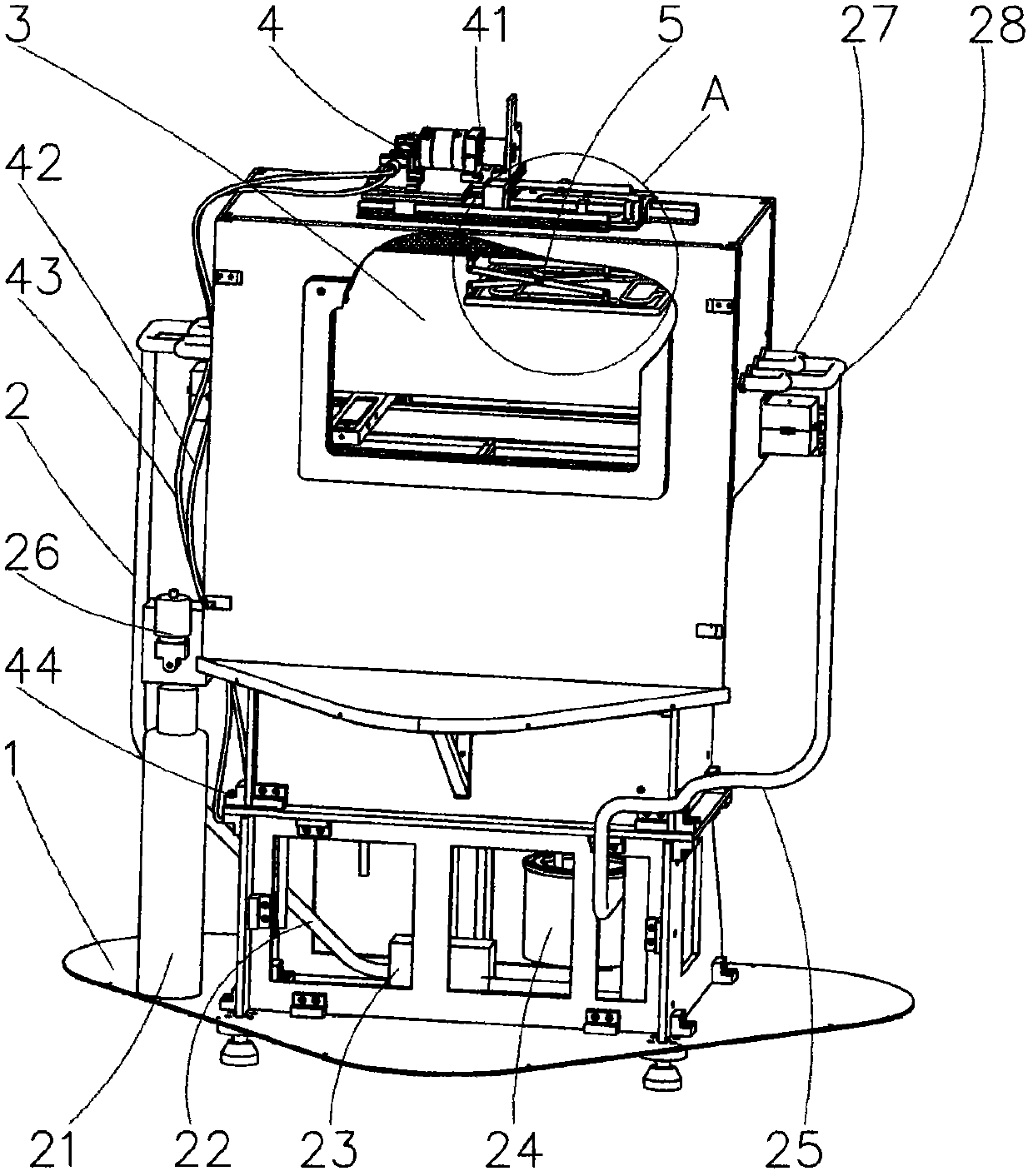

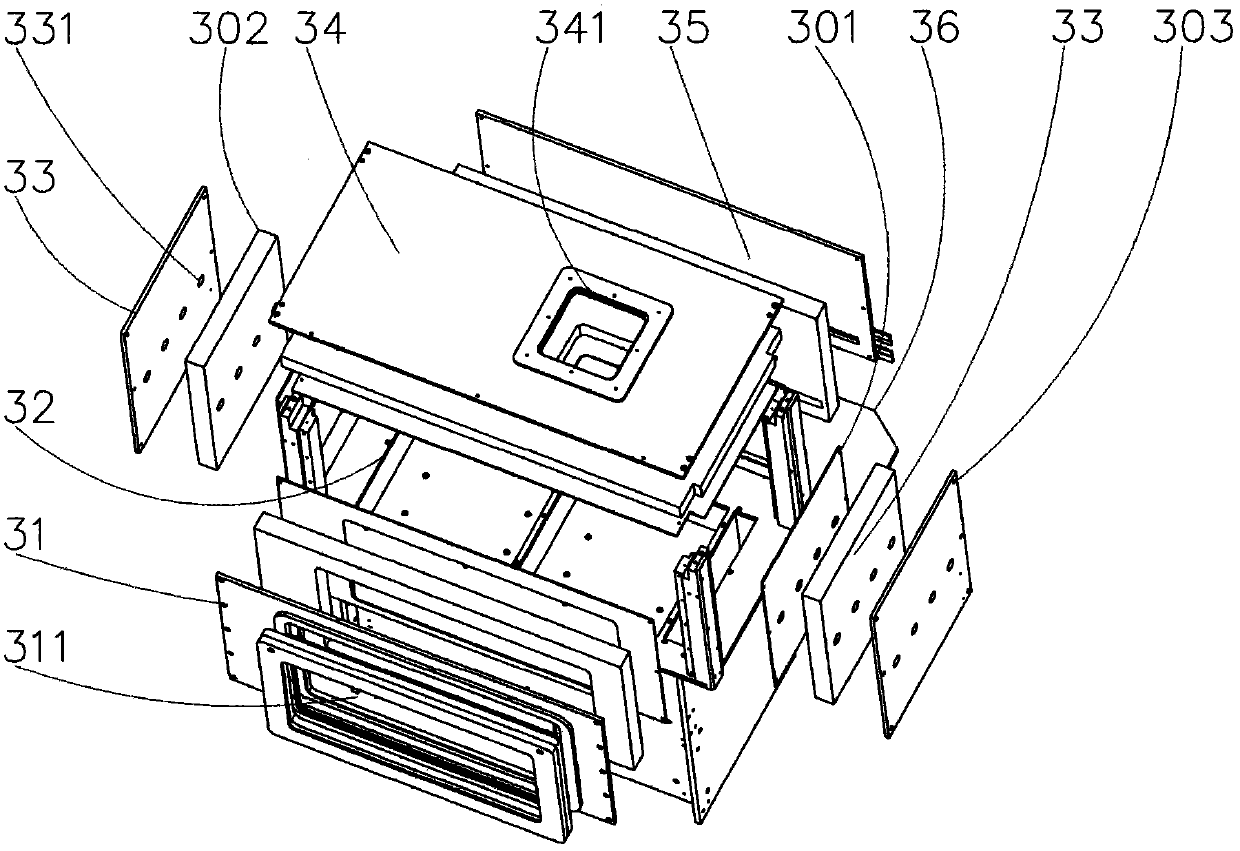

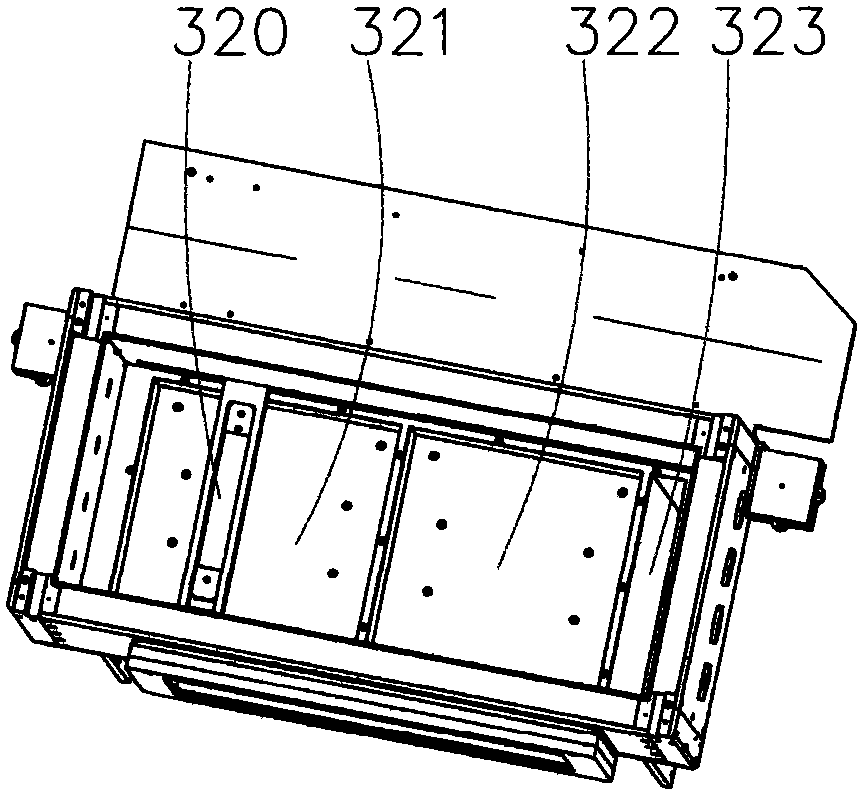

Manufacturing equipment of laser additive

ActiveCN103737933AReduce in quantityReduce lossesIncreasing energy efficiencyEngineeringProtection system

The invention provides manufacturing equipment of a laser additive. The manufacturing equipment comprises a frame, a work cavity, a laser system, an atmosphere protection system and a preheating system, wherein the work cavity is a sealed cavity defined by a heat insulation sandwich panel; a scanning galvanometer of a laser system is arranged at the top of the external part of the work cavity; the preheating system is a three-dimensional flexible heating system, and has a plurality of radiation heating layers with adjustable interlayer spaces arranged at the top inside the work cavity; an air feed pipe and an air return pipe of the atmosphere protection system are divided into a plurality of passages to be respectively connected with two sides of the work cavity through U-shaped tee joints, so that the circulation of inactive gas inside the work cavity is achieved. By adopting the manufacturing equipment of the laser additive, the space can be effectively saved, the heat loss is reduced, the heating efficiency is improved, the energy consumption is reduced, the temperature inside the work cavity is relatively even in distribution, the protective effect on the processing process caused by an internal atmosphere is obvious, different types of materials (metal, macromolecule and the like) can be molded, the processing deformation is reduced, and the excellent quality of molded spare parts is ensured.

Owner:GUANGZHOU OGGI3D ELECTROMECHANICAL

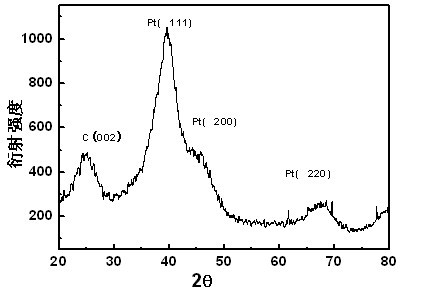

Method for preparing carbon-loaded platinum-based electro-catalyst by microwave organosol method

ActiveCN102327771ASmall granularityEvenly dispersedCell electrodesCatalyst activation/preparationBULK ACTIVE INGREDIENTBiological activation

The invention provides a method for preparing a carbon-loaded platinum-based electro-catalyst by a microwave organosol method. The method comprises the following steps of: putting metal precursor solution and a complexing agent into an organic solvent, and adding a pretreated carrier carbon powder material under stirring, so that the finally-obtained catalyst comprises 20 to 50 mass percent of active ingredient; adjusting the pH value of the solution to be more than 8 by using alkaline solution, performing a microwave radiation heating reaction on the mixed solution, and adding acid solution after the reaction to adjust the pH to be less than 5; performing ultrasonic gel breaking on the reaction solution, performing suction-filtration and washing until the filtrate does not comprise chloride ions through detection; and drying filter cakes, grinding, performing activation heat treatment, and thus obtaining the carbon-loaded platinum-based electro-catalyst. The catalyst prepared by the method has small active ingredient particles, is dispersed on a carbon carrier to a great extent and has relatively high activity; and the method has a simple and quick preparation process, is low in cost and makes mass industrial production easily realized.

Owner:SOUTH CHINA UNIV OF TECH

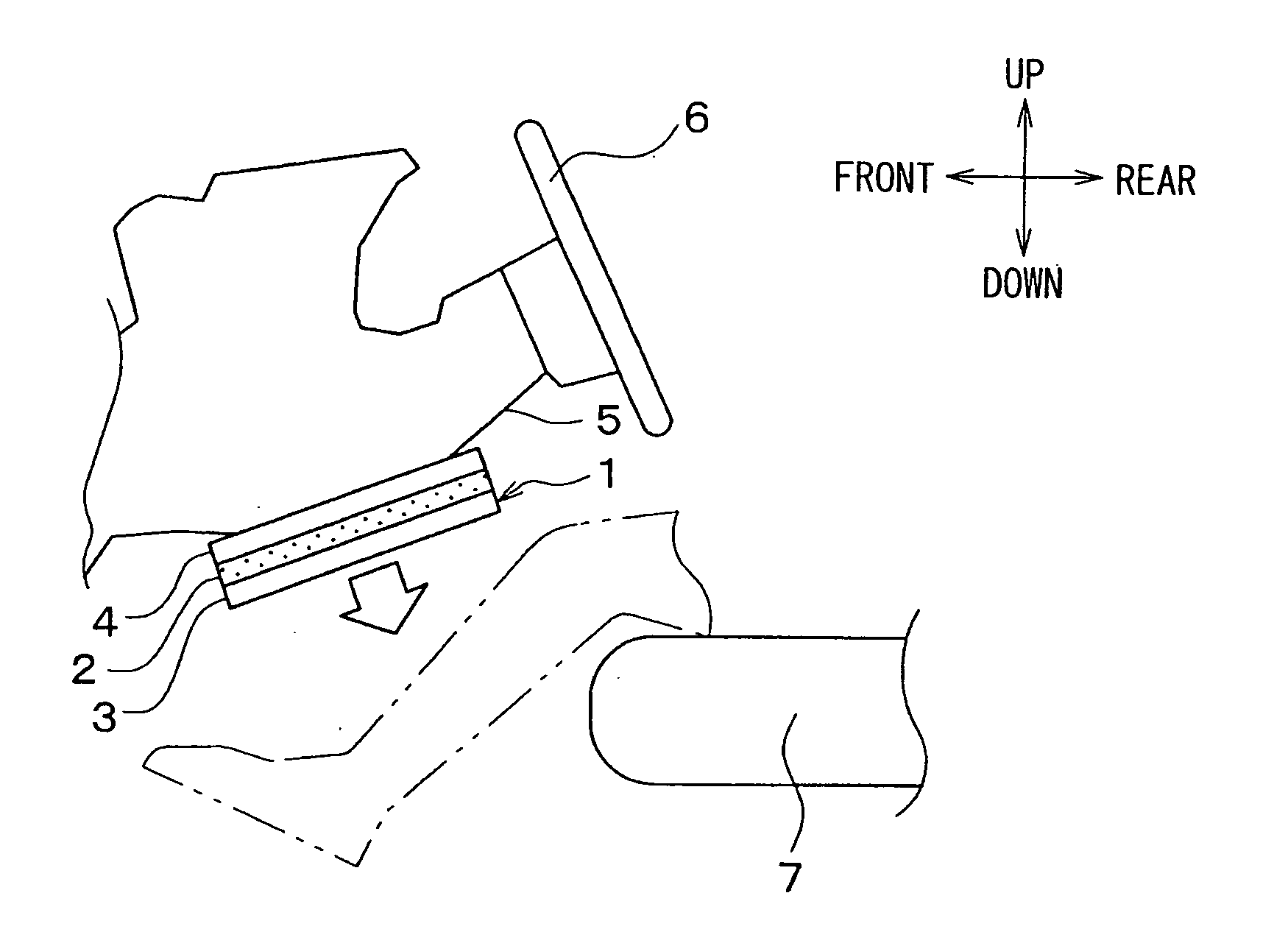

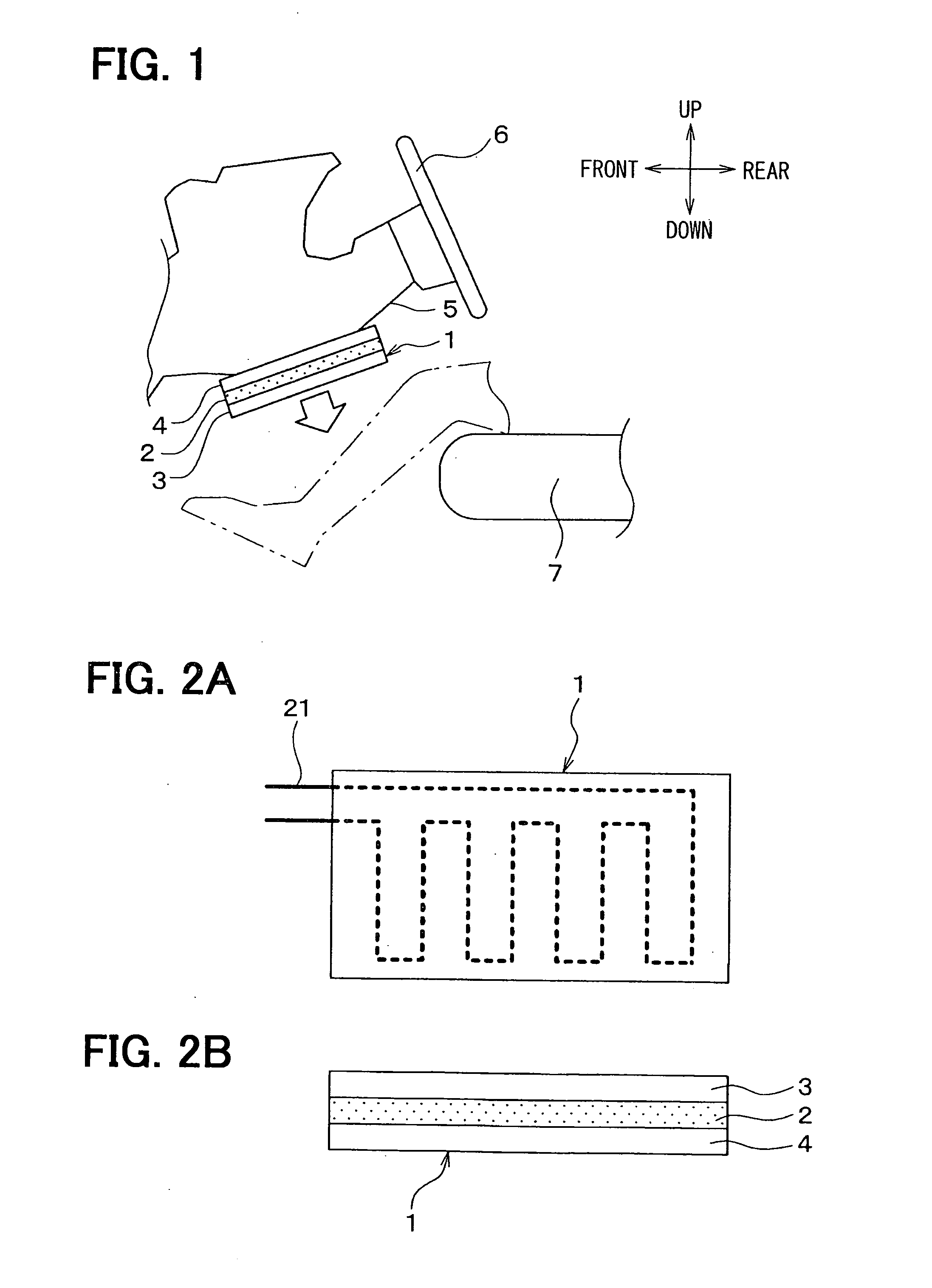

Radiation heating system for vehicle

InactiveUS20120061365A1Electric heatingVehicle heating/cooling devicesEngineeringThermal transmittance

A radiation heating system for a vehicle includes a heating device and an exterior member. The heating device serves as a heat source and is for generating radiation heat to warm up an interior of the vehicle. The exterior member is disposed on a vehicle interior-side of the heating device. Given that: thermal transmittance of the exterior member is K′ [W / (m2−K)]; thermal transmittance of a human body is K4 [W / (m2−K)]; bloodstream temperature of the human body is Tm [K]; and surface temperature of the heating device is Th [K], K′ is set so as to satisfy a relationship expressed in: (2×Th×K′+Tm×K4) / (2×K′+K4)≦333.

Owner:DENSO CORP

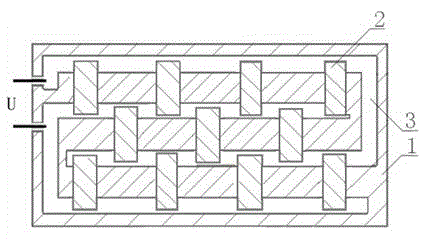

Uniform radiation microwave heating method and device

InactiveCN1826026AOvercome the defect of uneven microwave field distributionOvercome the defect of uneven distributionDomestic stoves or rangesLighting and heating apparatusImpedance ConverterRadiation heating

This invention relates to a heating method with uniform radiated microwaves and a device, in which, said method includes: a microwave device generates microwaves transmitted by a waveguide impedance converter and output to a corresponding couple cavity from the waveguide port to be reflected and scattered to output multiple microwave beams to the heating cavity uniformly from multiple couple holes on a sidewall of the couple cavity and these microwave beams enter into the heating cavity to radiate on the heated object, which greatly improves the un-uniform distribution of microwave energies in the heating cavity.

Owner:TSANN KUEN CHINA ENTERPRISE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com