Manufacturing equipment of laser additive

A kind of manufacturing equipment and laser additive technology, applied in the field of additive manufacturing, can solve the problems of unreasonable setting and inconvenient operation, and achieve the effects of improving heating efficiency, saving space, and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be further described below in conjunction with the accompanying drawings.

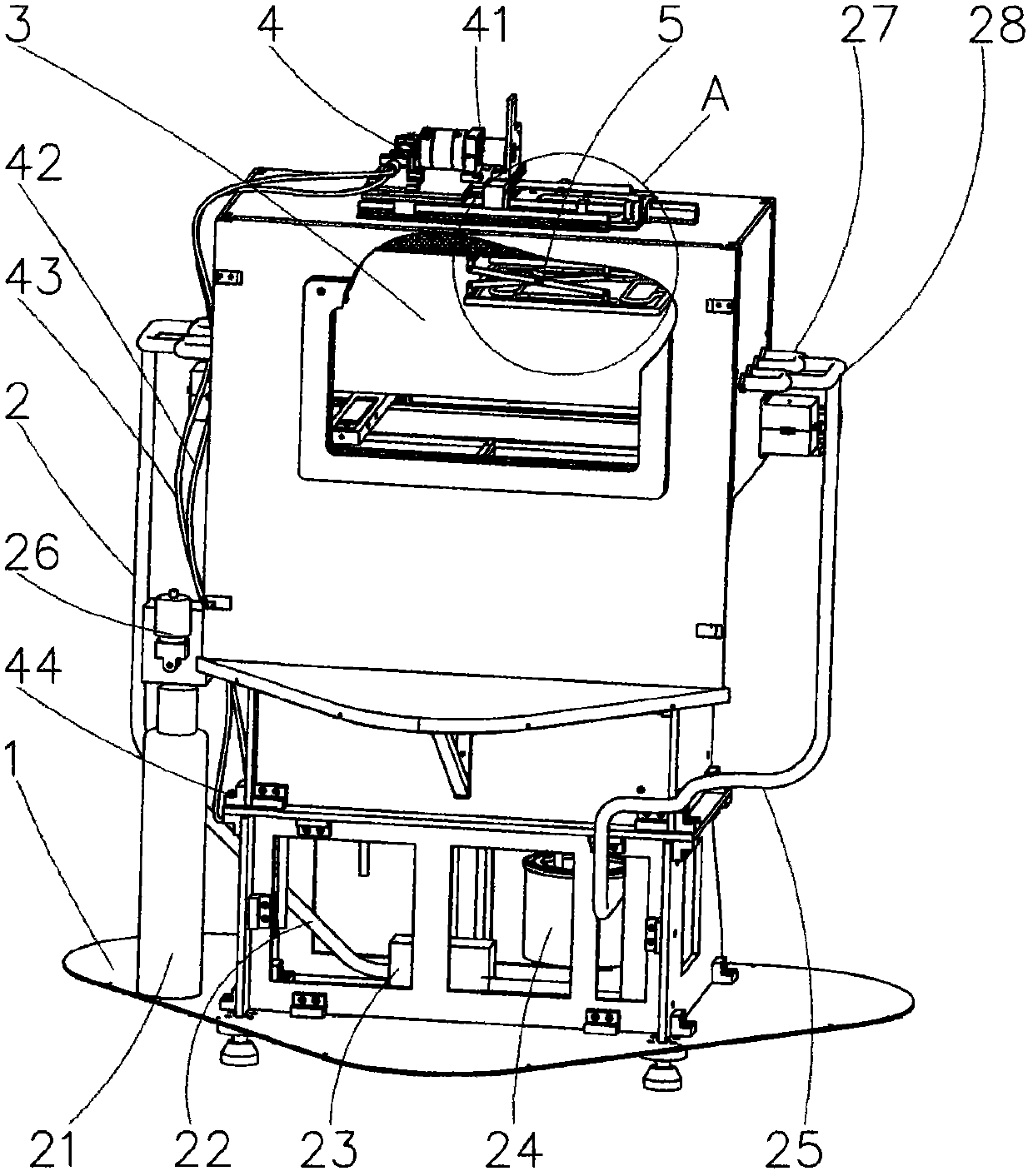

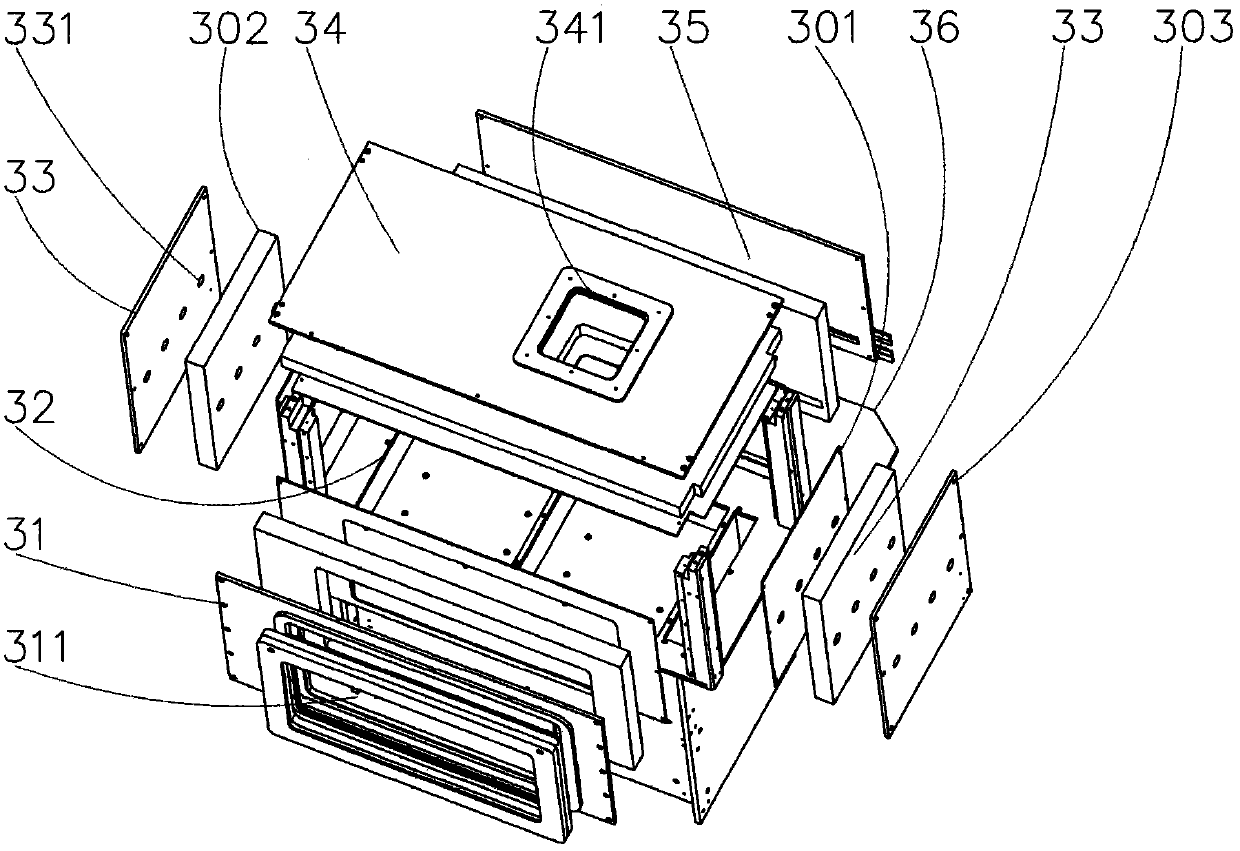

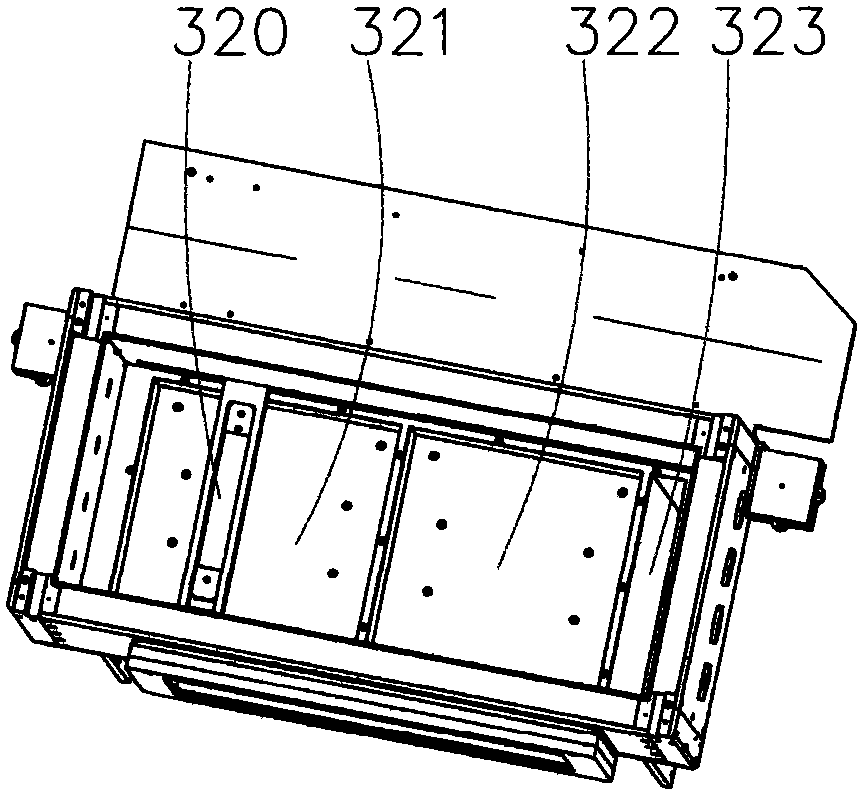

[0020] see Figure 1 ~ Figure 4 , the laser additive manufacturing equipment of the present invention is made up of modules such as frame 1, working cavity 3, laser system 4, atmosphere protection system 2 and preheating system 5, and working cavity 3 is installed on the top of frame 1; Working cavity 3 is A closed cavity surrounded by a workbench 36, a top board 34, a front board 31, a back board 35 and two side boards 33, the top board 34, the front board 31, the back board 35 and the side boards 33 are thermal insulation interlayer boards, It is composed of heat insulation layer 301, heat preservation layer 302 and panel layer 303, which can reduce the heat loss in the enclosed cavity; the cylinder body 32 for powder molding and the top plate are installed on the workbench 36 at the lower part of the working cavity 3 34 is provided with a laser syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com