Microwave synthesis process for ZSM-11 molecular sieve

A technology of ZSM-11 and microwave synthesis, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., to achieve the effect of high crystallinity, pure crystal phase and controllable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

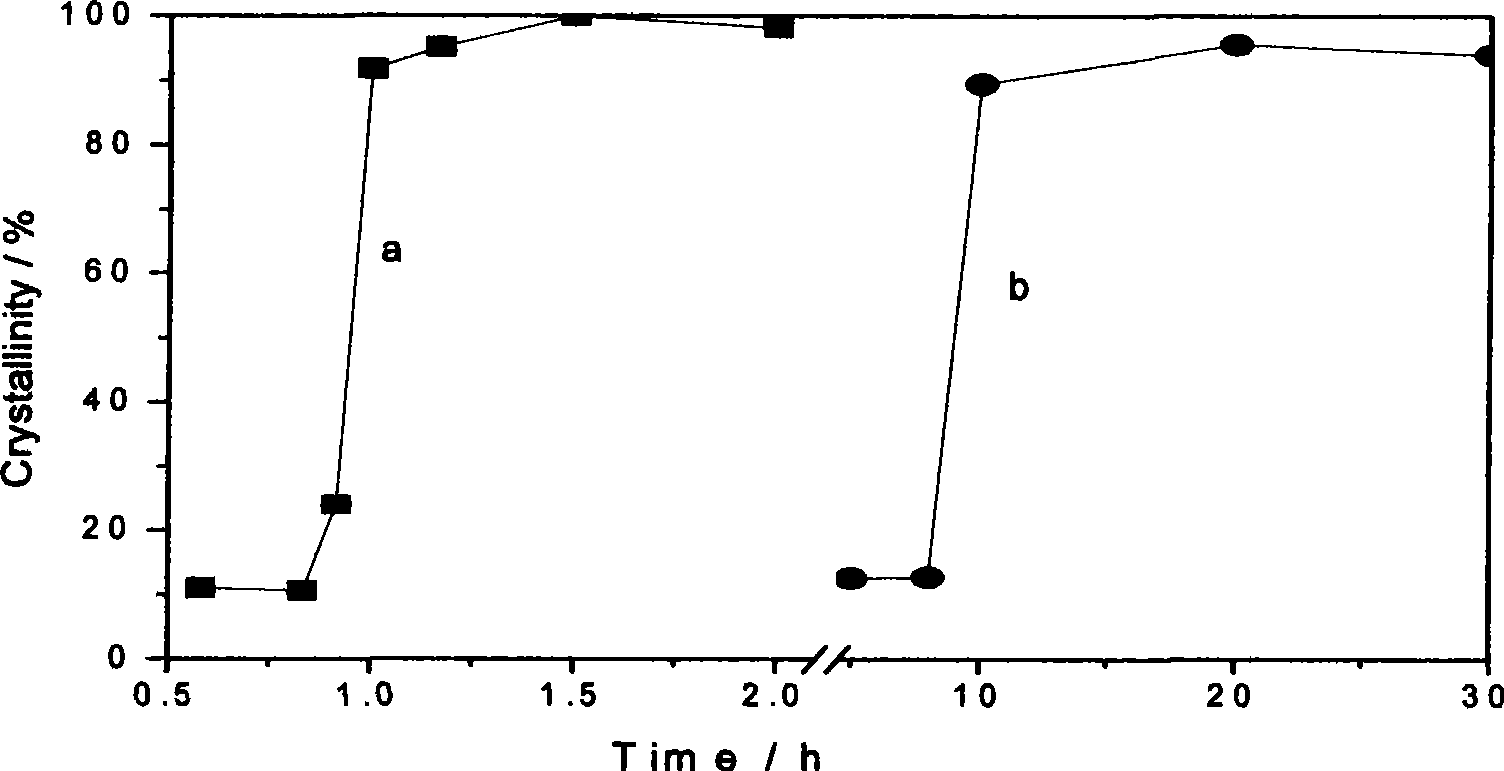

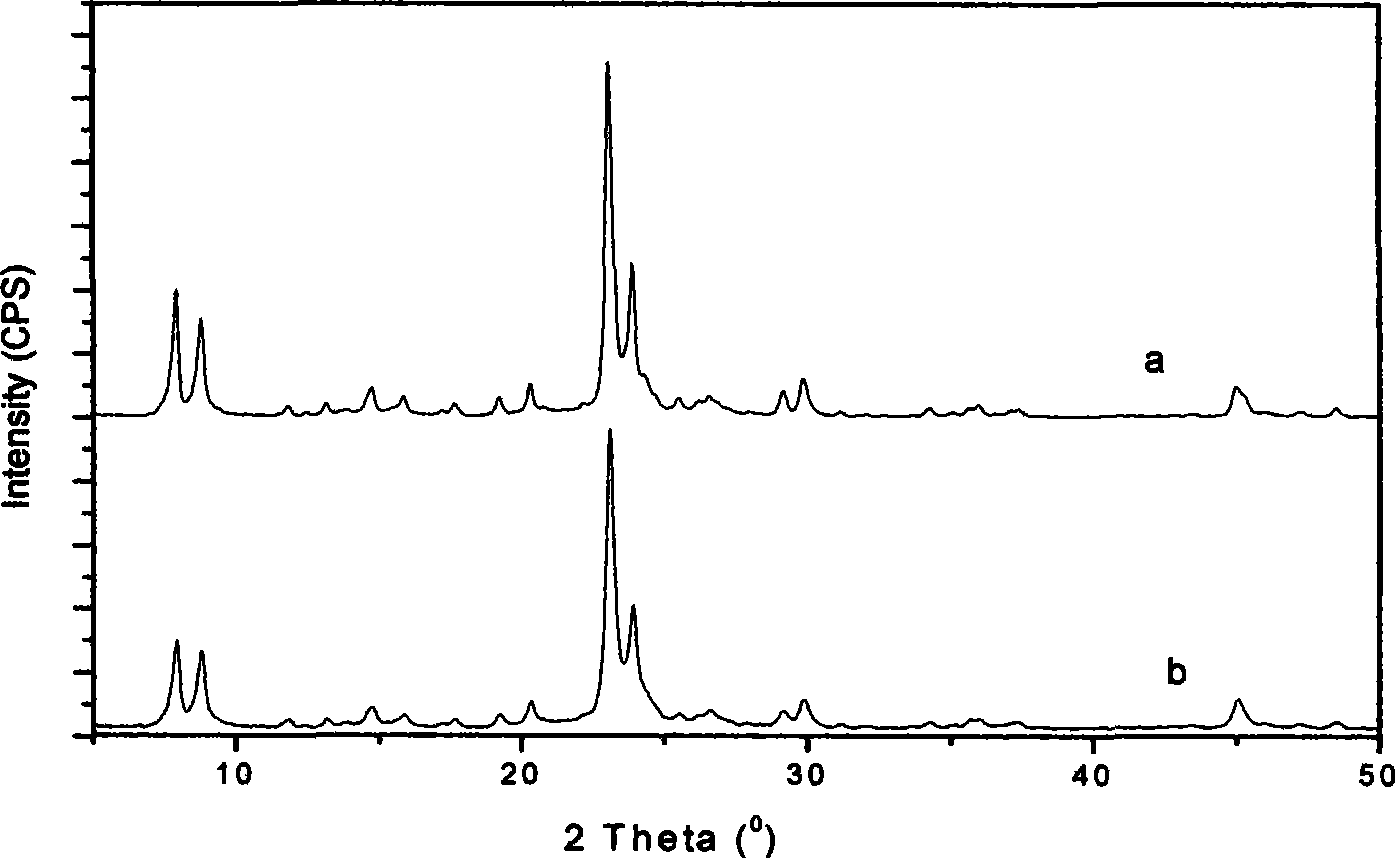

Embodiment 1

[0018] 15g silica sol (SiO 2 25.59 wt%, Na 2 O 0.31wt%, Al 2 o 3 0.10wt%, H 2 (273.99wt%, other 0.01wt%, hereinafter the same), 3.22g tetrabutylammonium bromide (99%), 10.4g deionized water add in the reactor and mix homogeneously, the mol ratio that obtains reaction mixture is: 12 Na 2 O: Al 2 o 3 : 80 SiO 2 : 15 TBABr: 3600 H 2 O (no seed crystals, the same below), under continuous stirring, add a uniform solution prepared by 0.43g aluminum sulfate, 0.74g sodium hydroxide and 20g deionized water, and then add 0.20g ZSM-11 seed crystals (accounting for raw silicon 5% of the total mass of aluminum oxide) was added into 10 g of deionized water for ultrasonic dispersion, and then the above-mentioned raw material mixture was added, and the stirring was continued until the mixture was uniform. Seal the reaction kettle, place it in a hydrothermal synthesis oven, and dynamically synthesize it by rotating the kettle body (100 rpm). After aging for 48 hours at room temperatu...

Embodiment 2

[0022] In Example 1, the amount of seed crystals added was changed to 0.04 g (accounting for 1% of the total mass of the raw material silicon-aluminum oxide), and the composition of other raw materials remained unchanged. The raw materials were mixed evenly, without aging, directly placed into a microwave synthesis reactor, and crystallized at 170°C for 6 hours. The product was ZSM-11 molecular sieve with a crystallinity of 79.2% and a particle size of 2.11 μm.

Embodiment 3

[0024] In Example 1, the raw materials and composition were unchanged. After the raw material mixture is evenly mixed, the kettle body is rotated (100rpm) at room temperature for aging for 9 days, transferred to a microwave synthesis reactor, and crystallized at 170°C for 2h. The product is ZSM-11 molecular sieve with a crystallinity of 99.7% and a particle size of 0.82μm .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com