Patents

Literature

65results about How to "Crystal phase pure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing iron phosphate for producing iron lithium phosphate material

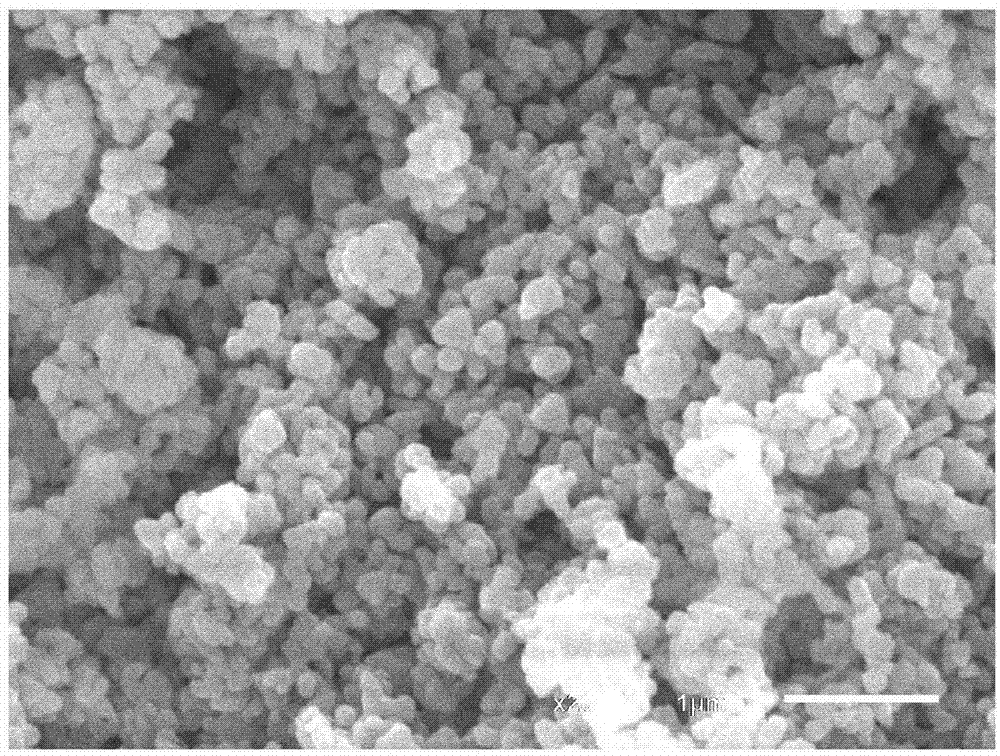

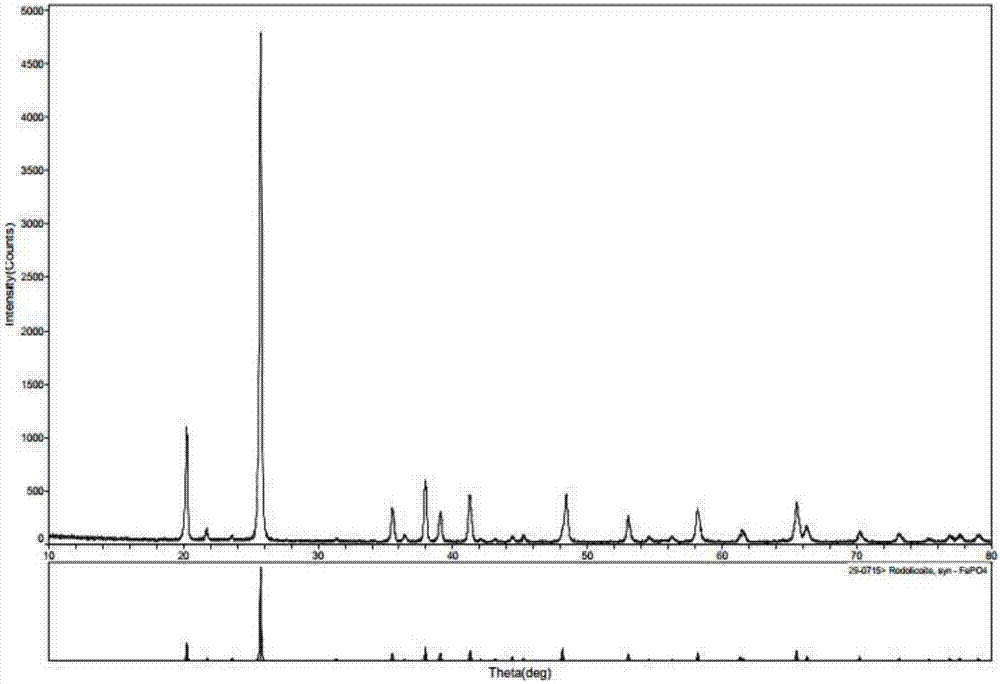

The preparation method of iron phosphate used for preparing lithium iron phosphate material in the present invention relates to heavy metal phosphate, and the steps are: dissolving analytically pure soluble iron salt in distilled water to prepare a 0.05-5M aqueous solution, and the added mass is the iron salt mass 0.01~3% of anionic surfactant, then add analytically pure phosphoric acid according to the molar ratio of Fe3+:PO43-=1:0.8~1.2 and stir evenly, and slowly add alkaline solution with a concentration of 1~9M under stirring , the feeding time is more than 1 hour, until the pH value of the solution reaches 6-7, the iron phosphate precipitate is filtered, and the filtered iron phosphate is washed 3-5 times with distilled water 2-5 times its weight. Dry at ~90°C to obtain the product FePO4·2H2O powder. The iron phosphate product with two crystal waters prepared by the method of the invention has high reactivity, and the performance of the lithium iron phosphate material made by using it is better than that of the lithium iron phosphate material made by commercially available iron phosphate products.

Owner:HEBEI UNIV OF TECH

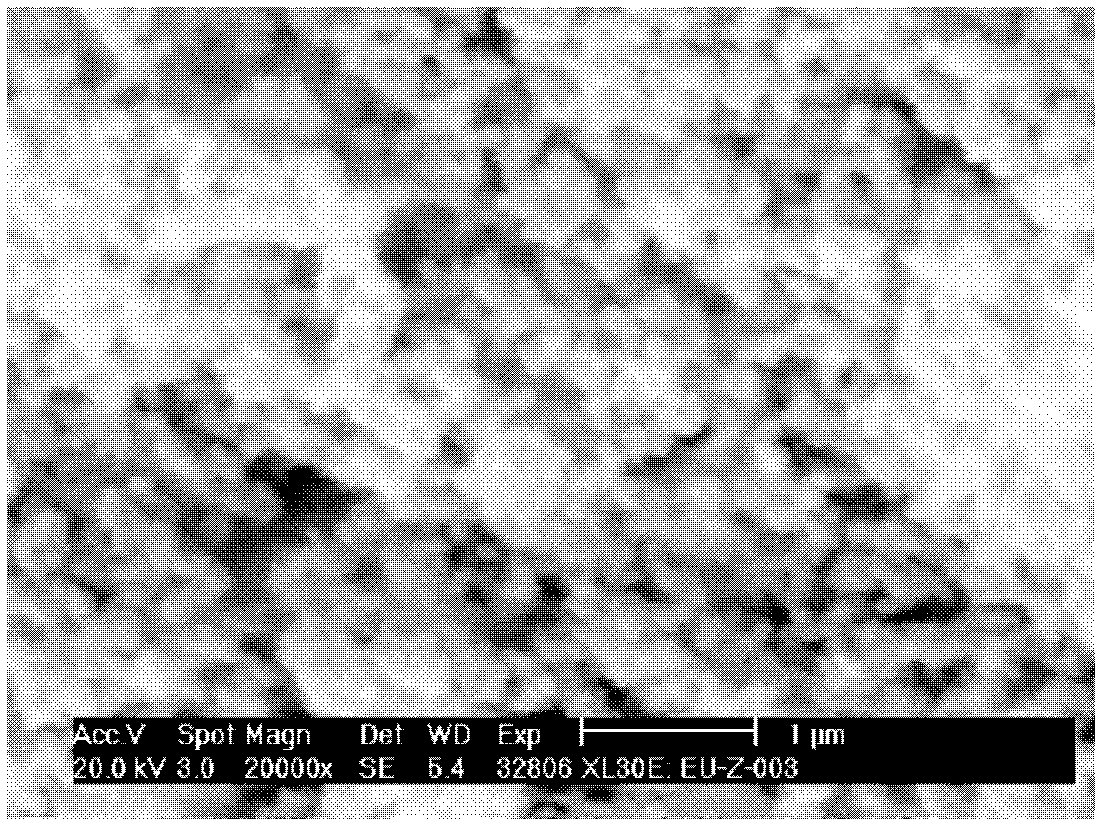

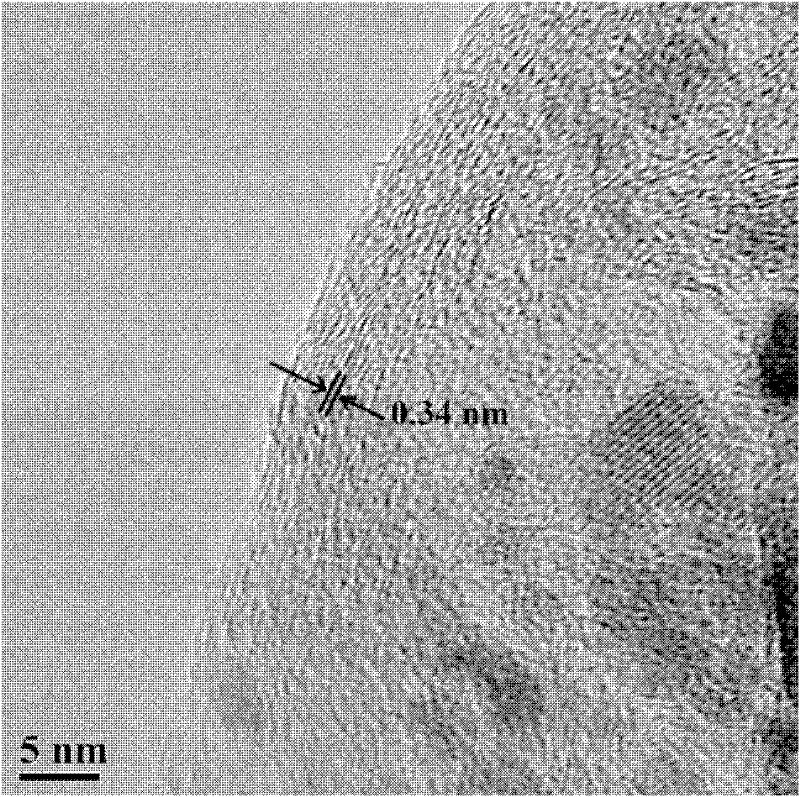

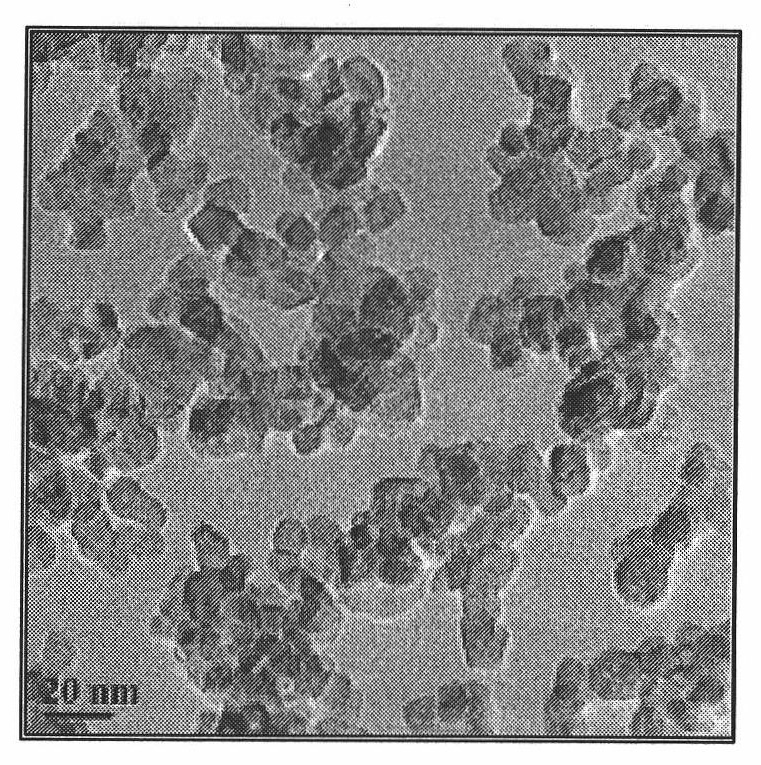

LiFePO4/C nano composite positive pole material and preparation method thereof

InactiveCN101159328AAchieve hybridControl chemical compositionElectrode manufacturing processesChemical industryPhosphateLithium-ion battery

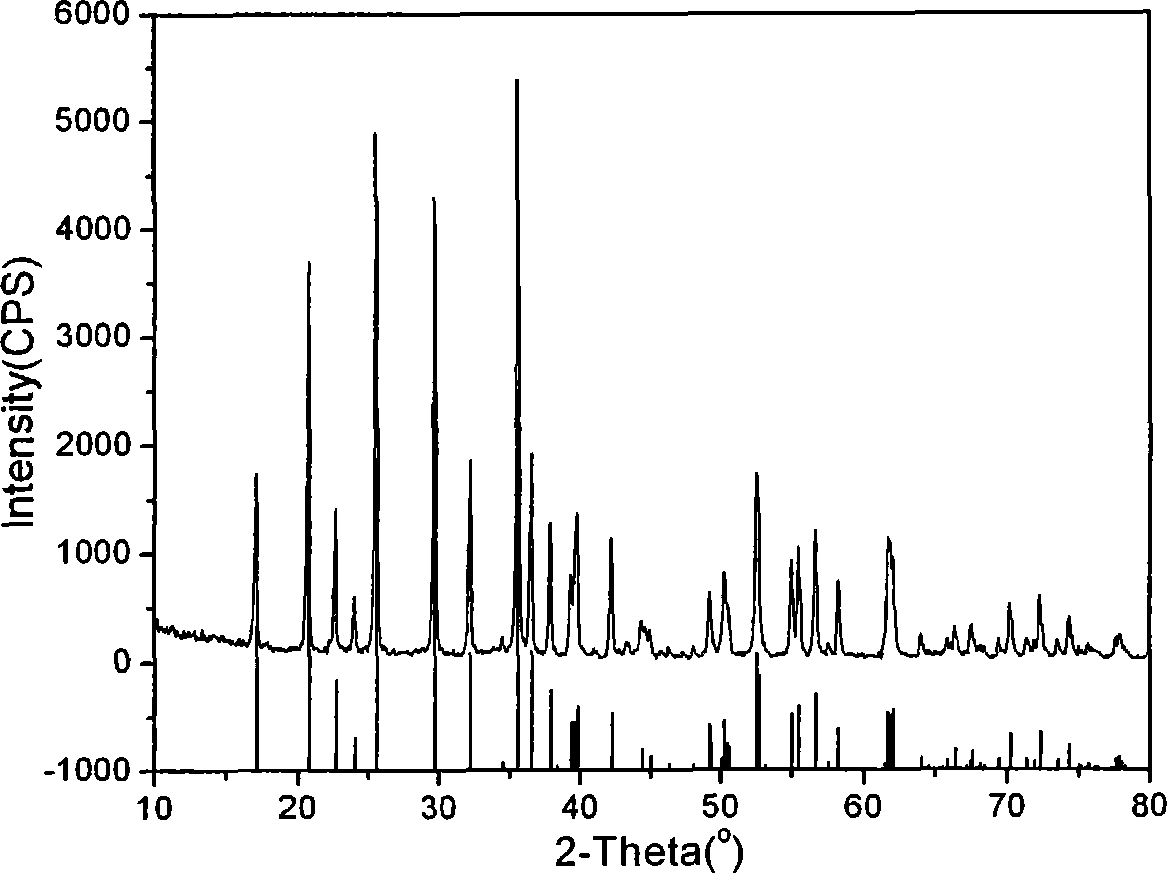

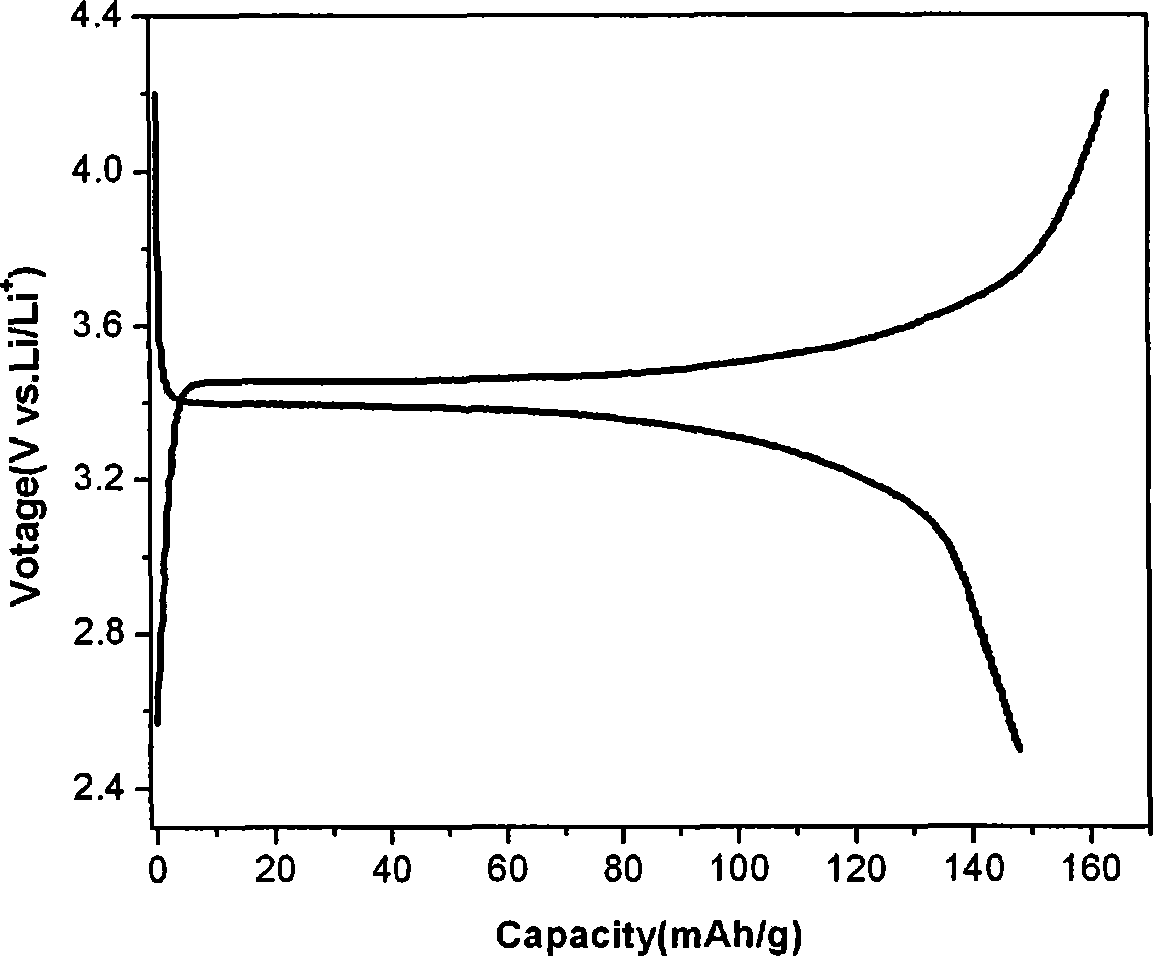

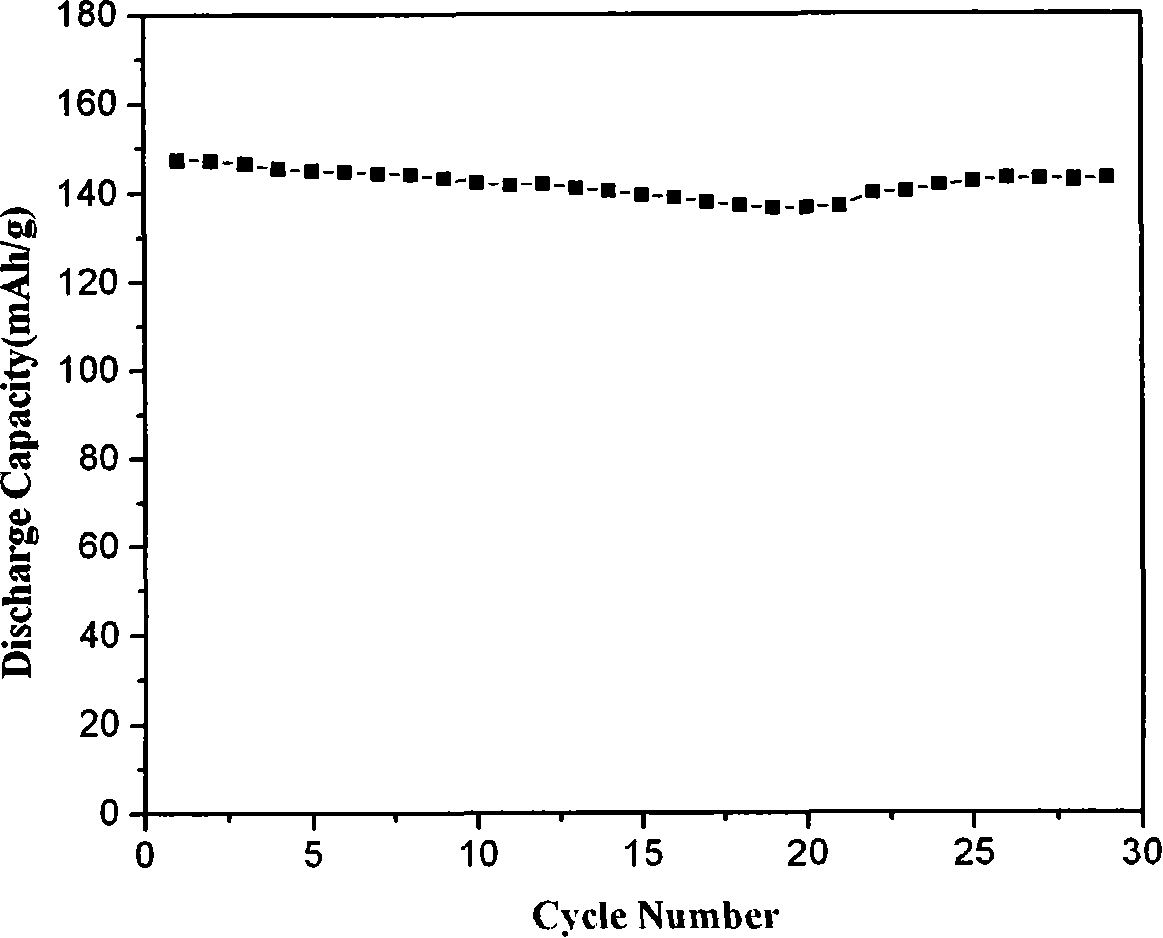

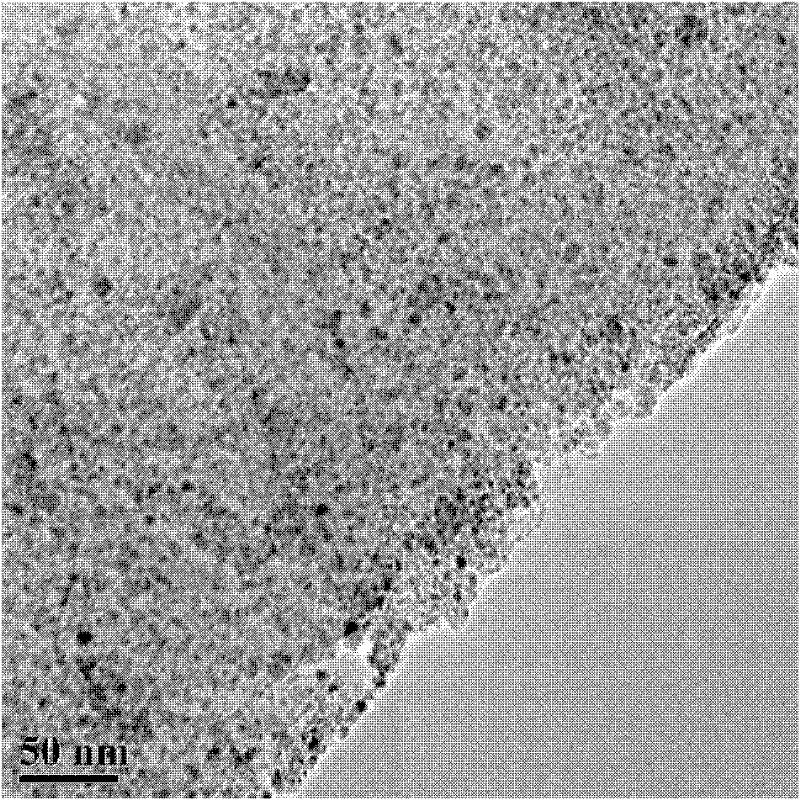

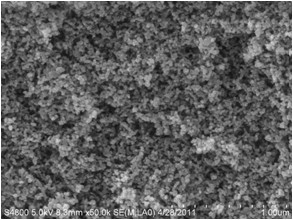

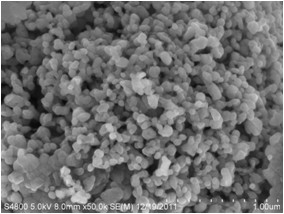

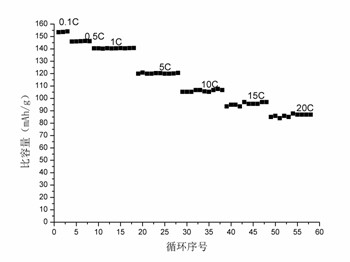

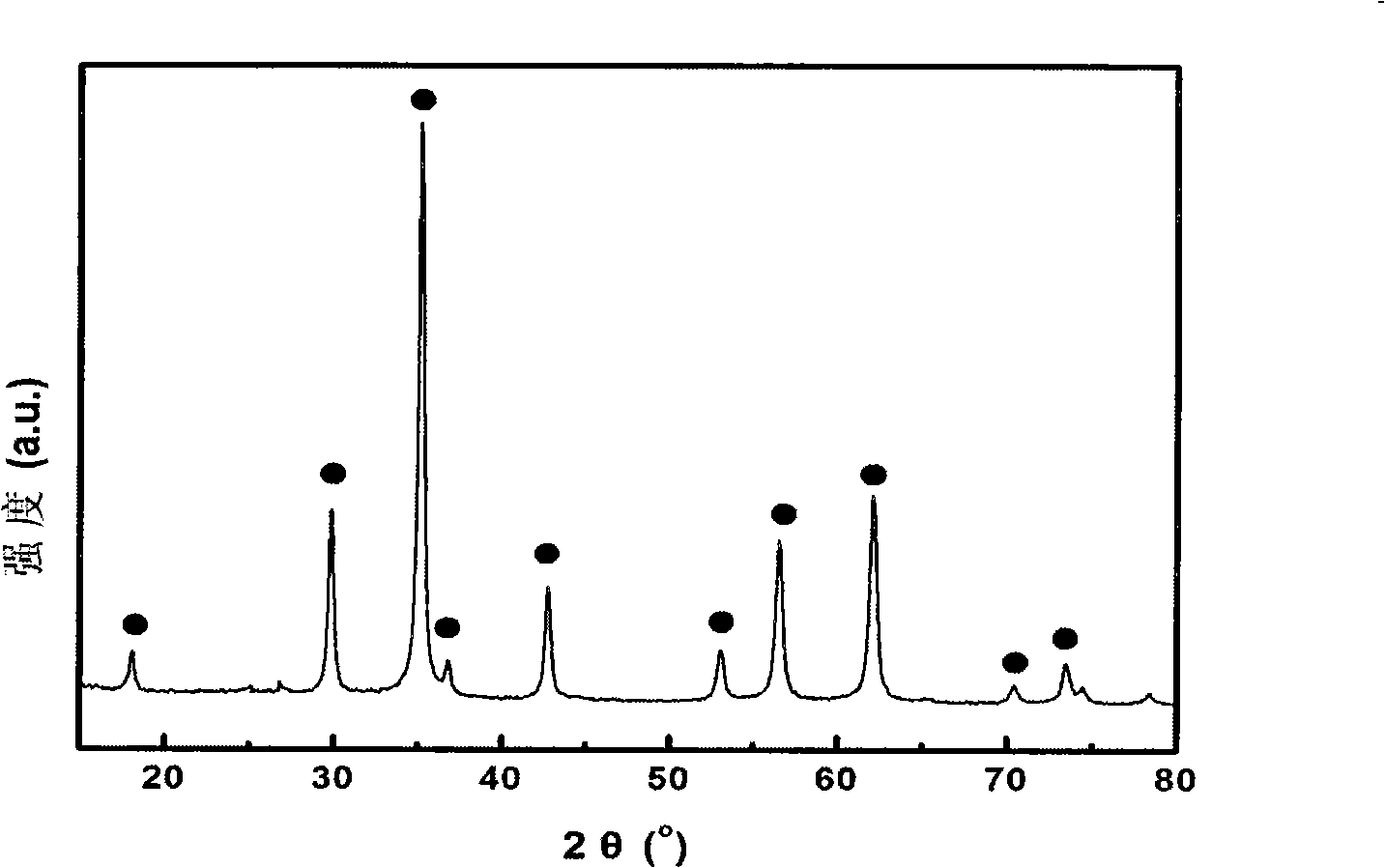

The invention discloses a nano-composite positive material LiFePO4 / C and a fabrication method, relating to a fabrication method of positive material of a lithium-ion battery. The invention uses the method of liquid-phase coprecipitation, the certain amount of lithium resource, iron resource and phosphate resource is weighted as the quality mol ratio of Li:Fe:P = (3.0-3.3):(1.0-1.1):(1.0-1.1), and the appropriate amount of carbon-doped material and organic surfactant is added in the reaction vessel; by controlling the reaction conditions like concentration, temperature etc. of the reaction solution, precursor gels are fabricated, and the precursor gels are separated, cleaned, filtered and dried to obtain precursor powder; the precursor powder is tableted and put into the crucible with microwave absorbent, and then the crucible is placed in the microwave oven, with the microwave power controlled between 100 to 600W and heated for 30 min, to obtain nano-sized composite positive material LiFePO4 / C. The technique method in the invention has the advantages of short periods, saved energy consumption, ease to control the process, suitability for industrialization and so on. The composite positive material LiFePO4 / C fabricated in the invention is characterized by high purity, small particle size lower than 100 nm, and good electrochemical properties.

Owner:上海微纳科技有限公司

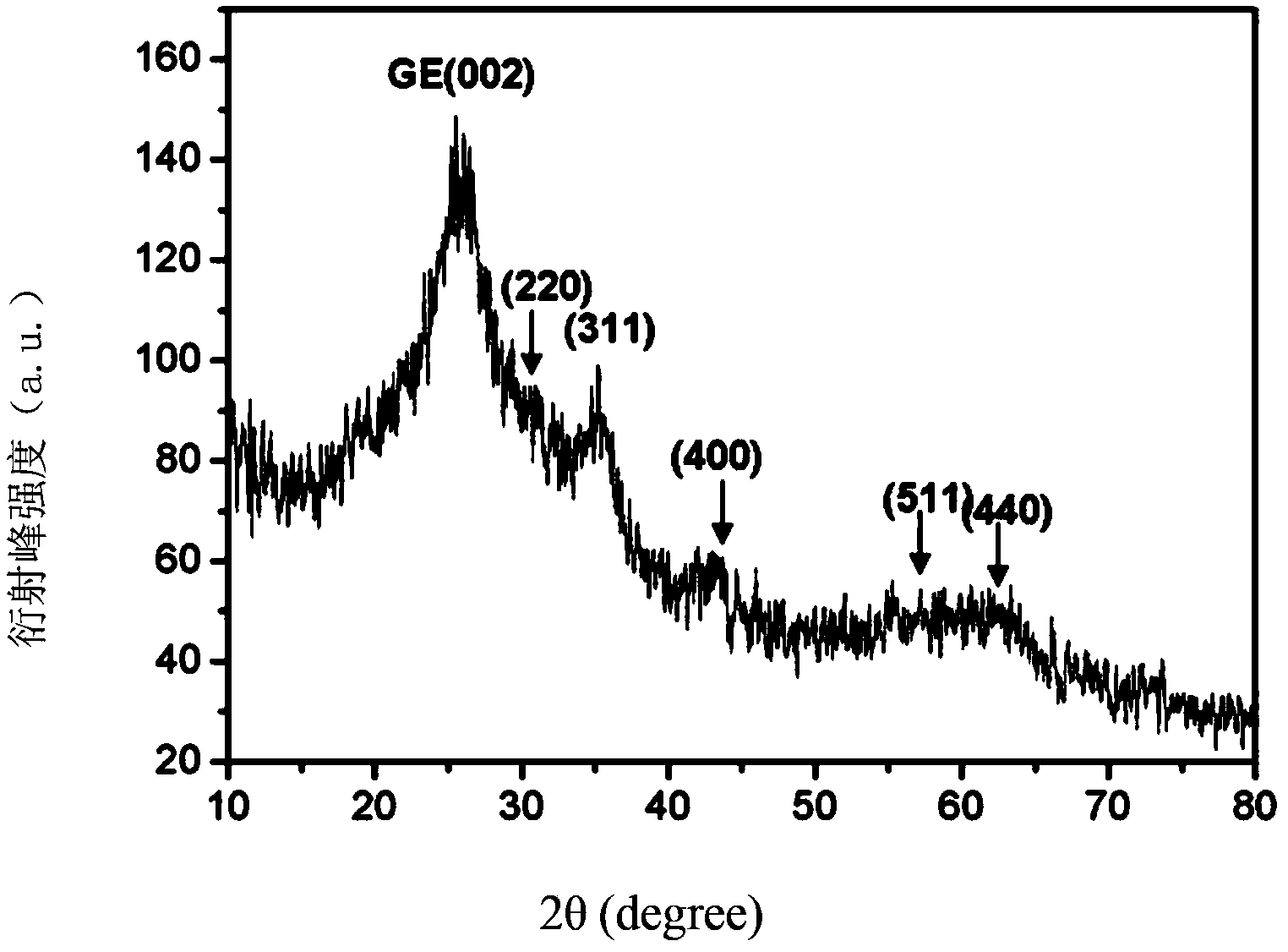

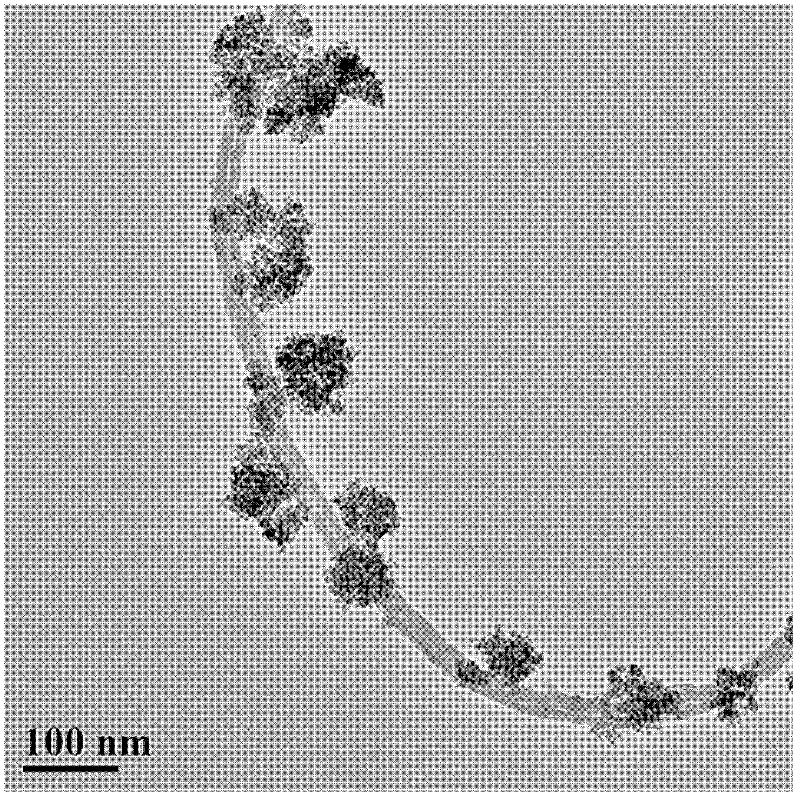

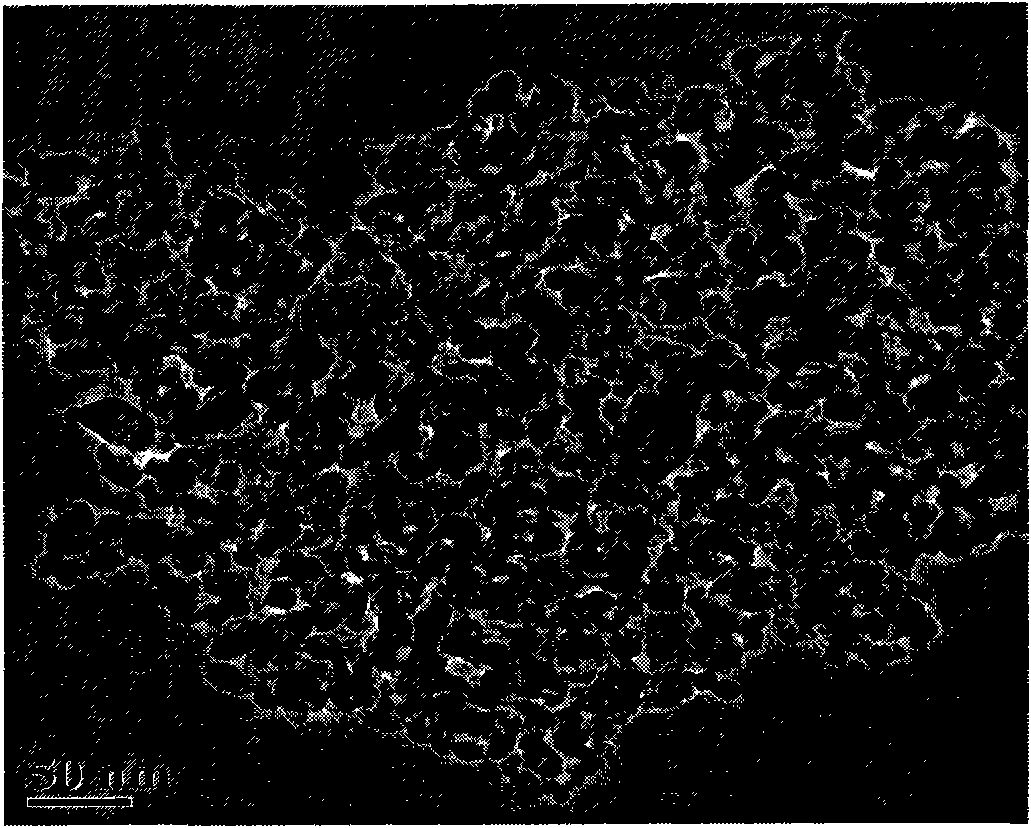

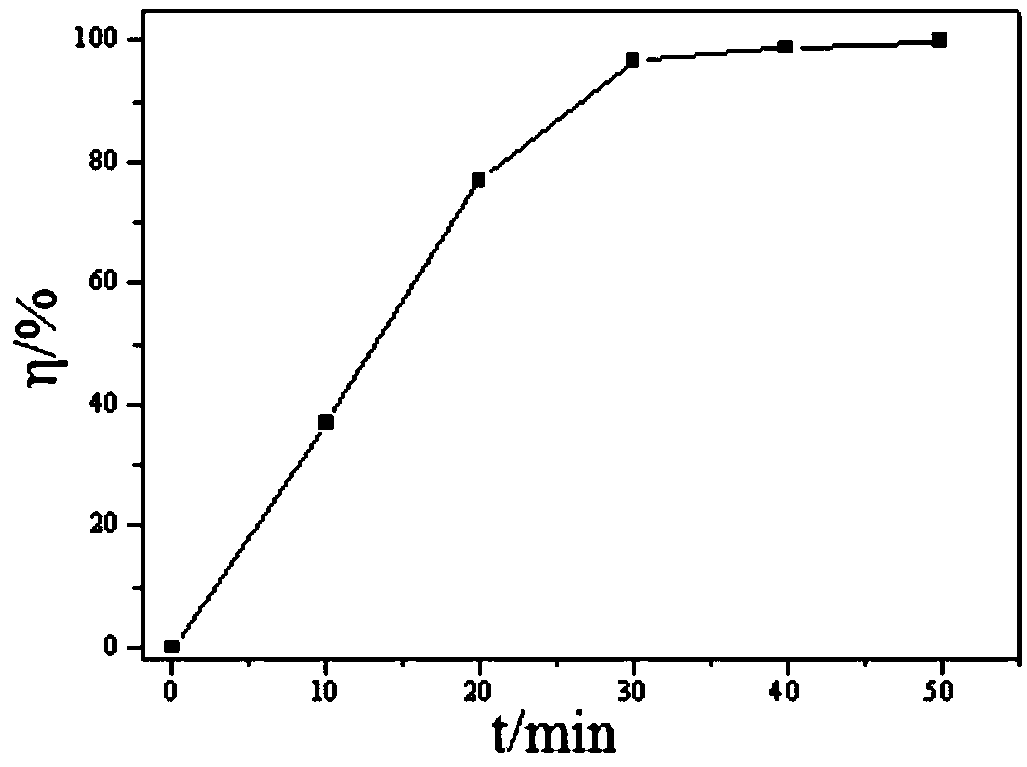

Preparation method of water-dispersible graphene/ferroferric oxide (Fe3O4) composite powder

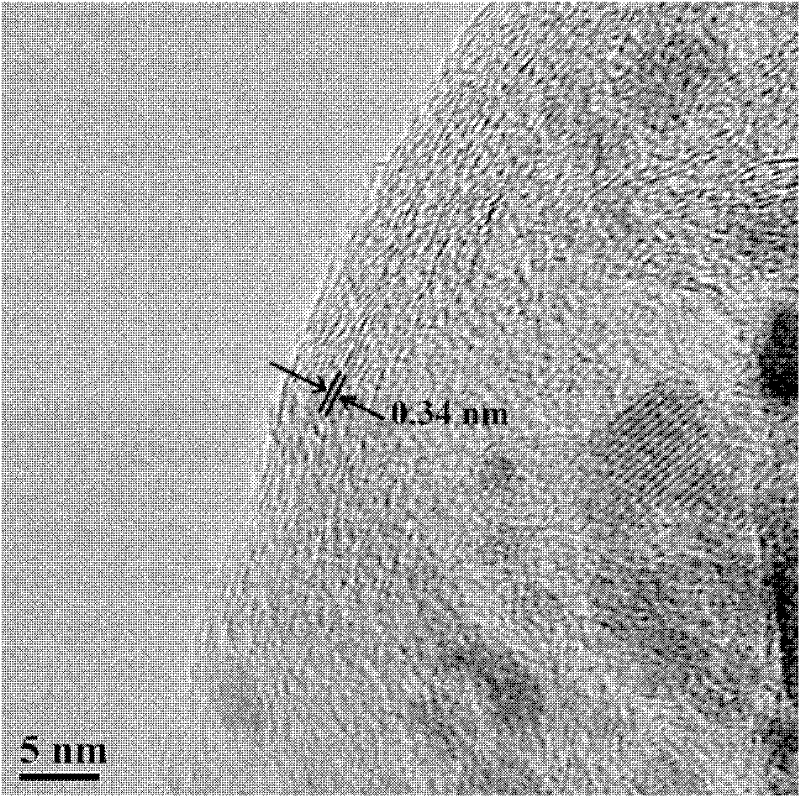

InactiveCN102173411AEasy to prepareLow requirements for production equipmentFerroso-ferric oxidesWater dispersibleFerrous salts

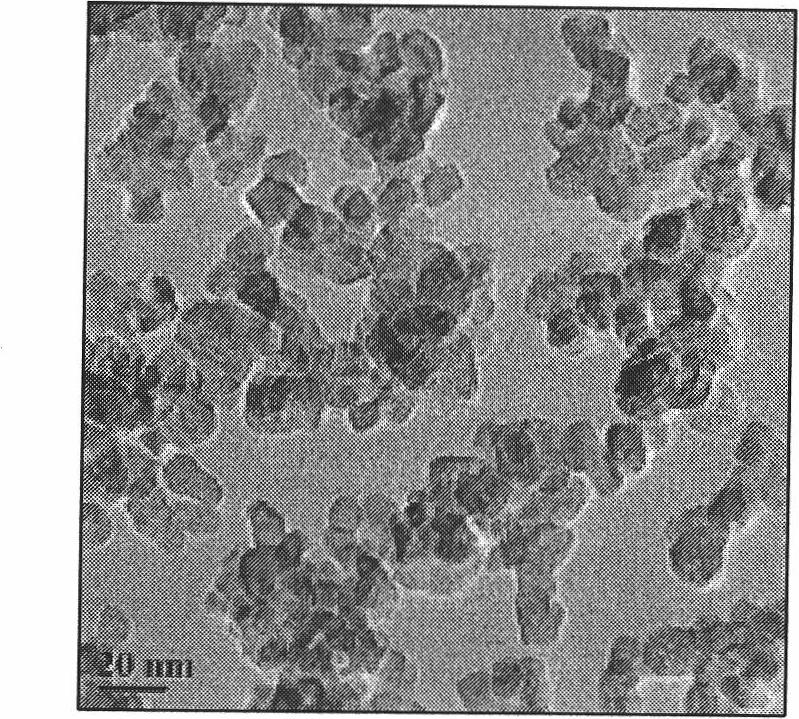

The invention relates to a preparation method of water-dispersible graphene / ferroferric oxide (Fe3O4) composite powder. The method comprises the following steps of: (1) ultrasonically dispersing graphite oxide and sodium polystyrene sulfonate into water at room temperature to form reaction liquid, raising a temperature to 90 to 110 DEG C, and reacting for 8 to 16 hours; (2) adding ferric salt and ferrous salt into the reaction liquid under the protection of nitrogen atmosphere at room temperature, adding ammonia water, reducing the temperature to 70 to 90 DEG C, reacting for 20 to 40 minutes, and then adding an oleic acid for continuous reaction; and (3) cooling to room temperature, collecting the graphene / Fe3O4 composite powder by using a magnet, washing and drying to obtain the finished product. The method is simple and easy for industrial production; Fe3O4 in the prepared composite powder has pure crystalline phase; the Fe3O4 is well combined with the graphene; the Fe3O4 has good dispersibility on a surface of the graphene and in a layer of the graphene; the composite powder is low in resistivity, high in magnetic intensity and good in underwater dispersibility and has a good application prospect.

Owner:DONGHUA UNIV

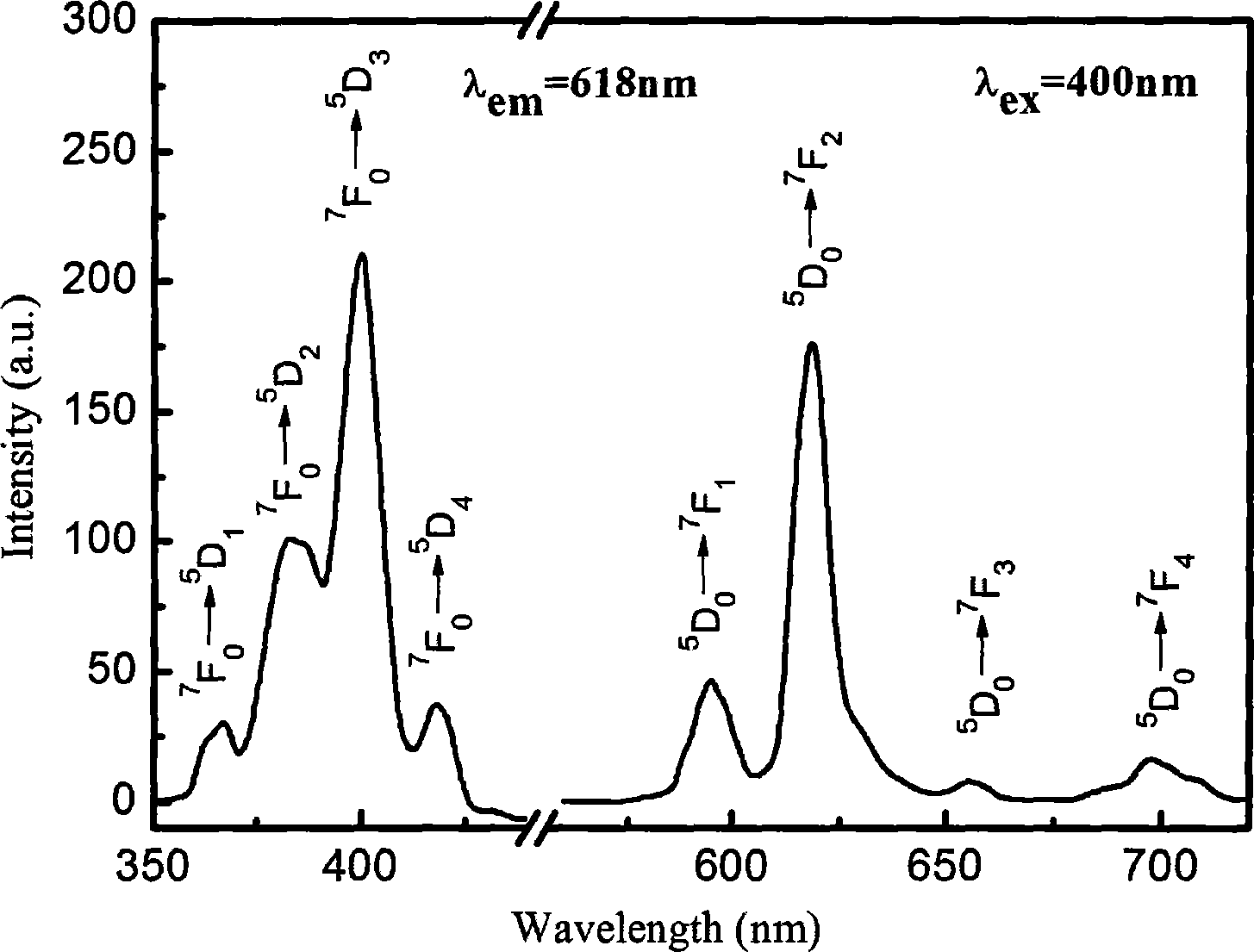

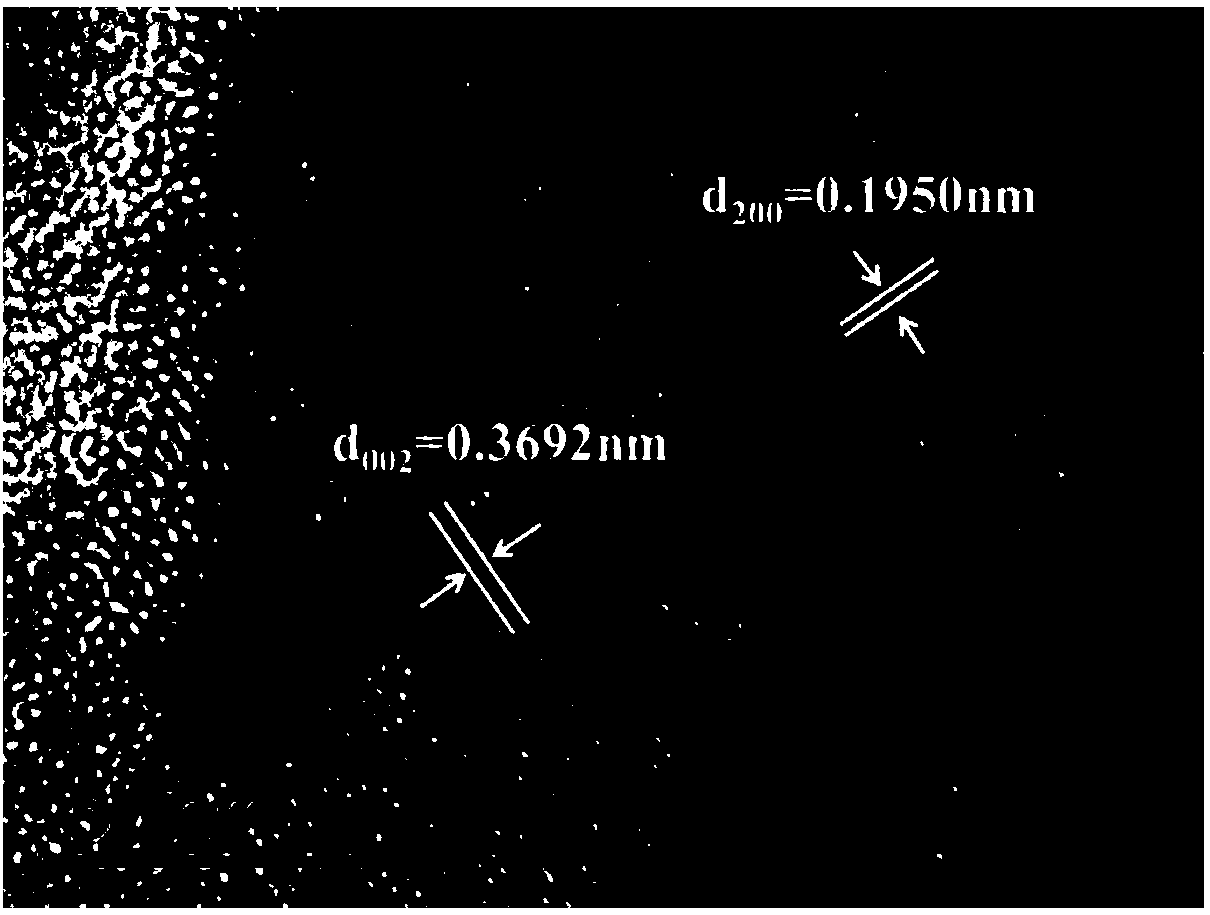

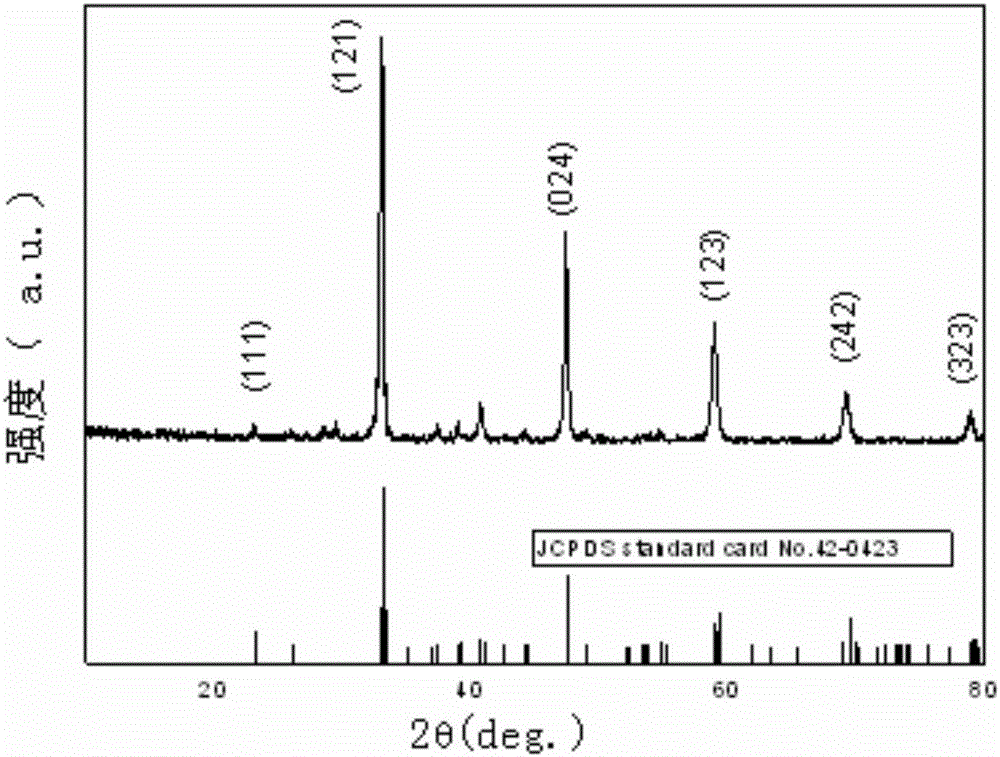

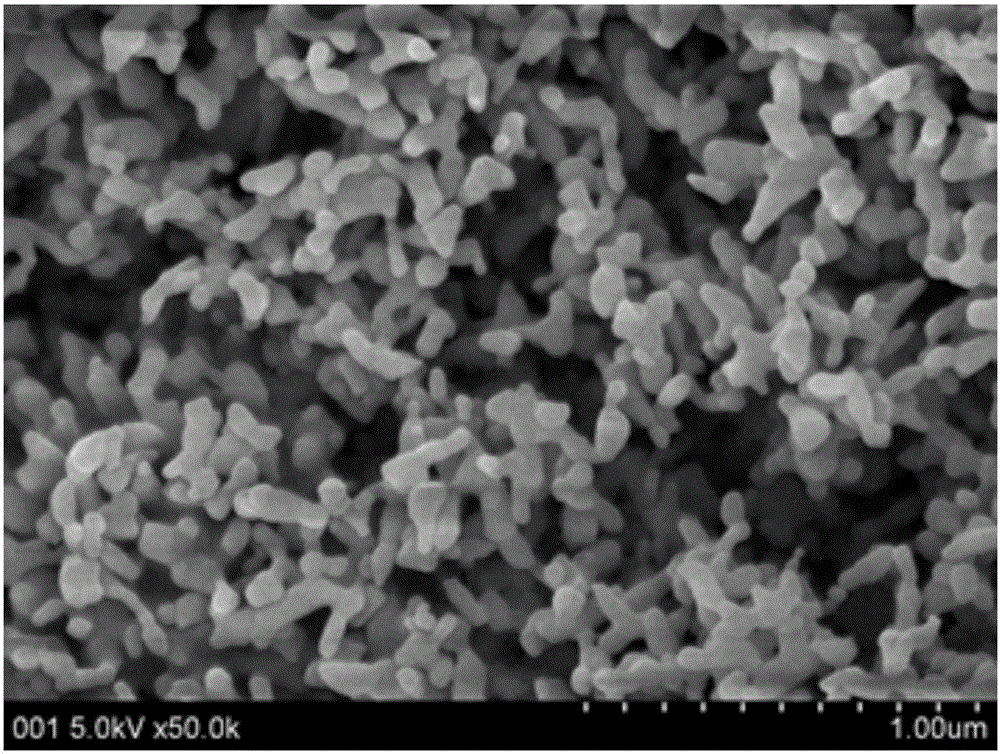

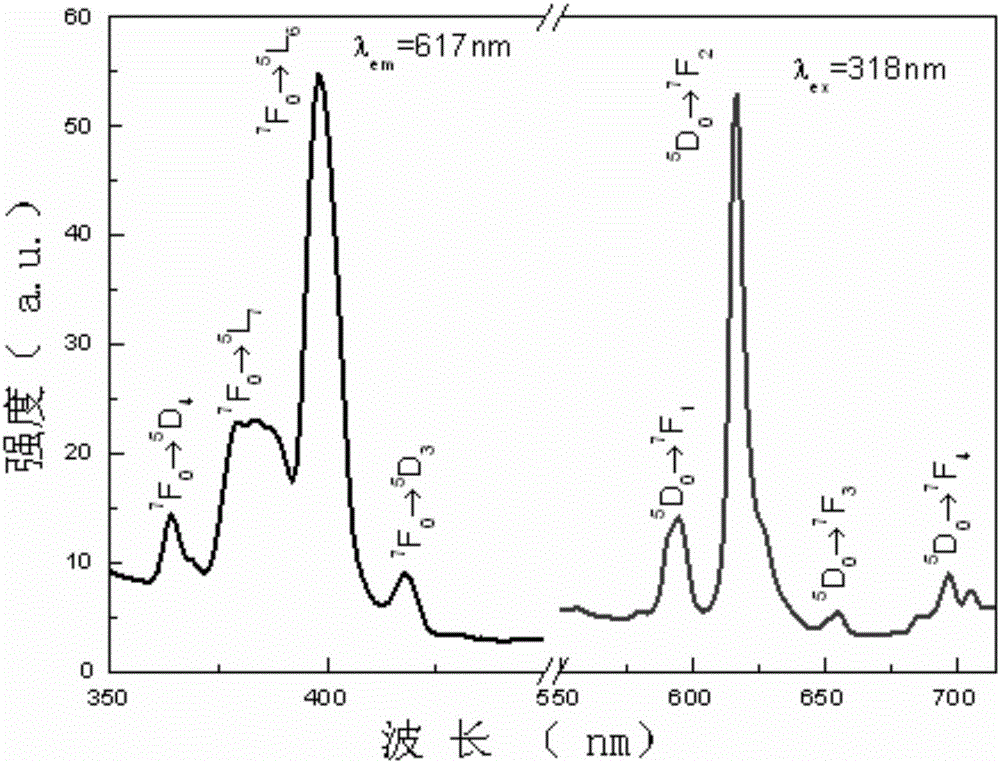

Preparation of doped calcium titanate (CaTiO3: Eu3+) fluorescent powder

InactiveCN101376523AGood chemical stabilitySmall grain sizeTitanium compoundsLuminescent compositionsAlcoholDissolution

The invention relates to a preparation method of Eu-doping calcium titanate CaTiO3:Eu<3+> fluorescent powders, which comprises the steps as follows: a soluble europium salt, a calcium salt and Ti(OC4H9)4 are weighed according to the mole ratio that is 1:49:50 to 1:4:5 among Eu<3plus>, Ca<2plus> and Ti<4plus>, and are respectively dissolved in absolute ethyl alcohol, and the confected solution is stirred for ample dissolution; (2) a mixed ethanol solution of the europium salt and the calcium salt is added in an ethanol solution of Ti(OC4H9)4, and a sol is obtained through stirring; (3) the sol is placed at the temperature ranging from 0 to 50 DEG C to obtain a wet gel which is put in a baking box for drying; (4) the dried gel is milled into powders, the obtained powders are calcined for 2 to 8 hours to obtain the CaTiO3:Eu<3plus> fluorescent powders. In the preparation method, the prepared CaTiO3:Eu<3plus> fluorescent powders have high chemical durability, small grain size, pure crystalling phase and low calcination temperature; the preparation method has simple technology, and is easy for industrialized production.

Owner:DONGHUA UNIV

Preparation of magnetic reduced graphene oxide composite material and method for removing quinolone antibiotics from water by the same

InactiveCN104096536AHigh magnetizationSimple processOther chemical processesMultistage water/sewage treatmentIron saltsFreeze-drying

Belonging to the technical field of water treatment, the invention relates to preparation of a magnetic reduced graphene oxide composite material. The method includes: (1) placing graphene oxide into ethylene glycol to undergo ultrasonic treatment; (2) dissolving sodium citrate in ethylene glycol to undergo heating reaction; (3) mixing FeCl3.6H2O with urea, then dissolving the mixture into a sodium citrate / ethylene glycol solution under magnetic stirring to obtain an ethylene glycol mixed solution of the iron salt and urea; (4) stirring and mixing the graphene oxide / ethylene glycol mixed solution and the ethylene glycol mixed solution of the iron salt and urea obtained in the preceding step to undergo reaction, then transferring the reaction product into a reaction kettle to undergo heating reaction and cooling; and (5) subjecting the obtained material to centrifugation, washing and filtering, and freeze drying, thus obtaining the product involved in the invention. The magnetic reduced graphene oxide prepared by the method provided by the invention has the advantages of pure crystal phase, difficult agglomeration, and high magnetization degree. Also, the process is simple and has low requirements for production equipment. The invention also relates to a method for removing quinolone antibiotics from water by the composite material.

Owner:TONGJI UNIV

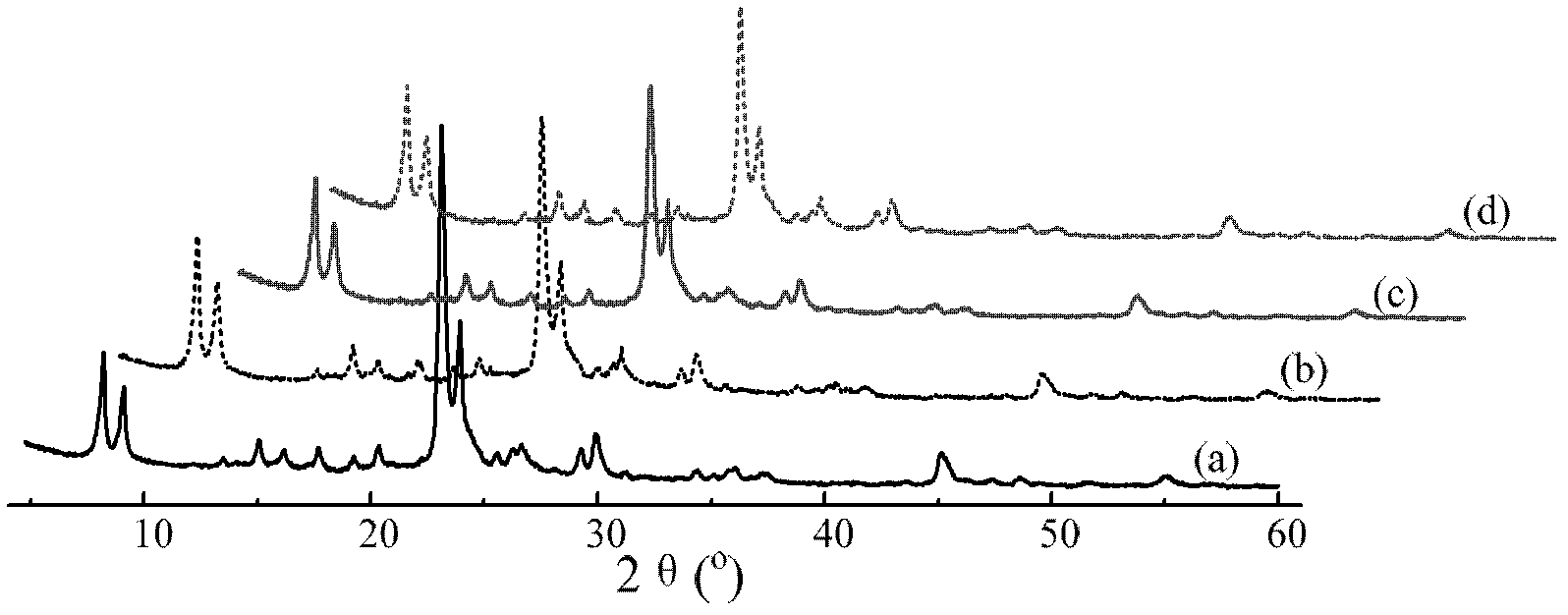

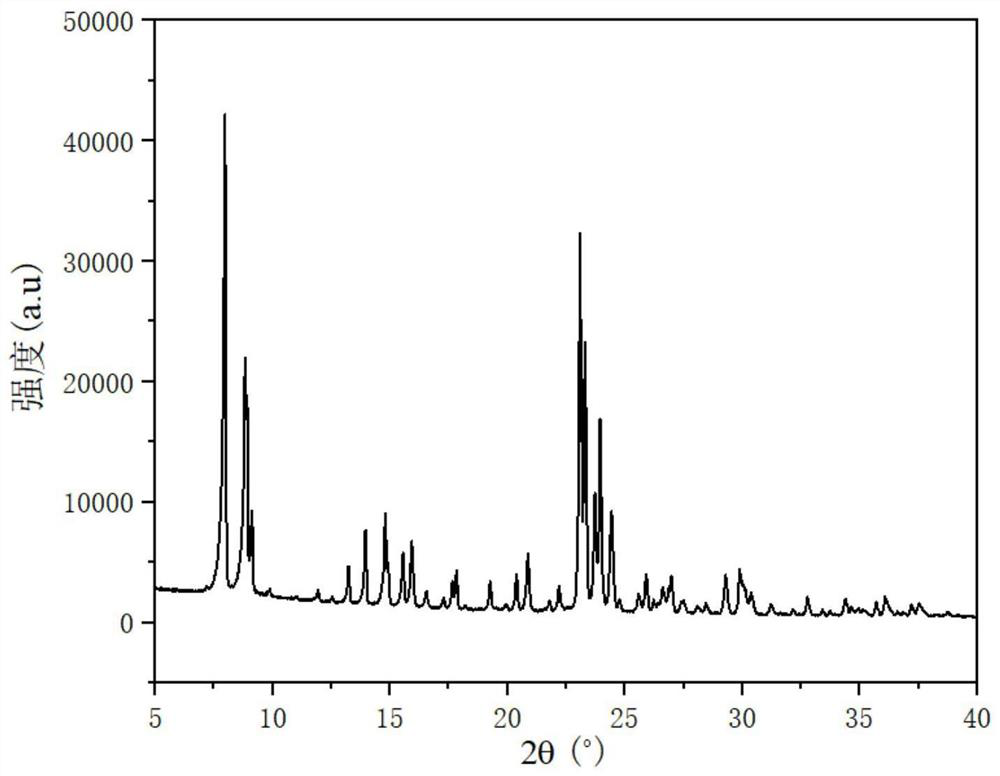

Method for preparing molecular sieve ZSM-5

InactiveCN102001679ASimple processUniform temperaturePentasil aluminosilicate zeoliteProduction rateGranularity

The invention relates to a method for preparing a molecular sieve ZSM-5 by preparing a precursor glue solution, crystallizing, filtering, drying and roasting. The invention adopts two crystallization methods, one method comprises the following steps of: directly illuminating the precursor glue solution in a sealed container by adopting a microwave field, and crystallizing by utilizing the coaction of the microwave effect and the autogenous hydrothermal pressure of the glue solution; and the other method comprises the following steps of: heating the precursor glue solution in the sealed container by adopting saturated steam for crystallization treatment, wherein the heating and the crystallization treatment can be simultaneously carried out in the microwave field. The saturated steam for the crystallization treatment is crystallized at 170-180 DEG C for 1-6h, 1-10 percent by weight of inoculating seeds are added after aging the precursor glue solution and before crystallizing the precursor glue solution which is prepared by adopting a template-free preparation method. The method of the invention has the following advantages of simple and practical process and uniform temperature in the crystallization process, obtains the molecular sieve with high crystallinity, pure crystal phase, controllable grain size, wider range and short crystallization time, can improve the production efficiency, decrease the cost and save energy.

Owner:YUEYANG YITIAN CHEM

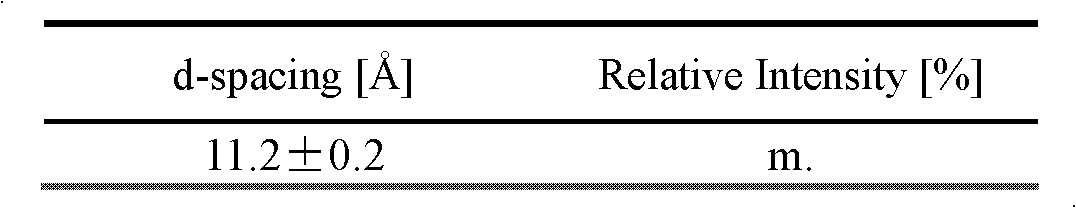

Preparation method of iron phosphate for preparing lithium iron phosphate and iron phosphate

ActiveCN102616763AUniform particle sizeAvoid reunionPhosphorus compoundsIron saltsLithium iron phosphate

The invention discloses a preparation method of iron phosphate for preparing lithium iron phosphate. The preparation method comprises the following steps of: (1) preparing cationic surfactant aqueous solution; (2) preparing soluble iron salt aqueous solution and soluble phosphate aqueous solution of 0.1-5 mol / L respectively; (3) adding the soluble iron salt aqueous solution and the soluble phosphate aqueous solution into the cationic surfactant aqueous solution in sequence at 25-50 DEG C under ultrasonic treatment and stirring according to a molar ratio of Fe: P of 1:0.8-1.2, wherein the speed is less than or equal to 60 ml / min, and the concentration of a cationic surfactant in reaction solution formed after all materials are added is 1-10 g / L; (4) adding ammonia water at 25-50 DEG C under ultrasonic treatment and stirring to adjust the pH of the solution to be 0-3, performing ultrasonic treatment for a time and continuously stirring for 30-180 minutes; and (5) washing the liquid obtained by the step (4) with de-ionized water or absolute ethanol and then drying at 70-90 DEG C to obtain powdery iron phosphate.

Owner:深圳市毓丰新材料有限公司

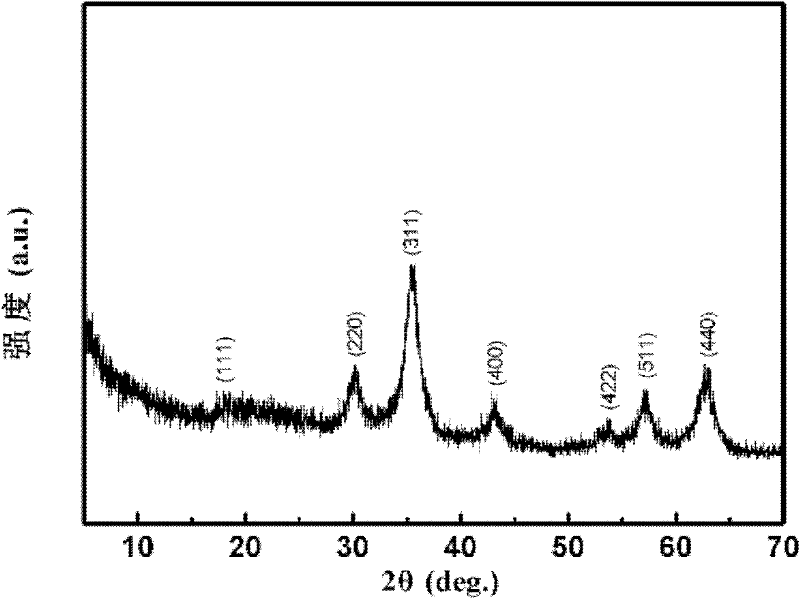

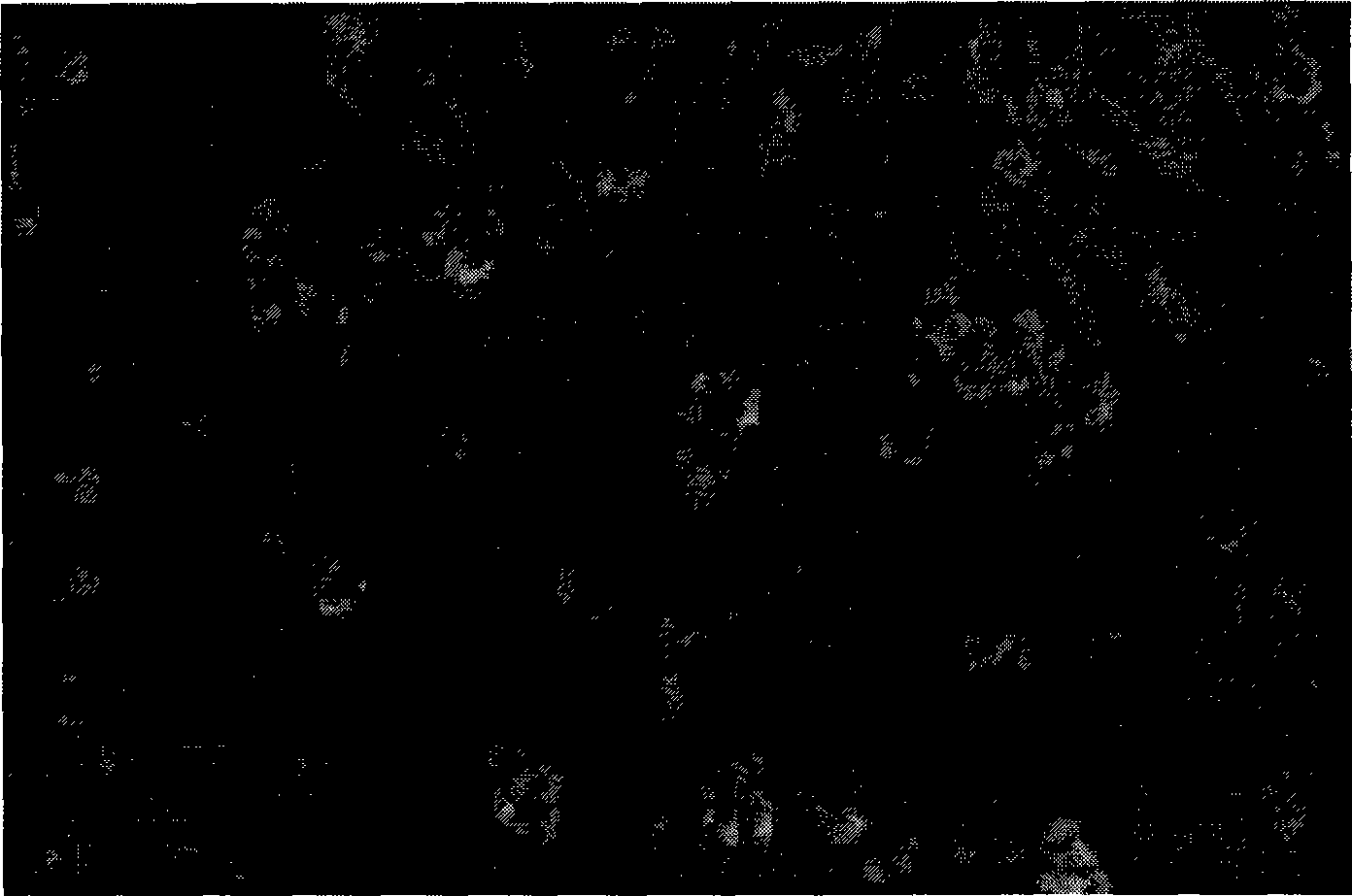

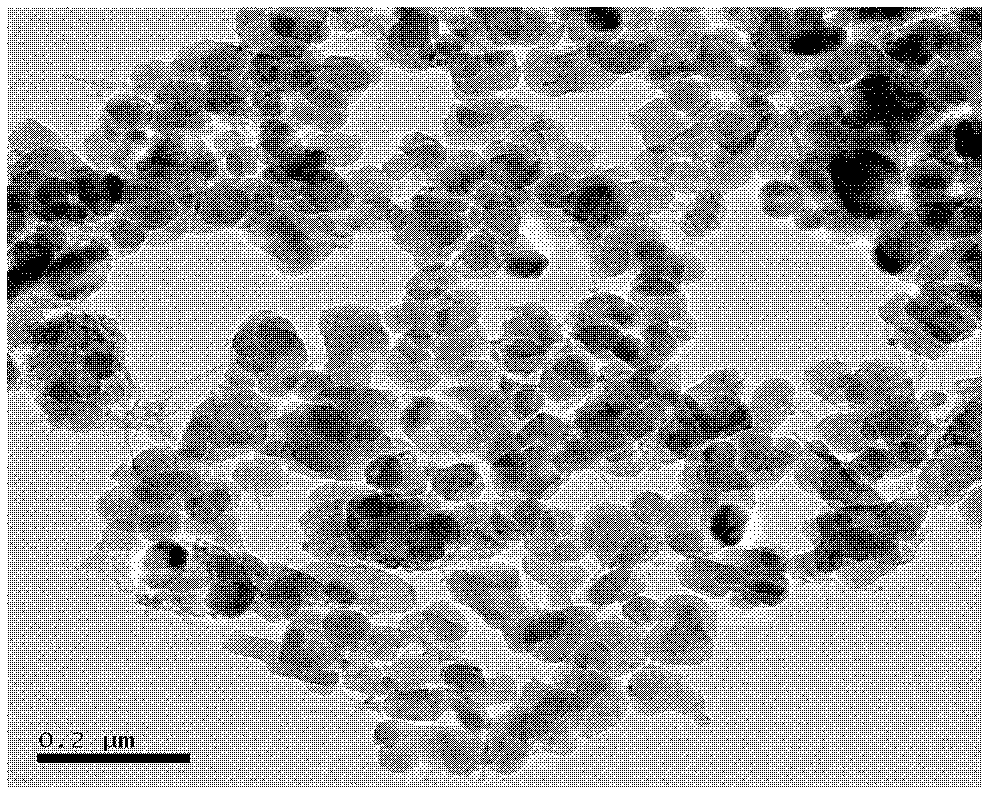

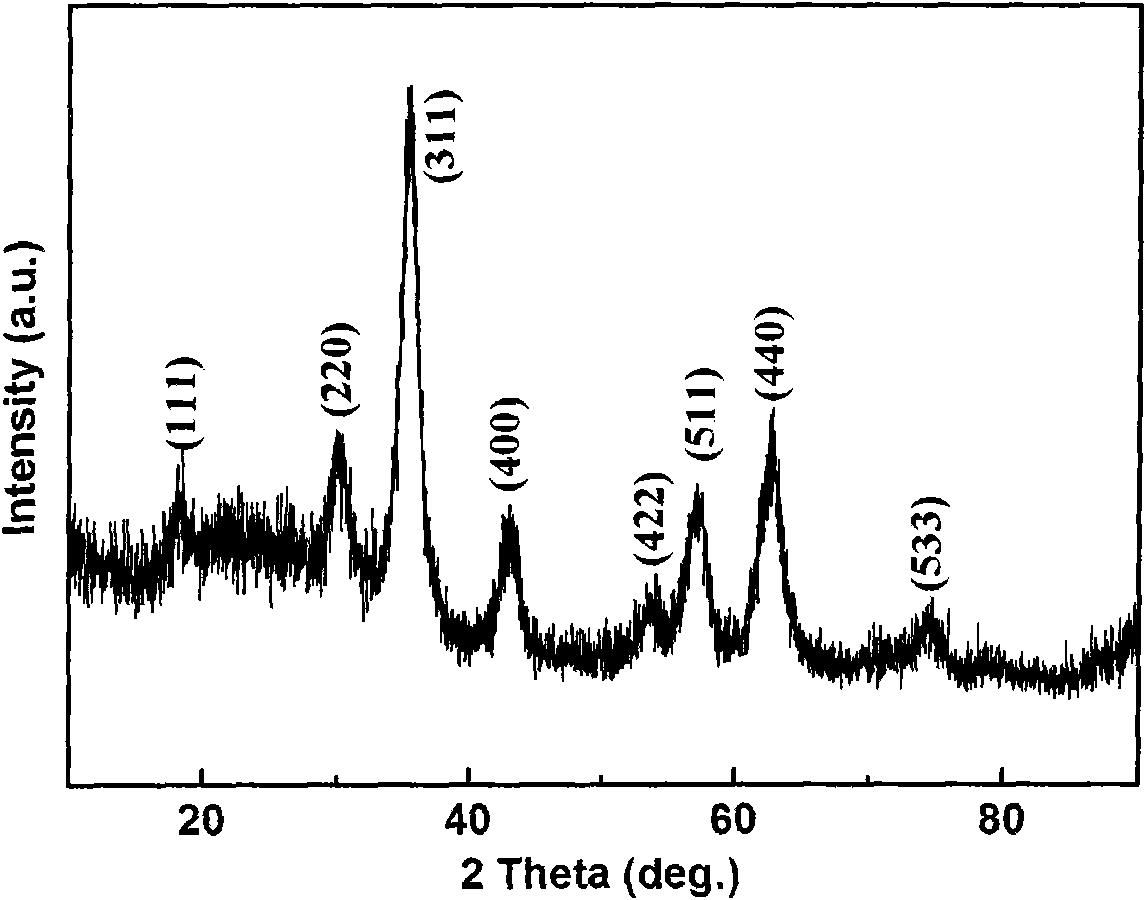

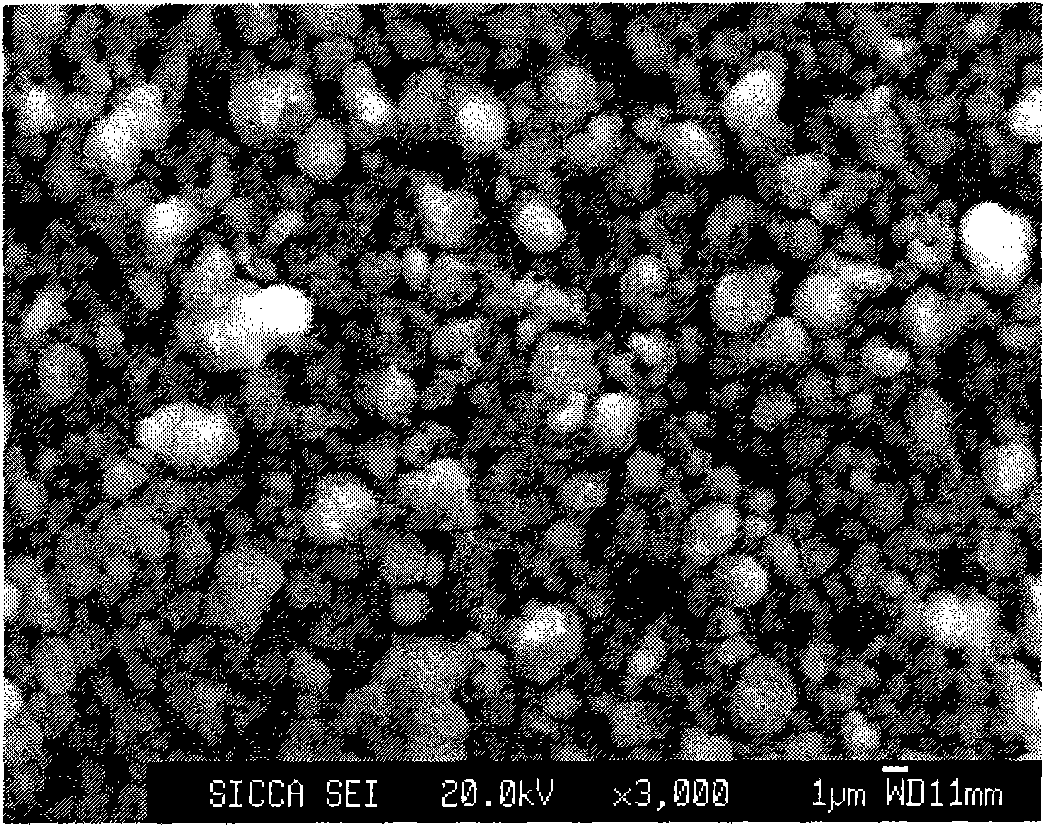

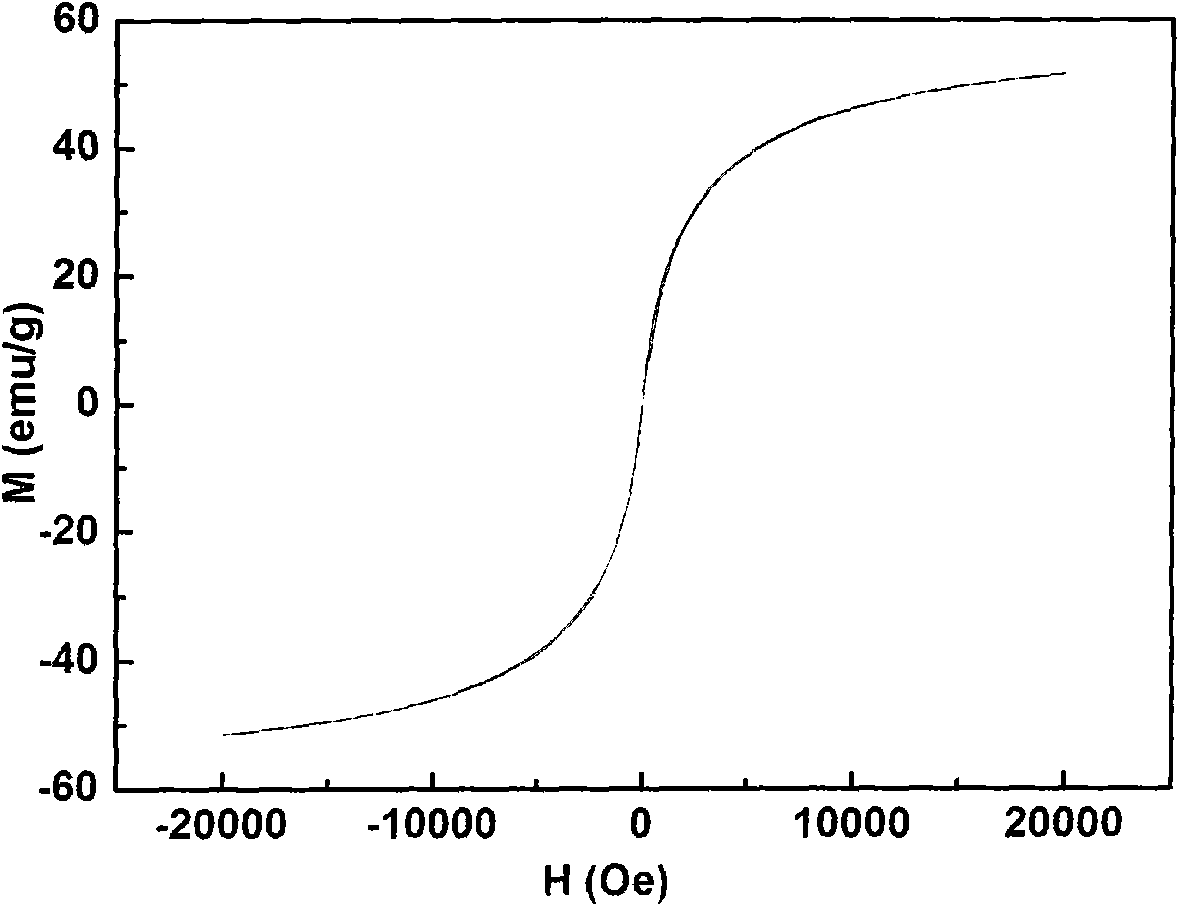

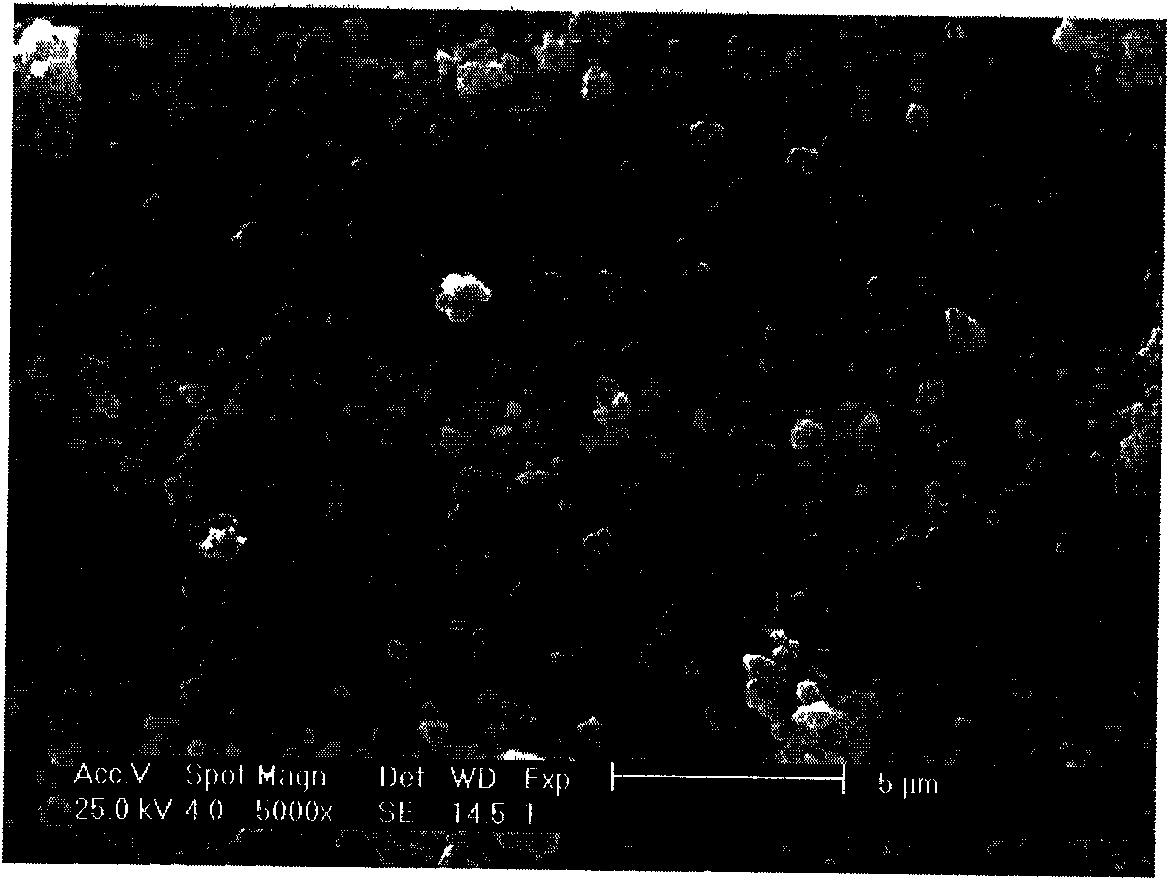

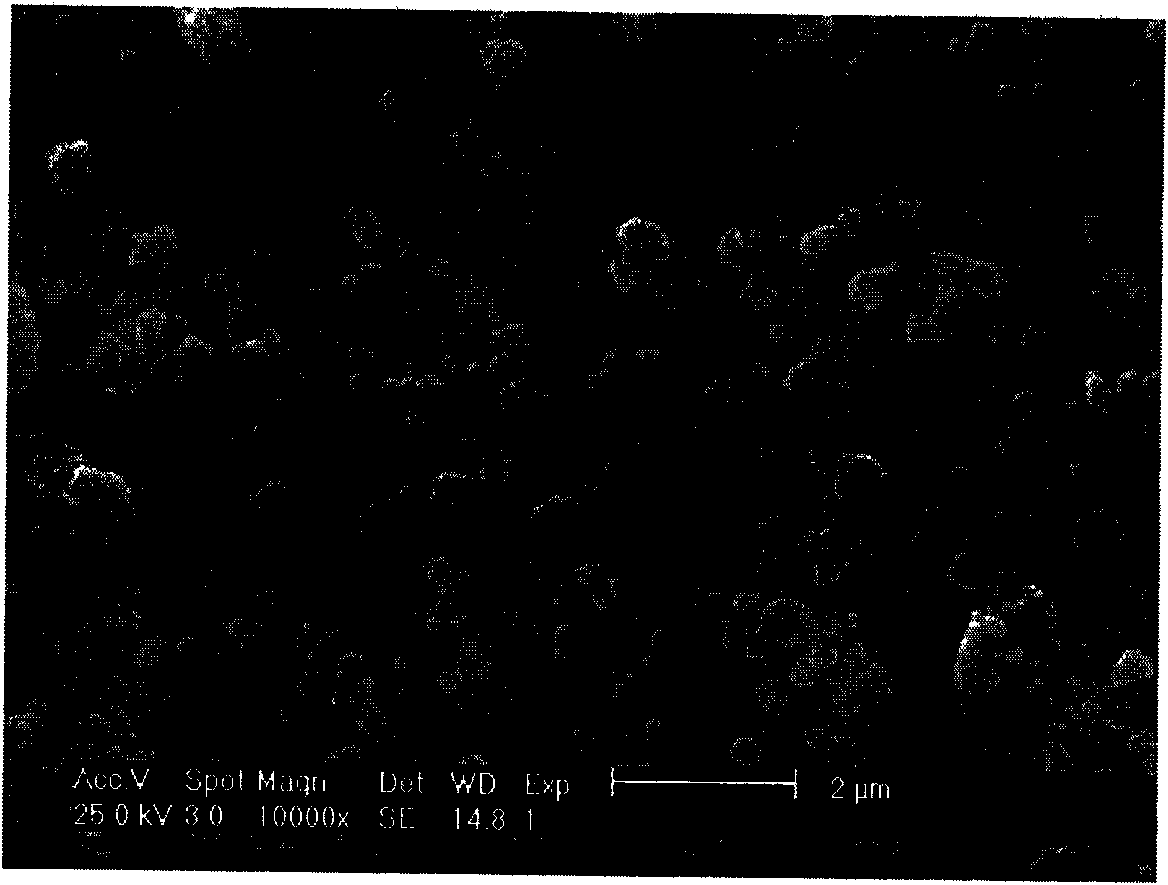

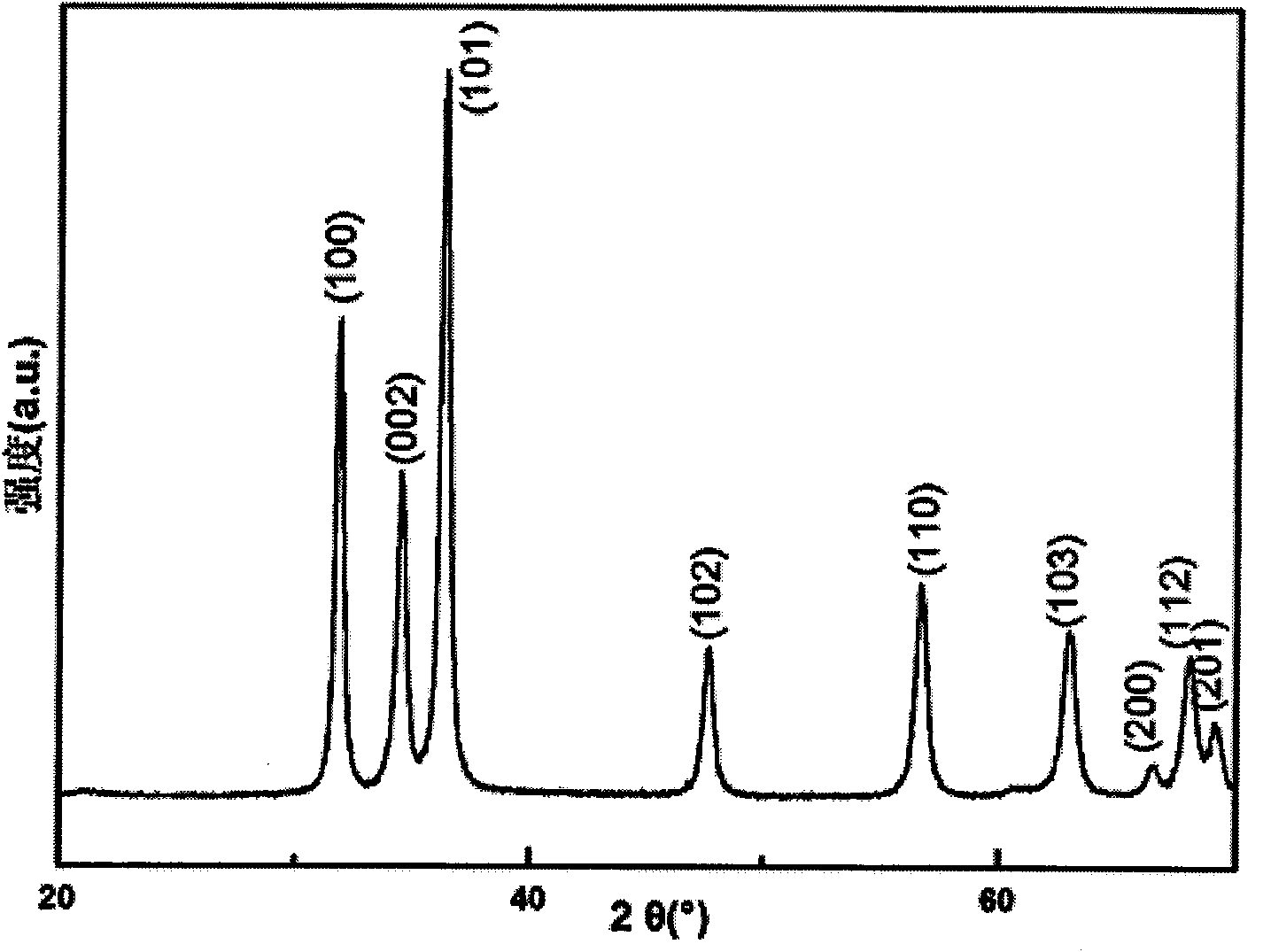

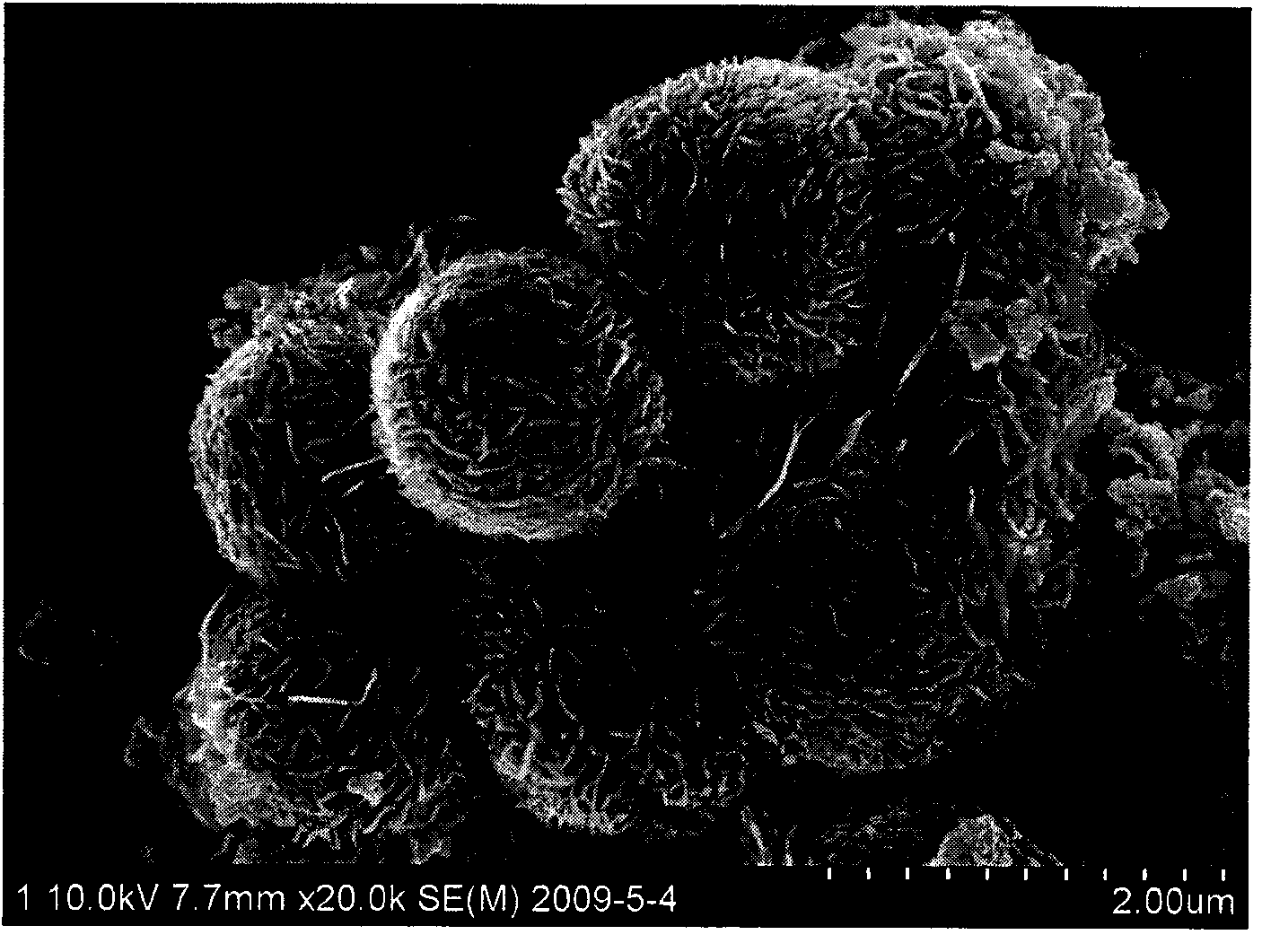

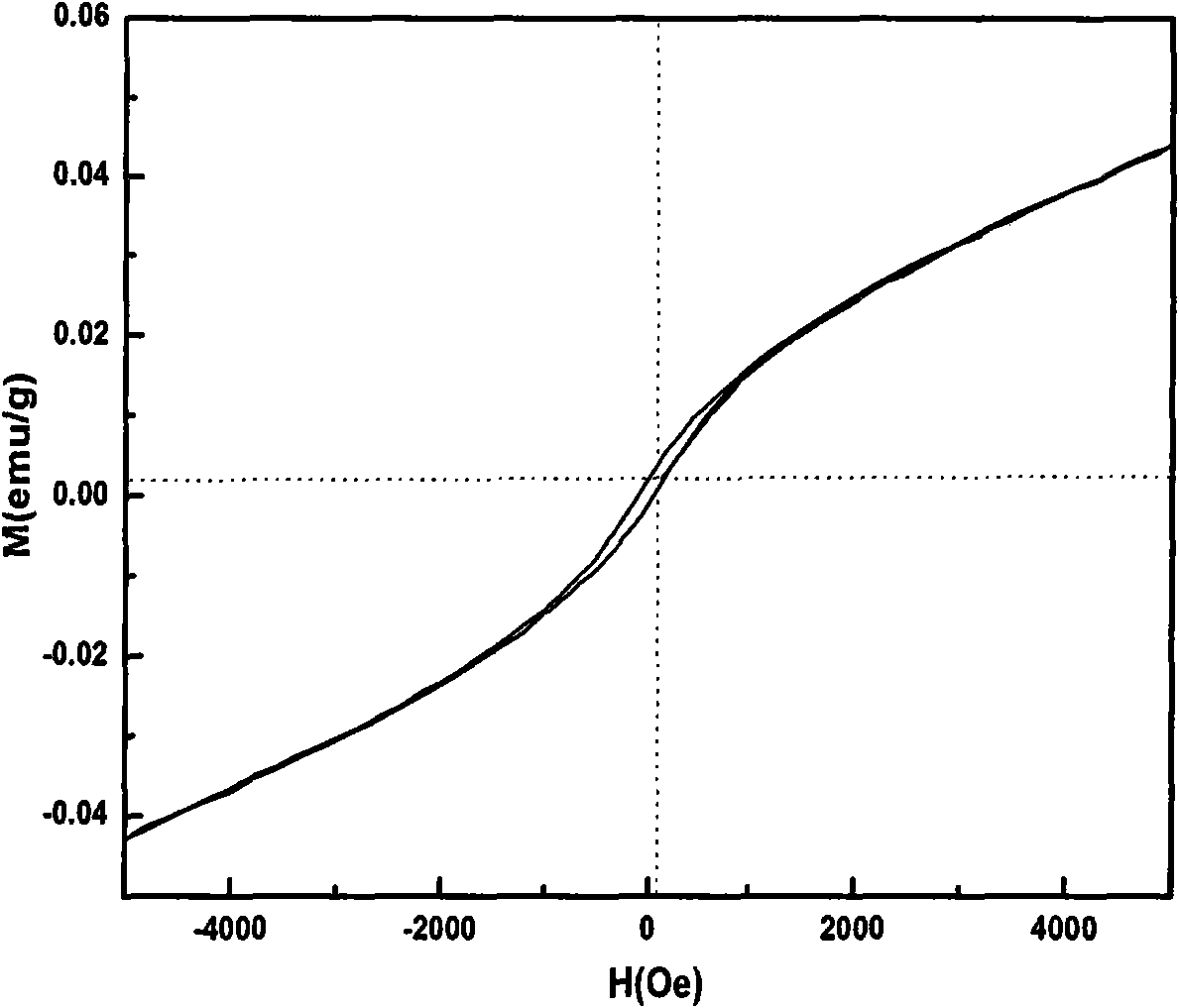

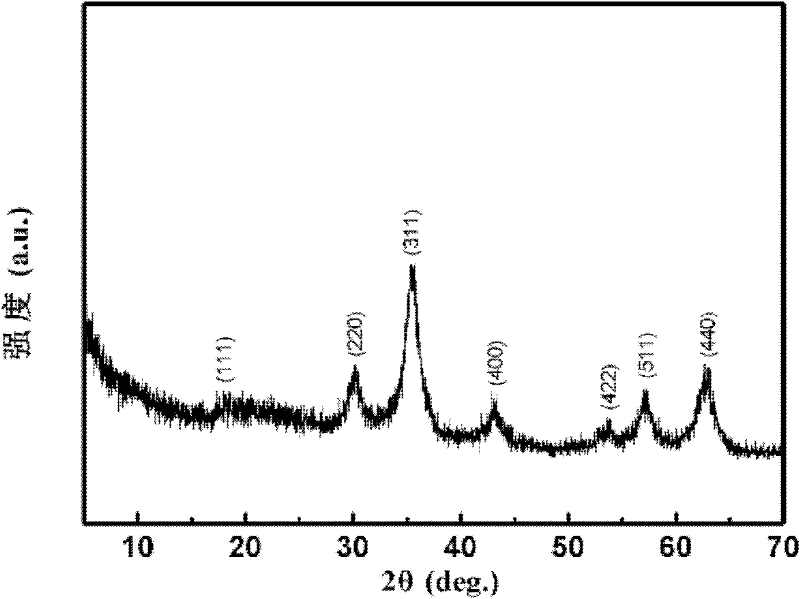

Preparation method of manganese-zinc ferrite magnetic nano microsphere

The invention relates to a method for preparing a Mn-Zn ferrite magnetic nano-sphere, which comprises the following steps: (1) weighting soluble iron salt, zinc salt and manganese salt according to the stoichiometric proportion at the normal temperature, and adding into 40-60ml of solvent with 98-99.5wt% of glycol; (2) adding 0.4-1.2ml of polyethylene glycol and 0.01-0.02g of polyvinyl pyrrolidon dispersant, adding 3.5-5g of alkaline additive, and mechanically stirring for 20-40min; (3) putting the soluble mixture into a reaction kettle, heating to 180-220DEG C, reacting for 8-12h, cooling to the room temperature, collecting the reaction product by a magnet, washing the product by deionized water, and drying to obtain the Mn-Zn ferrite Mn1-xZnxFe2O4 magnetic nano-sphere, wherein x ranges from 0.2 to 0.8. The invention has simple preparation process and easy industrialized production, and the obtained magnetic nano-sphere has pure crystal phase, good dispersibility and high magnetization.

Owner:DONGHUA UNIV

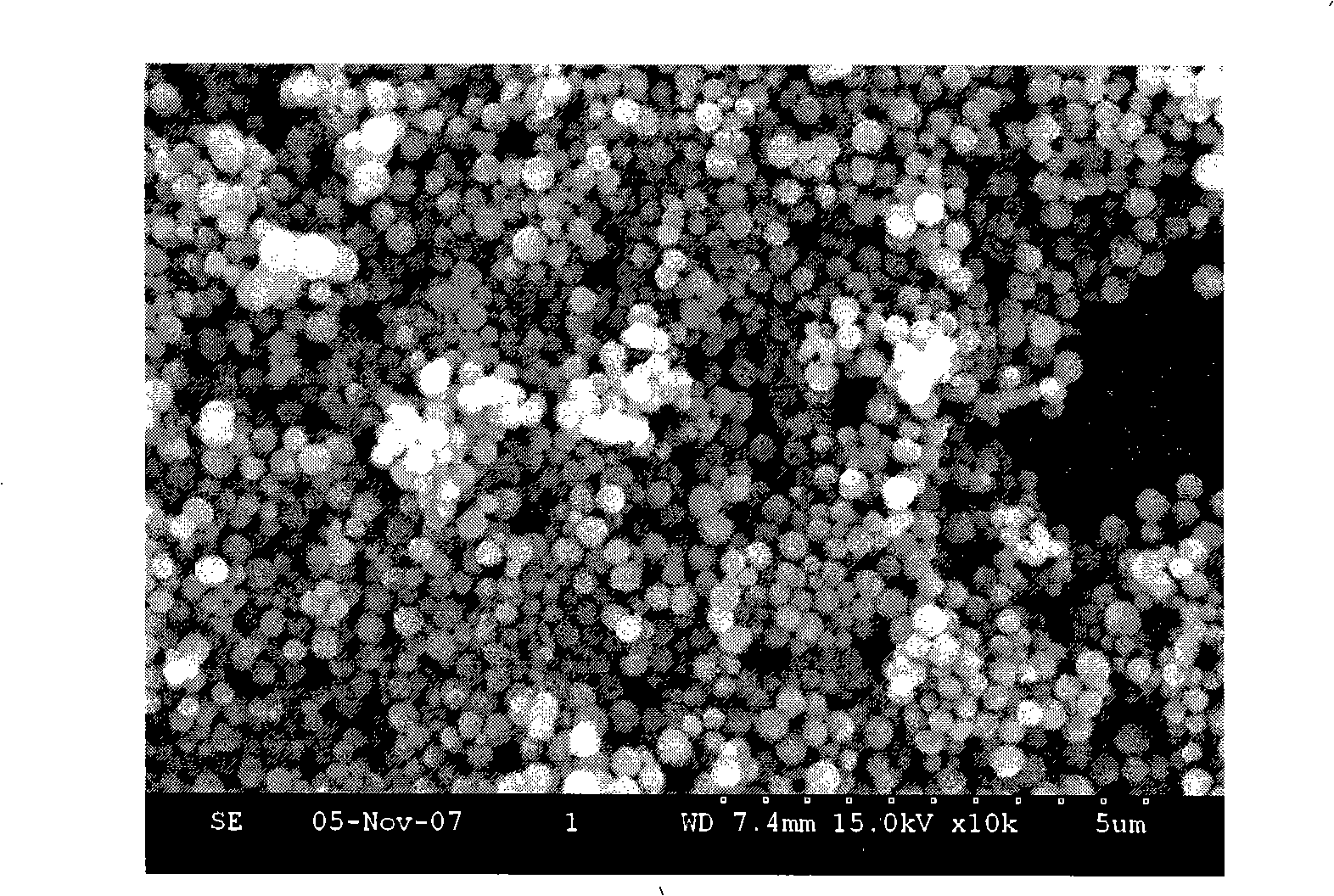

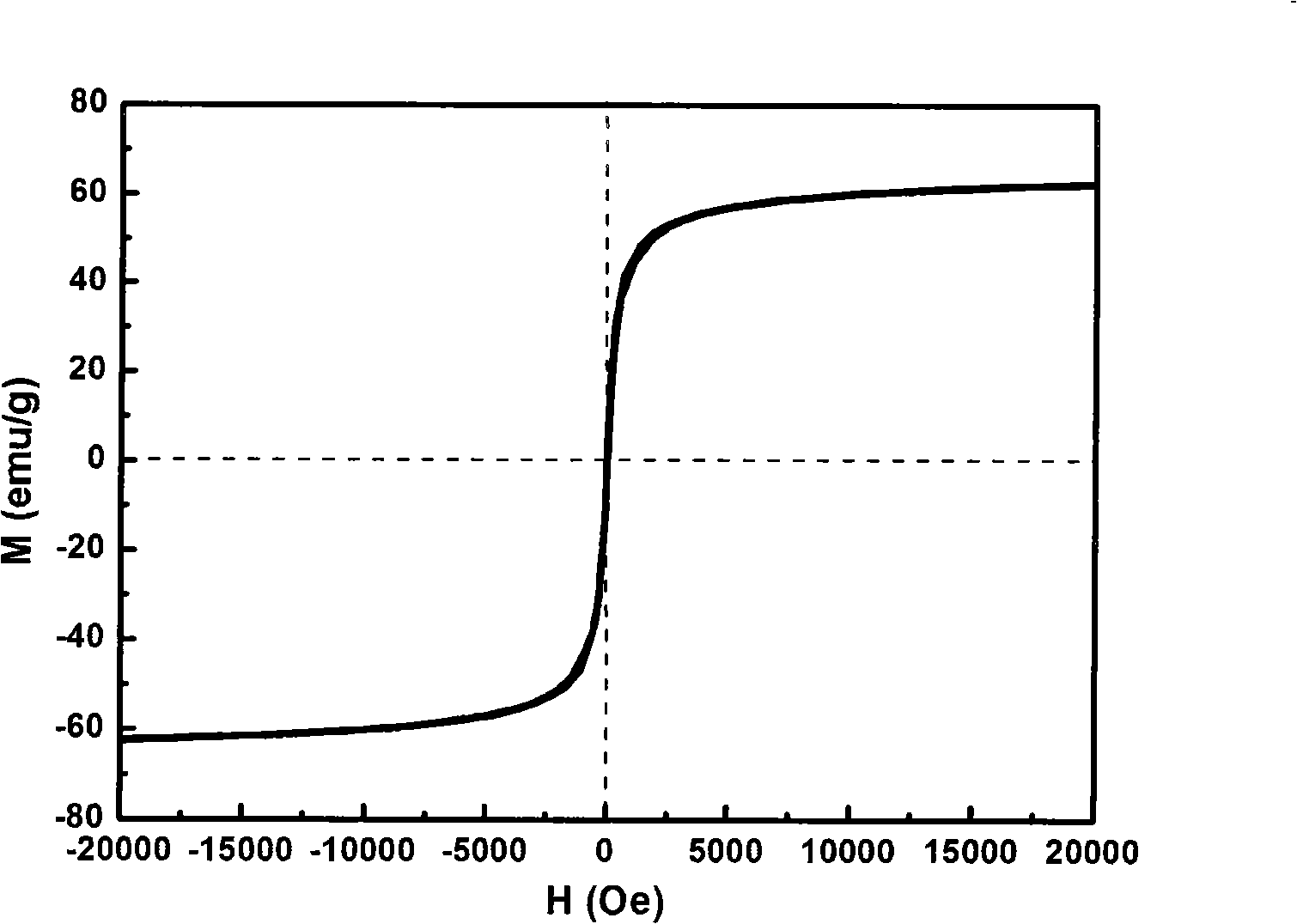

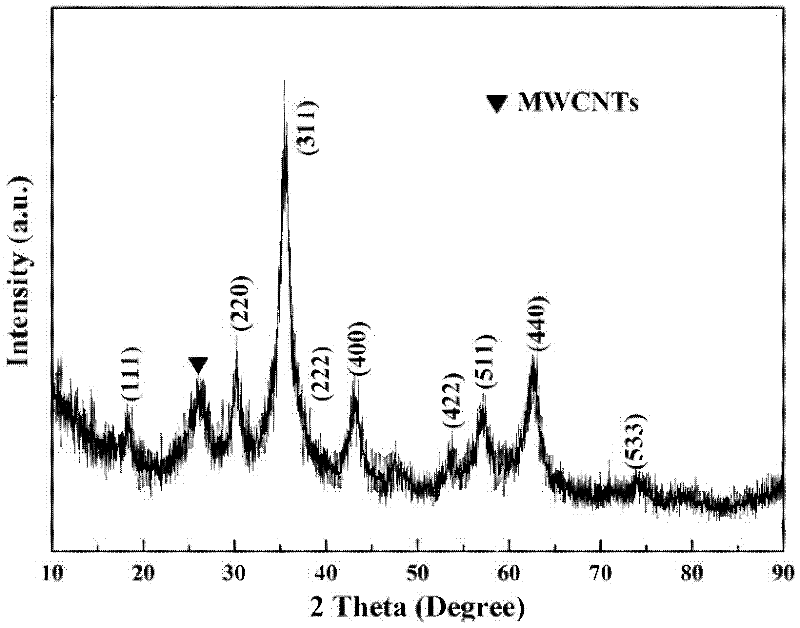

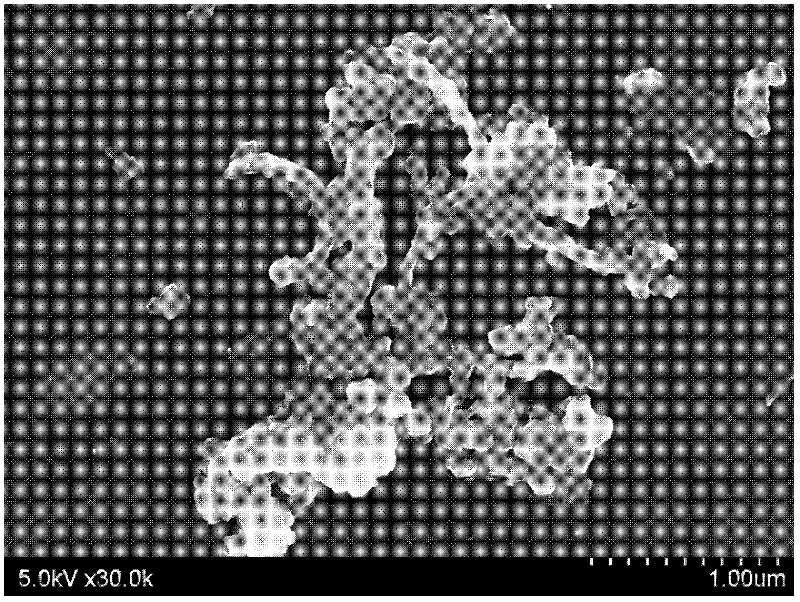

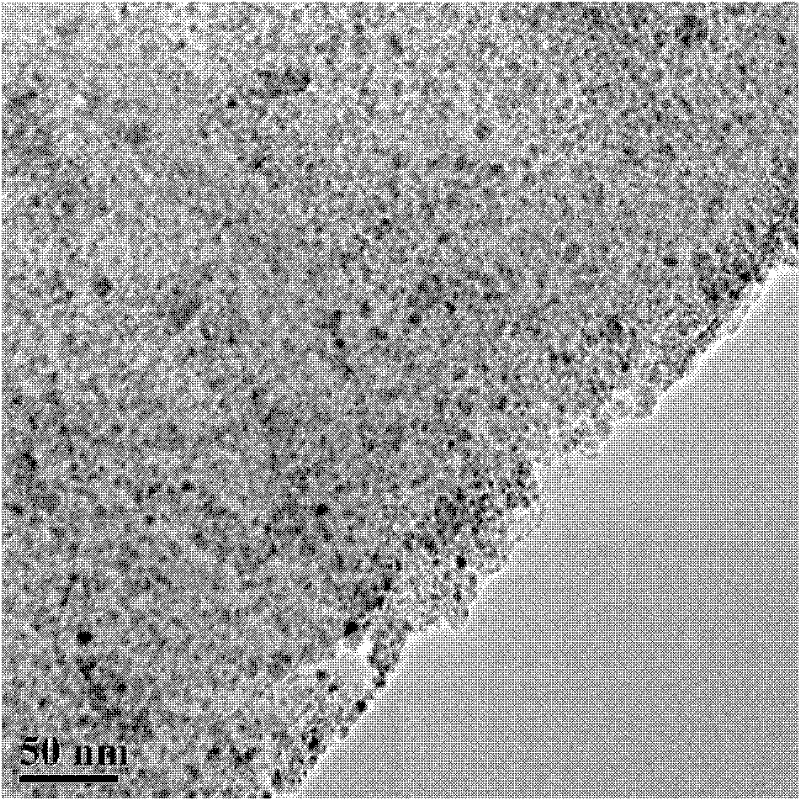

Preparation method of magnetic nano compound material of cobalt-nickel ferrite/multi-wall carbon nano pipe

InactiveCN102350282ASimple processLow requirements for production equipmentMicroballoon preparationMicrocapsule preparationNickel saltCarbon nanotube

The invention relates to a preparation method of a magnetic nano compound material of a cobalt-nickel ferrite / multi-wall carbon nano pipe, which comprises the following steps of: (1) carrying out acidifying treatment on the surface of cobalt-nickel ferrite by using acid with strong oxidizing property; and (2) dispersing a multi-wall carbon nano pipe after the acid treatment into a glycol water solution at room temperature, then adding iron salt, cobalt salt and nickel salt and adding polyethylene glycol and anhydrous sodium acetate after completely dissolving so as to form reaction liquid; and putting the reaction liquid into a reaction kettle, heating to react for 8 to 16h, then cooling to the room temperature, collecting a product by using a magnet, then washing and finally drying so as to obtain the magnetic nano compound material of the cobalt-nickel ferrite / multi-wall carbon nano pipe. The preparation method disclosed by the invention is simple and is easy for industrialized production; and the prepared Col-xNixFe2O4 / MWCNTs magnetic nano compound material has pure crystalline phase, good dispersivity, smaller crystal grains and high magnetization intensity.

Owner:DONGHUA UNIV

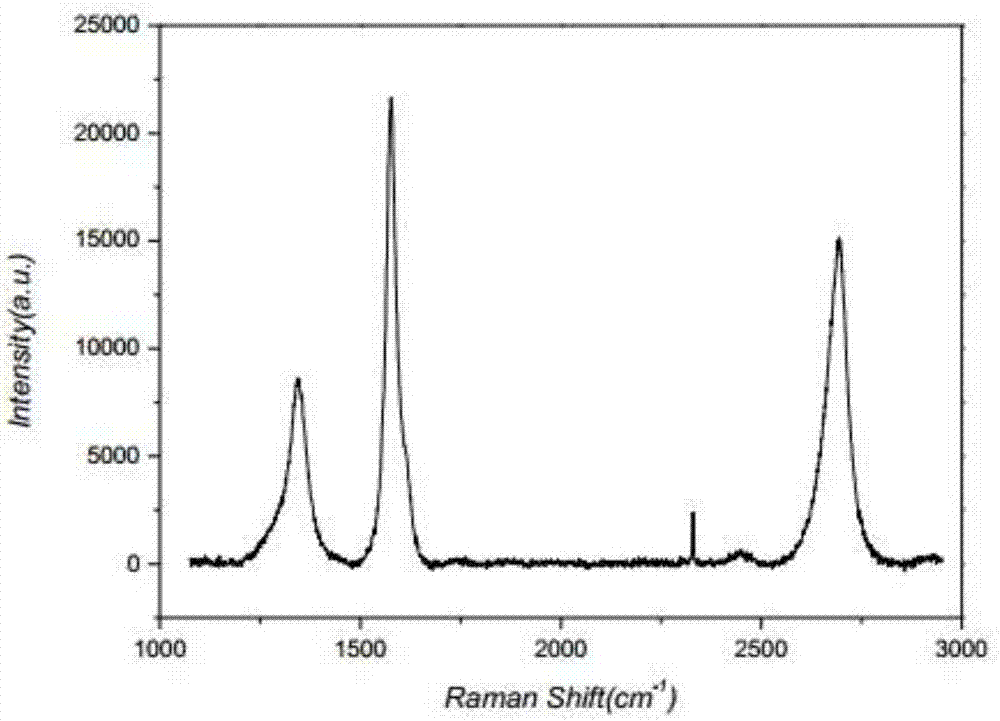

Method for preparing graphene on silicon base without metal catalyst

ActiveCN106868469AFew stepsSimple processVacuum evaporation coatingSputtering coatingHexagonal boron nitrideGas phase

The invention discloses a method for preparing graphene on a silicon base without a metal catalyst. According to the method, a method of radio frequency magnetron sputtering technology and chemical vapor deposition is adopted, a hexagonal boron nitride target serves as a magnetron sputtering target material, and the silicon base with a 300 nm silicon dioxide <100> crystal orientation serves as a sputtering substrate, by directly depositing a boron-nitrogen thin film on the silicon base to serve as a catalyst, the graphene grows on the silicon base, the step of sputtering deposition of the metal catalyst is omitted, and the effects of optimizing the process, saving resources and reducing cost are achieved. Meanwhile, by controlling parameters in the chemical vapor deposition process, the graphene obtained through preparation is good in consistency and has good thermal and chemical stability.

Owner:SHANDONG UNIV

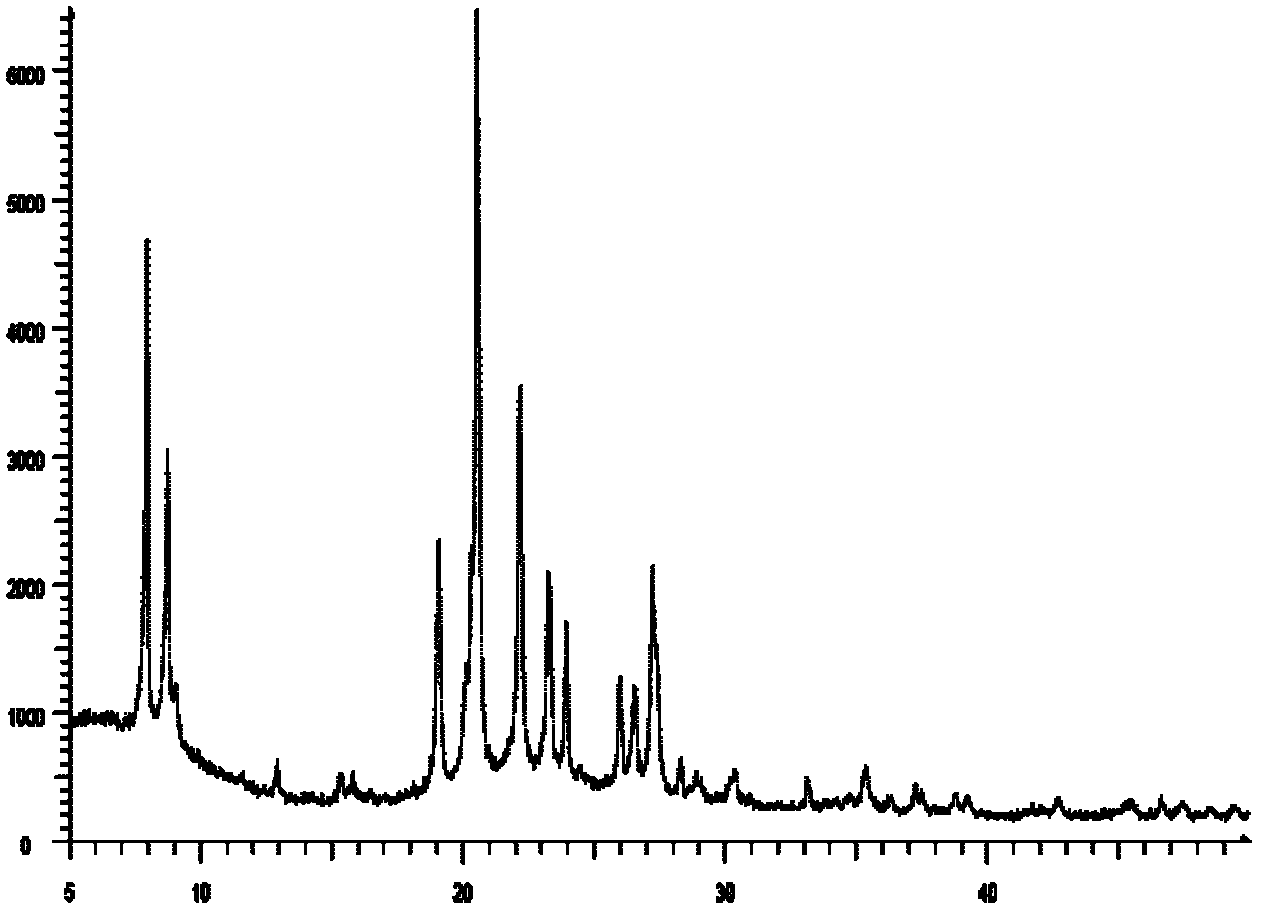

Preparation method of EUO structural nano silica-alumina molecular sieves

InactiveCN103121691ASimple processShort synthesis timeCrystalline aluminosilicate zeolitesMolecular sieveHydrogen

The invention relates to a preparation method of EUO structural nano silica-alumina molecular sieves, and mainly solves problems of large particle size, low yield, and impure crystalline phase of EUO structural sial zeolites prepared by existing technology. The preparation method includes evenly mixing an aluminum source, an silicon source, a template R, seed crystals and water to obtain an initial gel mixture with a molar ratio of (1 - 150) Na2O: (15 - 300) SiO2: Al2O3: (1 - 20) R: (200 - 3500) H2O; adjusting the hydrogen by inorganic acid or inorganic base, placing the mixture in a reactor to crystallize for 12 hours to 7 days on a condition of 140-200 DEG C temperature, and recycling solid productions to prepare so as to obtain pure phase EUO structural nano silica-alumina molecular sieves. According to the technical scheme, the preparation method solves the problems effectively and can be used in industrial production of the EUO structural nano silica-alumina molecular sieves.

Owner:CHINA PETROLEUM & CHEM CORP +1

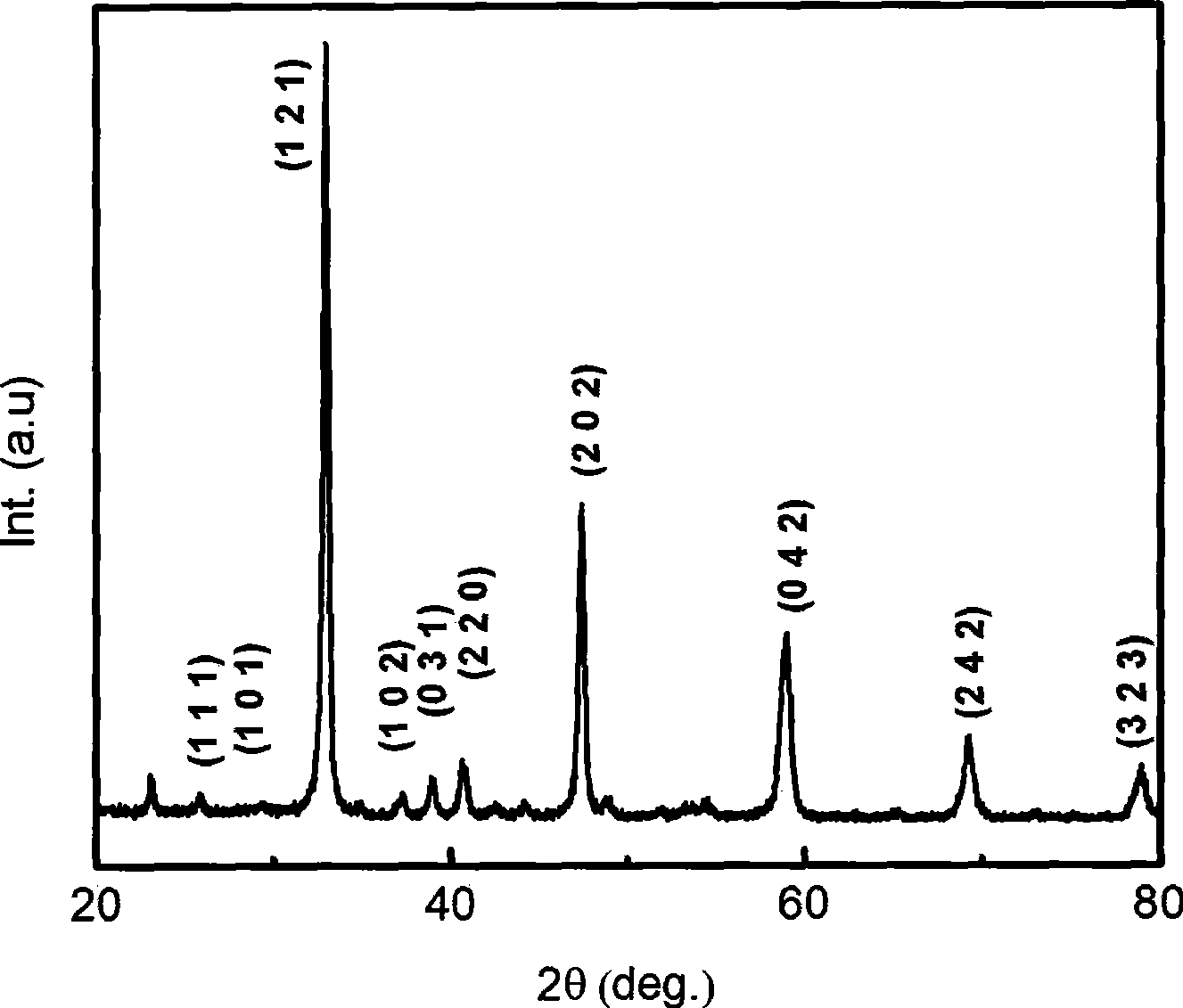

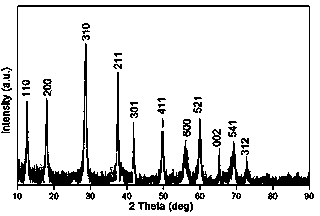

Method for preparing Co1-xNixFe2O4 magnetic nano-powder by solvothermal method

InactiveCN101891483AEasy to prepareLow requirements for production equipmentNickel saltMagnetization

The invention relates to a method for preparing Co1-xNixFe2O4 magnetic nano-powder by a solvothermal method. The method comprises the following steps of: (1) weighing soluble ferric salt, nickel salt and cobalt salt at room temperature, dispersing the soluble ferric salt, the nickel salt and the cobalt salt into solution of ethylene glycol monomethyl ether, adding anhydrous sodium acetate after the salts are fully dissolved and stirring the mixture to form reaction liquid; (2) putting the reaction liquid into a reaction kettle, raising the temperature to be between 180 and 220 DEG C and performing a reaction for 8 to 16 hours; and (3) cooling the reaction product to the room temperature, washing the product by using distilled water and absolute ethyl alcohol respectively and drying the washed product to obtain the Co1-xNixFe2O4 magnetic nano-powder. The preparation method of the invention is simple and easy for industrialized production. The prepared Co1-xNixFe2O4 magnetic nano-powderhas pure crystalline phase, small crystallite dimension and high magnetization intensity.

Owner:DONGHUA UNIV

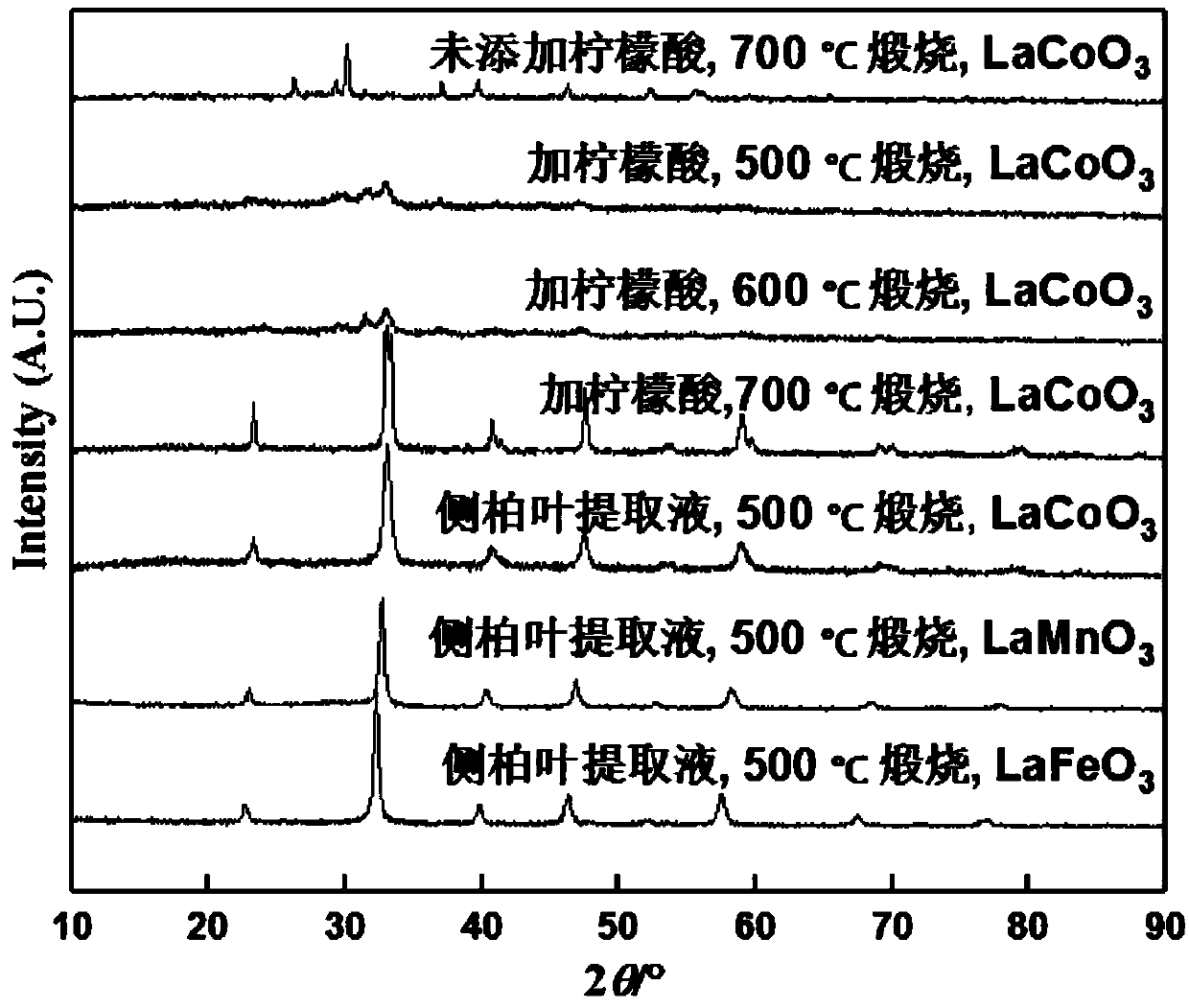

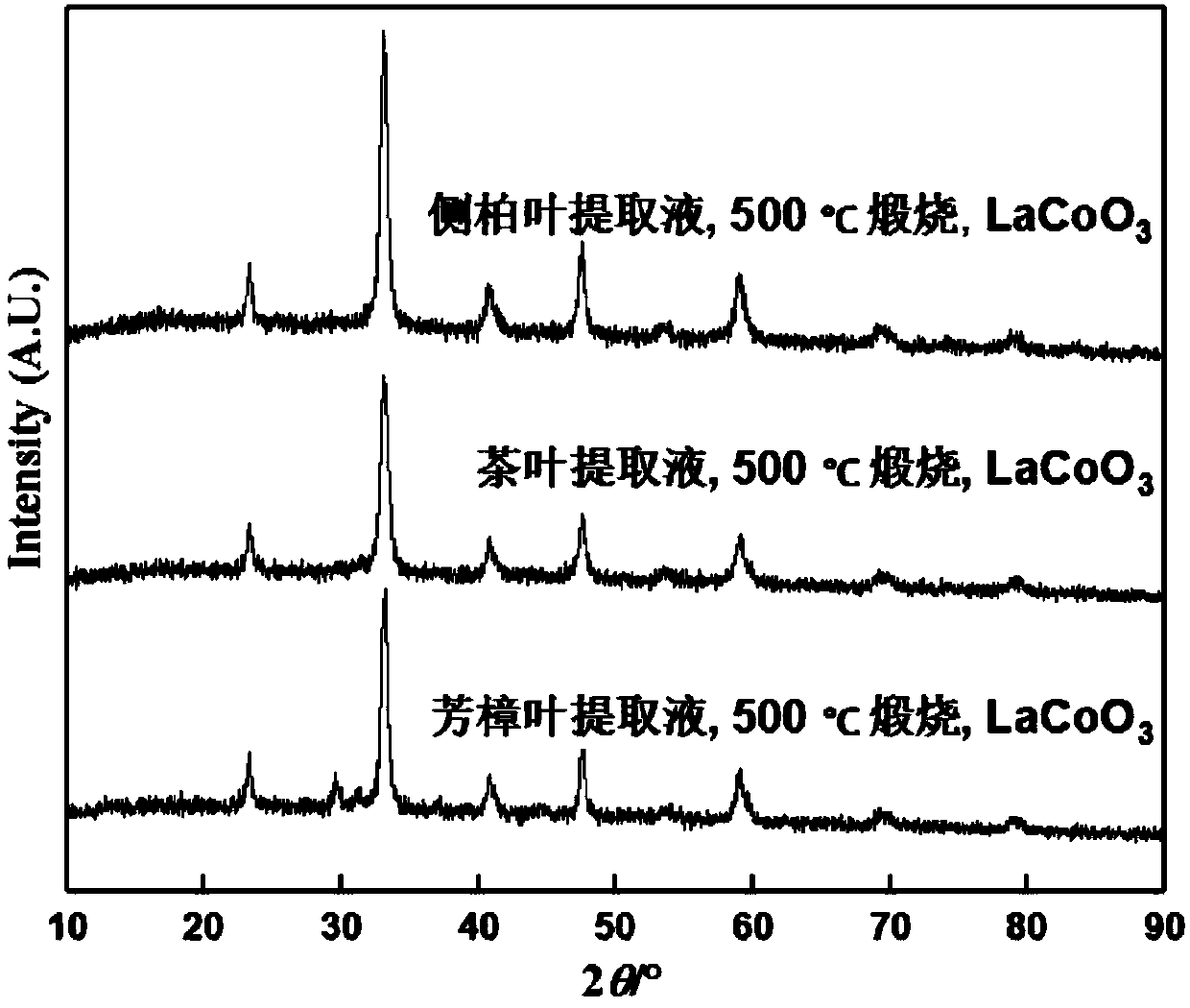

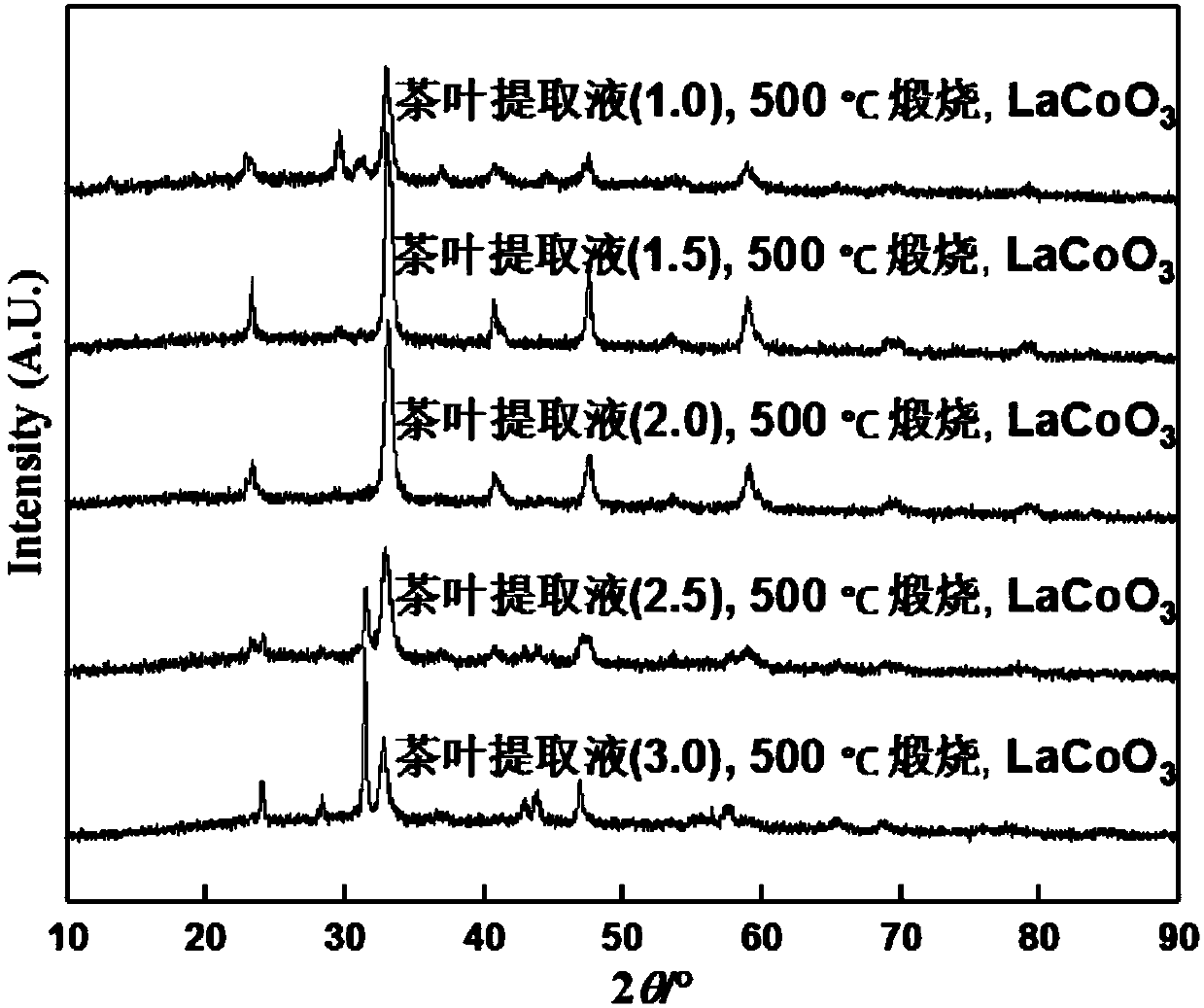

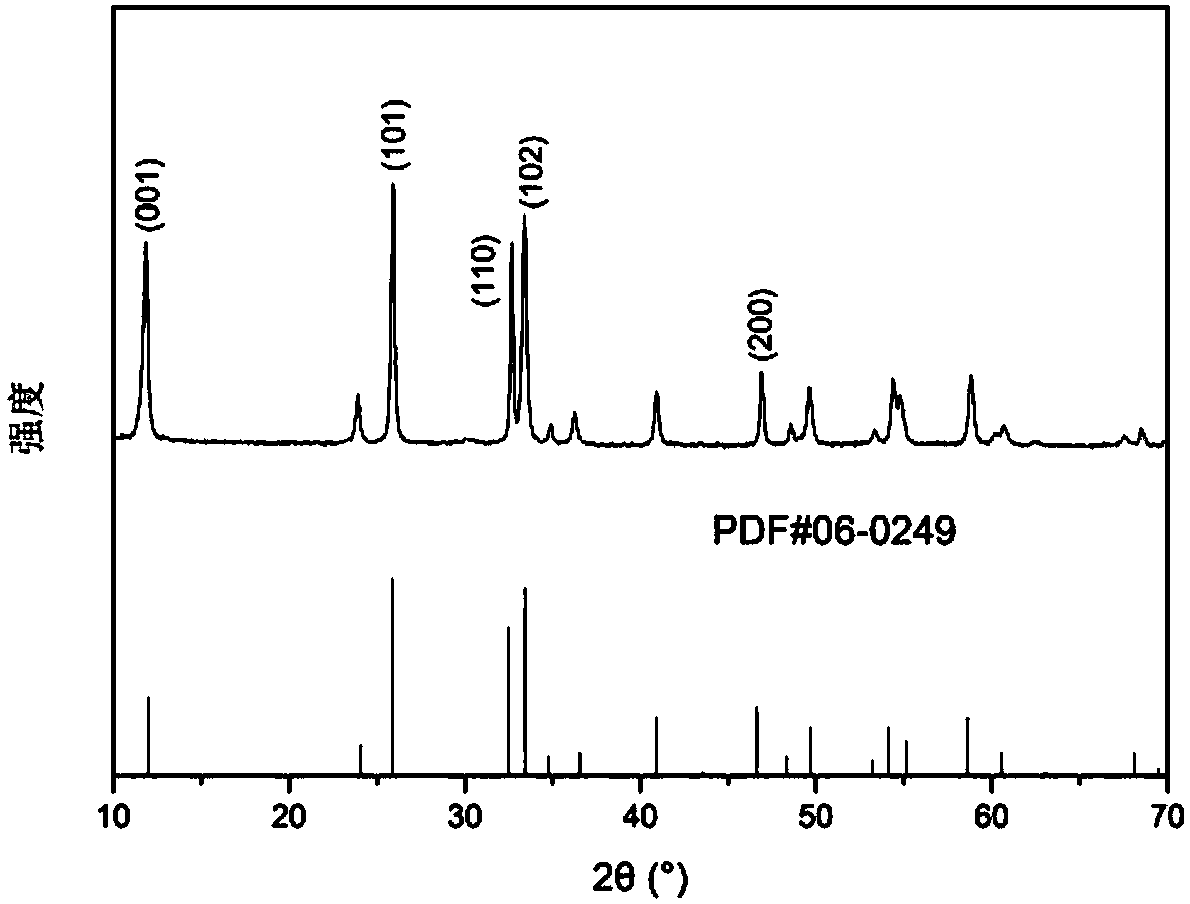

Green synthesis method of lanthanum-based perovskite

ActiveCN108046339AIncrease contentWide variety of sourcesIron compoundsCobalt compoundsSynthesis methodsCalcination

The invention discloses a green synthesis method of lanthanum-based perovskite. The method includes the steps that firstly, phyteral is extracted with water, and a phyteral extracting solution is prepared; lanthanum nitrate and metal salt are added into the phyteral extracting solution, after the materials are stirred and dissolved, the materials are dried, the materials are calcined at the low temperature, and the lanthanum-based perovskite is obtained. According to the synthesis method, the raw material content is rich, the raw materials are cheap and easy to obtain, regeneration is easy, the process is simple, operation is convenient, a pure-phase perovskite type oxide can be obtained at the low calcination temperature (500 DEG C), and industrial production of the perovskite type oxideis promoted.

Owner:XIAMEN UNIV

Preparation method and application of {010} high-energy facet exposed BiOCl nanosheet

InactiveCN108275721ACrystal phase pureSimple preparation processCell electrodesSecondary cellsChemical reactionHigh energy

The invention relates to a preparation method and application of a {010} high-energy facet exposed BiOCl nanosheet. The preparation method comprises the following steps of uniformly mixing a bismuth source, a chlorine source and an alkali source according to a certain ratio, applying the mechanical force of high-energy ball milling to chemical reaction, then performing heat treatment at 200-600 DEG C, and then performing impurity removal with washing, solid-liquid separation and drying to prepare BiOCl nanosheet. The prepared BiOCl material is formed by a nanosheet with the thickness being 5-50nm and the side length being 150-250nm, and the {010} facet exposure degree is 60-90 percent. The preparation method has the advantages of simpleness in preparation technology, easiness in realizingindustrial production, low cost of the preparation technology, environmental protection and the like. The prepared {010} high-energy facet exposed BiOCl nanosheet is widely applied to the fields of super capacitors, alkaline storage batteries, lithium ion batteries, photocatalysts, pearlescent pigments and medicines and the like.

Owner:XIANGTAN UNIV

(SrxCay)0.97TiO3:Eu3+0.03 fluorescent powder and preparing method thereof

InactiveCN105038785AGood chemical stabilitySmall grain sizeLuminescent compositionsChemical stabilityEuropium

The invention relates to (SrxCay)0.97TiO3:Eu3+0.03 fluorescent powder and a preparing method thereof. The preparing method comprises the steps that oxalate dehydrate is dissolved in ethyl alcohol to obtain a solution A; ammonium oxalate is dissolved in water to obtain a solution B; tetrabutyl titanate is dissolved in ethyl alcohol to obtain a solution C; strontium nitrate, calcium nitrate and europium nitrate are dissolved in deionized water to obtain a settled solution D; the solution A and the solution B are added to the solution C in sequence to be stirred to obtain a solution E, then the solution D is added to the solution E dropwise to be stirred for reaction for 1-2 h, sediment is obtained, and then washing, drying and roasting are conducted to obtain the fluorescent powder. The obtained fluorescent powder is high in chemical stability, small in grain size, pure in crystalline phase, and high in stability and light intensity. Roasting temperature is low, energy consumption is low, and production equipment is simple.

Owner:DONGHUA UNIV

Collosol-coating preparation method of lithium iron phosphate being the positive electrode material of lithium ion battery

InactiveCN101577326AAvoid prone to uneven mixing problemsAvoid separationElectrode manufacturing processesPhosphorus compoundsSodium-ion batteryVolumetric Mass Density

The invention relates to a collosol-coating preparation method of lithium iron phosphate being the positive electrode material of a lithium ion battery, pertaining to the technical field of lithium ion battery. The technique of the invention comprises the following steps of: 1. preparing starch suspension: starch is dispersed in distilled water and then a ferric source, a lithium source compound and a phosphorus source compound are mixed into the starch suspension; 2. compound dispersion: firstly, shear liquid-phase dispersion is conducted and colloid grinding is then conducted; 3. hydrolysis: after dispersion, the suspension is put into a reaction kettle at a temperature slowly increasing to 85-100 DEG C and constant temperature is kept for 1-5h; 4. drying: a gelatinous solution is added into a casting machine and a base body is coated with a pulp layer with the thickness of 1-5mm by a drawing knife and the pulp layer is dried at the temperature of 80-110 DEG C to form compact dried gel; and 5. heat treatment: the dried gel is arranged in a gas sintering furnace and heat treatment is conducted at high temperature of 600-800 DEG C under the protection of inert gas to obtain a product. The preparation method has the advantages of high tap density of lithium iron phosphate, high discharge capacity, simple technique, stable product performance, high yield, applicability to industrialization and the like.

Owner:HEBEI LITAO BATTERY MATERIAL

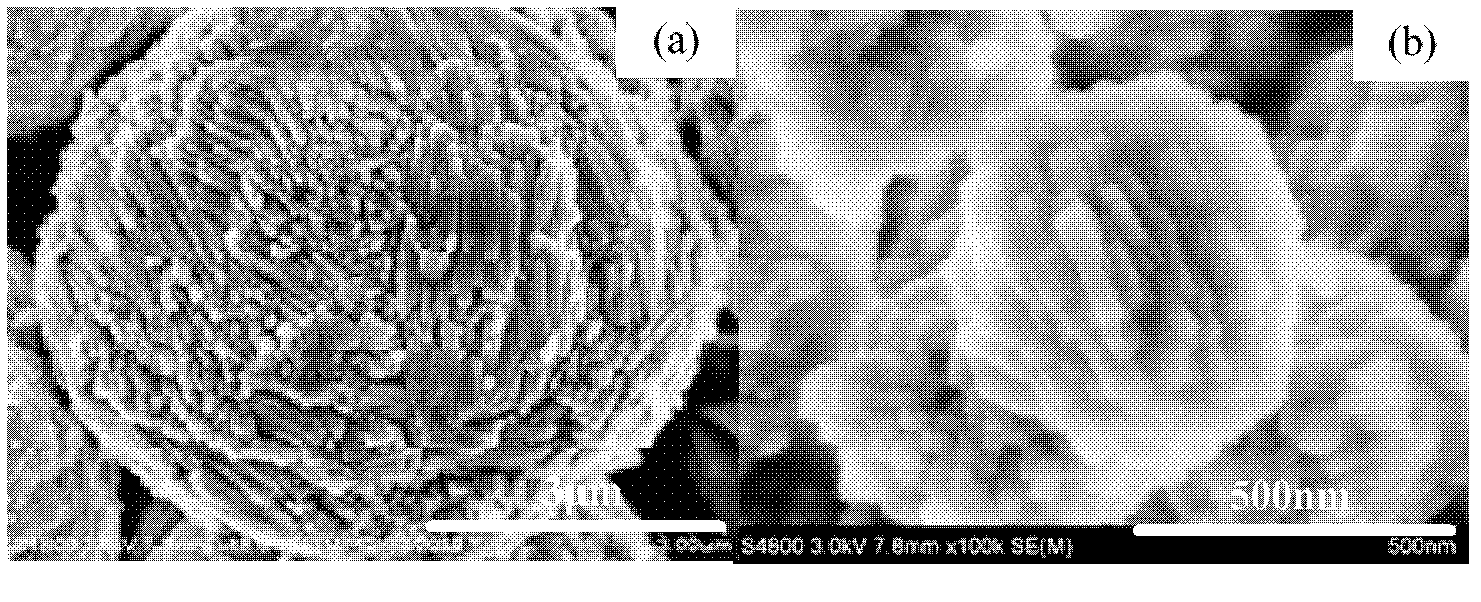

Self-assembled nano film MnO2 adsorption agent capable of high-efficiently adsorbing heavy metals and preparation method of adsorption agent

InactiveCN103920449AGuarantee structureEasy to operateOther chemical processesWater/sewage treatment by sorptionSorbentEnergy consumption

The invention relates to a self-assembled nano film MnO2 adsorption agent capable of high-efficiently adsorbing heavy metals and a preparation method of the adsorption agent, and belongs to the field of metal environmental protection. The adsorption agent has a nano film grading layered structure, in the size of 700 nanometers, which is formed by self-assembling sheets in the thickness of 2 to 3 nanometers. The preparation method comprises the following steps of dissolving KMnO4, NH4H2PO4 and Na2SO4.10H2O into deinoized water and mixing, reacting at a constant temperature in a reaction kettle, washing precipitates, drying the precipitates and the like. Raw materials of the absorption agent are cheap and easily available, the reaction condition is simple, the energy consumption is low, the adsorption agent has a good effect for removing heavy metal ions in an acid medium, and the application prospect is wide.

Owner:YUNNAN UNIV

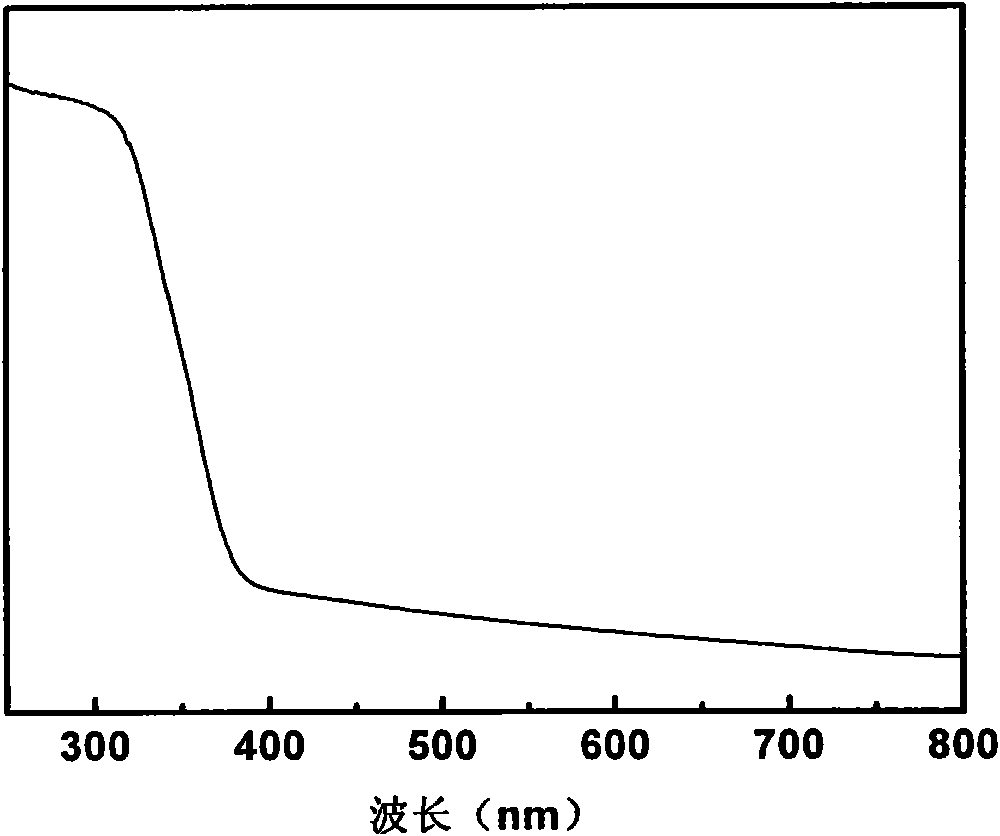

Preparation of fluorine and carbon co-doped nano-titanium dioxide visible light photocatalyst

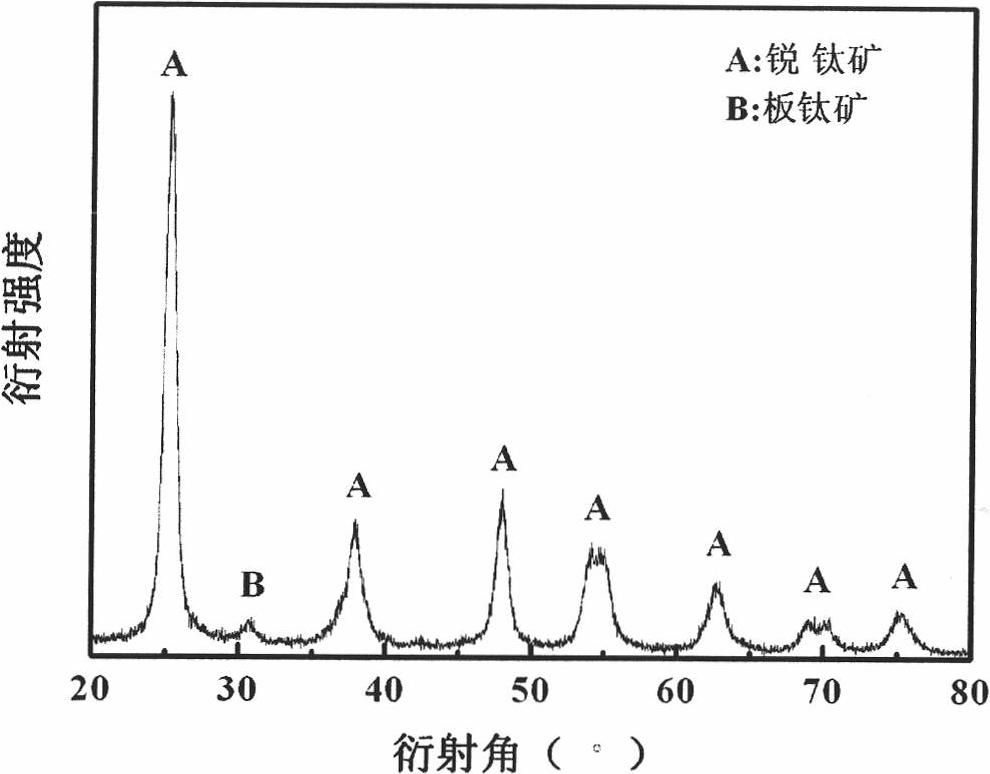

InactiveCN101862664AConvenient sourceMild reaction conditionsPhysical/chemical process catalystsEthylenediamineLight response

The invention relates to a preparation method of a fluorine and carbon co-doped nano-titanium dioxide visible light photocatalyst, comprising the following steps of: dropping an anhydrous alcohol solution of tetrabutyl titanate into an ammonium fluoride water solution and ethylene diamine by mixing; hydrolyzing by mixing at room temperature, wherein a mol ratio of fluorine to titanium is 0.05:1-0.2:1, and a mol ratio of the ethylene diamine to the tetrabutyl titanate is 0.16:1-0.48:1; obtaining collosol; obtaining flaxen gel by drying the collosol; and obtaining the fluorine and carbon co-doped nano-titanium dioxide photocatalyst by calcining the gel. In the preparation method, the reaction condition is mild and is easy to control, devices are simple, raw materials are easy to purchase, and a synthetic process is simple and is easy to industrially produce; the prepared fluorine and carbon co-doped nano-titanium dioxide photocatalyst has high specific surface, pure crystalling phase, more surface acid sites and visible light response.

Owner:DONGHUA UNIV

Spherical iron phosphate and preparation method and application thereof

ActiveCN107986253AWeakened molecular forcesReduce the propensity to reuniteCell electrodesSecondary cellsPhosphate ionPhosphoric acid

The invention discloses spherical iron phosphate and a preparation method and application thereof. The preparation method comprises the following steps: adding a disperser into iron-phosphorus mixed liquor containing iron ion and phosphate anion, thus obtaining mixed liquor A; under a heating condition, adding urea into the mixed liquor A to regulate a pH value, and continuously heating to obtainmixed liquor B containing crystal-form iron phosphate; filtering the mixed liquor B, adding a filter cake into water to prepare mixed liquor C, atomizing the mixed liquor C by a spray gun, leading into a roasting furnace, and roasting at a temperature of 550 to 750 DEG C to obtain the spherical iron phosphate. The spherical iron phosphate is pure in crystalline phase, good in crystallinity, spherical in shape, uniform in grain fineness distribution and high in tap density, and can serve as a precursor for synthesizing spherical lithium iron phosphate with high tap density; the spherical iron phosphate can eliminate microscopic composition difference caused by different diffusion paths in a reaction, so as to generate the lithium iron phosphate with a uniform structure, and thus the performance of the lithium iron phosphate is improved.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

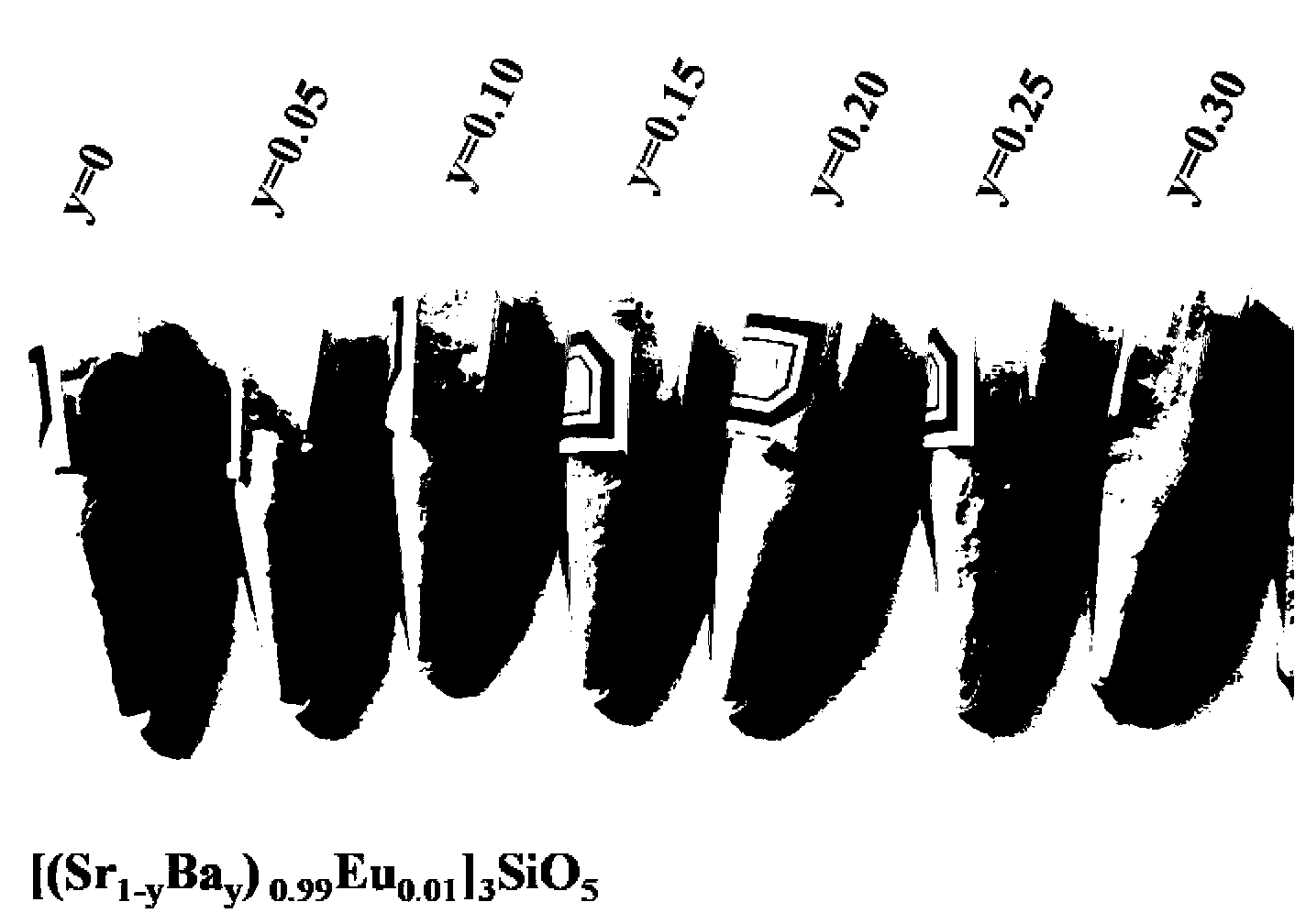

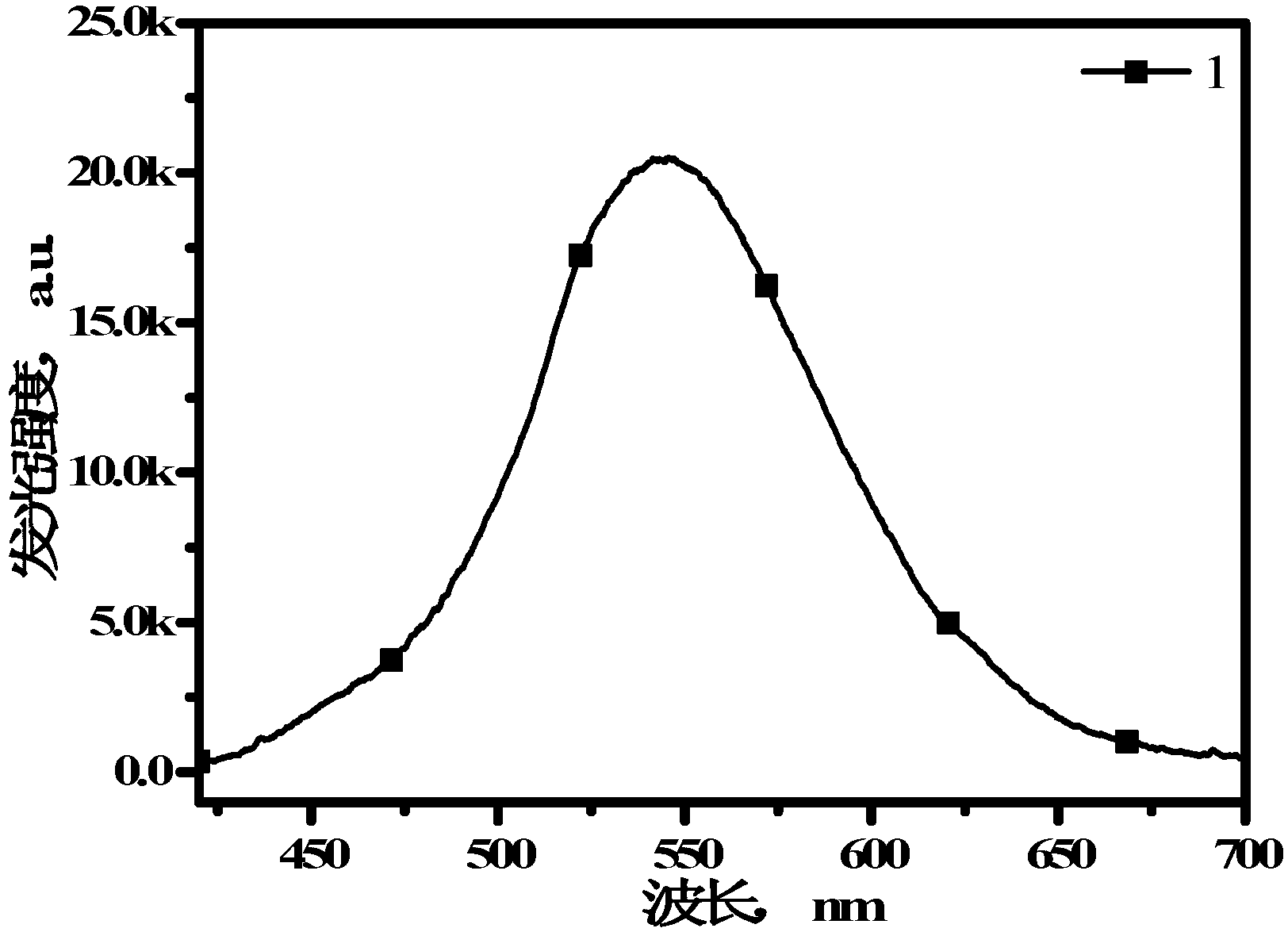

Silicate-based fluorescent material and synthetic method thereof

ActiveCN103013502ALow costImprove luminous efficiencyLuminescent compositionsColor rendering indexPeak value

The invention discloses a silicate-based fluorescent material and a synthetic method thereof. The chemical formula of the silicate-based fluorescent material is (Ae1-xEux)3SiO5, wherein Ae is one or more of Sr<2+>, Ba<2+>, Ca<2+>, Zn<2+>, Sm<2+>, Nd<2+> and Tm<2+>; and x is equal to 0.5-5%. The silicate-based fluorescent material is prepared by adopting a solid phase reaction method. The chemical stability of the silicate-based fluorescent material Ae3SiO5:Eu<2+> is good, the peak value of the emission spectrum can be red-shifted to 600nm, the red spectral component produced when a blue light chip is matched with a yellow fluorescent powder for packaging a white-light LED (Light-Emitting Diode) can be effectively made up for, and the color rendering index can be improved.

Owner:HEFEI UNIV OF TECH

Method for preparing nickel-doped zinc oxide (NixZn1-xO) magnetic microspheres by alcohol-thermal method

InactiveCN101767812AEasy to prepareLow costZinc oxides/hydroxidesInorganic material magnetismNickel saltMicrosphere

The invention relates to a method for preparing nickel-doped zinc oxide (NixZn1-xO) magnetic microspheres by an alcohol-thermal method, which comprises the following steps of: (1) at room temperature, dissolving soluble zinc salt and nickel salt into glycol for mechanical stirring, and adding anhydrous sodium acetate and polyglycol for ultrasonic dispersion; (2) putting the mixture into a reaction kettle for reacting at the temperature of 180 DEG C-220 DEG C, and naturally cooling the reaction products to room temperature; and (3) centrifugally separating, washing and drying the products to obtain the NixZn1-xO magnetic microspheres. The invention has simple method and low cost and is suitable for industrial production. The prepared NixZn1-xO magnetic microspheres have pure crystalline phase, uniform sizes, good dispersibility and excellent ferromagnetism at room temperature, and can not be aggregated easily.

Owner:DONGHUA UNIV

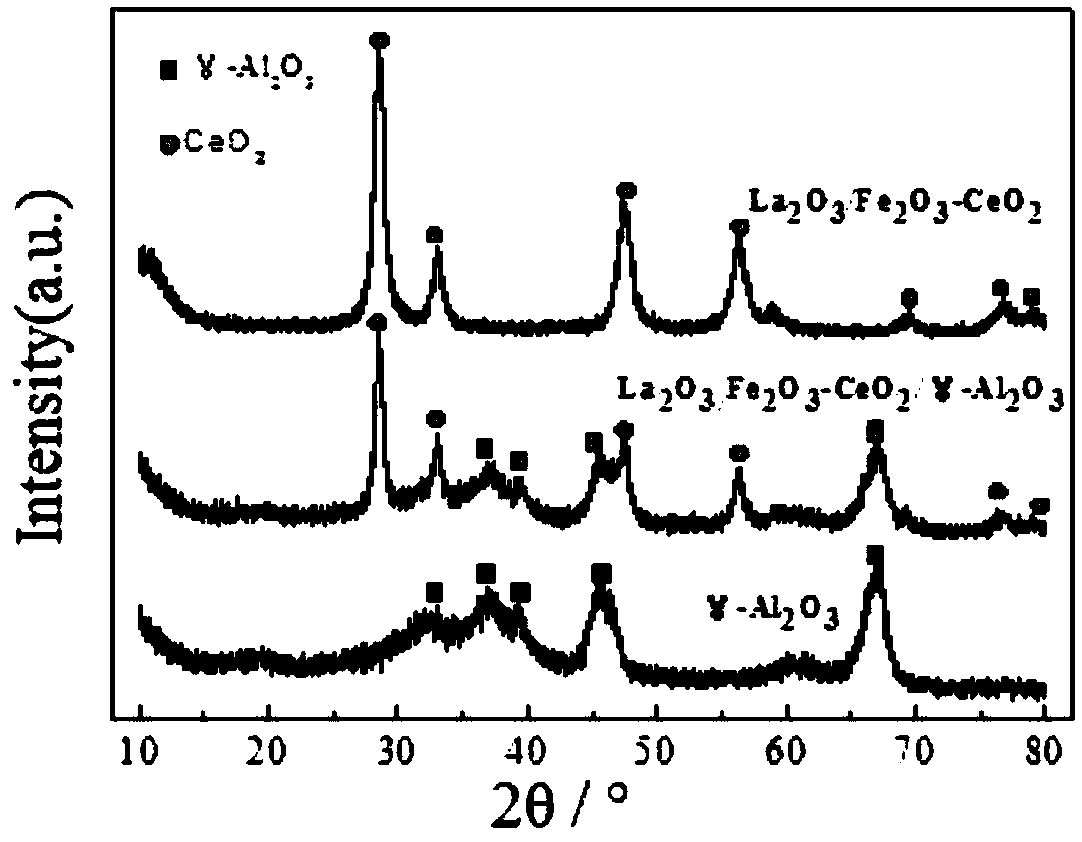

Cerium dioxide-based composite catalyst, and preparation method and application thereof

ActiveCN108906067AEvenly dispersedUniform sizeWater/sewage treatment by irradiationWater treatment compoundsCerium nitrateCerium(IV) oxide

The invention discloses a cerium dioxide-based composite catalyst, and a preparation method and application thereof. According to the catalyst provided by the invention, gamma-Al2O3 is used as a carrier, and an active component of the catalyst is composed of La2O3, Fe2O3 and CeO2, wherein the mass ratio of the active component to the carrier is 0.01-0.2, and the molar ratio of the sum of the La2O3and Fe2O3 to the CeO2 is 0.01-0.1. According to the invention, cerium nitrate, lanthanum nitrate, ferric nitrate and ammonium bicarbonate are taken as raw materials, and the catalyst active componentLa2O3 / Fe2O3-CeO2 is prepared by using a co-precipitation method. Due to the doping of lanthanum and iron, cerium dioxide lattices are distorted and generate defects, so that the oxidation-reduction capability of cerium dioxide is enhanced, and therefore a good photocatalytic performance is achieved. A nano sheet-shaped gamma-Al2O3 carrier is taken to support the active component by adopting an impregnation method, so that the cerium dioxide-based composite catalyst is obtained. The catalyst disclosed by the invention has high catalytic degradation activity on printing and dyeing wastewater. The preparation method is simple, the cost is low, and industrial production is easy to realize.

Owner:ZUNYI NORMAL COLLEGE

Preparation method of water-dispersible graphene/ferroferric oxide (Fe3O4) composite powder

InactiveCN102173411BEasy to prepareLow requirements for production equipmentFerroso-ferric oxidesWater dispersibleOleic Acid Triglyceride

The invention relates to a preparation method of water-dispersible graphene / ferroferric oxide (Fe3O4) composite powder. The method comprises the following steps of: (1) ultrasonically dispersing graphite oxide and sodium polystyrene sulfonate into water at room temperature to form reaction liquid, raising a temperature to 90 to 110 DEG C, and reacting for 8 to 16 hours; (2) adding ferric salt andferrous salt into the reaction liquid under the protection of nitrogen atmosphere at room temperature, adding ammonia water, reducing the temperature to 70 to 90 DEG C, reacting for 20 to 40 minutes,and then adding an oleic acid for continuous reaction; and (3) cooling to room temperature, collecting the graphene / Fe3O4 composite powder by using a magnet, washing and drying to obtain the finishedproduct. The method is simple and easy for industrial production; Fe3O4 in the prepared composite powder has pure crystalline phase; the Fe3O4 is well combined with the graphene; the Fe3O4 has good dispersibility on a surface of the graphene and in a layer of the graphene; the composite powder is low in resistivity, high in magnetic intensity and good in underwater dispersibility and has a good application prospect.

Owner:DONGHUA UNIV

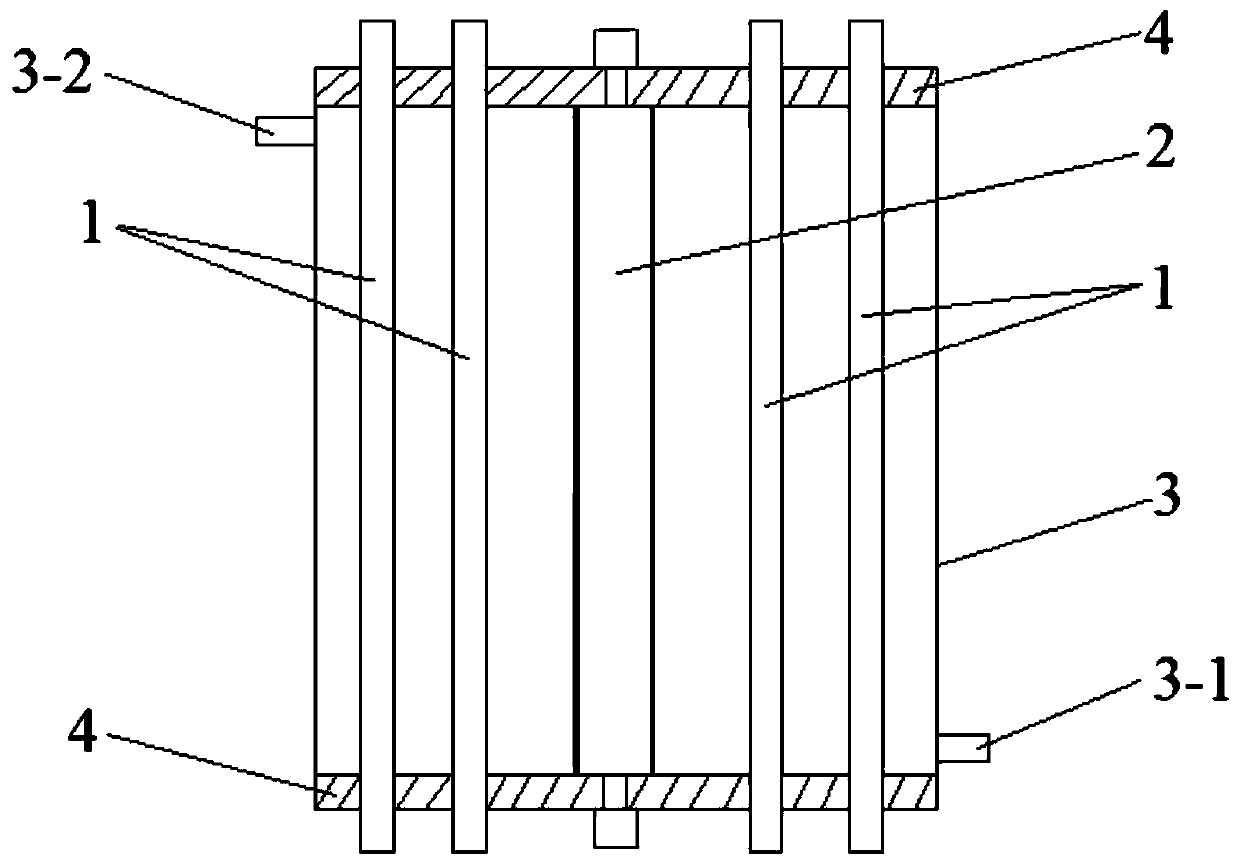

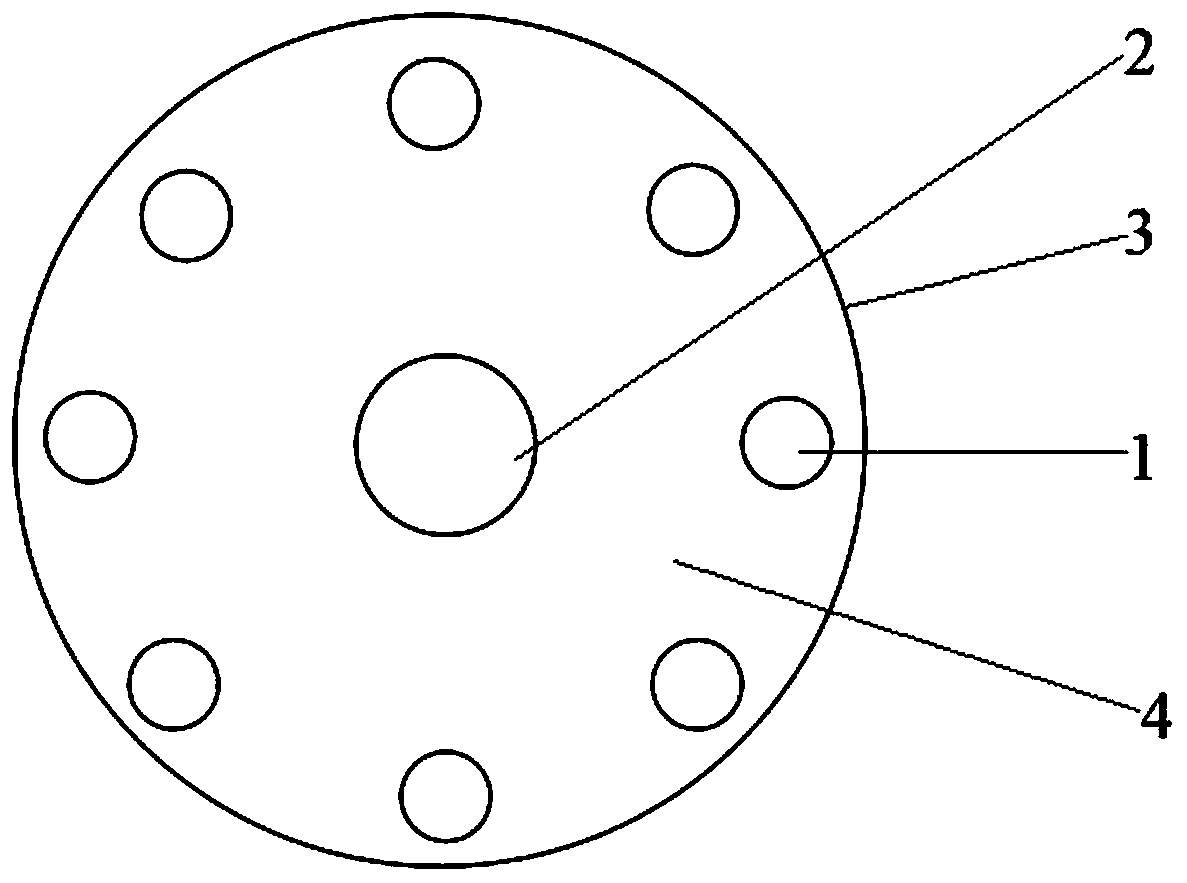

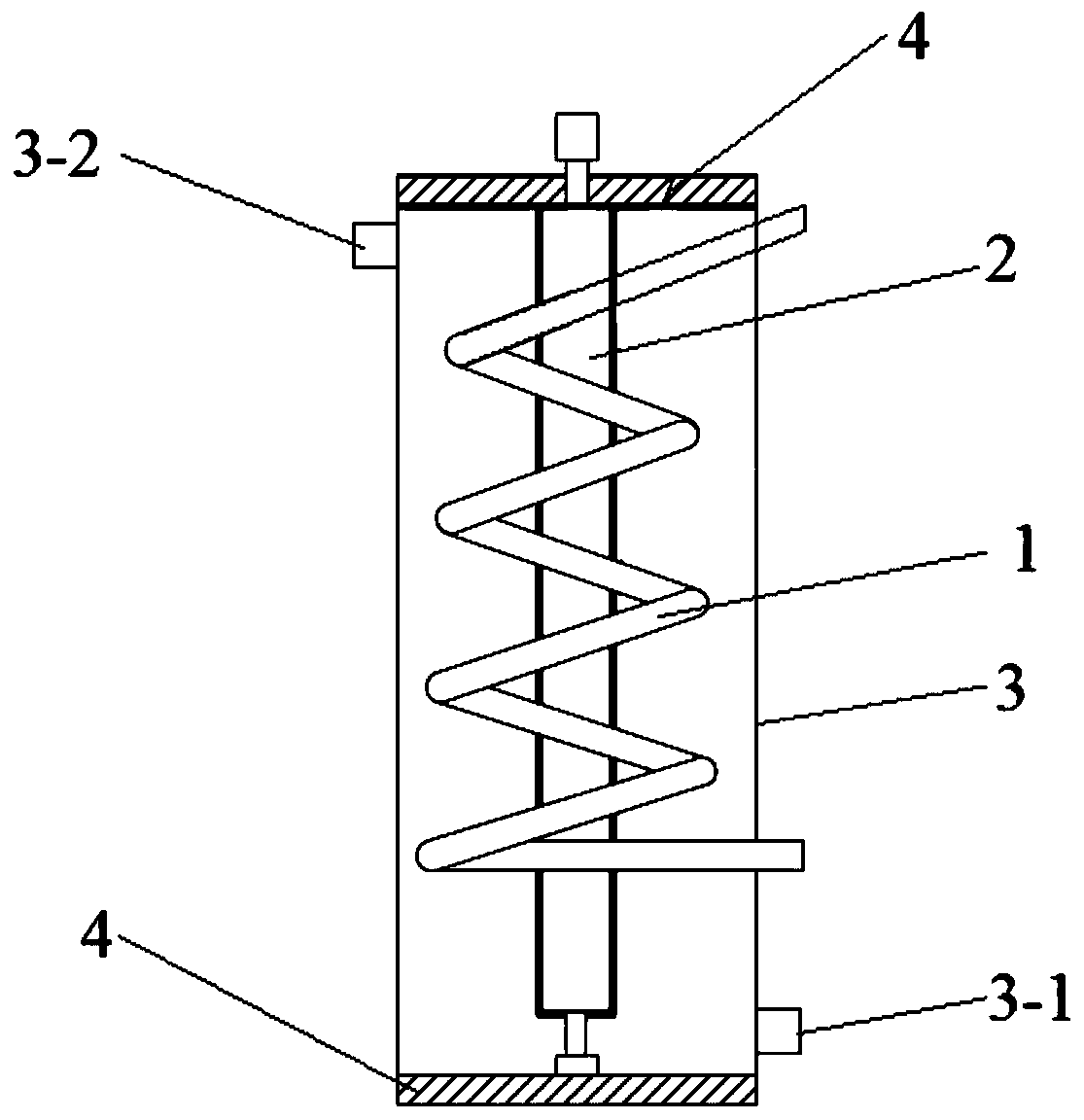

Method and device for rapidly and continuously preparing zeolite molecular sieve from solid waste through ultraviolet irradiation

ActiveCN111268690AReduce manufacturing costReduce pollutionOther chemical processesWater contaminantsMolecular sievePhoto irradiation

The invention provides a method and a device for quickly and continuously preparing a zeolite molecular sieve by using solid waste through ultraviolet irradiation. The method comprises the following steps: (1) mixing raw material powder prepared from at least one of lithium silicon powder, silicon aluminum gangue tailings and red mud with acid liquor, carrying out a stirring reaction, and washingand drying the obtained solid phase; (2) mixing the obtained pretreated raw material with an alkaline substance, roasting the mixture in a nitrogen atmosphere, then crushing and sieving the roasted material and mixing it with a solvent; and (3) continuously introducing the obtained molecular sieve precursor into a channel made of a quartz glass material, enabling the molecular sieve precursor to flow in the channel at a constant speed, applying ultraviolet irradiation covering the whole channel to the channel, collecting a reaction product at the outlet end of the channel, performing solid-liquid separation, and washing and drying the obtained solid product to obtain the zeolite molecular sieve. Resource utilization of solid waste is achieved, the production cost is reduced, the productionperiod is shortened, and meanwhile the quality of the zeolite molecular sieve is improved.

Owner:SICHUAN UNIV

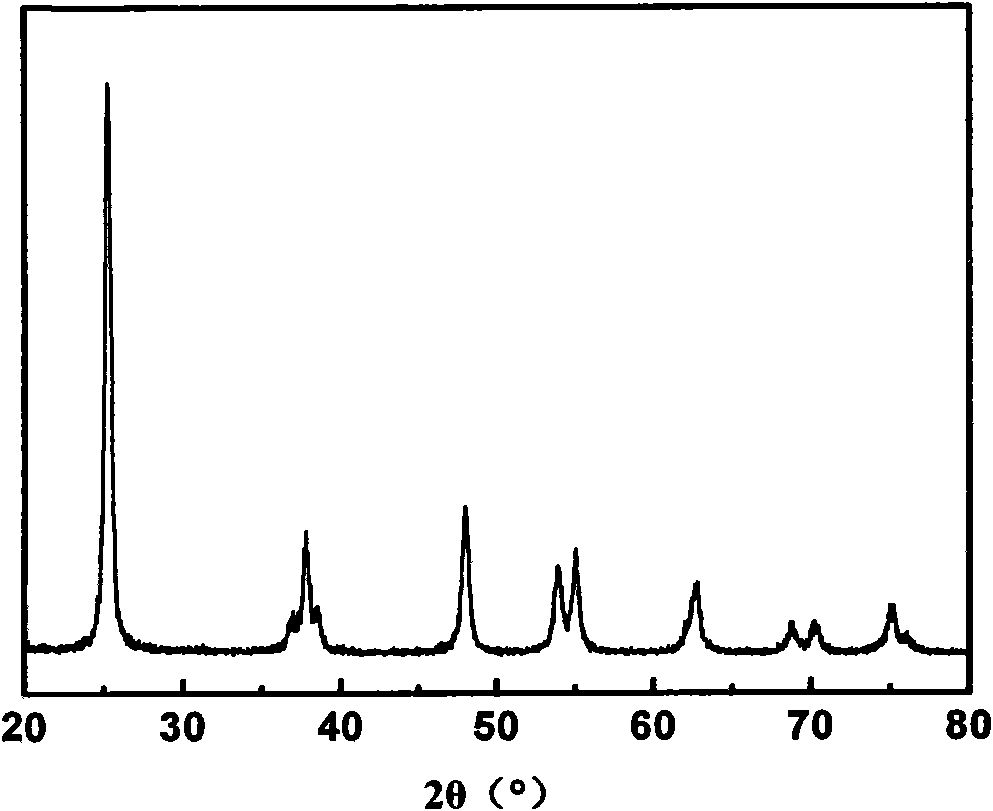

ZSM-11 molecular sieve with hierarchical porous structure and preparation method thereof

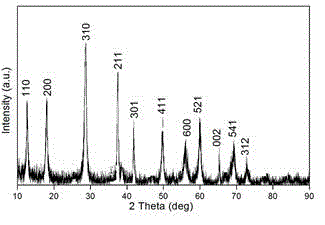

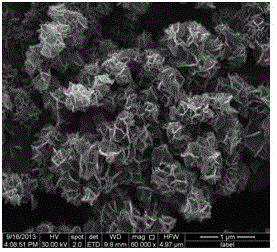

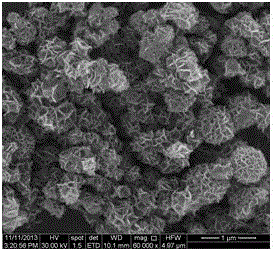

InactiveCN102557071BImprove performanceCrystal phase purePentasil aluminosilicate zeoliteHeat stabilityX-ray

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of fluorine and lanthanum co-doped nano titanic oxide visible light photocatalyst

InactiveCN101474556BConvenient sourceMild reaction conditionsMetal/metal-oxides/metal-hydroxide catalystsPure crystalLight response

The invention relates to a preparation method for fluorine and lanthanum codoped nanometer TiO2 visible-light photocatalyst, in which titanium alkoxide, lanthanum nitrate and fluoride are used as the raw materials. First, the fluoride is dissolved in the water, and then the titanium alkoxide and the lanthanum nitrate absolute ethyl alcohol solutions are dipped into the fluoride water solution while stirring, and finally the monodisperse TiO2 sol is obtained after stirring at room temperature for a certain period of time for hydrolyzation. Then the TiO2 sol is dried to obtain light-yellow gel which can produce the nanometer TiO2 photocatalyst while calcined at different temperatures. The method has mild and easily-controlled reaction conditions, simple equipment, easily purchased raw materials, simple synthesized process and easy industrial production. And the prepared fluorine and lanthanum codoped nanometer TiO2 photocatalyst has the properties of high specific surface, pure crystal phase, multiple surface acidity points and visible light response.

Owner:DONGHUA UNIV

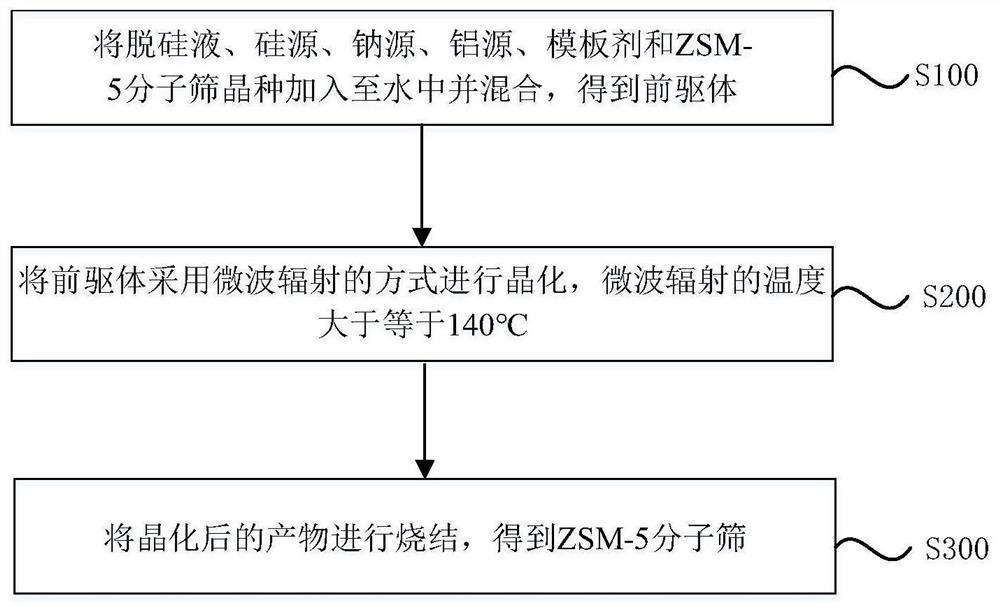

ZSM-5 molecular sieve and preparation method and application thereof

PendingCN113830788AReduce dosageImprove performanceOther chemical processesPentasil aluminosilicate zeoliteMolecular sieveCrystallinity

The invention provides a ZSM-5 molecular sieve and a preparation method and application thereof. The preparation method comprises the steps: 1, adding desilicication liquid, an aluminum source, a template agent and ZSM-5 molecular sieve seed crystal into water and mixing to obtain a precursor, wherein the precursor comprises SiO2, Na2O, Al2O3, the template agent and water, and the molar ratio of Na2O to SiO2 is (0.05-0.4): 1; and (2) crystallizing the precursor in microwave radiation at a microwave radiation temperature greater than or equal to 140 DEG C, and sintering to obtain the ZSM-5 molecular sieve. According to the present invention, the production cost is low, the preparation process is simple, the crystallization time is short, and the prepared ZSM-5 molecular sieve has characteristics of high relative crystallinity, pure crystal phase, high specific surface area and strong adsorption.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for producing iron phosphate for producing iron lithium phosphate material

The invention discloses a preparation method of iron phosphate for preparing lithium iron phosphate material, and relates to heavy metal phosphate. The steps of the method are as follows: analyticallypure soluble molysite is dissolved in distilled water, thereby being prepared into 0.05 to 5 M water solution, and being added with anionic surface-active agent with the mass being 0.01 to 3 percentof the mass of the molysite, then analytically pure phosphoric acid is added according to the mol ratio of Fe<3+>:PO4<3-> equal to 1:0.8 to 1.2 and stirred, alkaline solution with the concentration of1 to 9 M is slowly added in stirring state, the adding time is more than 1 hour until the Ph value of the solution reaches 6 to 7, the deposited matter of iron phosphate is filtered, the filtered iron phosphate is cleaned for 3 to 5 times with distilled water with the 2 to 5 times weight of the iron phosphate, the iron phosphate is dried in the range of 60 to 90 DEG C under a vacuum condition, and the finished FePO4.2H2O powder is gotten. The iron phosphate product with two crystal water prepared by the invention has high reaction activity, and the performance of the lithium iron phosphate material prepared with the iron phosphate product is superior to the lithium iron phosphate material prepared with the commercial iron phosphate product.

Owner:HEBEI UNIV OF TECH

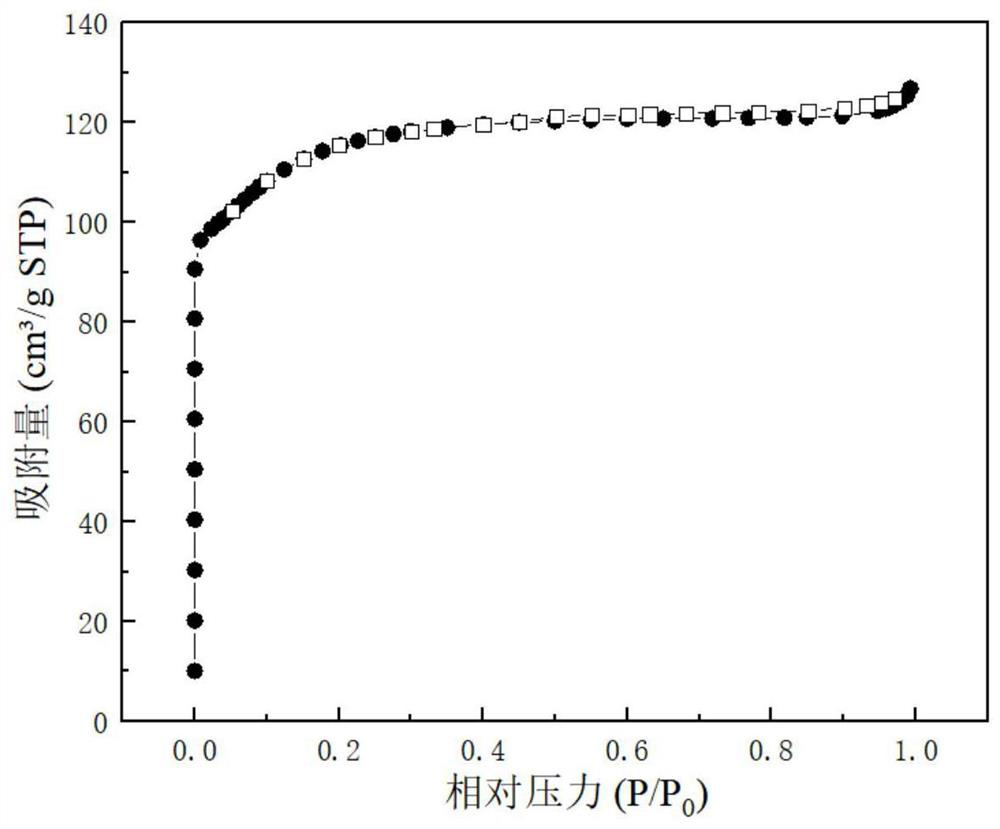

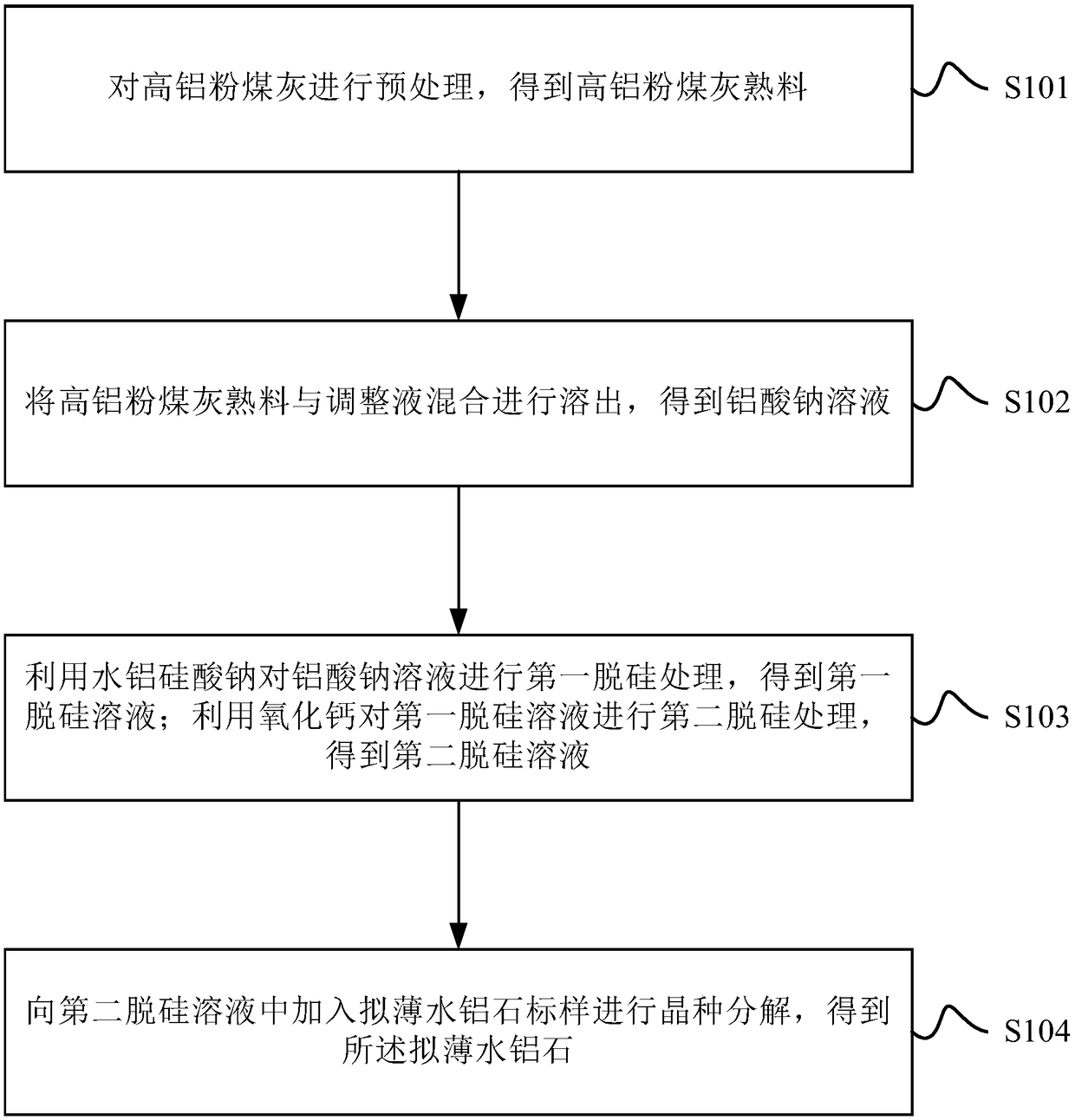

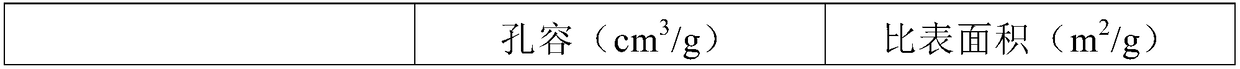

Method for preparing pseudo-boehmite by using high-alumina fly ash

InactiveCN108793212AReduce pollutionImprove economyAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSodium aluminateAdditional values

The invention provides a method for preparing pseudo-boehmite by using high-alumina fly ash. The method comprises the following steps: 1) pretreating the high-alumina fly ash to obtain a high-aluminafly ash clinker; 2) mixing the high-alumina fly ash clinker and a correction liquor, dissolving out to obtain a sodium aluminate solution; 3) using hydro-sodium aluminosilicate to desilicicate the sodium aluminate solution for the first time, obtaining a first desilicication solution; using calcium oxide to desilicicate the first desilicication solution for the second time, obtaining a second desilicication solution; 4) adding a pseudo-boehmite standard sample into the second desilicication solution to precipitate a seed crystal, and obtaining the pseudo-boehmite. The invention provides a novel technical method for preparing the pseudo-boehmite with high additional value by using the high-alumina fly ash, and the environment pollution pressure brought about by the fly ash is alleviated while the utilization level of the fly ash is improved.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT +1

Self-assembled nano-film mno2 adsorbent and preparation method for efficiently adsorbing heavy metals

InactiveCN103920449BImprove fullyCrystal phase pureOther chemical processesWater/sewage treatment by sorptionSorbentEnergy consumption

The invention relates to a self-assembled nano film MnO2 adsorption agent capable of high-efficiently adsorbing heavy metals and a preparation method of the adsorption agent, and belongs to the field of metal environmental protection. The adsorption agent has a nano film grading layered structure, in the size of 700 nanometers, which is formed by self-assembling sheets in the thickness of 2 to 3 nanometers. The preparation method comprises the following steps of dissolving KMnO4, NH4H2PO4 and Na2SO4.10H2O into deinoized water and mixing, reacting at a constant temperature in a reaction kettle, washing precipitates, drying the precipitates and the like. Raw materials of the absorption agent are cheap and easily available, the reaction condition is simple, the energy consumption is low, the adsorption agent has a good effect for removing heavy metal ions in an acid medium, and the application prospect is wide.

Owner:YUNNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com