ZSM-11 molecular sieve with hierarchical porous structure and preparation method thereof

A technology of ZSM-11 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problem that nano-molecular sieve cannot realize industrial application value, the grain size of nano-molecular sieve is reduced, Solve problems such as poor thermal and hydrothermal stability, achieve good thermal and hydrothermal stability, reduce benzene content, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Under stirring conditions, prepare the following two working solutions respectively:

[0045] Mixture I: 15g of silica sol (40% SiO 2 , 60%H 2 O, hereinafter the same), 0.97g tetrabutylammonium bromide (99%), 11.3g deionized add in the beaker and mix homogeneously;

[0046] Mixture II: a homogeneous solution prepared from 1.33g of aluminum sulfate, 1.50g of sodium hydroxide and 15g of deionized water;

[0047] Under constant stirring, slowly add mixture II to mixture I, continue to stir until uniform, and the mass ratio of the obtained reaction mixture is Na 2 O:Al 2 o 3 : SiO 2 :(TBA) 2 O:H 2 O=9.0:1.0:50:0.75:1000, transfer the obtained initial gel to a reaction kettle with a polytetrafluoroethylene lining, seal it and place it in a hydrothermal synthesis oven, and keep the temperature at 90°C for 24h, Then the temperature was raised to 150°C and the temperature was maintained for 24h. After the reaction kettle was cooled, the solid was separated from the mot...

Embodiment 2

[0050] Under stirring conditions, prepare the following two working solutions respectively:

[0051] Solution I: Add 15g silica sol, 3.23g tetrabutylammonium bromide, and 40.2g deionized into a beaker and mix well.

[0052] Solution II: a homogeneous solution prepared by 1.33g aluminum sulfate, 2.00g sodium hydroxide and 40g deionized water

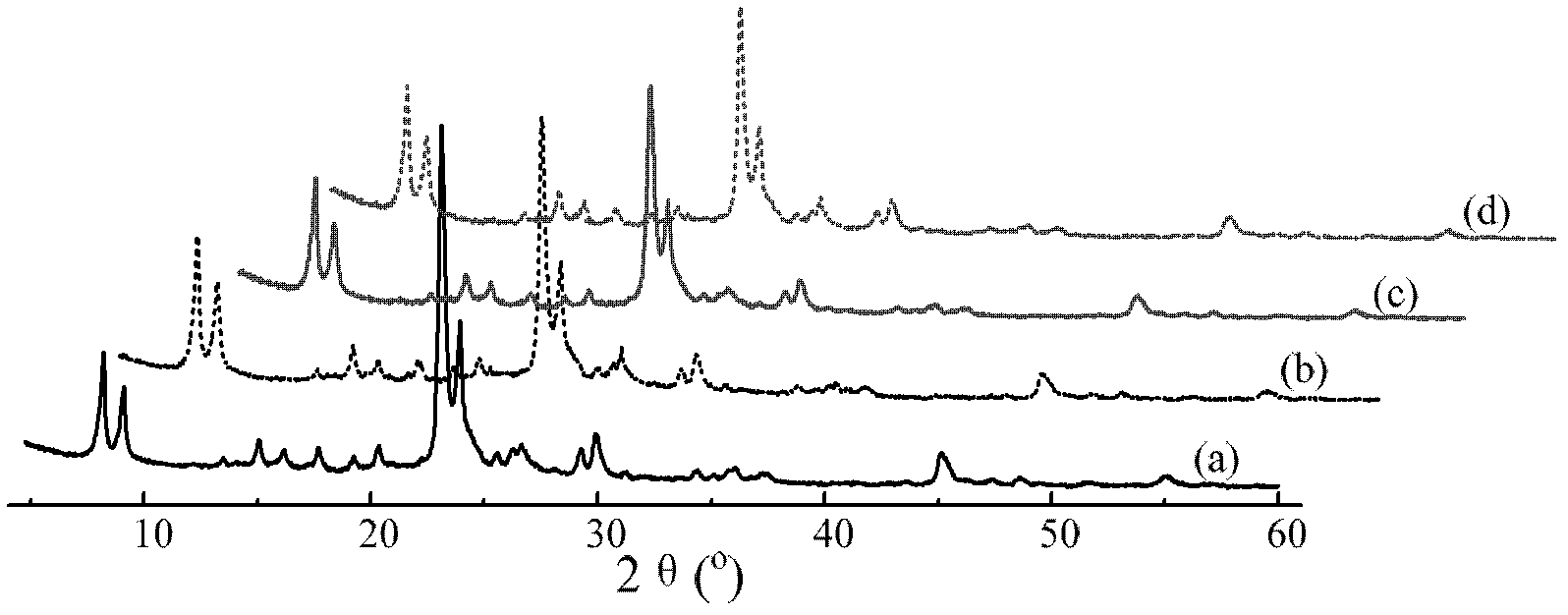

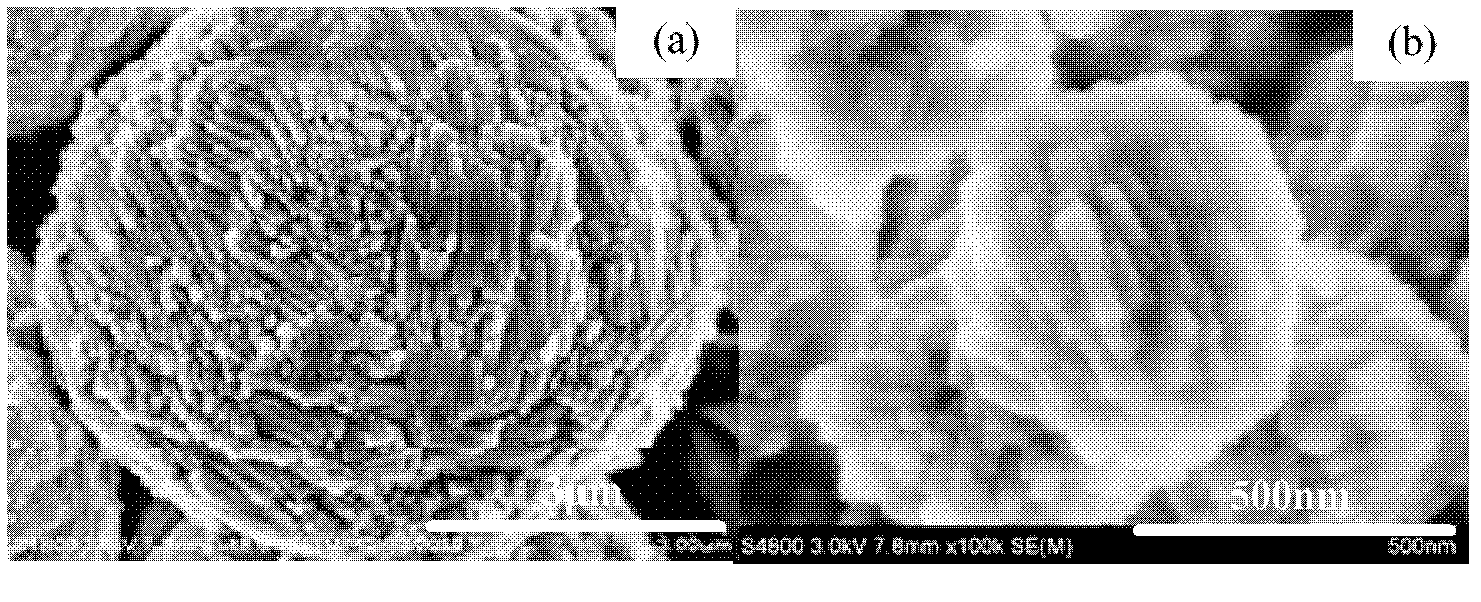

[0053] Under continuous stirring, slowly add solution II to solution I, and continue stirring until uniform. The molar ratio of the initial gel is Na 2 O:Al 2 o 3 : SiO 2 :(TBA) 2 O:H 2 O=12.0:1.0:50:2.5:2500. The crystallization conditions are the same as in Example 1. The final product powder is analyzed by X-ray diffraction, and the result is the same as figure 1 (a) are basically consistent, and its morphology measured by scanning electron microscopy is consistent with that of figure 2 (a) match.

Embodiment 3

[0055] The raw materials, composition and process flow of this example are the same as in Example 1, the difference is: after the raw materials are mixed evenly, they are transferred to a reaction kettle with a polytetrafluoroethylene lining, and after sealing, the temperature is kept at 90°C for 384h, and then the temperature is raised Continue constant temperature to 180°C for 8h. The product is ZSM-11 molecular sieve with a crystallinity of 98.39% and a particle size of 1.5 μm. The final product powder is analyzed by X-ray diffraction, and the result is the same as figure 1 (a) are basically consistent, and its morphology measured by scanning electron microscopy is consistent with that of figure 2 (a) match.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com