Self-assembled nano-film mno2 adsorbent and preparation method for efficiently adsorbing heavy metals

A technology for adsorbing heavy metals and nano-films, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the limited application prospects of the template method, cumbersome template removal steps, and easily damaged product structure and other problems, to achieve the effect of easy recovery, excellent removal ability and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

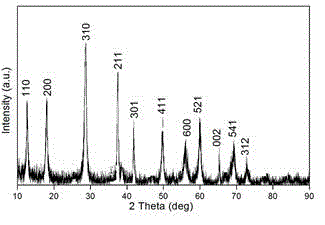

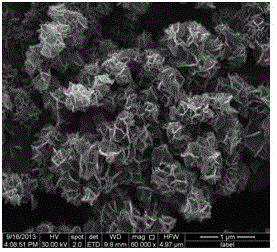

[0024] Take raw material reagent 0.28g KMnO 4 , 0.01g NH 4 h 2 PO 4 , 0.01g Na 2 SO 4 10H 2 O was respectively dissolved in an appropriate amount of deionized water. After fully dissolving, the solutions were mixed and a certain amount of deionized water was added to make the total volume of the final solution 90 ml. Stir for 15 minutes, transfer the solution to a 100ml stainless steel polytetrafluoroethylene reaction kettle, keep it in an oven at 140°C for 48 hours, turn off the power and let it cool down to room temperature naturally with the furnace, centrifuge the precipitate, and wash it with deionized water and ethanol several times. Vacuum drying at 70°C overnight to obtain nano-film self-assembled hierarchical layered MnO 2 Adsorbent material.

Embodiment 2

[0026] Take raw material reagent 0.28g KMnO 4 , 0.01g NH 4 h 2 PO 4 , 0.01g Na 2 SO 4 10H 2 O was respectively dissolved in an appropriate amount of deionized water. After fully dissolving, the solutions were mixed and a certain amount of deionized water was added to make the total volume of the final solution 90 ml. Stir for 15 minutes, transfer the solution to a 100ml stainless steel polytetrafluoroethylene reaction kettle, keep it in a 160°C oven for 48 hours, turn off the power and let it cool down to room temperature naturally with the furnace, centrifuge the precipitate, and wash it with deionized water and ethanol several times. Vacuum drying at 70°C overnight to obtain nano-film self-assembled hierarchical layered MnO 2 Adsorbent material.

Embodiment 3

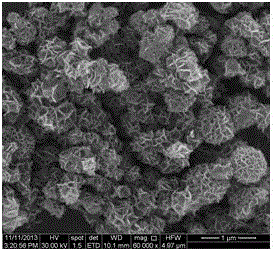

[0028] Take raw material reagent 0.28g KMnO 4 , 0.01g NH 4 h 2 PO 4 , 0.01g Na 2 SO 4 10H 2 O was respectively dissolved in an appropriate amount of deionized water. After fully dissolving, the solutions were mixed and a certain amount of deionized water was added to make the total volume of the final solution 90 ml. Stir for 15 minutes, transfer the solution to a stainless steel polytetrafluoroethylene 100ml reaction kettle, keep it in a 180°C oven for 48 hours, turn off the power and let it cool down to room temperature naturally with the furnace, centrifuge the precipitate, and wash it with deionized water and ethanol several times. Vacuum drying at 70°C overnight to obtain nano-film self-assembled hierarchical layered MnO 2 Adsorbent material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com