Device for spreading large-tow carbon fibers through combination of sound wave method and mechanical multi-roller method

A sonic method and carbon fiber technology, applied in the field of large tow carbon fiber expansion devices, can solve the problems of limited expansion width, carbon fiber breakage, vibration frequency limitation, etc., and achieve the effect of wide expansion width, small crossover between fibers, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

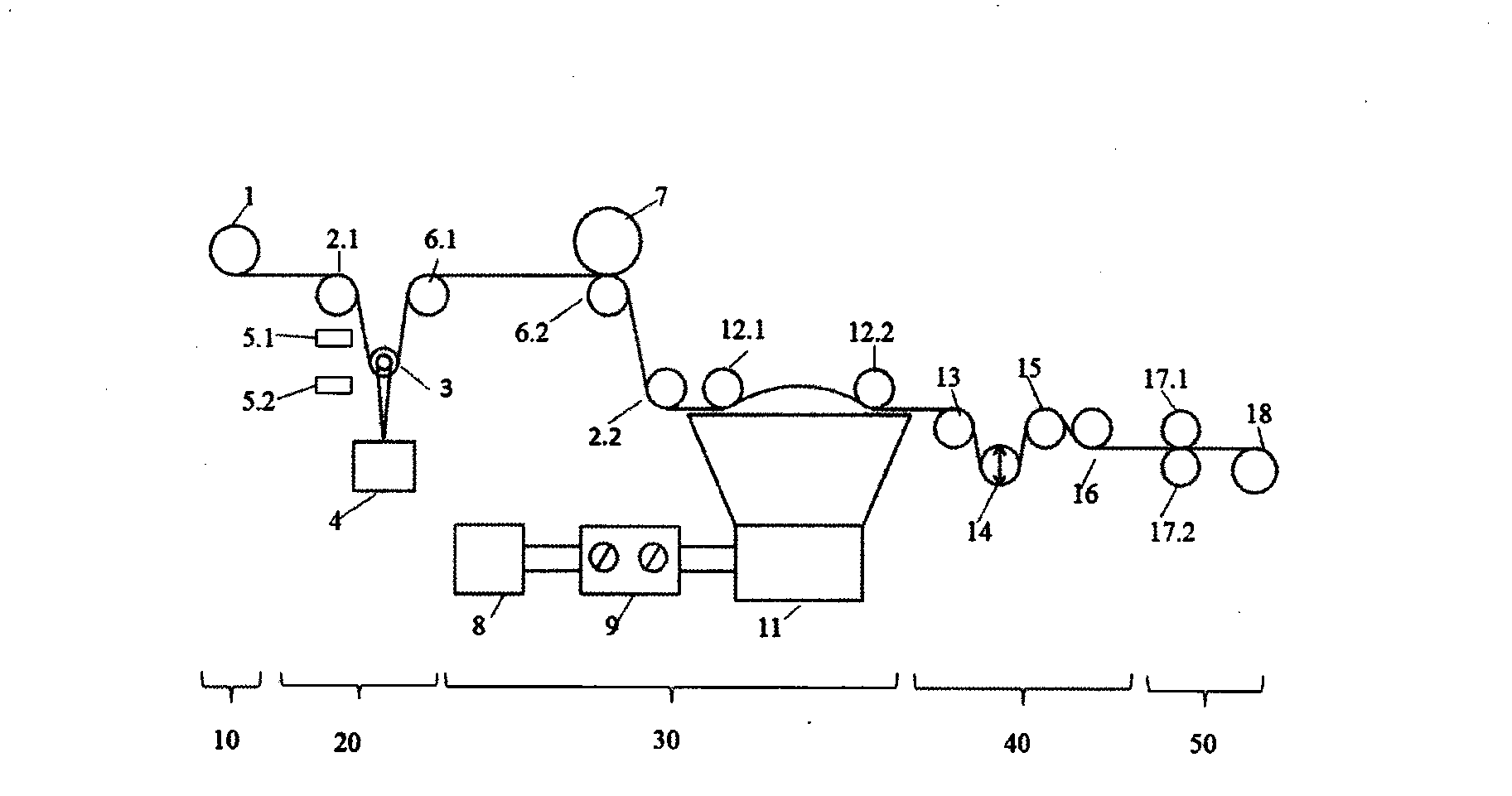

[0023] combine figure 1 , The present invention provides a large tow carbon fiber spreading device combining the sonic method and the mechanical multi-roller method. Expand the large-tow carbon fiber system by combining the sonic fiber expansion method and the mechanical multi-roller fiber expansion method, including the yarn unwinding device 10 composed of the creel 1 for placing the fiber bobbin, the fiber bundle is wound on the fiber bobbin, After the fiber bundle is drawn out from the creel 1, it is introduced into the tension control device 20 through the first guide roller 2.1.

[0024] The tension control device 20 adjusts the surface tension of the fiber bundle by adjusting the position of the tension stabilizing roller 3 between the first yarn guiding roller 2.1 and the first supporting roller 6.1. The position of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com