Patents

Literature

38results about How to "Uniform crystal phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

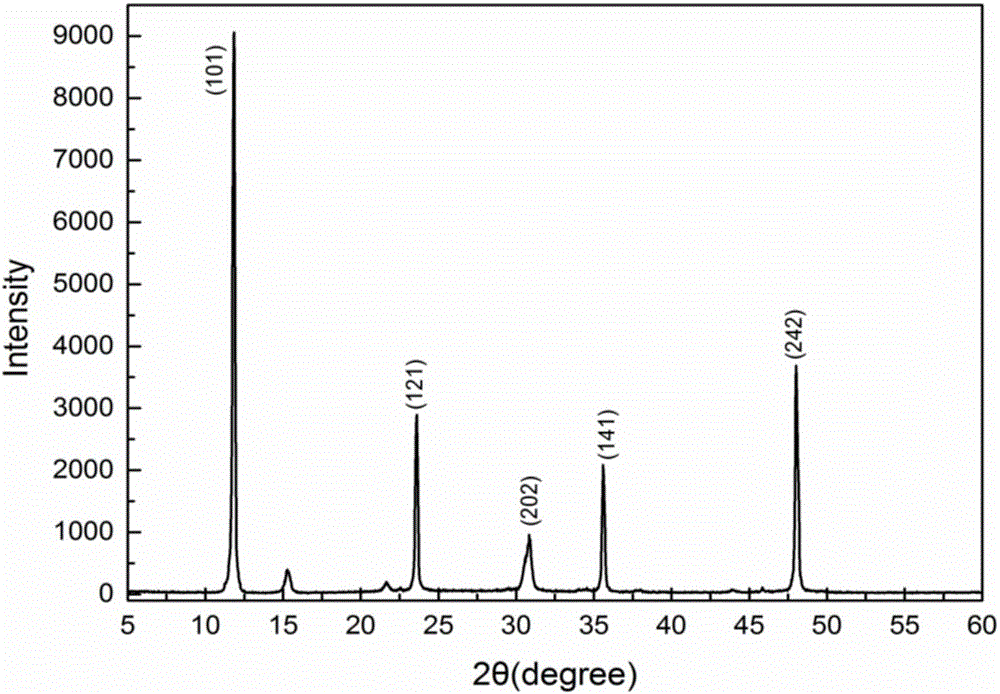

Process for producing iron phosphate for producing iron lithium phosphate material

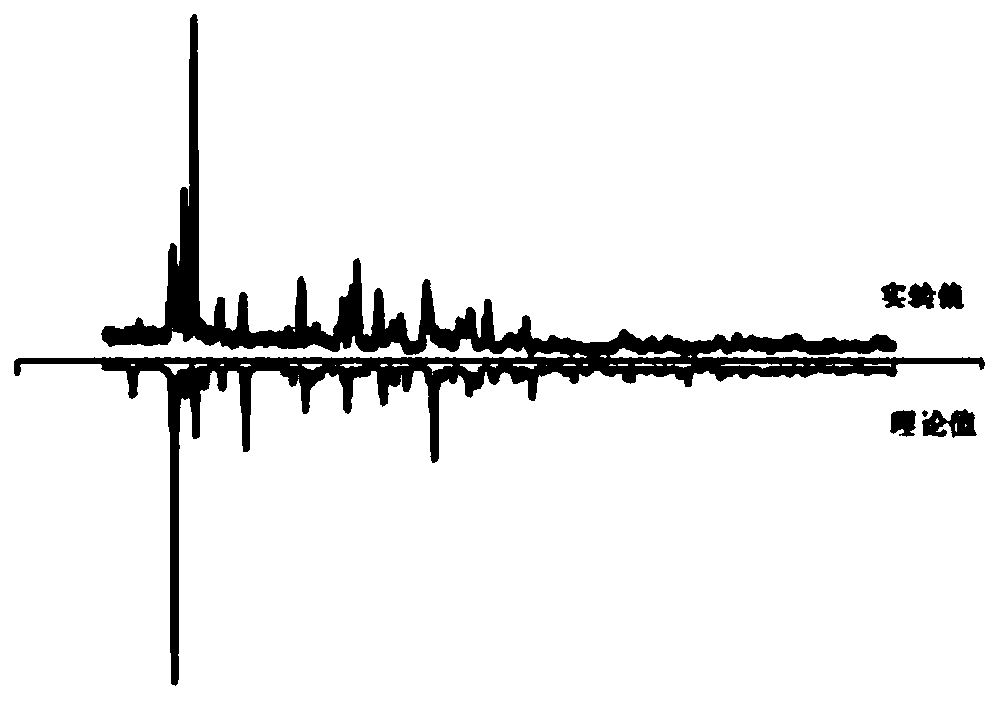

The preparation method of iron phosphate used for preparing lithium iron phosphate material in the present invention relates to heavy metal phosphate, and the steps are: dissolving analytically pure soluble iron salt in distilled water to prepare a 0.05-5M aqueous solution, and the added mass is the iron salt mass 0.01~3% of anionic surfactant, then add analytically pure phosphoric acid according to the molar ratio of Fe3+:PO43-=1:0.8~1.2 and stir evenly, and slowly add alkaline solution with a concentration of 1~9M under stirring , the feeding time is more than 1 hour, until the pH value of the solution reaches 6-7, the iron phosphate precipitate is filtered, and the filtered iron phosphate is washed 3-5 times with distilled water 2-5 times its weight. Dry at ~90°C to obtain the product FePO4·2H2O powder. The iron phosphate product with two crystal waters prepared by the method of the invention has high reactivity, and the performance of the lithium iron phosphate material made by using it is better than that of the lithium iron phosphate material made by commercially available iron phosphate products.

Owner:HEBEI UNIV OF TECH

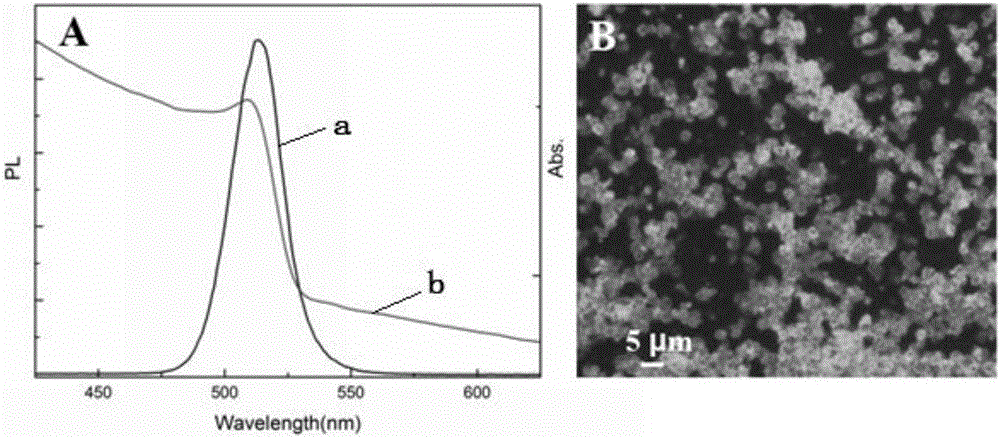

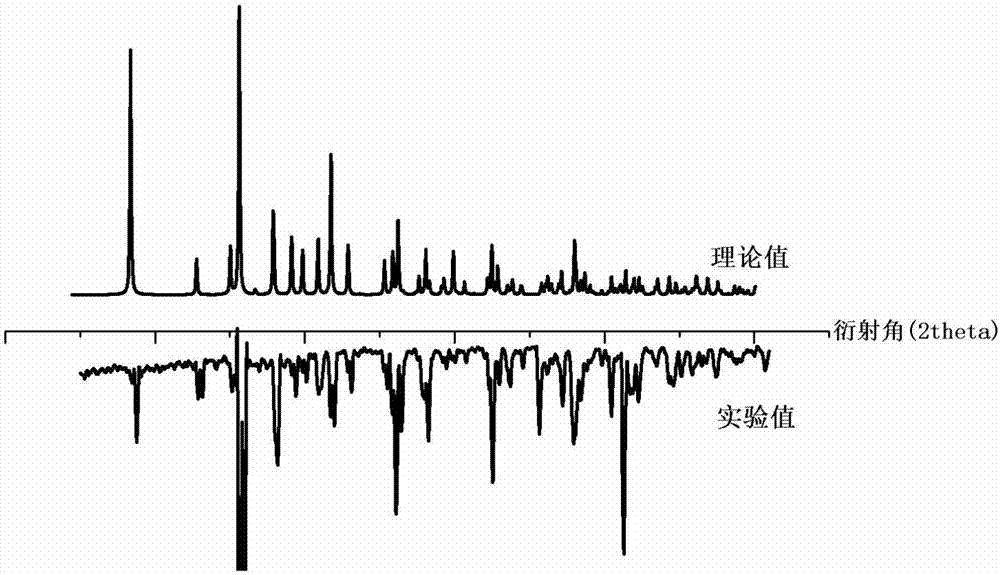

CsPb2Br5 nanosheet and preparation method thereof

The invention discloses a preparation method of a CsPb2Br5 nanosheet. The method comprises the following steps: adding excess oleic acid into an octadecylene solution containing Cs2CO3, heating to complete reaction of the Cs2CO3 under the protection of nitrogen to obtain a cesium oleate precursor solution; adding PbBr2 into the eighteen octadecylene solution, heating the solution to the oxygen content of 0 under the protection of nitrogen, heating again, adding oleylamine and oleic acid until complete dissolution of PbBr2, injecting the cesium oleate precursor solution, heating for 60-120 min under the condition of nitrogen, and finally reducing the reaction temperature of the reaction liquid to complete termination; and centrifuging and purifying the organic solution, and storing in organic solution. The prepared CsPb2Br5 nanosheet has homogeneous phase, good crystal structure, good uniformity, high yield, high fluorescence efficiency and stable structure, can be used in industrial production, and has potential application value in solar cells, light emitting diodes (QLED) and microlaser.

Owner:CHONGQING UNIV

Process for preparing molybdenum nitride and use thereof as hydrogenation and desulfurizing catalyst

InactiveCN1401580AUniform crystal phaseHigh desulfurization activityMolybdenum halidesRefining to eliminate hetero atomsHydrodesulfurizationOxygen

A process for preparing molybdenum nitride from MoO3 includes multi-stage thermal reaction in the mixed atmosphere of N2 and H2, cooling in inert gas and purifying in oxygen. Said product can be used as hydrodesulfurizing catalyst for hdyrodesulfurizing at 250-450 deg.C and 0.2-20 MPa. Its advantages are simple process and low cost.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method of high-performance cerium-zirconium solid solution material

ActiveCN106732521AUniform structureUniform crystal phaseGas treatmentZirconium compoundsCeriumOxygen

The invention belongs to the technical field of preparation of solid materials and particularly relates to a preparation method of a high-performance cerium-zirconium solid solution material. The preparation method comprises the following steps: uniformly mixing metal cerium salt, metal zirconium salt and a surfactant by adopting a spray charging mode; inducing generation of a precipitation by adjusting the charging speed and using a crystal seed generated in the solution; finally, carrying out a hydrothermal aging and roasting process to obtain a cerium-zirconium composite material. According to the preparation method disclosed by the invention, the formation of the precipitation is induced by using tiny crystal seeds generated in an early-stage solution of the precipitation through the spray charging mode and control over the charging speed, so that the uniformity in a precipitating process is improved, and further the formation of a cerium-zirconium solid solution is promoted. The method has the advantages of simple preparation process and low production cost; the prepared cerium-zirconium solid solution has the characteristics of homogenized structure, small particle size, great specific surface area, good stability and the like; moreover, the high-performance cerium-zirconium solid solution material has excellent oxygen storing / discharging property and is the high-performance cerium-zirconium solid solution material with large-scale production and an industrial application prospect.

Owner:FUDAN UNIV

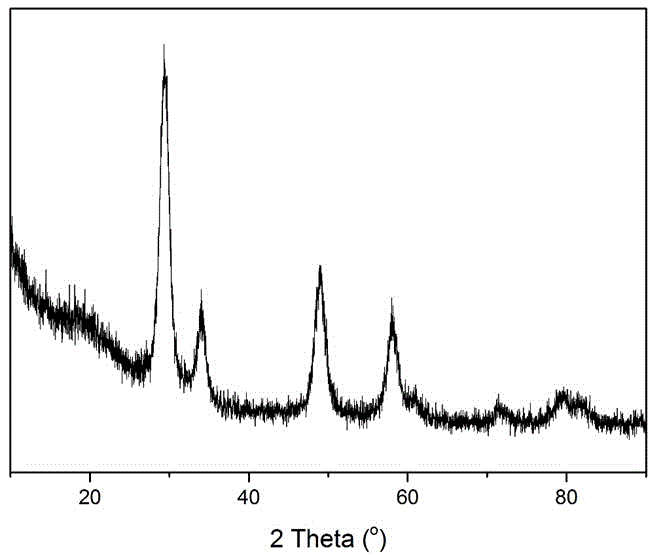

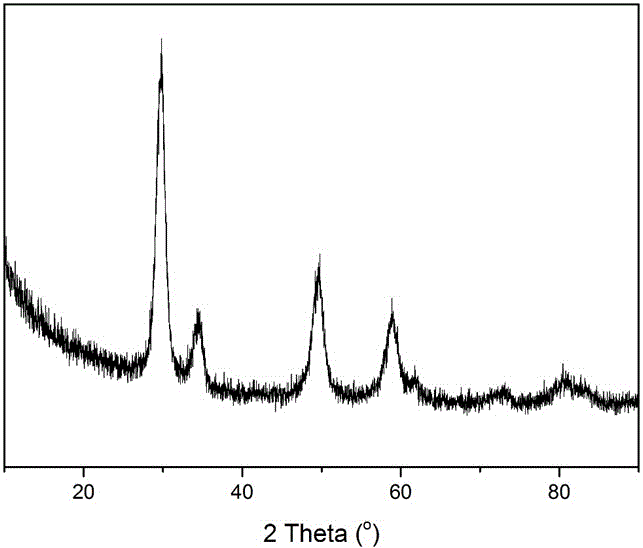

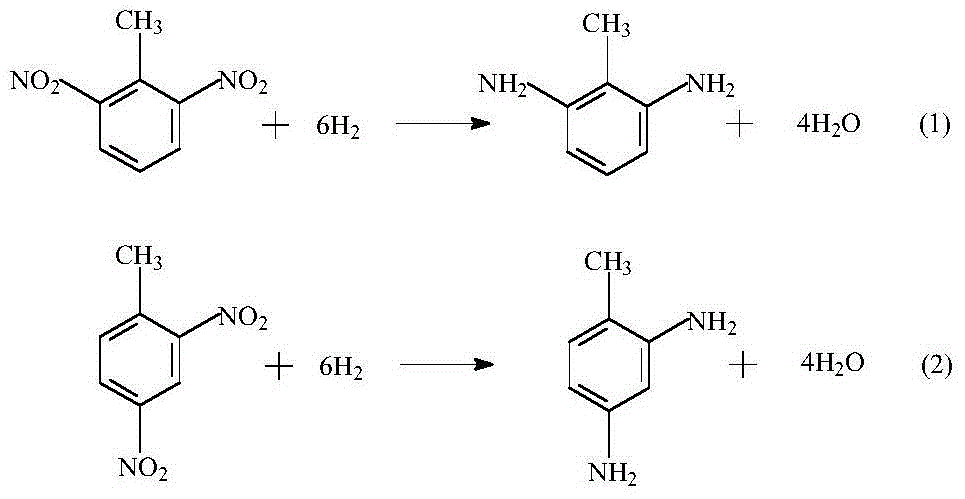

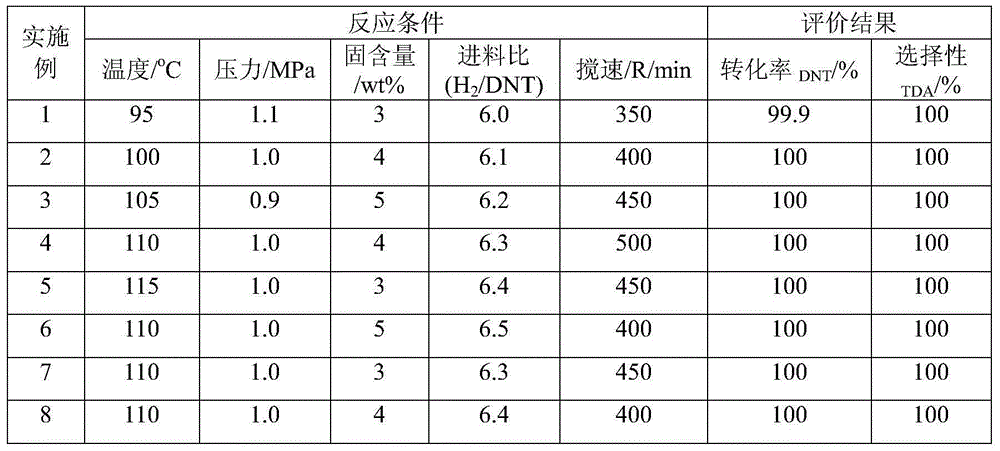

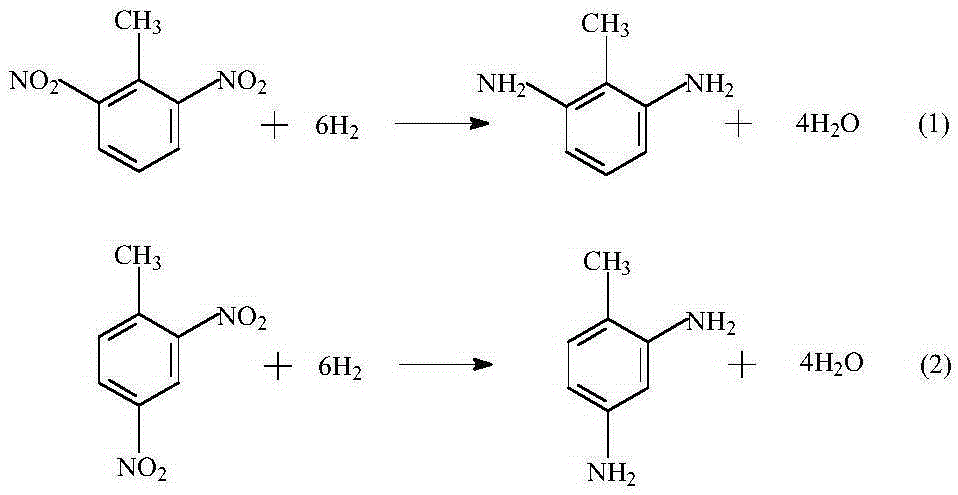

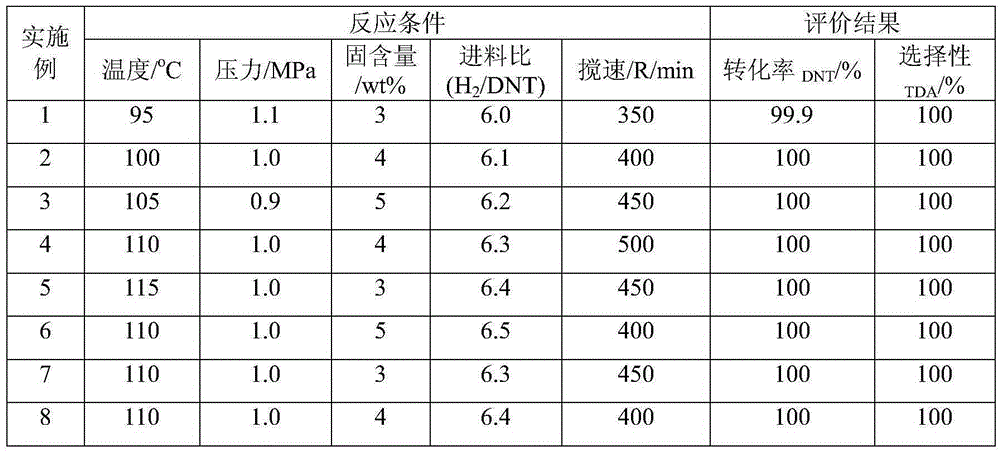

Raney nickel catalyst used for low-pressure hydrogenation of dinitrotoluenem, preparation method and application thereof

InactiveCN103977818AReduce energy consumptionTemperature rises fastOrganic compound preparationAmino compound preparationTolueneSolvent

A Raney nickel catalyst used for low-pressure hydrogenation of dinitrotoluenem. The catalyst is characterized by comprising, by mass, 80-90 wt% of nickel, 5-10 wt% of aluminium and 1.65-10 wt% of an auxiliary agent metal, wherein the nickel is in the form of a simple substance, the aluminium is in the form of the simple substance of an oxide and the auxiliary agent metal is in the form of the oxide. The catalyst is low in price and has an excellent performance of catalytic hydrogenation of the dinitrotoluenem (DNT) without an additional solvent and under a low-pressure condition of 1Mpa.

Owner:TAIYUAN UNIV OF TECH +1

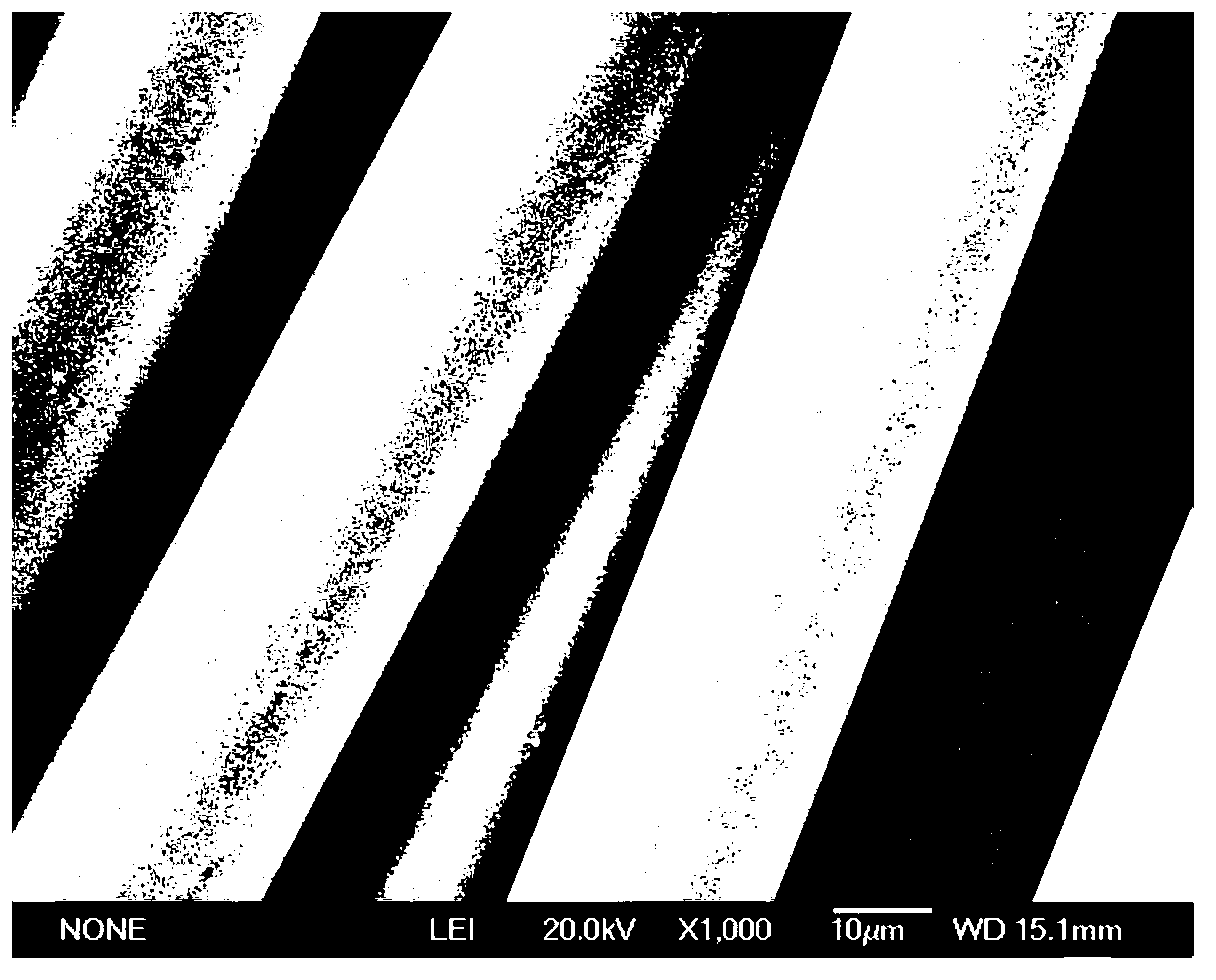

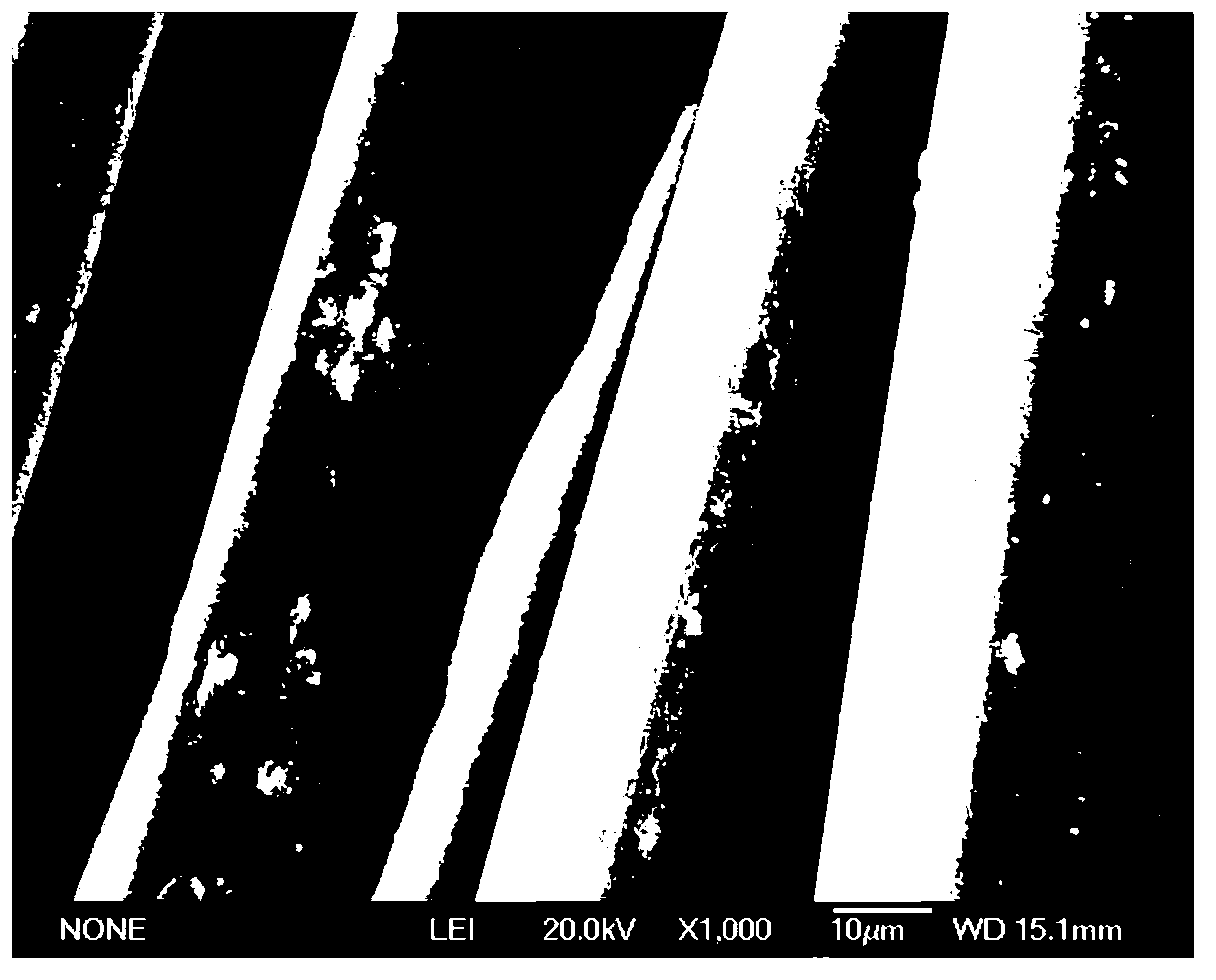

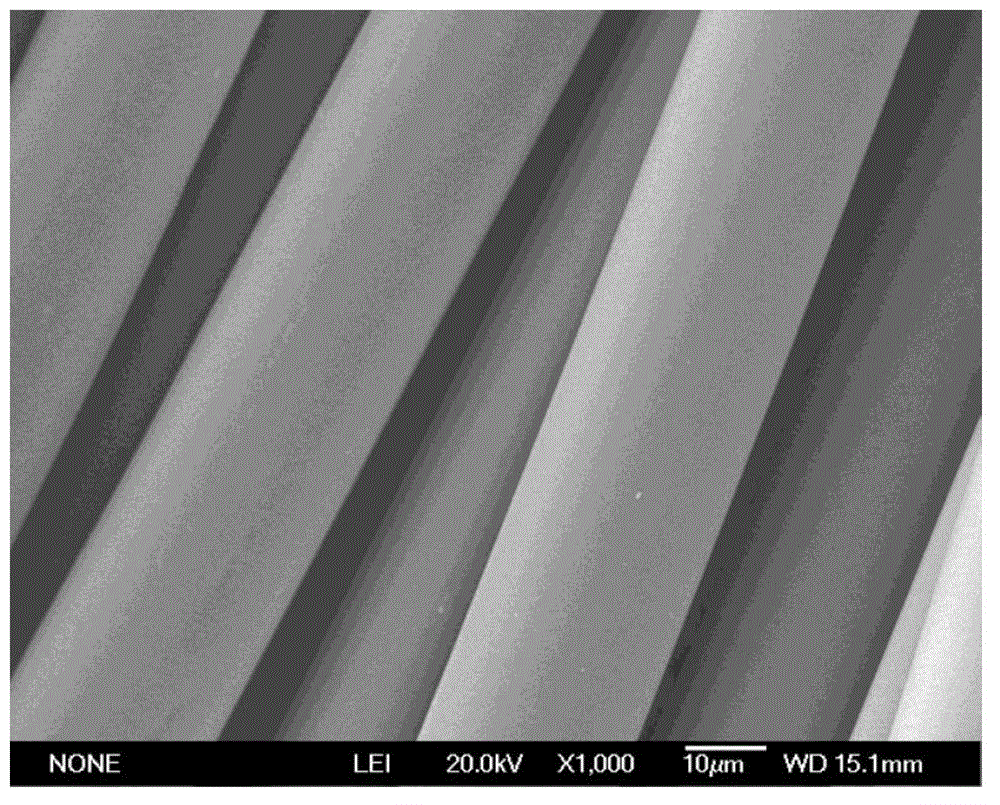

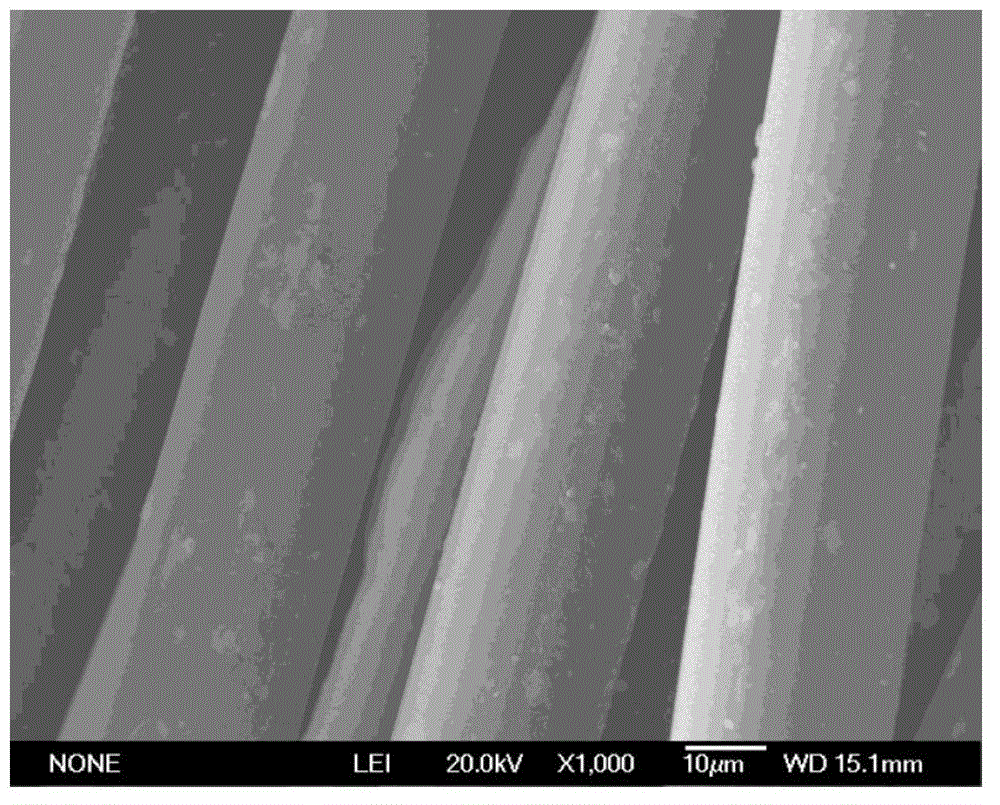

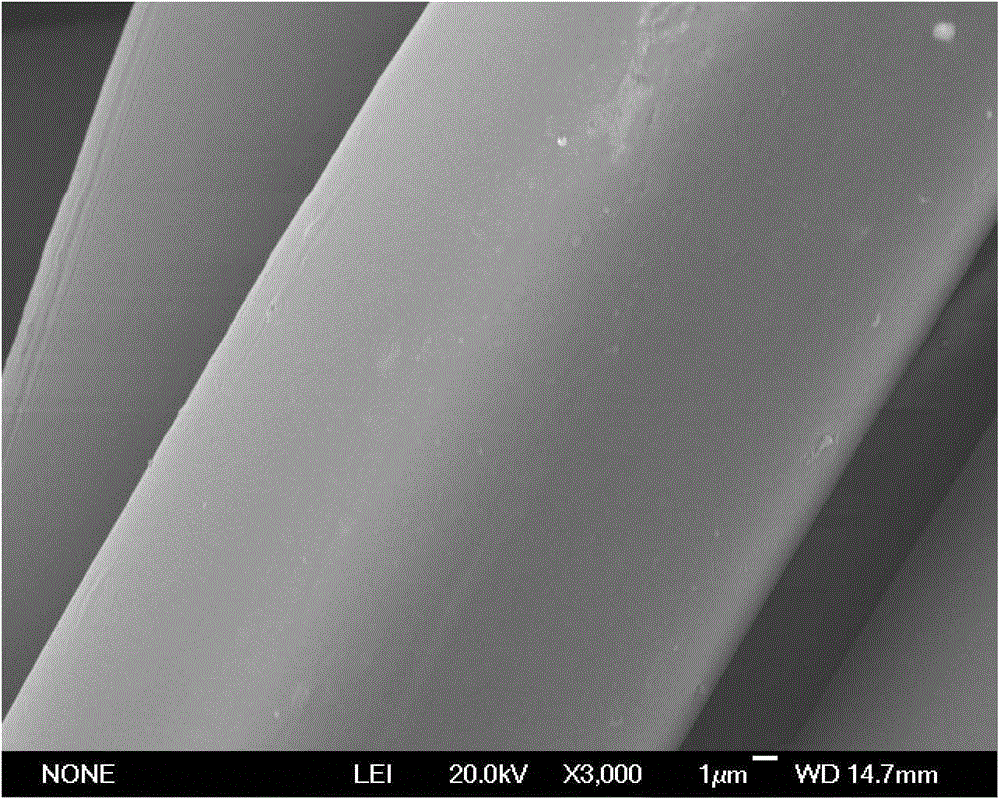

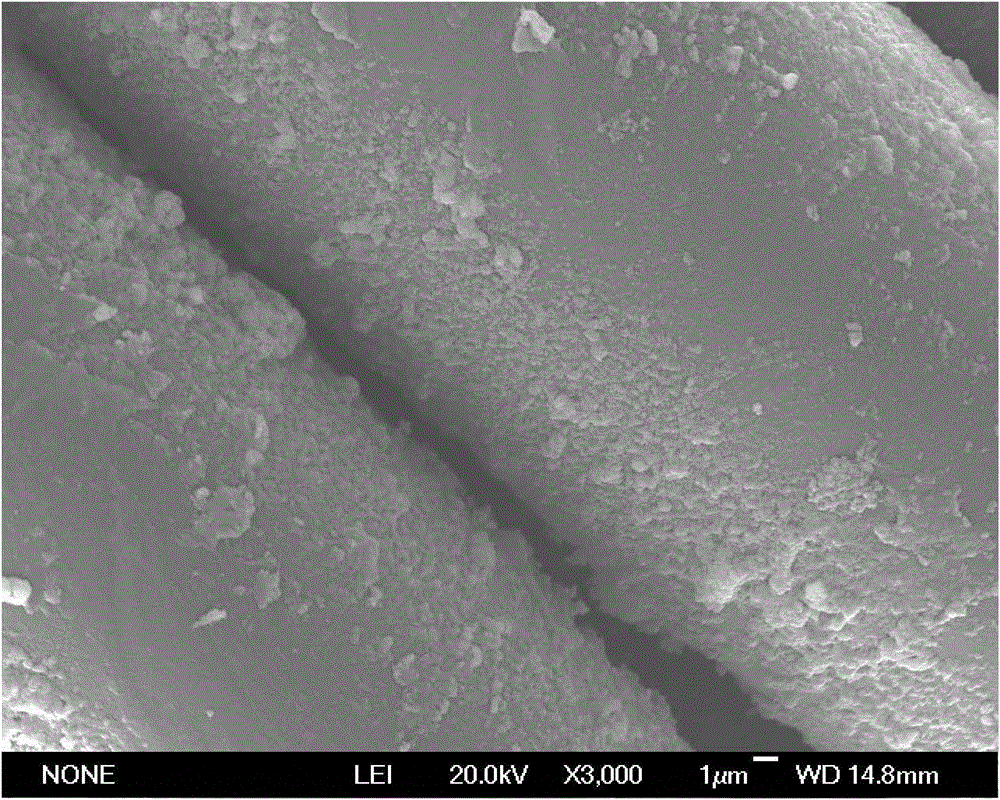

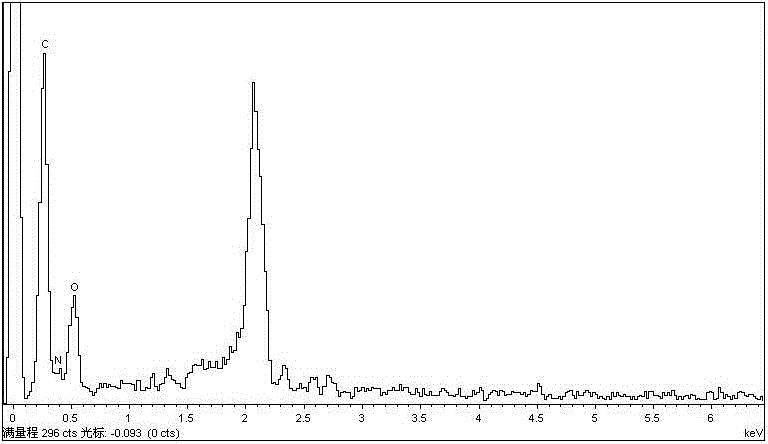

Method for modifying and dyeing polyester fiber by use of silver-doped nano titanium dioxide disperse dye

ActiveCN103215804AImprove photocatalytic activityImprove antibacterial propertiesFibre typesDyeing processDisperse dyeSodium hydroxide

The invention discloses a method for modifying and dyeing polyester fiber by use of silver-doped nano titanium dioxide disperse dye. The method comprises the following steps of: soaking the polyester fiber in a sodium hydroxide solution for etching; cleaning and drying the etched polyester fiber; preparing a modification and dyeing mixed solution; performing modification and dyeing composition finishing on the polyester fiber after the etching treatment in the first step by use of the modification and dyeing solution; and finally, cleaning and drying the modified polyester fiber. The method disclosed by the invention solves the problems that the polyester fiber prepared by an existing modification method has low photocatalytic activity under visible light, a poor self-cleaning function and non-lasting washing resistance and that the modified polyester fiber or fabric has poor handfeel and air permeability.

Owner:XI'AN POLYTECHNIC UNIVERSITY

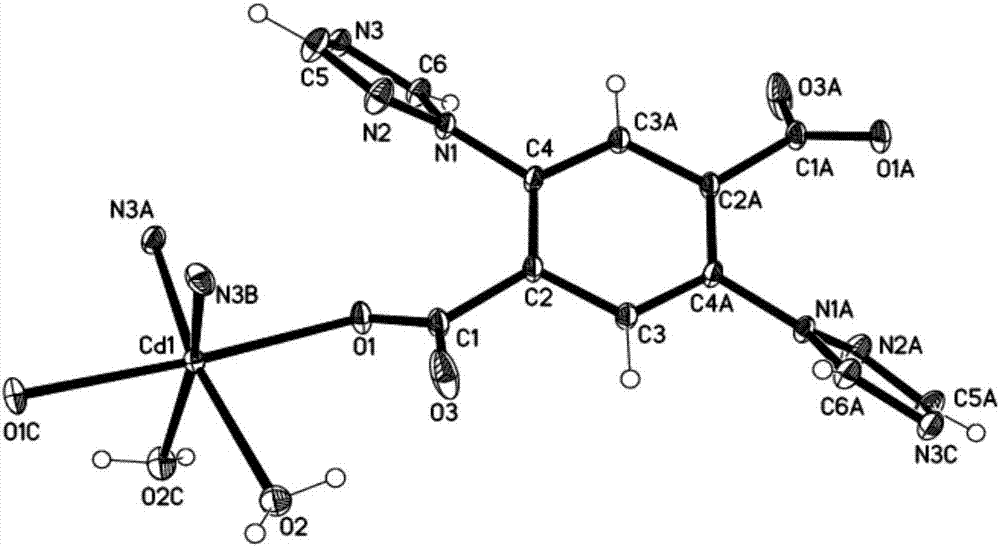

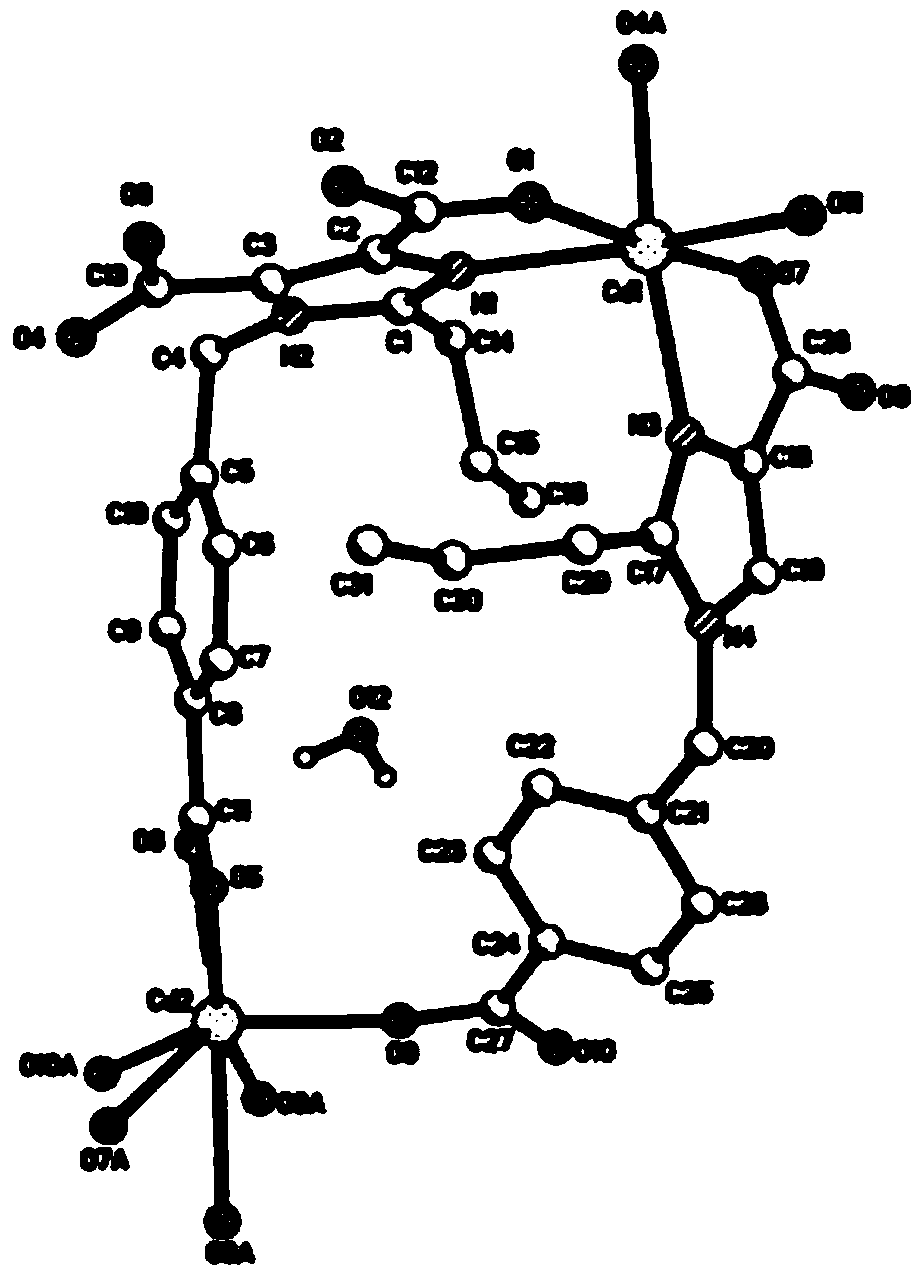

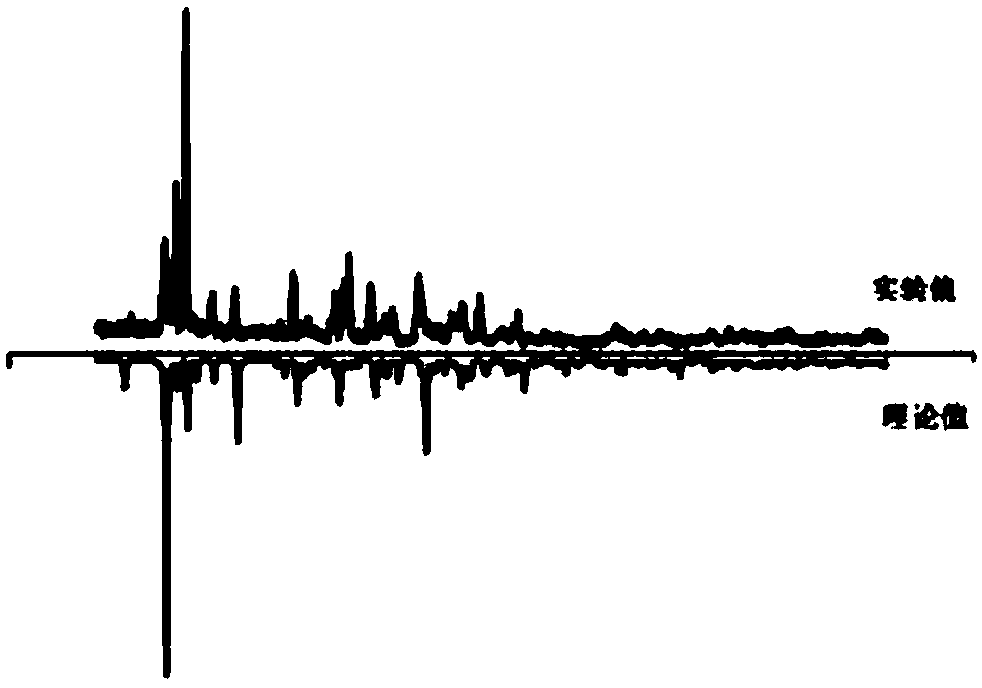

Two-dimensional cadmium organic framework coordination compound and preparation method and application thereof

ActiveCN107936954AEasy to prepareLow costOrganic chemistry methodsFluorescence/phosphorescenceBulk crystalFluorescence

The invention discloses a two-dimensional cadmium organic framework coordination compound and a preparation method and application thereof. The two-dimensional cadmium organic framework coordination compound adopts a chemical formula as follows: [Cd([mu]5-Hcbic)]n, in which H3cbic is 1-(4-benzoyl)-1H-benzimidazole-5,6-dicarboxylic acid. The preparation method comprises the following steps: addingH3cbic and cadmium chloride according to a molar ratio of 1:2 into H2O and CH3CN according to a volume ratio of 4:3, stirring for 30 minutes at room temperature, and reacting for 72 hours in a sealedreaction kettle at 160 DEG C to obtain colorless bulk crystals, with the yield of 63%. The two-dimensional cadmium organic framework coordination compound adopts a two-dimensional framework structure,in which cadmium ions adopt a six-coordinated mode. In an aqueous solution, under excitation of 230nm wavelength light, Fe<3+> can quench fluorescence of the two-dimensional cadmium organic frameworkcoordination compound, so that the two-dimensional cadmium organic framework coordination compound can be used as a fluorescent probe for detecting the Fe<3+>.

Owner:SHANXI UNIV

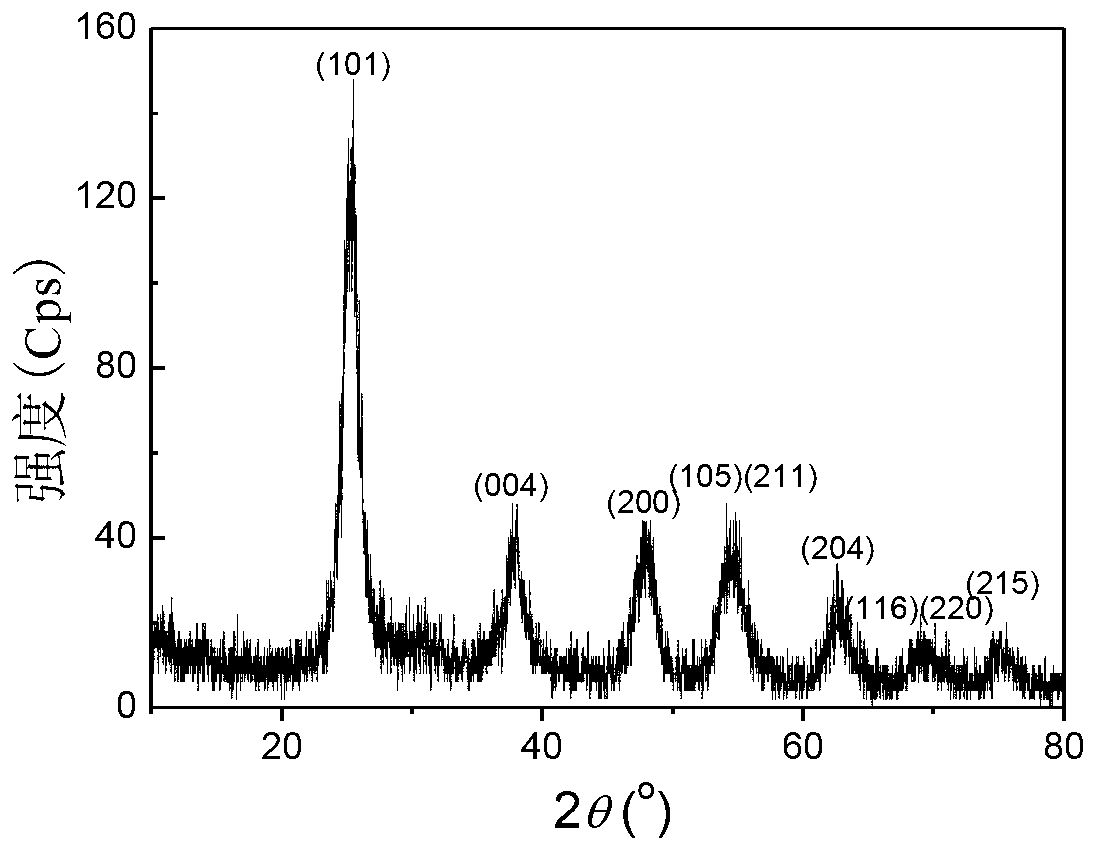

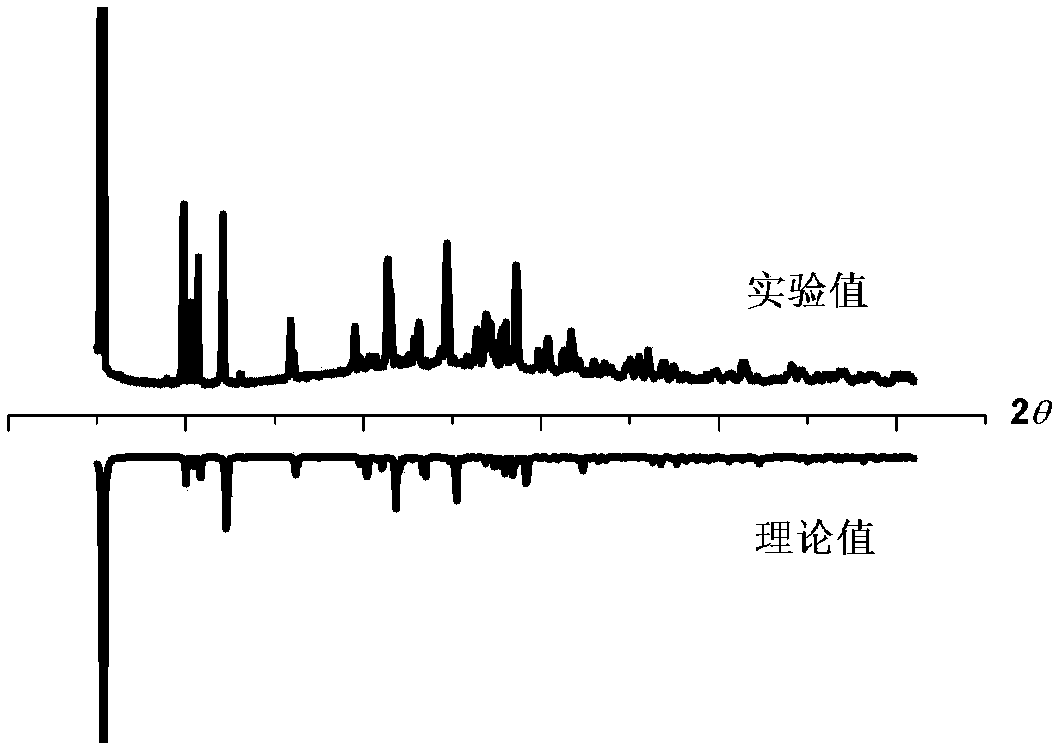

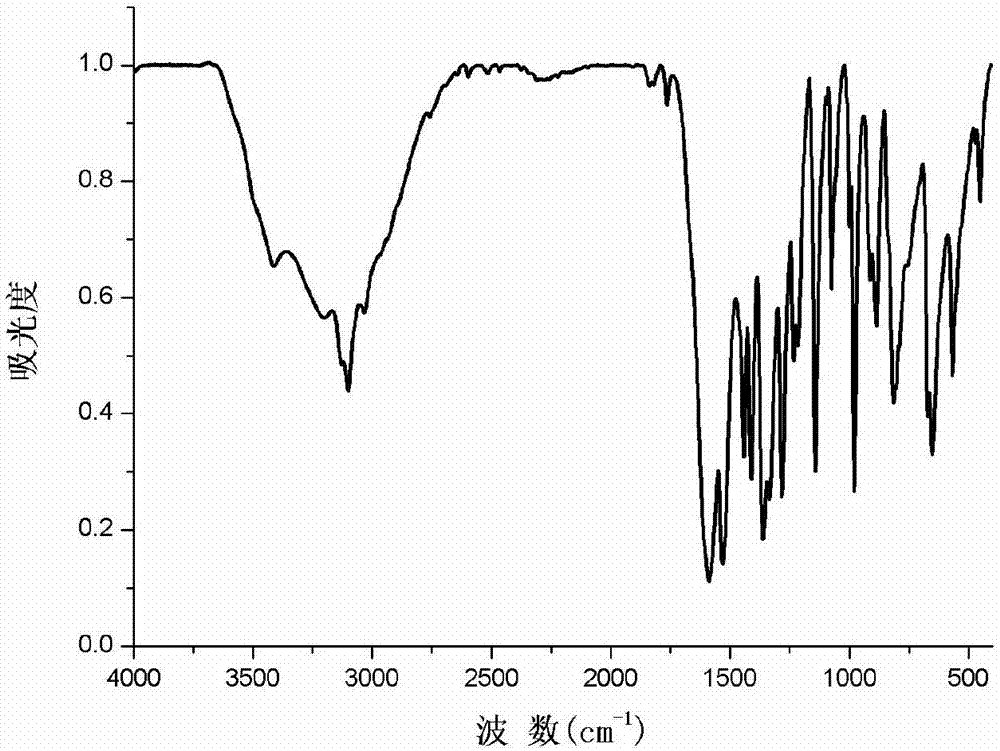

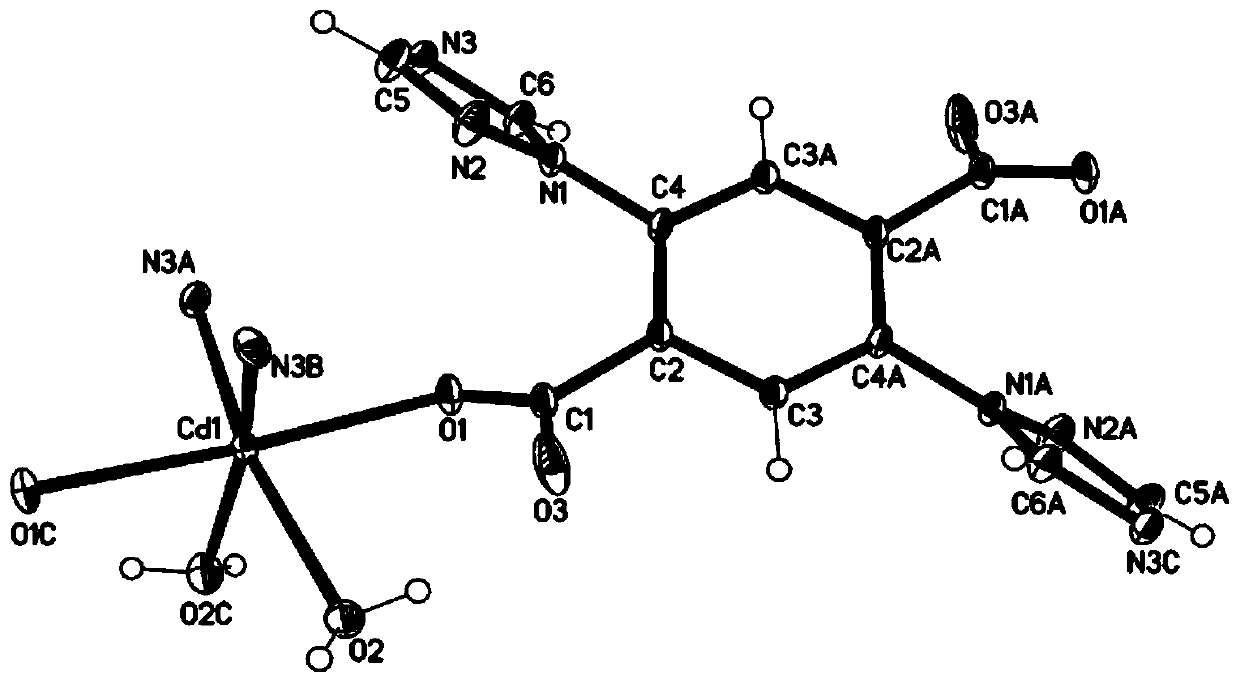

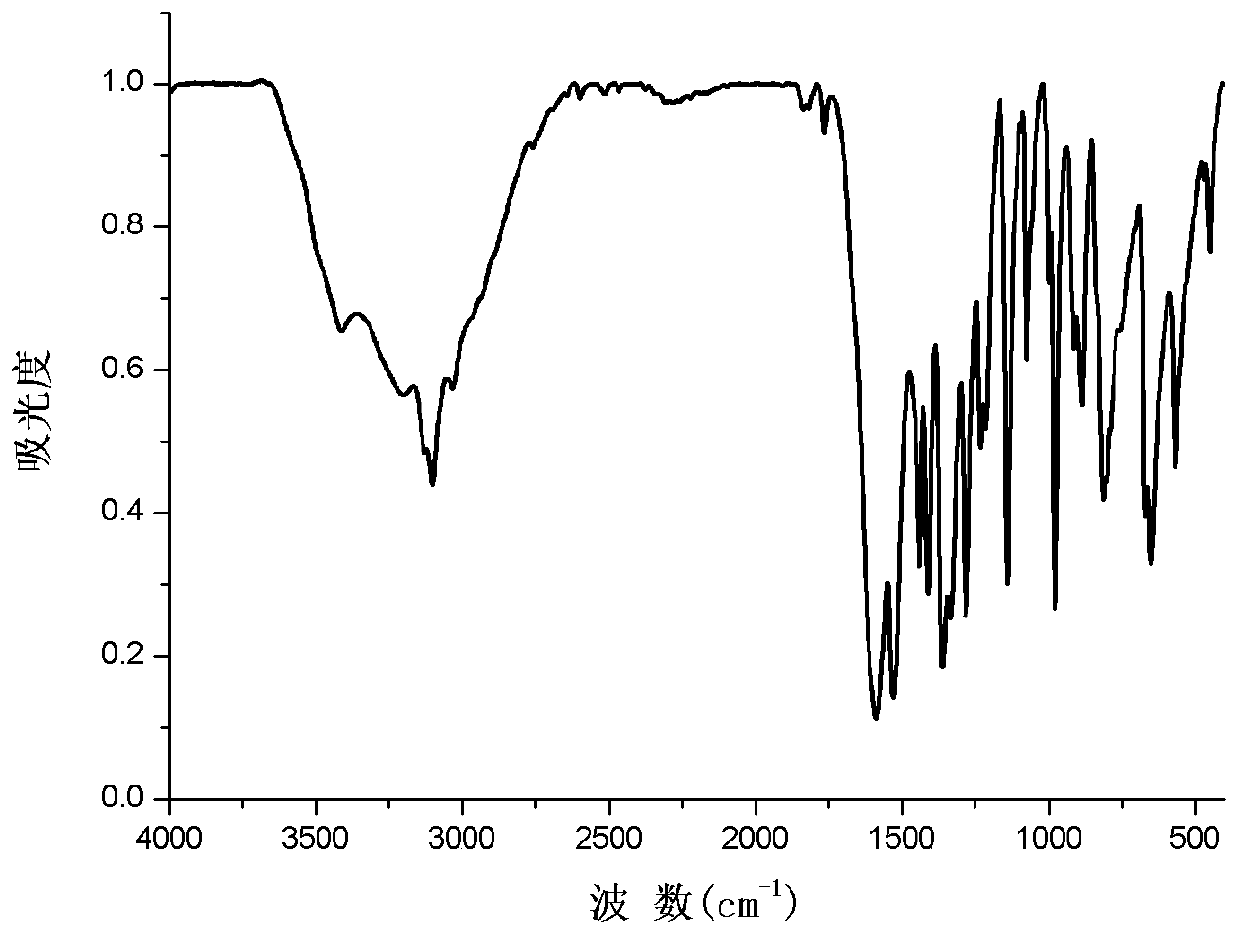

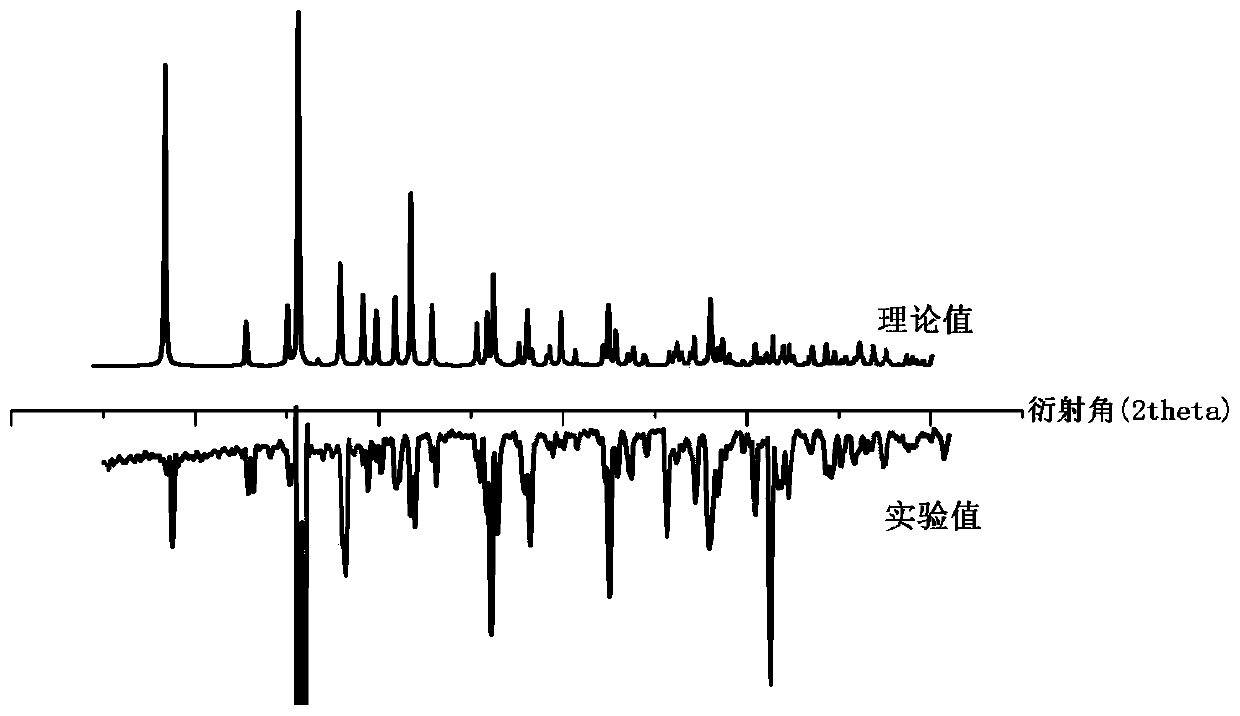

Cadmium organic framework compound and preparation method thereof

ActiveCN107417712AEasy to prepareLow costOrganic chemistry methodsGroup 2/12 organic compounds without C-metal linkagesCadmium CationCoordination complex

The invention discloses a cadmium organic framework compound and a preparation method thereof. A chemical formula of the compound is [Cd(L)(H2O)2]n, wherein H2L is 2,5-di(1H-1,2,4-triazolyl)terephthalic acid. The preparation method comprises the following steps: adding the H2L and cadmium nitrate with the mol ratio of 1 to 2 into H2O and DMF (Dimethyl Formamide) with the volume ratio of 4 to 1; after stirring the components at the room temprature for 30min, enabling a mixture to react at 120 DEG C for 72h in a closed reaction kettle, so as to obtain a colorless rhombus-shaped crystal, with the yield of 76 percent. The compound disclosed by the invention has a three-dimensional framework structure; a cadmium ion adopts a six-coordinated octahedral coordination mode. When the solid-state compound is stimulated by light with the wavelength of 320nm, the compound has an emission peak at a the part with the wavelength of 414nm and a CIE chromaticity coordinate is (0.15, 0.0439) and is located in a blue-ray region; the compound can be used as an optical material.

Owner:SHANXI UNIV

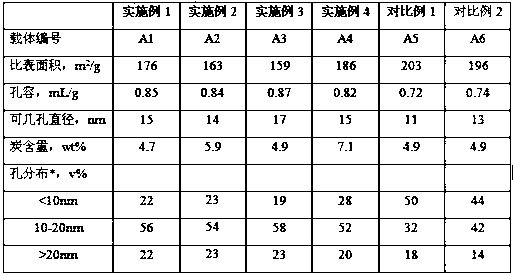

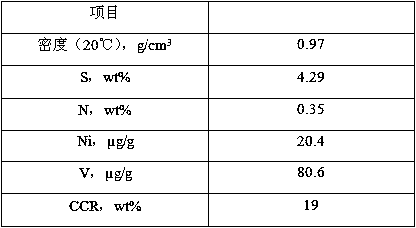

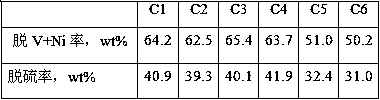

Charcoal-containing alumina support and preparation method therefor

ActiveCN109420483AAvoid destructionLarge granularityCatalyst carriersHydrocarbon oils treatmentSlurryFuel oil

The invention discloses a charcoal-containing alumina support and a preparation method therefor. The method comprises the following steps: (1) mixing pseudo-boehmite with water, carrying out pulping,adding a mixed acid solution of organic acid and inorganic acid, and carrying out heated refluxing treatment; (2) adding an alkaline nitrogen containing compound into the step (1), carrying out sealedhydrothermal treatment, and subjecting the slurry subjected to the hydrothermal treatment to washing and drying; (3) subjecting a physical pore-enlarging agent and the material obtained in the step (2) to kneading forming, and subjecting the formed substance to drying and roasting, so as to obtain an alumina support; (4) subjecting the alumina support obtained in the step (3) to imbibition with apolyol and / or monosaccharide containing solution, and carrying out drying and roasting; and (5) carrying out microwave treatment on the material obtained in the step (4). The charcoal-containing alumina support prepared by the method is suitable for serving as a hydrotreating support for heavy oil and residual oil, particularly a hydrodemetalization catalyst support, and a hydrodemetalization catalyst prepared from the hydrodemetalization catalyst support not only has relatively high hydrodemetalization activity, but also has good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

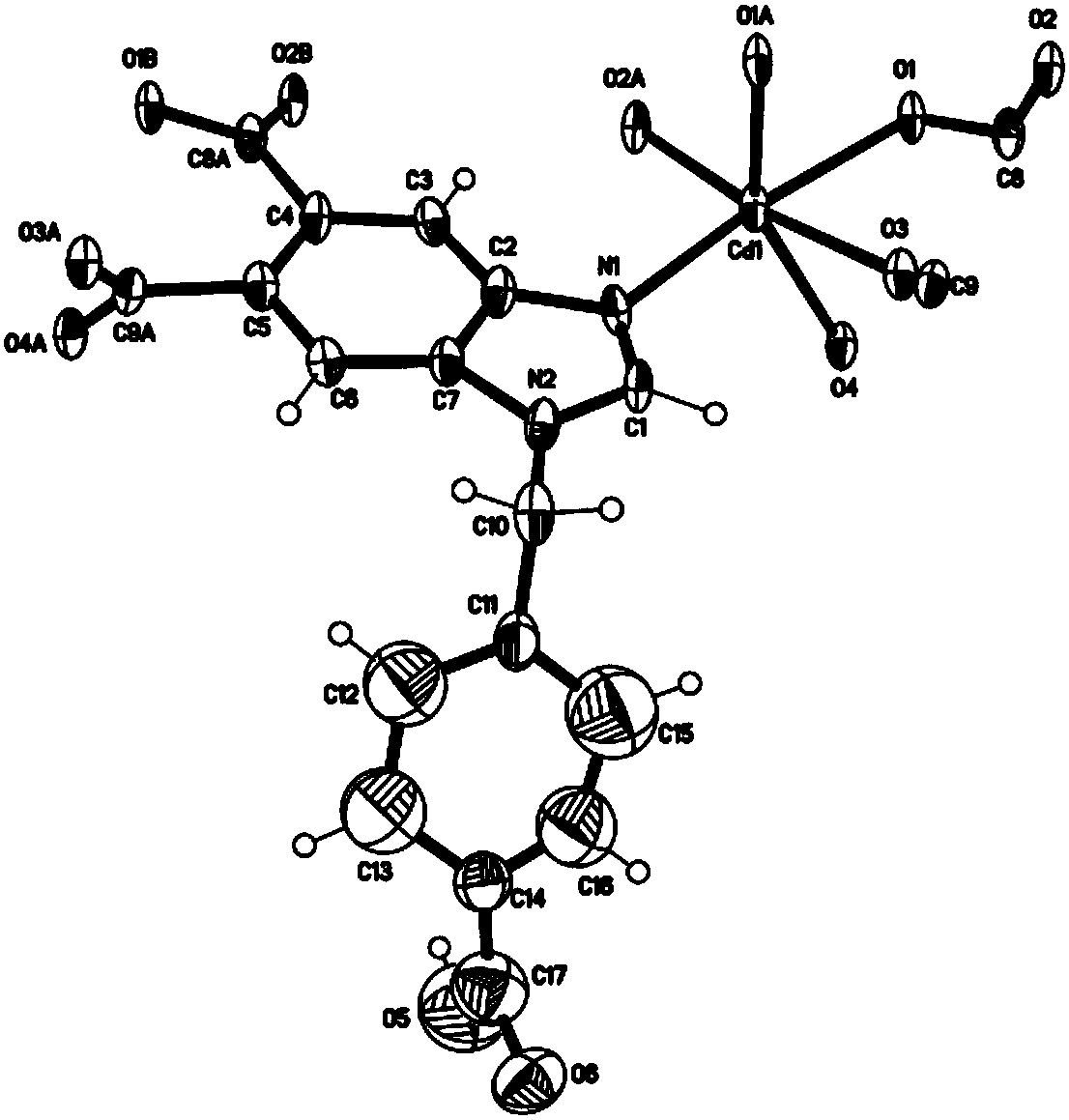

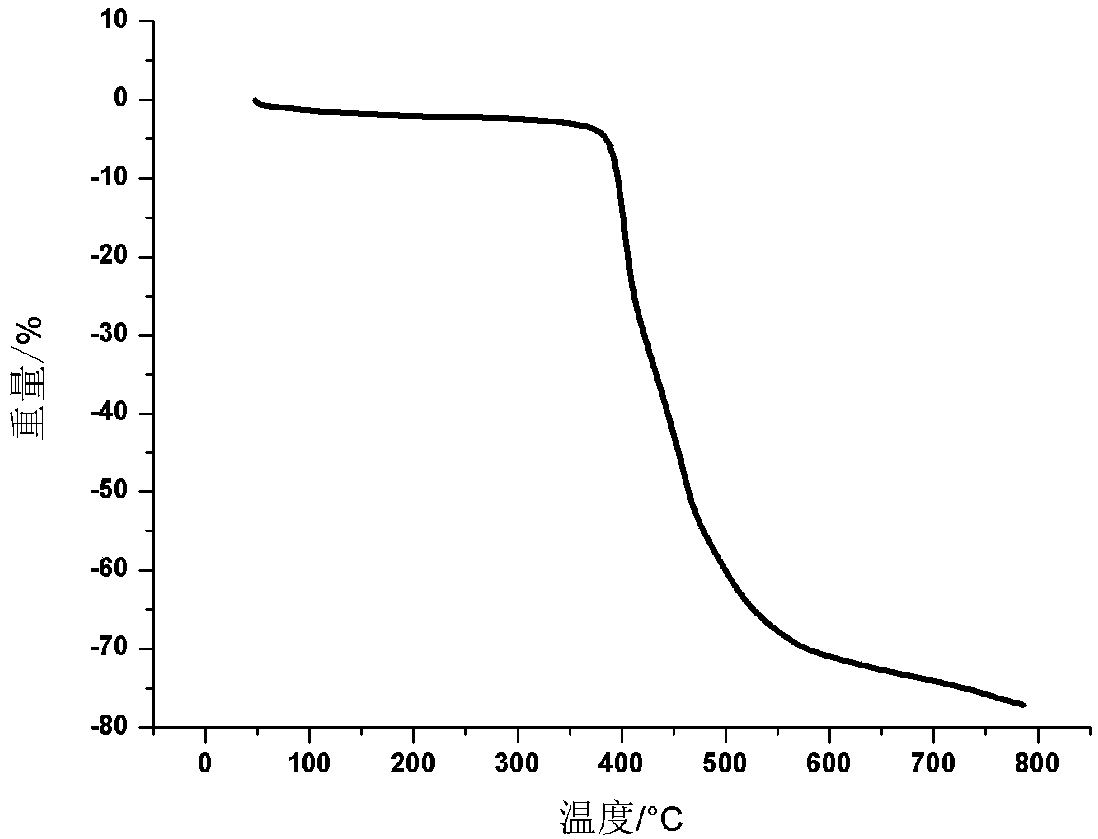

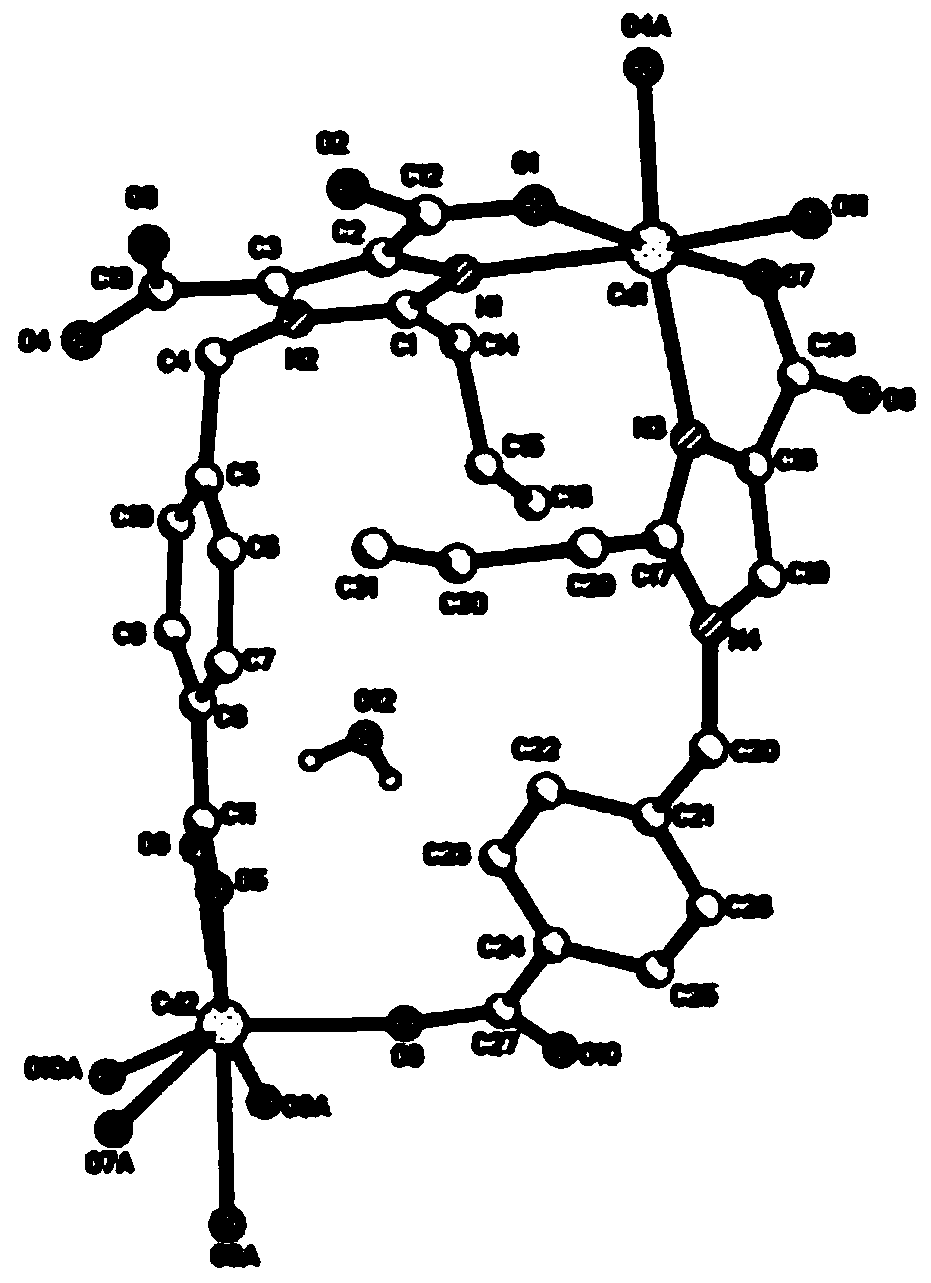

Dicaryon cadmium organic framework complex as well as preparation method and application thereof

ActiveCN108373477AEasy to prepareLow costOrganic chemistry methodsGroup 2/12 organic compounds without C-metal linkagesBulk crystalDecomposition

The invention discloses a dicaryon cadmium organic framework complex as well as a preparation method and application thereof. A chemical formula of the complex is [Cd2(Mu3-cpima)(Mu3-Hcpimda)(H2O)]n,wherein H3cpimada is 1,4-benzoyl-2-propyl-1H-imidazole-4,5-dicarboxylic acid, H2cpiama is another ligand generated by the ligand H3cpimda in reaction through decomposition, namely 1,4-benzoyl-2-propyl-1H-imidazole-4-formic acid. The preparation method comprises the following steps: adding 1,4-benzoyl-2-propyl-1H-imidazole-4,5-dicarboxylic acid and cadmium chloride in the molar ratio of 1:2 into H2O and acetonitrile in the volume ratio of 10:2, and carrying out reaction for 72 hours at the temperature of 160 DEG C in a closed reaction kettle, so that colorless bulk crystals are obtained, and yield is 67%. The complex disclosed by the invention has a two-dimensional skeleton structure, and center metal cadmium (II) ions respectively adopt a hexa-coordinate mode and a seven-coordinate mode. When a light with the wavelength of 340nm is used for exciting the solid-state complex, the emission peak of the complex appears at 400nm, CIE color coordinates are (0.24, 0.21) and are located in a blue light region, and the complex can be applied as an optical material.

Owner:SHANXI UNIV

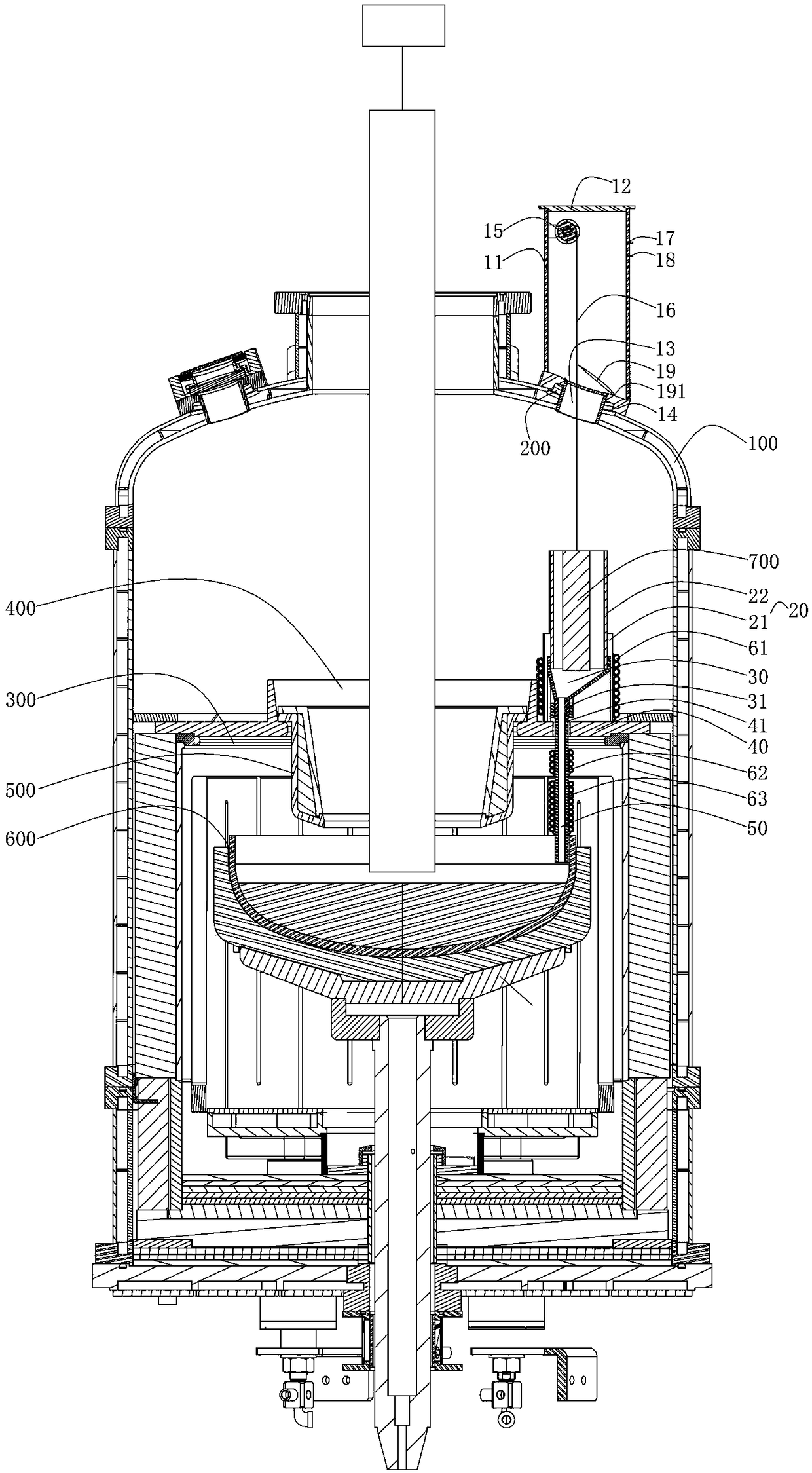

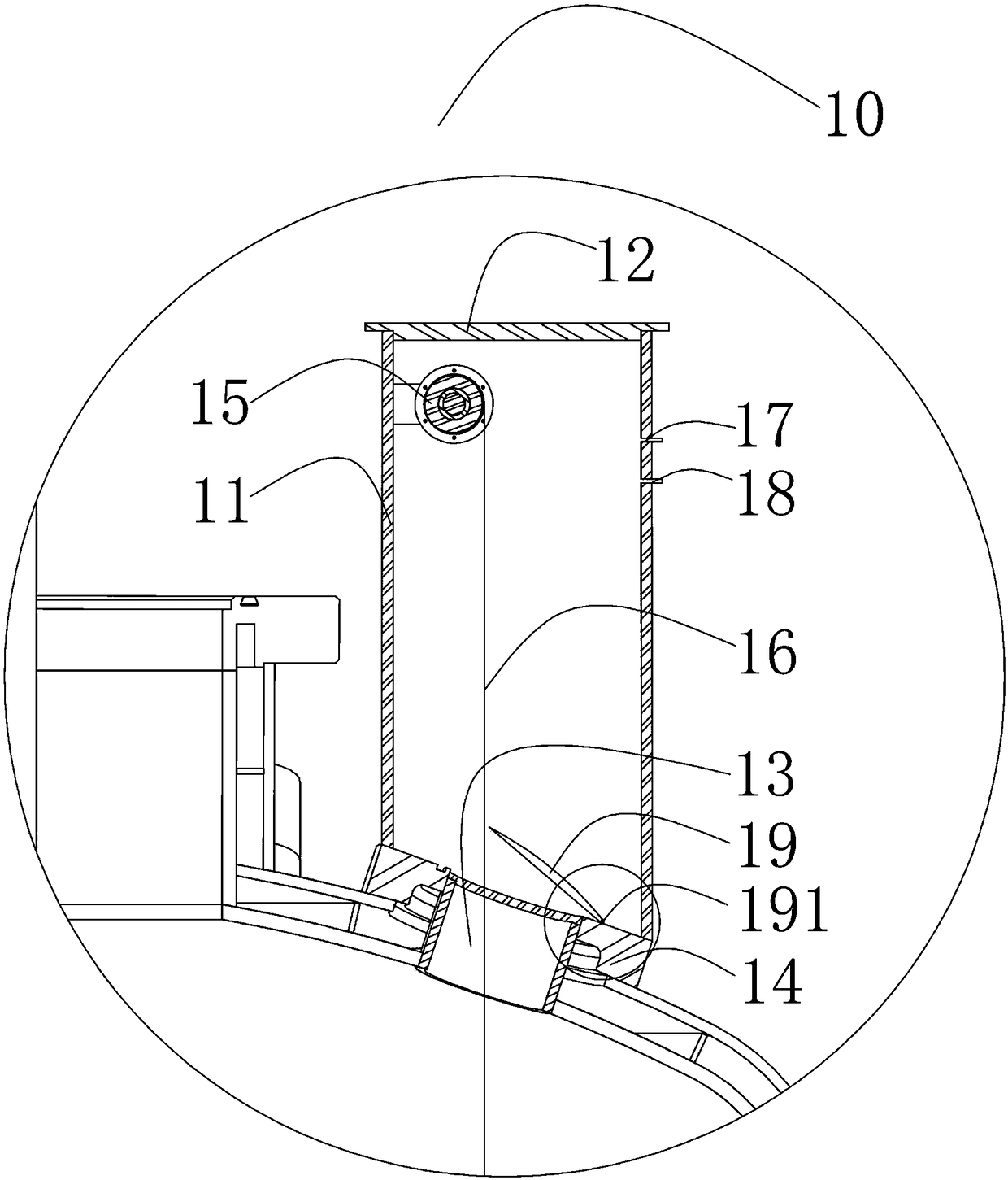

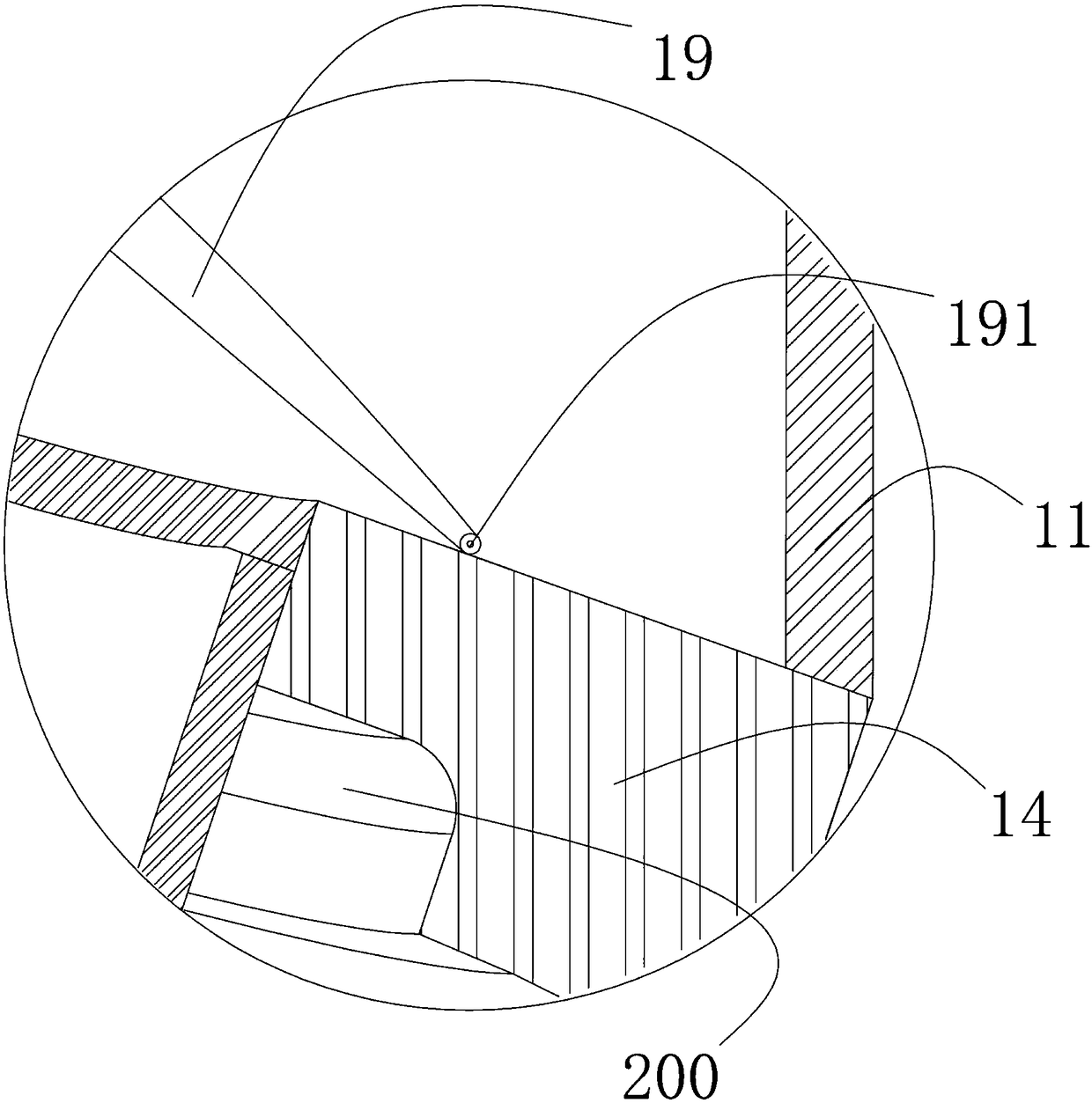

Novel continuous charging device used for single crystal furnace

PendingCN109023508ASolve for uniformitySolving Consistency IssuesPolycrystalline material growthBy pulling from meltPre-chargeLiquid crystal

The invention a novel continuous charging device used for a single crystal furnace. The novel continuous charging device used for the single crystal furnace comprises a material storage device, a transition device, a fixing device, a liquid exporting device and a heating device and also comprises a batch charging device, wherein the batch charging device is arranged on the upper end of a furnace body; the just lower end of the batch charging device is provided with a material storage device; the material storage device is arranged on the lower end of the furnace body; the inlet end of the transition device is connected with the material storage device; the transition device is arranged on the upper end of the fixing device; the inlet end of the liquid exporting device is connected with theoutlet end of the transition device; the outlet end of the liquid exporting device is arranged on the inner wall of a quartz crucible; the heating device surrounds the outer sides of the transition device and the liquid exporting device. By use of the novel continuous charging device, the problems in the prior art that silicon liquid crystal phase distribution is uneven and silicon liquid consistency is poor after silicon materials are fused are thoroughly solved, pre-charging is not required, charging and material melting time is shortened, silicon rod fusion efficiency and levels are improved, crystal pulling efficiency is improved, labor intensity and production cost are effectively lowered, and meanwhile, the novel continuous charging device is convenient for popularization since input is low.

Owner:宁夏旭樱新能源科技有限公司

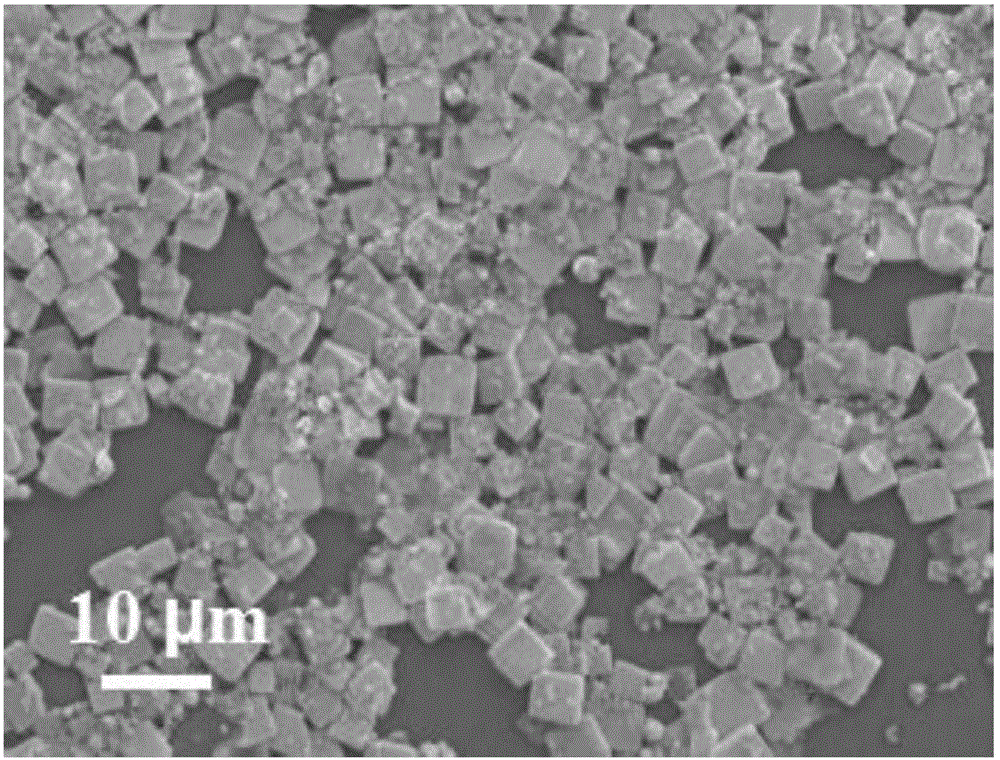

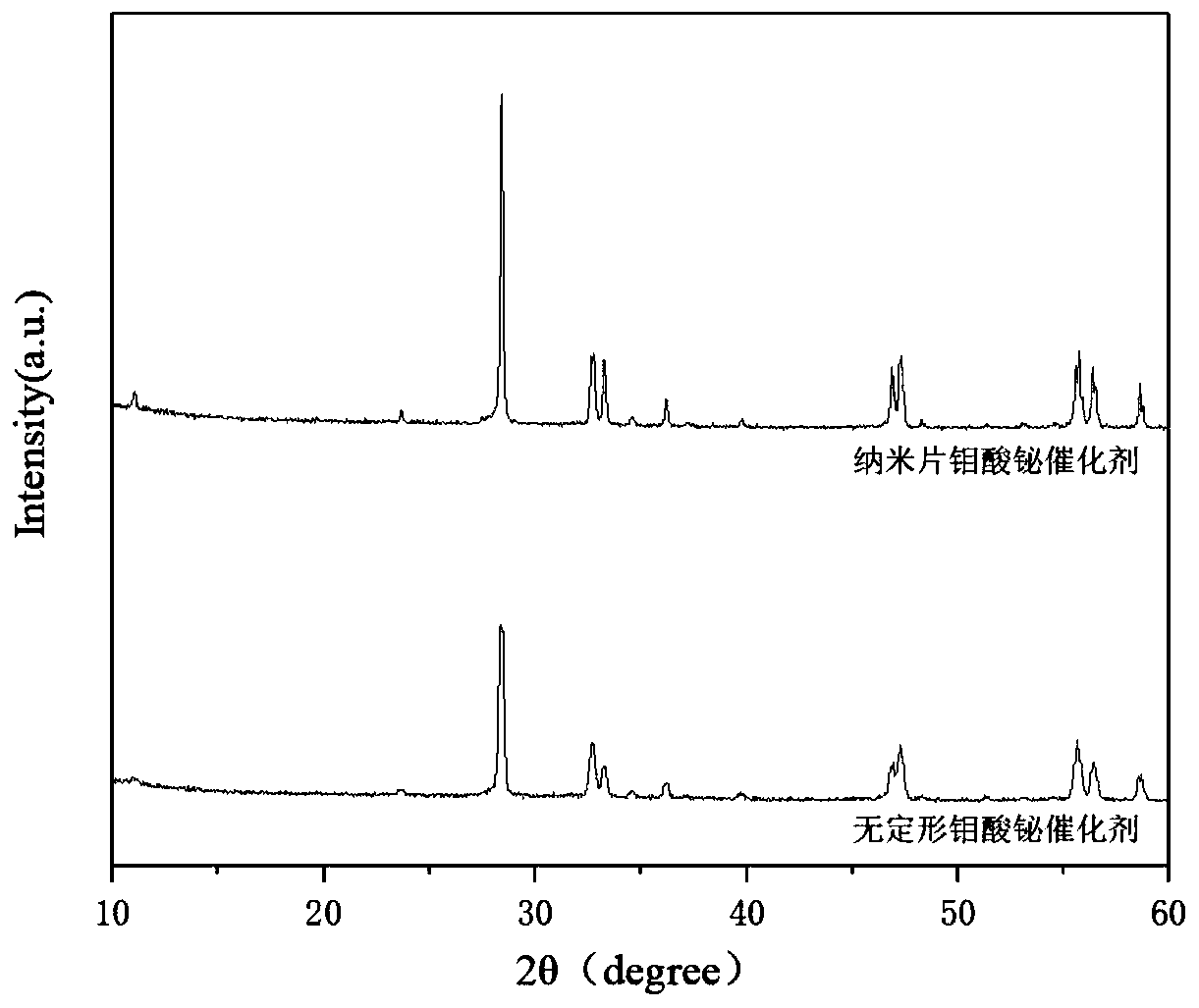

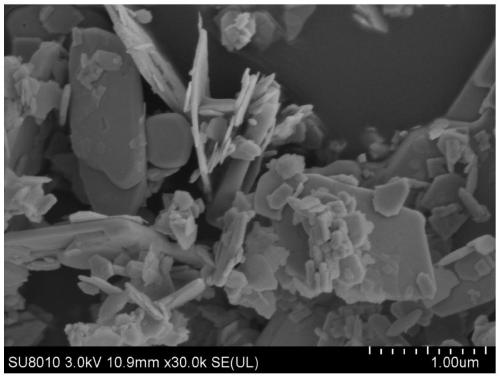

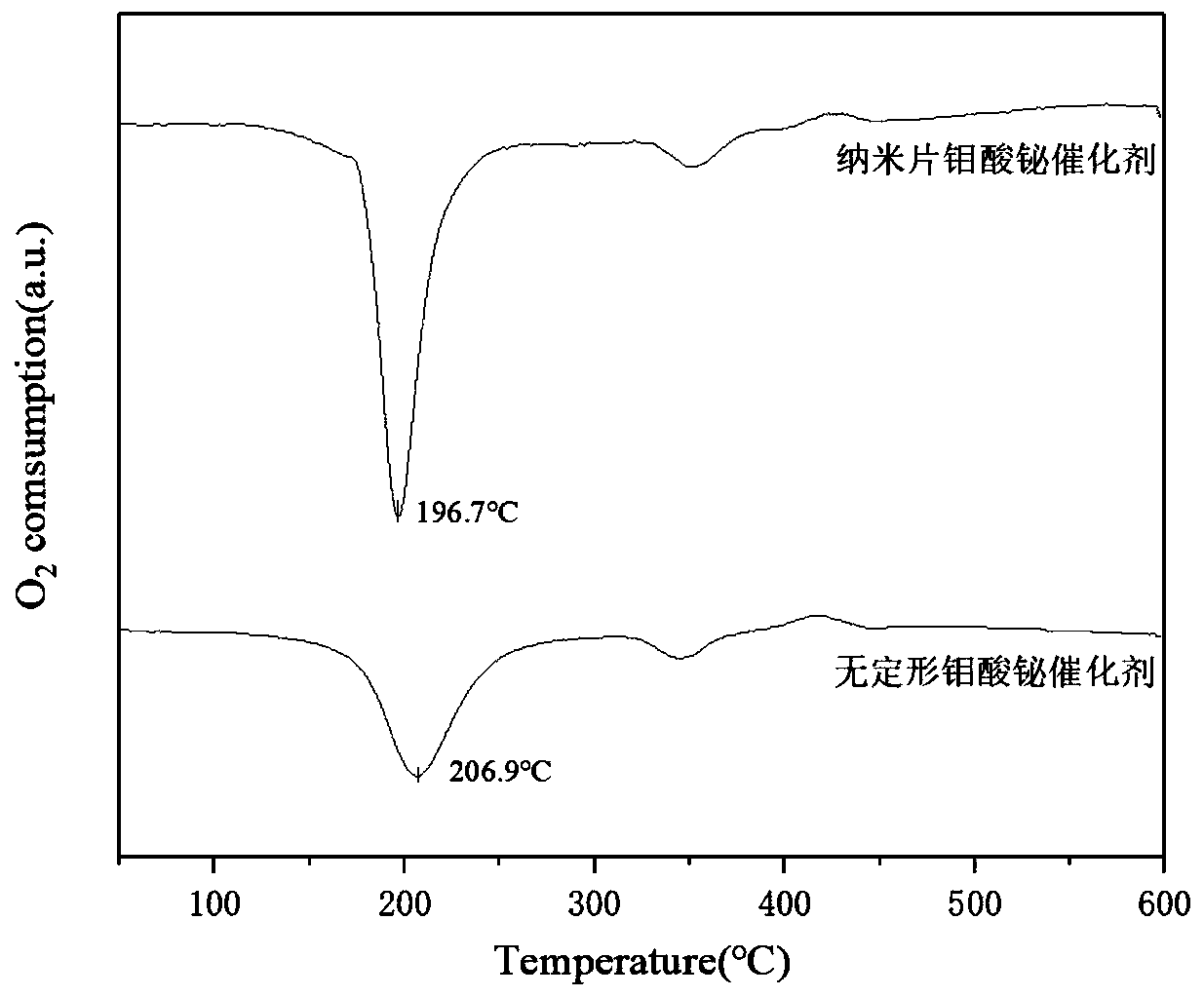

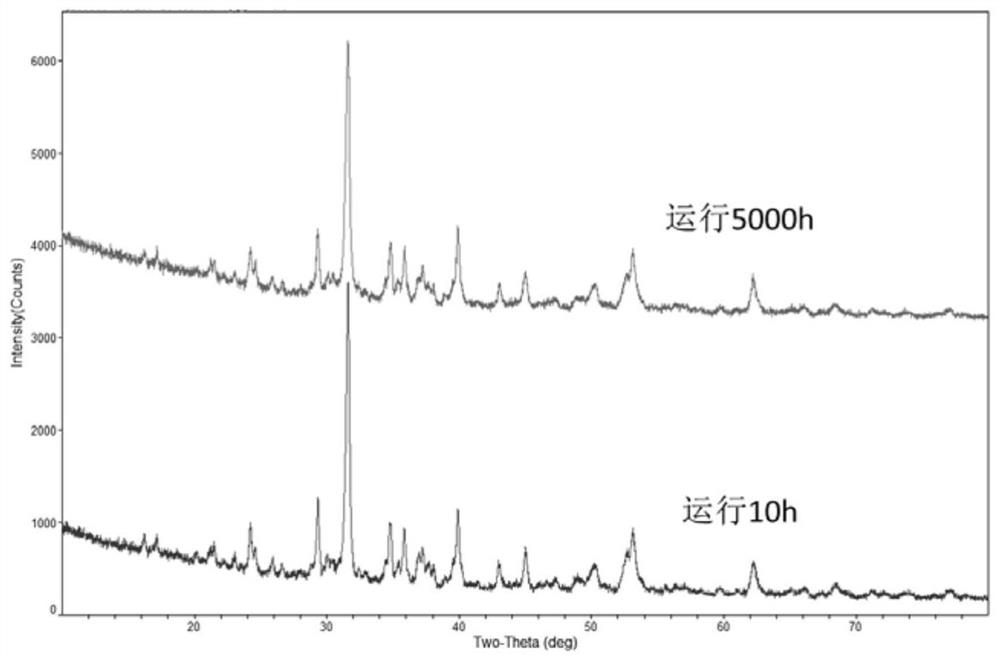

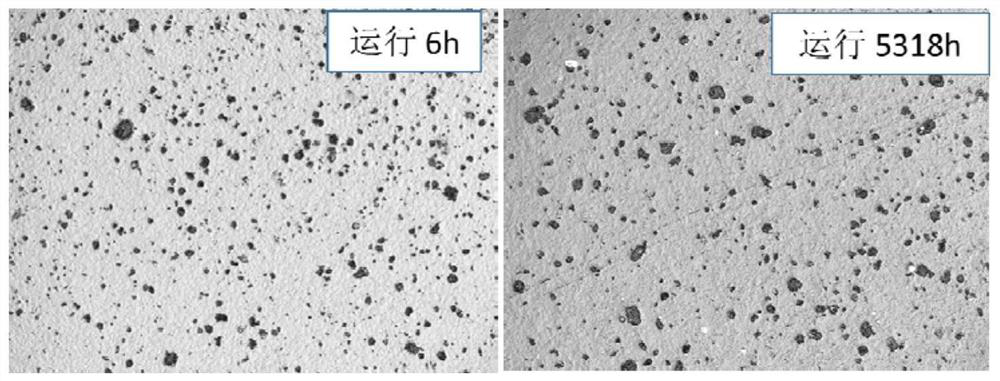

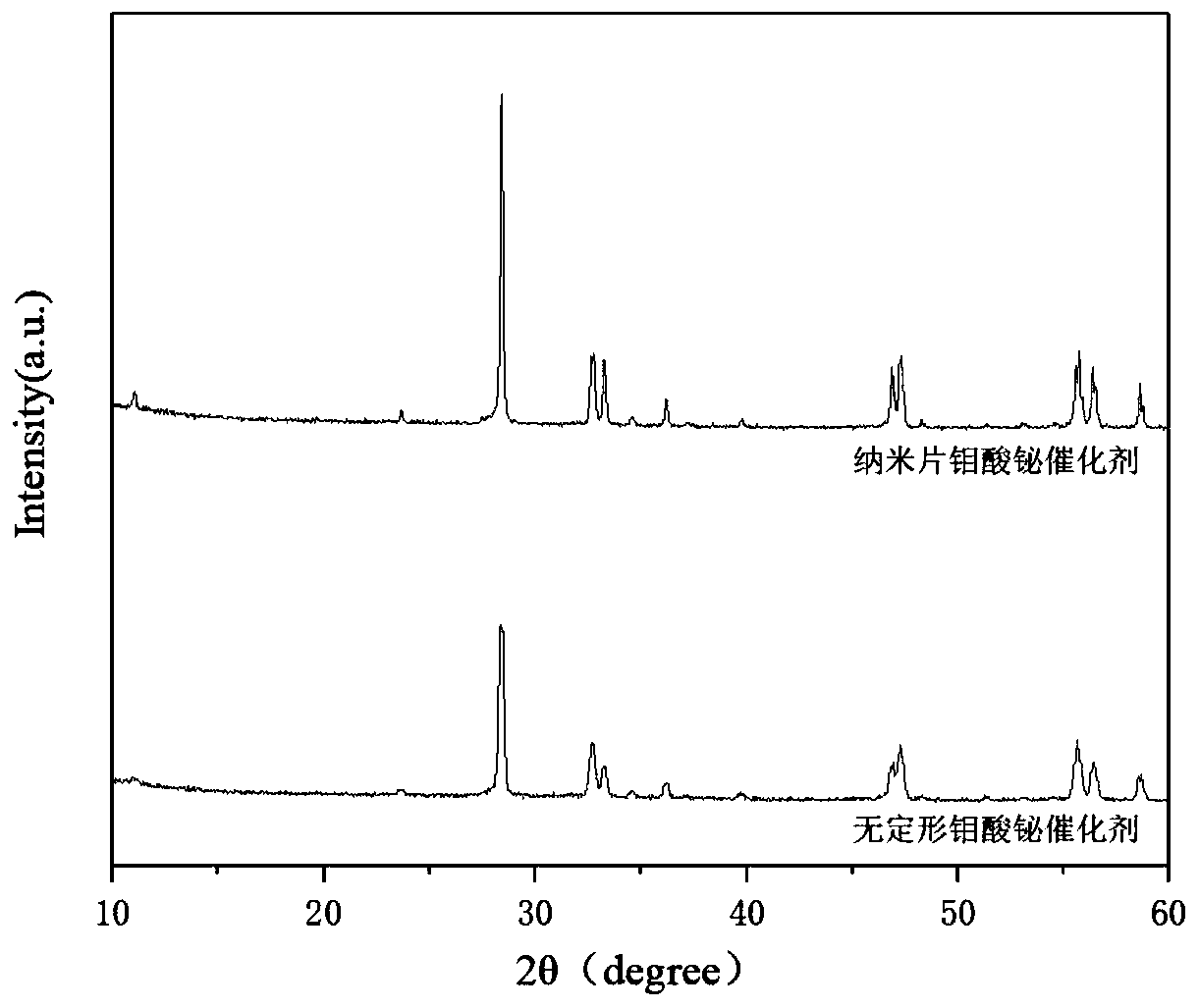

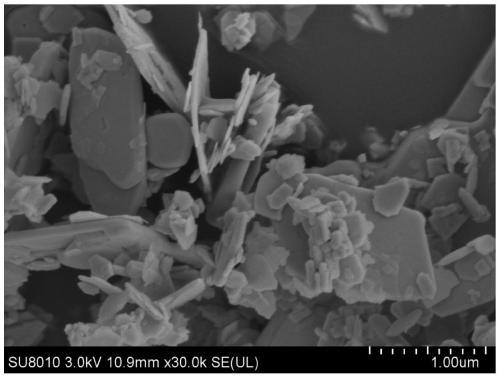

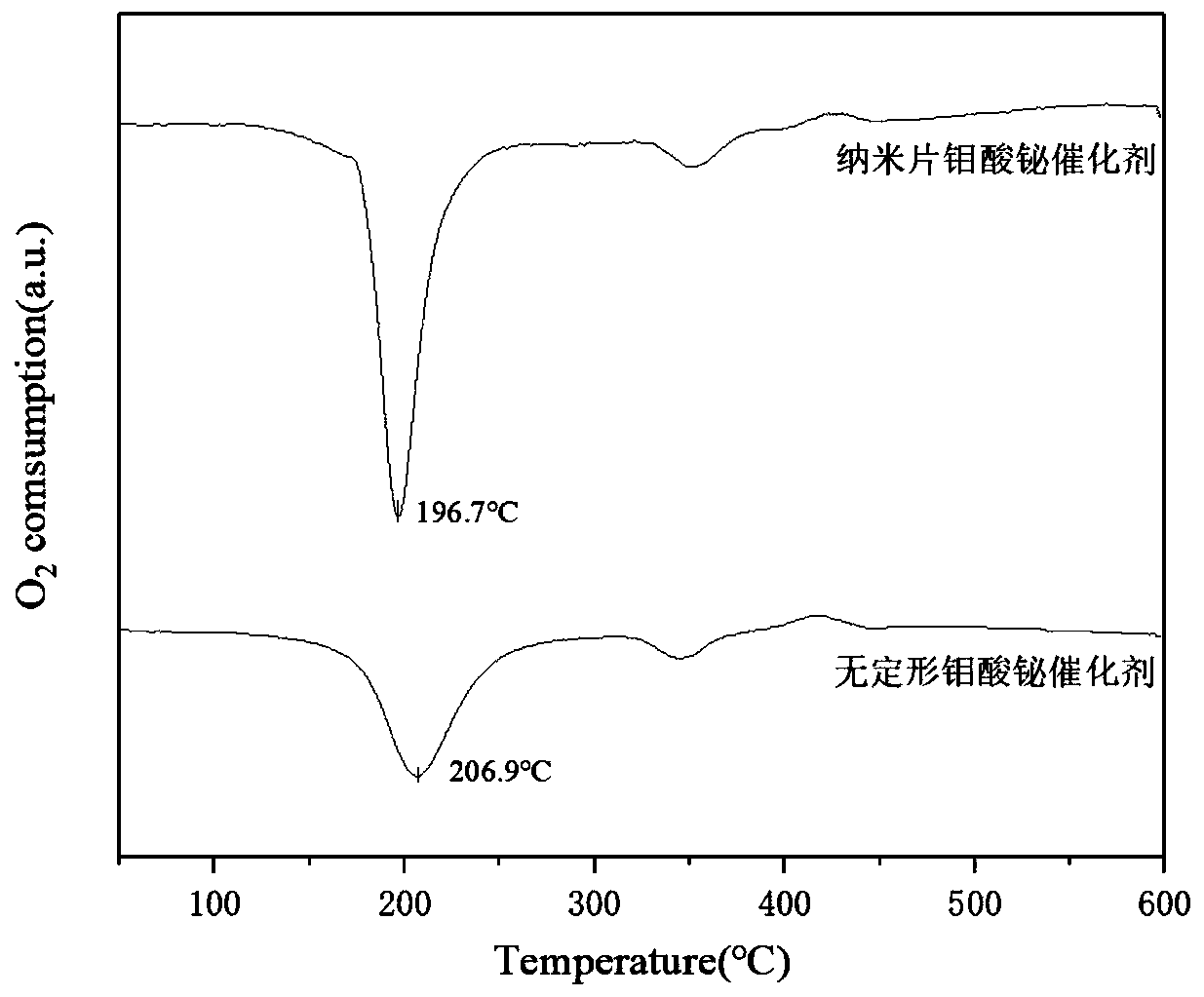

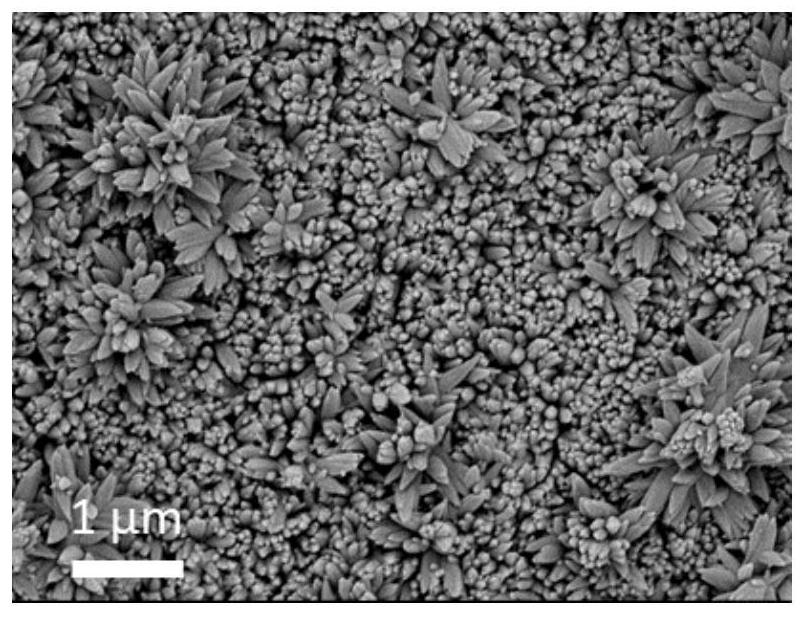

Application of bismuth molybdate catalyst with nanosheet structure in catalytic synthesis of 1,3-butadiene

ActiveCN109967066AGood effectSimple processHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsMolybdateDehydrogenation

The invention discloses a method for synthesizing 1,3-butadiene by using a bismuth molybdate catalyst with a nanosheet structure. According to the method, the bismuth molybdate catalyst with the nano-sheet structure is first prepared, and then the nanosheet catalyst is used for the oxidative dehydrogenation of 1-butene to produce 1,3-butadiene. More specifically, a bismuth salt, a molybdenum saltand deionized water are mixed according to a certain molar ratio, the pH value is adjusted by an alkaline solution, the mixture after full stirring is transferred to a PTFE lined container for hydrothermal reaction, the product is subjected to centrifugal separation, washing, drying and roasting, and then the product is subjected to grinding and sieving to obtain the bismuth molybdate catalyst with the nanosheet structure. Compared with a bismuth molybdate catalyst prepared by the traditional co-precipitation method, the catalyst has the nanosheet-shaped morphology, and exhibits better reaction performance in the reaction.

Owner:ZHEJIANG UNIV

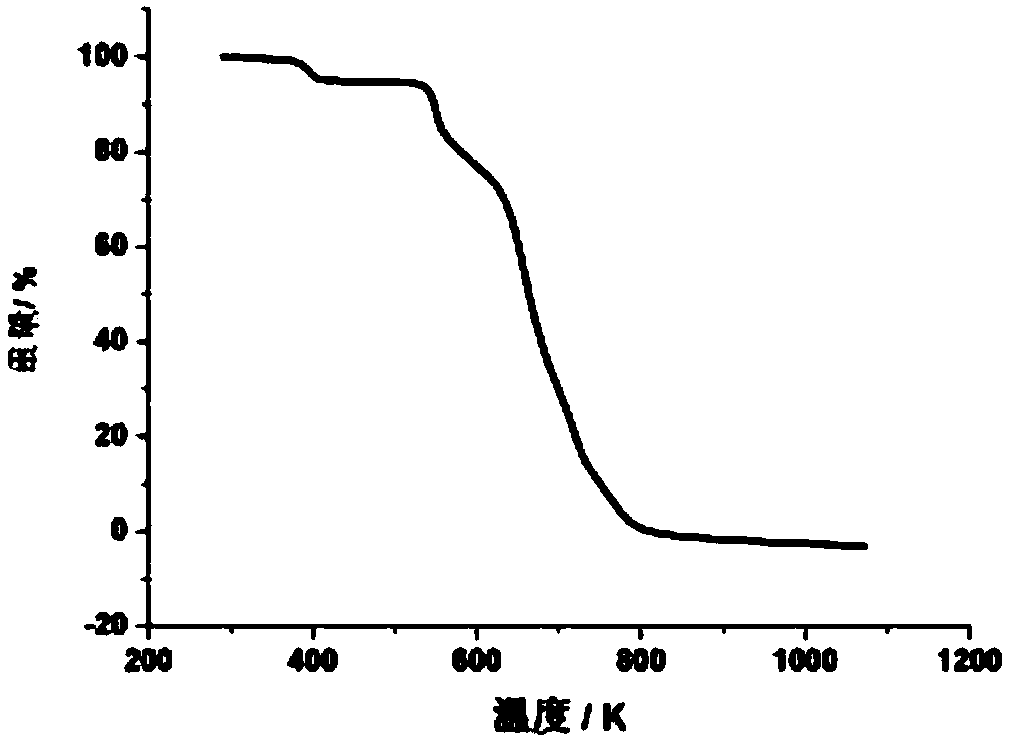

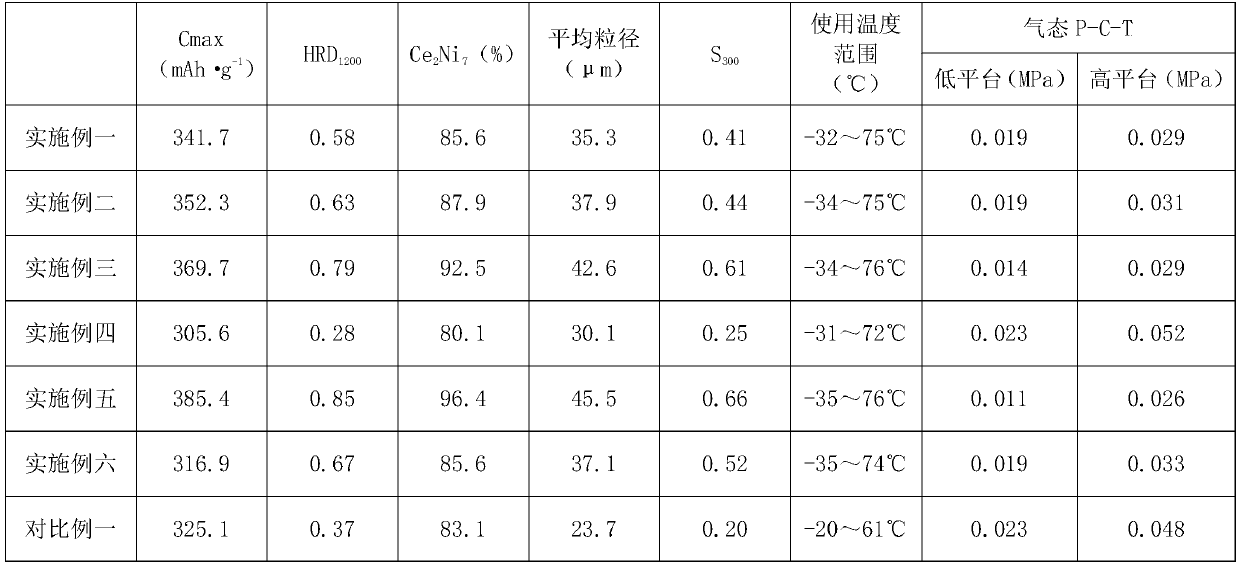

Preparation method for hydrogen storage alloy material

ActiveCN110157951AShorten process timeReduce the number of process cyclesHydrogen separation using solid contactCeriumManganese

The invention relates to a production technology for a nickel-hydrogen battery electrode material, and particularly discloses a preparation method for a hydrogen storage alloy material; the preparation method comprises the following steps of: a, measuring raw materials according to a proportion; b, sequentially inputting the raw materials into a smelting furnace with argon gas protection accordingto the feeding order of yttrium, lnthanum, cerium, manganese, samarium and nickel; c. removing moisture in the materials; d, removing low boiling point volatiles; e. fully melting the raw materials;f, repeatedly crushing and melting; g, inputting a product into the smelting furnace, wherein the temperature is raised to 850-920 DEG C, the temperature is kept for 5-10min, and then the temperatureis cooled to the normal temperature at a rate of 20-50 DEG C / min. The advantages are as follows: 1) solving the problem of Mg volatilization during alloy smelting; 2) greatly reducing the effect ofimpurities on the alloy; 3) making the internal crystal phase of the alloy more stable and increasing the number of cycles of the alloy; 4) improving the capacity of the alloy hydrogen storage material; expanding the applicable temperature of the alloy hydrogen storage material; reducing the hydrogen absorption and desorption pressure, and 5) making the alloy crystal phase more uniform.

Owner:YIBIN TIANYUAN GRP CO LTD

Process for producing iron phosphate for producing iron lithium phosphate material

The invention discloses a preparation method of iron phosphate for preparing lithium iron phosphate material, and relates to heavy metal phosphate. The steps of the method are as follows: analyticallypure soluble molysite is dissolved in distilled water, thereby being prepared into 0.05 to 5 M water solution, and being added with anionic surface-active agent with the mass being 0.01 to 3 percentof the mass of the molysite, then analytically pure phosphoric acid is added according to the mol ratio of Fe<3+>:PO4<3-> equal to 1:0.8 to 1.2 and stirred, alkaline solution with the concentration of1 to 9 M is slowly added in stirring state, the adding time is more than 1 hour until the Ph value of the solution reaches 6 to 7, the deposited matter of iron phosphate is filtered, the filtered iron phosphate is cleaned for 3 to 5 times with distilled water with the 2 to 5 times weight of the iron phosphate, the iron phosphate is dried in the range of 60 to 90 DEG C under a vacuum condition, and the finished FePO4.2H2O powder is gotten. The iron phosphate product with two crystal water prepared by the invention has high reaction activity, and the performance of the lithium iron phosphate material prepared with the iron phosphate product is superior to the lithium iron phosphate material prepared with the commercial iron phosphate product.

Owner:HEBEI UNIV OF TECH

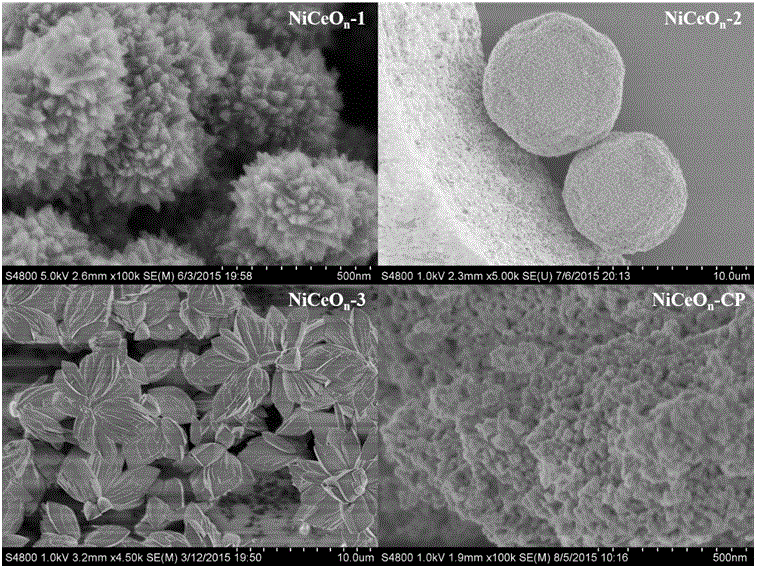

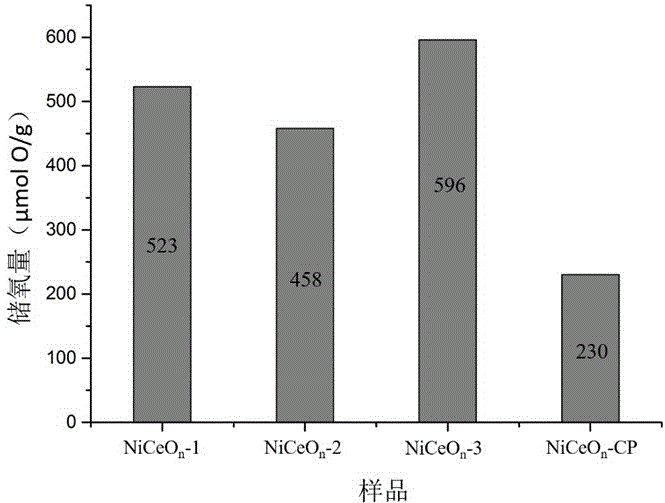

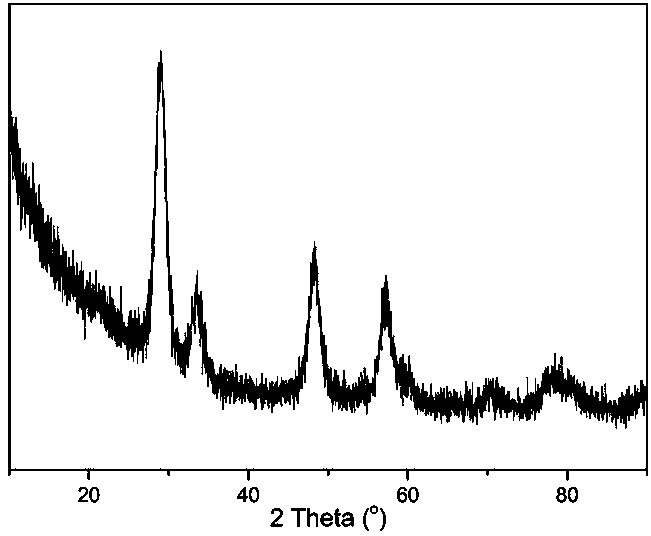

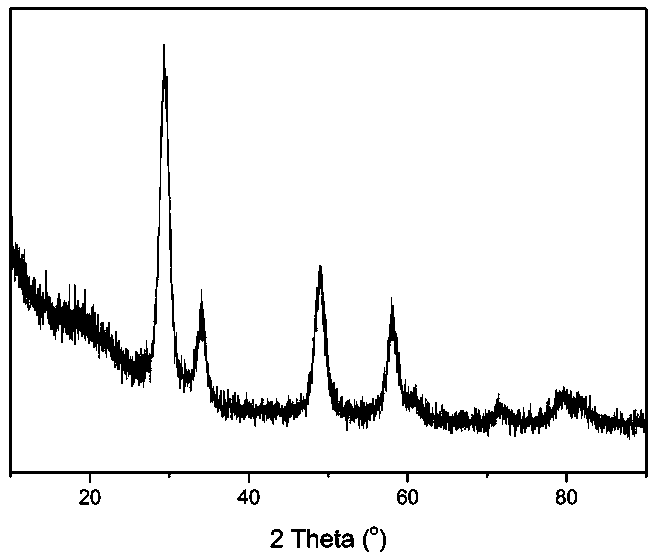

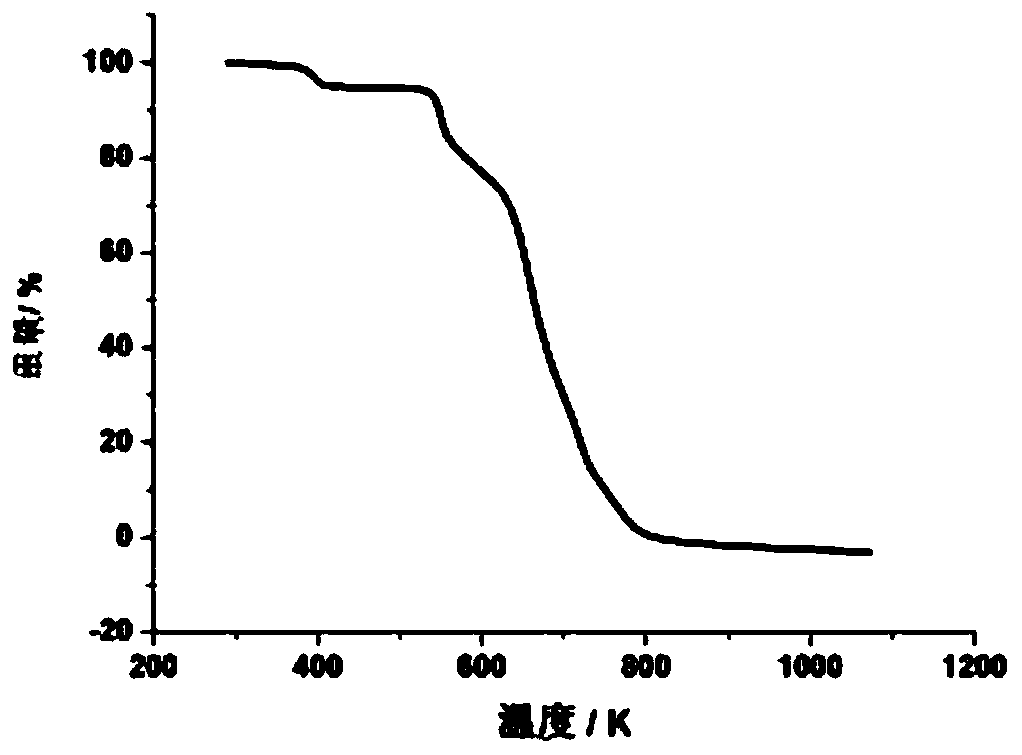

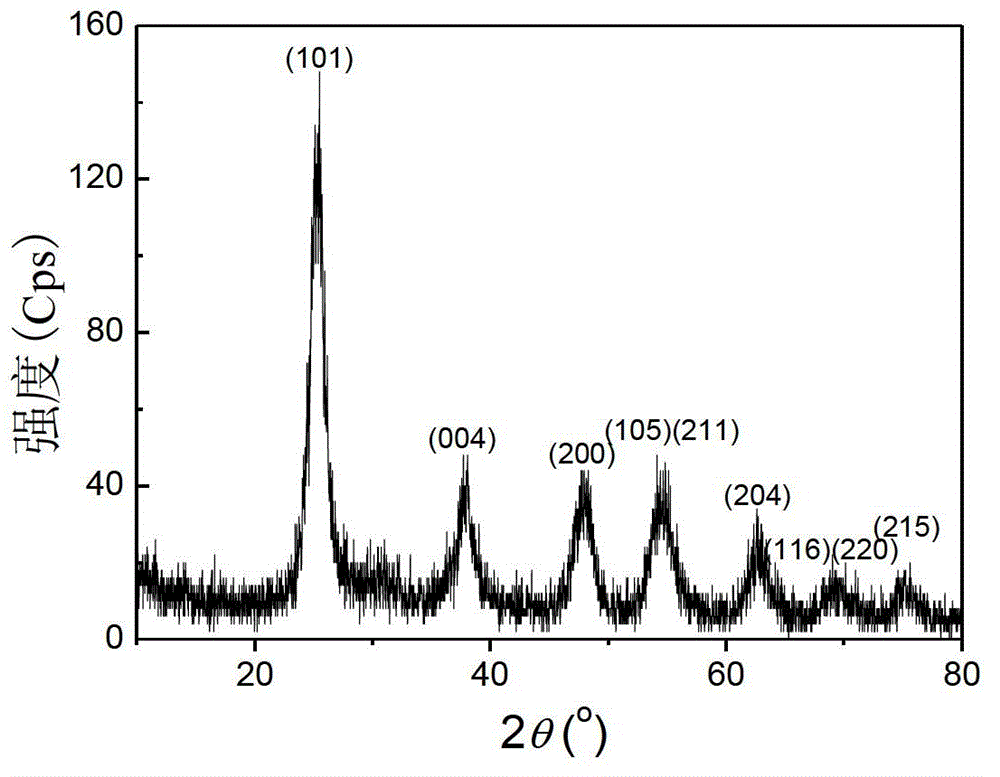

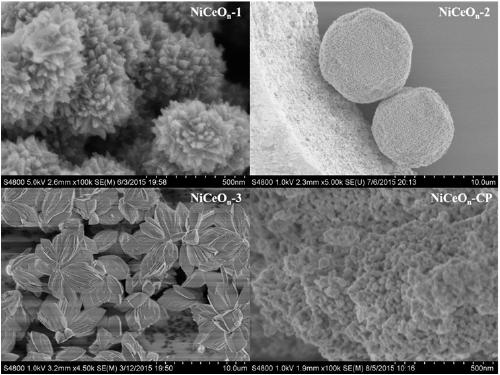

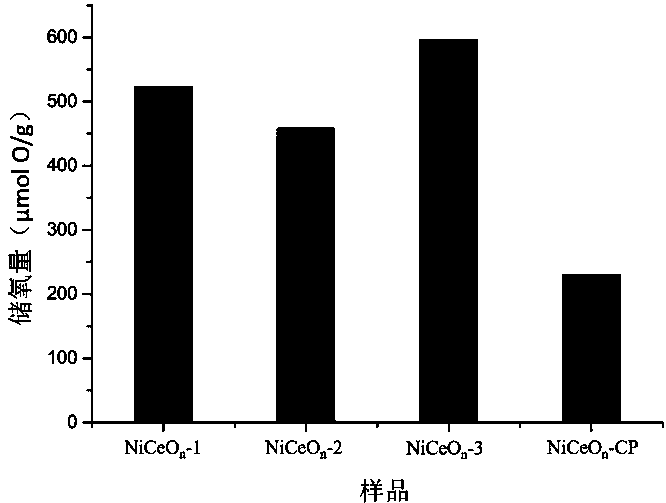

Method for preparing nickel-cerium solid solution material through ultrasonic assistance

ActiveCN106745334AUniform crystal phaseImprove doping efficiencyNickel compoundsDispersityNickel salt

The invention belongs to the technical field of solid material preparation, and particularly relates to a method for preparing a nickel-cerium solid solution material through ultrasonic assistance. The method comprises the steps that nickel salt, cerium salt, organic acid and an organic macromolecular structure guide agent sufficiently interact through the ultrasonic assistance in a solvent heat treatment manner; and under a self-assembly effect, a flower-shaped or spherical nickel-cerium solid solution with a uniform crystalline phase is formed. The nickel-cerium solid solution material prepared by the method is lower in nickel content, has the characteristics of high specific surface area, high nickel atom dispersity, small crystal particle size, uniform crystalline phase and the like, has excellent oxidoreduction performance and oxygen storage and release performance, has the oxygen storage quantity of 400-600 [mu]mol O / g, and has good application prospects in the fields of environment catalysis, solid fuel batteries, sensors and the like.

Owner:FUDAN UNIV

A kind of preparation method of high-performance cerium-zirconium solid solution material

ActiveCN106732521BUniform structureUniform crystal phaseGas treatmentZirconium compoundsPhysical chemistryCerium

The invention belongs to the technical field of solid material preparation, and is specifically a preparation method of high-performance cerium-zirconium solid solution material. The present invention uses spray feeding to uniformly mix metal cerium salts, metal zirconium salts, precipitants and surfactants, and by adjusting the feeding rate, the crystal seeds generated in the solution are used to induce the formation of precipitates, and finally through hydrothermal treatment After the aging and roasting process, the cerium-zirconium composite material is obtained. The present invention uses the method of spray feeding and controlling the feeding speed to induce the formation of precipitates by utilizing the tiny crystal seeds produced in the solution in the early stage of precipitation, thereby improving the uniformity of the precipitation process and thus promoting the formation of cerium-zirconium solid solution. The preparation process of this method is simple and the production cost is low. The prepared cerium-zirconium solid solution has the characteristics of uniform structure, small particle size, large specific surface area, good stability, etc., and has excellent oxygen storage / release performance. It is a large-scale High-performance cerium-zirconium solid solution materials with promising production and industrial applications.

Owner:FUDAN UNIV

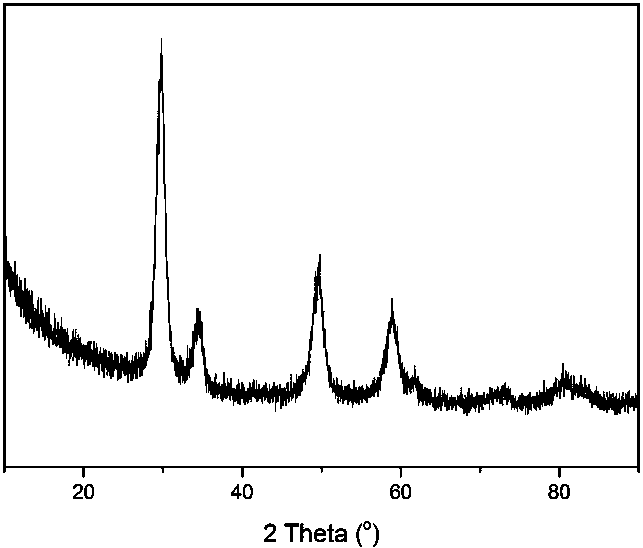

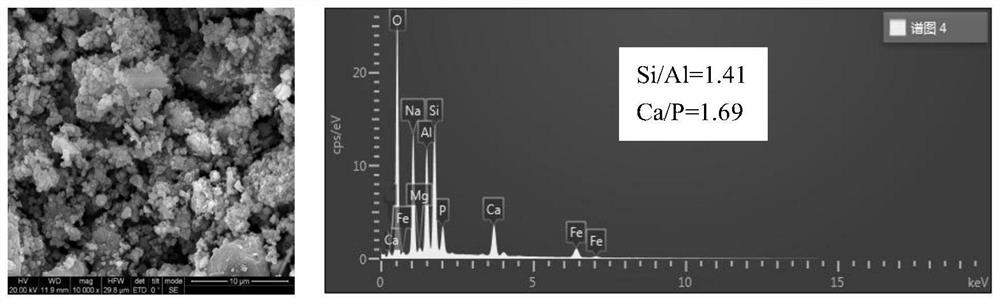

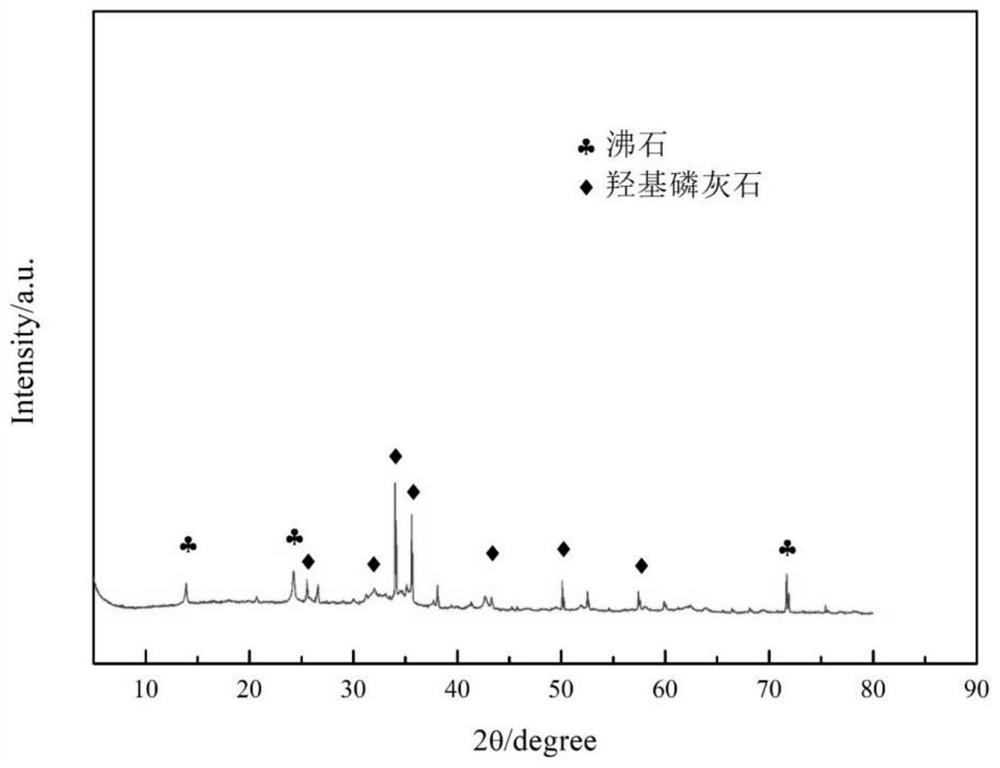

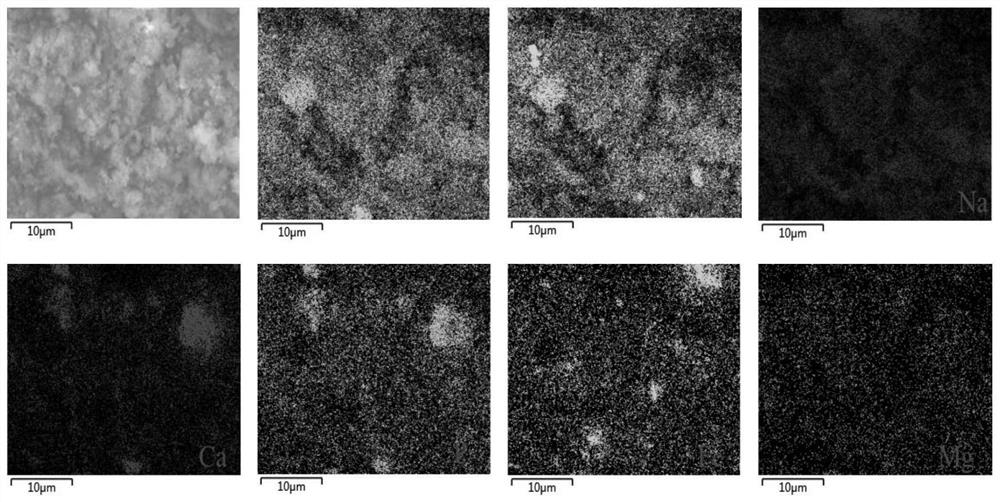

Preparation method of blast furnace slag-based composite material

ActiveCN113086958AHigh crystallinityImprove conversion rateOther chemical processesRecycling and recovery technologiesSlagPhosphate

The invention discloses a preparation method of a blast furnace slag-based composite material, and belongs to the technical field of recycling of industrial waste residues. The method mainly comprises the following steps: (1) alkali fusion of blast furnace slag, (2) a reaction with phosphate, and (3) hydrothermal aging to prepare the blast furnace slag-based hydroxyapatite-zeolite composite material with high added value, and comprehensive utilization of useful components in the blast furnace slag is realized. The method disclosed by the invention has the characteristics of strong adaptability, simple process, convenience in operation, mild reaction conditions, high added value of products and the like; according to the method, the blast furnace slag is used as a cheap raw material, so that the environmental problem caused by massive stockpiling of the blast furnace slag can be effectively relieved, and the construction and operation cost of a storage yard of an enterprise can be reduced to a certain extent.

Owner:NANJING UNIV OF TECH

Glass, and preparation method and application thereof

PendingCN112047638AGuaranteed chemical stabilityEnsure structural stabilityThermal dilatationFuel cells

The invention relates to the technical field of glass production, and especially relates a glass, and a preparation method and application thereof. The glass provided by the invention comprises, by weight, 20-50% of CaO, 10-40% of MgO, 10-40% of SiO2, 1-30% of B2O3, 0-5% of ZrO2, 0-5% of Al2O3 and 0-5% of La2O3. According to the glass, the proportion of each component is adjusted, the ratio of a glass phase to a ceramic phase is adjusted, the thermal expansion coefficient of the glass is increased, the thermal expansion coefficient of the glass is measured to be 10.95-11.65 ppm / DEG C through experiments, and the thermal expansion coefficient is large, and is matched with the thermal expansion coefficient of a common material stainless steel of a connector of a solid oxide fuel cell, so therisk of battery leakage caused by mismatching of thermal expansion coefficients of the two can be reduced.

Owner:CHAOZHOU THREE CIRCLE GRP +1

Application of Bismuth Molybdate Catalyst with Nanosheet Structure in Catalytic Synthesis of 1,3-Butadiene

ActiveCN109967066BGood effectSimple processHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsButenePtru catalyst

Owner:ZHEJIANG UNIV

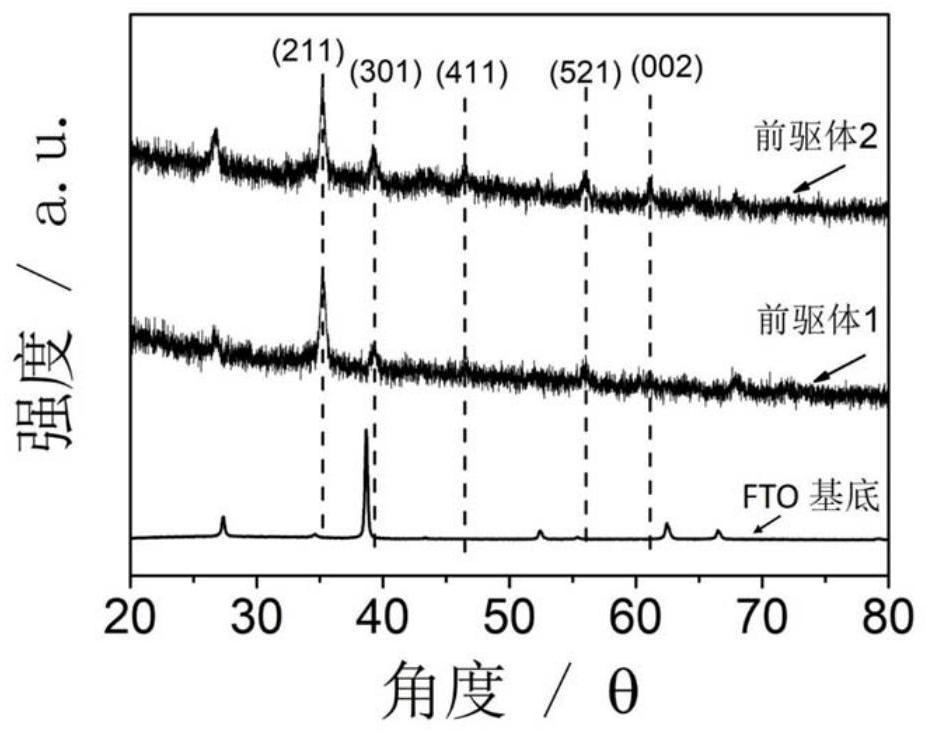

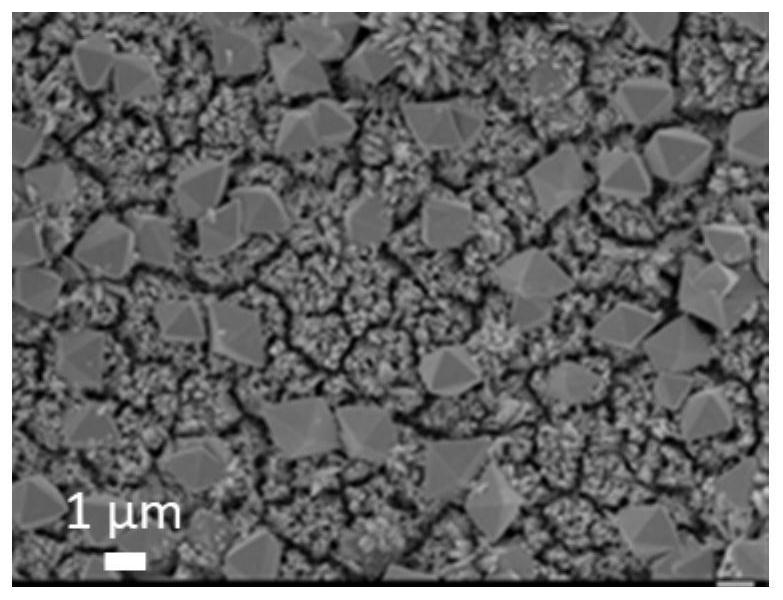

A method for preparing polyhedral iron oxyhydroxide film by corrosion recrystallization method

Owner:GUANGZHOU UNIVERSITY

A kind of cadmium organic framework complex and preparation method thereof

ActiveCN107417712BEasy to prepareLow costLuminescent compositionsCadmium organic compoundsCadmium CationTerephthalic acid

The invention discloses a cadmium organic framework compound and a preparation method thereof. A chemical formula of the compound is [Cd(L)(H2O)2]n, wherein H2L is 2,5-di(1H-1,2,4-triazolyl)terephthalic acid. The preparation method comprises the following steps: adding the H2L and cadmium nitrate with the mol ratio of 1 to 2 into H2O and DMF (Dimethyl Formamide) with the volume ratio of 4 to 1; after stirring the components at the room temprature for 30min, enabling a mixture to react at 120 DEG C for 72h in a closed reaction kettle, so as to obtain a colorless rhombus-shaped crystal, with the yield of 76 percent. The compound disclosed by the invention has a three-dimensional framework structure; a cadmium ion adopts a six-coordinated octahedral coordination mode. When the solid-state compound is stimulated by light with the wavelength of 320nm, the compound has an emission peak at a the part with the wavelength of 414nm and a CIE chromaticity coordinate is (0.15, 0.0439) and is located in a blue-ray region; the compound can be used as an optical material.

Owner:SHANXI UNIV

A kind of binuclear cadmium organic framework complex and its preparation method and application

ActiveCN108373477BEasy to prepareLow costOrganic chemistry methodsGroup 2/12 organic compounds without C-metal linkagesBulk crystalPhotochemistry

The invention discloses a dicaryon cadmium organic framework complex as well as a preparation method and application thereof. A chemical formula of the complex is [Cd2(Mu3-cpima)(Mu3-Hcpimda)(H2O)]n,wherein H3cpimada is 1,4-benzoyl-2-propyl-1H-imidazole-4,5-dicarboxylic acid, H2cpiama is another ligand generated by the ligand H3cpimda in reaction through decomposition, namely 1,4-benzoyl-2-propyl-1H-imidazole-4-formic acid. The preparation method comprises the following steps: adding 1,4-benzoyl-2-propyl-1H-imidazole-4,5-dicarboxylic acid and cadmium chloride in the molar ratio of 1:2 into H2O and acetonitrile in the volume ratio of 10:2, and carrying out reaction for 72 hours at the temperature of 160 DEG C in a closed reaction kettle, so that colorless bulk crystals are obtained, and yield is 67%. The complex disclosed by the invention has a two-dimensional skeleton structure, and center metal cadmium (II) ions respectively adopt a hexa-coordinate mode and a seven-coordinate mode. When a light with the wavelength of 340nm is used for exciting the solid-state complex, the emission peak of the complex appears at 400nm, CIE color coordinates are (0.24, 0.21) and are located in a blue light region, and the complex can be applied as an optical material.

Owner:SHANXI UNIV

Method for modifying and dyeing polyester fiber by use of silver-doped nano titanium dioxide disperse dye

ActiveCN103215804BImprove photocatalytic activityImprove antibacterial propertiesFibre typesDyeing processDisperse dyeSodium hydroxide

The invention discloses a method for modifying and dyeing polyester fiber by use of silver-doped nano titanium dioxide disperse dye. The method comprises the following steps of: soaking the polyester fiber in a sodium hydroxide solution for etching; cleaning and drying the etched polyester fiber; preparing a modification and dyeing mixed solution; performing modification and dyeing composition finishing on the polyester fiber after the etching treatment in the first step by use of the modification and dyeing solution; and finally, cleaning and drying the modified polyester fiber. The method disclosed by the invention solves the problems that the polyester fiber prepared by an existing modification method has low photocatalytic activity under visible light, a poor self-cleaning function and non-lasting washing resistance and that the modified polyester fiber or fabric has poor handfeel and air permeability.

Owner:XI'AN POLYTECHNIC UNIVERSITY

A kind of ultrasonic-assisted method for preparing nickel-cerium solid solution material

ActiveCN106745334BUniform crystal phaseImprove doping efficiencyNickel compoundsDispersityNickel salt

The invention belongs to the technical field of solid material preparation, and particularly relates to a method for preparing a nickel-cerium solid solution material through ultrasonic assistance. The method comprises the steps that nickel salt, cerium salt, organic acid and an organic macromolecular structure guide agent sufficiently interact through the ultrasonic assistance in a solvent heat treatment manner; and under a self-assembly effect, a flower-shaped or spherical nickel-cerium solid solution with a uniform crystalline phase is formed. The nickel-cerium solid solution material prepared by the method is lower in nickel content, has the characteristics of high specific surface area, high nickel atom dispersity, small crystal particle size, uniform crystalline phase and the like, has excellent oxidoreduction performance and oxygen storage and release performance, has the oxygen storage quantity of 400-600 [mu]mol O / g, and has good application prospects in the fields of environment catalysis, solid fuel batteries, sensors and the like.

Owner:FUDAN UNIV

Raney nickel catalyst for low-pressure hydrogenation of dinitrotoluene and its preparation method and application

InactiveCN103977818BReduce energy consumptionTemperature rises fastOrganic compound preparationAmino compound preparationSolventToluene

A Raney nickel catalyst used for low-pressure hydrogenation of dinitrotoluenem. The catalyst is characterized by comprising, by mass, 80-90 wt% of nickel, 5-10 wt% of aluminium and 1.65-10 wt% of an auxiliary agent metal, wherein the nickel is in the form of a simple substance, the aluminium is in the form of the simple substance of an oxide and the auxiliary agent metal is in the form of the oxide. The catalyst is low in price and has an excellent performance of catalytic hydrogenation of the dinitrotoluenem (DNT) without an additional solvent and under a low-pressure condition of 1Mpa.

Owner:TAIYUAN UNIV OF TECH +1

Modification of Nylon Swimsuit Fabric and Dyeing Composite Finishing Method

ActiveCN103757875BLittle impact on hand feelingWide spectral response rangeFibre typesDyeing processSulfonatePre treatment

The invention discloses a modifying and dyeing composite finishing method for brocade ammonia swimming wear fabric. The modifying and dyeing composite finishing method is specifically implemented according to the following steps: step 1) performing pretreatment on the brocade ammonia swimming wear fabric by using a sodium hydroxide solution, then sequentially soaking in an ethanol solution, washing with deionized water, and finally drying to obtain the clean brocade ammonia swimming wear fabric; step 2) preparing a composite finishing solution containing tetrabutyl titanate, ethanol, silver nitrate, sodium dodecyl sulfonate, an acid dye and a water repellent agent, namely AG-7620, and performing modifying and dyeing composite finishing on the brocade ammonia swimming wear fabric obtained in the step 1) in a hydrothermal environment; step 3) preparing a washing solution, washing the modified and dyed brocade ammonia swimming wear fabric obtained in the step 2) with the washing solution, and finally drying the modified and dyed brocade ammonia swimming wear fabric. According to the modifying and dyeing composite finishing method for the brocade ammonia swimming wear fabric, disclosed by the invention, the modification and the dyeing can be simultaneously performed on the brocade ammonia swimming wear fabric.

Owner:HOSA IND FUJIAN

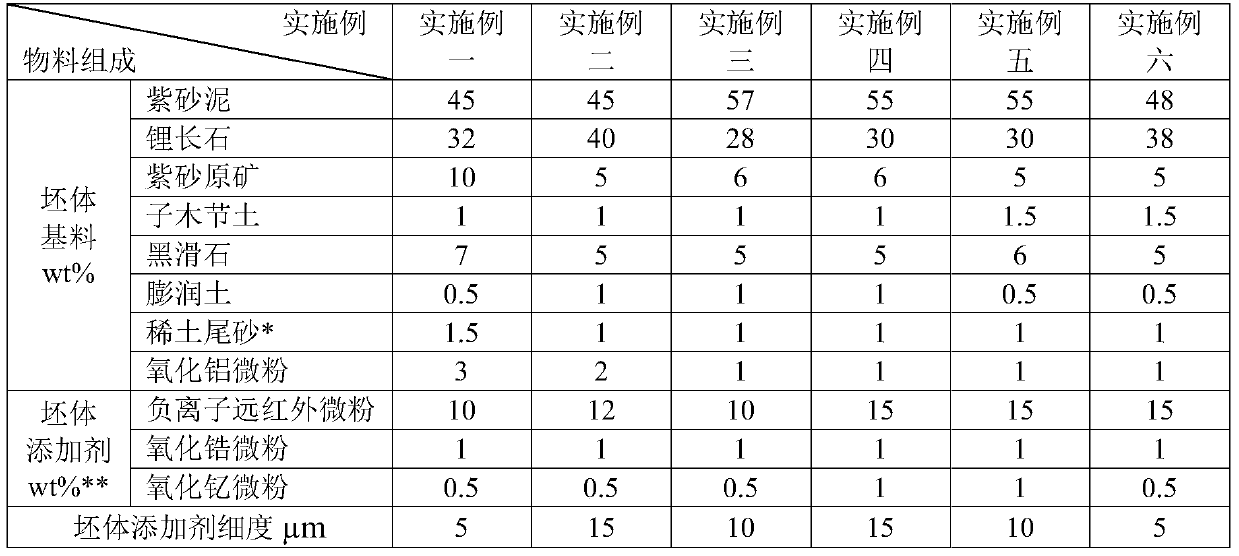

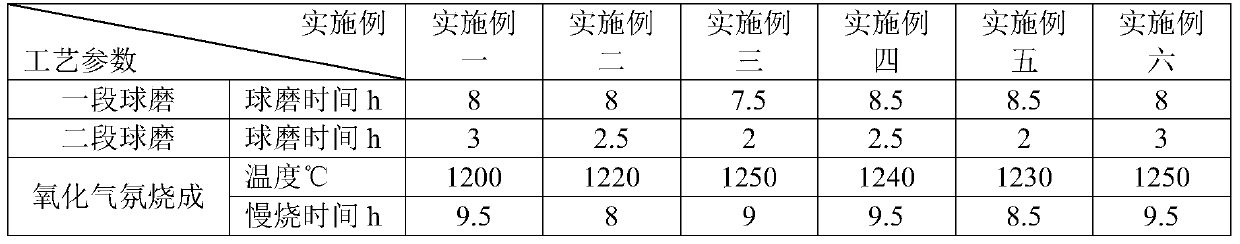

A heat-resistant purple sand cooker with high performance, low expansion and far-infrared radiation function and its preparation method

The invention discloses a high-performance low-expansion heat-resistant purple clay cookware with a far-infrared radiation function. The purple clay cookware is composed of a blank base material and a blank additive. The blank base material is composed of 45-57wt% of purple clay, 28-40wt% of lithium feldspar, 5-10wt% of purple clay crude ore, 1-3wt% of knar clay, 5-9wt% of black talc, 0.5-1.5wt% of bentonite, 1-3wt% of rare earth tailings, and 1-3wt% of alumina micro powder. Relative to the blank base material, the blank additive comprises 10-15wt% of anionic far-infrared micro powder, 1-2wt% of zirconia micro powder, and 0.5-1wt% of yttrium oxide micro powder. The invention also discloses a preparation method of the high-performance low-expansion heat-resistant purple clay cookware with far-infrared radiation function. The heat-resistant purple clay cookware provided by the invention has low production cost and good moldability. According to the invention, product thermal shock resistance, mechanical strength and far-infrared emissivity are effectively improved, such that consumer application safety and healthcare needs can be met. Therefore, the cookware and the preparation method are beneficial for promoting the technological progress and application development of purple clay cookware industry.

Owner:景德镇市景火瓷业有限公司

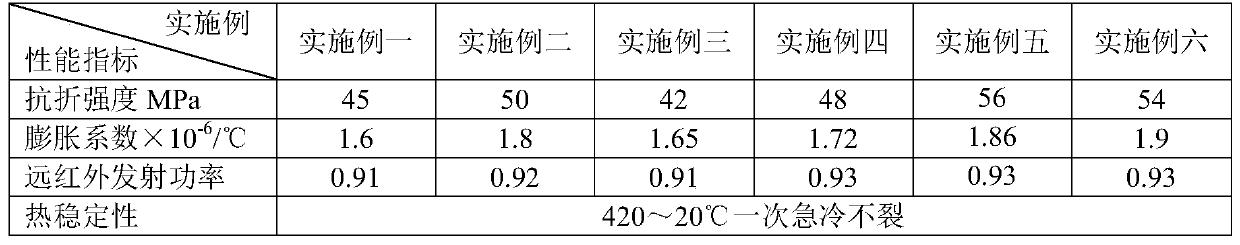

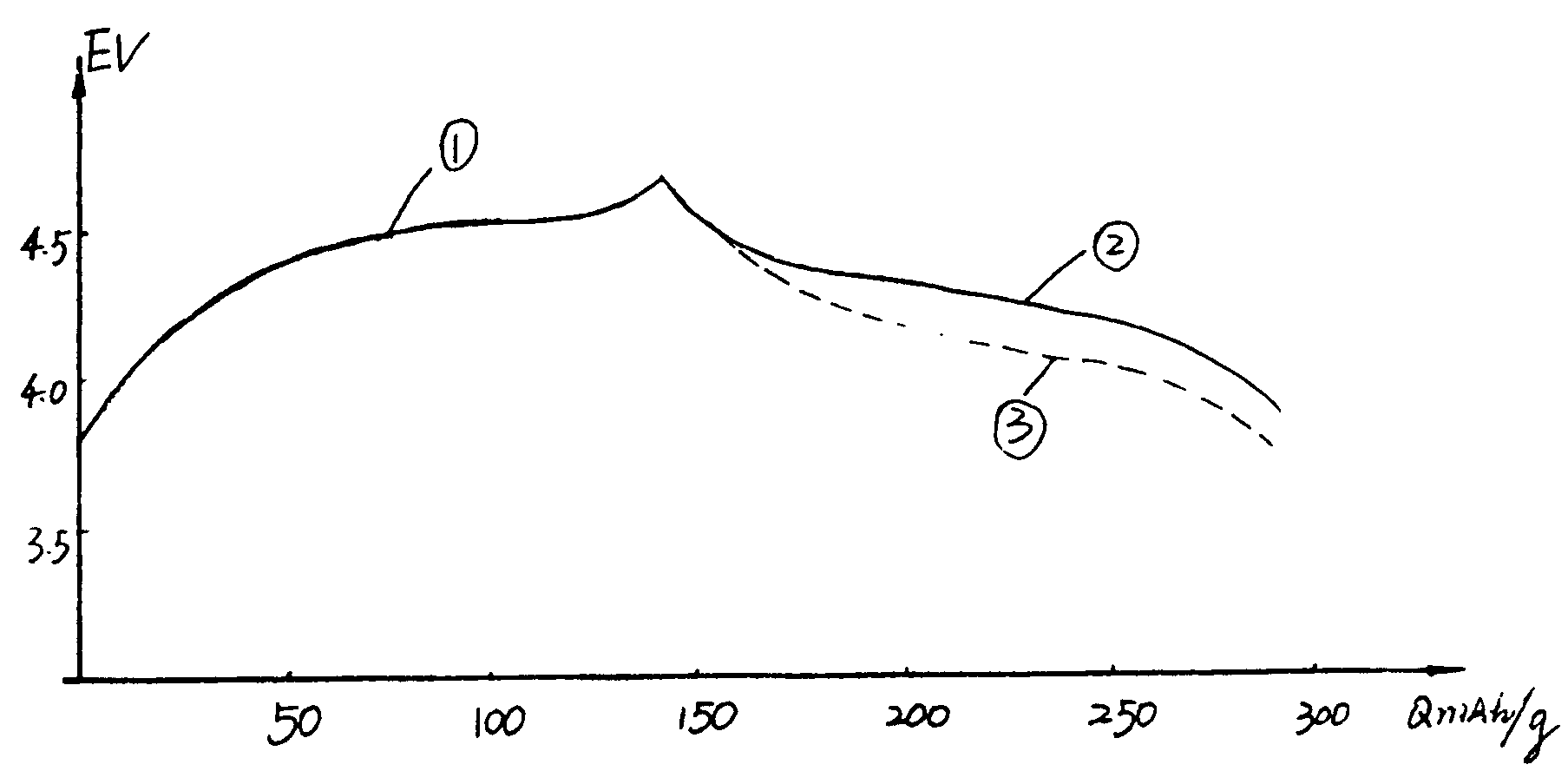

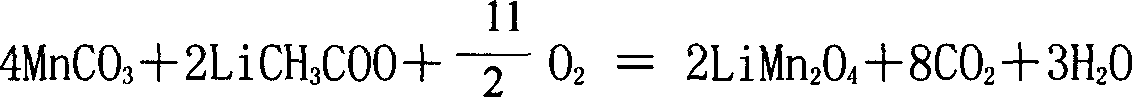

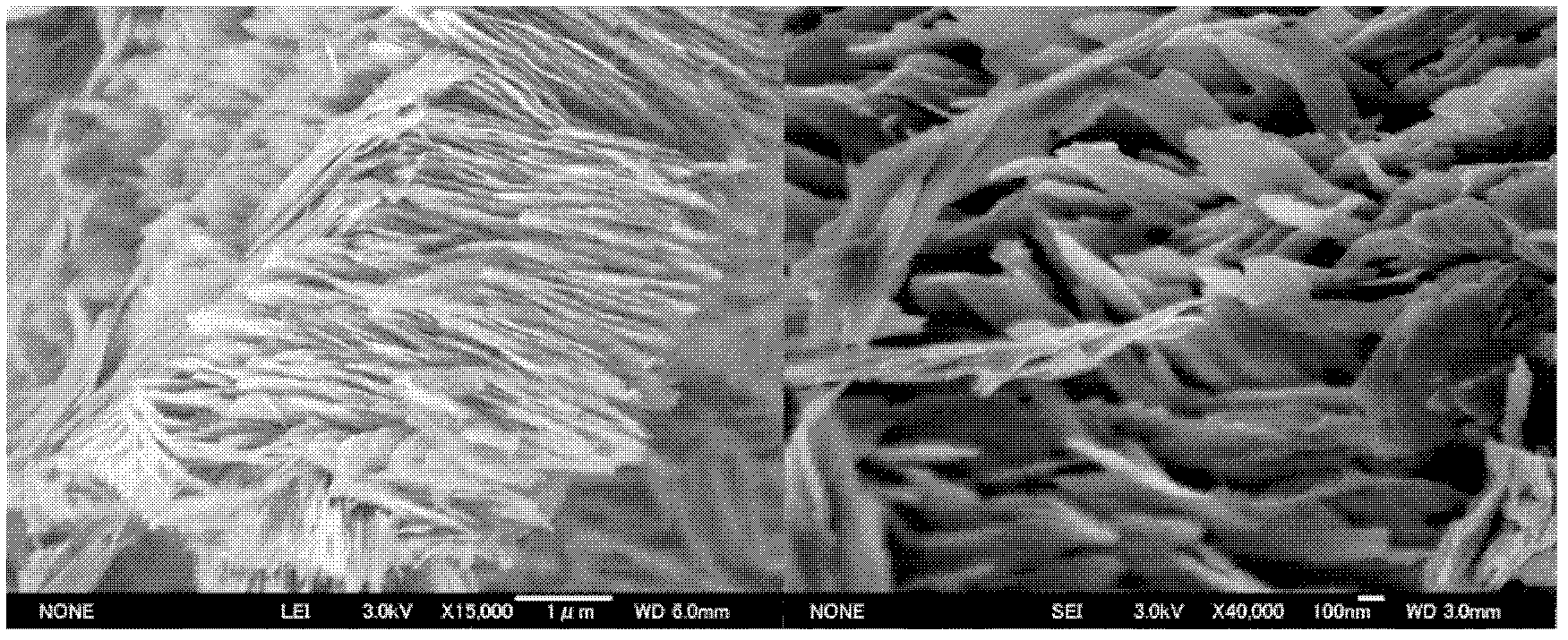

Drying and melting process of preparing LiMn2O4 latex as positive electrode material for lithium ion battery

InactiveCN1288772CUniform crystal phaseImprove discharge performanceElectrode manufacturing processesSecondary cellsEmulsionPolyvinyl alcohol

The latex drying and melting process of preparing LiMn2O4 is suitable for production of the positive pole film for power type lithium ion battery. The positive pole LiMn2O4 powder of the present invention is prepared with MnCO3 and LiCH3COO as material and through mixing in certain ratio, dopping with small amount of ions, mixing with PVDF and PVA to form emulsion, drying, smelting at 850 deg.c and powdering treatment. The battery with the positive pole of the said positive pole LiMn2O4 powder has operating potential of 3.7-4.15 V, specific capacity over 135 mA.h / g and discharge capacity over 128 mA.h / g.

Owner:江苏海四达电源有限公司

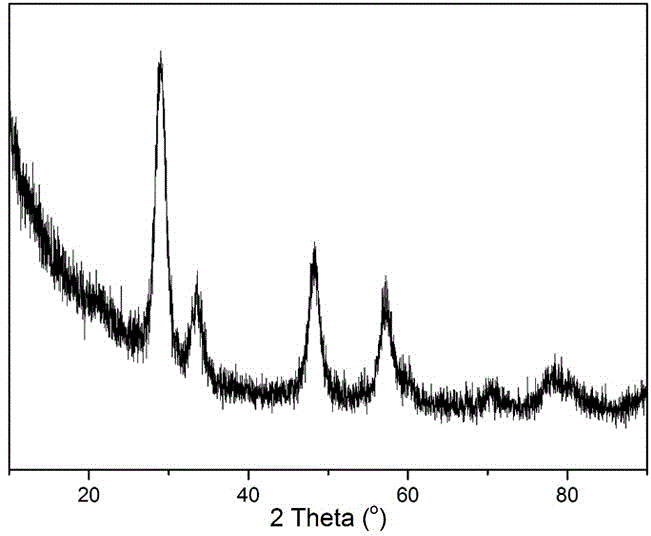

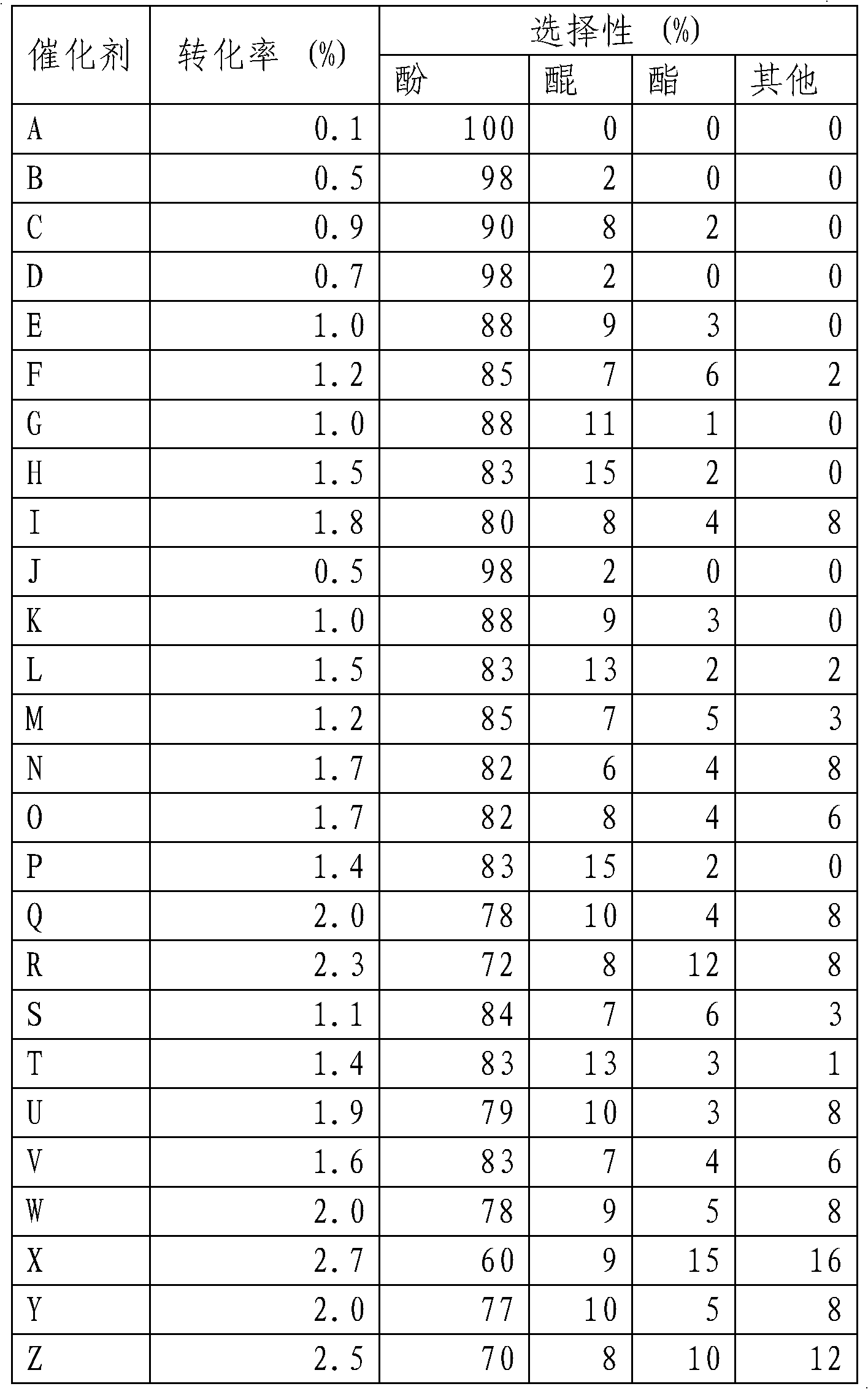

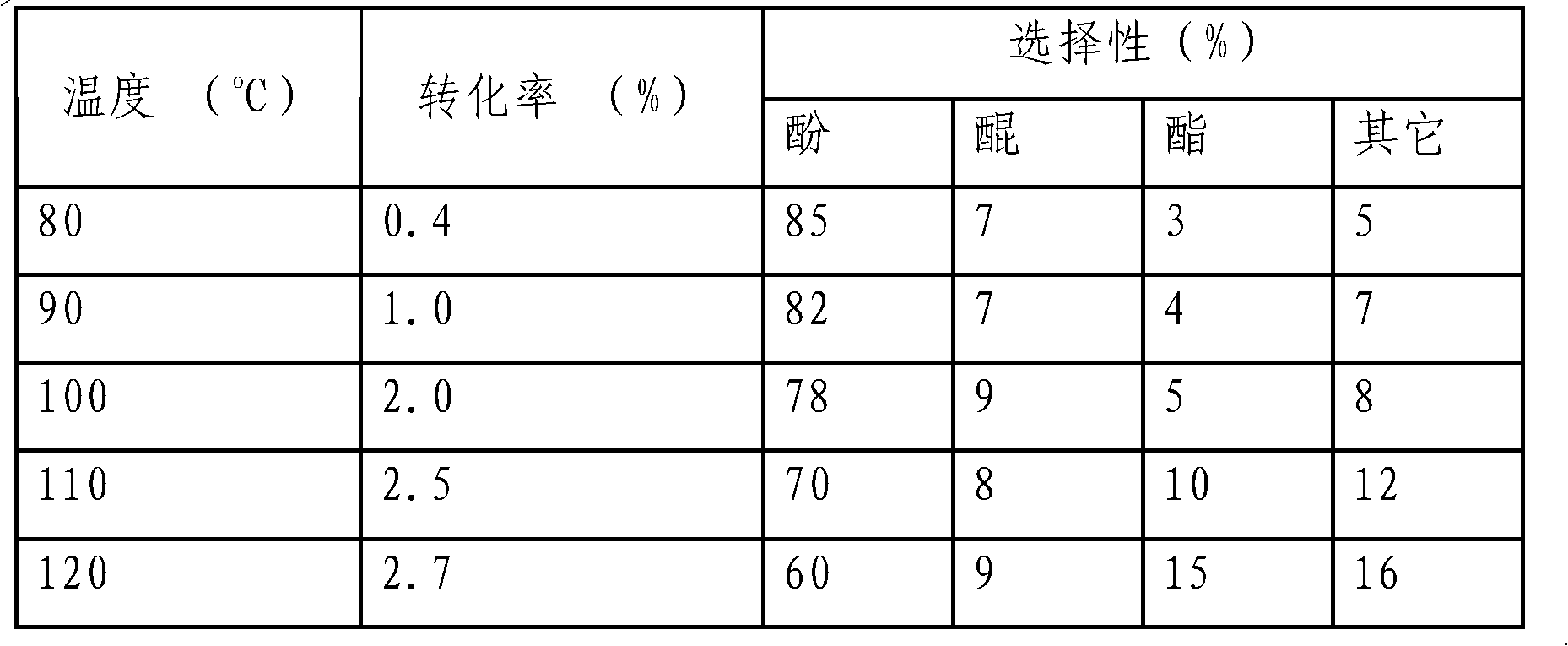

Preparation of VO2 nanosheet material and applications thereof

ActiveCN102910675BControl growth rateEasy to operateOrganic chemistryOrganic compound preparationPhenolRaw material

The invention relates to a preparation of a VO2 nanosheet material and applications thereof. The preparation is characterized in that one or more of ethylene glycol, glycerin, erythritol, xylitol, mannitol, sorbitol, fructose, glucose and the like are used as a reducing reagent, and one or more of V2O5, NH4VO3, VOPO4, VOCl3, VO (C3H7O)3 are used as a vanadium source. The reducing temperature is 100-180 DEG C, and the reaction time is 10-40 hours. The VO2 nanosheet material is used as a catalyst, molecular oxygen is used as an oxygen source, liquid phase catalytic oxide benzene is prepared into phenol, and the selectivity of the phenol can achieve 80 percent. The method has the characteristics of cheap raw materials, simplicity in process, convenience in operation, uniform morphology, high purity of products and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

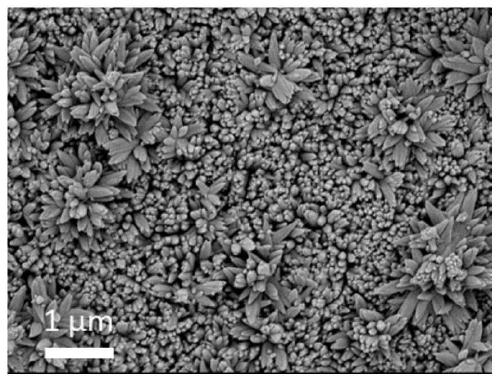

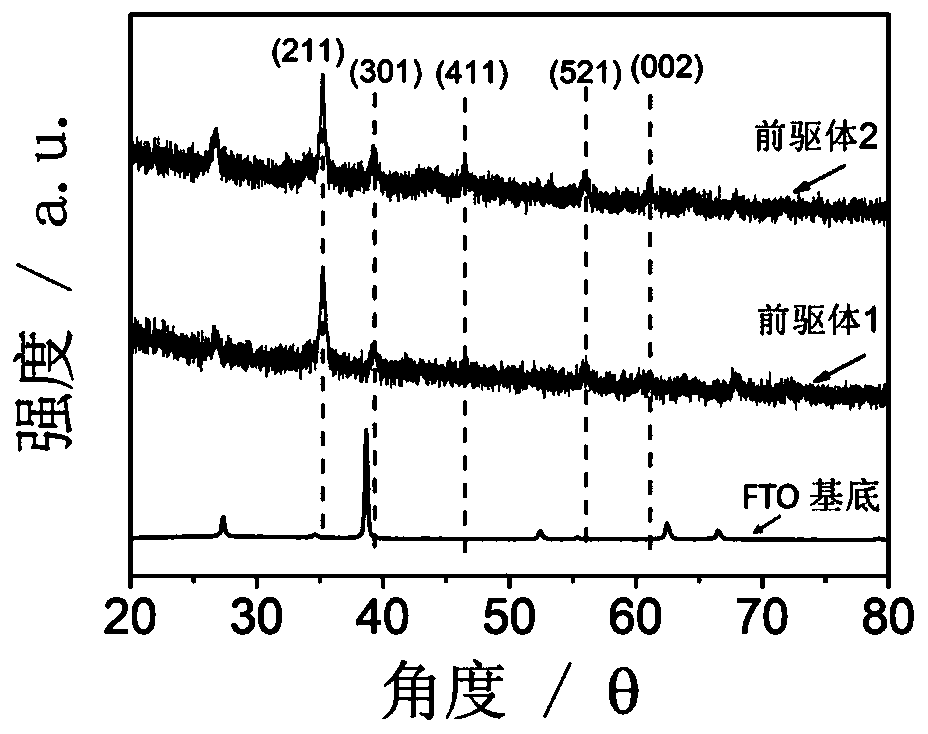

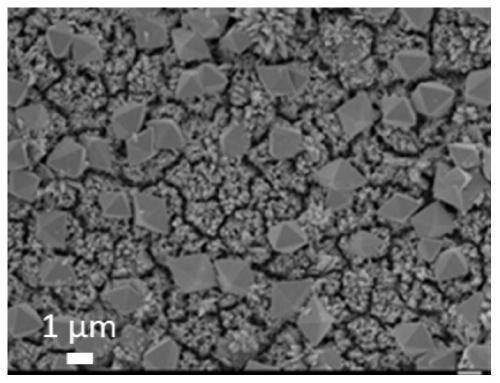

Method for preparing polyhedral iron oxyhydroxide thin film through corrosion recrystallization method

The invention belongs to the field of inorganic nano-materials, and discloses a method for preparing a polyhedral iron oxyhydroxide thin film through a corrosion recrystallization method. The method utilizes the principle of corrosion recrystallization and adopts a 'from-top-to-bottom' reaction mode, and by adjusting precursor sample characteristics and reaction parameters, cubic, octahedral and polyhedral beta-FeOOH nano-crystalline thin films with regular morphology, the uniform size, high binding force with substrates and different crystal face exposure characteristics are obtained successfully. The method has the advantages that through a 'from-bottom-to-top' method, the product purity is high, and separation and extraction are not needed, meanwhile inherits advancement that catalystswith different morphology can be prepared through a 'solution precipitation method' under the same reaction system by adjusting the reaction parameters, can serve as a wide nano-material preparation method, and provides guiding significance for preparation of other nano-materials.

Owner:GUANGZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com