A method for preparing polyhedral iron oxyhydroxide film by corrosion recrystallization method

An iron oxyhydroxide and polyhedron technology, applied in the field of inorganic nanomaterials, can solve the problems of demanding experimental details, poor stability, complex preparation process, etc., and achieve the effects of easy large-scale preparation, mild reaction conditions, and simple and easy-to-obtain methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: Preparation of octahedral iron oxyhydroxide film

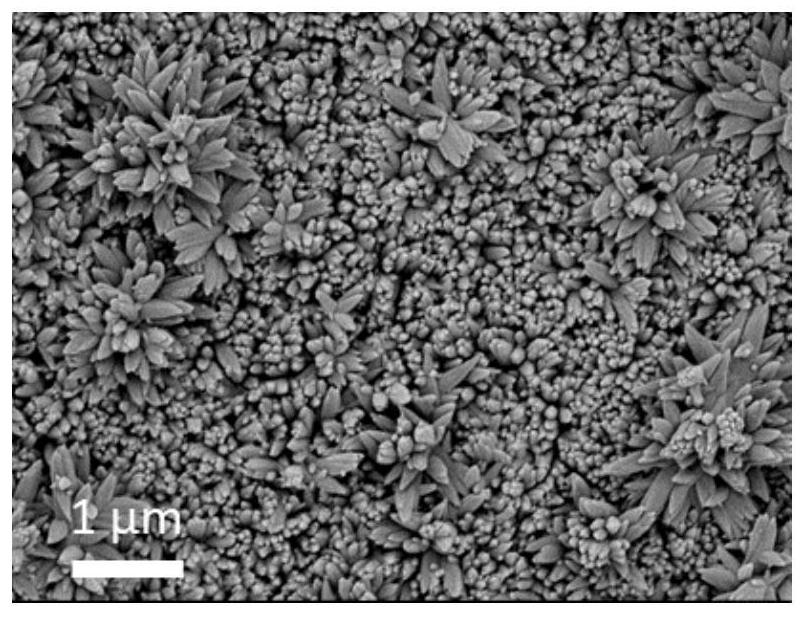

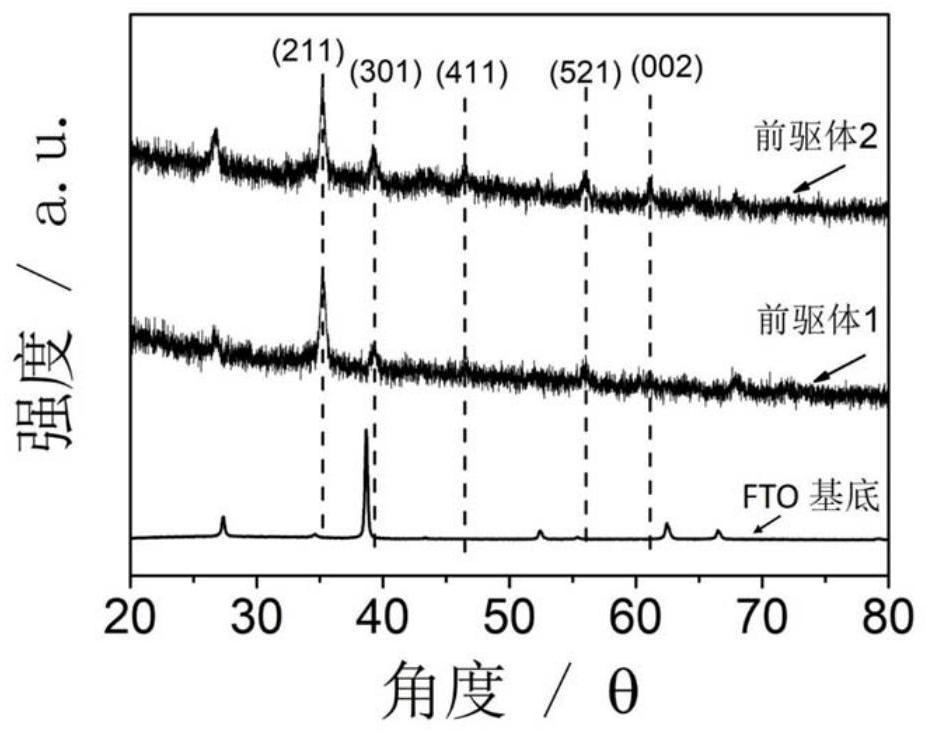

[0056] (1) Preparation of iron oxyhydroxide nanowire film precursor 2: 0.1g FeCl 3 ·6H 2 O and 0.4g NaNO 3 Add it to 9mL of 1.09mol / L dilute hydrochloric acid in turn, wait until it is completely dissolved, stir until uniform, then add 1mL of ethanol, stir for about 1-5min, and finally add 0.2mL of 0.05M H 2 PtCl 6 After the aqueous solution was stirred for 3 minutes, the reaction solution was transferred to the lining of a 20mL reaction kettle, and the cleaned FTO stood obliquely in the lining of the reaction kettle, with the conductive side of the FTO facing down. After reacting for 2 hours, the reactor was taken out from the oven, and after cooling to room temperature, the yellow sample was taken out, which was the iron oxyhydroxide nanowire film precursor 2 . figure 1 It is the SEM figure of the iron oxyhydroxide nanowire film precursor 2 prepared in embodiment 1, from figure 1 It can be seen that...

Embodiment 2

[0059] A kind of preparation of octahedral iron oxyhydroxide thin film, comprises the following steps:

[0060] (1) Preparation of iron oxyhydroxide nanowire film precursor 2: 0.27g FeCl 3 ·6H 2 O and 0.85g NaNO 3 Add it to 5mL of 1.09mol / L dilute hydrochloric acid in turn, wait until it is completely dissolved, stir until uniform, then add 5mL of ethanol, stir for about 1-5min, and finally add 0.35mL of 0.65M H 2 PtCl 6 After stirring for 3 minutes, transfer the reaction solution to a 20mL liner, in which the cleaned FTO stands obliquely, with the conductive side facing down, and finally transfers it to an oven, and reacts at 100°C for 4 hours to obtain a yellow color The sample shows that iron oxyhydroxide is successfully prepared from the color judgment;

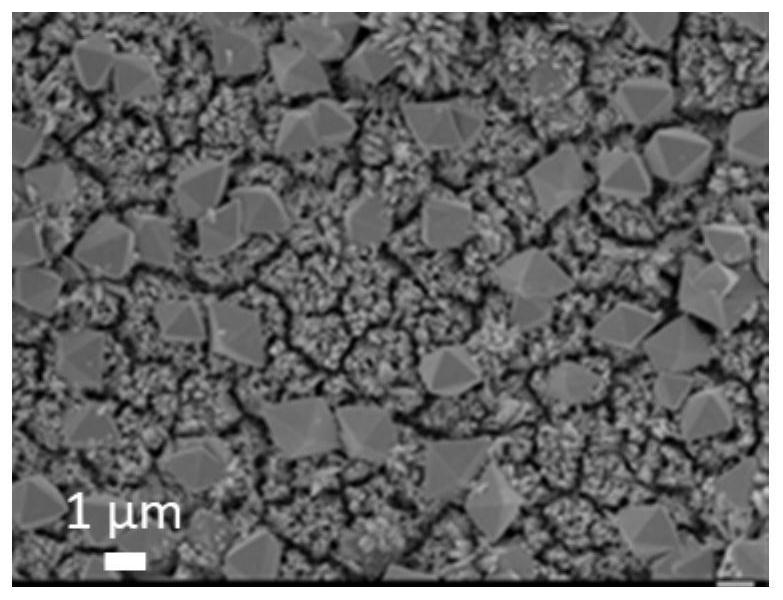

[0061] (2) Place the thin film precursor 2 prepared in step (1) upright in a clean polytetrafluoroethylene liner (20mL), with the side where the thin film precursor 2 grows facing down; reconfigure the solution and we...

Embodiment 3

[0063] A kind of preparation of octahedral iron oxyhydroxide thin film, comprises the following steps:

[0064] (1) Preparation of iron oxyhydroxide nanowire film precursor 2: 0.4g FeCl 3 ·6H 2 O and 0.90 g NaNO 3 Add it to 1mL of 1.09mol / L dilute hydrochloric acid in turn, wait until it is completely dissolved, stir until uniform, then add 9mL of ethanol, stir for about 1-5min, and finally add 0.5mL of 0.1M H 2 PtCl 6 After stirring for 3 minutes, transfer the reaction solution to the lining of a 20mL reactor, in which the cleaned FTO is placed obliquely, with the conductive side facing down, and finally transfer the reactor to an oven, and react at 100°C for 6 hours, that is A yellow sample can be obtained, judging from the color that iron oxyhydroxide is successfully prepared;

[0065] (2) Place the precursor film 2 prepared in step (1) upright in a clean polytetrafluoroethylene liner (20mL), with the side where the precursor film 2 grows facing down; then prepare the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com