Preparation process of silicon-based ceramic aerogel based on ceramic sintering technology

A preparation process and airgel technology, which is applied in the field of silicon-based ceramic airgel preparation technology, can solve the problems that the use temperature is difficult to exceed 1000°C, the use temperature of airgel is not high, and the pores are easy to collapse and break, and achieve microscopic Perfect structure, reduced particle size, and reduced crystallization barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation process of silicon-based ceramic airgel based on ceramic sintering technology, comprising the following steps:

[0030] Step S1, weighing the following raw materials by weight: 10 parts of ethyl orthosilicate, 50 parts of deionized water, 50 parts of absolute ethanol, 15 parts of zirconium oxychloride, 10 parts of zirconium nitrate, 3 parts of sodium fluoride, 3 parts of Silicon oxide, 5 parts silicon nitride, 30 parts glycerin and 50 parts trimethylchlorosilane;

[0031] Step S2, add tetraethyl orthosilicate, deionized water and absolute ethanol into the beaker, heat in a constant temperature water bath at 50°C and magnetically stir at a speed of 120r / min, add 10% ammonia water dropwise until flocs appear in the beaker, Add 10% dilute hydrochloric acid to adjust the pH until the pH is 5.6, mix zirconium oxychloride and zirconium nitrate into the beaker, add sodium fluoride, and stir magnetically at a speed of 150r / min until a colloid is formed;

[0032] ...

Embodiment 2

[0040] A preparation process of silicon-based ceramic airgel based on ceramic sintering technology, comprising the following steps:

[0041] Step S1, weighing the following raw materials by weight: 12 parts of ethyl orthosilicate, 55 parts of deionized water, 52 parts of absolute ethanol, 16 parts of zirconium oxychloride, 10 parts of zirconium nitrate, 4 parts of sodium fluoride, 5 parts of Silicon oxide, 6 parts silicon nitride, 35 parts glycerin and 55 parts trimethylchlorosilane;

[0042] Step S2, add tetraethyl orthosilicate, deionized water and absolute ethanol into the beaker, heat in a constant temperature water bath at 50°C and magnetically stir at a speed of 120r / min, add 10% ammonia water dropwise until flocs appear in the beaker, Add 10% dilute hydrochloric acid to adjust the pH until the pH is 5.6, mix zirconium oxychloride and zirconium nitrate into the beaker, add sodium fluoride, and stir magnetically at a speed of 150r / min until a colloid is formed;

[0043] ...

Embodiment 3

[0047] A preparation process of silicon-based ceramic airgel based on ceramic sintering technology, comprising the following steps:

[0048] Step S1, weighing the following raw materials by weight: 13 parts of ethyl orthosilicate, 60 parts of deionized water, 65 parts of absolute ethanol, 18 parts of zirconium oxychloride, 11 parts of zirconium nitrate, 4 parts of sodium fluoride, 6 parts of Silicon oxide, 6 parts silicon nitride, 45 parts glycerin and 65 parts trimethylchlorosilane;

[0049] Step S2, add tetraethyl orthosilicate, deionized water and absolute ethanol into the beaker, heat in a constant temperature water bath at 50°C and magnetically stir at a speed of 120r / min, add 10% ammonia water dropwise until flocs appear in the beaker, Add 10% dilute hydrochloric acid to adjust the pH until the pH is 5.6, mix zirconium oxychloride and zirconium nitrate into the beaker, add sodium fluoride, and stir magnetically at a speed of 150r / min until a colloid is formed;

[0050] ...

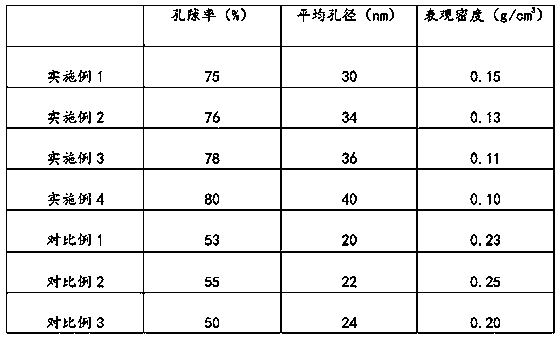

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com