Preparation method of graphene oxide/silicon dioxide hybrid aerogel

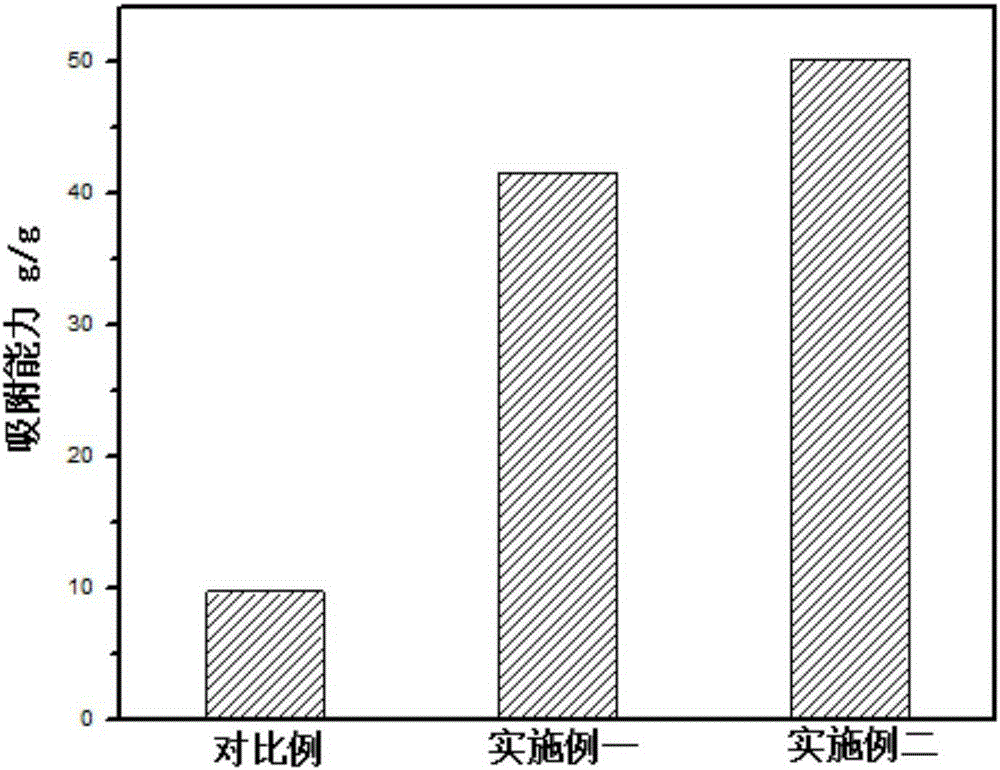

A silica and graphene technology, applied in the field of aerogels, can solve the problems of inability to resist, poor gel network structure strength, etc., and achieve the effects of good adsorption, strong solvent adsorption, and guaranteeing strength and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of graphene oxide / silica hybrid airgel, the steps are as follows: A, preparation of silica microspheres: 0.05mol ethyl orthosilicate is added to 9ml of distilled water, then slowly drop Add the 0.5mol / L oxalic acid solution into the tetraethyl orthosilicate aqueous solution, wherein the molar ratio of oxalic acid and tetraethyl orthosilicate is 1:50; stir for 5 hours at 25°C; then add the ammonia solution with a concentration of 1mol / L , adjusting the pH value of the reaction system to pH = 7, stirring for 10 min to obtain a dispersion containing silica microspheres;

[0042] B. Preparation of hybrid hydrogel: Dilute the dispersion of silica microspheres with water 10 times to obtain a diluted dispersion of silica microspheres; then dilute the dispersion of silica microspheres with a concentration of 0.8mg / ml Mix equal volumes of the graphene oxide dispersion, stir for 15 minutes at a stirring speed of 50 r / min, and then ultrasonicate for 15 minutes...

Embodiment 2

[0046] A preparation method of graphene oxide / silica hybrid airgel, the steps are as follows: A, preparation of silica microspheres: 0.05mol ethyl orthosilicate is added to 9ml of distilled water, then slowly drop Add the 0.5mol / L oxalic acid solution into the tetraethyl orthosilicate aqueous solution, wherein the molar ratio of oxalic acid and tetraethyl orthosilicate is 1:50; stir for 5 hours at 25°C; then add the ammonia solution with a concentration of 1mol / L , adjusting the pH value of the reaction system to pH = 7, stirring for 10 min to obtain a dispersion containing silica microspheres;

[0047] B. Preparation of hybrid hydrogel: Dilute the dispersion of silica microspheres with water 20 times to obtain a diluted dispersion of silica microspheres; then dilute the dispersion of silica microspheres with a concentration of 0.8mg / ml Mix equal volumes of the graphene oxide dispersion, stir for 15 minutes at a stirring speed of 50 r / min, and then ultrasonicate for 15 minutes...

Embodiment 3

[0057] A preparation method of graphene oxide / silica hybrid airgel, the steps are as follows: A, preparation of silica microspheres: 0.1mol ethyl orthosilicate is added to 18ml of distilled water, then slowly drop Add oxalic acid solution with a concentration of 0.6mol / L to an aqueous tetraethyl orthosilicate solution, where the molar ratio of oxalic acid and ethyl orthosilicate is 1:100; stir for 6 hours at 30°C; then add ammonia with a concentration of 0.5mol / L aqueous solution, adjust the pH value of the reaction system to pH = 6.5, and stir for 45 minutes to obtain a dispersion containing silica microspheres;

[0058] B. Preparation of hybrid hydrogel: Dilute the dispersion of silica microspheres with water 5 times to obtain a diluted dispersion of silica microspheres; then dilute the dispersion of silica microspheres with oxidized The graphene dispersion was mixed in equal volumes, stirred for 10 minutes, the stirring speed was 100r / min, and then ultrasonicated for 10 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com