A method for preparing composite zirconia precursor

A technology of composite zirconia and precursors, applied in zirconia and other directions, can solve the problems of uneven and restricted zirconia powder, and achieve the effect of perfect microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

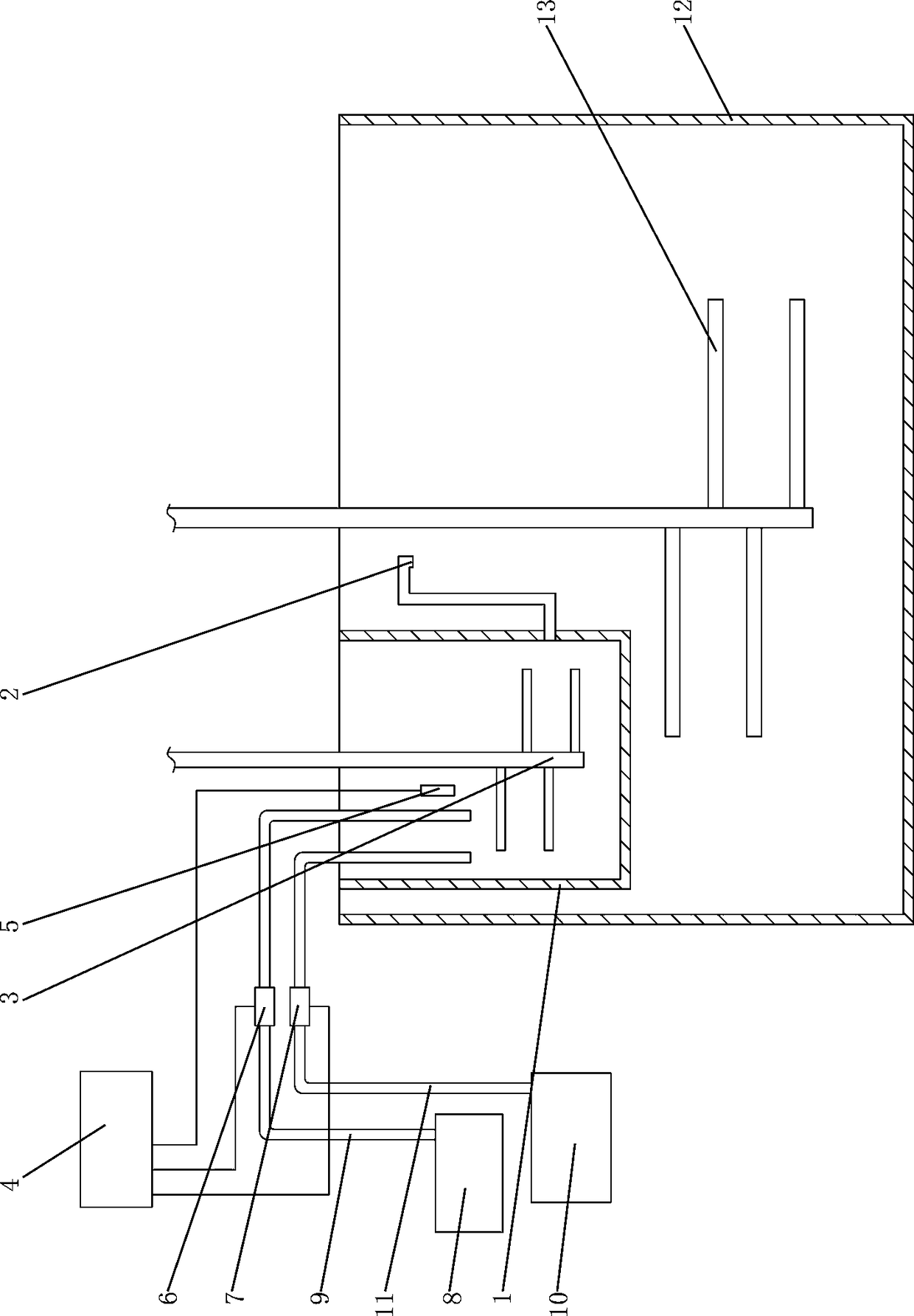

Image

Examples

Embodiment 1

[0026] In this embodiment, the method for preparing the composite zirconia precursor includes the following steps:

[0027] (1) Add the powder raw materials into pure water, and dissolve fully to obtain a mixed zirconium feed solution (dissolution time is 3 hours);

[0028] The powder raw material is made of zirconium oxychloride (ZrOCl 2 ·8H 2 O), yttrium oxide (Y 2 o 3 ) and crystalline aluminum chloride (AlCl 3 .6H 2 O) composition, by weight, the ratio of zirconium oxychloride, yttrium oxide, and crystalline aluminum chloride is 245: 5: 1.

[0029] (2) deploying ammonia water with a weight percentage concentration of 8%;

[0030] (3) First add pure water with a depth of 8cm into the overflow reactor; then continuously add the mixed zirconium feed liquid obtained in step (1) and ammonia water obtained in step (2) into the overflow reactor, while adding Stir the feed liquid in the overflow reactor to mix the feed liquid evenly, and control the pH value of the feed liq...

Embodiment 2

[0038] In this embodiment, the method for preparing the composite zirconia precursor includes the following steps:

[0039] (1) Add the powder raw material into pure water, and get the mixed zirconium feed solution after fully dissolving (dissolving time is 6 hours);

[0040] The powder raw material is made of zirconium oxychloride (ZrOCl 2 ·8H 2 O), yttrium oxide (Y 2 o 3 ) and crystalline aluminum chloride (AlCl 3 .6H 2 O) composition, by weight, the ratio of zirconium oxychloride, yttrium oxide, and crystalline aluminum chloride is 250: 5.5: 1.1.

[0041] (2) deploying ammonia water with a concentration of 8.5% by weight;

[0042] (3) First add pure water with a depth of 9cm into the overflow reaction kettle; then continuously add the mixed zirconium feed solution obtained in step (1) and ammonia water obtained in step (2) into the overflow reaction kettle, while adding Stir the feed liquid in the overflow reactor to mix the feed liquid evenly, and control the pH val...

Embodiment 3

[0050] In this embodiment, the method for preparing the composite zirconia precursor includes the following steps:

[0051] (1) Add the powder raw materials into pure water, and dissolve fully to obtain a mixed zirconium feed solution (dissolution time is 1 hour);

[0052] The powder raw material is made of zirconium oxychloride (ZrOCl 2 ·8H 2 O), yttrium oxide (Y 2 o 3 ) and crystalline aluminum chloride (AlCl 3 .6H 2 O) composition, by weight, the ratio of zirconium oxychloride, yttrium oxide, and crystalline aluminum chloride is 240: 4.5: 0.9.

[0053] (2) deploying ammonia water with a weight percentage concentration of 7.5%;

[0054] (3) First add pure water with a depth of 8.5cm into the overflow reaction kettle; then continuously add the mixed zirconium feed solution obtained in step (1) and ammonia water obtained in step (2) into the overflow reaction kettle, while adding Stir the feed liquid in the overflow reactor to mix the feed liquid evenly, and control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com