Bioactive coating on the surface of a porous metal material and its preparation method

A porous metal, bioactive technology, applied in the field of biomedical materials, to achieve the effects of strong controllability, warm conditions, and easy batch production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

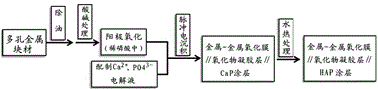

Method used

Image

Examples

Embodiment 1

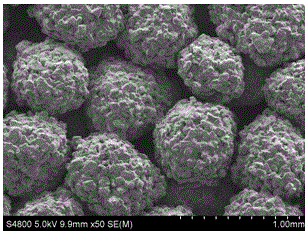

[0053] Low porosity porous titanium features: cylindrical (Φ8×20 mm), porosity ~40%, macropore size: ~230 microns, such as figure 2 shown.

[0054] 1) Preprocessing

[0055] a) Degreasing: Wash the porous titanium with ultrasonic oscillation in acetone and ethanol for 5-10 minutes in turn, repeat twice, then wash twice with ultrasonic oscillation in deionized water for later use.

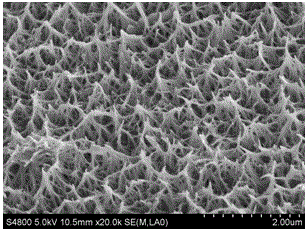

[0056] b) Acid-base treatment: Immerse the deoiled porous titanium in 2M HNO 3 solution, put it at room temperature for half an hour, take it out, rinse it with deionized water until it is neutral; then, immerse it in a polytetrafluoroethylene cup filled with 6 M NaOH solution, keep it in an oven at 60°C for 4 hours, and remove it. Ultrasonic cleaning with deionized water until the pH of the washing solution is close to neutral. The typical multi-pit network morphology of the porous titanium surface after strong alkali treatment is as follows: image 3 shown.

[0057] 2) Anodizing treatment

...

Embodiment 2

[0070] High porosity porous titanium features: cylindrical shape (Φ8×20 mm), porosity ~73%, macropore size ~400 microns, such as Figure 5 shown.

[0071] 1) pretreatment and anodic oxidation step are with embodiment 1;

[0072] 2) Pulse electrodeposited calcium phosphate coating

[0073] The composition of the electrolyte, the pouring of the porous titanium and the electrodeposition temperature are the same as those in Example 1. The cathodic electrodeposition conditions are: the cathode pulse current density is 6 mA / cm 2 , the pulse duration is 0.8s, the pulse pause (current density is 0) time is 9.2s, mechanical stirring, electrodeposition (counted by the number of cycles) ends after 90 cycles, soaked in deionized hot water and washed three times before use.

[0074] 3) Hydrothermal treatment: Same as Example 1. After steps 2) and 3), the surface morphology of porous titanium is as follows Image 6 shown.

Embodiment 3

[0075] Example 3: Characterization of Porous Titanium Surface Coatings

[0076] Taking the coating prepared in Example 1 as an example, the coating structure, thickness, crystal form and adhesion of the surface calcium phosphate were evaluated.

[0077] 1) Coating structure and thickness

[0078] Figure 7 The typical cross-sectional morphology of the multilayer coating prepared on the porous titanium surface of the present invention is shown. The thickness of the HAP coating prepared under the conditions of Example 1 is 1.0 micron, and the thickness of the dense oxide film and intermediate gel layer on the titanium surface is about 0.5 micron.

[0079] 2) Crystal form and composition of calcium phosphate on coating surface

[0080] Typical XRD characteristics of coatings on porous titanium surfaces ( Figure 8 ), the four strongest diffraction peaks correspond to the main characteristic peaks of HAP. At the same time, the characteristic peaks of TiO2 and titanium also app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com