Patents

Literature

117results about How to "Convenient and perfect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

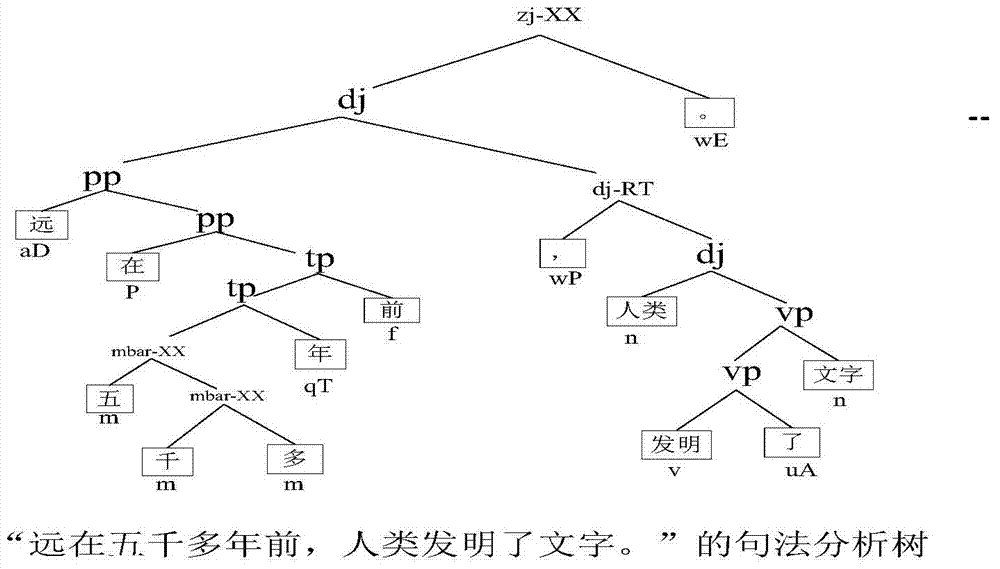

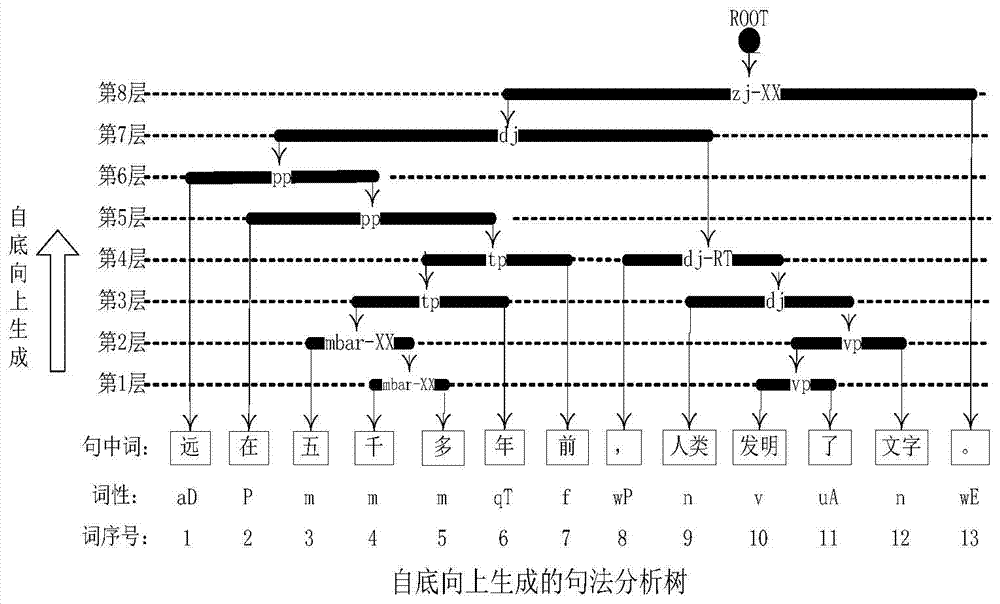

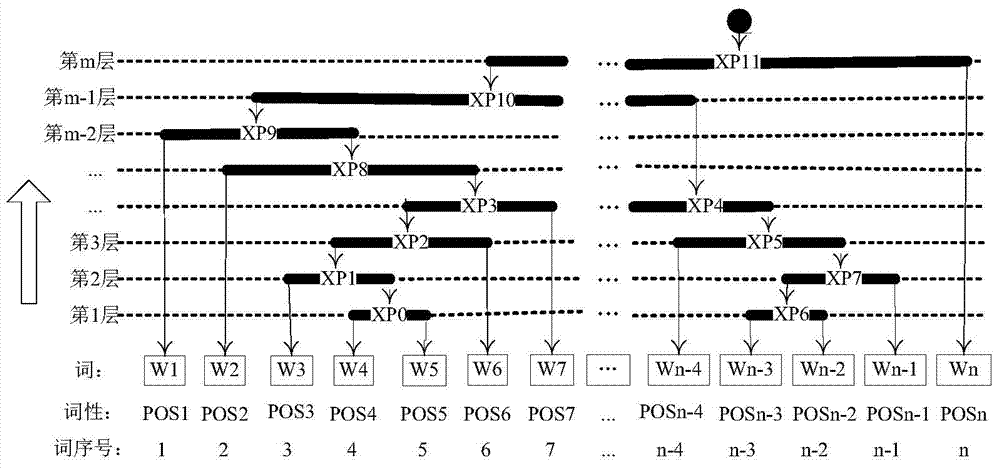

Syntactic analysis method based on sliding semantic string matching

InactiveCN103500160ASolve backtracking difficultiesSolve the problem of insufficient jurisdictionSpecial data processing applicationsContext-sensitive grammarSyntax

The invention belongs to the field of computer natural language processing, and relates to a method for carrying out high-quality syntactic analysis on human natural language sentences, in particular to a syntactic analysis method based on sliding semantic string matching. The method is characterized in that when a rule base is built, hierarchic flattening transformation is firstly carried out on a usual phrase syntax tree, then semantic code labeling is carried out on the chunking information of each layer, and therefore the chunking rules of context-sensitive grammar of N elements are extracted; in the syntactic analysis process, the optimal chunking rules are matched to carry out stacking chunking type analysis through a sliding semantic string matching model; errors in the lower layer are found and corrected in the higher layer through an error correction template, and heuristic backtracking in the stacking chunking type syntactic analysis is achieved; template information is directly added to a semantic template index, and a machine can learn new syntactic rules immediately. The method solves the problems that a PCFG type syntactic analysis level can hardly be further improved and the correct chucking rules are hard to choose in the stacking chunking type syntactic analysis, and improves the existing syntactic analysis level.

Owner:DALIAN UNIV OF TECH

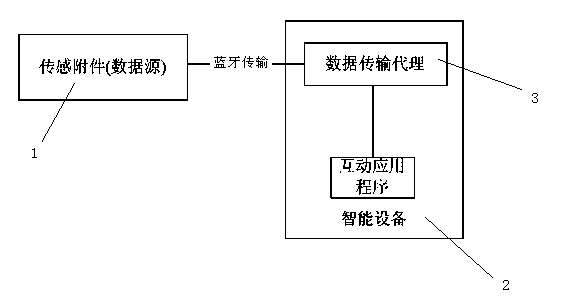

Excise and fitness system based on mode of Internet of Things

InactiveCN104181875AConvenient and perfectImprove durabilityTotal factory controlProgramme total factory controlThe InternetStandard form

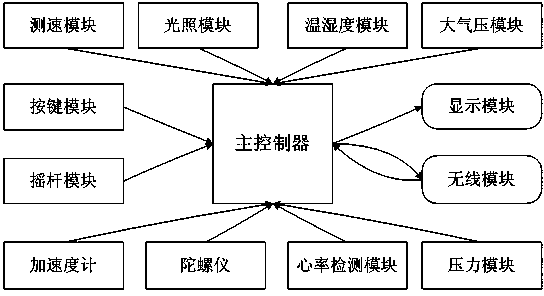

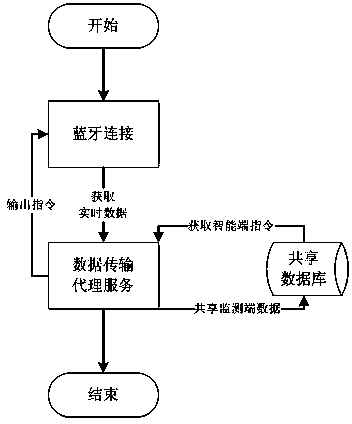

The invention discloses a wireless interactive data agent system of an excise and fitness product based on a mode of Internet of Things. The system unifies development standards of data transmission and interactive application programs, and adopts data of a unified standard data format and sends, receives and shares the data through a data transmission agent. The system mainly aims at manufacturing data interfaces of a standard format and uniformly using the data transmission agent to combine traditional fitness equipment with the technology of Internet of Things so as to establish a health interactive exercise and fitness platform and reduce a development difficulty of an interactive health exercise platform application; and the system is mainly used as a data transmission bridge for development of the Internet of Things.

Owner:ZHEJIANG UNIV CITY COLLEGE

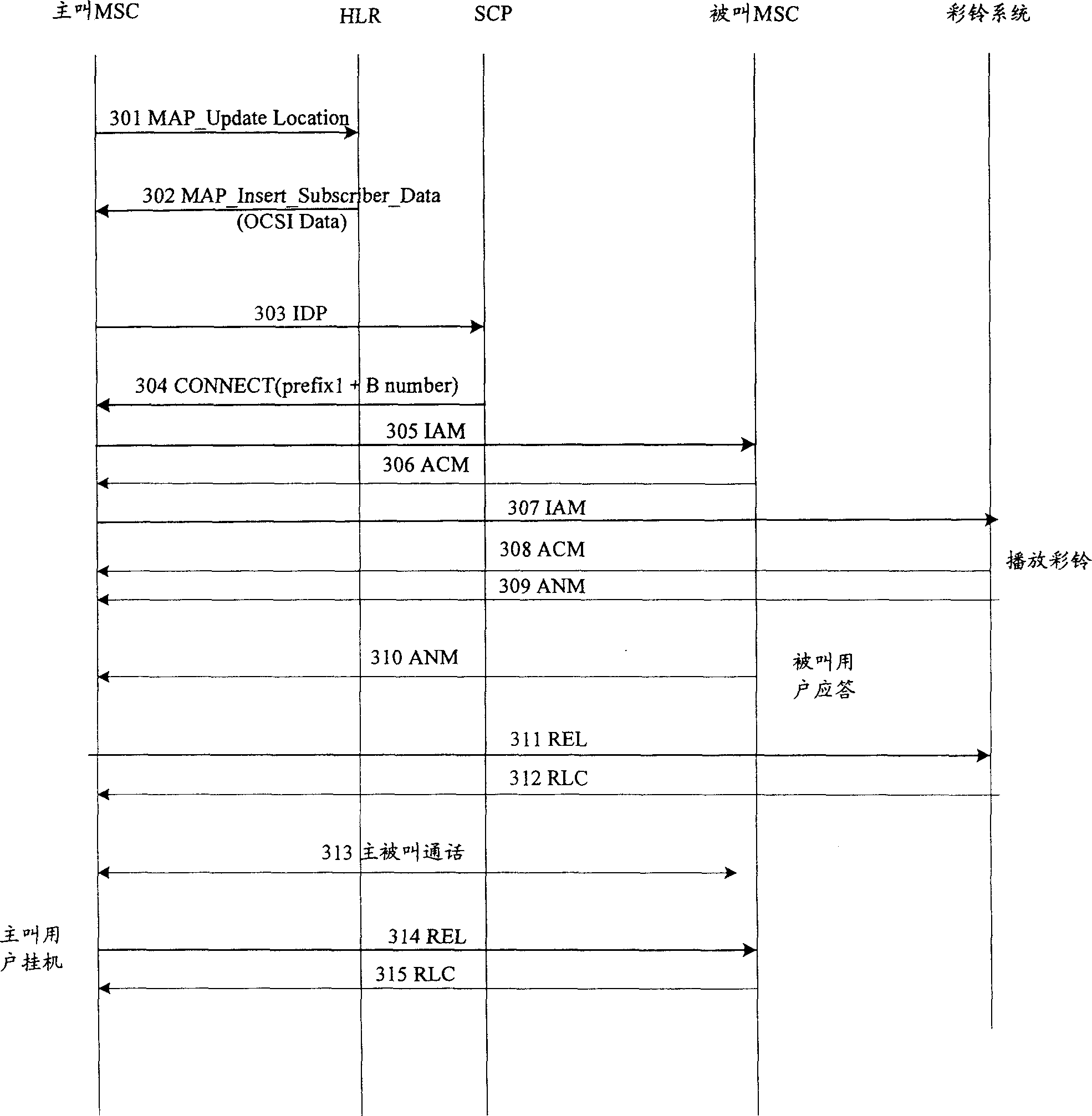

Method for realizing color return-bell-sound business

ActiveCN1816077AConvenient and perfectBeneficial speedSpecial service for subscribersRadio/inductive link selection arrangementsPersonalizationRing back tone

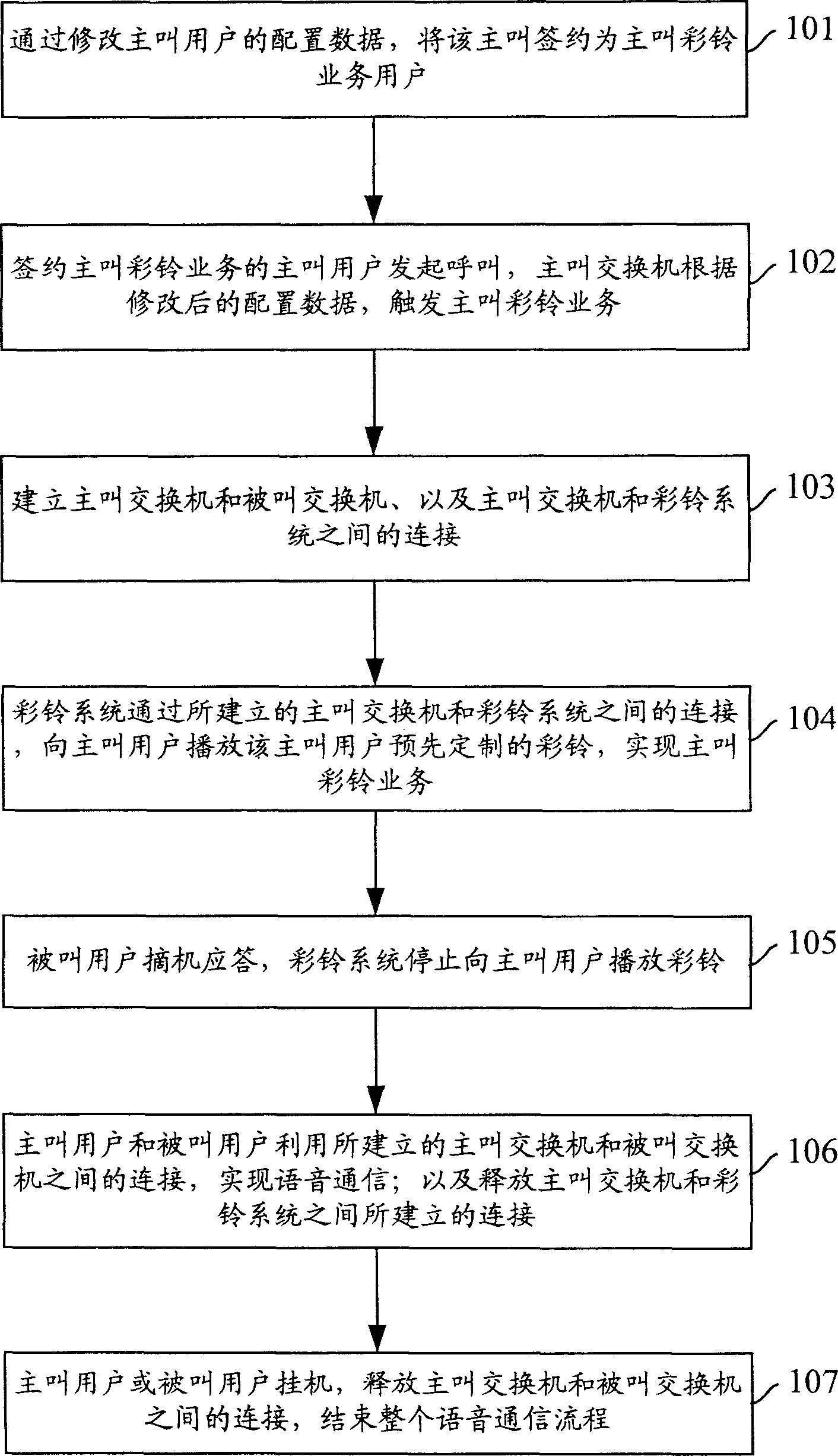

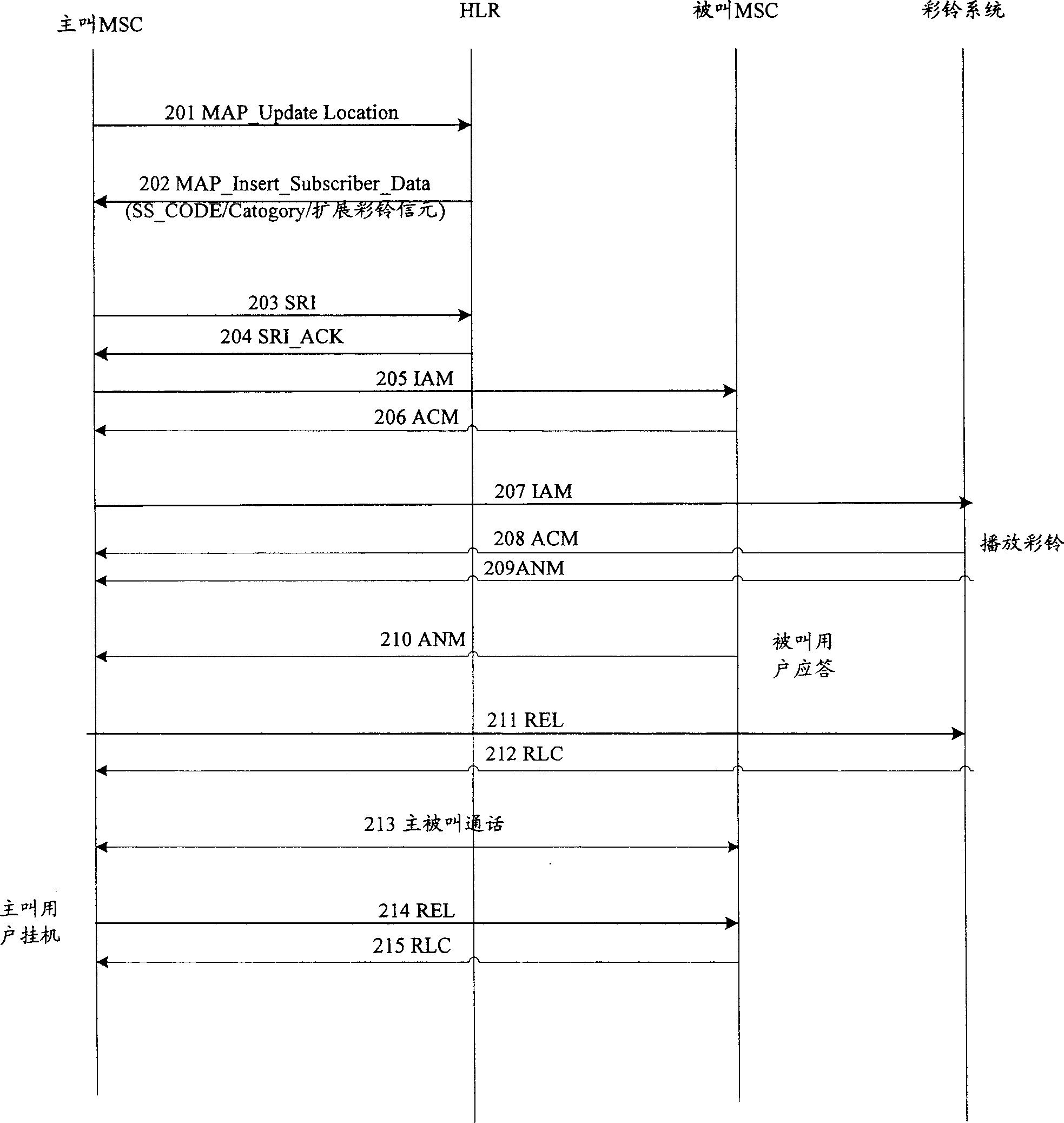

The invention includes following steps: (1) modifying configuration data of a calling user signs the calling user as user of diversiform ringing service; (2) the calling user of signing the calling diversiform ringing service launches a call; based on the modified configuration data, calling exchanger triggers calling diversiform ringing service; (3) building link between calling exchanger and called exchanger, as well as calling exchanger and diversiform ringing system; (4) through the link setup between calling exchanger and diversiform ringing system, the diversiform ringing system plays diversiform ringing sound customized by calling user in advance to the calling user so as to realize calling diversiform ringing service. Being applicable to mobile communication network and fixed network, the invention satisfies individualized requirement, and prevents misunderstanding caused by that the calling user is inadaptable to diversiform ring back tone customized by called user,

Owner:HUAWEI TECH CO LTD

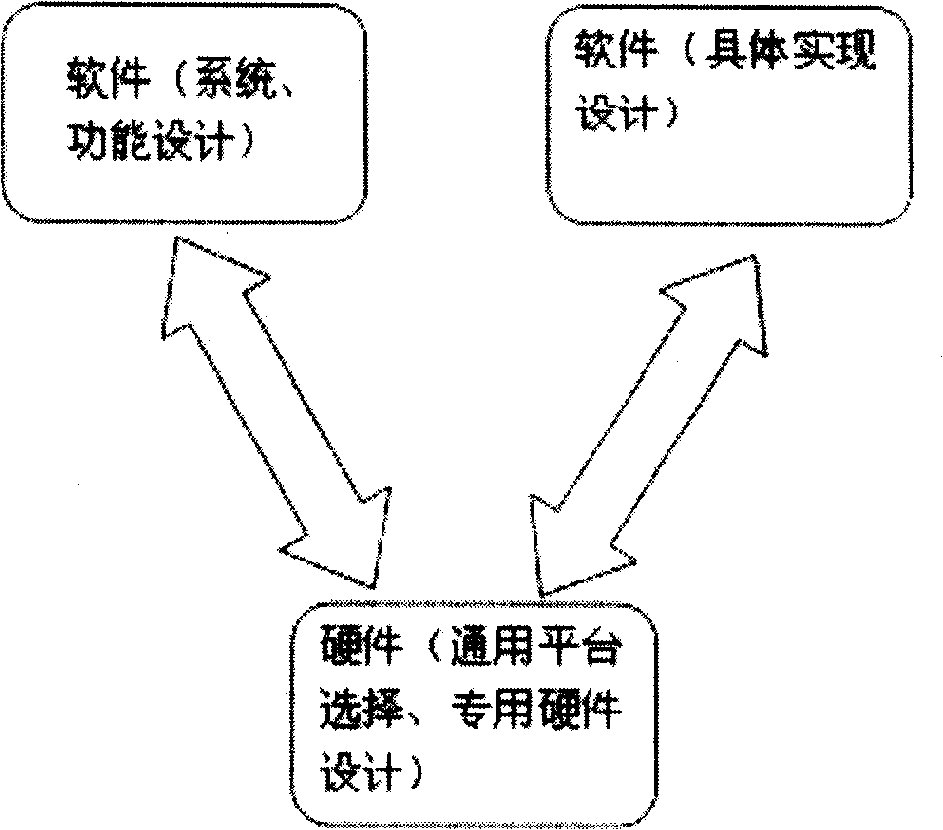

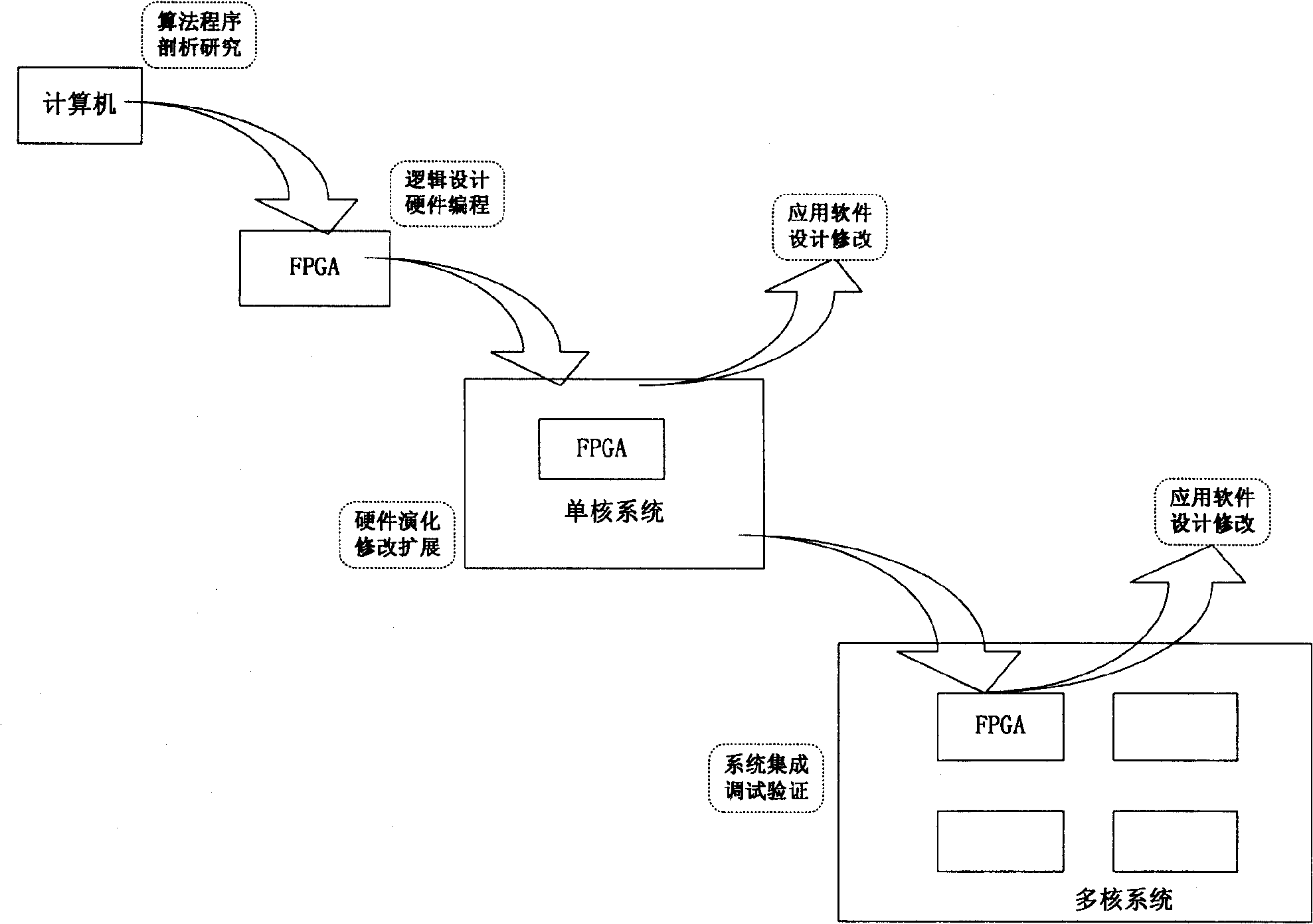

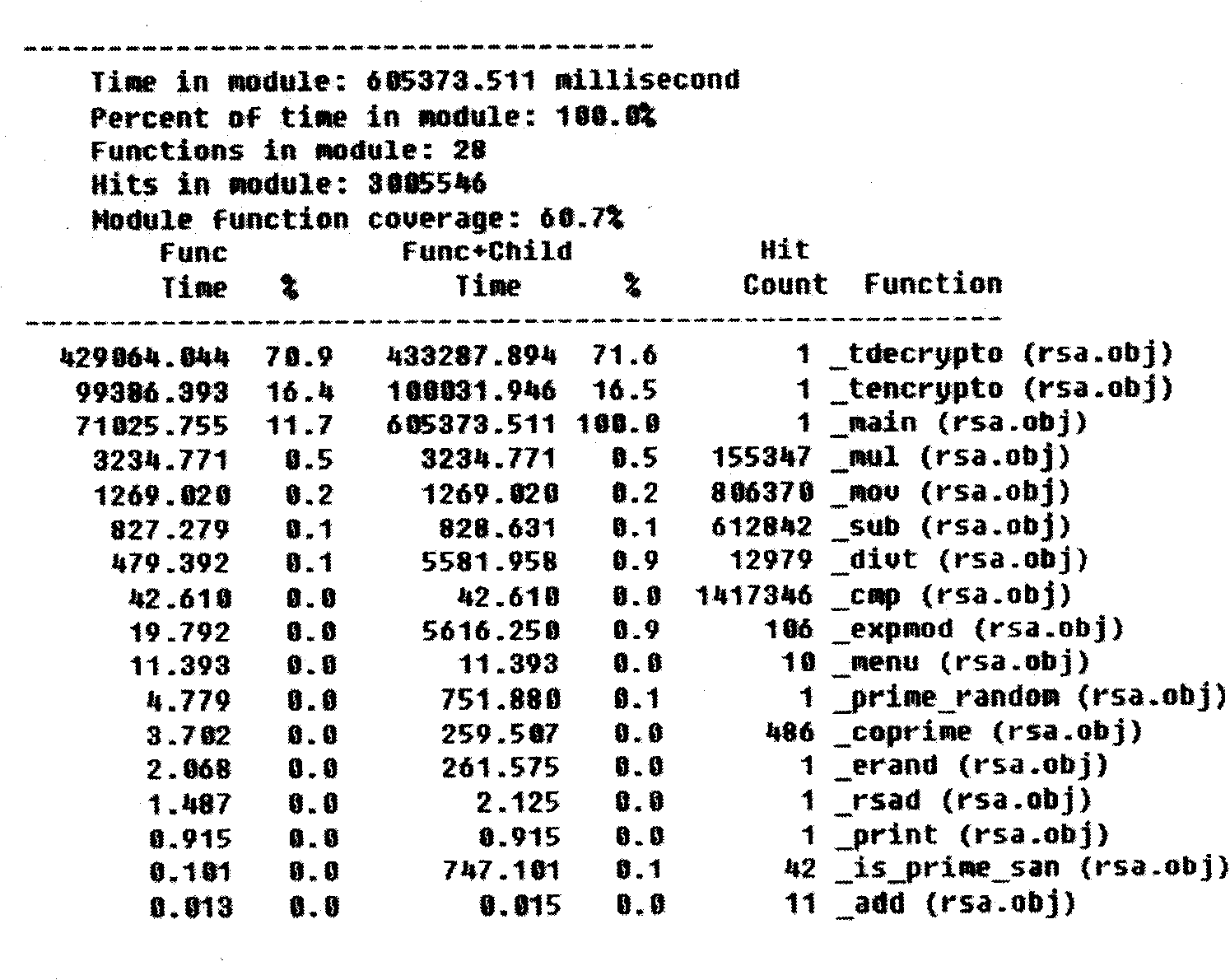

Software and hardware cooperating design method for arithmetic acceleration

InactiveCN101493862AChanging the status quo of secular stagnationImprove compatibilitySpecial data processing applicationsAnalysis dataSystem requirements

The invention discloses a software and hardware collaborative design method of algorithm acceleration. The method has six steps of: step 1: static analysis of algorithm and software; step 2: using software analysis tools to carry out dynamic actual measurement analysis of the software so as to obtain a basic data chart of software operation; step 3: making overall structure and function design of a multi-core hardware system by combination of system requirements, the algorithm analysis and the software actual measurement analysis data; step 4: using appropriate modeling tools (RML) to describe the whole system; step 5: constructing a function process abstract chart GCG (including a function call chart of operation time parameters) on the base of the step 2 and discussing the distribution of the software in the multi-core system by using the chart GCG as the subject; and step 6: carrying out the software and hardware realization of a prototype system according to a proposal obtained from the step 5 and evaluating the realization results. The method has good compatibility, is applicable to the urgent demand for the design of a multi-core system on chip (SOC) and promotes the improvement of multi-core design tools. The method has very high utility value and promising application prospect.

Owner:BEIHANG UNIV

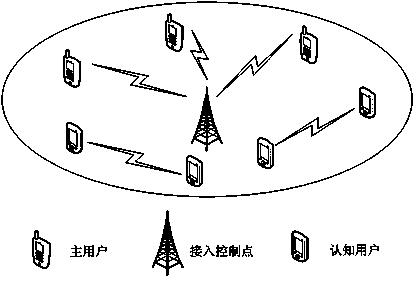

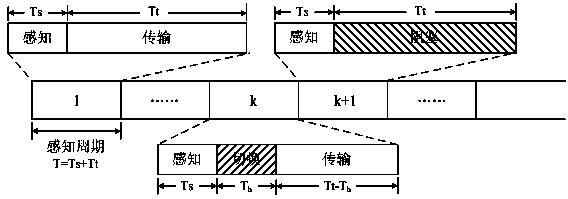

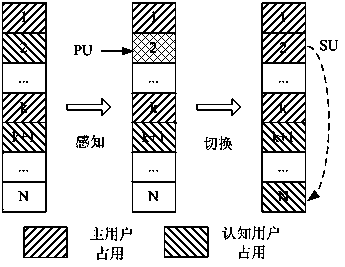

Method for channel switching of cognitive user and performance analysis method of method for channel switching of cognitive user

InactiveCN103763722AImprove throughputConvenient and perfectWireless communicationCognitive userFrequency spectrum

The invention provides a method for channel switching of a cognitive user and a performance analysis method of the method for channel switching of the cognitive user and relates to the technical field of opportunity frequency spectrum access systems in the wireless communication technology. The method for channel switching comprises the steps that a periodical cognition-transmission time slot structure is adopted by the cognitive user for conducting data transmission and the cognitive user determines whether channel switching is conducted or not in each cognition period according to the fact whether a master user appears on a currently-occupied channel; according to the performance analysis method, a closed expression of performance parameters such as the average non-switching probability, the switching probability, the blocking probability, the switching relay and the like of the cognitive user is provided, the method can effectively and easily analyze the cognitive user channel switching performance in a quantitative mode, assessment of the channel switching performance, namely the indexes of the non-switching probability, the successful-switching probability, the blocking probability, the average switching relay and the like, of the cognitive user is achieved. According to the method, the theoretical and practical significance is brought for researching operation that a switching mechanism of the opportunity frequency spectrum access system is optimally designed and the handling capacity of a cognitive network is improved.

Owner:NANJING UNIV OF POSTS & TELECOMM

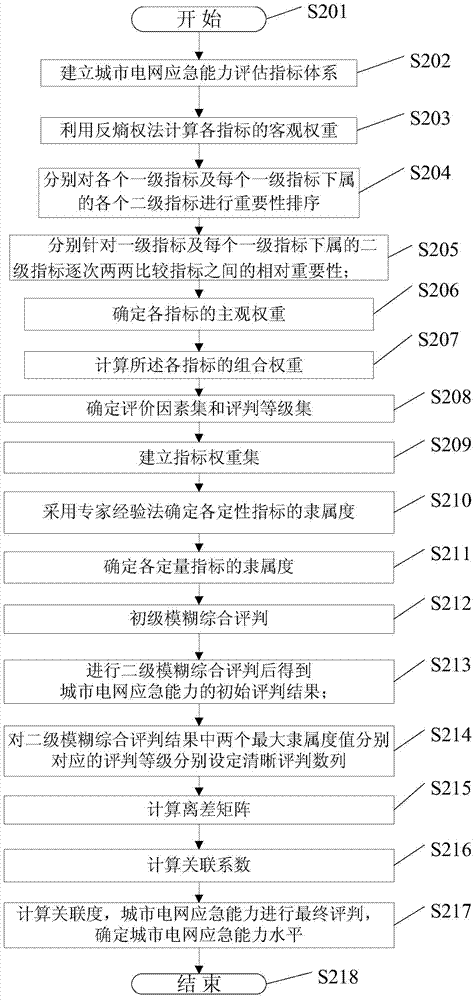

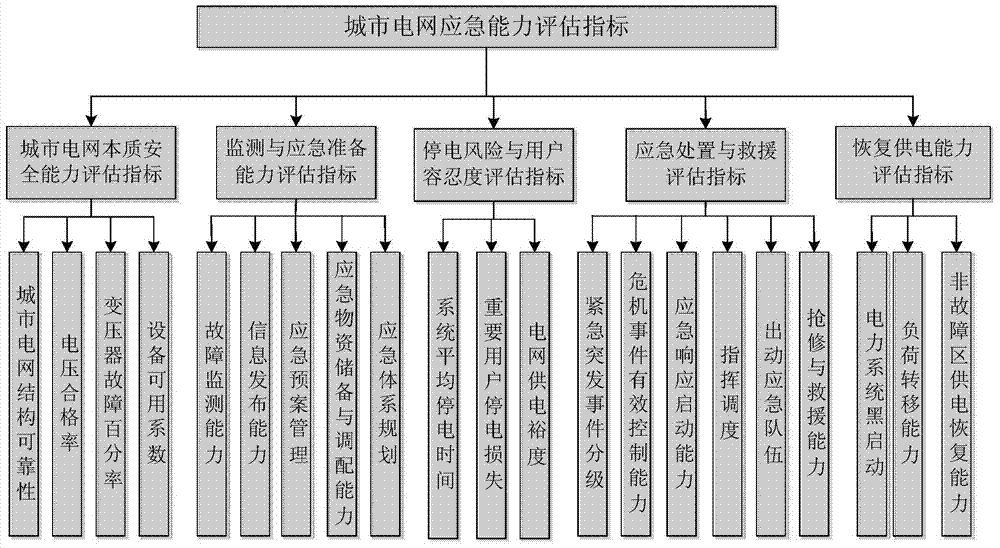

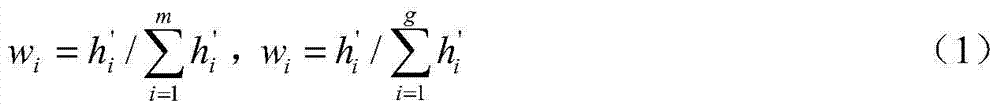

Urban power grid emergency capacity assessment method

InactiveCN104123681AConvenient and perfectOvercome limitationsData processing applicationsEntropy weight methodElectric power system

The invention discloses an urban power grid emergency capacity assessment method and belongs to the technical field of electrical power system emergency. The urban power grid emergency capacity assessment method comprises the steps of utilizing an anti-entropy weight method to calculate objective weights of emergency capacity assessment indexes of all levels of urban power grids, utilizing a G1 method to calculate subjective weights of the emergency capacity assessment indexes of all levels of urban power grids on the basis, and linearly combining the subjective weights and the objective weights to obtain combined weights of the emergency capacity assessment indexes of all levels of urban power grids, wherein the disadvantage of the limitation of solely subjective weight calculation or solely objective weight calculation is successfully overcome, and the accuracy of the weight calculation is improved; utilizing fuzzy comprehensive judgment to perform initial judgment on the urban power grid emergency capacity, utilizing a grey relational degree method to correct an initial judgment result, performing final judgment on the urban power grid emergency capacity to confirm the urban power grid emergency capacity level. The urban power grid emergency capacity assessment method well masters the situation of the urban power grid emergency capacity and has important practical significance on perfection of the urban emergency capacity promoting work.

Owner:STATE GRID CORP OF CHINA +2

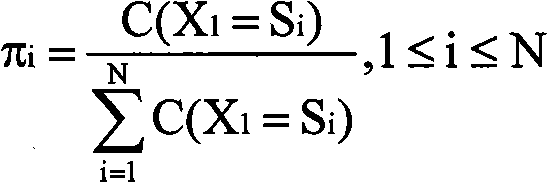

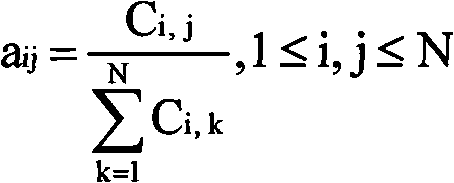

Program -class operating system debug method based on serial mode excavation

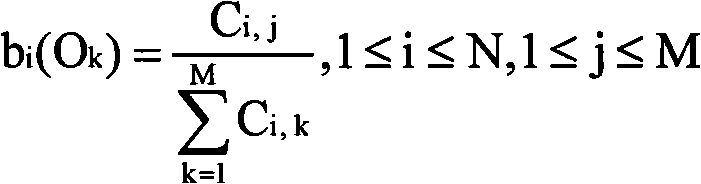

InactiveCN101308473APrecise positioningRapid positioningSoftware testing/debuggingOperational systemSerial pattern

The invention discloses a program-level operating system debugging method based on sequential pattern mining, comprising the following steps: to find all the frequent system calling sequential patterns through sequential pattern mining; to compute all the parameters in a hidden Markov model to identify abnormal system calling sequences. The method makes use of the sequential pattern mining method to carry through pattern mining to the system calling sequence set in the desktop operating system to find all the frequent sequence set, and also makes use of the frequent sequence set to train the hidden Markov model so as to eventually identify the abnormal system calling sequences through the Markov model to accurately and quickly target the bug location of the entire desktop operating system to help the user to improve the operating system.

Owner:ZHEJIANG UNIV

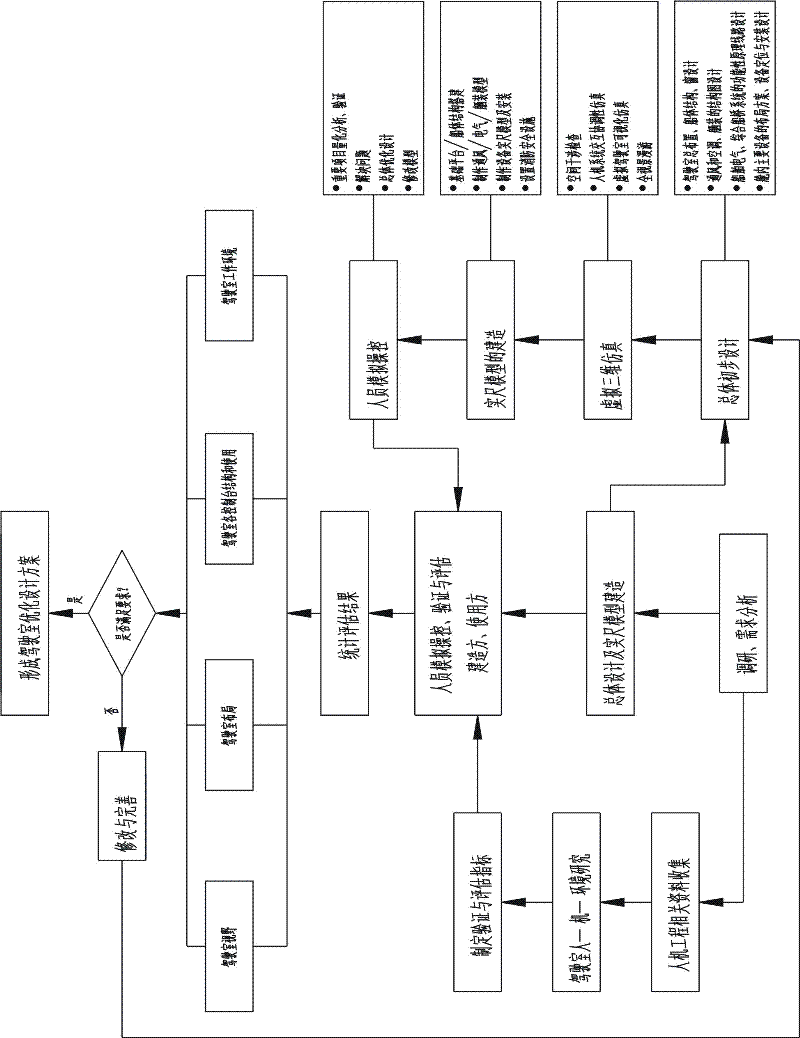

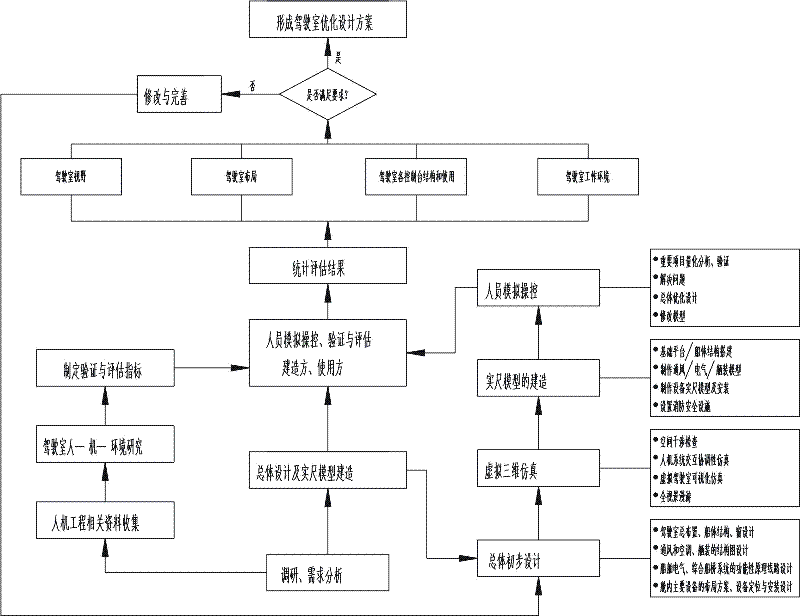

A verification and evaluation method for ship bridge

ActiveCN102295057AEasy to tryConvenient verificationVessel partsThree dimensional simulationWorking environment

The invention discloses a method for verifying and evaluating a ship cab. The method comprises the following steps: (1) totally and primarily designing; (2) carrying out virtual three-dimensional simulation; (3) building a full-scale model: on the basis of steps (1) and (2), manufacturing a ship structure, main equipment and an air conditioner and cable pipeline model by using a selected wooden material at the ratio of 1:1 according to the on-board building requirement, positioning and installing the main equipment and the pipeline mode, fitting out and decorating the inside of the cabin so as to comprehensively display the design of the whole cab; and (4) carrying out personnel simulation control, verification and evaluation: carrying out simulated control in the full-scale model built in the step (3) by personnel, and carrying out ergonomic verification and evaluation on cab view field, cab layout, the structure and use of each control console in the cab and the working environment of the cab. The method has the beneficial effects that: 1) the design scheme of the ship cab is optimized to the maximum degree; 2) the on-board building risk is lowered; 3) multi-party participation is enhanced; 4) and cost is lowered.

Owner:CHINA SHIP DEV & DESIGN CENT

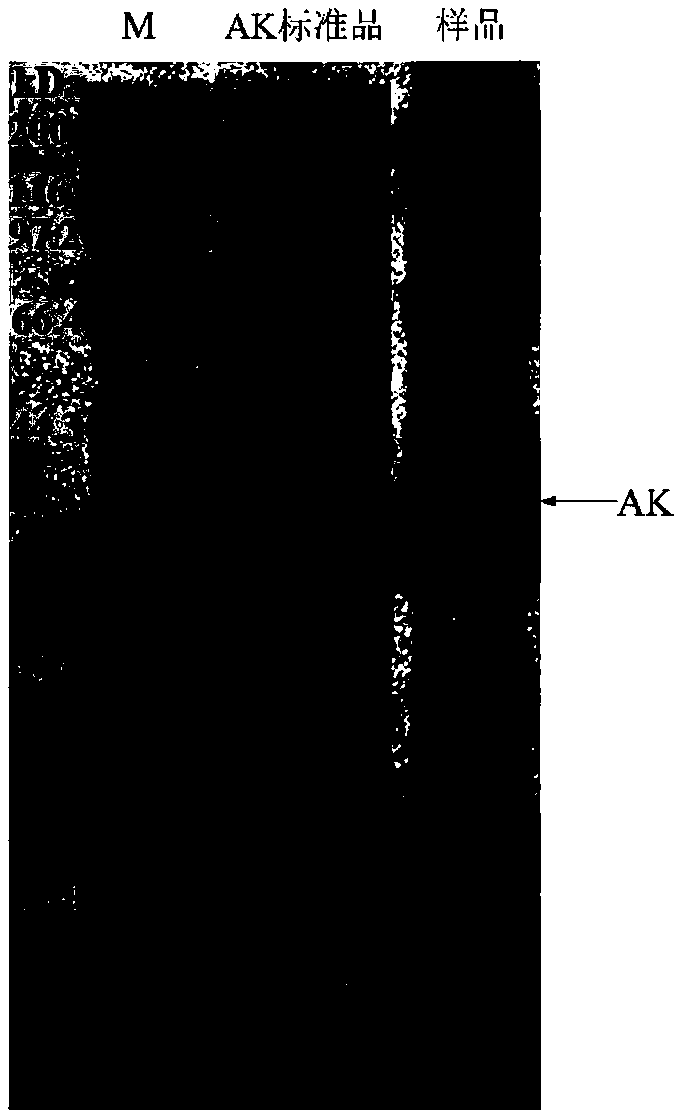

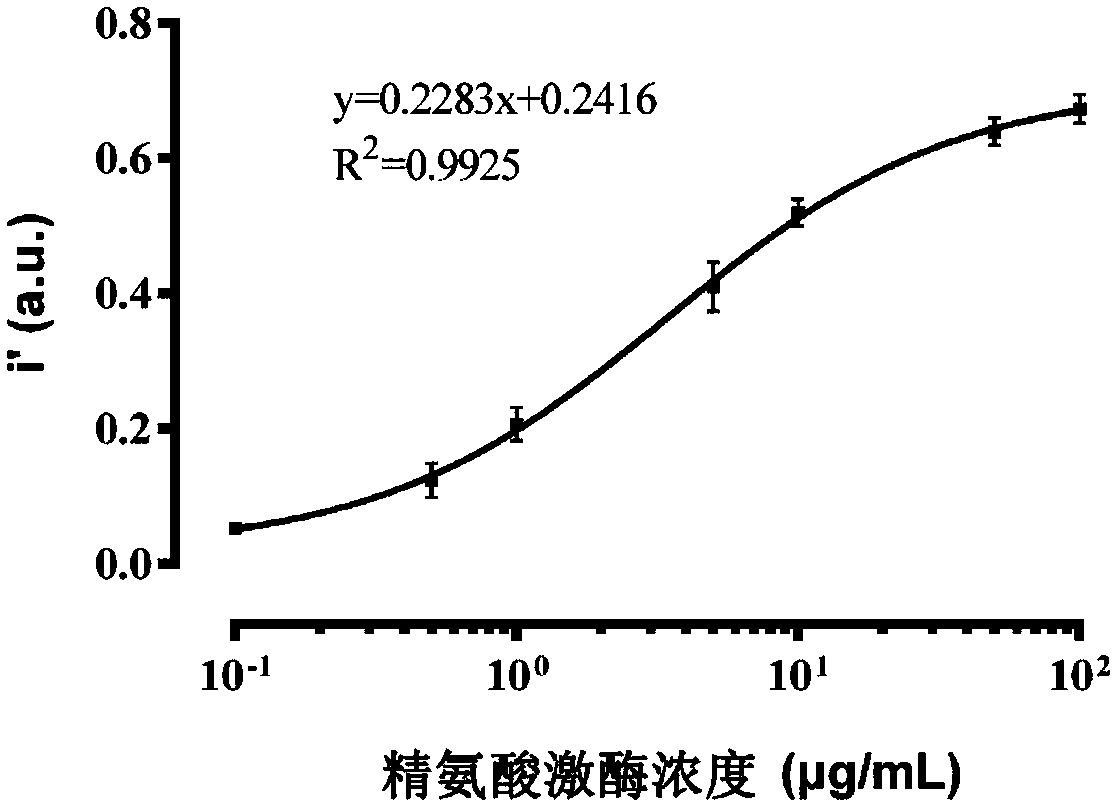

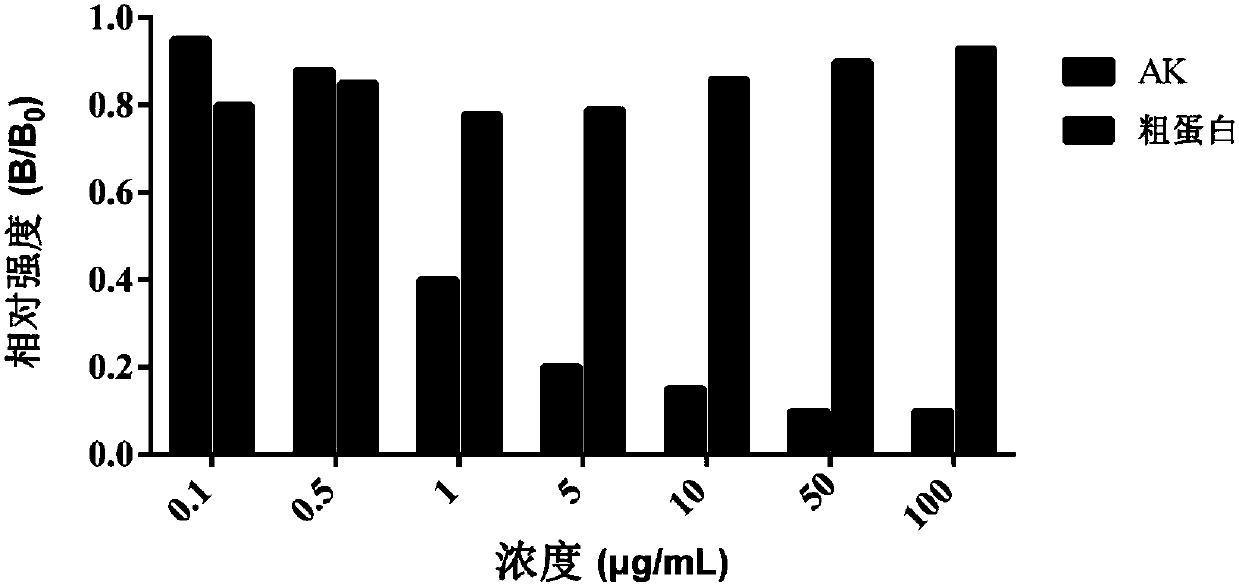

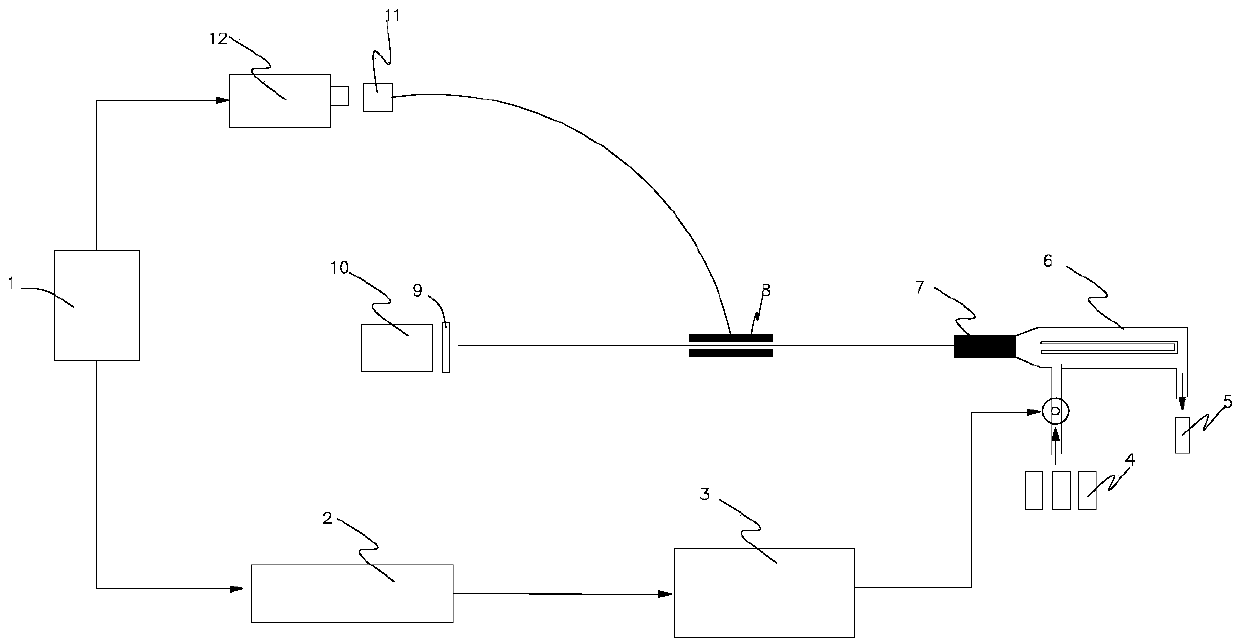

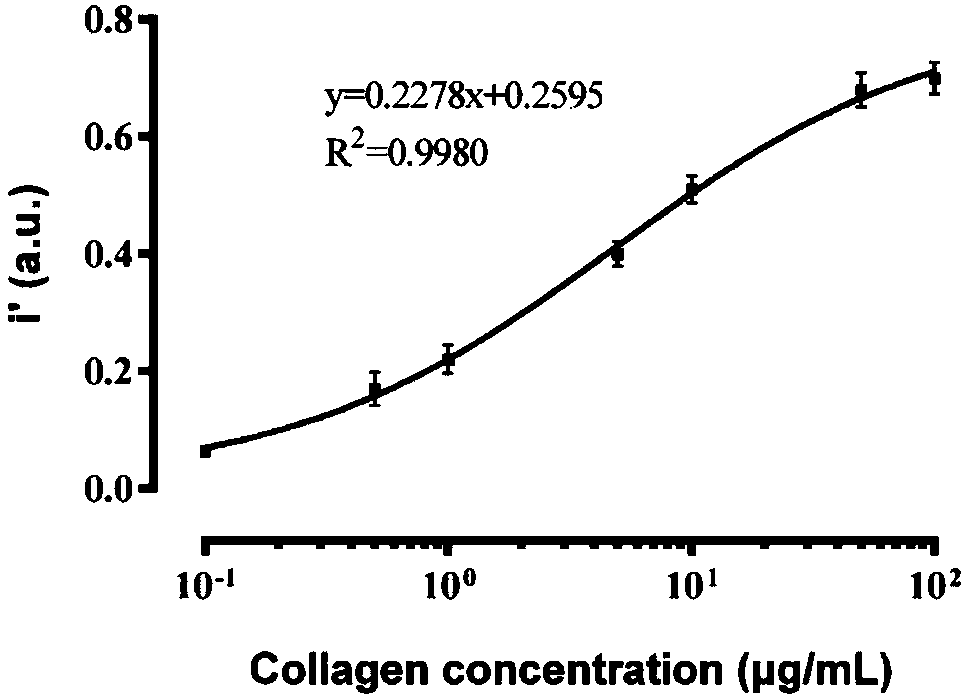

Method for detecting crustacean allergen by utilizing near-field optical wave targeting sensor based on antibody technology

InactiveCN107918018AConvenient and perfectHigh sensitivityBiological material analysisBiological testingAntigenFluorescence

The invention discloses a method for detecting crustacean allergen by utilizing a near-field optical wave targeting sensor based on an antibody technology. The method comprises the following steps: coupling Cy5.5 fluorescent dye and an allergen monoclonal antibody, coating an optical fiber with arginine kinase antigen, firstly performing the pre-reaction for a sample to be detected and a marker antibody, then injecting a mixed solution into a sample pool, inserting an optical fiber probe into the sample pool, enabling a coated antigen on an optical fiber to be combined with unreacted marker antibody, then acquiring and detecting the variation of fluorescent intensity by utilizing a near-field optical wave targeting sensor, and detecting the content of the allergen in the sample solution. The method is simple in operation, accurate in result, high in biological specificity, and capable of quantitatively detecting trace arginine kinase in an aquatic product and a product thereof, and hasimportant significance on promotion of the development of an aquatic product allergen marking system.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

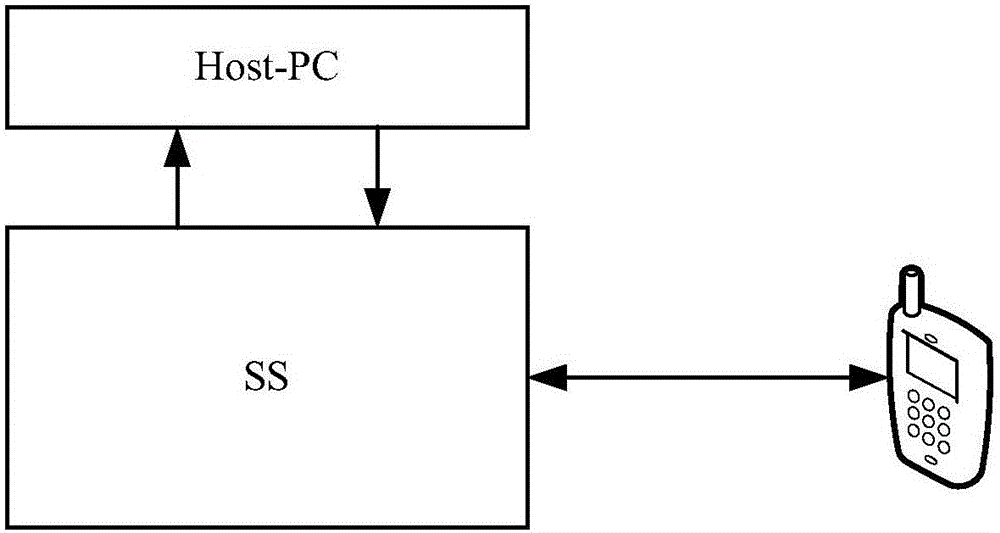

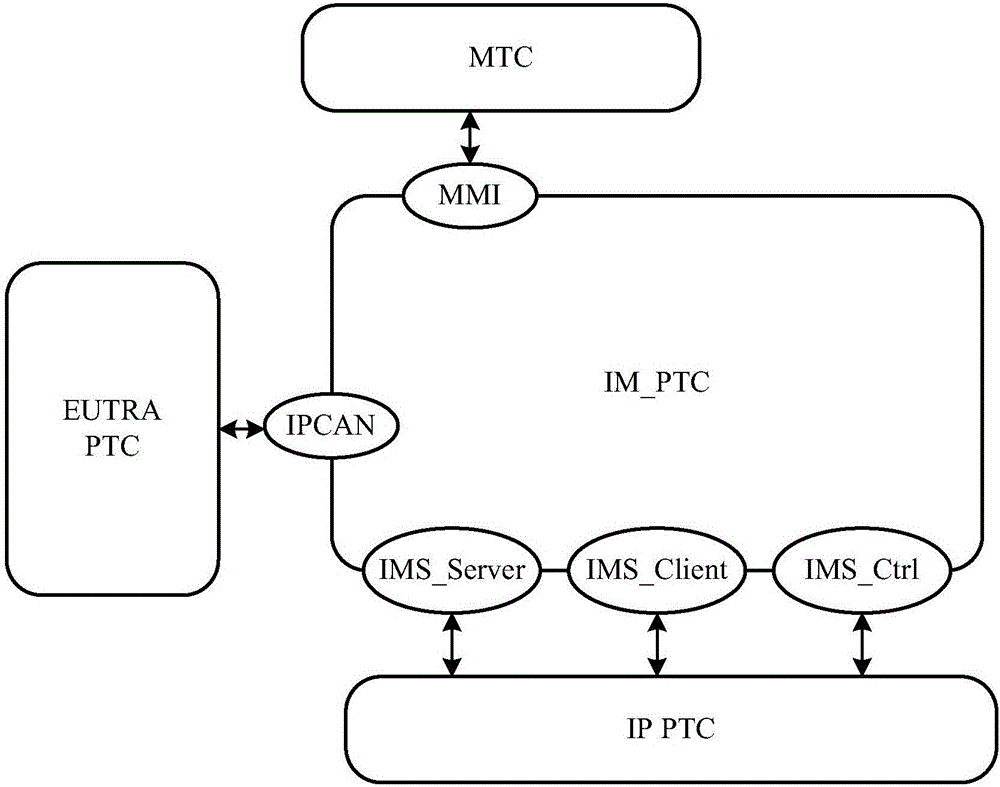

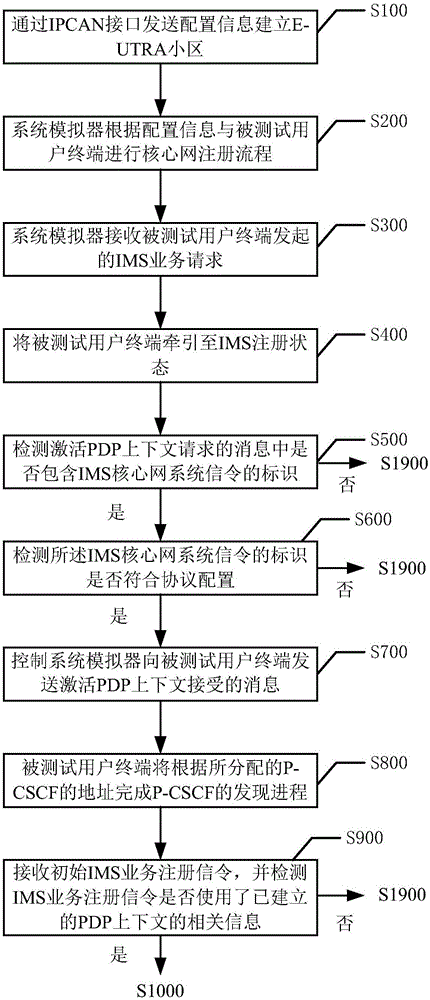

Method and system for testing terminal IMS registration consistency

ActiveCN106209521AConvenient and perfectOptimize the testing processData switching networksWireless communicationSoftware engineeringComputer science

The invention discloses a method and system for testing terminal IMS registration consistency. Based on a special test language configuration test interface, the terminal IMS registration consistency can be better tested by designing a corresponding test process, and it is conducive to optimizing the test process and prompting the perfection of terminal functions.

Owner:BEIJING TAIDE DONGTENG COMM TECH

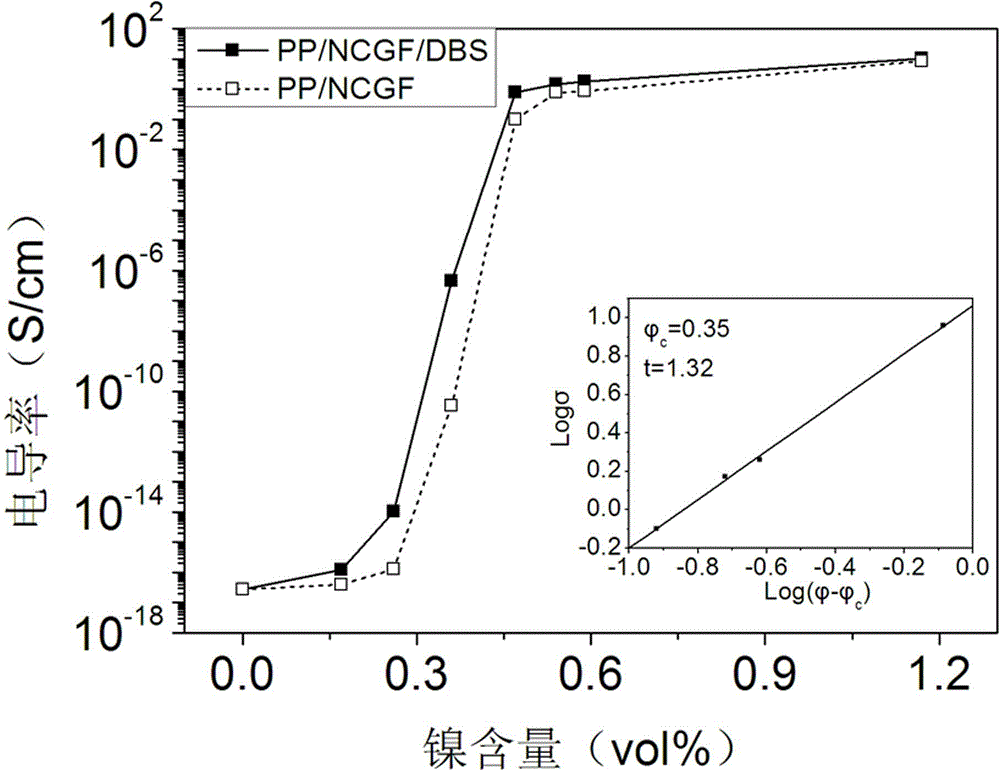

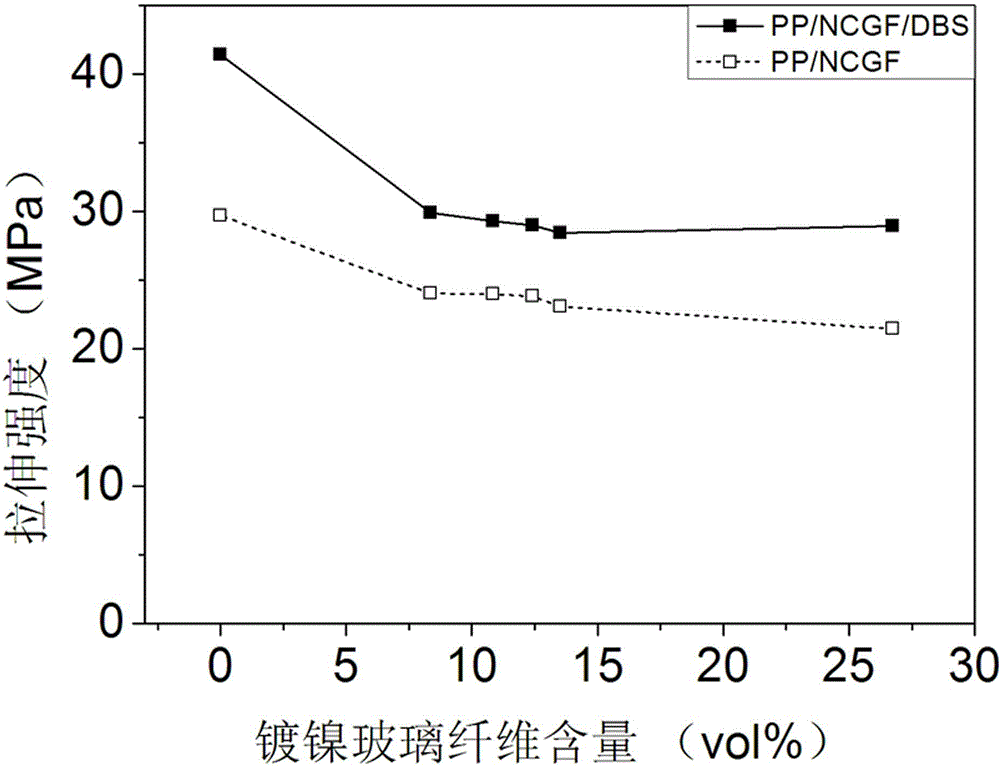

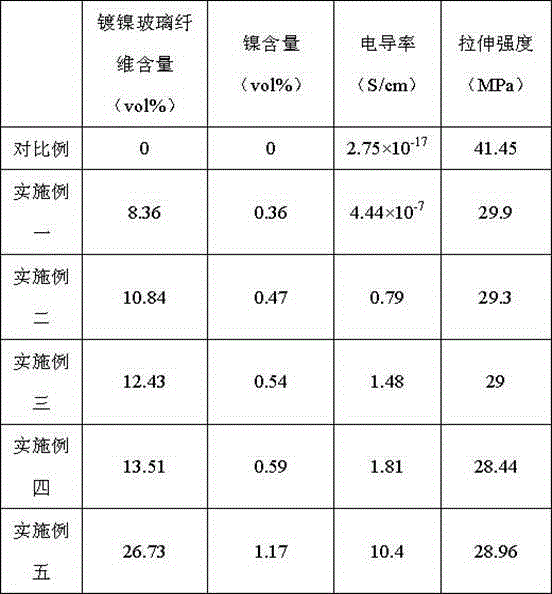

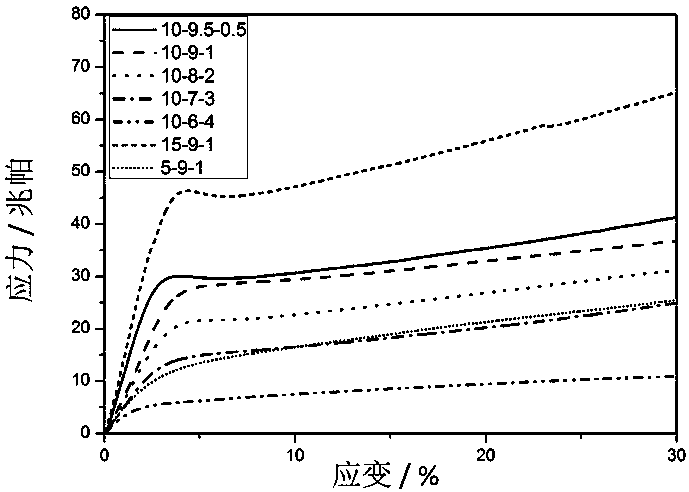

Preparation method of polypropylene (PP)/nickel-coated glass fiber (NCGF) composite material

The invention relates to a preparation method capable of enhancing electric conductivity and mechanical properties of a polypropylene (PP) / nickel-coated glass fiber (NCGF) composite material. According to the method, PP, a nucleator and NCGF are processed by melt blending to obtain the PP / NCGF composite material with favorable electric conductivity and mechanical properties. The nucleator is added to enhance the crystallinity of the PP and increase the crystalline region occupied volume. Under the volume elimination effect of the crystalline region, the electric conduction glass fibers are uniformly distributed in the amorphous region to enhance the effective concentration of the amorphous region and promote the formation of the electric conduction network, thereby obviously enhancing the electric conductivity of the composite material. The added nucleator enhances the crystallinity of the PP, enables the crystal grain to be uniform and refined, and is beneficial to the enhancement of the strength of the composite material. The method is simple in operational process and can easily implement industrial production. The prepared composite material has favorable electric conductivity and stability, and can be used in the fields of electromagnetic shielding, electronic and electric appliances, static resistance and the like.

Owner:ZHONGBEI UNIV

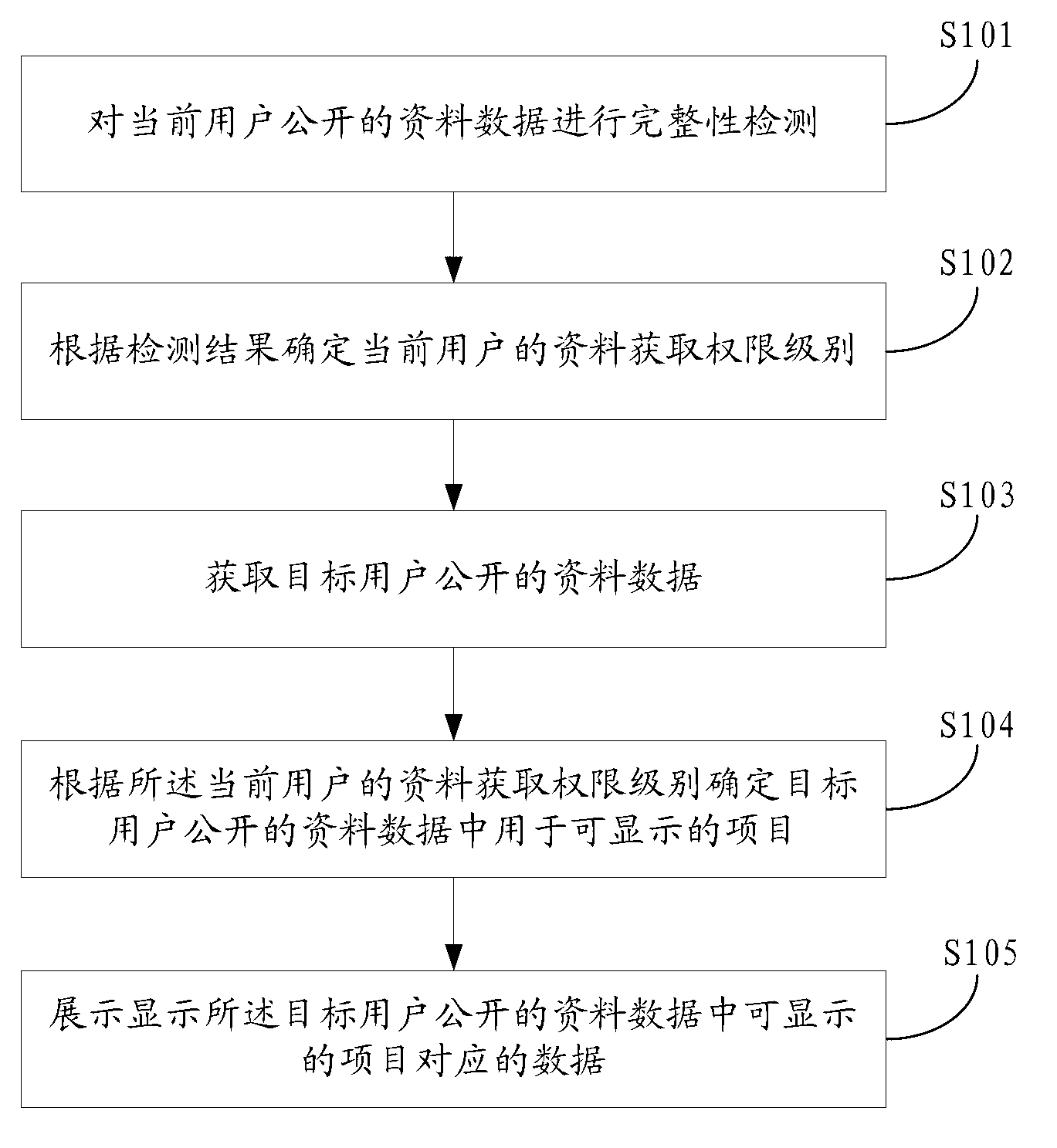

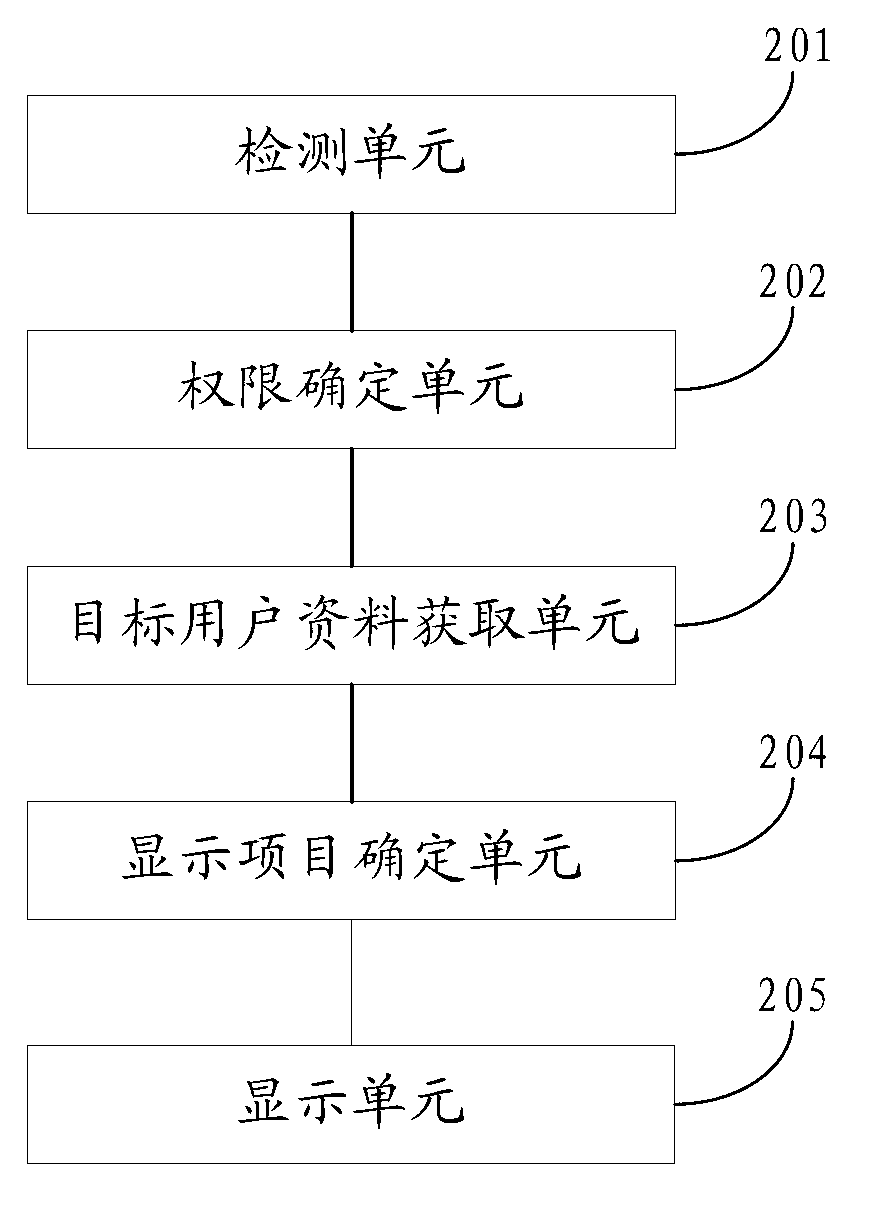

Method and system for processing data opened by user

ActiveCN103268453AConvenient and perfectGood data baseDigital data protectionData acquisitionInstant messaging

The invention discloses a method and a system for processing data opened by a user. The system comprises a detection unit, an authority determination unit, a target user data acquisition unit, a display item determination unit, a display unit and an join-group judgment unit, wherein the detection unit is used for performing integrity detection on the data opened by the current user; the authority determination unit is used for determining the data acquisition authority level of the current user; the target user data acquisition unit is used for acquiring the data opened by the target user or user group; the display item determination unit is used for determining a displayable item in the data opened by the target user or user group; the display unit is used for displaying the data corresponding to the item in the data opened by the target user or user group; and the join-group judgment unit is used for determining whether the current user is allowed to be joined according to the data acquisition authority level of the current user when receiving a request of the current user for applying for joining in the target user group. The method and the system are beneficial to guiding the user to perfect the user data of the user, and furthermore, a good data foundation is provided for realizing related functions of instant messaging.

Owner:BEIJING QIHOO TECH CO LTD

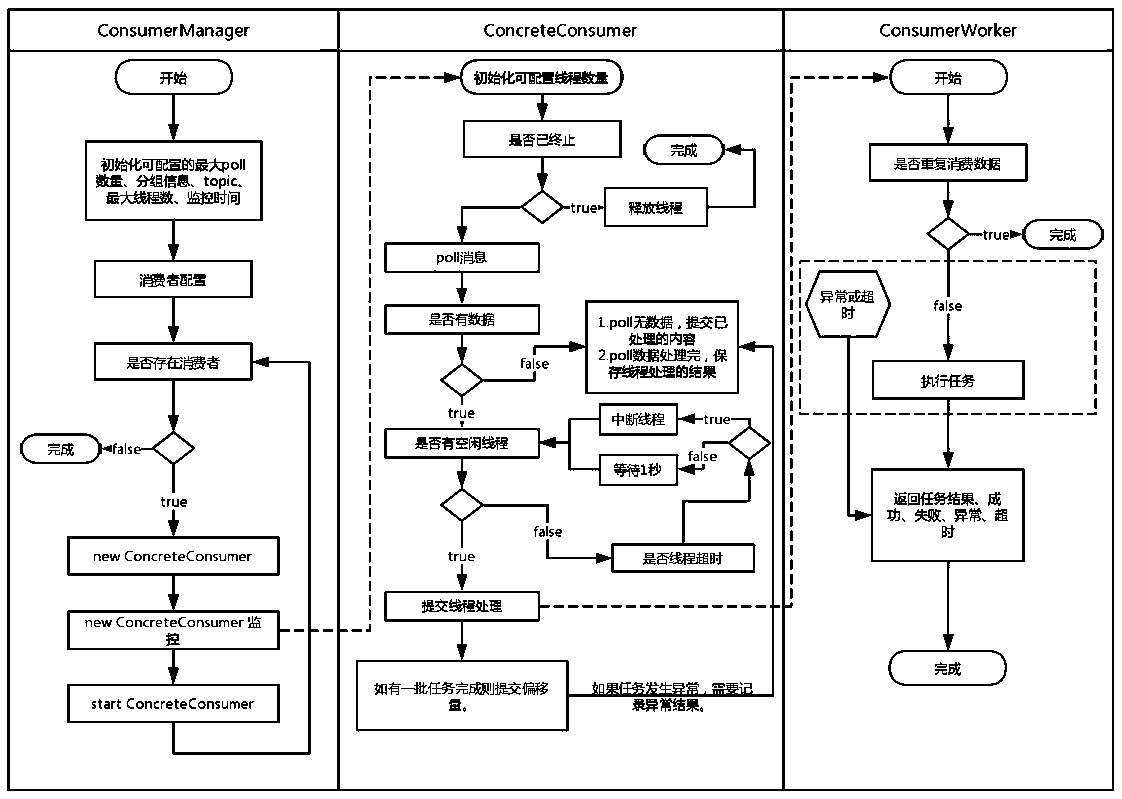

Stable high-throughput asynchronous task processing method based on kafka

ActiveCN110377486AIntegrity guaranteedTake advantage ofProgram initiation/switchingHardware monitoringTask completionCoupling

The invention relates to an asynchronous task processing method for realizing stable high throughput based on kafka. An asynchronous task mode based on kafka is adopted; in the processing mechanism for asynchronous tasks, a management thread is adopted to monitor various activity conditions of the working thread and is combined with the timing task to output the execution condition of the asynchronous task according to the frequency of the monitoring interval time; a timeout task processing mechanism and an abnormal task processing mechanism are provided, the monitoring task consumption situation, the statistics task execution time and the task completion detail situation are increased, parameters can be optimized and adjusted through the statistics situation, statistical information can be written into a log, and a user can analyze the performance through the log. According to the invention, the coupling of the system to the service system can be greatly reduced.

Owner:福建南威软件有限公司

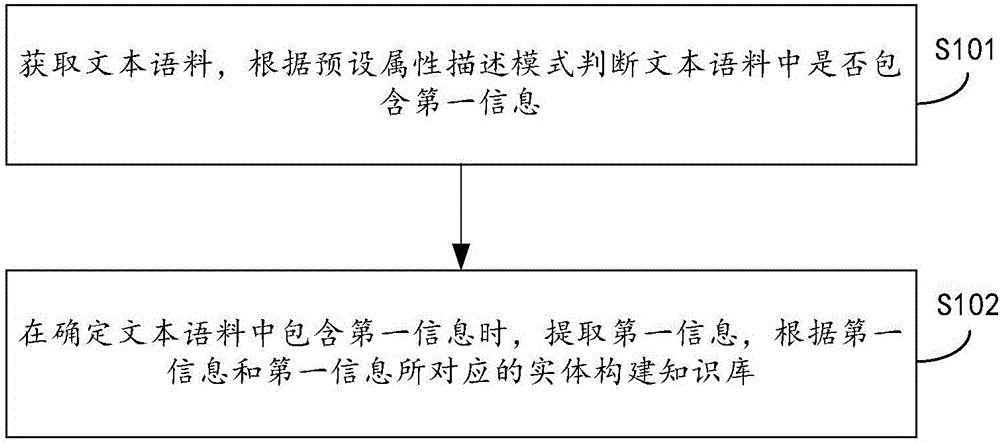

Knowledge base construction method and device

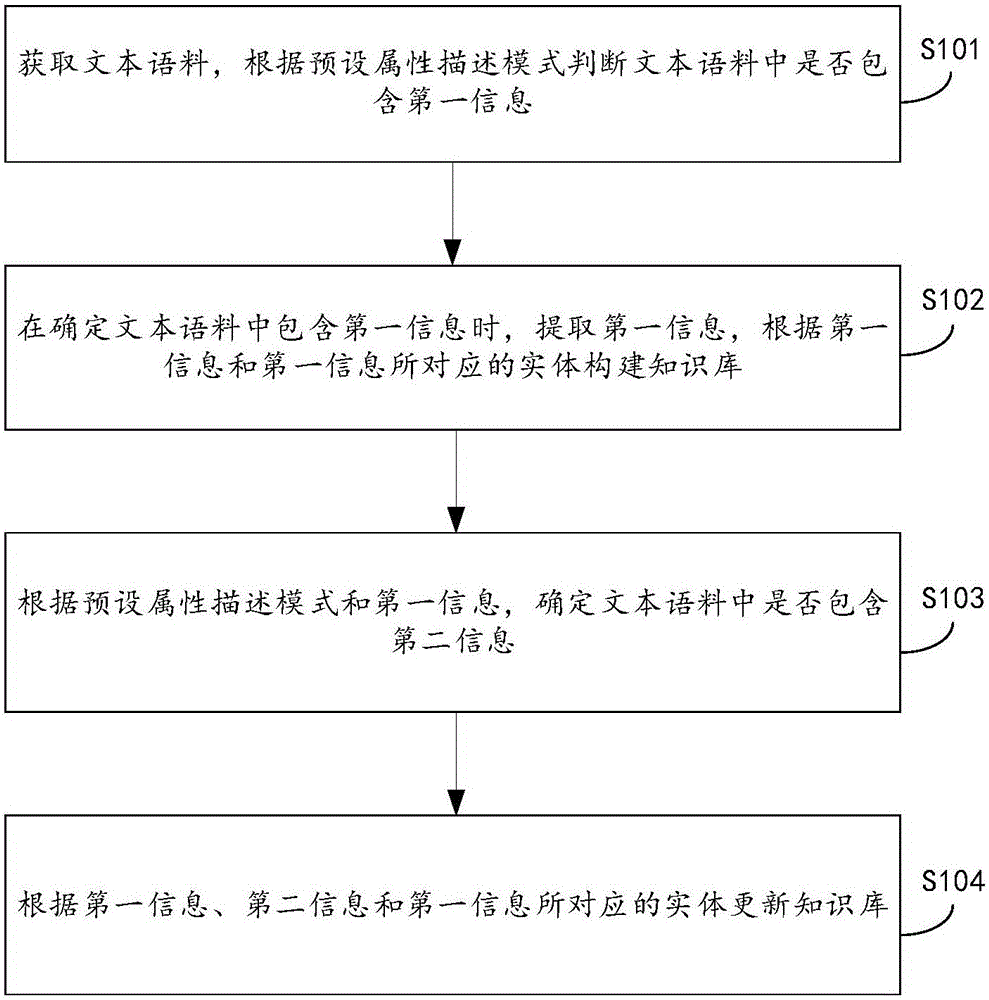

ActiveCN105138631ABuild fastSave human effortDatabase updatingNatural language data processingKnowledge miningKnowledge base

The invention relates to a knowledge base construction method and device. The knowledge base construction method includes the steps that text linguistic data are obtained, and whether the text linguistic data contain first information is judged according to a preset attribute description mode, wherein the first information includes attribute information of entities in a preset entity set; when it is determined that the text linguistic data contain the first information, the first information is extracted, and a knowledge base is constructed according to the first information and entities corresponding to the first information. According to the embodiment of the knowledge base construction method and device, in the process of constructing the knowledge base, it is unnecessary to perform knowledge mining in a manual mode, in this way, labor is saved, and the construction speed of the knowledge base is increased.

Owner:XIAOMI INC

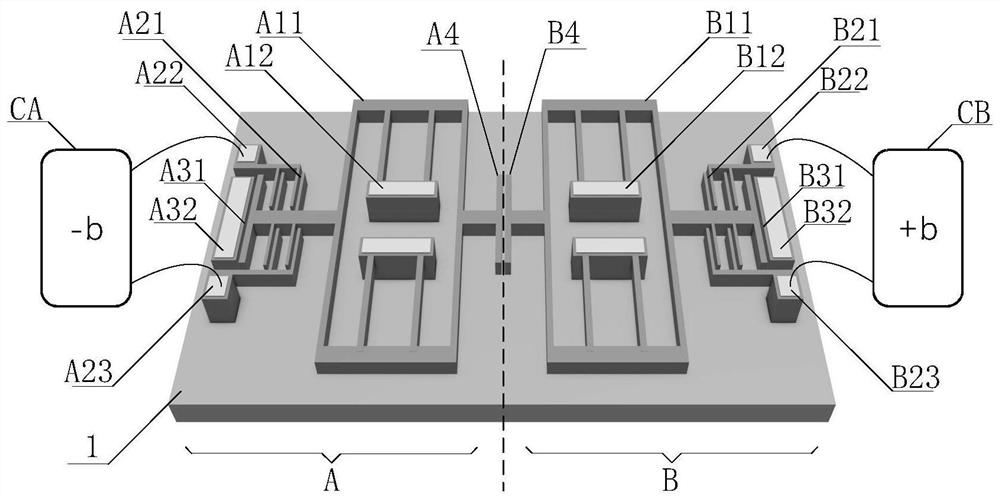

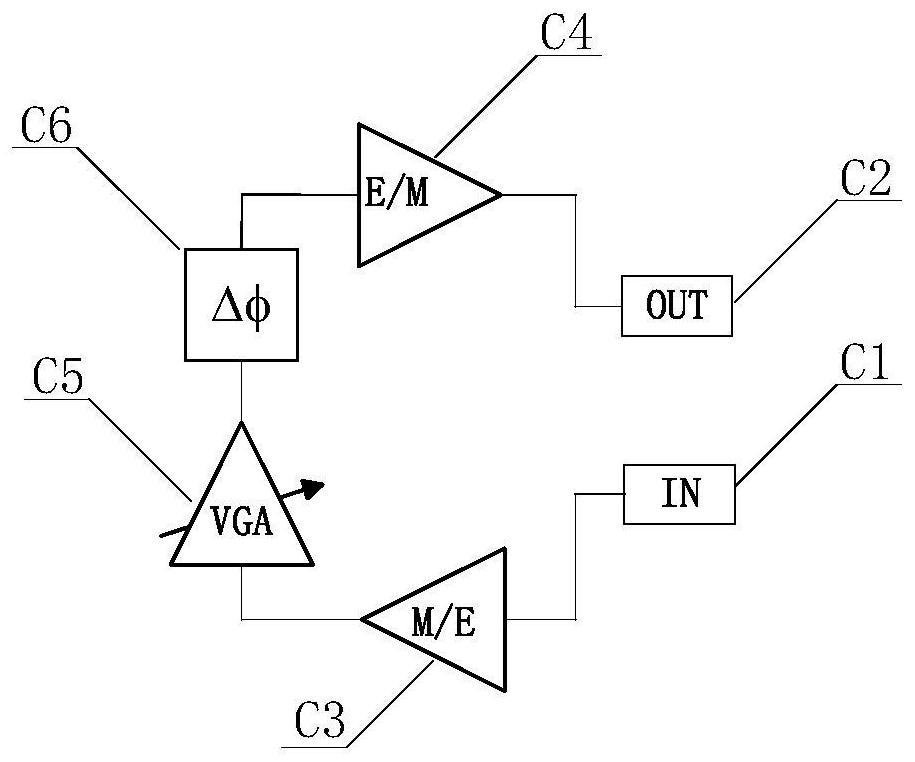

PT symmetric side-moving micro electro mechanical system

ActiveCN111732070AConvenient and perfectHigh sensitivityTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesMicro electrical mechanical systemsHemt circuits

The invention discloses a PT symmetric side-moving micro electro mechanical system. The micro electro mechanical system comprises a substrate, a first micro electro mechanical structure, a second micro electro mechanical structure, a first adjustable damping circuit and a second adjustable damping circuit, wherein the first micro electro mechanical structure and the second micro electro mechanicalstructure are arranged on the substrate, and the first micro electro mechanical structure and the second micro electro mechanical structure share the substrate and are of a mirror symmetry structure;the equivalent damping of the first adjustable damping circuit acting on the first micro electro mechanical structure and the equivalent damping of the second adjustable damping circuit acting on thesecond micro electro mechanical structure are opposite in sign and equal in size. According to the invention, the micro electro mechanical system can obtain perturbation response performance with higher sensitivity.

Owner:SOUTHEAST UNIV

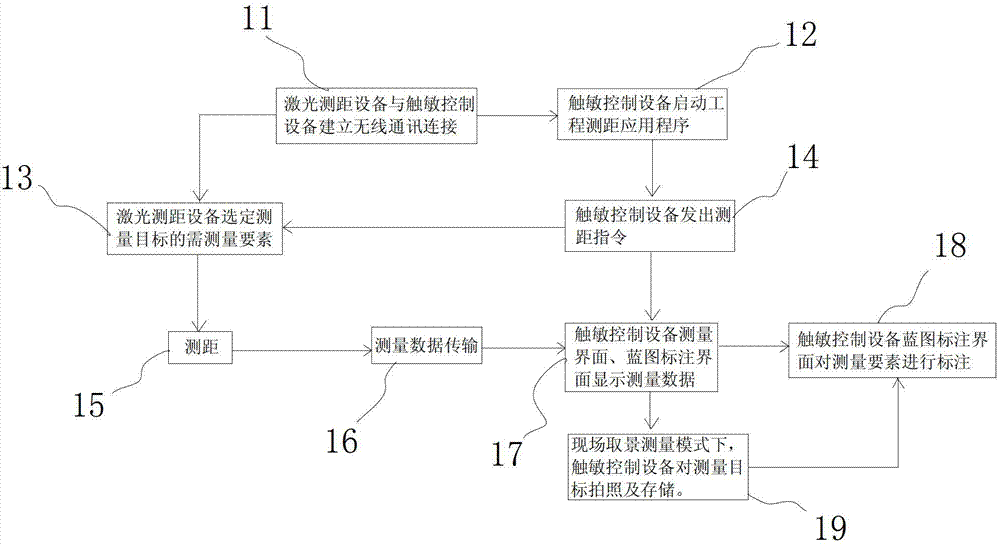

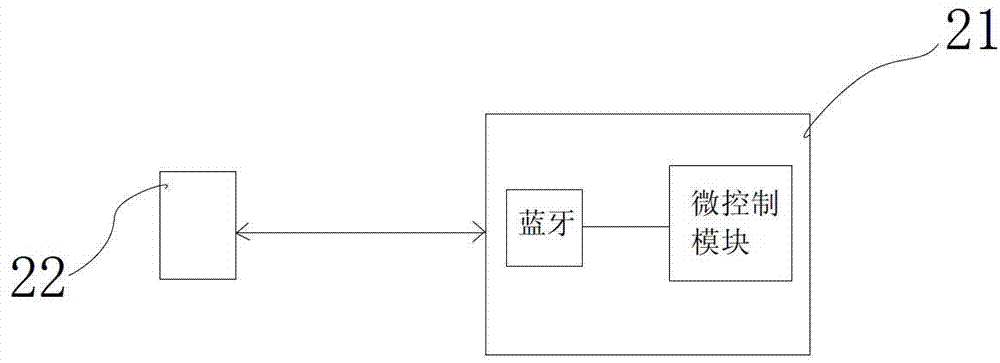

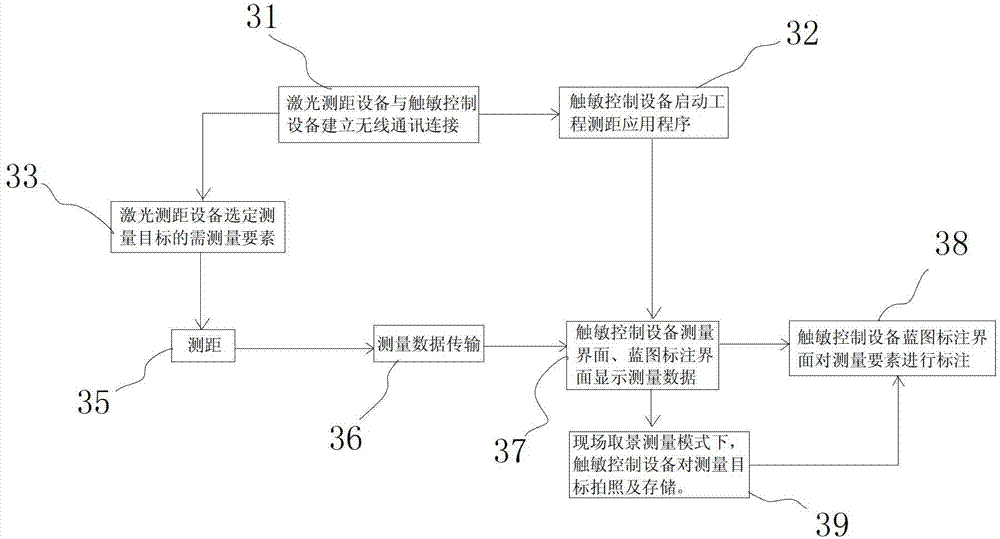

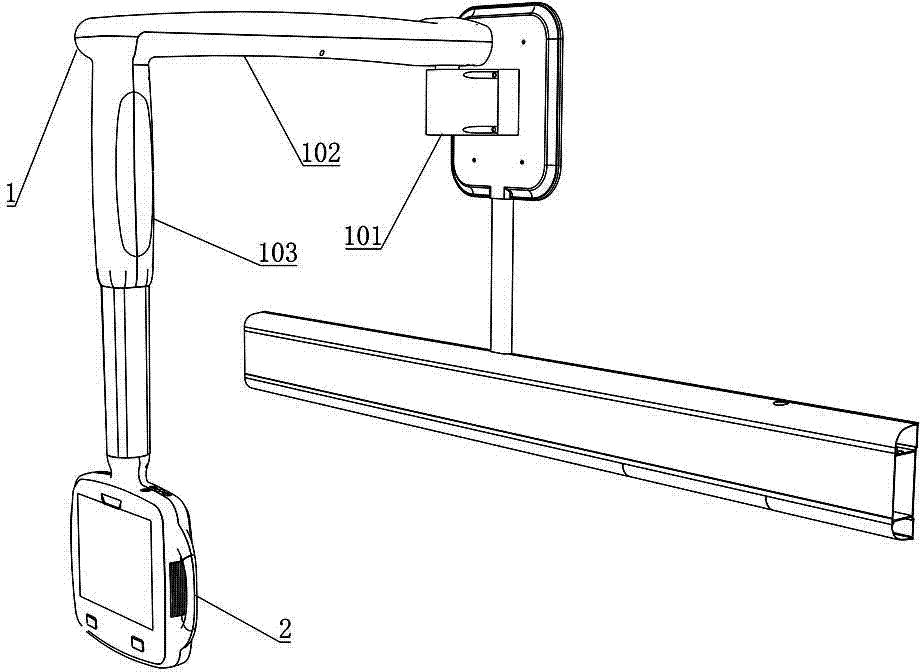

Method and device for generating project blueprint by remote control distance measurement

ActiveCN102878978AEasy to storeIncrease pleasureData processing applicationsOptical rangefindersData synchronizationLaser ranging

Owner:SHENZHEN EVERBEST MACHINERY IND

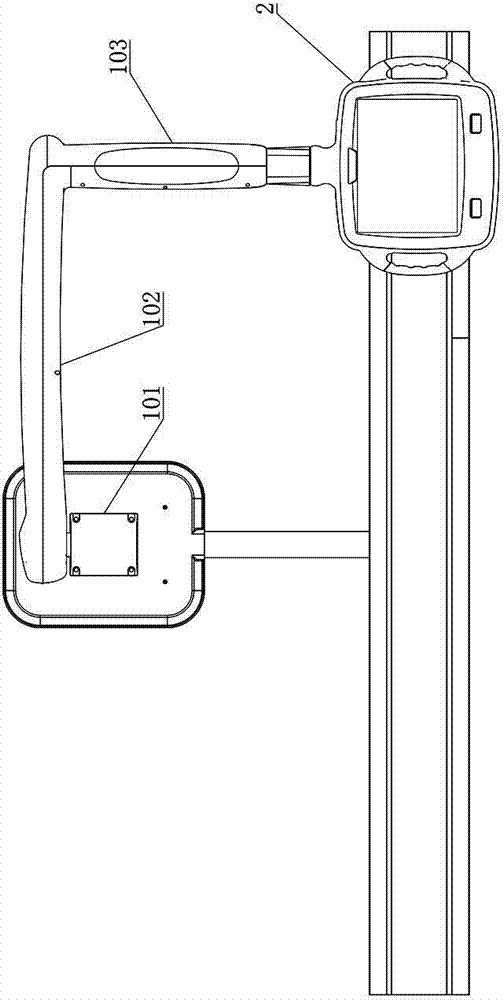

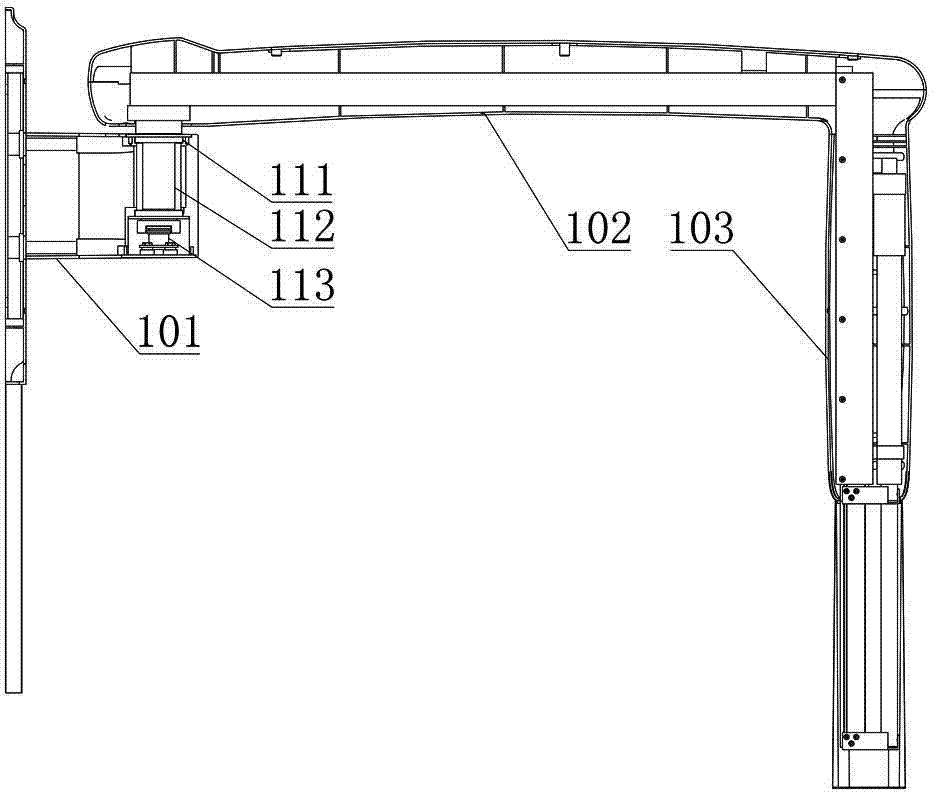

Bedside terminal and digital sickbed system

InactiveCN103655088ALarge transfer rangeImprove versatilityNursing bedsTwo-way working systemsEngineeringMedical equipment

The invention discloses a bedside terminal. The bedside terminal comprises a bedside support and a double-screen digital bedside terminal body, wherein the bedside support comprises a support base and a support rod, the support base is arranged on the wall of a sickbed bedside, the support rod is movably connected with the support base, the support rod horizontally rotates around the support base, and the double-screen digital bedside terminal body is movably arranged at the other end of the support rod. The bedside terminal has the advantages of being multifunctional and convenient to move. The invention further discloses a digital sickbed system. The digital sickbed system comprises an aisle information publish terminal, a gate screen, an inpatient area monitoring terminal, a workstation and the sickbed bedside terminal, wherein the double-screen digital bedside terminal body of the bedside terminal, the gate screen, the inpatient area monitoring terminal and the workstation are connected through a network terminal, and carry out mutual communication, the double-screen digital bedside terminal body is connected with the network terminal through a medical equipment entry box, and the aisle information publish terminal is connected with the network terminal, receives signals of the network terminal, and displays the signals. The digital sickbed system can effectively promote communication between doctors and patients.

Owner:湖南新云医疗装备工业有限公司

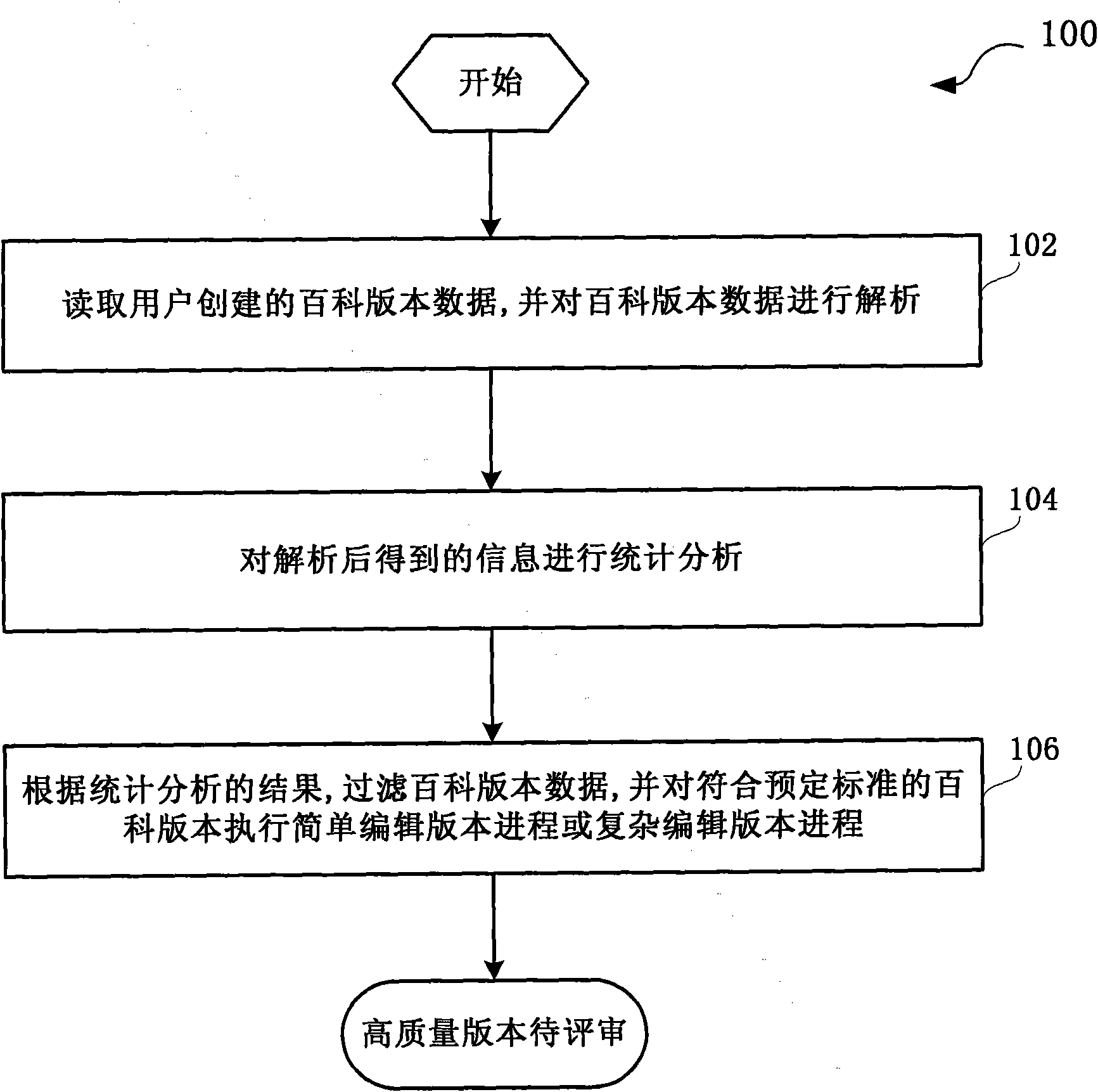

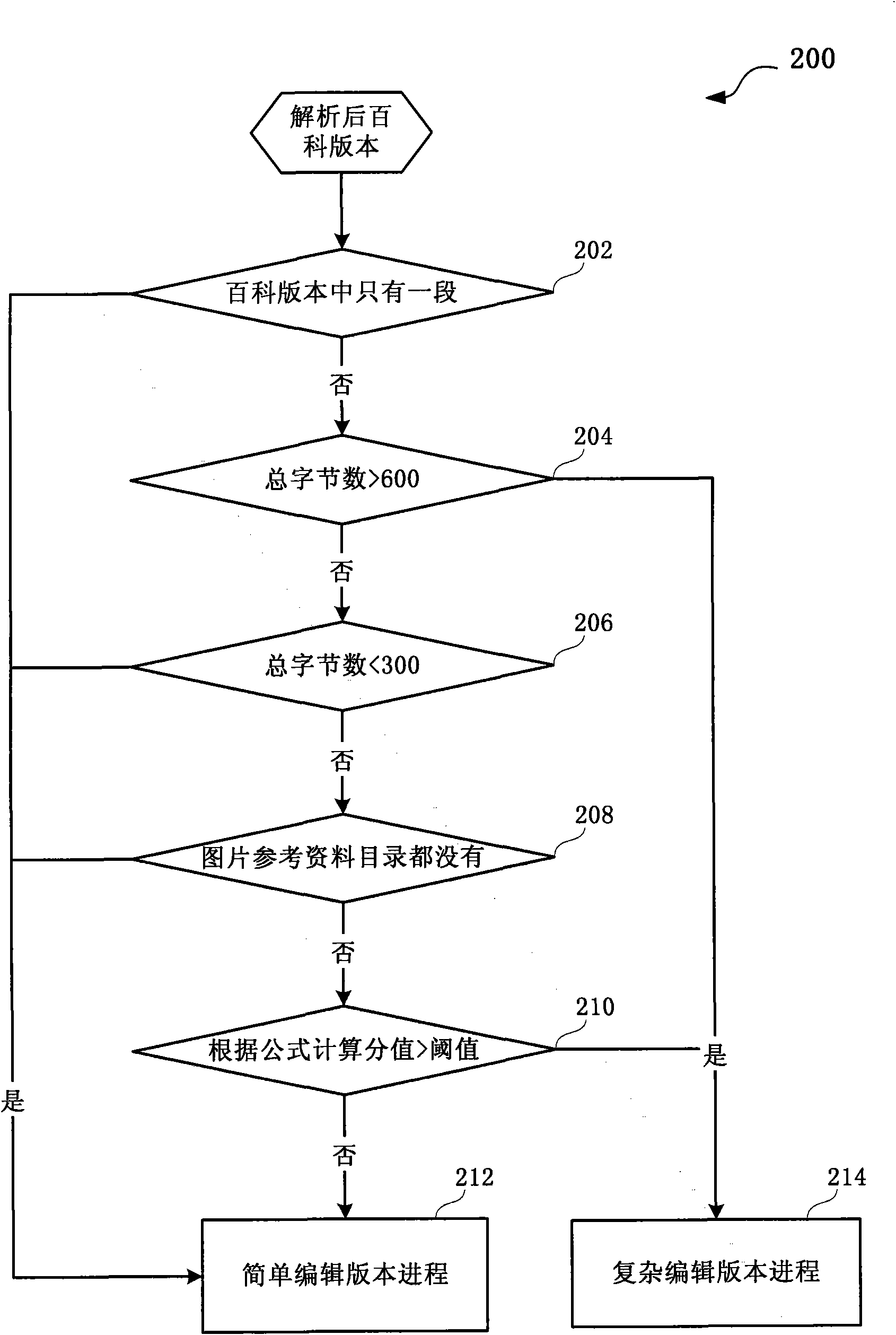

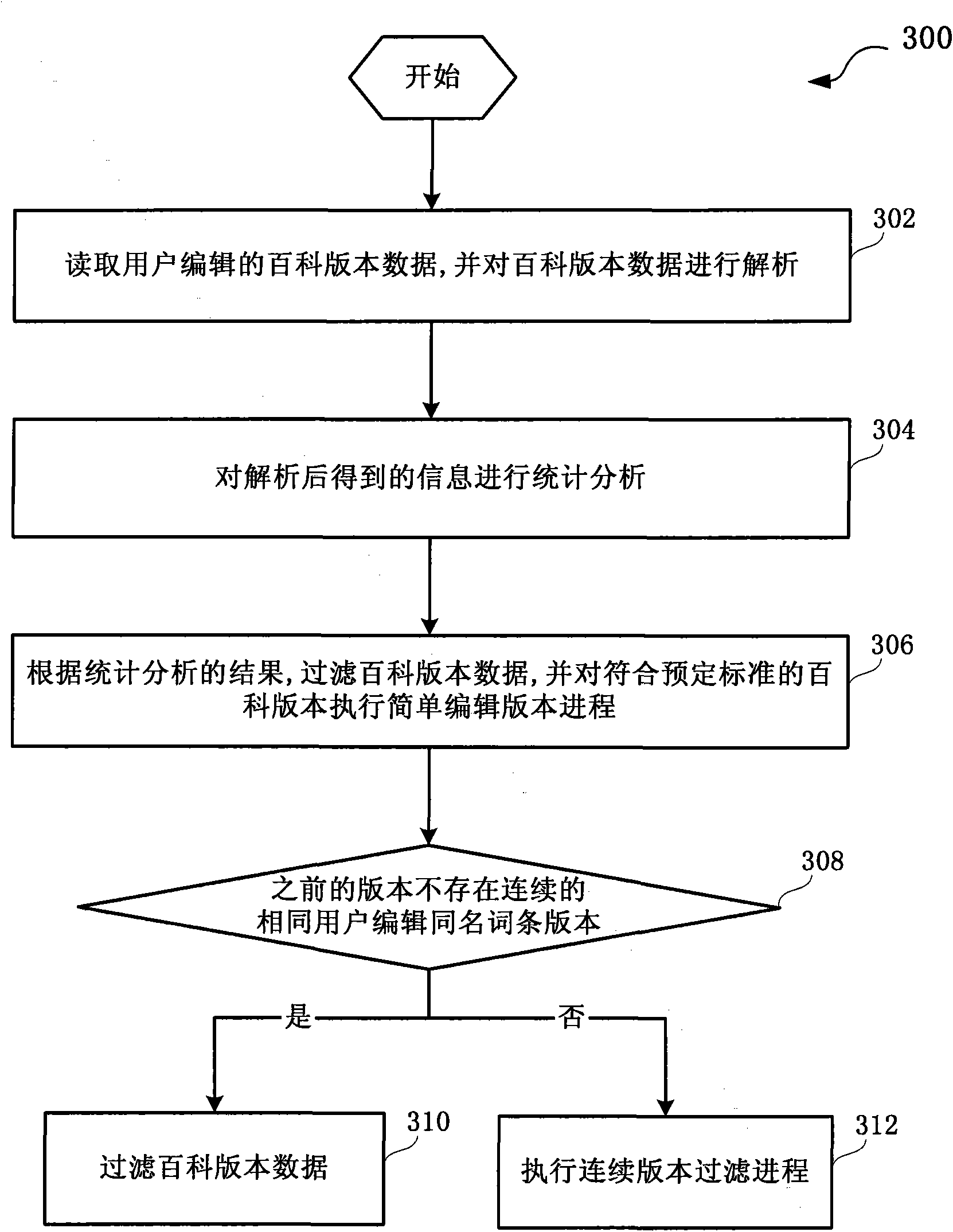

Method and system for screening high-quality versions

ActiveCN102314453AImprove editingEasy to digSpecial data processing applicationsStatistical analysisSoftware engineering

The invention discloses a method and a system for screening high-quality versions. The method comprises the following steps of: reading encyclopedia version data created by a user, and analyzing the encyclopedia version data; performing statistical analysis on information acquired through analysis; and filtering the encyclopedia version data according to a statistical analysis result, and performing a simple version editing process or a complex version editing process on encyclopedia versions which meet the predetermined standard. By the method and the system, the screening efficiency of complexly edited encyclopedia version data is effectively improved on the premise of reducing manual screening input; the encyclopedia versions subjected to the simple version editing process or the complex version editing process are further subjected to a continuous version filtering process, so that high-quality encyclopedia versions to be audited are more accurately screened from mass encyclopedia data; and the high-quality versions and non-high-quality versions are quickly and accurately screened, so that the user is pertinently guided in continuously perfecting entry information, and the hierarchical management of encyclopedia users is perfected.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

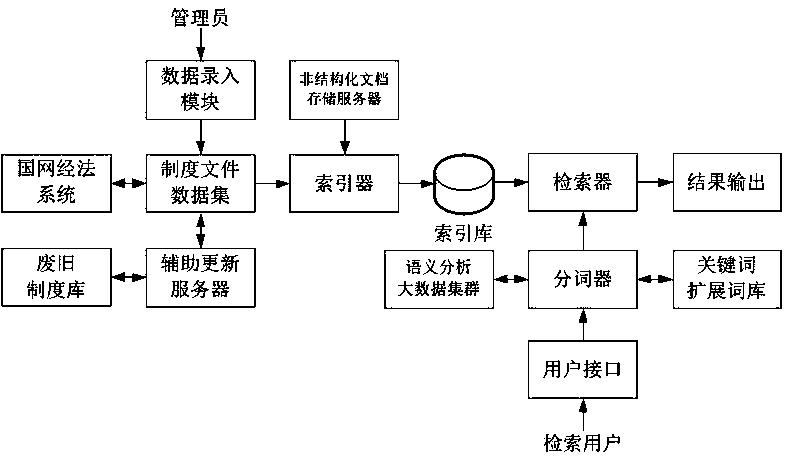

Unstructured document management and rule entry management integrated system

PendingCN109871468ASolve outstanding problemsConvenient and perfectOther databases indexingOther databases queryingIndexerData set

The invention discloses an unstructured document management and rule and system entry management integrated system which comprises a data input module used for inputting rule and system files; The system file data set is used for storing rule file data; The indexer is used for constructing an index for the rule file data; The index library is used for storing all file indexes; The word segmentation device is used for analyzing at least one retrieval keyword from retrieval information input by a user; And the retriever is used for determining a target file index matched with the retrieval keyword from the file indexes in the index library, determining target description information corresponding to the target file index and displaying the target description information. The invention provides a storage and retrieval platform integrating unstructured document management and rule entry management, a user can quickly and accurately obtain a full-text retrieval result of a rule, and meanwhile, the cloud storage, access and management functions of the unstructured document can be realized.

Owner:GUANGYUAN POWER SUPPLY COMPANY OF STATE GRID SICHUAN ELECTRIC POWER

Cement foamed heat insulation core material, inorganic compound heat insulation plate, manufacturing method and mold

ActiveCN104478354AConvenient and perfectPromote sustainable developmentCeramic shaping apparatusCeramicwareFiberFoaming agent

The invention discloses a cement foamed heat insulation core material, an inorganic compound heat insulation plate, a manufacturing method and a mold. The core material is manufactured by mixing the following components in percentage by weight: 31-35% of fly ash, 49.7-62.8% of silicate cement, 0.8-1.2% of water repellent, 0.6-8% of early strength agent, 4-5% of foaming agent, 0.4-0.6% of high molecular fibers and 0.4-0.5% of composite foaming agent. Renewable resources are sufficiently utilized, and the provided inorganic compound heat insulation plate has excellent heat insulation performance, high strength, excellent breaking resistance and good sound insulation performance, is inorganic, green, low in manufacturing cost and as long as a building in service life and achieves a non-combustible level A. The inorganic compound heat insulation plate can be solidified with a concrete structure into a whole as a secondary template when a structural body is poured, and can also be used for solving the problem about external wall heat insulation and floor heat insulation without influencing the structural body.

Owner:重庆安吉升科技有限公司 +1

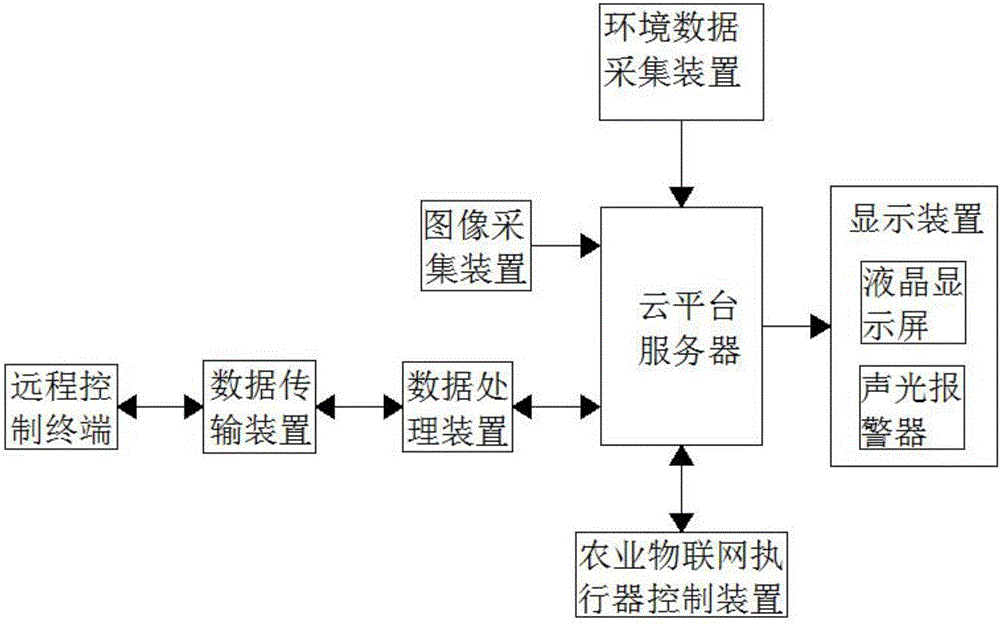

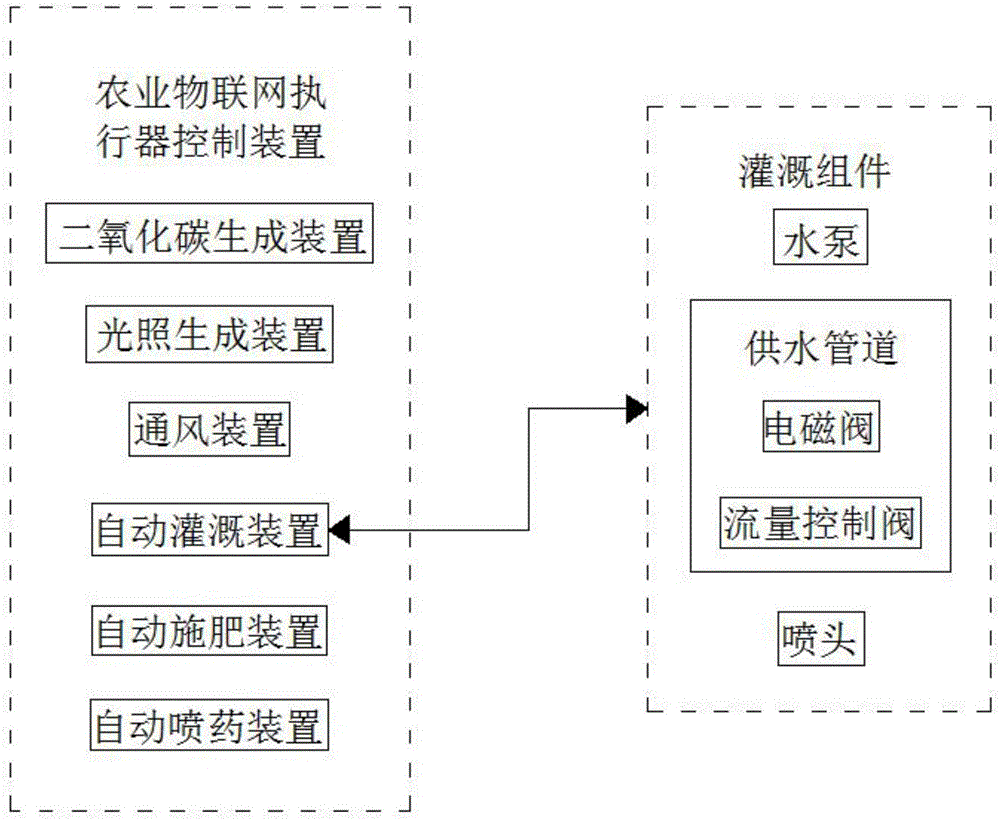

Internet-of-things application system

InactiveCN106790731AThe principle is simpleConvenient and perfectData processing applicationsClosed circuit television systemsData acquisitionThe Internet

The invention discloses an Internet-of-things application system in the technical field of modern agriculture. The Internet-of-things application system comprises an image acquisition device, wherein the image acquisition device is in signal output connection with a cloud platform server; the data processing device is in bidirectional electric connection with a data transmitting device, and the data transmitting device is in bidirectional signal connection with a remote control terminal; the cloud platform server is in signal input connection with an environmental data acquisition device; the cloud platform server is in signal output connection with a display device; the cloud platform server is in bidirectional signal connection with an agricultural Internet-of-things actuator control device; an automatic irrigation device is in bidirectional signal connection with an irrigation assembly which comprises a water pump; a water inlet end of the water pump is connected to a water supply pipe, and the water supply pipe comprises an electromagnetic valve and a flow control valve; the flow control valve and the electromagnetic valve are both in signal connection with a remote control terminal; and the water pump is also connected to a sprayer by means of a pipe. The system is simple in principle, and capable of effectively promoting productivity.

Owner:HENAN INST OF ENG

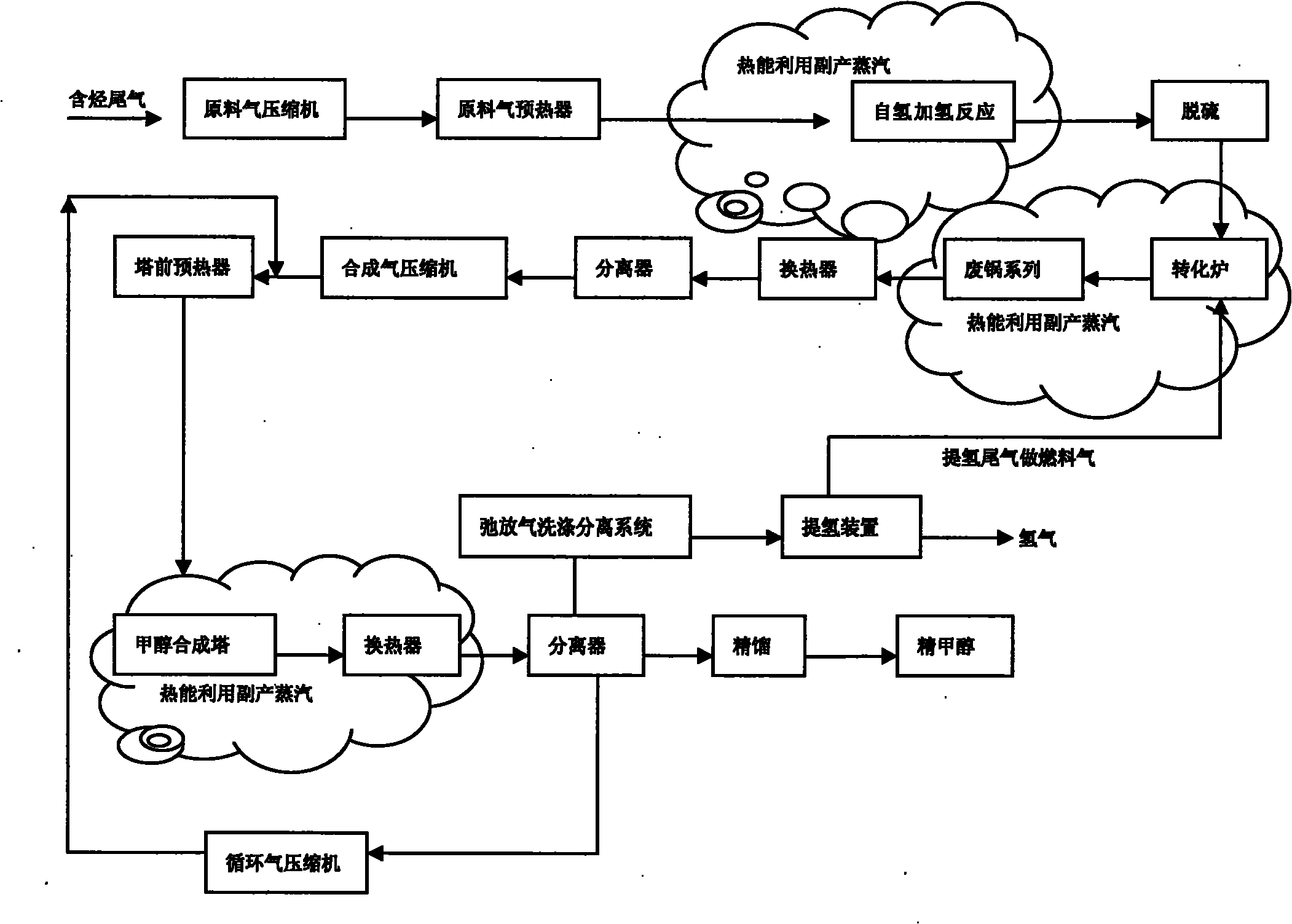

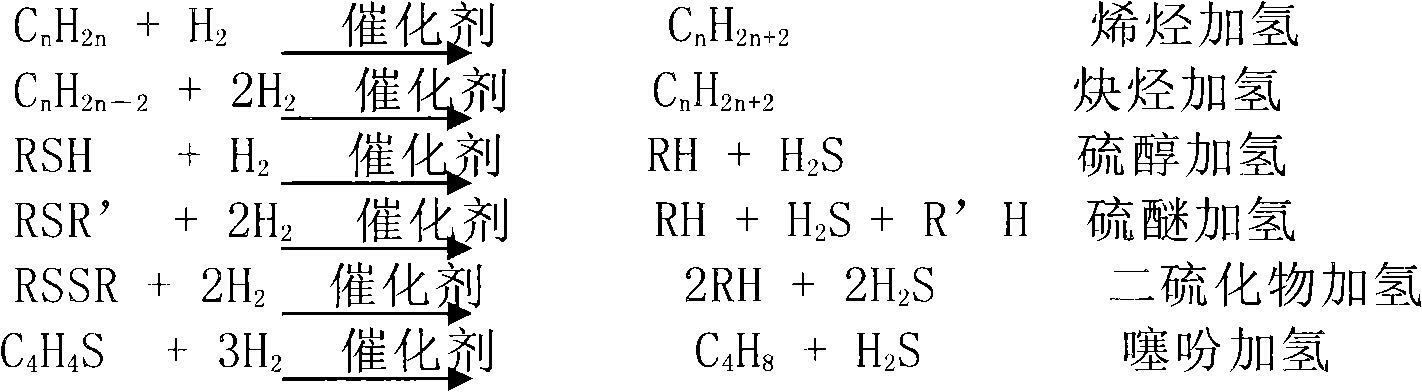

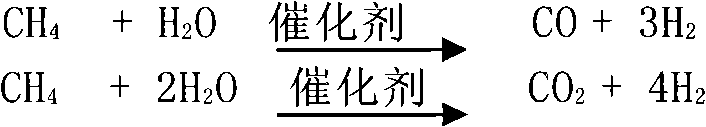

Method for producing methanol, coproduct hydrogen and byproduct steam by utilizing hydrocarbonaceous tail gas

InactiveCN101823936AEmission reductionReduce pollutionHydrogenOrganic compound preparationExhaust gasScrap

The invention discloses a method for producing methanol, coproduct hydrogen and byproduct steam by utilizing hydrocarbonaceous tail gas. The invention is characterized in that the method includes the following steps: A, hydrocarbonaceous tail gas is subject to self hydrogenation under the action of catalyst, unsaturated hydrocarbon is converted into saturated hydrocarbon, and meanwhile sulfocompound generates sulphur compound which can be easily removed under the action of catalyst; and heat generated in the reaction is utilized to produce steam; B, sulphur compound removal is carried out on the products obtained by the step A; C, the products obtained by the step B react with the steam to prepare hydrogen, carbon monoxide and carbon dioxide under the action of catalyst; D, the products obtained by the step C are used for preparing methane under the action of catalyst; E, methane and hydrogen are respectively collected. The invention has the beneficial effects that: resource is reasonably utilized, energy conservation and emission reduction and environmental protection can be realized; carbon element is converted into methane, emission of carbon dioxide is reduced, a desulphurization device is adopted to remove organic sulphur and inorganic sulphur in tail gas, sulphur compound emission is reduced, and the method is beneficial to environmental protection. Waste is fully utilized and recycled, and industry chain is improved.

Owner:SHANGHAI HUISAI ENG TECH

Fibroin/cellulose derivative composite material and preparation method thereof

The invention belongs to the technical field of natural polymer materials, and particularly relates to a fibroin / cellulose derivative composite material and a preparation method thereof. The preparation method comprises the steps: heating a mixed aqueous solution of a fibroin aqueous solution and hydroxypropylmethylcellulose or hydroxypropylcellulose or methylcellulose for curing, then immersingthe cured material in a solution which can induce transformation of fibroin for ageing, and performing drying so as to prepare the high-strength fibroin bulk material. The preparation process is simple, green and mild, energy-saving and efficient, has low cost, and the mechanical properties of the final bulk material can be controlled through simple adjustment of the solid content and blending ratio; and the prepared natural macromolecular-based high-strength material can be applied to the field of biomedicine.

Owner:FUDAN UNIV

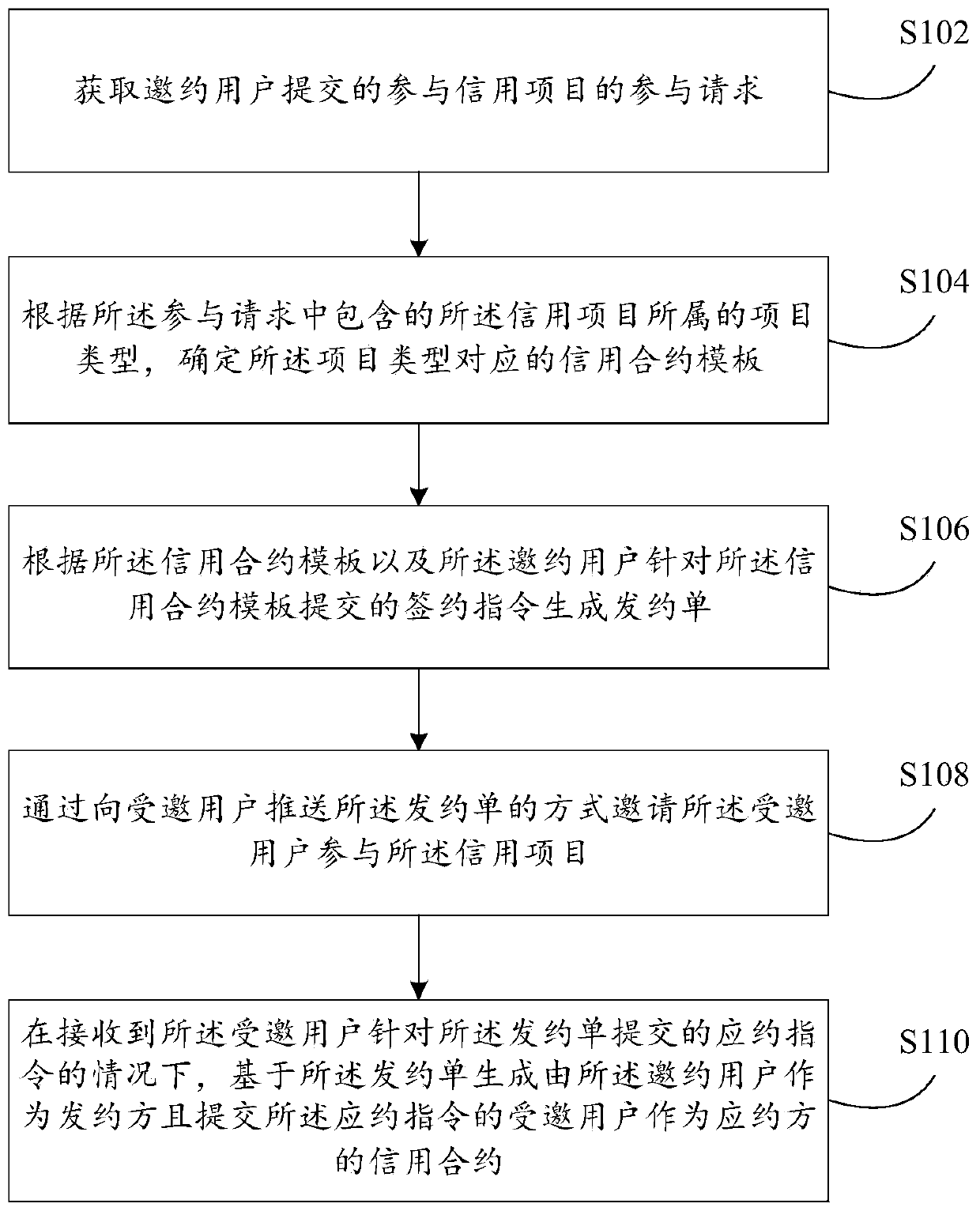

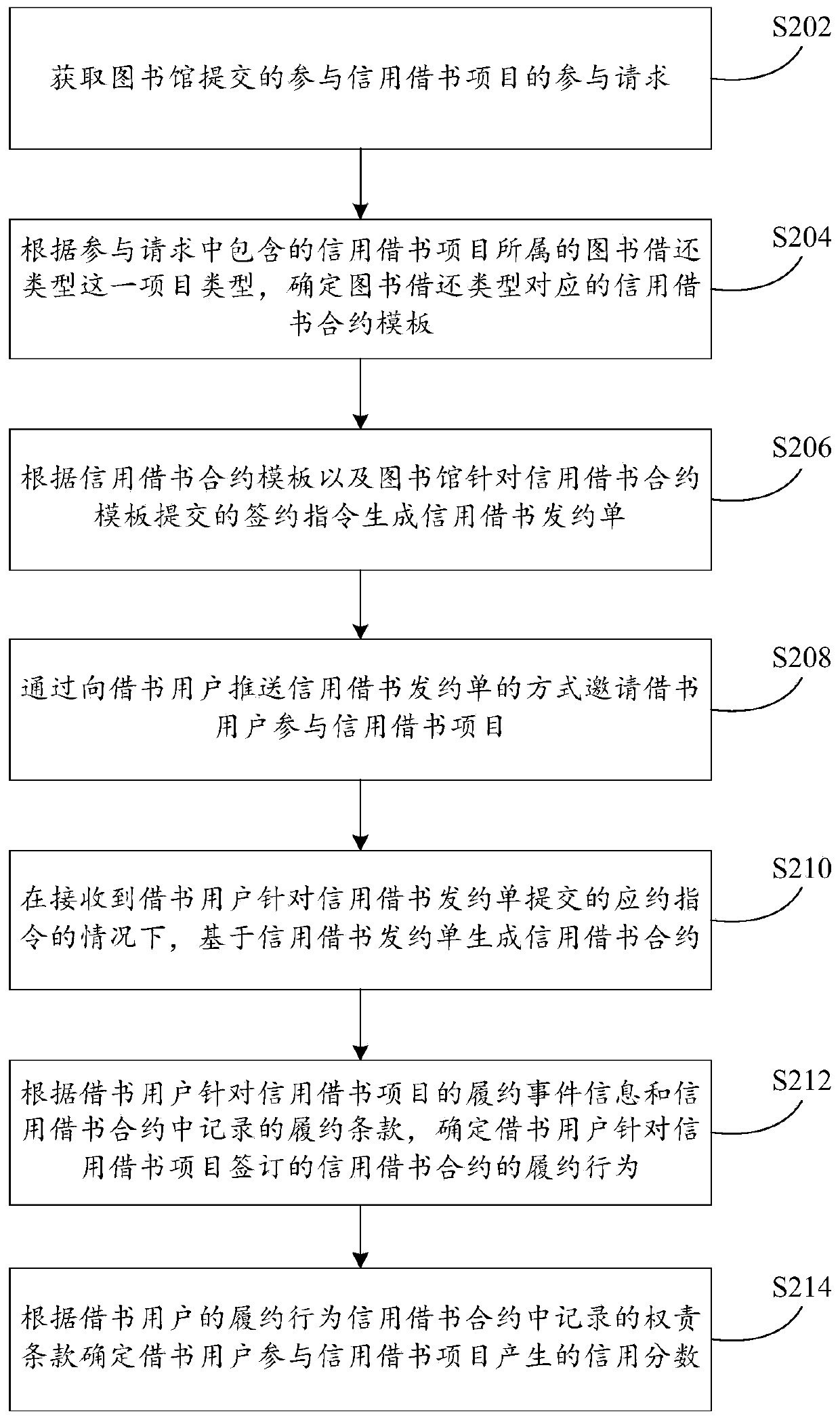

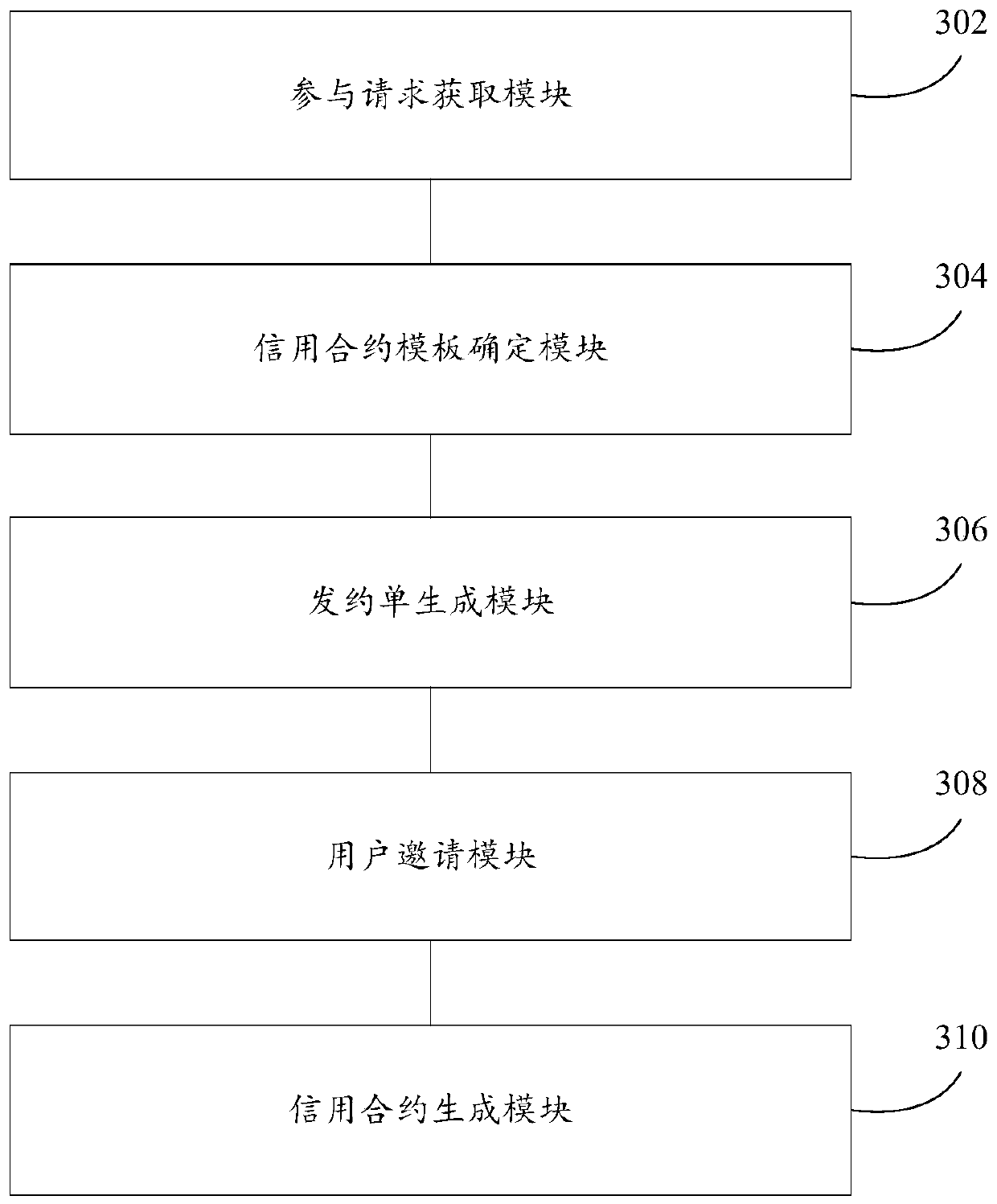

Credit contract processing method and device

ActiveCN110570270AIncrease engagementIncrease credibilityBuying/selling/leasing transactionsCredit systemUser participation

The invention provides a credit contract processing method and device, and the method comprises the steps: obtaining a participation request, submitted by an invited user, of participating in a creditproject; determining a credit contract template according to the participation request; generating a contract issuing list according to the credit contract template and a contract signing instructionsubmitted by the invited user for the credit contract template; inviting the invited user to participate in the credit project by pushing the issuing order to the invited user; and generating a credit contract based on the contract issuing list when a contract application instruction submitted by the invited user for the contract issuing list is received. According to the credit contract processing method provided by the invention, the rights and interests of all participants of the credit project are guaranteed, the credibility of the credit project is improved, the user participation degreeof the credit project is further improved, and the promotion of the popularization of the credit project and the improvement of a credit system are facilitated.

Owner:ADVANCED NEW TECH CO LTD

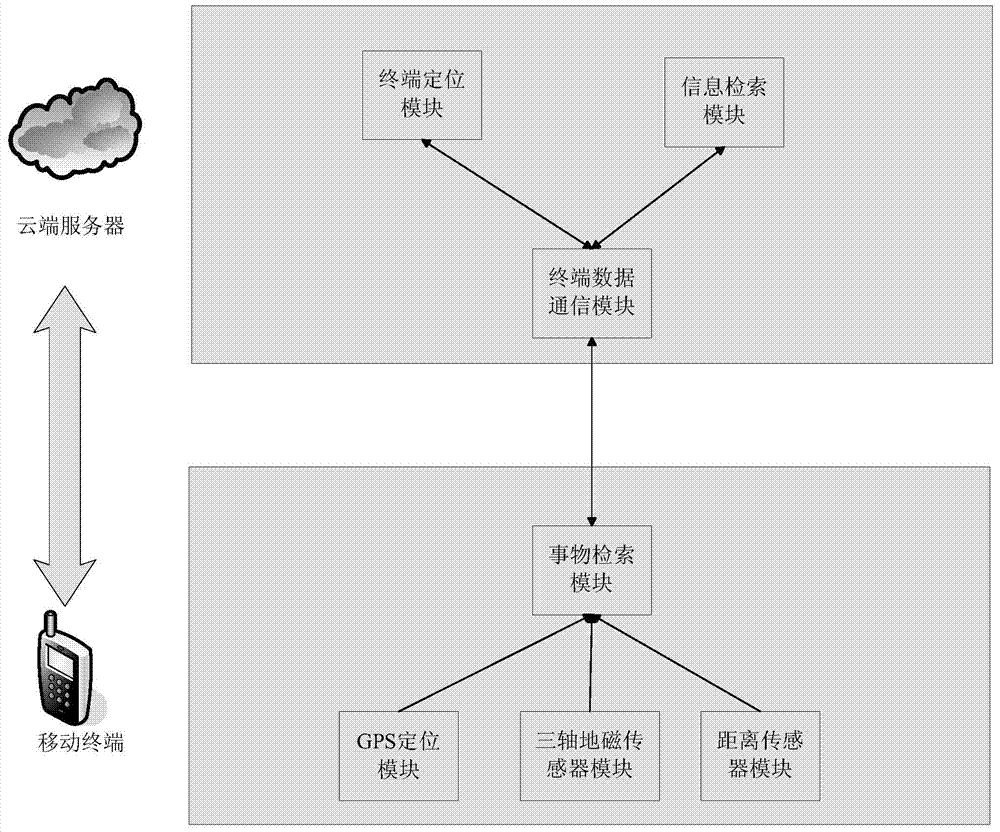

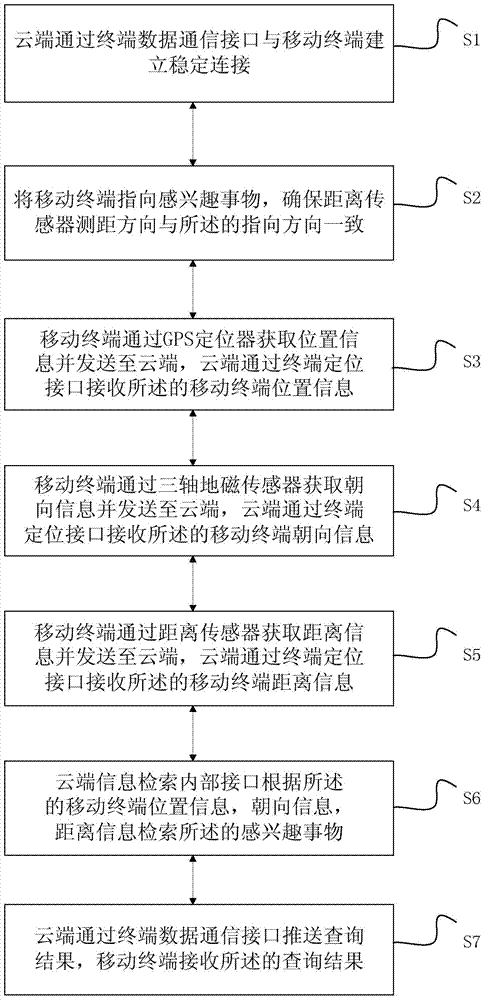

Interested object information acquisition method and system with mobile terminals coordinating with cloud terminal

InactiveCN104753982AConvenient and perfectImprove interactivityTransmissionDistance sensorsGlobal Positioning System

The invention belongs to the technical field of virtual reality, and particularly relates to an interested object information acquisition method and system with mobile terminals coordinating with a cloud terminal. The system mainly comprises mobile terminals for acquiring the location information, orientation information and distance information of mobile terminals, and a cloud service interface for counting and managing the location information of a plurality of mobile terminals, retrieving and analyzing interested objects inquired by the mobile terminals, and feeding back the interested objects to mobile terminal equipment via a terminal data communication interface. Through adoption of the interested object information acquisition method and system, high interactivity and expandability are achieved. A cloud retrieval scenery information database can be better perfected in future data analysis according to the identification and description of a tourist about interested sceneries. A GPS (Global Positioning System) positioner is used, and a three-axis geomagnetic sensor and a distance sensor are used for positioning, so that the flow is saved and the energy consumption is lowered in comparison to a conventional picture lookup way.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

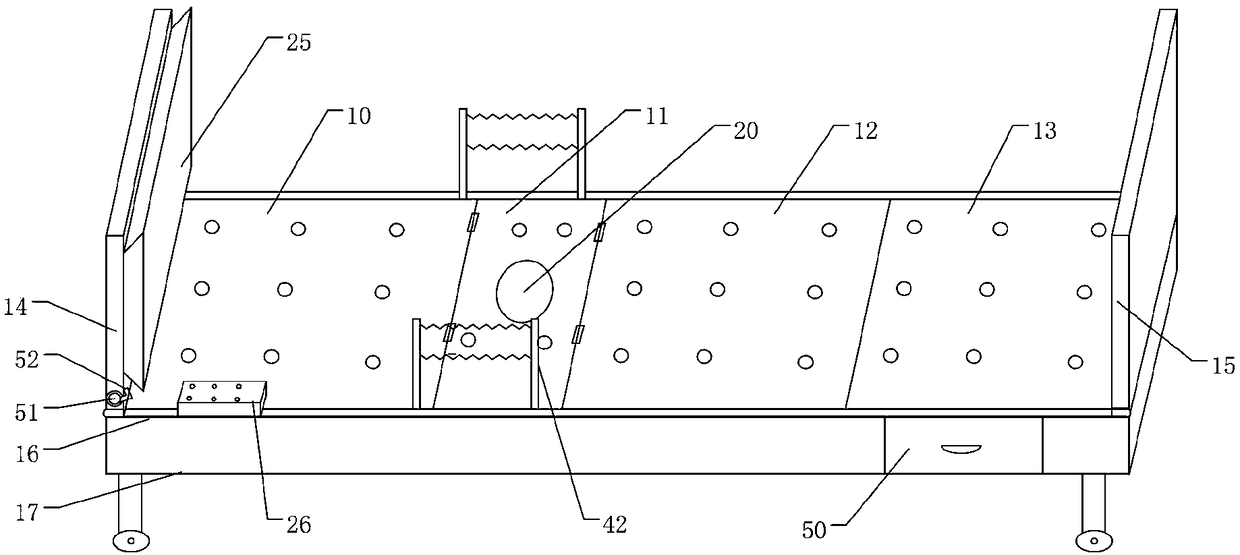

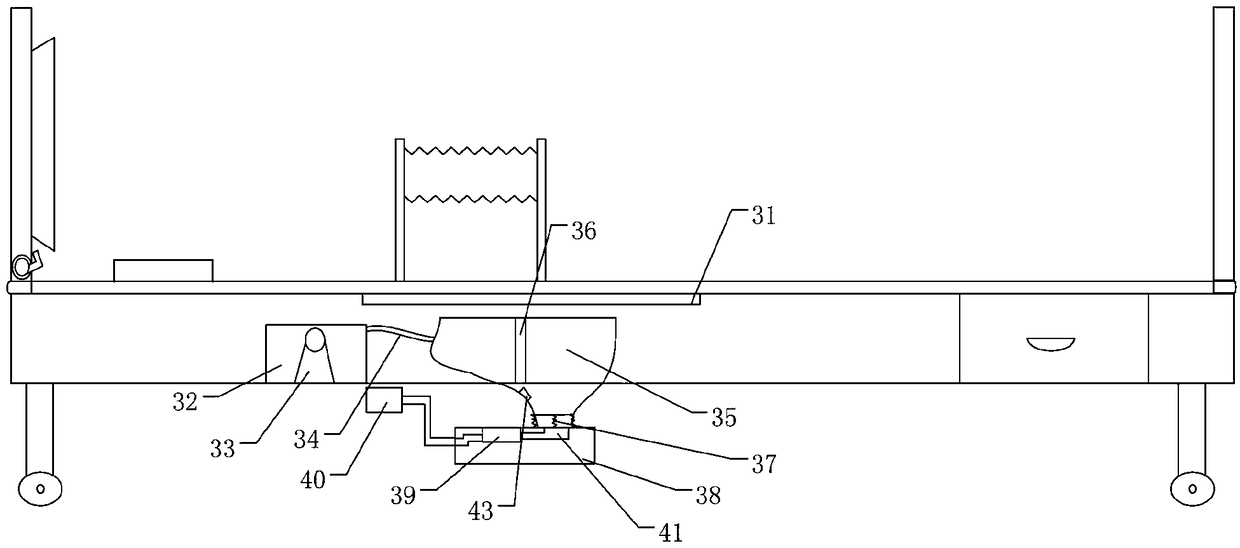

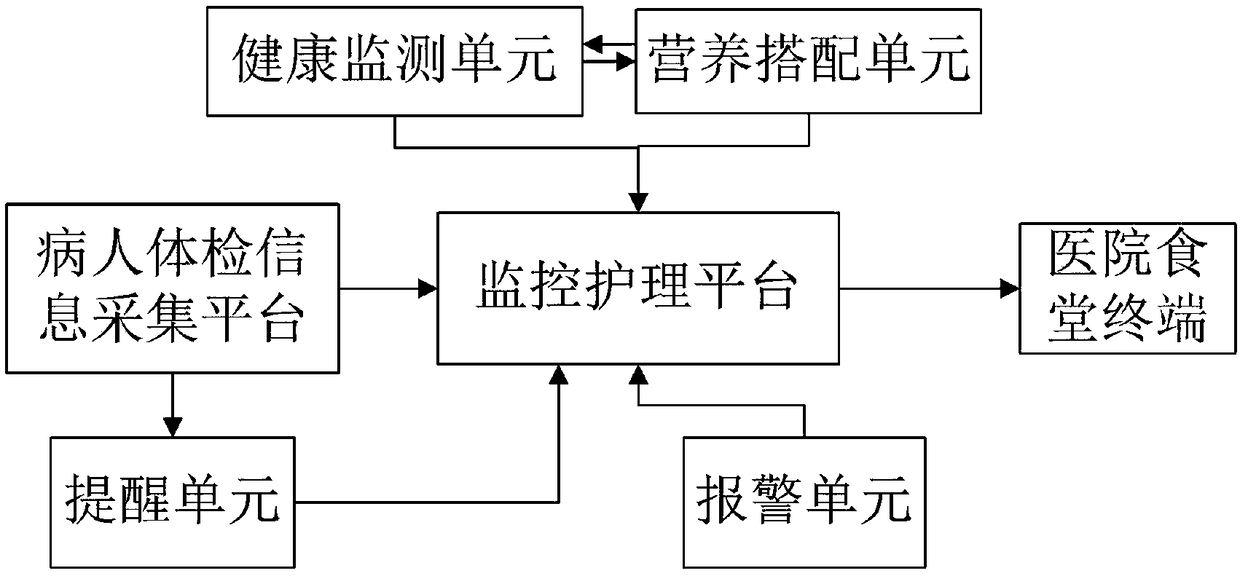

Multifunctional nursing bed based on hospital network platform

ActiveCN108814850ATreatment plan adjuvant therapyProtect physical and mental healthNutrition controlNursing bedsPhysical exerciseBed boards

The invention discloses a multifunctional nursing bed based on a hospital network platform. The multifunctional nursing bed comprises a bed rack, a toilet mechanism, a health monitoring unit, a nutrition matching unit and a monitoring nursing platform; the bed rack comprises a bed frame, a bed side and a bed tail; the toilet mechanism is arranged on the lower surface of the bed frame; the health monitoring unit is arranged in the toilet mechanism and comprises a sampling module, an analysis module and a self-cleaning module; the nutrition matching unit comprises nutritional matching data, andthe nutritional matching data stores various dish and soup recipes and nutritional values and effects of various ingredients in the dish and soup recipes; the monitoring nursing platform comprises a patient health information database recording information related to a patient. The multifunctional nursing bed comprises a bed board, the bed rack, an exercise mechanism and the toilet mechanism. By means of the multifunctional nursing bed, the health condition of the patient can be analyzed and monitored, the patient can conveniently go to the toilet, and sewage is automatically cleaned away.

Owner:广州市桂勤器械设备工程有限公司

Detection method of fish allergen

InactiveCN107918019AConvenient and perfectProtect healthBiological testingFluorescence/phosphorescenceAntigenAquatic product

The invention discloses a detection method of fish allergen. The detection method is characterized in that a monoclonal antibody is marked by a Cy5.5 fluorescent dye; by performing the indirect competitive immune reaction, the marking antibody which does not react with a to-be-detected antigen is captured by a coating antigen which is immobilized at the surface of an optical fiber probe, the fluorescent dye is excited by a near-field light wave at the surface of the optical fiber probe to produce fluorescent light, the fluorescent light is collected by the optical fiber probe, and the contentof to-be-detected allergen is measured according to the change of fluorescent intensity of the to-be-detected sample and a standard curve. The detection method has the advantages that the operation issimple and convenient, the result is accurate, the specificity is strong, the trace parvalbumin in aquatic products and prepared products thereof can be quantitatively detected, and the important meaning is realized for prompting the development of the allergen marking system of the aquatic product and ensuring the health of a consumer.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

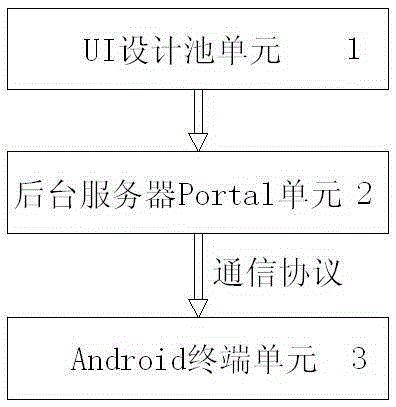

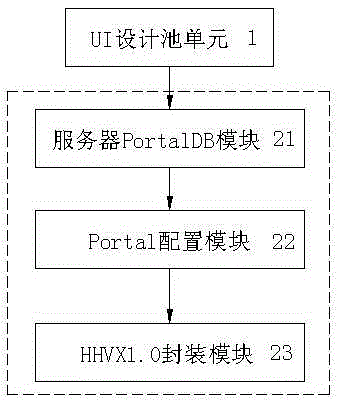

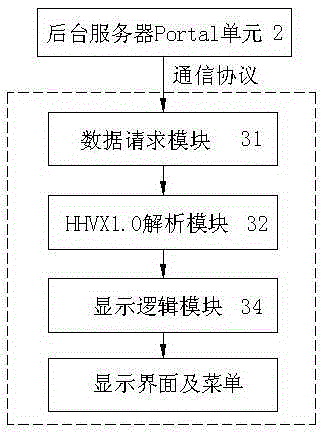

Software development system and mode based on template design under Android platform

InactiveCN105302562AConvenient and perfectReduce branchesSpecific program execution arrangementsSoftware development processTemplate design

The invention discloses a software development system and mode based on template design under an Android platform. The system comprises a UI design pool unit, a background server Portal unit and an Android terminal unit. A communication protocol is arranged between the background server Portal unit and the Android terminal unit. The UI design pool unit is used for setting all supported UI interface systems. The UI interface systems are imported into a MySQL database through the background server Portal unit, so that a template code and a menu code are well configured, and are packaged into Json format data through the communication protocol. The Android terminal unit analyzes the data which are packaged to be in the Json format through the communication protocol, and accordingly the template code is recognized and skips to a corresponding interface. According to the software development system and mode, after the modified menu is clicked, an Android App software code does not need to be adjusted again for the interfaces which should be displayed, and the background server Portal unit is used for configuration directly. The same set of Android project engineering code is used in the unified mode, a plurality of sets of App engineering do not need to be maintained, product engineering code branches are reduced, repeated development and test work is also reduced, and cost is lowered.

Owner:SHENZHEN HONGHUI ZHITONG TECH CO LTD

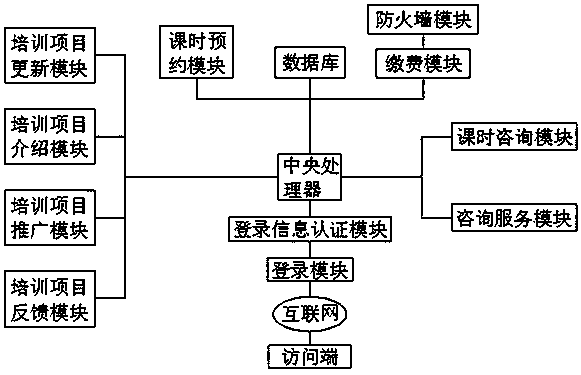

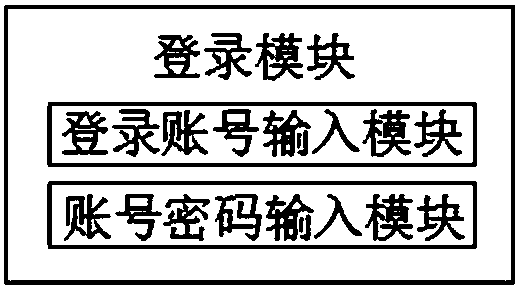

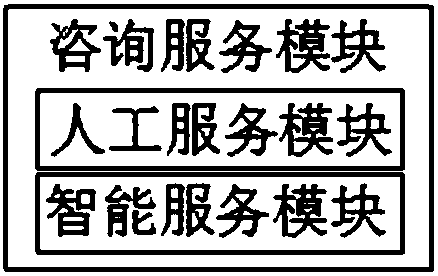

Internet-based occupational skill training service system

InactiveCN108111610AEasy to understandImprove publicityData processing applicationsDatabase queryingPaymentSkill sets

The invention relates to the technical field of occupational skill training, in particular to an Internet-based occupational skill training service system. The system comprises an access terminal, theInternet, a login module, a login information authentication module, a central processing unit (CPU), and a database, wherein the access terminal is connected with the login module based on the Internet; the login module is electrically connected with the login information authentication module; the login information authentication module is electrically connected with the CPU; the CPU is electrically connected with the database; data used for occupational skill training services is stored in the database; and the CPU is electrically connected with a training project promotion module, a training project introduction module, a class hour consultation module, an inquiry consultation module, a class hour scheduling module, and a payment module. The system provided by the invention has the advantages that a user can learn about specific project contents and class hours of the occupational skill training services, so that occupational skill training can be effectively promoted, and the good services can be provided.

Owner:广州众慧教育科技有限公司

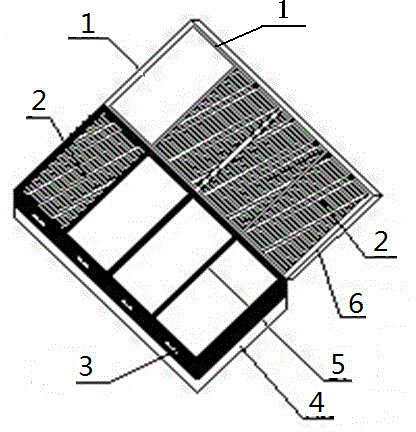

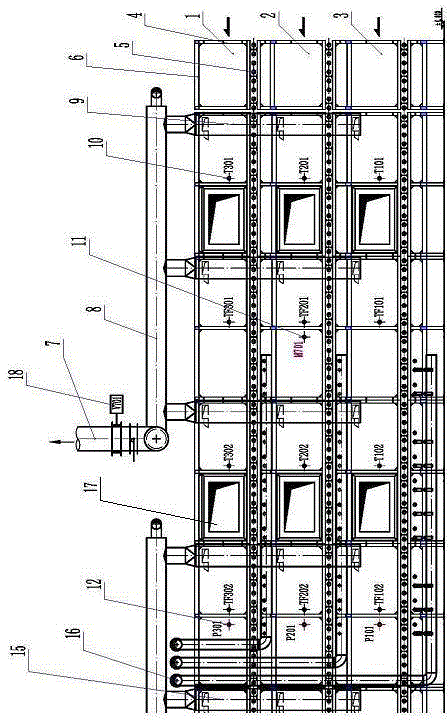

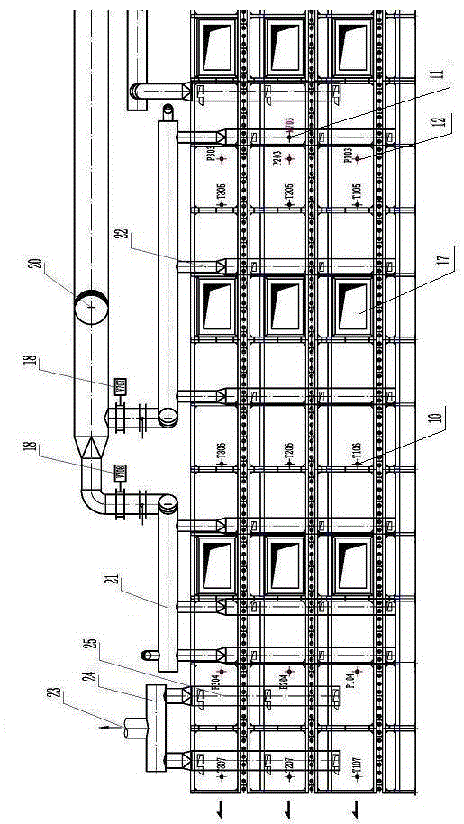

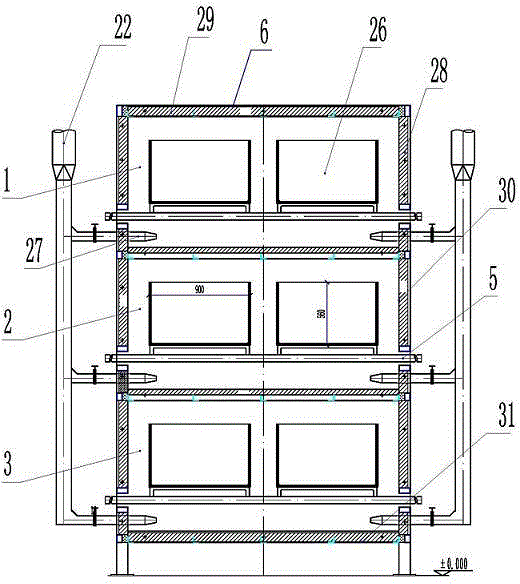

Production process and curing drying equipment for solar polycrystalline silicon quartz crucible

InactiveCN103954112AControl drying dimensional accuracyReduced strengthDrying gas arrangementsCeramic shaping apparatusMetal frameworkEngineering

A production process and curing drying equipment for a solar polycrystalline silicon quartz crucible solve the problem that the wall thickness of the existing crucible is not uniform, the thermotechnical curing equipment cannot achieve the set process demands and the like. The production process is characterized in that the an organic monomer is added in quartz ceramic mud and a crucible product is obtained after the quartz ceramic mud is molded in a nonporous die; the process flow comprises the steps of melting a high-purity quartz raw material, preparing the quartz ceramic mud, pouring, solidifying and molding, curing and drying, sintering, detection, packing obtaining a finished product and storing in a warehouse. The kiln body of the curing drying equipment is of a three-layer structure, temperature measuring holes, humidity measuring holes, pressure measuring holes, hot air regulating holes and observation doors are arranged at two sides of a kiln wall of each layer of roller kiln; a circulation air pipeline, a hot air supplying pipeline, a damp air discharging pipeline and a cooling air pipeline are arranged above a metal frame; distributed control is performed by adopting a full integration automated control system, the waste heat of the a kiln furnace is furthest used under the condition of ensuring the drying quality of the quartz crucible product, and the aims of energy saving and cost reducing are achieved.

Owner:HUANGGANG CITY HUAYAO ZHONGQI KILN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com