Method for producing methanol, coproduct hydrogen and byproduct steam by utilizing hydrocarbonaceous tail gas

A technology of by-product steam and tail gas, applied in separation methods, chemical instruments and methods, hydrogen, etc., can solve the problems of wasting raw materials and components, and achieve the effects of reducing emissions, promoting industrial chains, and promoting perfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with embodiment:

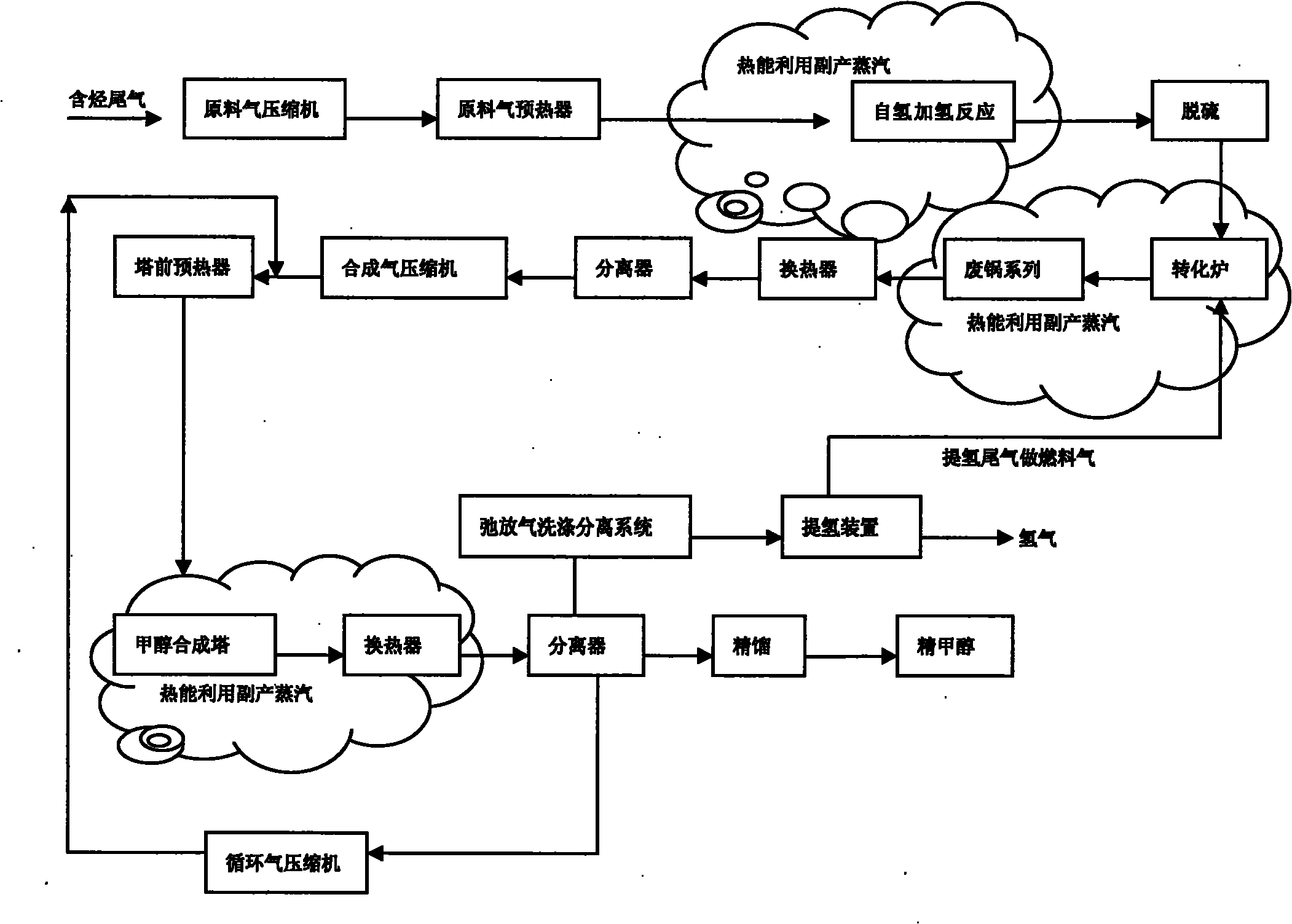

[0043] Such as figure 1 Shown:

[0044] A method for producing methanol by using hydrocarbon-containing tail gas to co-produce hydrogen by-product steam, comprising the steps of:

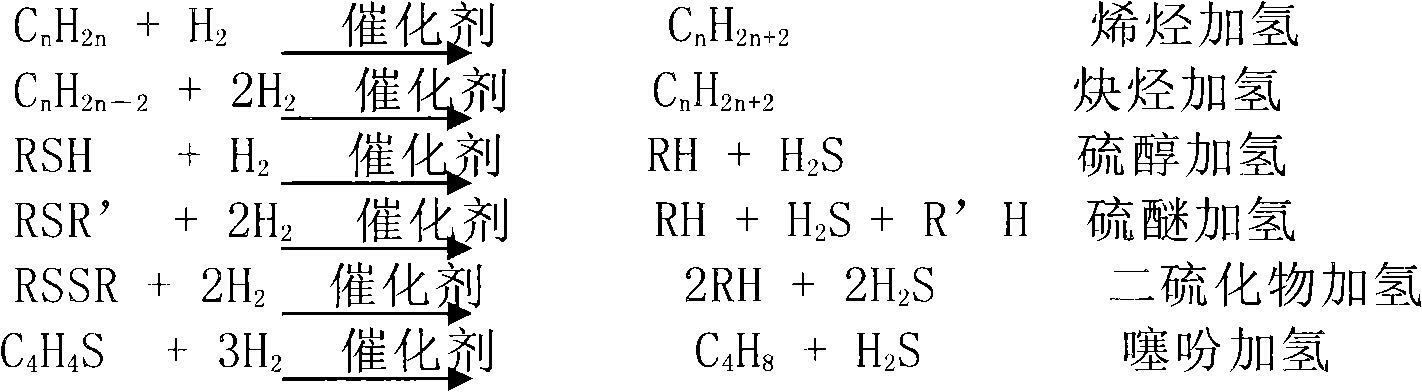

[0045] After the hydrocarbon-containing tail gas is compressed by the feed gas compressor, it enters the feed gas preheater, and then undergoes a hydrogenation reaction under the action of a catalyst, so that the sulfur-containing compound can be converted into an easy-to-remove sulfur compound under the action of the catalyst; and the heat generated by the reaction is used produce water vapor;

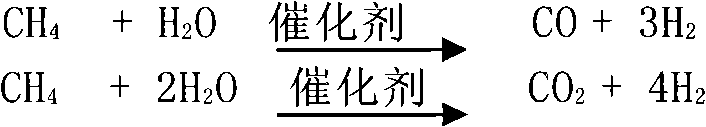

[0046] After removal of sulfur compounds, the obtained product passes through the reformer, waste pot series, heat exchanger, separator, synthesis gas compressor, pre-tower preheater, and then enters the methanol synthesis tower. In the reformer, the raw material is Gas and water vapor react to produce hydrogen, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com