Patents

Literature

808results about How to "Good for mass manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

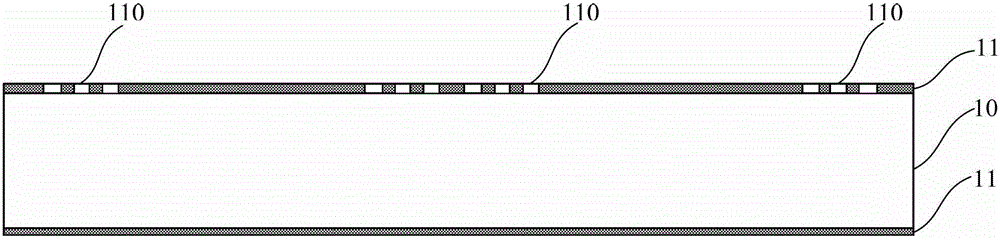

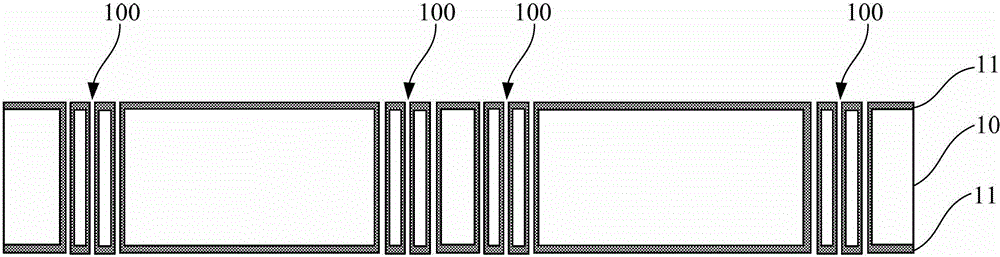

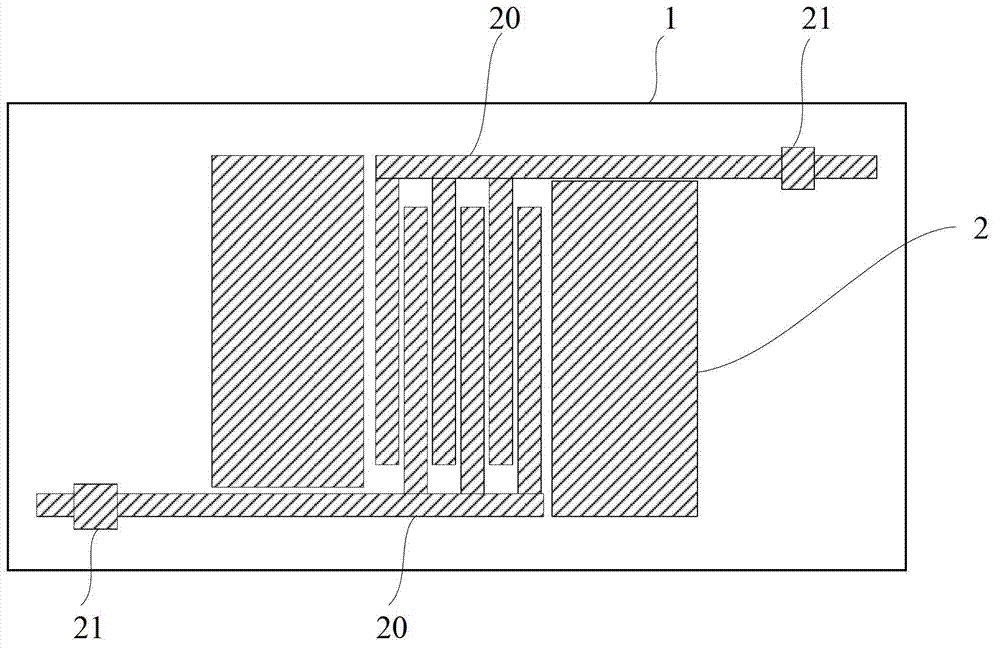

Lens antenna

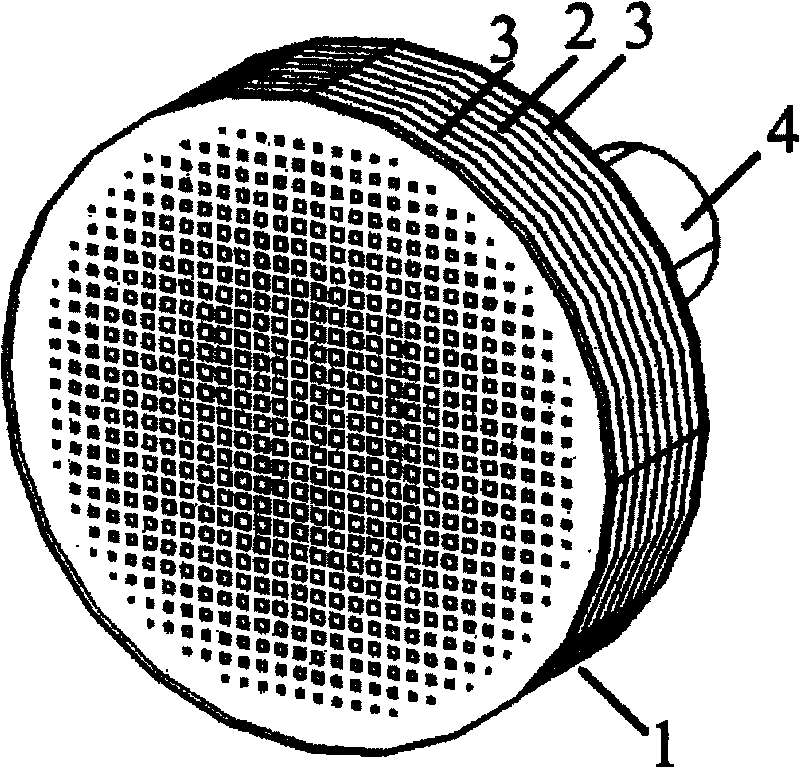

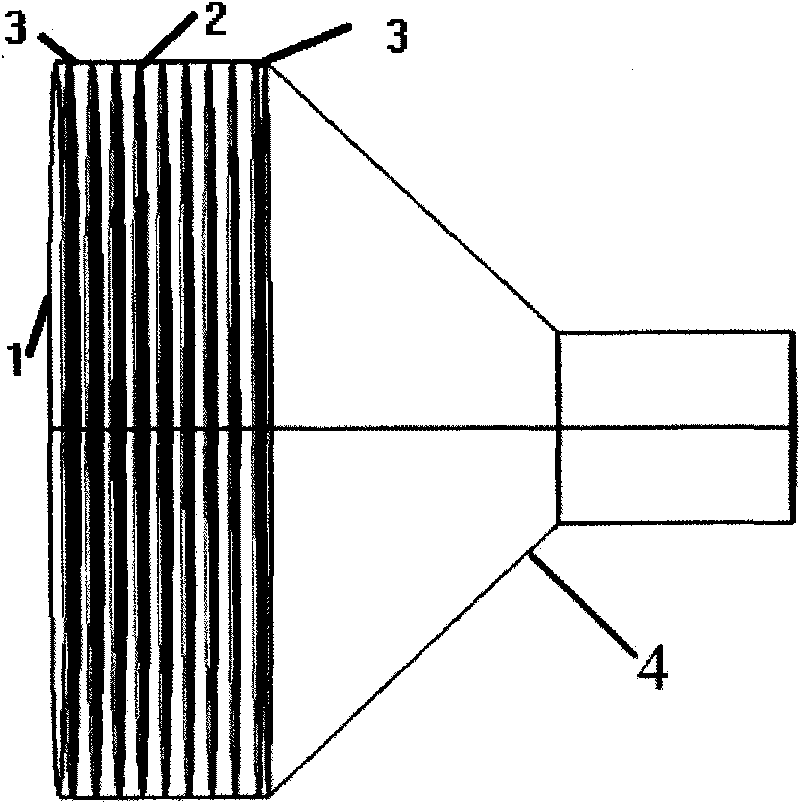

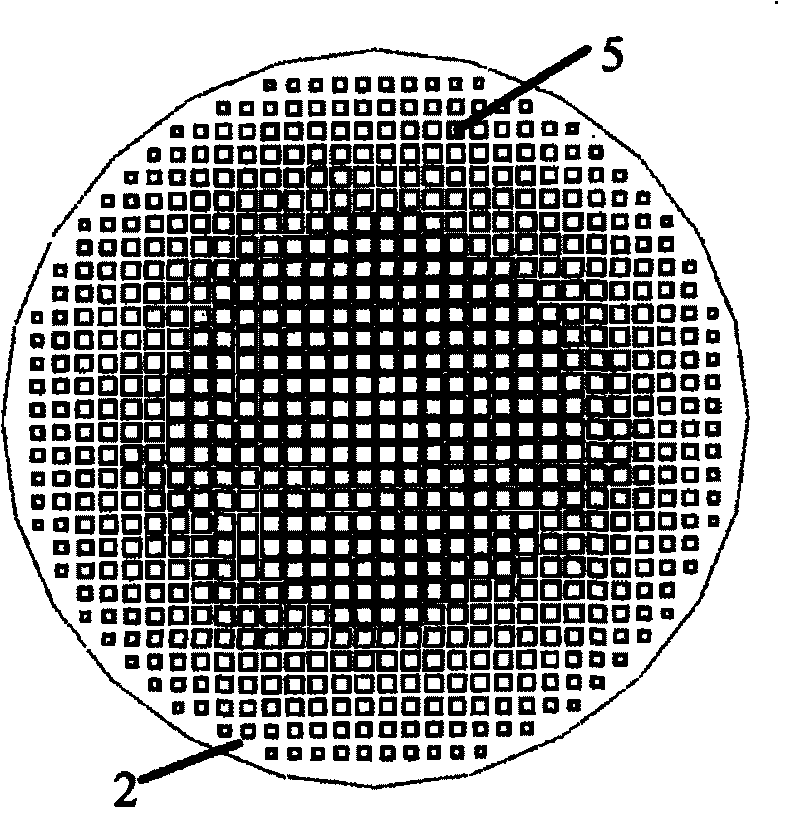

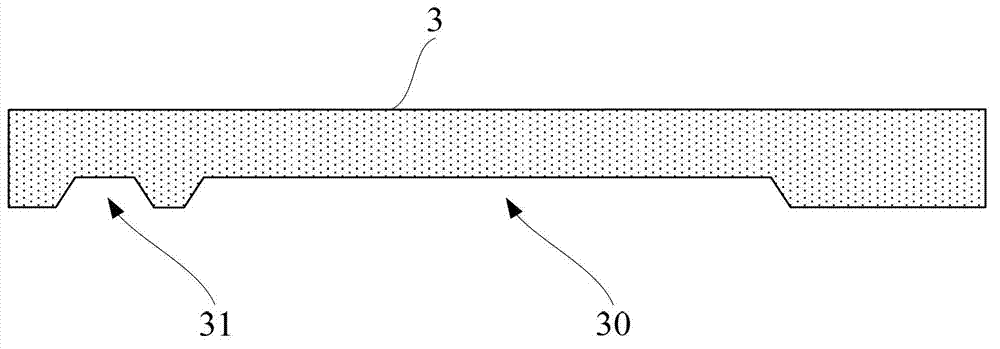

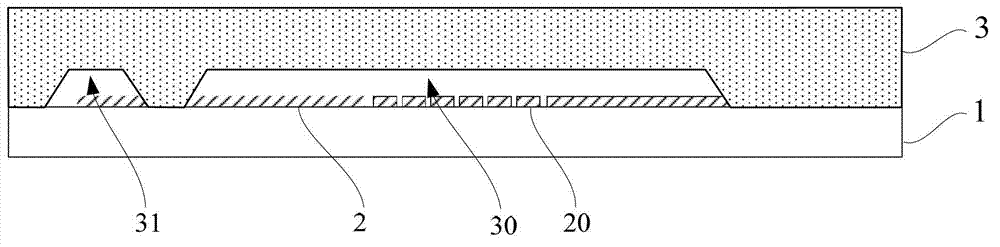

The invention relates to a lens antenna which comprises a metal loudspeaker (4) and a lens (1), wherein the metal loudspeaker (4) is provided with a feed source; the feed source is embedded in the smaller-diameter end of the metal loudspeaker (4), and the lens (1) is embedded in the larger-diameter end of the metal loudspeaker (4); the lens (1) comprises a core plate (2); the core plate (2) is a planar dielectric plate, and one of the planes is provided with a plurality of core-plate disresonance basic units; a core-plate metal square frame (5) is printed in each core-plate disresonance basicunit; and the areas of the core-plate disresonance basic units and the core-plate metal square frames (5) gradually decrease from the center to the edge of the core plate (2). As the core plate (2) is planar, the lens (1) is easy to manufacture. In addition, the lens (1) also comprises matching plates (3) positioned on both sides of the core plate (2). The matching plates (3) can reduce the reflection of the electromagnetic waves on the interface of the lens (1) and the air.

Owner:SOUTHEAST UNIV

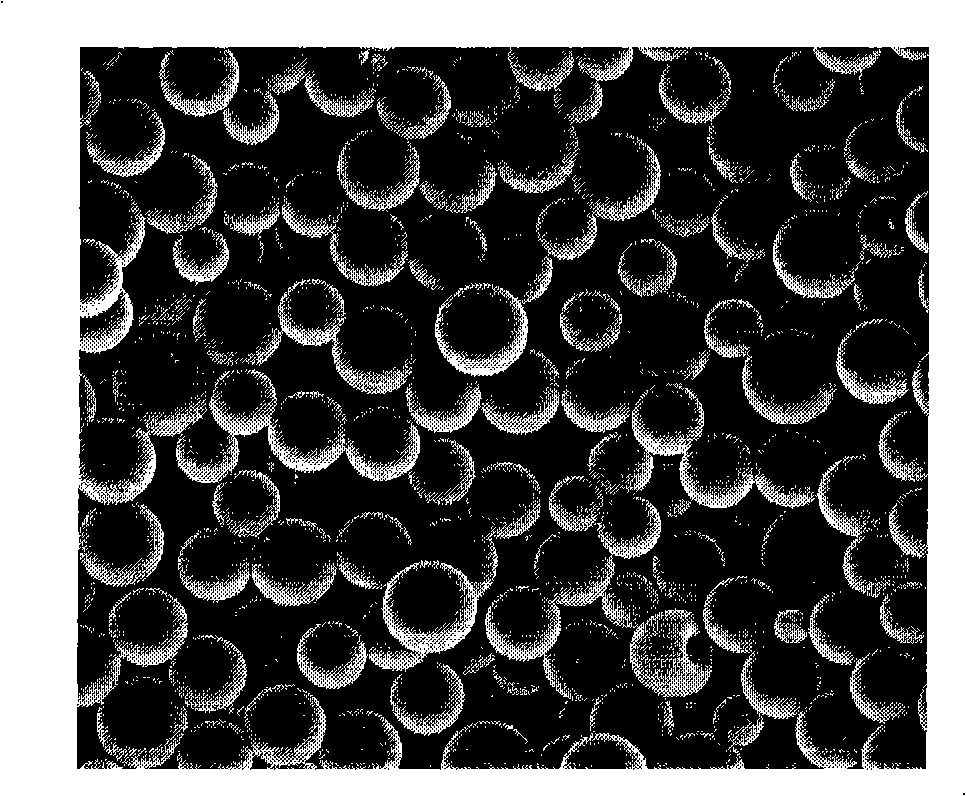

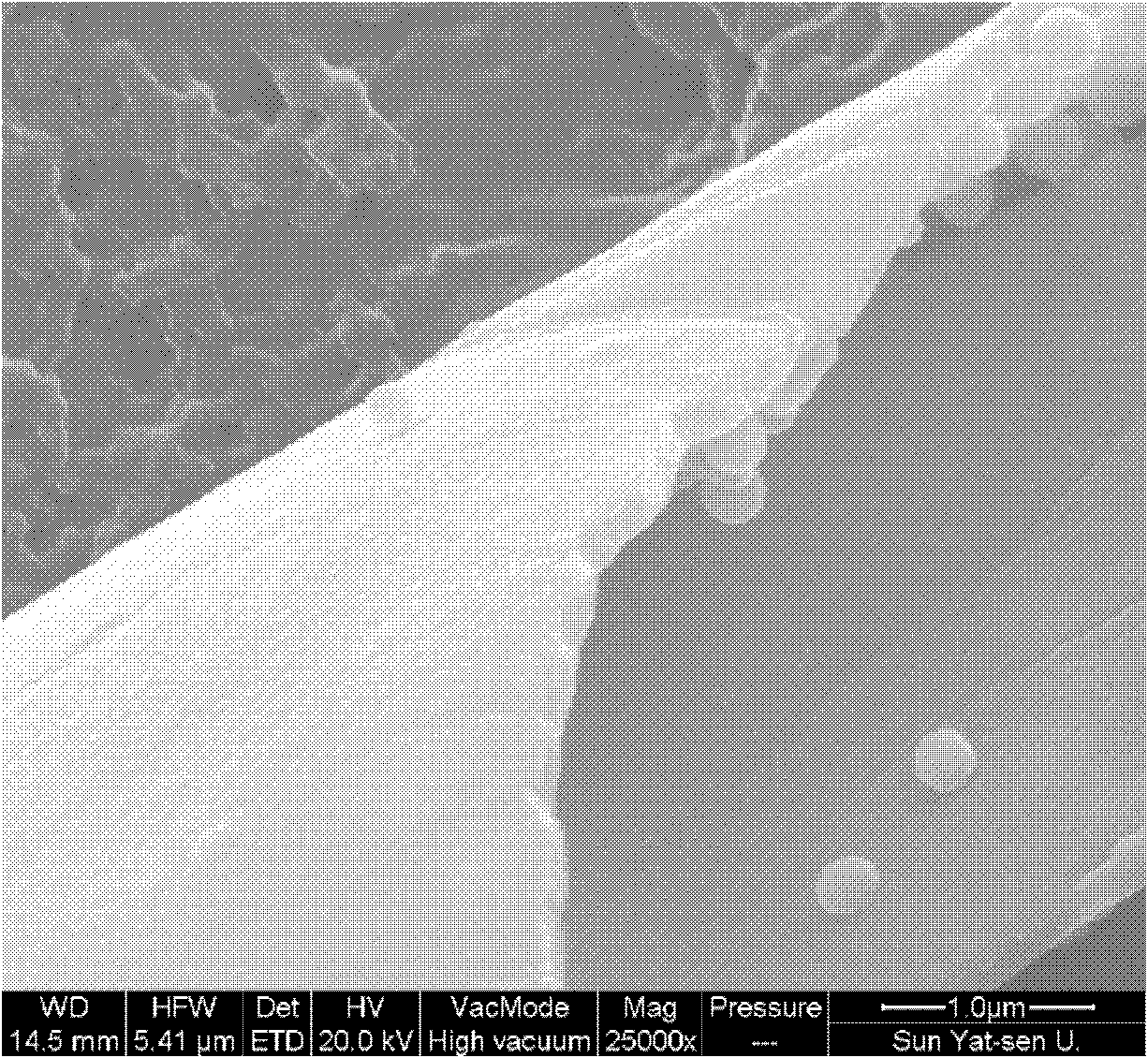

Improved process for preparing porous microsphere active carbon

The improved process for preparing high strength porous microsphere active carbon includes the following steps: oxidizing thermosetting resin ball at 60-400 deg.c in oxygen containing atmosphere or pre-treating thermosetting resin ball at 60-300 deg.c in oxidizing acid, SO2 or SO3; carbonizing at 600-1200 deg.c in helium, nitrogen or their mixture atmosphere; and activating at 600-1200 deg.c in activating water vapor atmosphere to obtain high strength porous microsphere active carbon with grain size of 10 micron to 2 mm, BET specific surface area of 500-4000 sq m / g, and grain strength of 50-200 MPa. The process is simple, low in cost and high in yield, and the prepared microsphere active carbon has high strength and high purity and is one excellent medical active adsorption material.

Owner:EAST CHINA UNIV OF SCI & TECH

Microwave multi-chip packaging structure using silicon through hole and manufacture method thereof

ActiveCN102723306AReduce lossIncrease packing densitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSystem in package

The invention provides a microwave multi-chip packaging structure using a silicon through hole and a manufacture method thereof. The method uses a temperature safety valve (TSV) to achieve two-sided integrated system-stage packaging structure, when a monolithic microwave integrated circuit (MMIC) chip needs integrating, a user does not need embed a substrate before wiring, and performance, reliability and rate of finished products of the packaging structure are improved. Simultaneously, processes such as injection, corrosion, release and high temperature annealing in a manufacture process can be used before integration of the MMIC, and components needing special processes can be assembled and integrated in advance on the other side of the substrate. Therefore, the substrate comprising active and passive devices, micro-electromechanical systems (MEMS), photoelectric devices and the like can be conveniently manufactured in a large scale before integration of the MMIC, and the manufacture method is simple in process, reduces cost, and is advanced and reliable at present.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

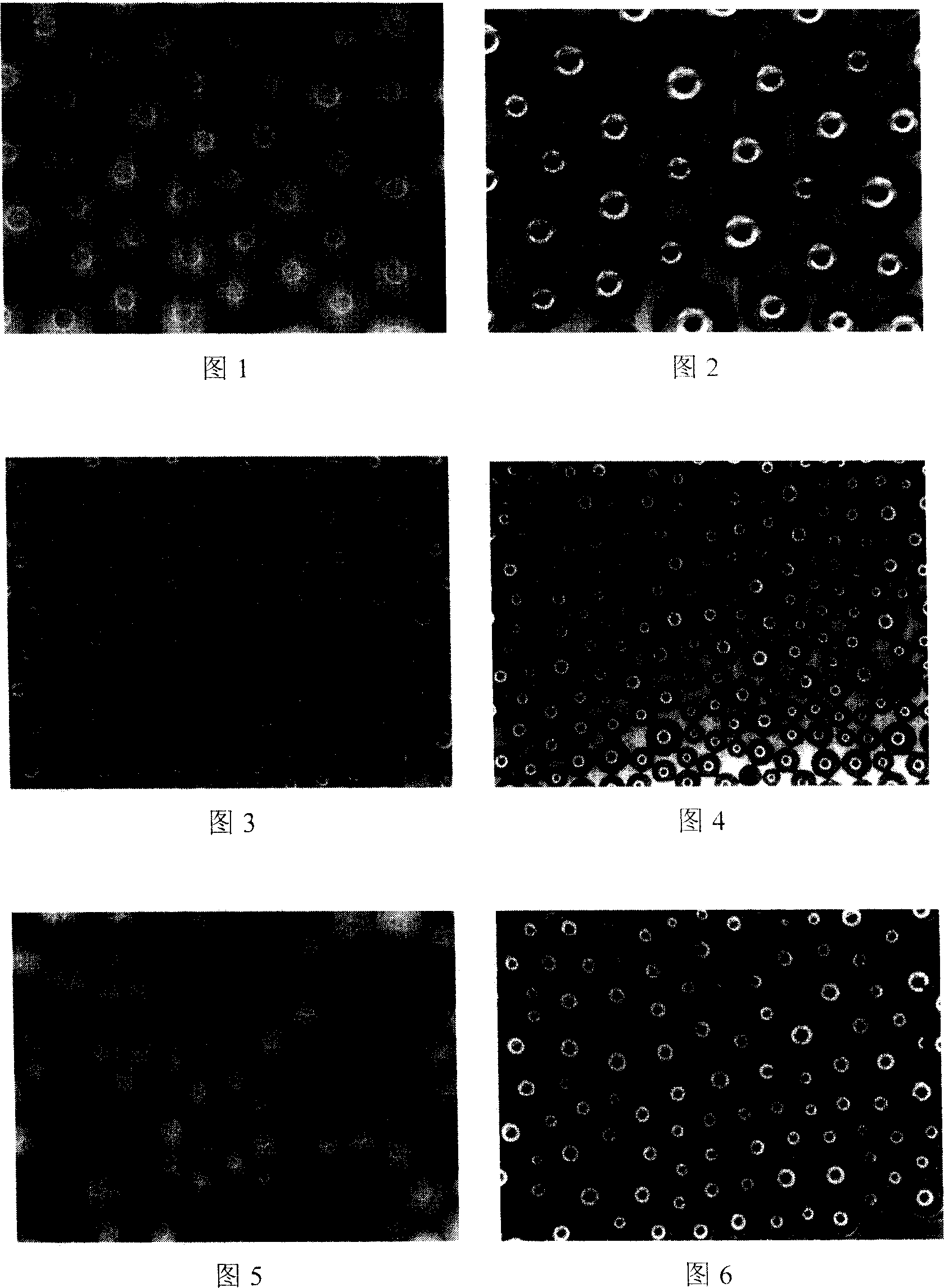

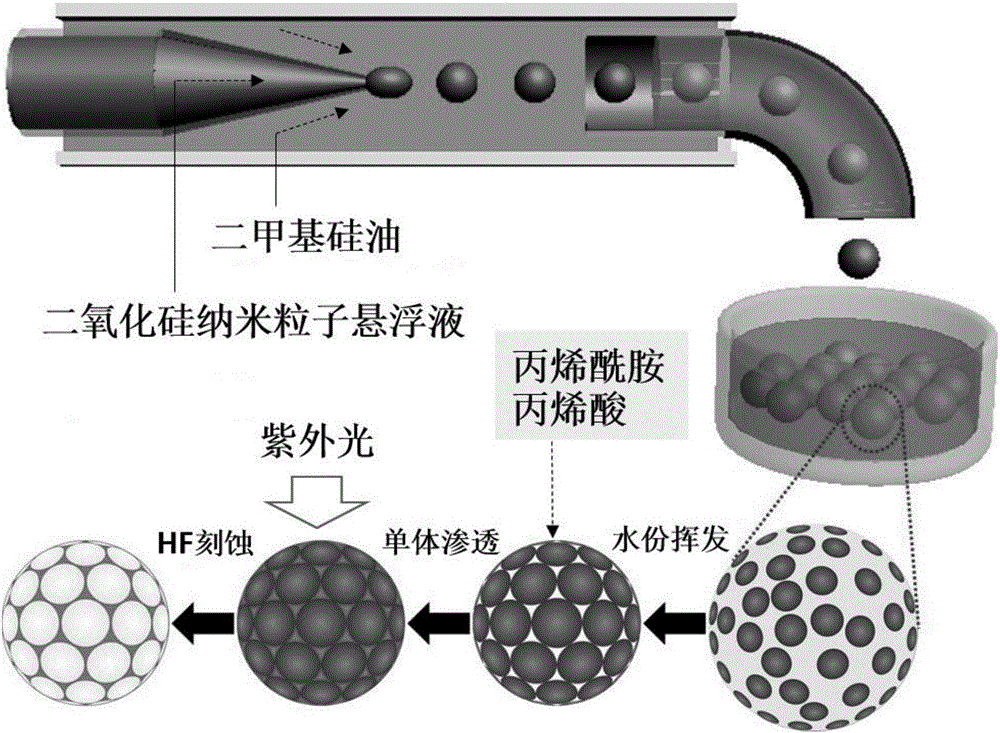

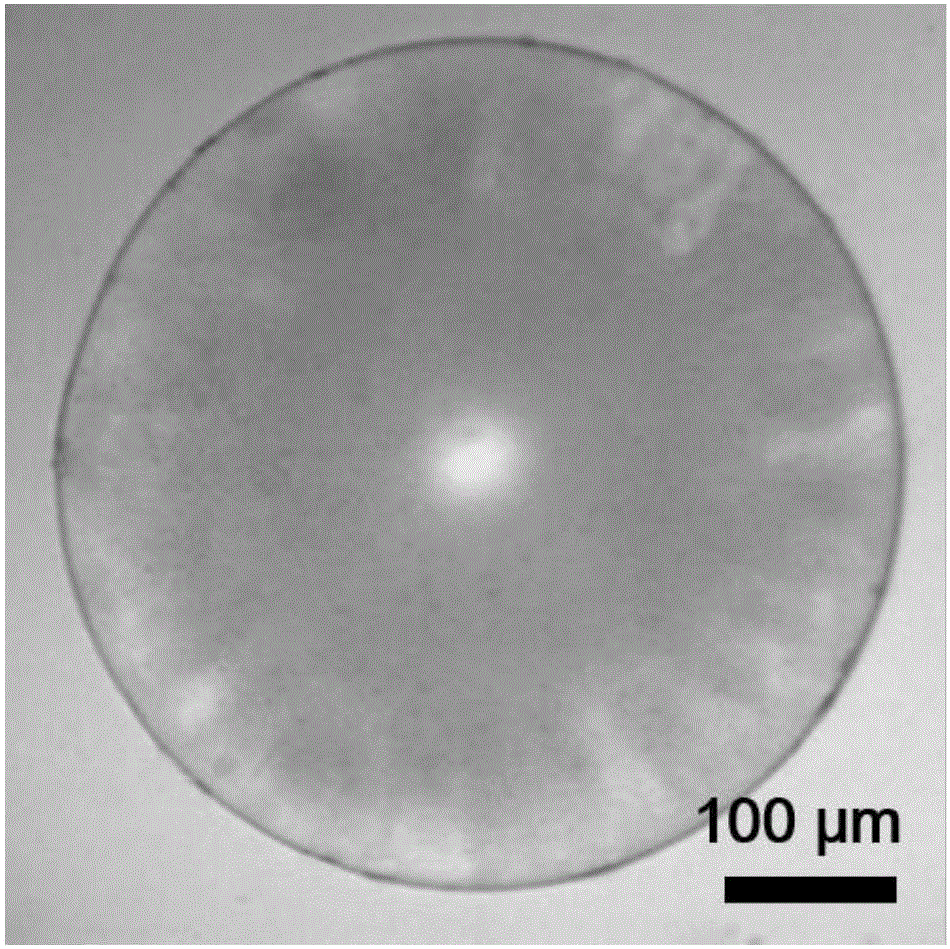

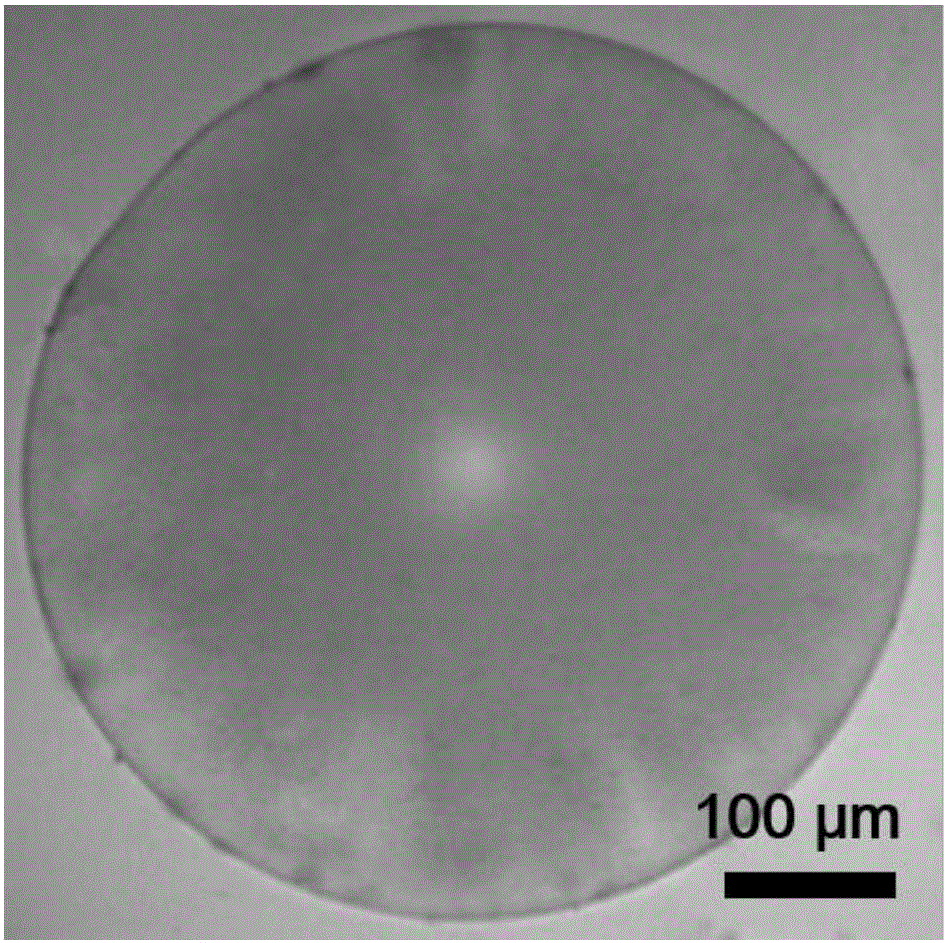

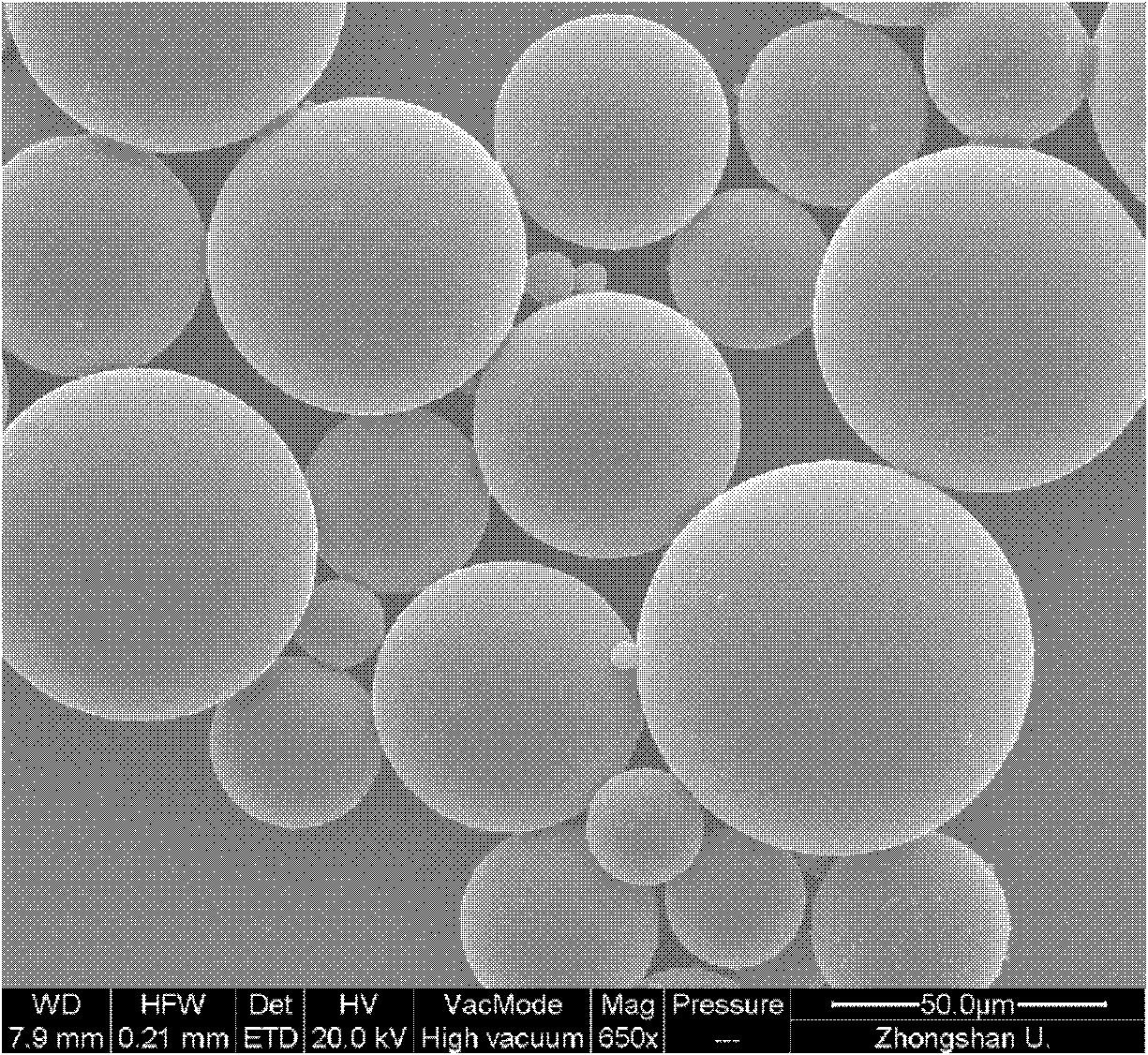

Hydrogel photonic crystal microspheres, and preparation method and application thereof

ActiveCN106040114ARealize naked eye detectionPerfect space symmetry sphereMaterial analysis by observing effect on chemical indicatorMicroballoon preparationPhotoinitiatorPhotonic crystal

The invention discloses hydrogel photonic crystal microspheres, and a preparation method and an application thereof. The preparation method comprises the steps of (1) preparation of silica emulsion droplets, (2) preparation of silica photonic crystal microspheres, (3) preparation of silica-hydrogel hybrid photonic crystal microspheres, and (4) preparation of inverse-opal-structured hydrogel photonic crystal microspheres. In the step (3), acrylamide, acrylic acid, methylene bisacrylamide and a photo-initiator are allowed to penetrate into the silica photonic crystal microspheres; ultraviolet irradiation is carried out, such that acrylamide and acrylic acid monomers are cured, such that the silica-hydrogel hybrid photonic crystal microspheres are obtained. With the method provided by the invention, the obtained hydrogel photonic crystal microspheres have a three-dimensional ordered porous structure, wherein the pores have a compact hexagonal stacking ordered structure. With the method, technical problems of angle dependence and slow response to small molecules of existing hydrogel photonic crystal films can be solved.

Owner:HUAZHONG UNIV OF SCI & TECH

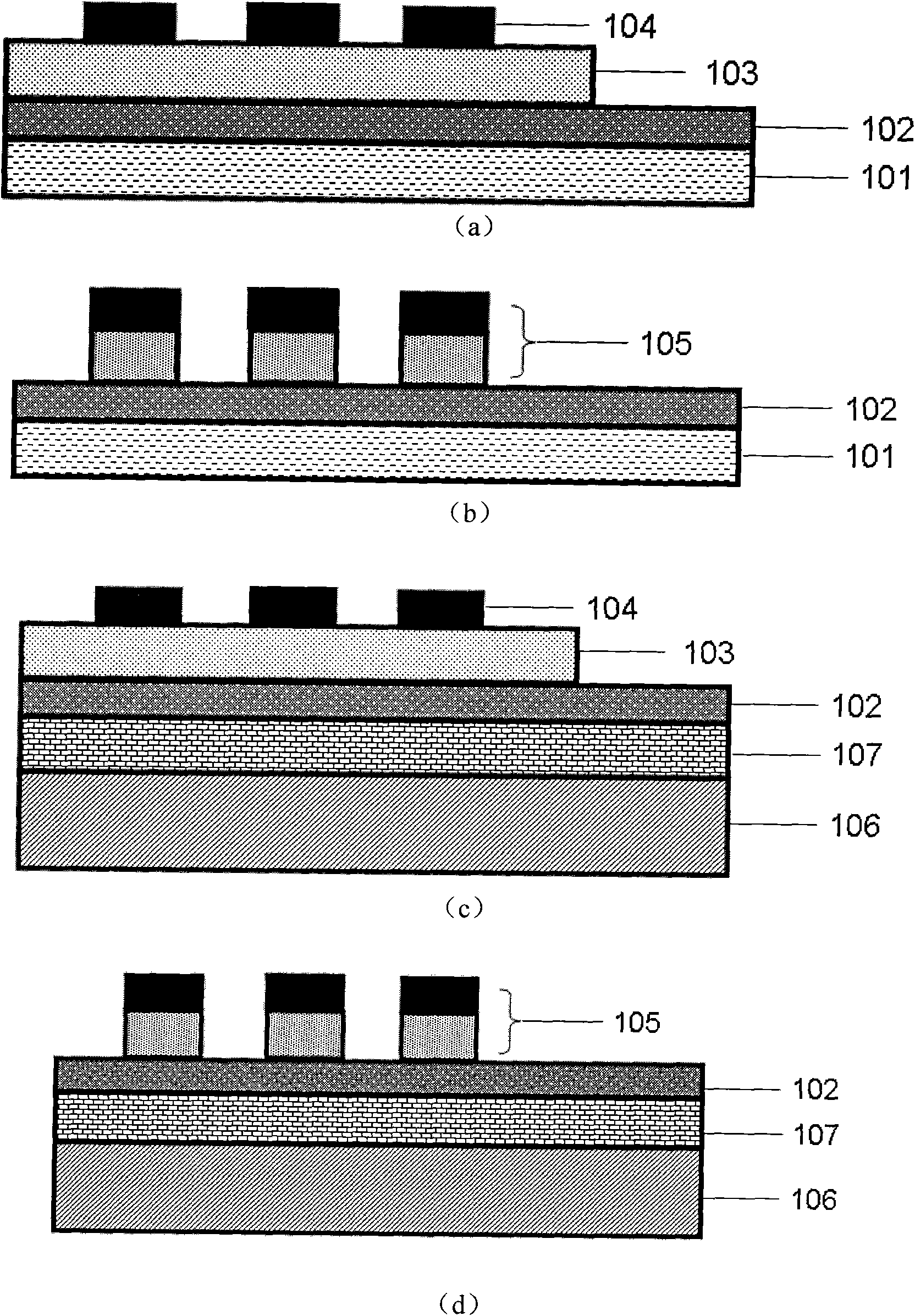

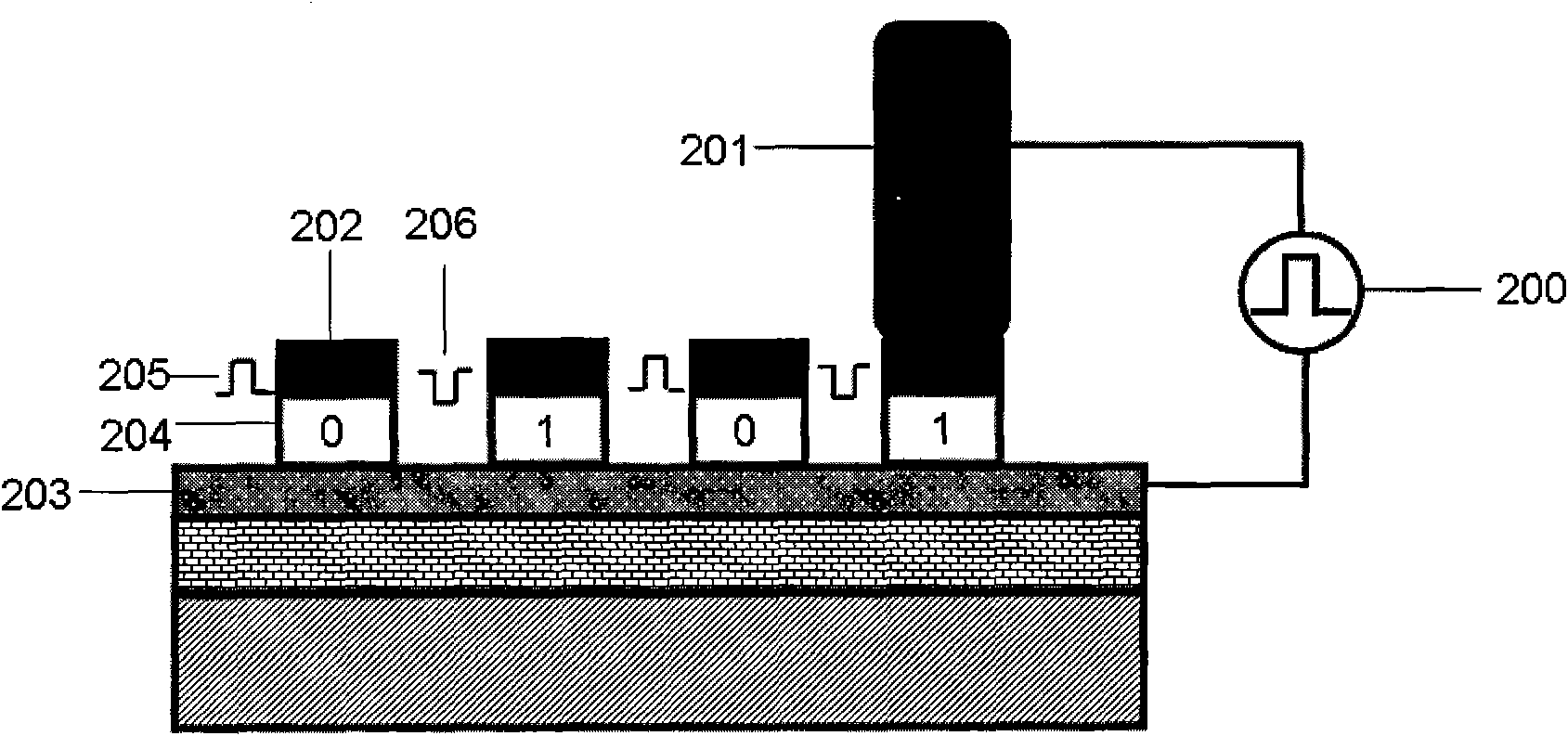

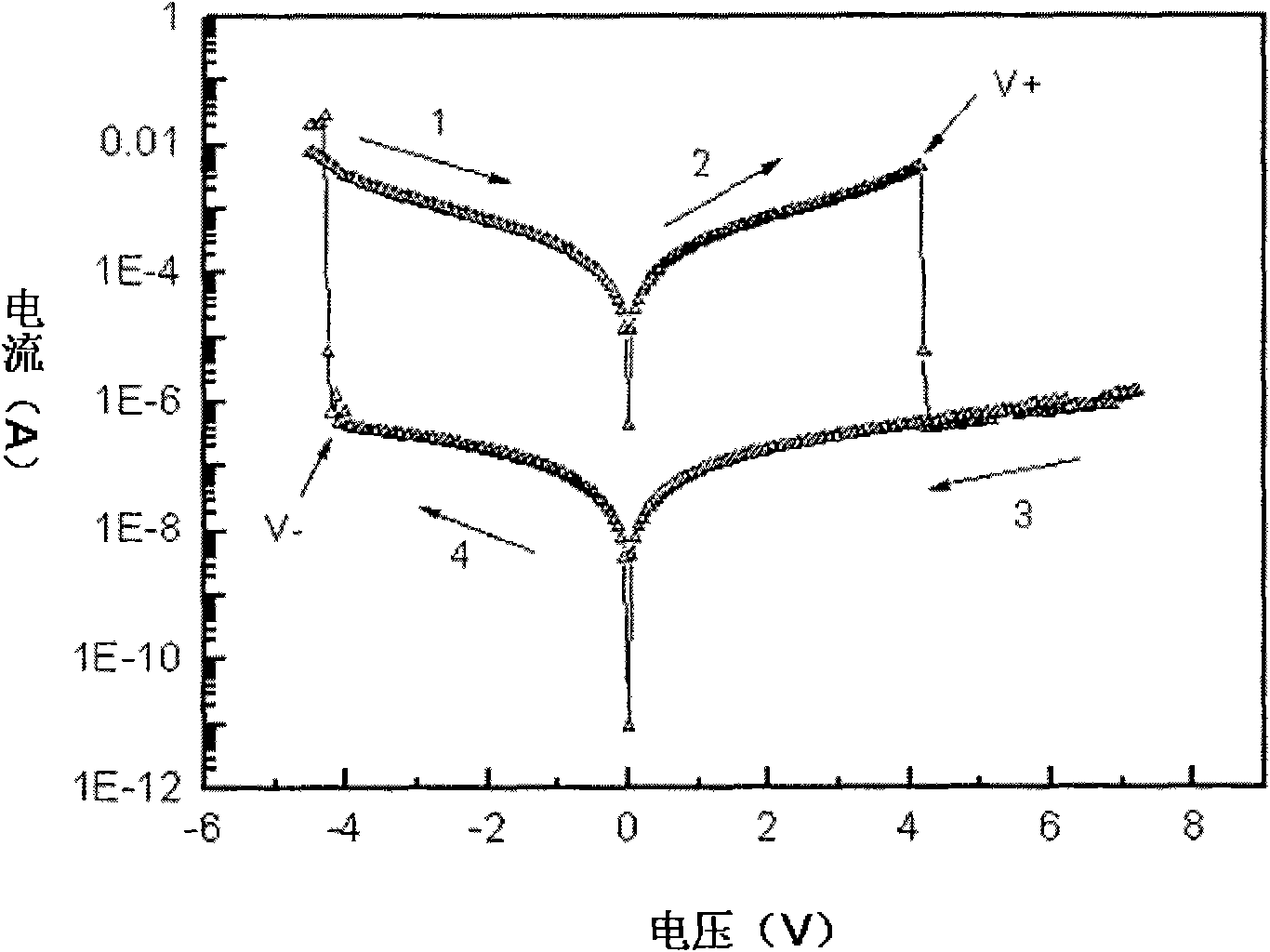

Resistive random access memory based on bismuth iron thin film system and manufacturing method thereof

ActiveCN101587936AHigh and low resistance state resistance value is stableWith magnetoelectric coupling effectElectrical apparatusDigital storageSputteringStatic random-access memory

The invention relates to a resistive random access memory based on bismuth iron thin film system and manufacturing method thereof. The memory comprises an insulating substrate (101) layer as the first layer, a lower electrode (102) as the second layer, a bismuth iron thin film (103) as the third layer, an upper electrode (104) as the fourth layer; the manufacturing method utilizes the method thermal evaporation or magnetron sputtering to grow the lower electrode on the insulating substrate layer, utilizes the method of magnetron sputtering, pulsed laser deposition or colloidal sol-gel to grow the bismuth iron thin film on the lower electrode, finally utilizes the method of thermal evaporation or magnetron sputtering to grow the upper electrode on the bismuth iron thin film, and utilizes the method of ultraviolet lithography, electron beam or ion beam etching to obtain the electrode pattern. The memory provided by the invention has excellent electroluminescent resistance effect and good stability, and has simple manufacturing method, low cost and is easy for manufacturing in large scale and commercial process.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

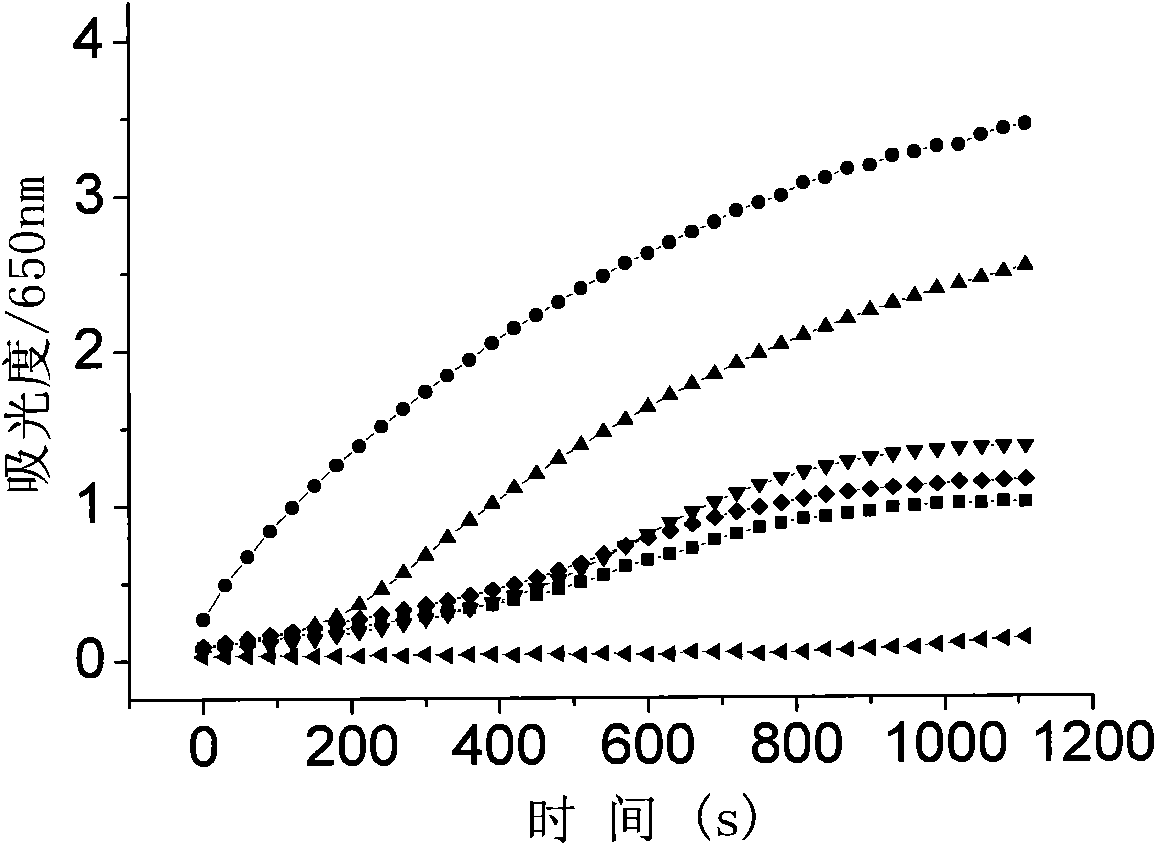

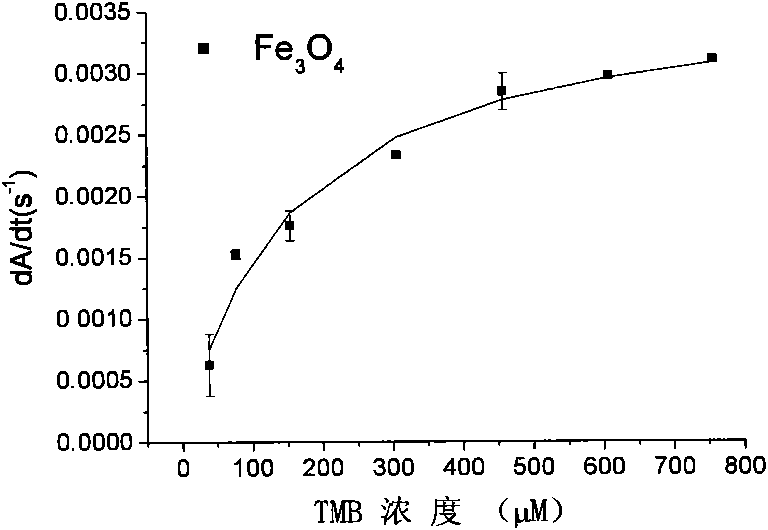

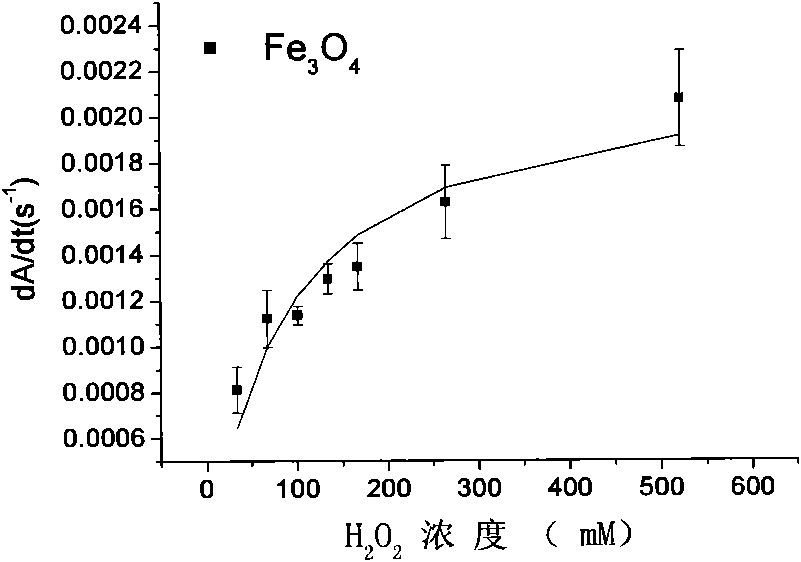

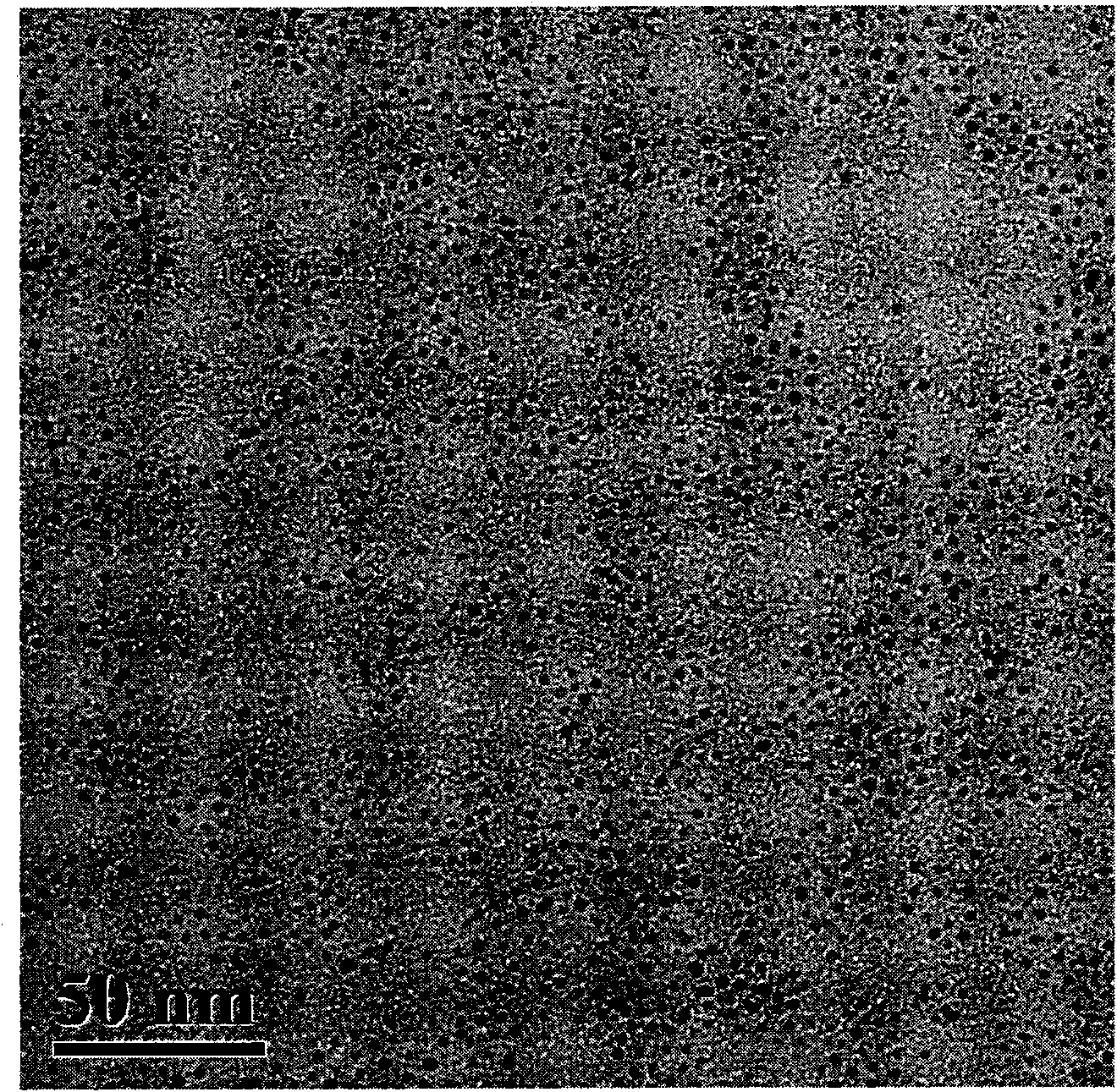

Method for applying magnetic gamma-Fe2O3 nano-particle mimetic enzyme to biological detection

InactiveCN101672771AImprove stabilityGood biocompatibilityMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsHorse radish peroxidaseHydrogen supply

The invention relates to a magnetic gamma-Fe2O3 nano-particle mimetic enzyme and provides a method for applying a magnetic gamma-Fe2O3 nano-particle mimetic enzyme to biological detection. The magnetic gamma-Fe2O3 nano-particle mimetic enzyme replaces a horse radish peroxidase (HRP) to be used in biological detection. The method comprises the following steps: coupling carboxyl groups on the surface of magnetic gamma-Fe2O3 nano-particles and a specific molecular probe to construct a specific nano probe; combining the nano probe with the specificity of the corresponding target molecules to be detected; developing by using a developer containing peroxides and hydrogen-supply zymolytes; and measuring the absorbency or carrying out the micro-observation so as to realize the qualitative and quantitative detection on target molecules.

Owner:SOUTHEAST UNIV

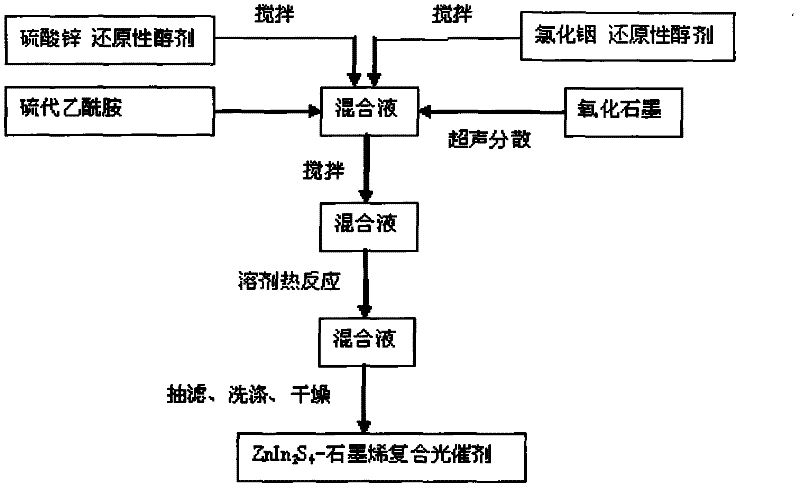

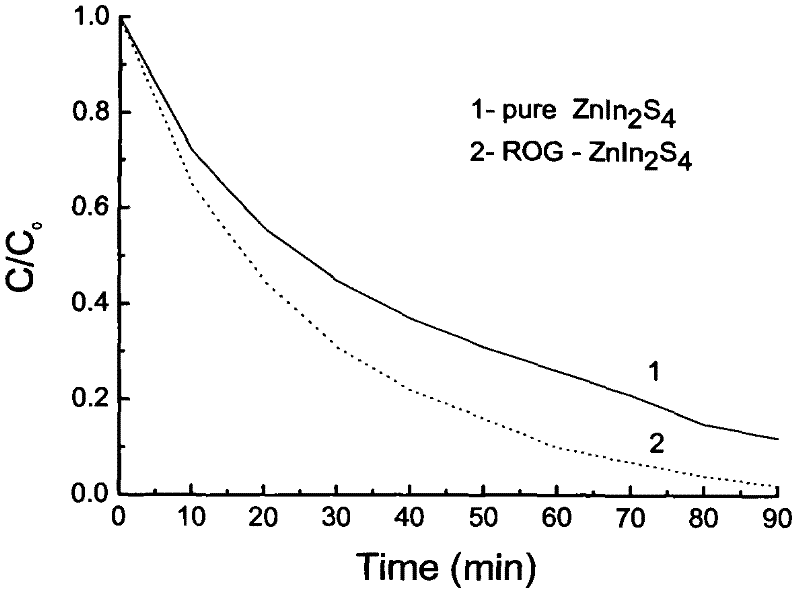

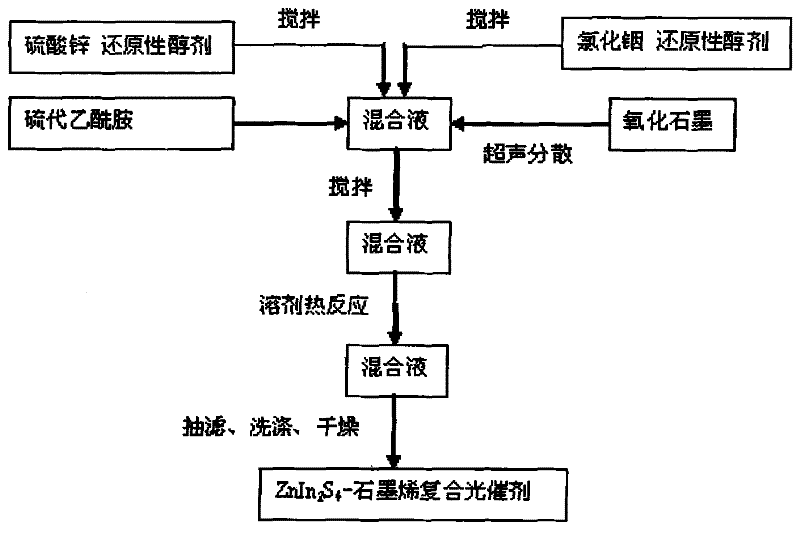

Preparation method and application of ZnIn2S4-graphene composited photochemical catalyst

InactiveCN102407147AReduce the chance of reunionLarge specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationFiltrationAlcohol agent

The invention discloses a preparation method and application of a ZnIn2S4-graphene composited photochemical catalyst. The preparation method comprises the following steps of: placing graphite oxide into a reducibility alcohol agent for ultrasonic dispersion; adding zinc sulfate and indium chloride into the reducibility alcohol agent, stirring and dissolving; adding thioacetamide into two systems after the two systems are mixed; transferring the mixed systems into a hydrothermal kettle for a reaction; and after the reaction is finished, carrying out vacuum filtration on the obtained product, washing, vacuumizing and grinding to obtain a nano ZnIn2S4-graphene composited photochemical catalyst. In the invention, grapheme is taken as a supporting material, and a solvothermal synthesis method is adopted to further prepare the nano ZnIn2S4-graphene composited photochemical catalyst. The catalyst prepared by using the method in the invention has the advantages of wide visible light responding range and high photocatalysis activity, can be used for transformation and use of solar energy and comprehensive ecological improvement, such as air purification, sewage disposal, hydrogen production through photodegradation, preparation of alcohol or hydrocarbon chemical fuels and the like by the photocatalysis and reduction of CO2.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

In-situ composite solid electrolyte, application thereof, all-solid-state battery and preparation method thereof

ActiveCN108550907AGood compatibilityEasy to prepareFinal product manufactureElectrolyte accumulators manufactureSolid state electrolyteAll solid state

The invention provides a preparation method for an all-solid-state battery. The method comprises the steps of S1, mixing lithium salt, additive and initiator to obtain mixed solution, wherein the additive is micromolecule monomer comprising unsaturated bond; and S2, carrying out in-situ polymerization and adhesion by the solution in a cathode layer, a solid electrolyte layer and an anode layer andamong the layers, thereby obtaining composite solid electrolyte, wherein a solid electrolyte layer comprises inorganic solid electrolyte and adhesive. Compared with the prior art, the method has theadvantages that through utilization of flowability of the micromolecule monomer additive comprising the unsaturated bond, solid particles are wetted sufficiently, ion transport channels are constructed through in-situ polymerization and solidification, electrode layers are adhered once, and a battery is moulded; the compatibility of the solid-solid interface in the all-solid-state battery can be effectively improved; and the preparation method is simple and fast, is compatible with the existing battery technology and is beneficial for large-scale preparation.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD +1

Double-effect composite membrane used for lithium sulphur battery and preparation method thereof

ActiveCN108461694AImprove the utilization rate of active substancesImprove stabilityCell component detailsHigh energyLithium–sulfur battery

The invention provides a double-effect composite membrane used for a lithium sulphur battery and a preparation method thereof. The membrane is composed of a functional composite layer and porous insulating film. The functional composite layer is a composite of conductive carbon base materials, polar materials and a binder, wherein the mass fraction of the conductive carbon base materials and polarmaterials is 5%-90% and 5%-90% respectively. The preparation method comprises the steps that the conductive carbon base materials and the polar materials are used for preparing the functional composite layer, the functional composite layer is loaded on the porous insulating film, and surface loading capacity of the functional composite layer is 0.1-3.0 mg cm-2. The composite membrane in the lithium sulphur battery regulates and controls reaction and deposition behaviors of active substances in different charge-discharge stages and significantly improves the utilization and stability of the active substances of the lithium sulphur battery. Compared with ordinary commercial polymer battery membranes, the composite membrane prolongs the cycle life of the lithium sulphur battery and improvesspecific energy, positive discharge capacity and coulombic efficiency. The method is simple in operation, is beneficial to large-scale preparation, and facilities wide commercial application of the high-energy density lithium sulphur battery.

Owner:TSINGHUA UNIV

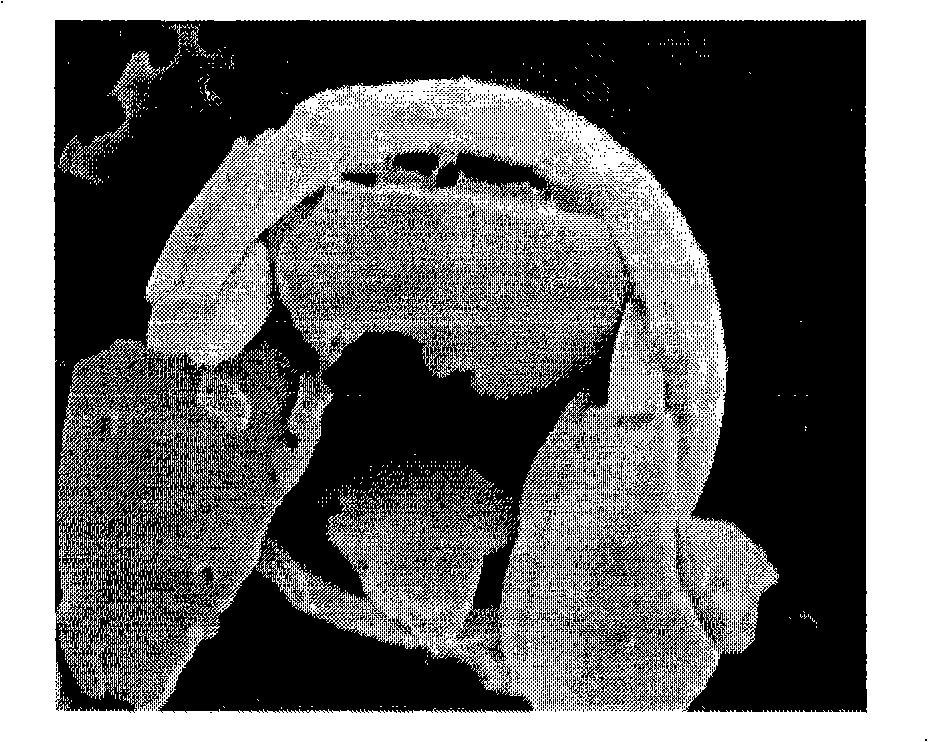

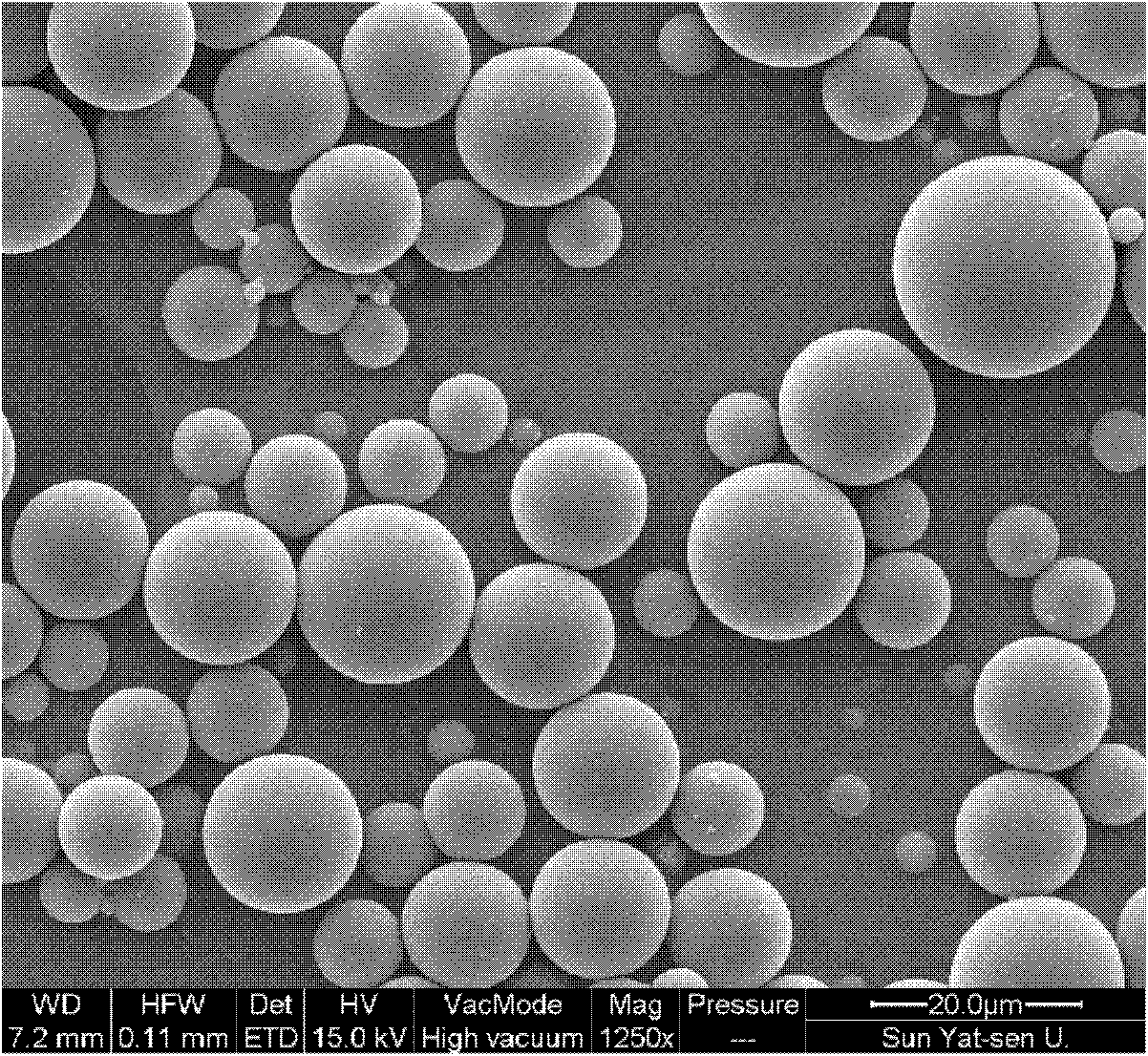

Epoxy resin micro-capsule and its preparation method

InactiveCN101319055AImprove sealingGood mechanical propertiesMicroballoon preparationMicrocapsule preparationEpoxyIn situ polymerization

The invention discloses an epoxy resin microcapsule and a preparation method thereof. The epoxy resin microcapsule comprises a capsule core and a capsule wall, wherein, the capsule core is an epoxy resin, and the capsule wall is a composition of an aepoxy acrylate resin, a polymerizable emulsifying agent, a crosslinking agent and an optical initiator; and the polymerization method of the capsule wall is ultraviolet irradiation and film forming through curing. The preparation method for the microcapsule comprises the following steps that: core materials, wall materials and an ultraviolet initiator are added into a water solution which is dissolved with a surfactant in turn under the condition of high-speed stirring; after an oil-in-water emulsion system is prepared by emulsification, ultraviolet light is immediately used for irradiating the emulsion, and the surface compositions of oil-in-water liquid droplets undergo in-situ polymerization and film forming through curing; a great dealof water is added for repeated sedimentation and water scrubbing; and microcapsule products are prepared through vacuum freeze drying of microcapsule deposits. The method has a simple technique, low energy consumption, quick speed and friendly environment. The capsule prepared takes the shape of a regular sphere, has good leak tightness and heat resistance, and can be widely applied to self-repairing of self-setting thread fasteners and thermosetting resin substrate composite materials.

Owner:SUN YAT SEN UNIV

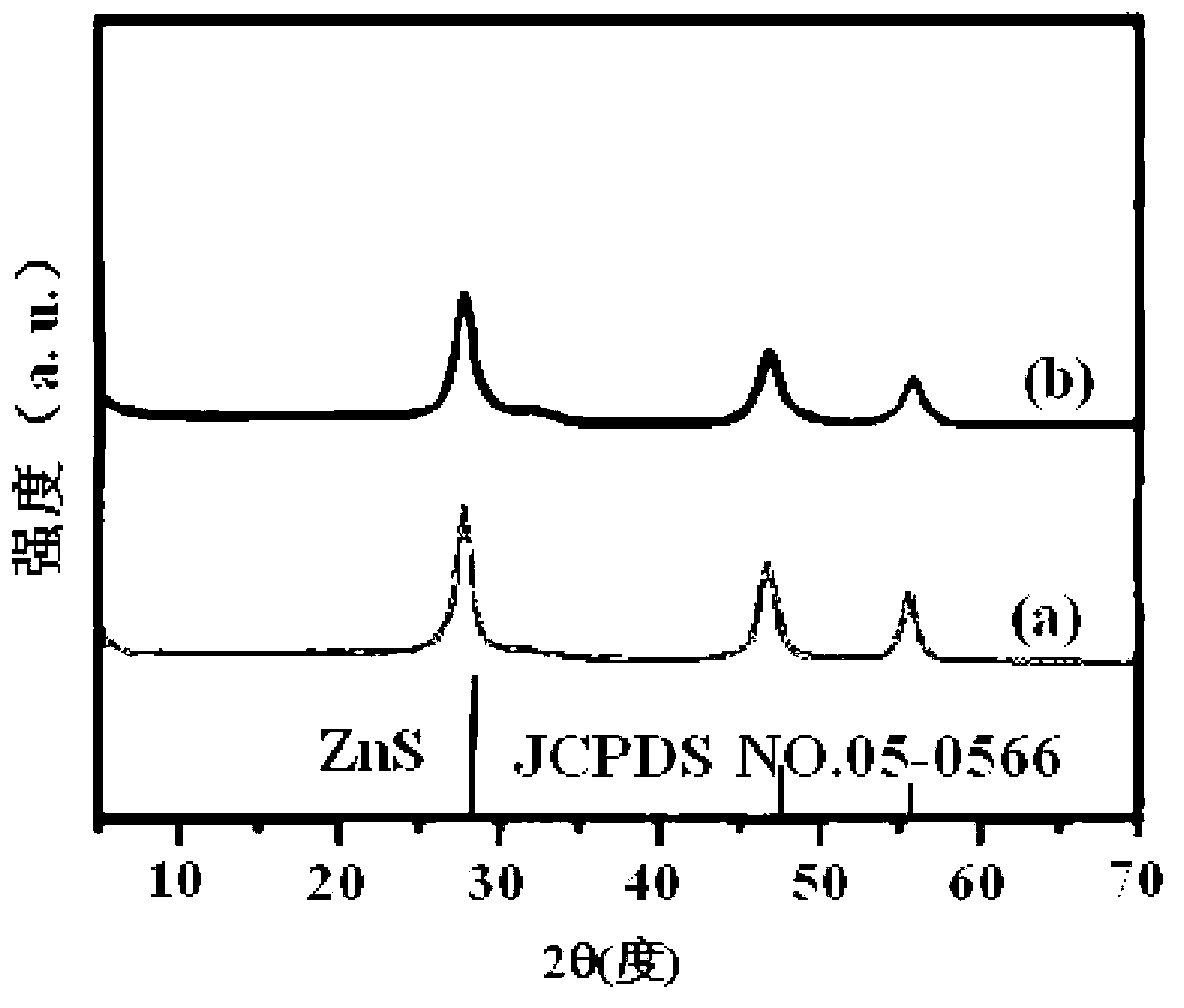

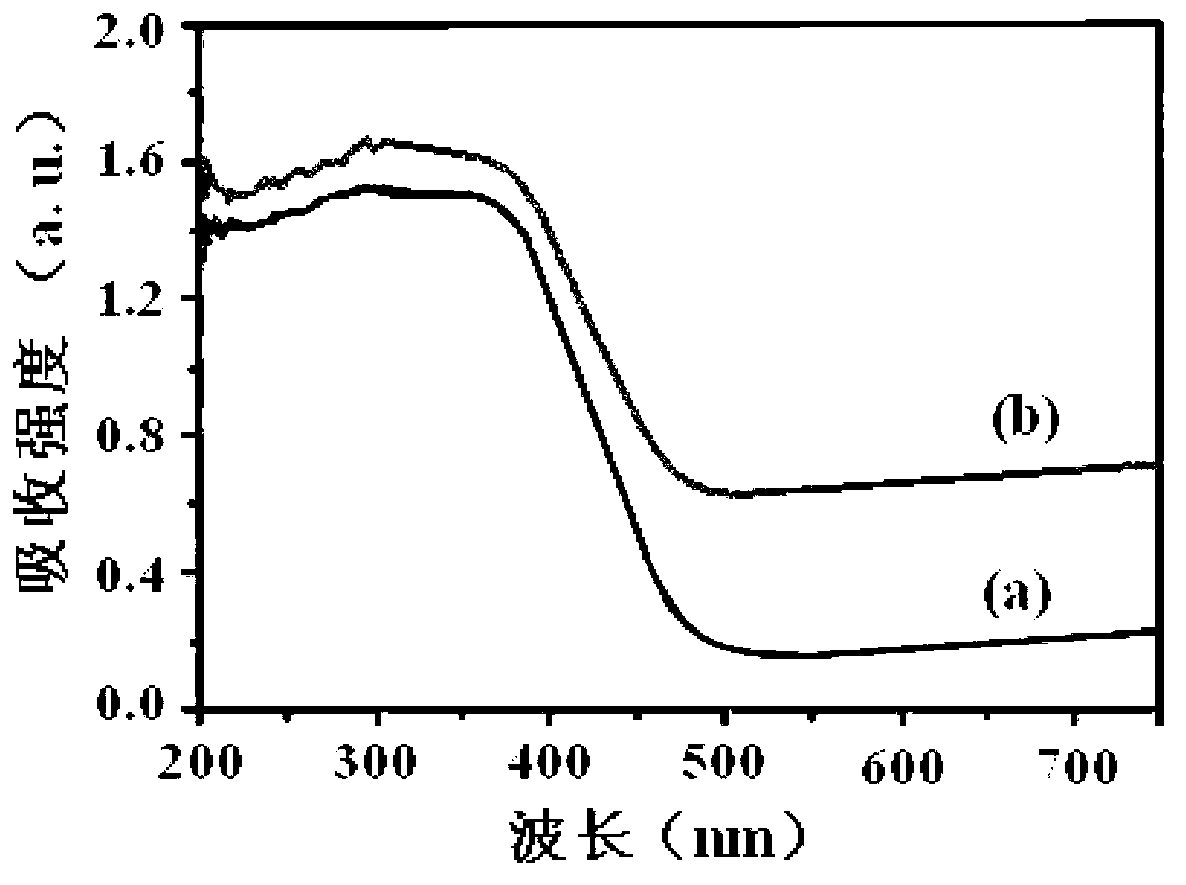

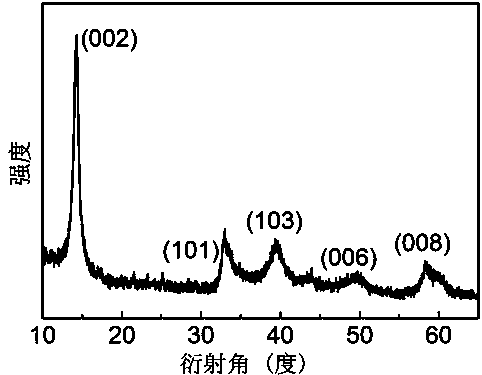

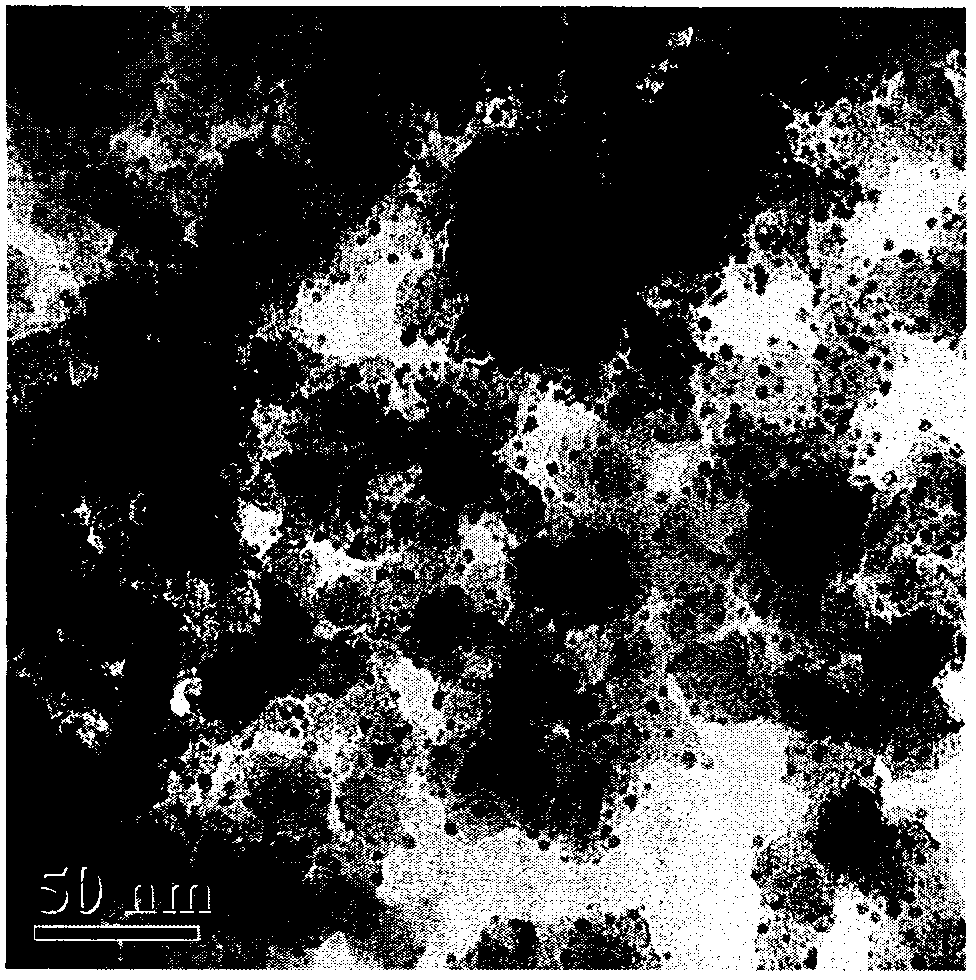

Preparation method of composite material of Zn0.8Cd0.2S and graphene

InactiveCN103316694AReduce the chance of particle agglomerationLarge specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationCvd grapheneZinc Acetate Dihydrate

The invention discloses a preparation method of a composite material of Zn0.8Cd0.2S and graphene, and belongs to the technical field of preparation of the composite material of a photocatalyst. The method comprises the following steps of: taking graphene oxide as an initial bearing material, zinc acetate dehydrate and cadmium acetate dehydrate as precursors for preparing Zn0.8Cd0.2S nano particles, and dimethyl sulfoxide as a sulphur source and a reducing agent; and achieving preparation of the Zn0.8Cd0.2S, reduction of the graphite oxide and composition of the Zn0.8Cd0.2S / graphene in one step by adopting a solvent thermal technology, so as to prepare the composite photocatalyst with visible light response. The composite material disclosed by the invention is simple and convenient in preparation method; the composite material of the Zn0.8Cd0.2S / graphene can be synthesized in one step; meanwhile, the graphene oxide is effectively reduced into the graphene; the product Zn0.8Cd0.2S particles are small and evenly distributed on the graphene, and display wide visible light response and high photocatalytic activity; and the degradation rate on methylthionine chloride under the optimal condition achieves 96%.

Owner:JILIN UNIV

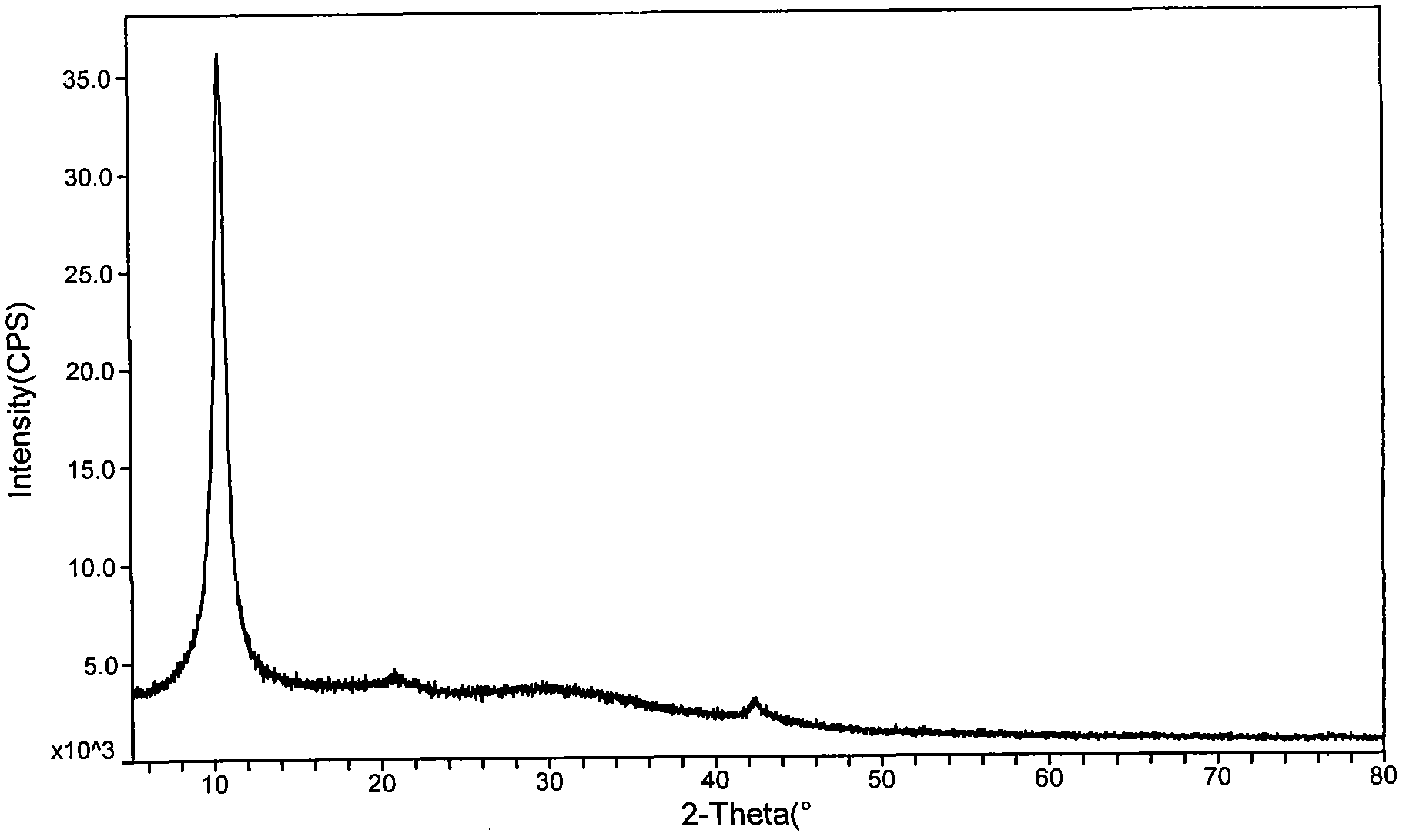

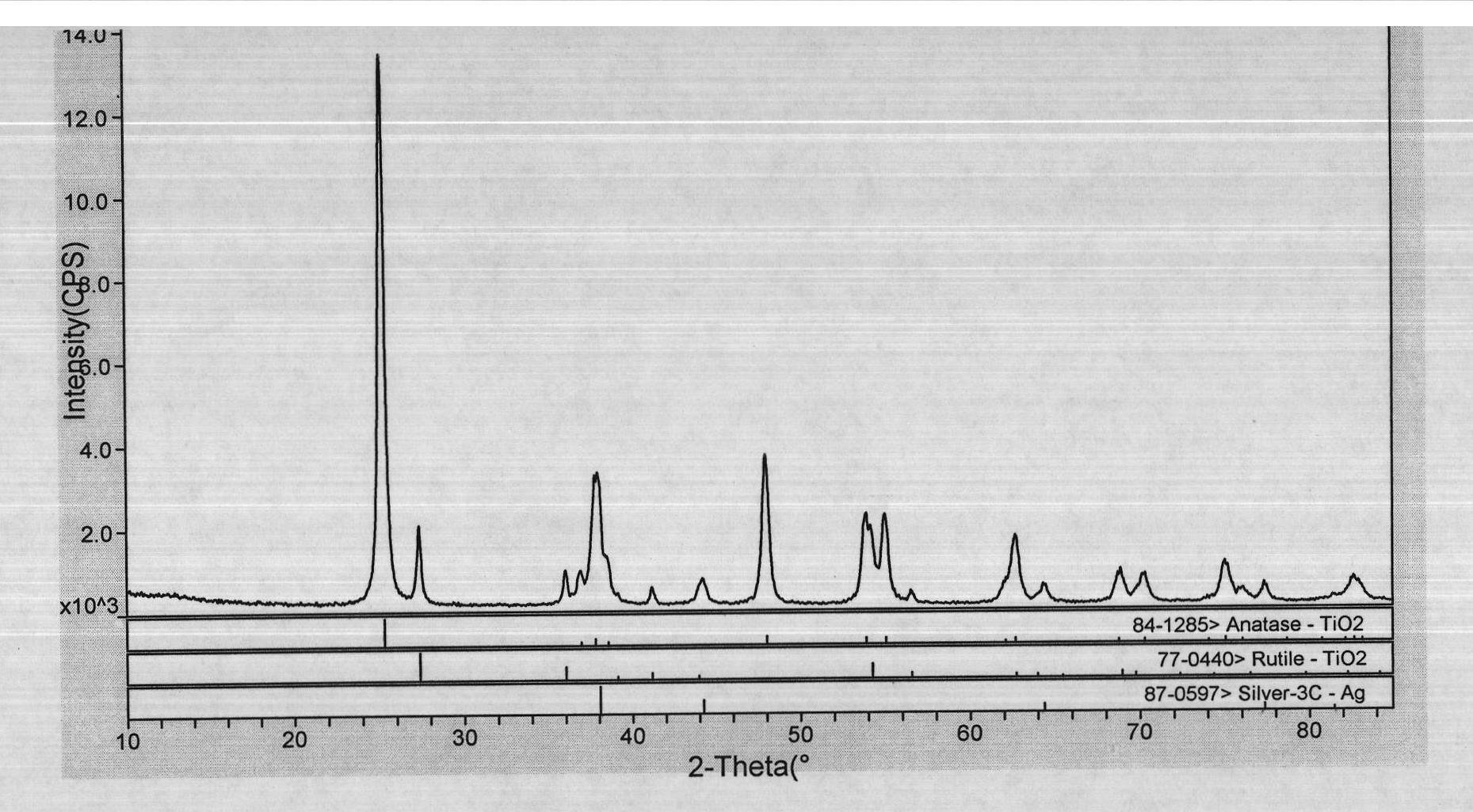

Ag/TiO2/graphene nanometer composite photocatalyst and preparation method thereof

InactiveCN102688755AEasy to formReagent savingMetal/metal-oxides/metal-hydroxide catalystsIonPhotocatalysis

The invention discloses an Ag / TiO2 / graphene nanometer composite photocatalyst and a preparation method thereof, belonging to the field of new materials. The Ag / TiO2 / graphene nanometer composite photocatalyst is prepared by assembling metal silver, nanometer titanium dioxide (P25) powder onto a two-dimensional lamellate graphene carrier material by using a photocatalytic oxidation-reduction method, using the two-dimensional lamellate graphene as the carrier material, the silver nitrate as the silver source and the nanometer titanium dioxide as the photocatalysis material, initiating the nanometer titanium dioxide to generate photoproduction electron and photoproduction hole by stimulating sunlight, capturing the photoproduction hole by a sacrifice agent, and restoring the silver ion and the graphite oxide to be metal Ag and graphene by the photoproduction electron. The invention has simple preparation method and low cost in reagent, is beneficial to large-scale preparation, and provides an environment-friendly method for preparing graphene load composite photocatalyst through the restoration of the graphite oxide.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

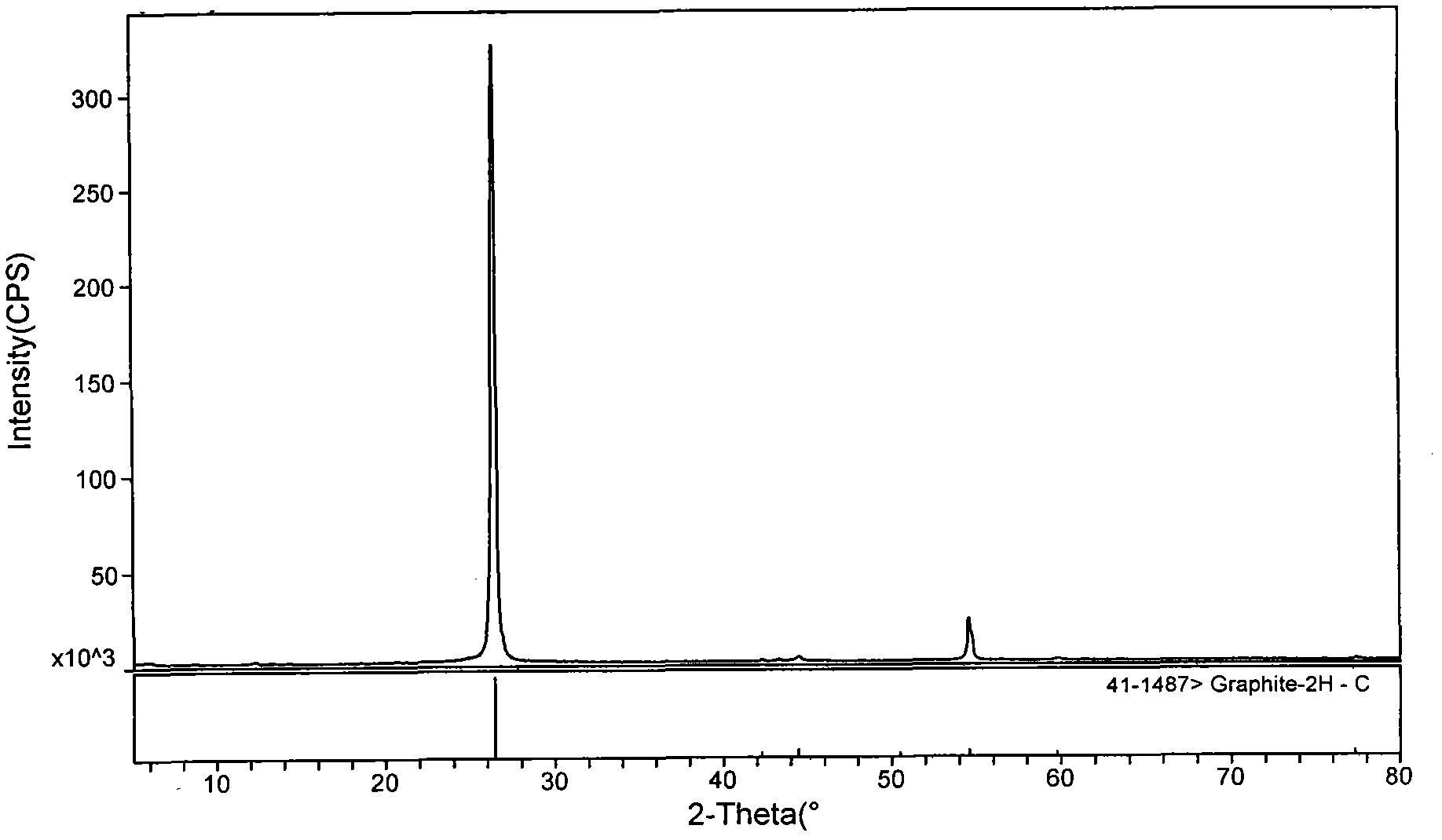

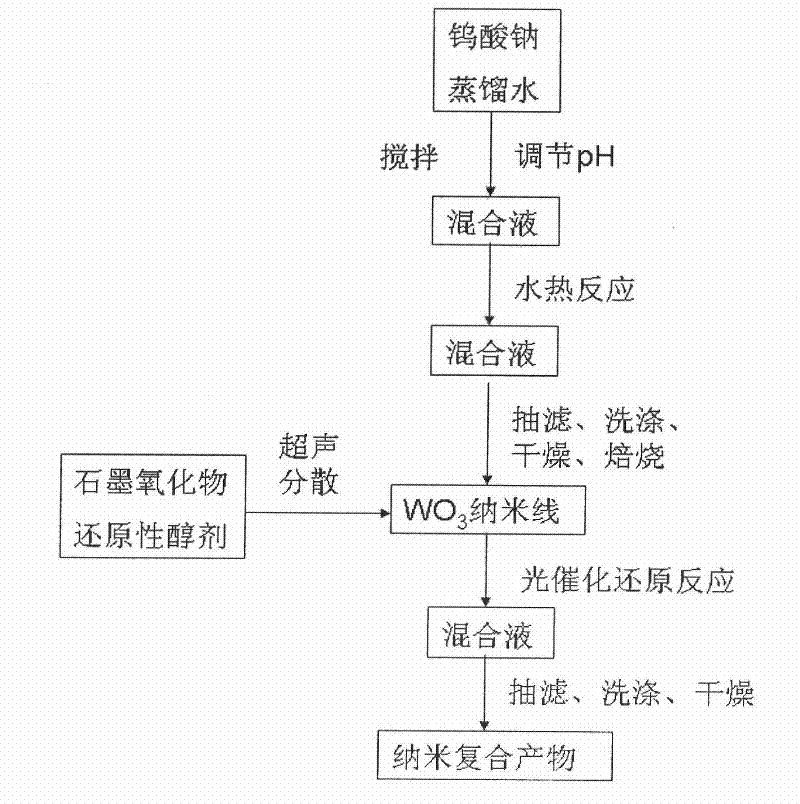

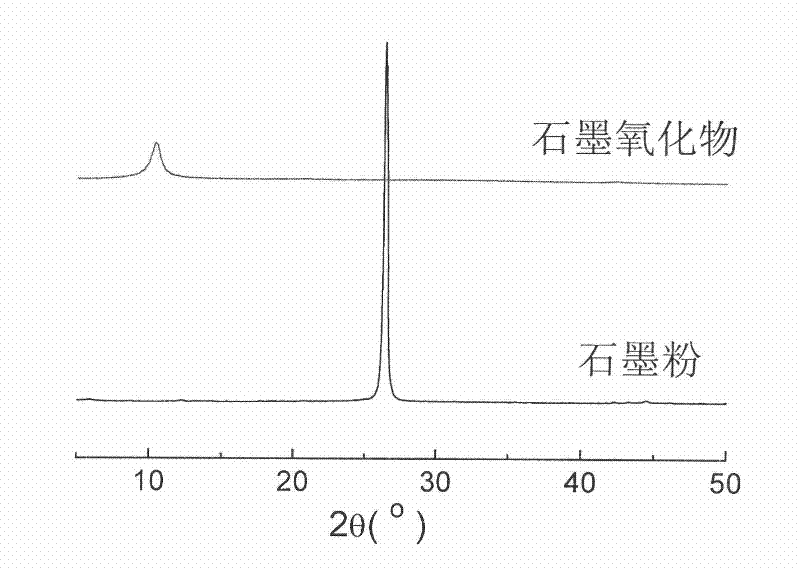

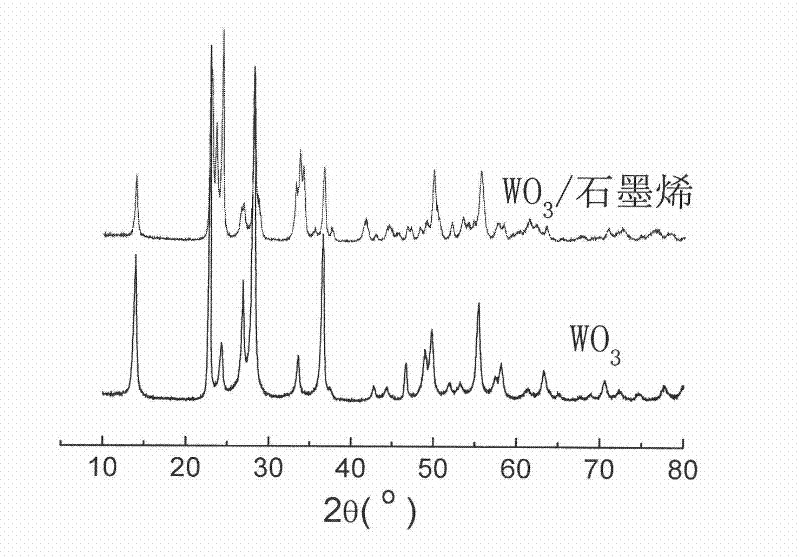

Graphene load tungsten trioxide (WO3) nanowire composite material and preparation method thereof

InactiveCN102531063AEasy to formReagent savingTungsten oxides/hydroxidesGrapheneCvd grapheneComposite structure

The invention discloses a graphene load tungsten trioxide (WO3) nanowire composite material and a preparation method thereof, which belong to the field of new materials. The nano composite material has a one-dimensional composite structure and a two-dimensional nano composite structure, the diameter of a WO3 nanowire is 10-30 nanometers, the length of the WO3 nanowire is 50-600 nanometers, and the WO3 nanowire penetrates through or is distributed on the inner layer or the surface of a layer-shaped grapheme main material. The preparation method comprises utilizing a two-dimensional grapheme as an auxiliary material and sodium tungstate as a tungsten source, generating the WO3 nanowire through a hydrothermal synthesis method, then mixing the WO3 nanowire with graphite oxide dispersing solution, and then obtaining the graphene load WO3 nanowire composite material by means of photocatalytic reduction. The preparation process is simple, reagents are cheap, large-scale preparation is facilitated, and simultaneously an environment-friendly preparation method is provided for reduction of graphite oxide and formation of the nano composite material.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

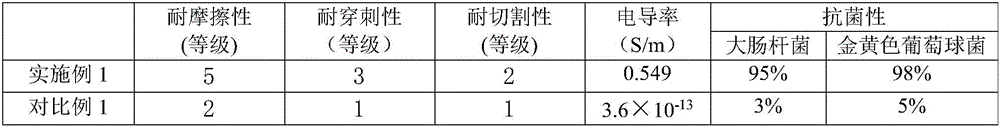

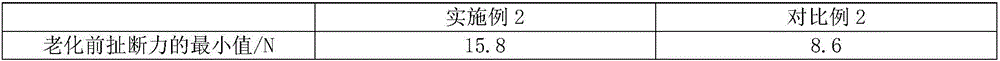

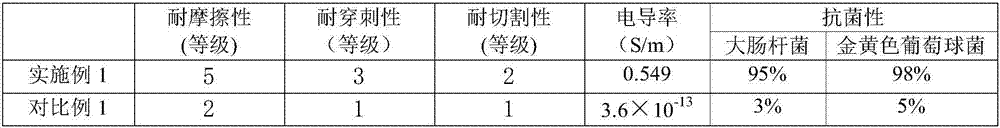

Graphene-latex functional high-strength protection glove and production method thereof

InactiveCN106065095AComfortable to wearImprove friction resistanceGlovesBulk chemical productionElectricityAviation

The invention discloses a graphene-latex functional high-strength protection glove and a production method thereof. The method comprises the following steps: (1) immersing a glove blank in a coagulating agent, immersing the glove blank in a graphene-latex composite liquid, and drying the immersed glove blank to obtain the glove; or (2) immersing the glove blank in the coagulating agent, drying the immersed glove blank, immersing the dried glove blank in the graphene-latex composite liquid, leaching the immersed glove blank, crimping the leached glove blank, drying the crimped glove blank, vulcanizing the dried glove blank, leaching the vulcanized glove blank, and drying the leached glove blank to obtain the glove. Compared with gloves in the prior art, the graphene-latex functional high-strength protection glove produced in the invention fully performs the advantages of high electricity conductivity, high strength, friction resistance and strong bacteriostasis of graphene, and has wide uses in the fields of the manufacturing industry, the medical industry, the chemical engineering industry and the space flight and aviation industry.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

Nitrogen-doped porous carbon nanosheet-supported non-noble metal catalyst and preparation method thereof

ActiveCN105879895ASimple processGood repeatabilityMaterial nanotechnologyPhysical/chemical process catalystsMetal oxide nanoparticlesPorous carbon

The invention relates to nitrogen-doped porous carbon nanosheet-supported non-noble metal catalyst and a preparation method thereof. The catalyst is made by embedding metal and metal oxide nanoparticles into nitrogen-doped porous carbon nanosheets or supporting them to the surfaces of the nitrogen-doped porous carbon nanosheets; the preparation method comprises: 1), synthesizing a polymerizable ionic liquid monomer; 2), reacting the obtained ionic liquid with a metal salt precursor, and drying to obtain an intermediate product, solid powder; 3), placing the obtained solid powder in a magnetic boat, placing in a tubular furnace fitted with a quartz tube, charging an inertial gas at a certain flow rate, heating to 600-1000 DEG, holding the temperature for 0.5-5 h, and naturally cooling to room temperature to obtain the catalyst. The poly-ionic liquid is used as the precursor, metal supporting capacity is high, the cost is low, oxygen reduction and oxygen evolution catalytic activity is high, the prepared product has stable performance, and the preparation method is simple and is easy to scale up and industrially apply.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of layered molybdenum sulfide nanosheet molecular separating membrane

InactiveCN103585896ALow costIncrease productionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisMaterials preparationFiltration

The invention discloses a preparation method of a layered molybdenum sulfide nanosheet molecule separating membrane. According to the preparation method, n-butyllithium is taken as an intercalation modular and enters a molybdenum sulfide crystal lattice after long-time stirring; water is added for decomposing n-butyllithium, so that the interlayer distances of a molybdenum sulfide sheet are enlarged; molybdenum sulfide is dispersed into monoatomic layer materials through ultrasonic treatment; redundant impurities are removed through dialysis, and a purified and clean molybdenum sulfide water solution is obtained; the obtained molybdenum sulfide water solution is treated with a vacuum filtration method, and the layered molybdenum sulfide nanosheet molecule separating membrane is obtained; and the thickness of the membrane is adjusted by adjusting the volume of the used molybdenum sulfide water solution. A molecule-selective separation membrane is obtained with a method of stacking the monoatomic layer materials to form the membrane; and the material preparation method is simple, the cost is low, and the obtained membrane has size selective separation performance on different molecules.

Owner:ZHEJIANG UNIV

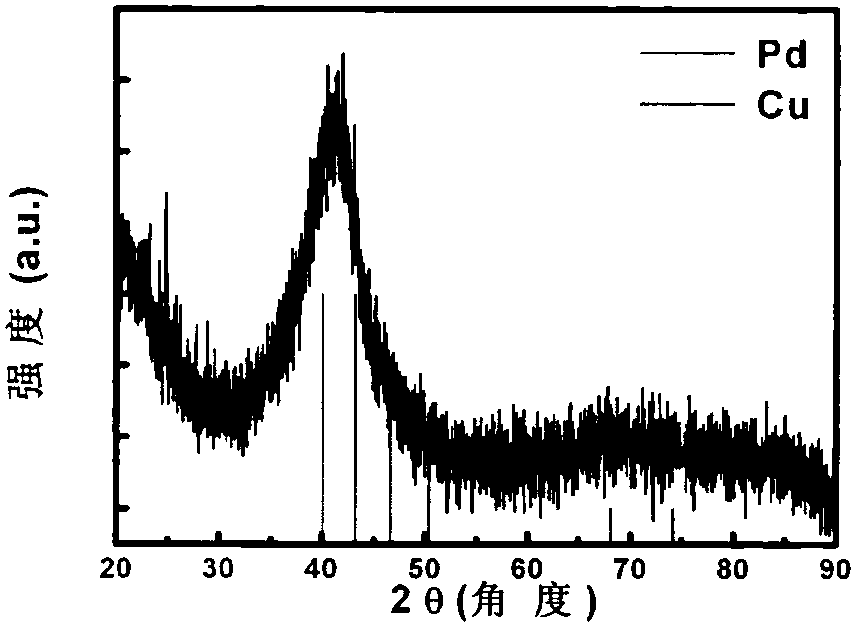

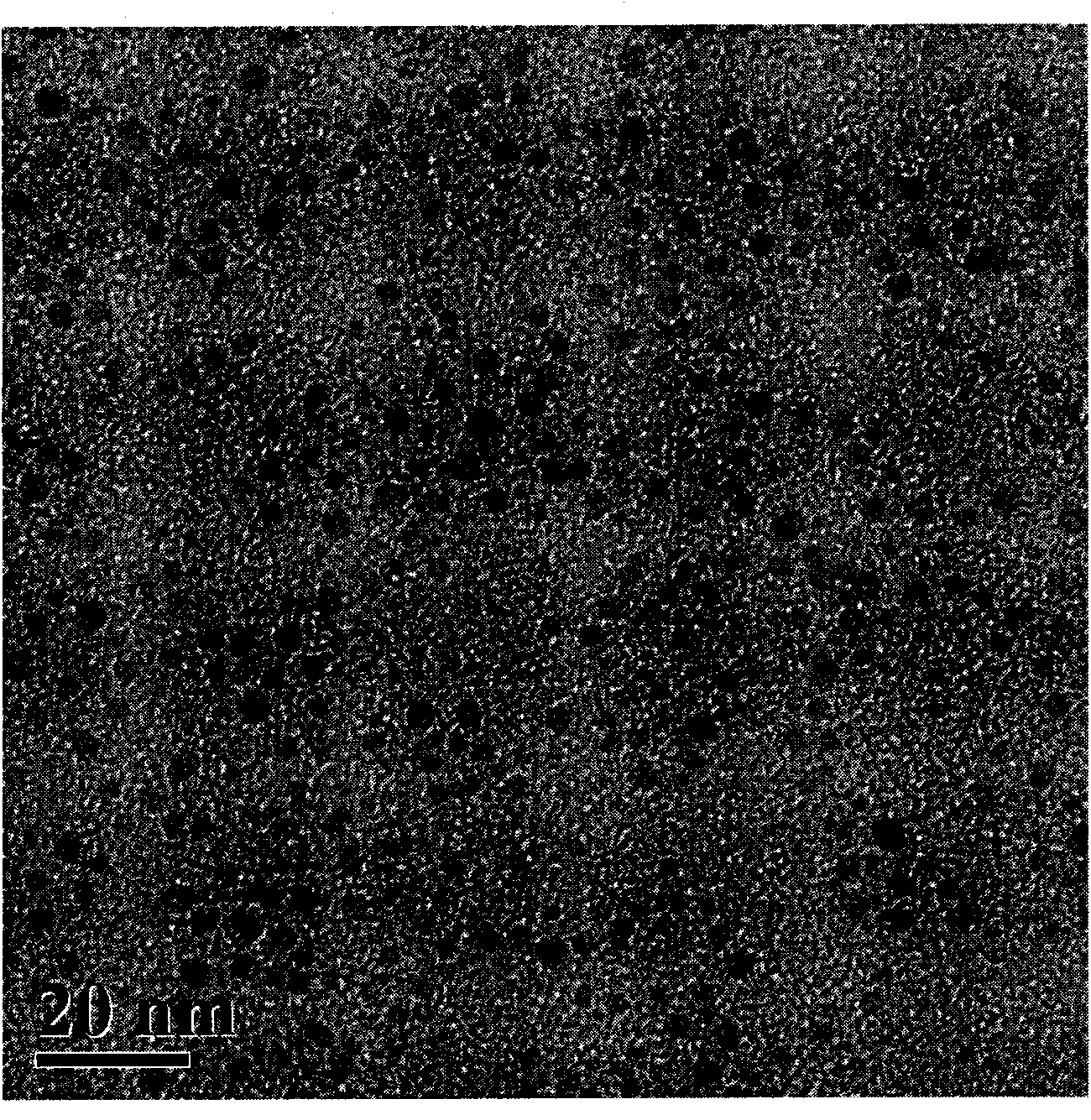

Method for preparing load type high-dispersion multi-component precious metal nanoparticle catalyst

InactiveCN102974365AGood dispersionUniform particle size distributionMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureSurface-active agents

The invention relates to a method for preparing a load type high-dispersion multi-component precious metal nanoparticle catalyst. The method comprises the steps of 1) under inert atmosphere, uniformly stirring a solvent and a surface active agent, then adding a precious metal precursor solution, rising the temperature, reacting for a certain period of time, cooling to the room temperature, adding normal hexane, and performing extraction layering; 2) uniformly mixing the obtained upper layer nanoparticle solution with a carrier, and stirring or performing ultrasonic treatment; and 3) centrifugating, washing and drying or baking the mixed solution to obtain the catalyst. For the precious metal catalyst, even under a relatively high carrying amount, relatively good precious metal nanoparticle dispersion degree can be still guaranteed; the particle sizes of the particles are uniformly distributed; the precious metal carrying amount is controlled easily and accurately; the particle sizes and the components of multi-component particles can be controlled; and the catalysis application range is wide. The process is simple; the preparation cost is low; the applicability is high; and load-type high-dispersion precious metal and the multi-component precious metal nanoparticle catalyst can be prepared in a large scale.

Owner:TIANJIN POLYTECHNIC UNIV

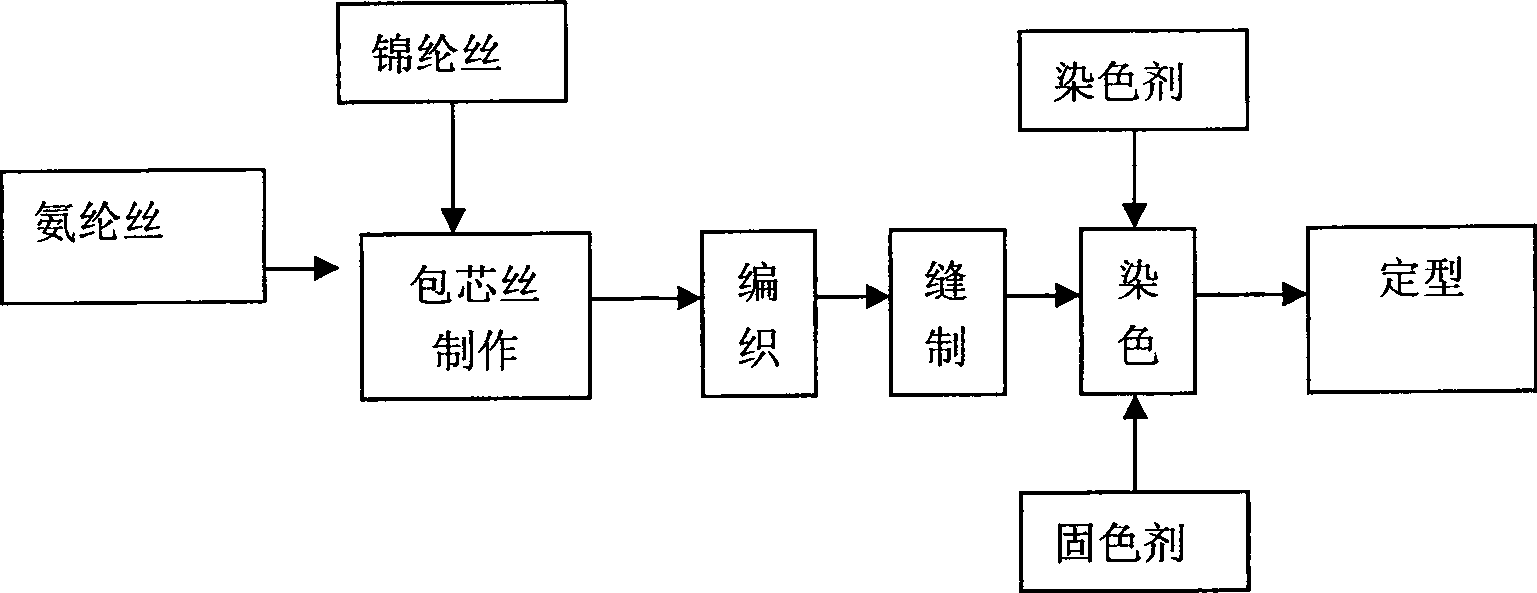

Technique for producing run-resistant spandex core-spun silk stockings

ActiveCN101496641AReduce manufacturing costGood for mass manufacturingDyeing processPanty-hoseYarnDyeing

The invention relates to a process for producing a spandex core-spun run resistant hosiery, which comprises the steps of manufacturing of core-spun yarns, weaving, dyeing and shaping, wherein during shaping, the core-spun yarns are melted by adopting proper temperature, so that the woven core-spun yarns are mutually adhered to form a net lace structure; the core-spun yarns among the hosiery net lace are mutually adhered, so that a compact netted structure is formed between the transverse direction and the longitudinal direction of the hosiery to change the prior weaving structure; and even if one or more of yarns of the hosiery are broken, the broken yarns are not laddered due to the adhering relation of the net laces, so the hosiery has the run resistant function.

Owner:深圳市润薇服饰有限公司

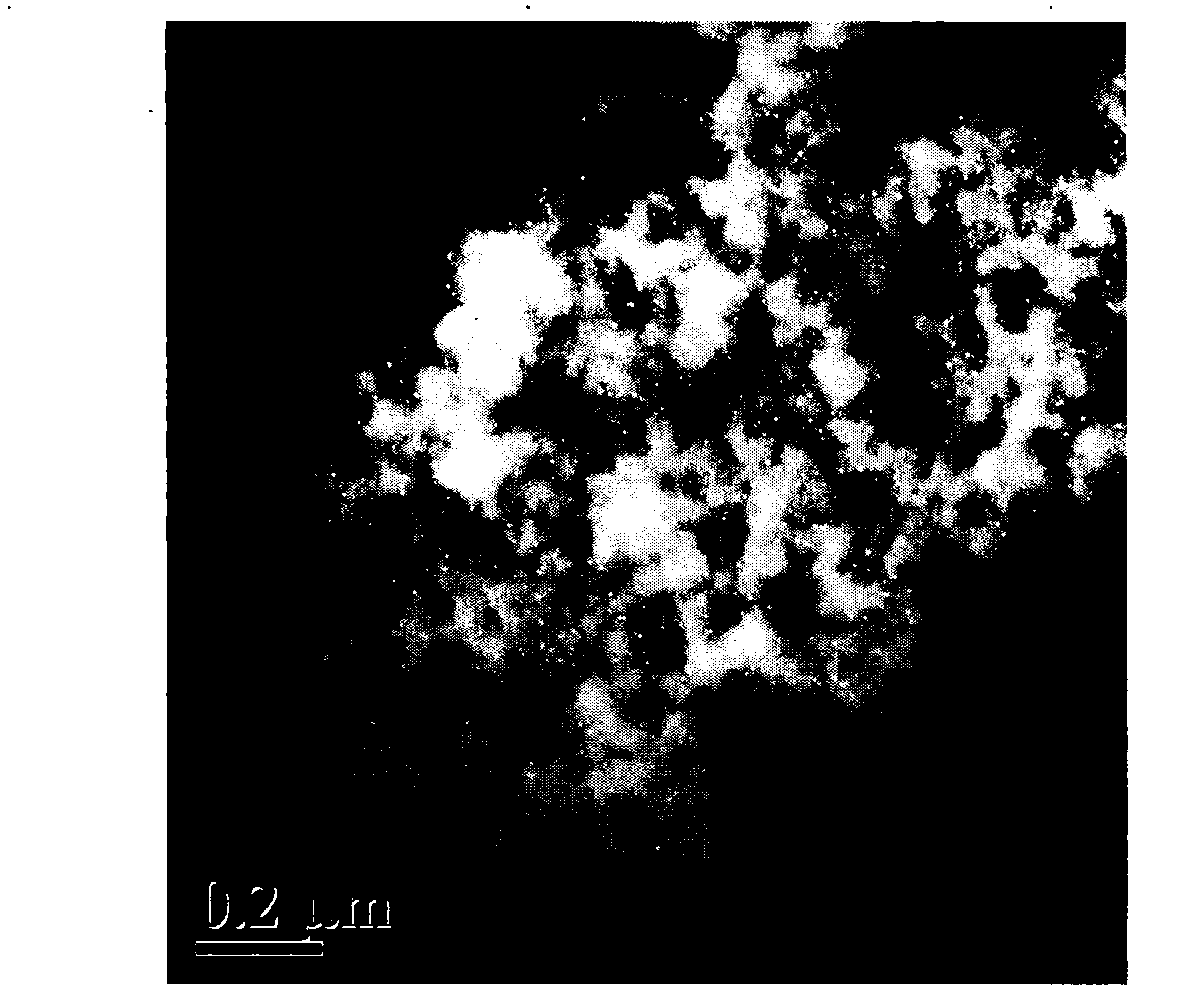

Method for preparing high-dispersion precious metal and alloy nanoparticles thereof

The invention relates to a method for preparing a high-dispersion precious metal and alloy nanoparticles thereof, which comprises: 1) uniformly stirring glycol and specific surfactant in a certain proportion in an inert atmosphere to prepare milky emulsion; 2) adding solution of precursor of the precious metal into the mixed solution, heating the resulting solution to a given temperature, keeping the temperature for a certain time period with stirring, cooling to room temperature, adding nonpolar solution and extracting; and 3) performing the rotary evaporation of upper solution to remove solvent, washing with ethanol or mixed solution of ethanol and normal hexane, centrifuging and obtaining the high-dispersion precious metal and the alloy nanoparticles thereof. The nanoparticles prepared by the method have uniform particle size and high monodispersity, and can be separated easily; the alloy is controllable in particle size and composition; the process is simple; the preparation cost is low; the solvent system is cheap; and the method is widely applicable and can realize large-scale preparation easily.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

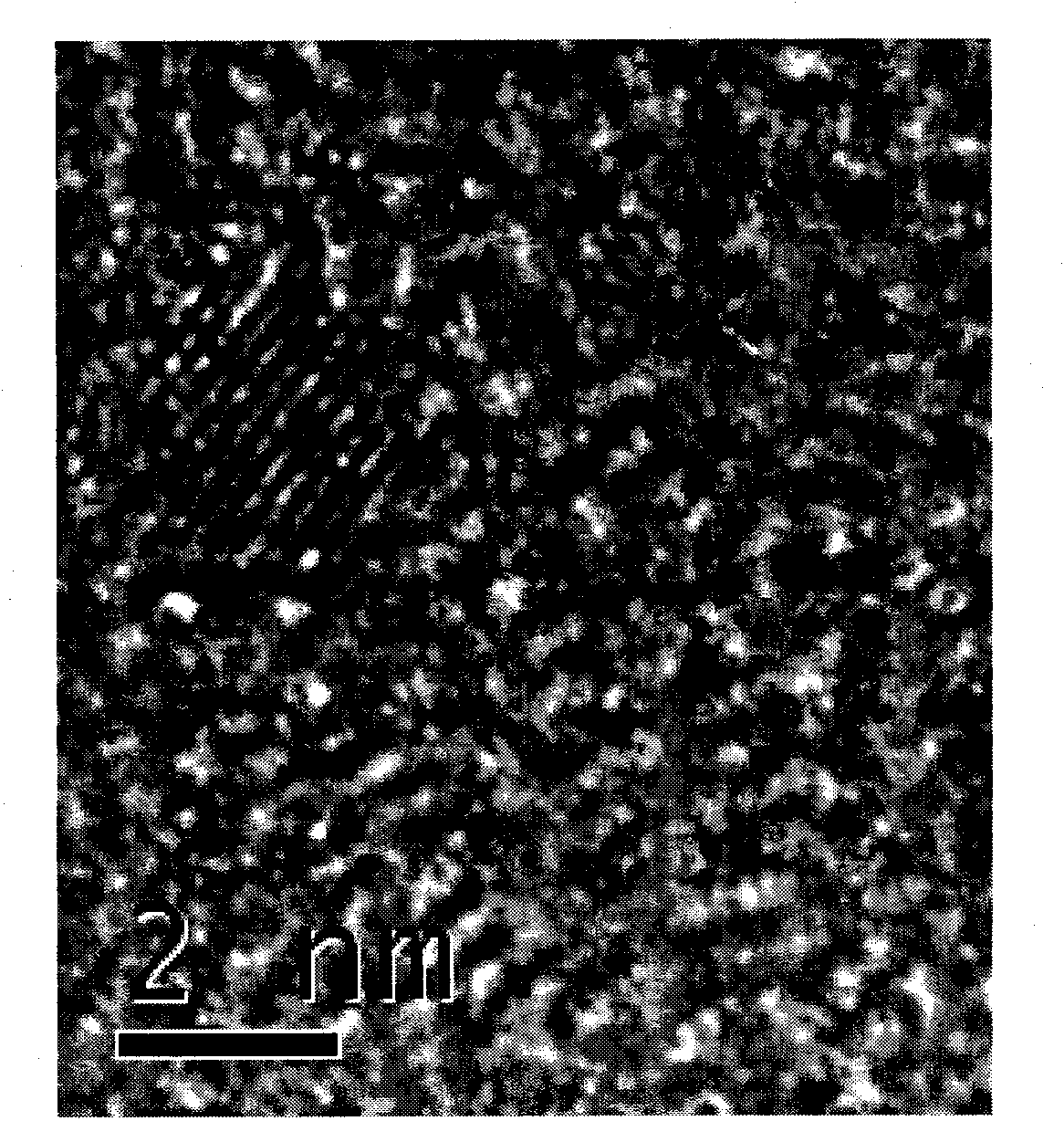

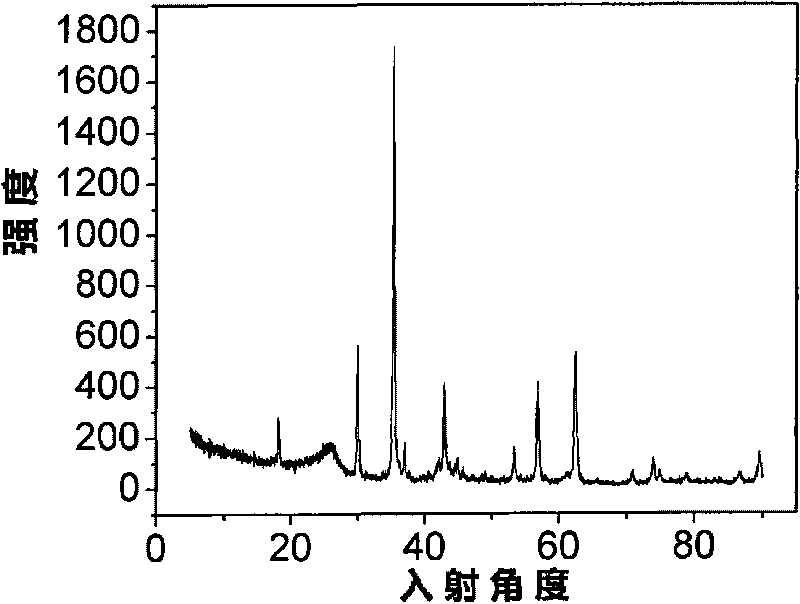

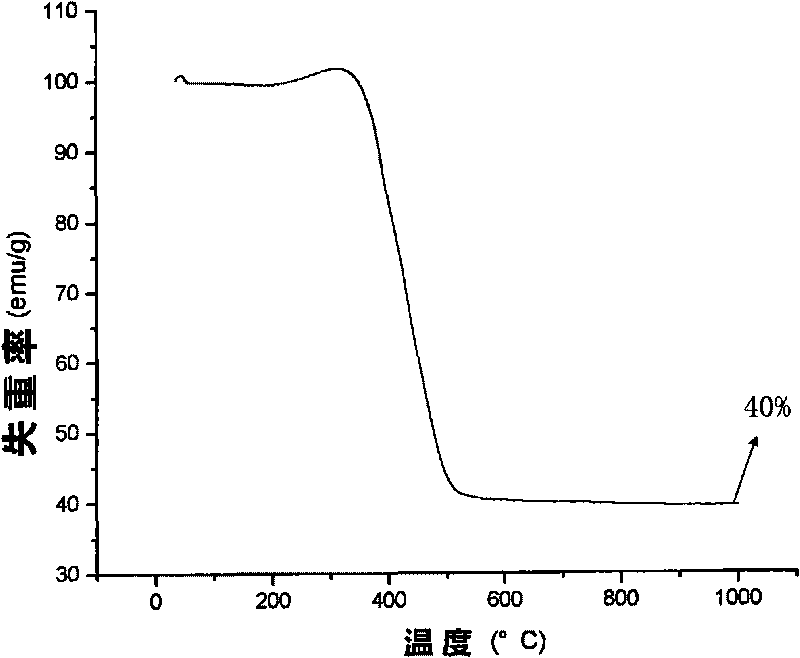

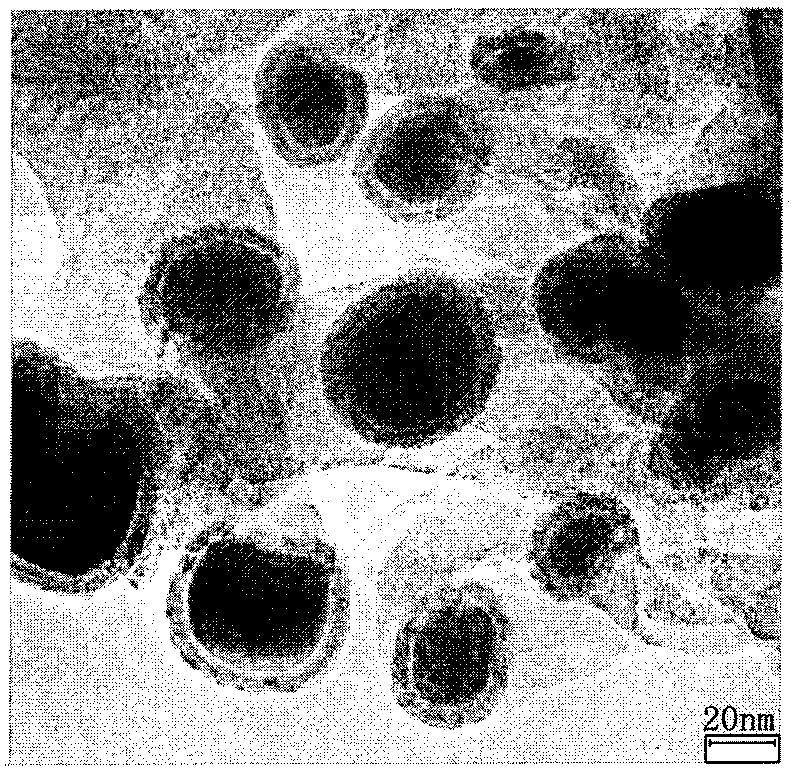

Lithium ion battery cathode material and preparation method thereof

ActiveCN101728526AHigh reversible capacityImprove cycle stabilityCell electrodesOxide compositeCarbon coated

The invention relates to a lithium ion battery cathode material and a preparation method thereof. The cathode material comprises a carbon-coated nano-metal oxide composite material, wherein a carbon-coated nano-metal oxide has a nuclear shell structure, grains are uniformly dispersed, the diameter range of the grains is 10-80nm, and the thickness of a carbon coating is 2.5-10nm. An electrode made of the cathode material has higher reversible capacity and excellent cyclical stability.

Owner:北京华科讯能石墨烯新技术研究院有限公司

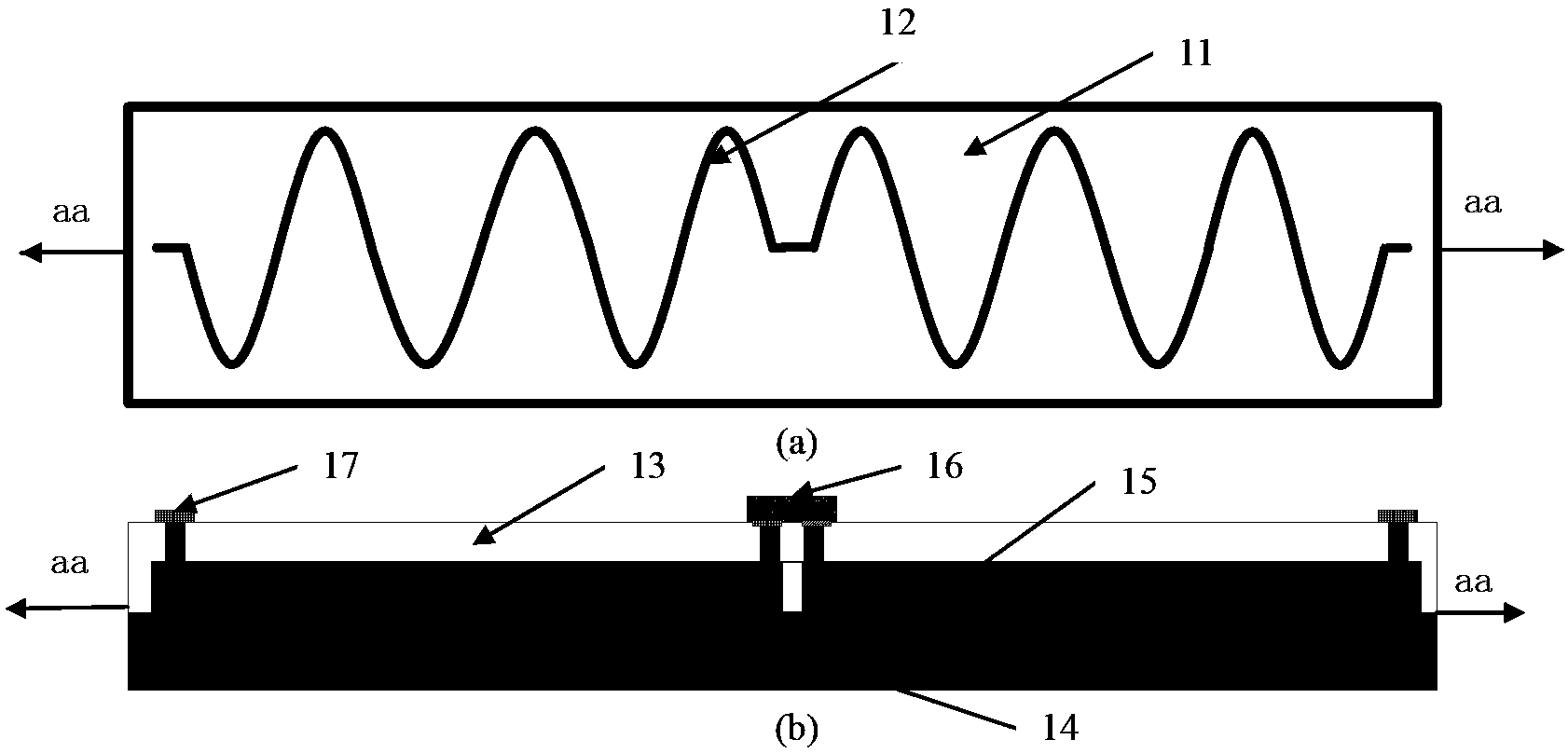

Frequency-adjustable stretchable liquid metal antenna and manufacture method thereof

ActiveCN103367880AImprove bending deformation abilityMeet complex deformation requirementsAntenna supports/mountingsRadiating elements structural formsCurve shapeLength change

The invention discloses a frequency-adjustable stretchable liquid metal antenna which comprises a stretchable base plate, wherein a curve-shaped liquid metal micro-flow way is machined on the stretchable base plate, and the liquid metal micro-flow way is internally filled with liquid metal or liquid metal alloy; when the stretchable base plate is transversely stretched, the liquid metal or the liquid metal alloy in the curve-shaped micro-flow way is lengthways and transversely deformed, and the length change of the stretched liquid metal antenna is controlled by presetting the proportional relation between the lengthways deformation and the transverse deformation, so that the work efficiency of the transversely-stretched liquid metal antenna can be adjusted. The invention further provides a manufacture method of the frequency-adjustable stretchable liquid metal antenna. According to the frequency-adjustable stretchable liquid metal antenna and the manufacture method of the liquid metal antenna, the length change of the stretched liquid metal antenna is controlled by presetting the proportional relation between the lengthways deformation and the transverse deformation, so that the work efficiency of the transversely-stretched liquid metal antenna can be adjusted.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of chitosan hollow microcapsule and preparation method thereof

InactiveCN102258967AAvoid lossRegulation and control of cyst wall propertiesMicroballoon preparationMicrocapsule preparationPolymer scienceCross linker

The invention discloses a chitosan hollow microcapsule and a preparation method thereof. Prepare a solution in a weak acid, mix the above solution with a metal salt solution with a concentration of 0.1-1mol / L by mechanical dispersion or pressure, then add 1-10 parts of cross-linking agent, and react at 30-60°C for 0.5 ~5h. The microcapsules prepared by the present invention are in regular spherical shape, high hollowness, narrow particle size distribution (the diameter of the microcapsule is 100nm-1mm, and the thickness of the capsule wall is 30nm-10μm), good heat resistance, low density, large specific surface area, and Good surface penetration ability, and the method of the invention has simple process, high production efficiency, easy realization of large-scale preparation, and the capsule size and capsule wall composition can also be adjusted as required.

Owner:SOUTH CHINA UNIV OF TECH

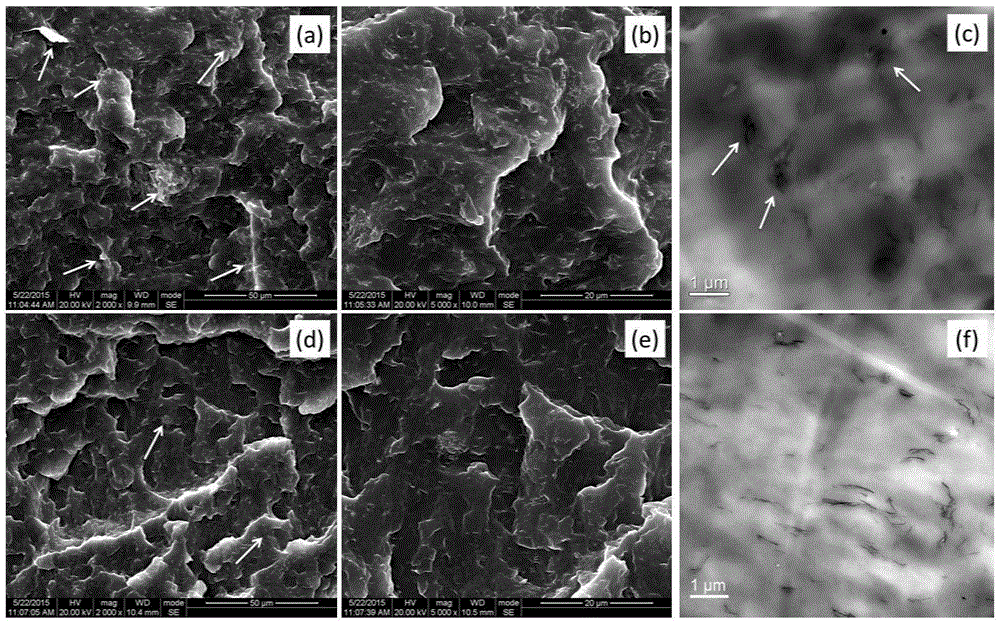

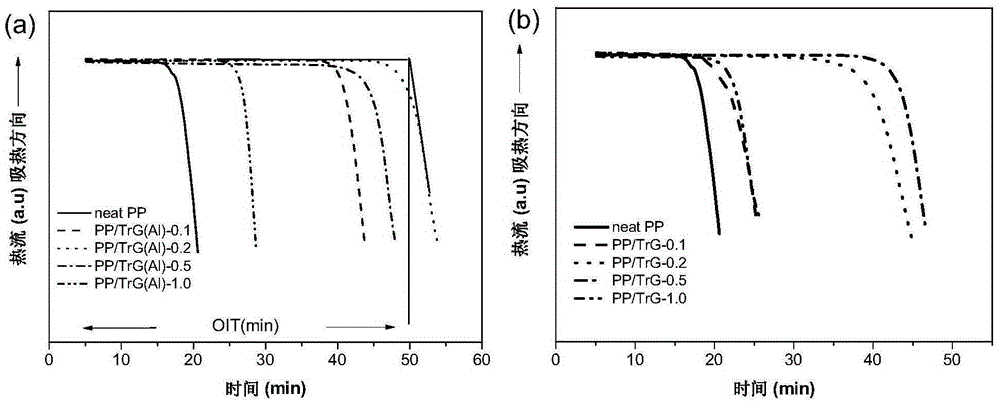

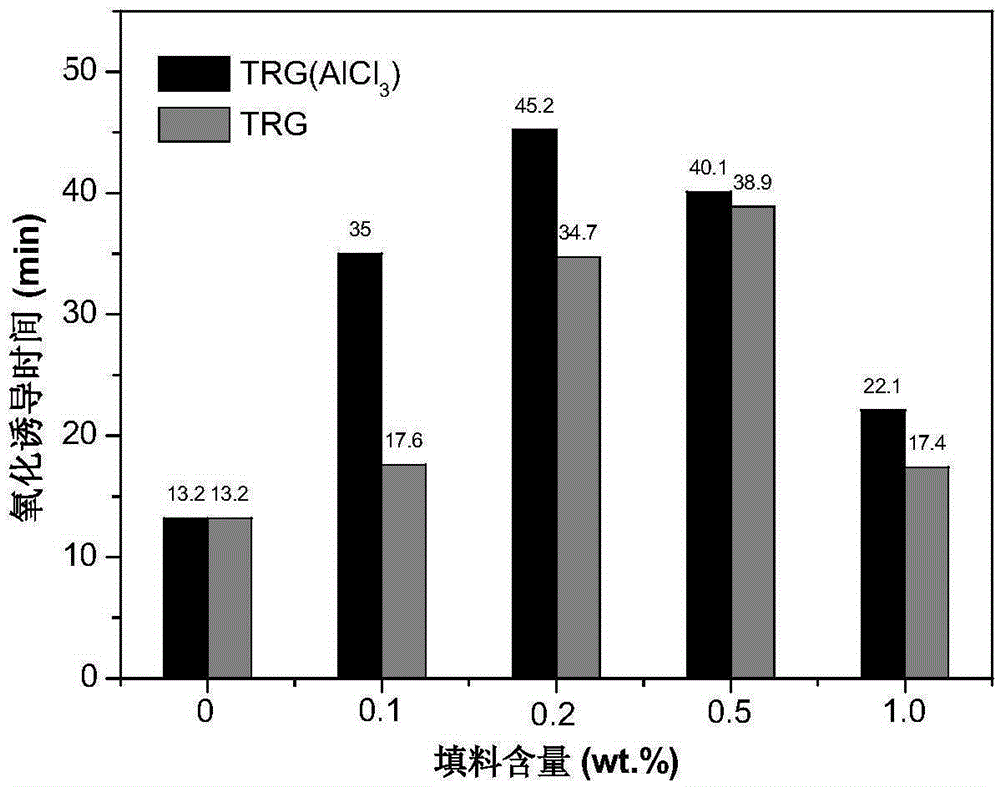

Method for improving dispersibility of graphene in polymer matrix

The invention provides a method for improving dispersibility of graphene in a polymer matrix. The method comprises the following steps: fusing and mixing a polymer, graphene and a Lewis acid catalyst according to a ratio of 100: 3-10: 0.1-2 so as to obtain polymer / graphene composite material master batch; and then removing the Lewis acid and mixing the prepared master batch with the polymer so as to obtain a nanocomposite with low graphene content. Compared with a polymer / graphene composite material prepared without treatment with the Lewis acid catalyst, the polymer / graphene composite material obtained in the invention has the following advantages: dispersion of graphene in the polymer matrix is more uniform; aggregate is obviously reduced; and more uniform dispersion of graphene is beneficial for further improvement of thermal oxidative stability of the composite material.

Owner:SICHUAN UNIV +1

Differential capacitive micro-acceleration transducer and manufacturing method thereof

ActiveCN102778586AIncrease stiffnessSize stiffnessDecorative surface effectsAcceleration measurementTransducerEngineering

The invention discloses a differential capacitive micro-acceleration transducer and a manufacturing method thereof. According to the method, the manufacturing of a movable mass block and an elastic beam is completed by using a bulk-silicon process, and the structure manufacturing and the releasing of a device structure are simultaneously completed by using a dry etching method; a movable electrode and the movable mass block are same in shape and size, so that an operation of repeated photoetching is avoided, thereby greatly simplifying the process; the stiffness of the designed elastic beam is small in the sensitive direction and large in the sensitive vertical direction, therefore, the elastic beam is higher in selectivity and anti-crosstalk capacity; and a device is simply and reliably packaged by using a wafer-level low-temperature vacuum aligned-bonding technology, thereby facilitating the large-scale manufacturing of the device. In addition, the differential capacitive micro-acceleration transducer disclosed by the invention adopts a variable-area type operating principle, so that the movable mass block is only damped by a sliding membrane in the process of moving, thereby improving the sensitivity.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Composite electrode material for lithium-sulfur battery anode and preparation method thereof

ActiveCN104716306APrevent dissolution and diffusionImprove cycle stabilityCell electrodesCarbon layerCarbonization

The invention relates to a composite electrode material for a lithium-sulfur battery anode and a preparation method thereof. The composite electrode material is composed of a carbon material and lithium sulfide. The electrode material takes the compound of lithium sulfide and the carbon material as the substrate, the carbonization reaction of a carbon-containing compound is utilized to generate a carbon layer on the substrate surface, the lithium sulfide is sealed and coated in the pore channels of carbon, and the mass fraction of lithium sulfide in the composite electrode material is 40%-89%. The lithium-sulfur battery anode material prepared by the method can effectively avoid dissolution and diffusion of polysulfides in a charge-discharge process, thereby improving the cyclic stability and capacity of the battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

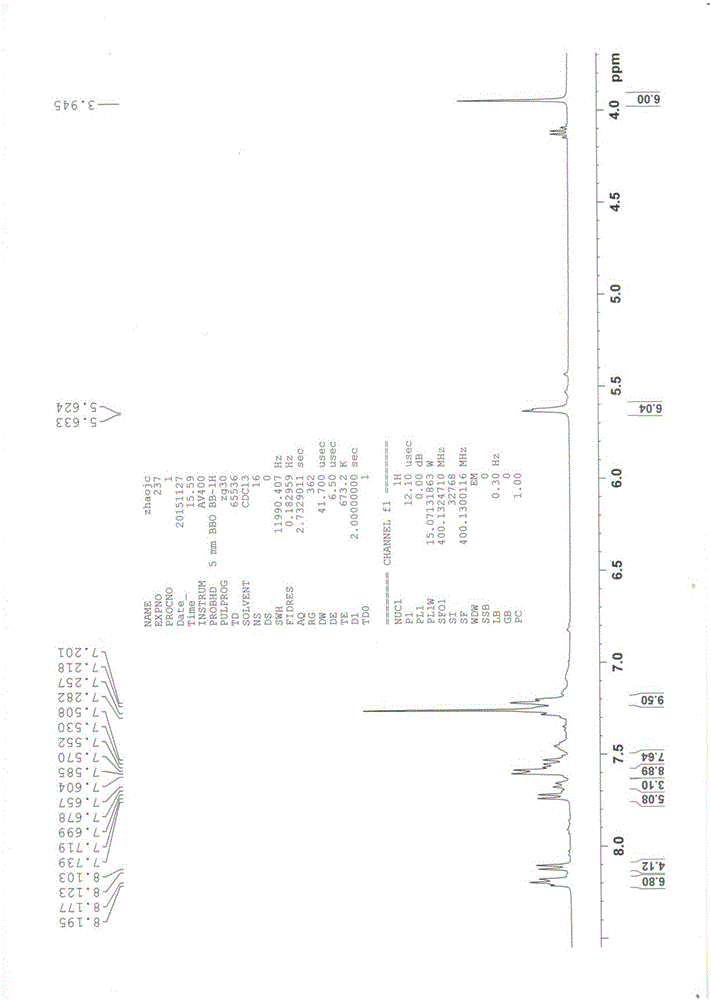

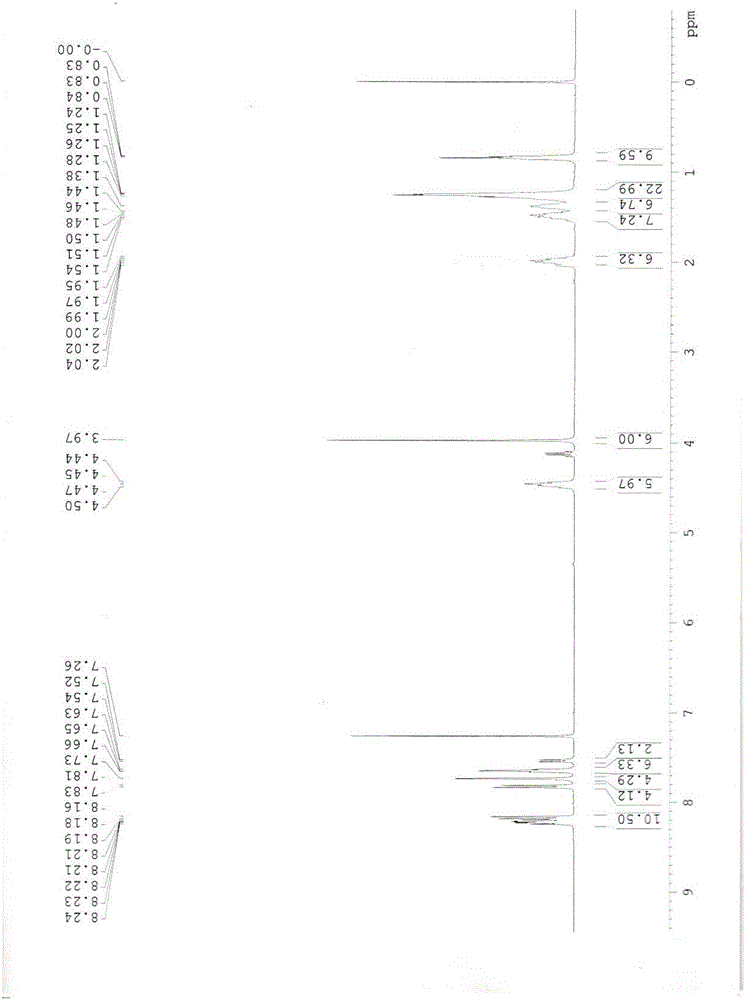

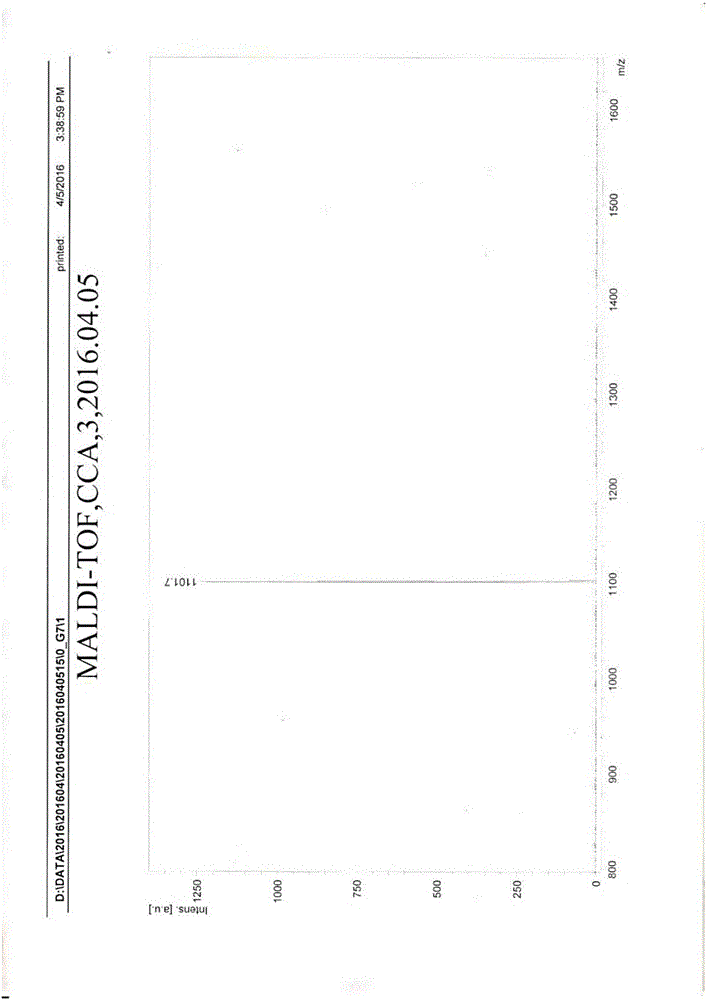

Organic fluorescent sensing material with high-sensitivity fluorescent response to several explosives, and preparation method application of organic fluorescent sensing material

ActiveCN106278996AQuick Security CheckPortable Security DetectionOrganic chemistryFluorescence/phosphorescenceCarbazoleFluorescence

The invention relates to an organic fluorescent sensing material with high-sensitivity fluorescent response to several explosives, and a preparation method application of the organic fluorescent sensing material. The material is obtained by self-assembling one or various carbazole derivatives through pi-pi interaction. The organic fluorescent sensing material disclosed by the invention has a typical P type material characteristic and high luminous stability, is suitable for being used for performing fluorescence detection on the explosives, and is particularly very effective for the detection of trace explosives (the concentration is at the ng level).

Owner:INST OF CHEM CHINESE ACAD OF SCI

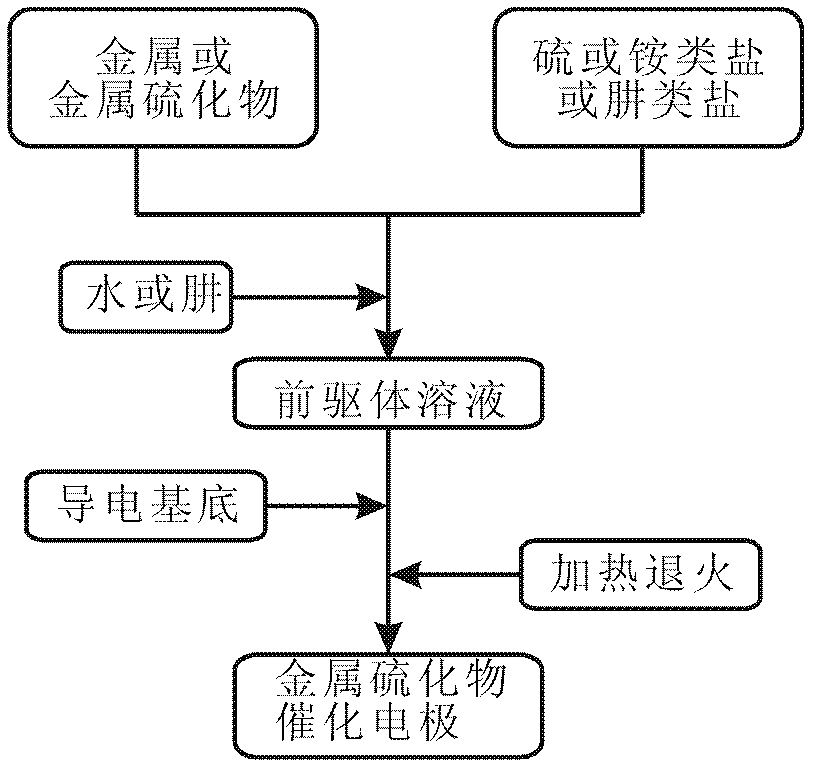

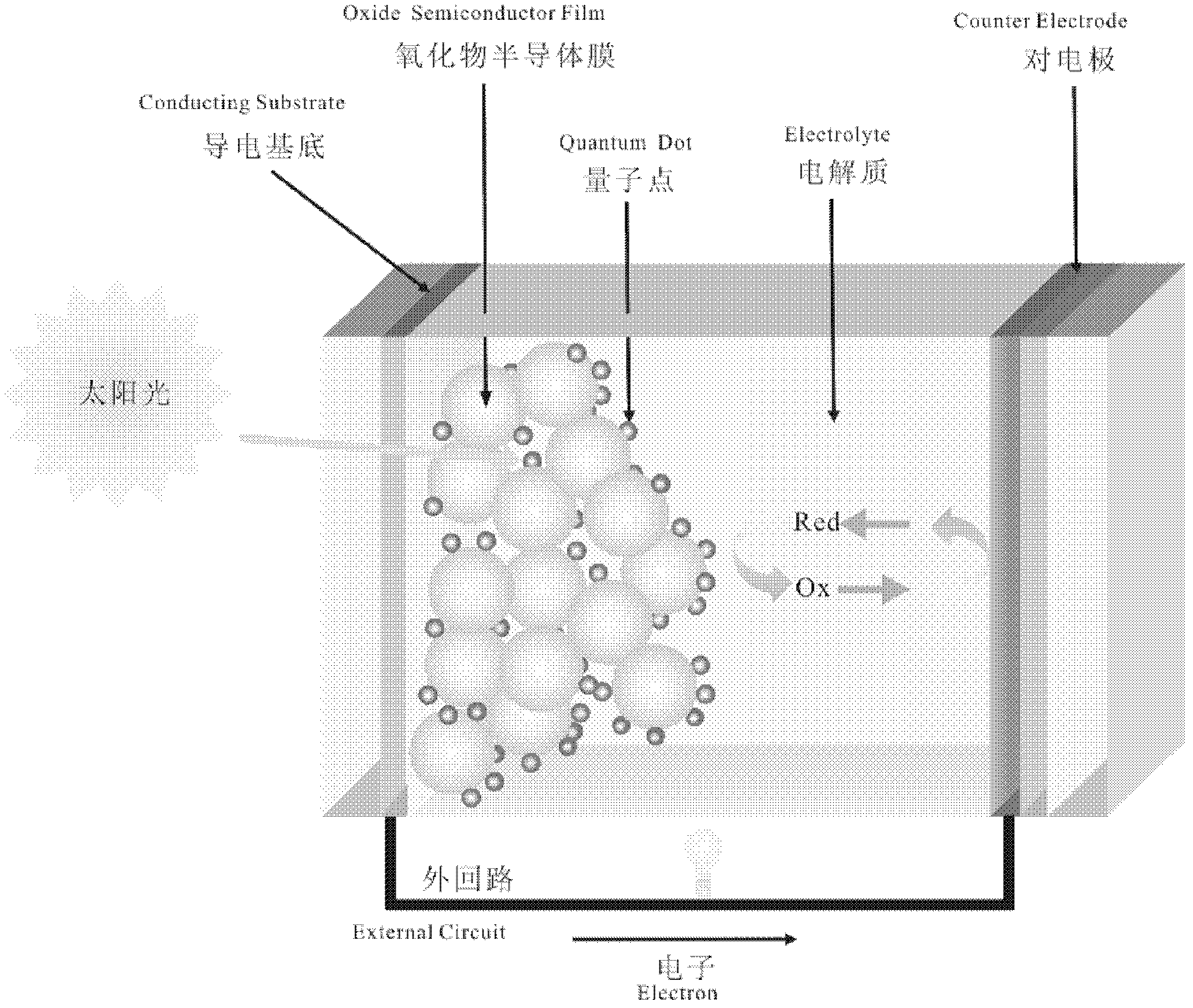

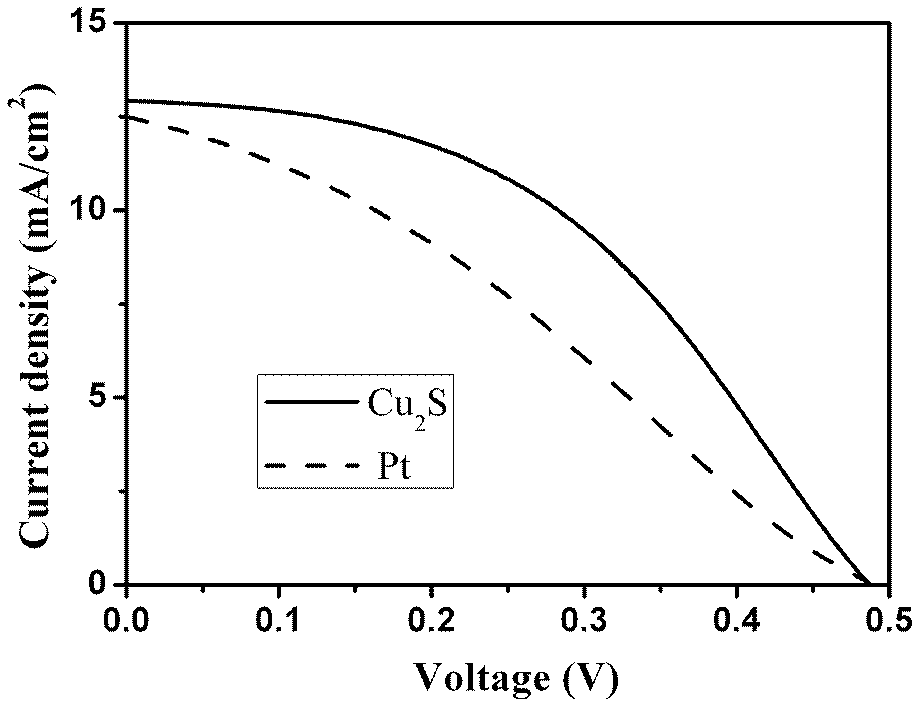

Preparation method for metal sulfide catalytic electrode and application thereof

InactiveCN102543477AHigh catalytic activityImprove photoelectric conversion performanceElectrolytic capacitorsCapacitor manufactureElectrically conductiveAmmonium

The invention discloses a preparation method for a metal sulfide catalytic electrode and application thereof. According to the invention, metal element or any one form or more than one form of metal sulfide is resolved in hydrazine together with a sulfur element or together with any one form or more than one form of sulfur ammonium salt or sulfur hydrazonium salt, thereby forming a NH4 or N2H5 kation; the metal and the sulfur element form a precursor solution of an anion; the precursor solution is coated on the transparent conductive substrate; and the obtained transparent conductive substrate adsorbing the precursor is subjected to heating and annealing processing, thereby obtaining the metal sulfide catalytic electrode.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

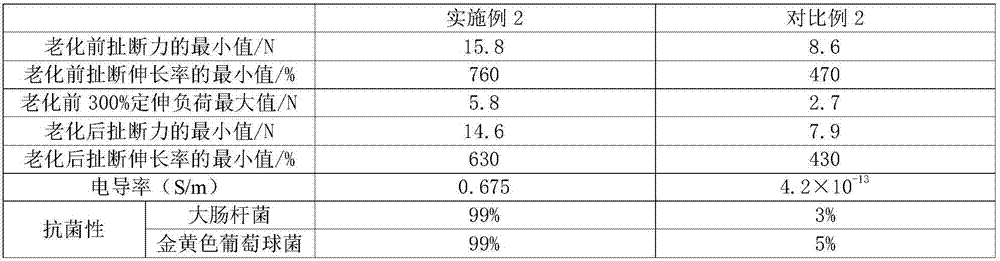

Graphene-latex functional high-strength protective gloves and preparation method thereof

InactiveCN107022124AComfortable to wearImprove friction resistanceGlovesBulk chemical productionChemical industryLatex glove

The invention discloses graphene-latex functional high-strength protective gloves and a preparation method thereof. The gloves are repeatedly usable graphene-latex protective gloves or disposable graphene-latex gloves. When the gloves are repeatedly usable graphene-latex protective gloves, the preparation method includes: dipping a glove blank in a coagulating agent and then in a graphene-latex compound liquid, and then performing drying; and when the gloves are disposable graphene-latex gloves, the preparation method includes: dipping a glove mold in a coagulating agent, performing drying, then conducting dipping in a graphene-latex compound liquid, and then carrying out edge curling, vulcanization and cooling. Compared with the prior art, the graphene-latex protective gloves prepared by the method provided by the invention give full play to the advantages of high conductivity, high strength, friction resistance, strong bacteriostasis and the like of graphene, and accordingly have wider application in manufacturing industry, medical industry, chemical industry, aerospace industry and other fields.

Owner:NANTONG QIANGSHENG SAFETY PROTECTION TECHNOLOGY CO LTD

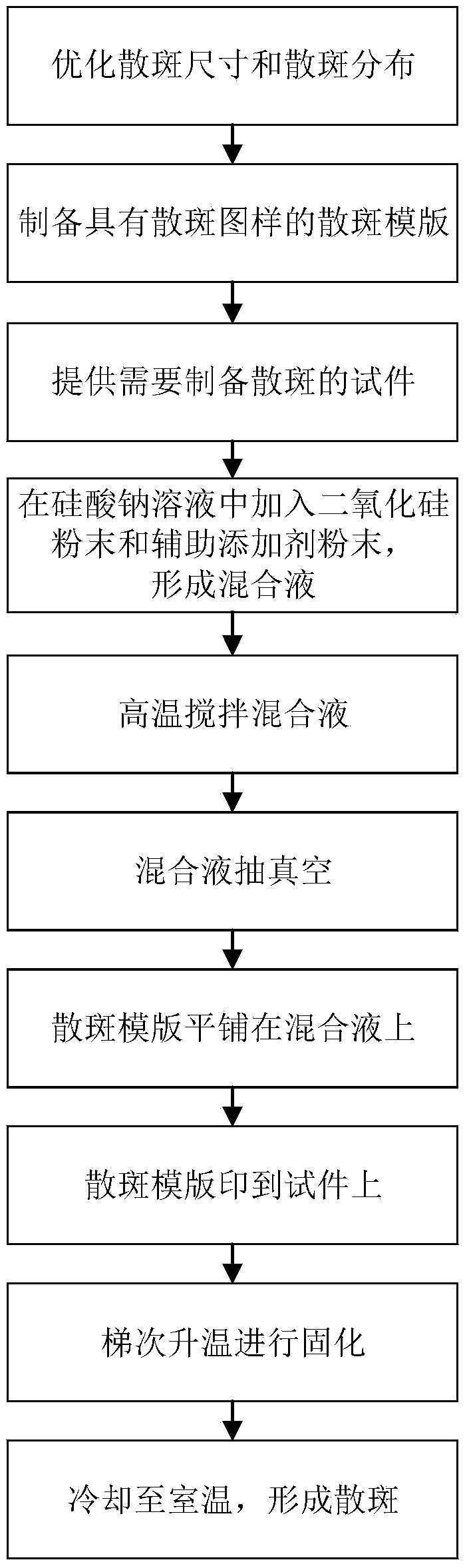

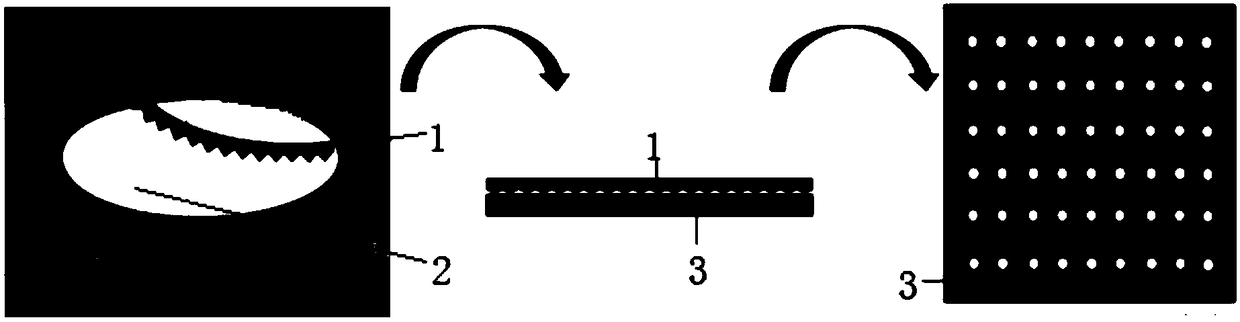

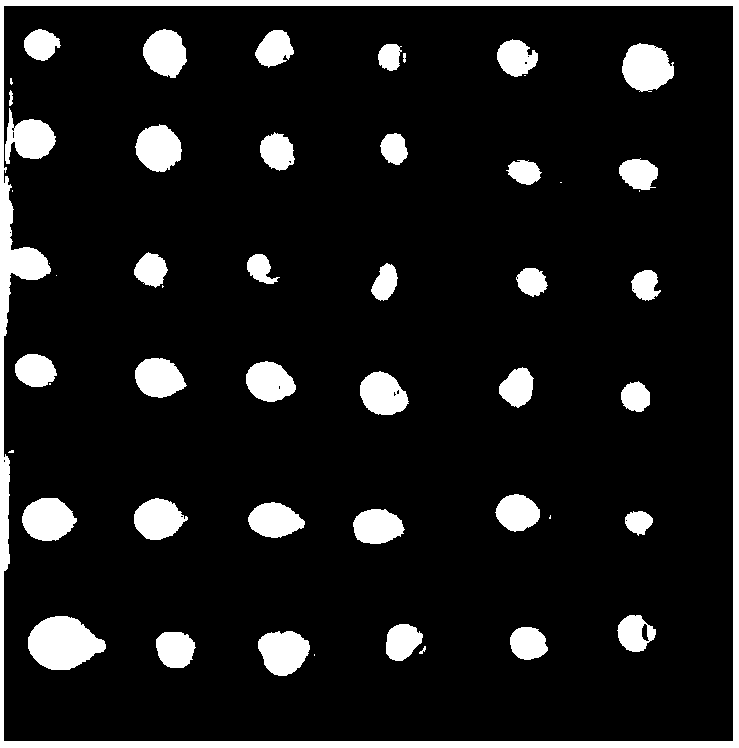

High-temperature speckle and controllable preparation method

ActiveCN108195298AGood high temperature resistance and high temperature adsorption performanceImproves curing strength and stabilityUsing optical meansToxicityEnvironmental resistance

The invention discloses a high-temperature speckle and controllable preparation method thereof. The high-temperature speckle uses a sodium silicate solution as a matrix, silicon dioxide powder and auxiliary additive powder are added to form a mixed liquid, the characteristics of short curing time, low curing temperature, good high-temperature-resistant performance, no toxicity and environmental protection are achieved, and sodium silicate itself has relatively high high-temperautre-resistant performance and high-temperature adsorption performance, and is suitable for being used for high-temperature speckle manufacture; a speckle template having a speckle pattern is prepared, thereby controlling the speckle size and speckle distribution; the speckle template can be repeatedly used, therebyfurther improving preparation efficiency; and after heating stirring, vacuumizing and gradient warming treatment, occurrence of a speckle bubbling phenomenon can be effectively reduced; materials of the high-temperature speckle are all conventional reagents, and are non-toxic under a normal using condition, thereby facilitating engineering practical application and large-scale manufacture; and thespeckle can meet a non-contact measurement requirement in high-temperature complex environments (thermal shock, and tension and compression deformation).

Owner:TSINGHUA UNIV

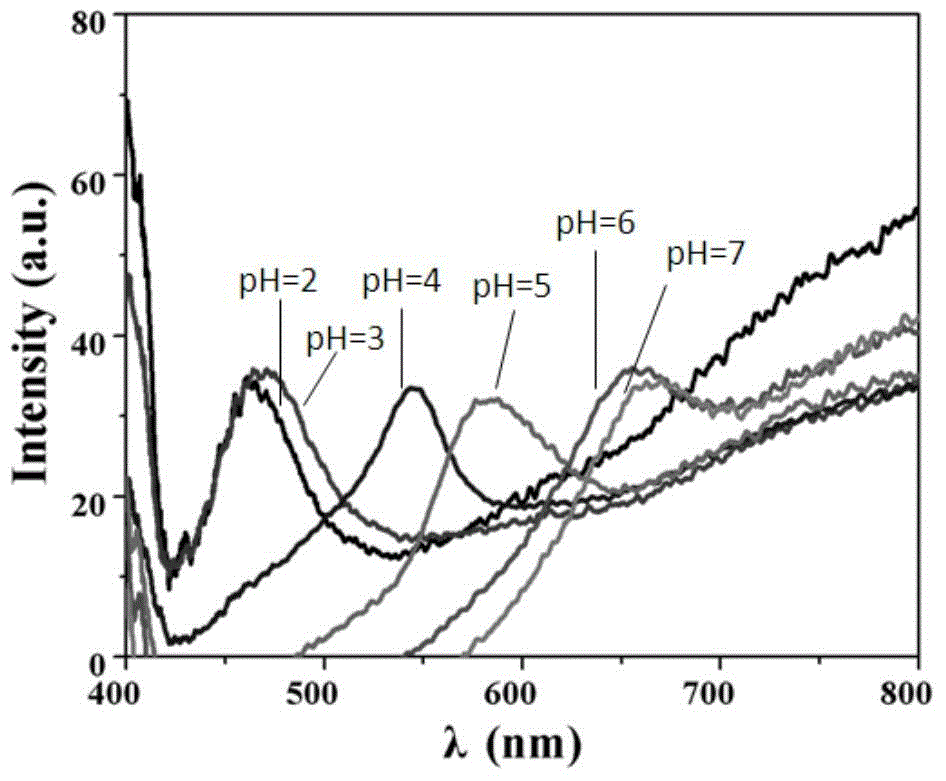

Photonic crystal hydrogel membrane with pH value and ionic strength response, preparation method and application thereof

ActiveCN104961906ABoth pHBoth strengthMaterial analysis by observing effect on chemical indicatorFerroso-ferric oxidesUltraviolet lightsColor changes

The invention discloses a photonic crystal hydrogel membrane with pH value and ionic strength response, a preparation method and an application thereof. The photonic crystal hydrogel membrane comprises Fe3O4 nano particles and polyacrylamide-methacrylate acetic acid hydrogel, wherein the Fe3O4 nano particles are uniformly dispersed in the hydrogel and are arranged in a one-dimensional chain shape, and the concentration of the nano particles in the membrane is 1 to 50 mg / mL. The preparation method of the photonic crystal hydrogel membrane comprises the steps of uniformly mixing the Fe3O4 nano particles and hydrogel monomers, so as to generate curing reaction through ultraviolet light, and soaking in a soluble carbonate aqueous solution at last, so as to obtain the required membrane. The preparation method has the advantages of simplicity in operation, strong repeatability and convenience in large-scale preparation, the carboxyl quantity of the obtained membrane is controllable, the membrane is monochromatic, obvious color change occurs under the stimulation of pH value or ionic strength, and naked-eye detection is facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com