Graphene-latex functional high-strength protective gloves and preparation method thereof

A technology for protective gloves and latex gloves, applied in gloves, protective clothing, clothing, etc., can solve problems such as human injury and poor anti-static performance, achieve low production costs, improve cutting resistance, and save production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

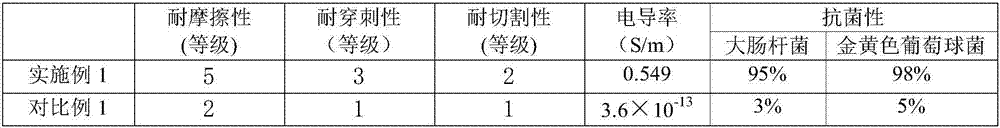

Embodiment 1

[0033] The present embodiment provides a kind of preparation method of graphene-latex protective gloves, and this method is the specific implementation method of preparing latex protective gloves, and specific implementation steps are as follows:

[0034] Step 1: by weight, 97 parts of methanol and 3 parts of calcium nitrate are prepared into coagulant;

[0035] Step 2: 100 parts of nitrile latex and 0.5 part of graphene oxide are formulated into uniform composite latex, and then thickened graphene-nitrile latex configured to 1000Pa with casein as a thickener (0.5-8 parts in content) ·S left and right for use;

[0036]Step 3: Preheat the glove mold to 30-40°C, then put the glove blank on the glove mold, soak the coagulant to prevent penetration, then soak the compound latex, and dry it in an oven after the rubber surface is basically solidified, the temperature is controlled at 70°C Dry for 20 minutes, then dry at 100-110°C for 40 minutes, and the gloves are molded and releas...

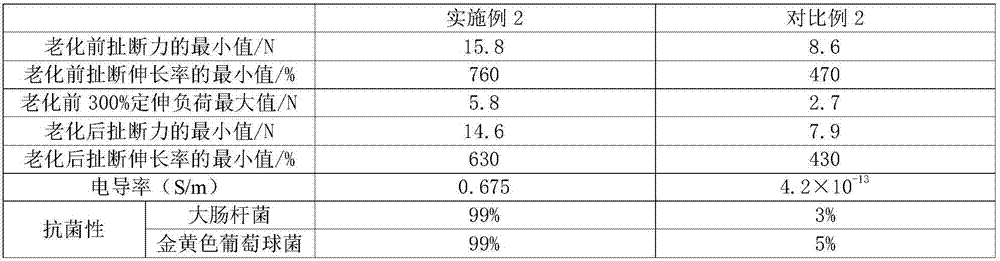

Embodiment 2

[0038] The present embodiment provides a kind of preparation method of graphene-latex protective glove, and this method is the specific implementation method of preparing disposable rubber glove, and described nitrile latex glove is made up of following component by weight:

[0039] Step 1: the coagulant is prepared by weight from 87 parts of water and 13 parts of calcium nitrate;

[0040] Step 2: 100 parts of nitrile latex, 5 parts of amino polymer modified graphene oxide, 1.4 parts of sulfur, 1.4 parts of zinc oxide, 1.8 parts of stabilizer, 0.8 part of anti-aging agent, and make composite latex;

[0041] Step 3: The preparation method is as follows: after drying the glove mold impregnated with the coagulant, then impregnating the prepared composite latex, then leaching and crimping, entering an oven at 116°C, drying for 60 minutes, and then Vulcanize in an oven with a temperature of 114°C, then leach, then dry in an oven with a temperature of 90°C, and then cool and demould...

Embodiment 3

[0046] The present embodiment provides a kind of preparation method of graphene-latex protective gloves, and this method is the specific implementation method of preparing latex protective gloves, and specific implementation steps are as follows:

[0047] Step 1: 8 parts of polyurethane latex, 0.3 part of graphene obtained by electrochemical stripping, and 0.2 part of titanium dioxide (titanium dioxide is used as a colorant in the rubber industry, and has the functions of reinforcement, anti-aging and filling. In white and colored rubber products Titanium dioxide is added to it, under sunlight, it is resistant to sunlight, does not crack, does not change color, has a large elongation and acid and alkali resistance), and 0.14 parts of additives are blended according to the mass ratio, and then N, N-dimethyl formazan Amide (if the viscosity of the polyurethane latex is too high, then use this material to dilute) to adjust the viscosity of the graphene latex to 300Pa S, then stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com