Preparation method of composite material of Zn0.8Cd0.2S and graphene

A composite material, graphene technology, applied in chemical instruments and methods, light water/sewage treatment, physical/chemical process catalysts, etc., can solve the problem that photogenerated electrons and holes cannot be effectively separated, limit photocatalytic activity, and reduce adsorption performance. and other problems, to achieve the effect of high photocatalytic activity and stability, improved photocatalytic activity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

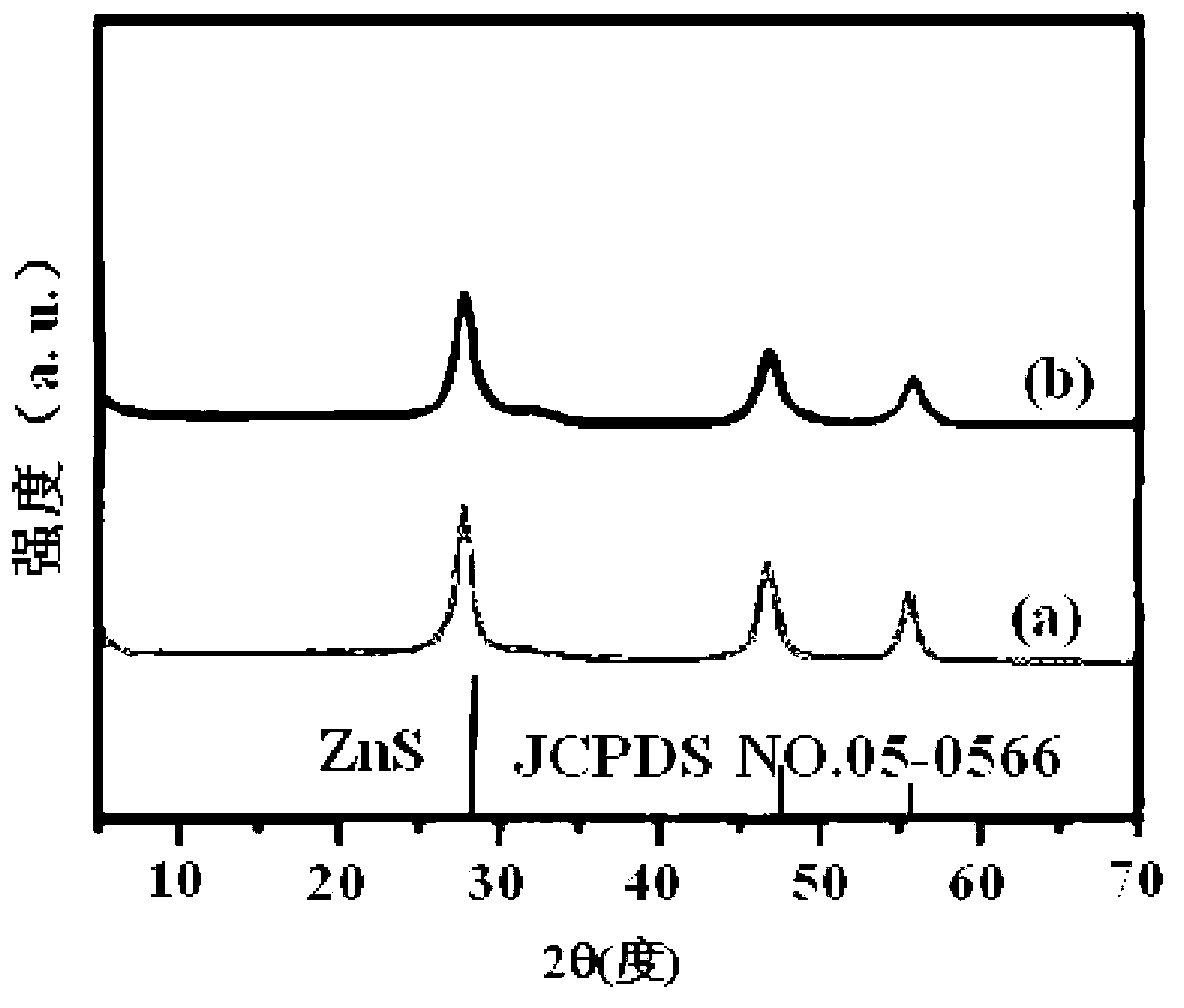

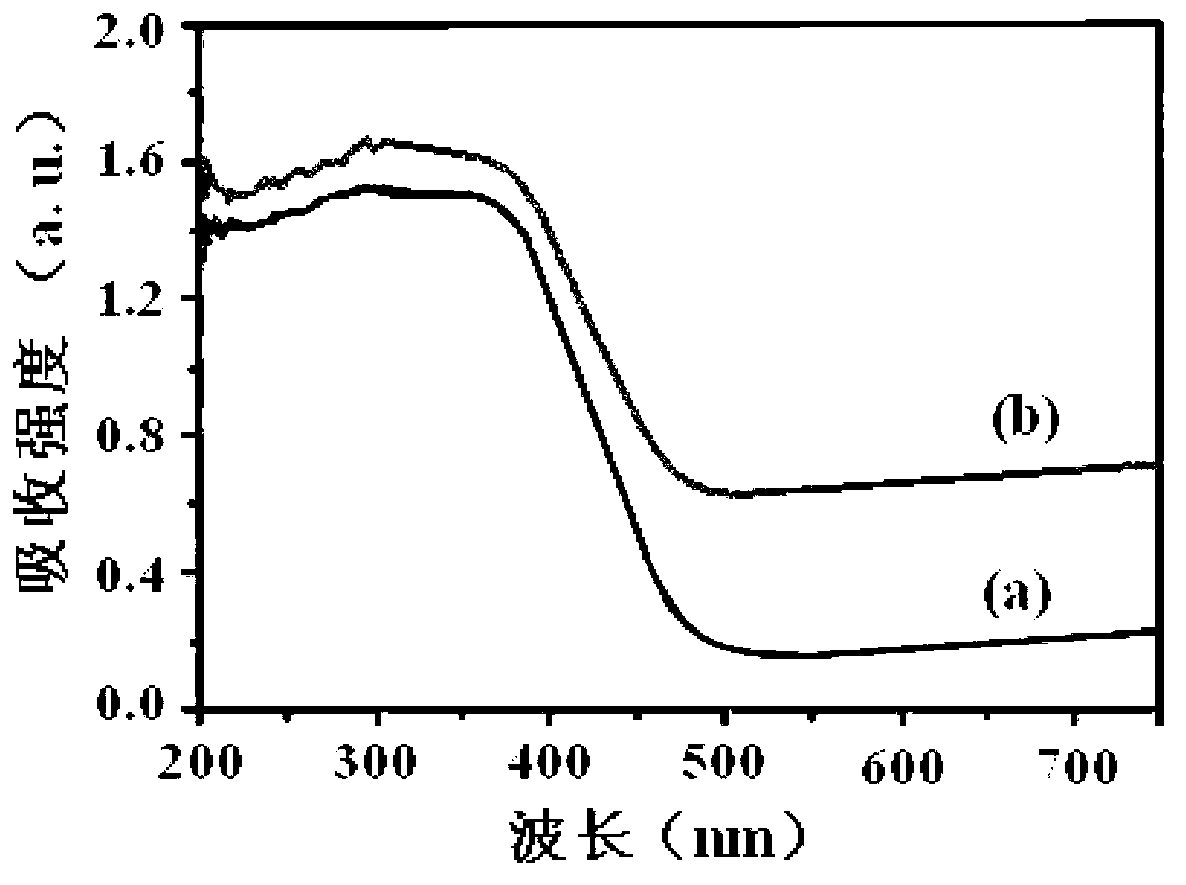

[0029] Embodiment 1: a kind of Zn of the present invention 0.8 CD 0.2 The preparation method of S / graphene (GZCS0.5) composite material, comprises the following steps:

[0030] (1) After mixing zinc acetate dihydrate (329mg) and cadmium acetate dihydrate (120mg) according to the molar ratio of 3.33:1, put them into dimethyl sulfoxide solvent (150mL) and stir for 30 minutes;

[0031] (2) Add 2.25mg of graphene oxide into the mixed solution in step (1), stir and disperse for 60 minutes; 120mg), the ratio of the sum of the weights is 0.5:100, that is, the percentage is 0.5%.

[0032] (3) Transfer the reaction system of step (3) to a 200mL reactor, and react at 180°C for 12 hours;

[0033] (4) Pour the product of step (4) into a centrifuge (5000 rpm) for centrifugation, wash with ethanol and deionized water, and vacuum dry at 60°C for 8 hours, then grind to obtain graphene oxide and Zn 0.8 Cd 0.2 S precursor with 0.5% Zn by weight 0.8 Cd 0.2 S / graphene composite (GZCS0.5).

Embodiment 2

[0035] Change the amount of graphene oxide in step (3) of embodiment 1 to 11 mg, and the rest of the steps are the same as in embodiment 1 to obtain graphene oxide and Zn 0.8 Cd 0.2 S precursor with 2.5% Zn by weight 0.8 Cd 0.2 S / graphene composites (GZCS2.5).

Embodiment 3

[0037] Change the amount of graphene oxide in step (3) of Example 1 to 22.5 mg, and the rest of the steps are the same as in Example 1 to obtain graphene oxide and Zn 0.8 Cd 0.2 S precursor with 5.0% Zn by weight 0.8 Cd 0.2 S / graphene composites (GZCS5.0).

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com