Ag/TiO2/graphene nanometer composite photocatalyst and preparation method thereof

A nanocomposite and photocatalyst technology is applied in the field of Ag/TiO2/graphene nanocomposite photocatalyst and its preparation, and achieves the effects of good environment, cheap reagents and simple formation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

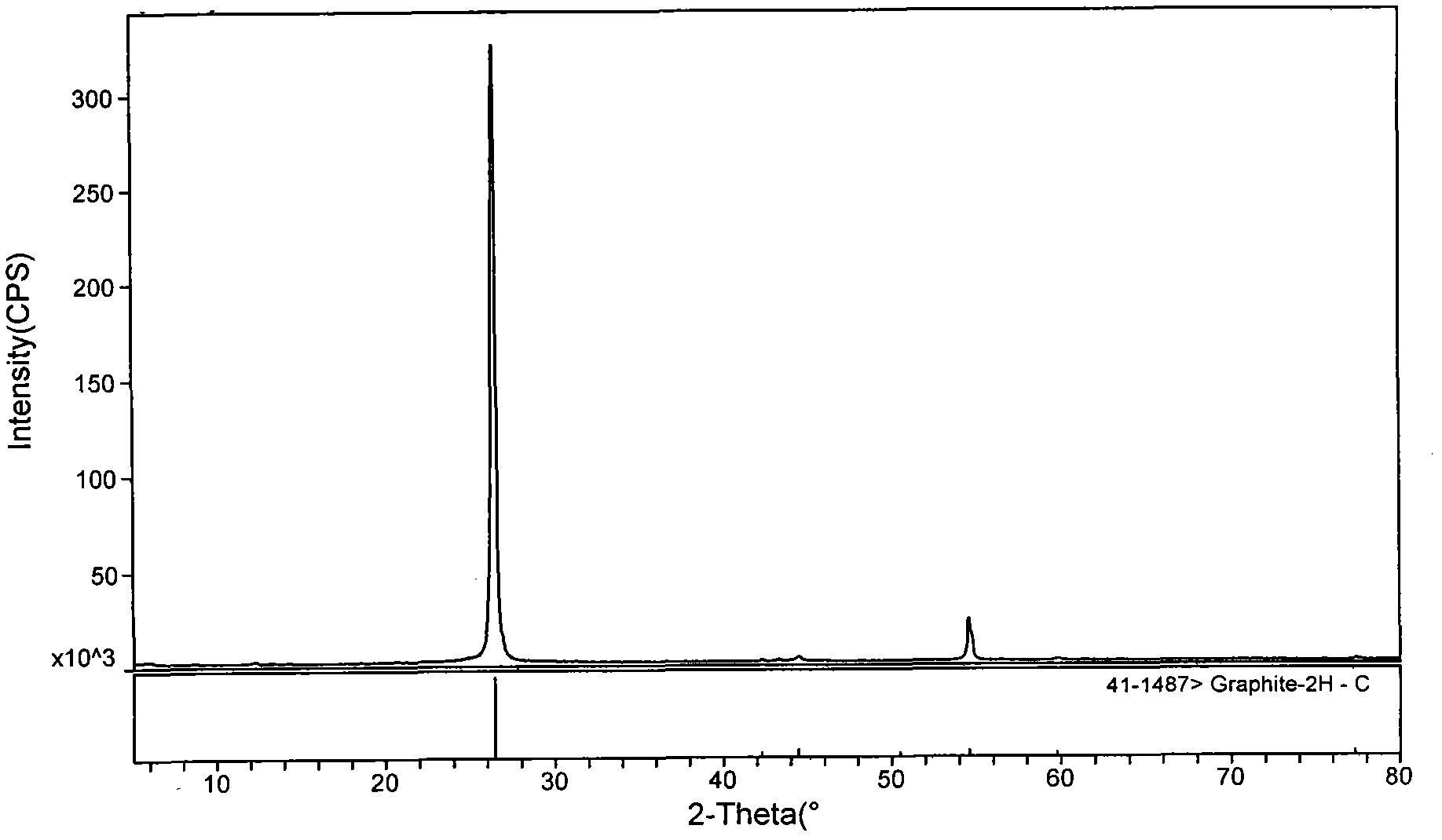

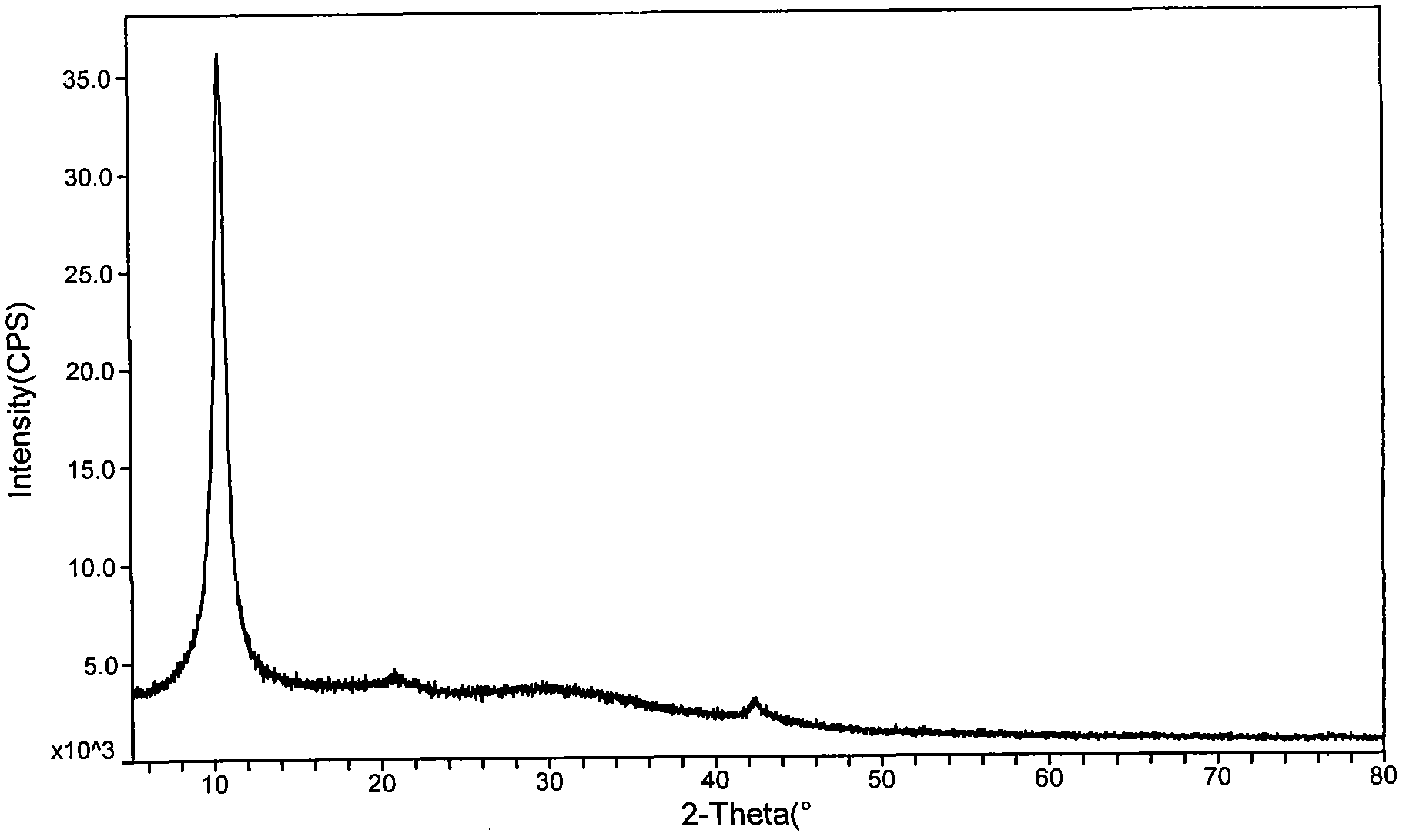

[0025] (1) Preparation of graphite oxide. Add 2g of graphite powder to potassium persulfate (1g) and concentrated sulfuric acid solution (15mL) of phosphorus pentoxide (1g) at 80°C, pre-oxidize for 6 hours, then cool to room temperature, filter with suction, and wash until neutral. Add pre-oxidized graphite powder (2g) to 50mL of concentrated sulfuric acid solution at 0°C, then slowly add 6g of potassium permanganate, then react at 35°C for 2 hours, and finally slowly add 100mL of deionized water and 20mL of 30% hydrogen peroxide terminated the reaction, suction filtered, washed, and dialyzed to obtain graphite oxide, whose XRD pattern is shown in figure 2 ;

[0026] (2) Preparation of graphite oxide dispersion. Ultrasonic disperse 50mg of graphite oxide in 50mL of absolute ethanol for 1 hour;

[0027] (3) Configuration of silver nitrate solution. Dissolve 85mg of silver nitrate in 100mL of distilled water;

[0028] (4) the graphite oxide dispersion liquid that step (2) ...

Embodiment 2

[0030] (1) with the step (1) in the implementation example 1;

[0031] (2) Preparation of graphite oxide dispersion. Ultrasonic disperse 50mg of graphite oxide in 50mL of methanol for 1 hour;

[0032] (3) with step (3) in the implementation example 1;

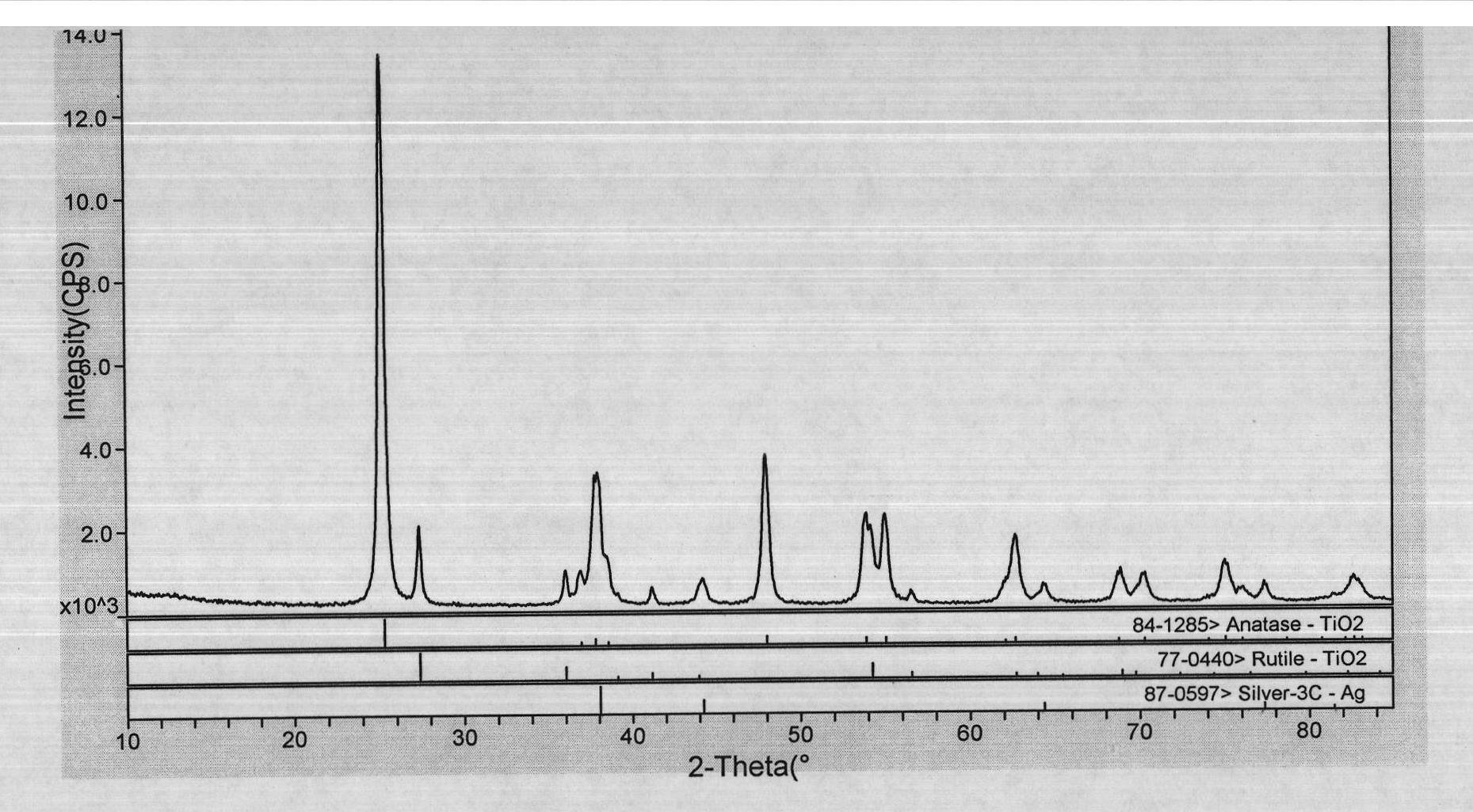

[0033] (4) the graphite oxide dispersion liquid that step (2) is made is mixed with the silver nitrate solution that step (3) is made, then 5g titanium dioxide (P25) is dispersed in the mixed solution, then transfers in the photocatalytic reactor, Photocatalytic reduction reaction under simulated sunlight for 3 hours, filtered, washed, and vacuum dried at 80°C for 12 hours to obtain Ag / TiO 2 / Graphene nanocomposite photocatalyst.

Embodiment 3

[0035] (1) with the step (1) in the implementation example 1;

[0036] (2) with the step (2) in the implementation example 1;

[0037] (3) Configuration of silver nitrate solution. Dissolve 170mg of silver nitrate in 100mL of distilled water;

[0038] (4) the graphite oxide dispersion liquid that step (2) is made is mixed with the silver nitrate solution that step (3) is made, then 5g titanium dioxide (P25) is dispersed in the mixed solution, then transfers in the photocatalytic reactor, Photocatalytic reduction reaction under simulated sunlight for 3 hours, filtered, washed, and vacuum dried at 80°C for 12 hours to obtain Ag / TiO 2 / Graphene nanocomposite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com