Patents

Literature

83results about How to "Improve the utilization rate of active substances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene-coated sulfur/porous carbon composite positive electrode material and preparation method thereof

ActiveCN103560235AUnique hierarchical core-shell structureIncrease contentCell electrodesHigh ratePorous carbon

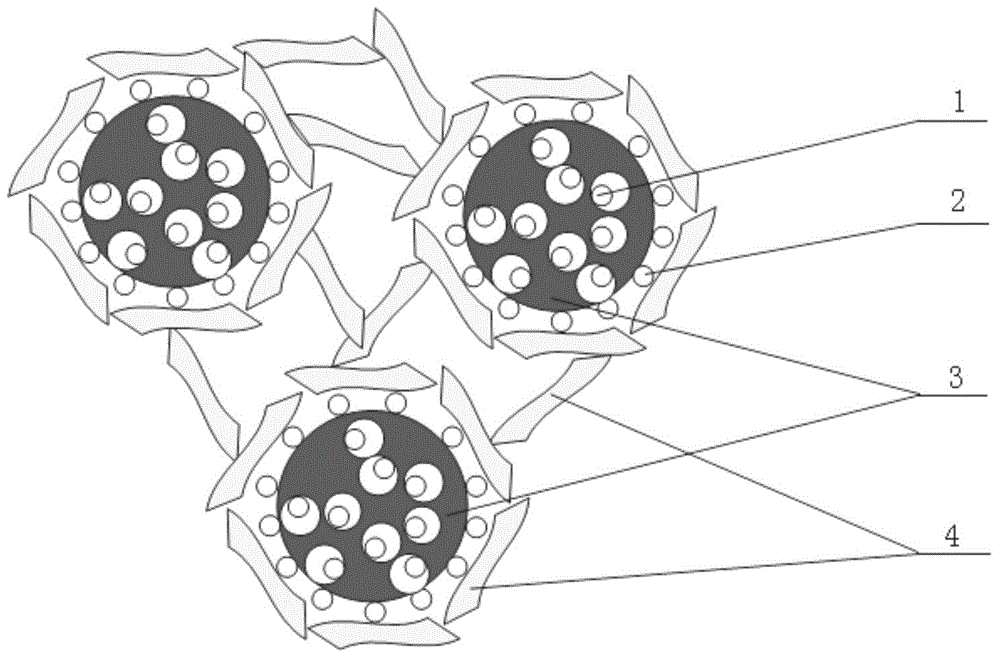

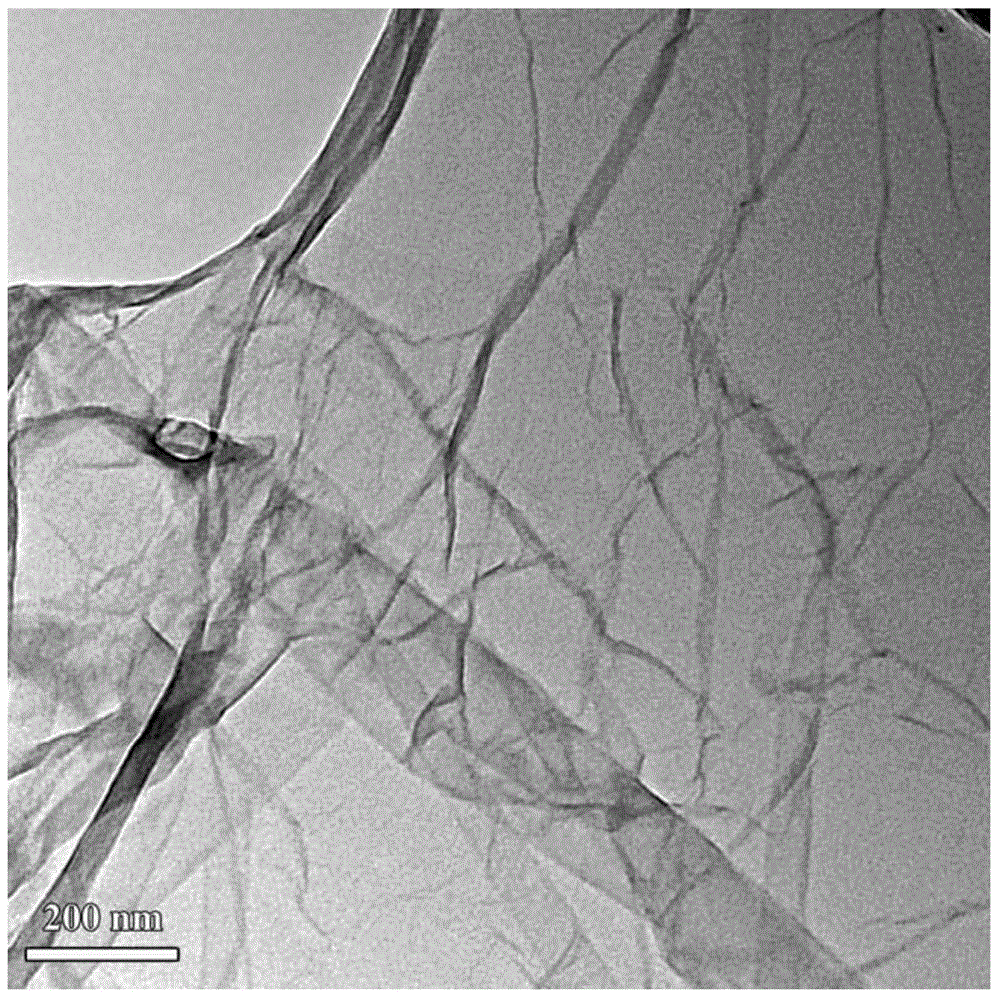

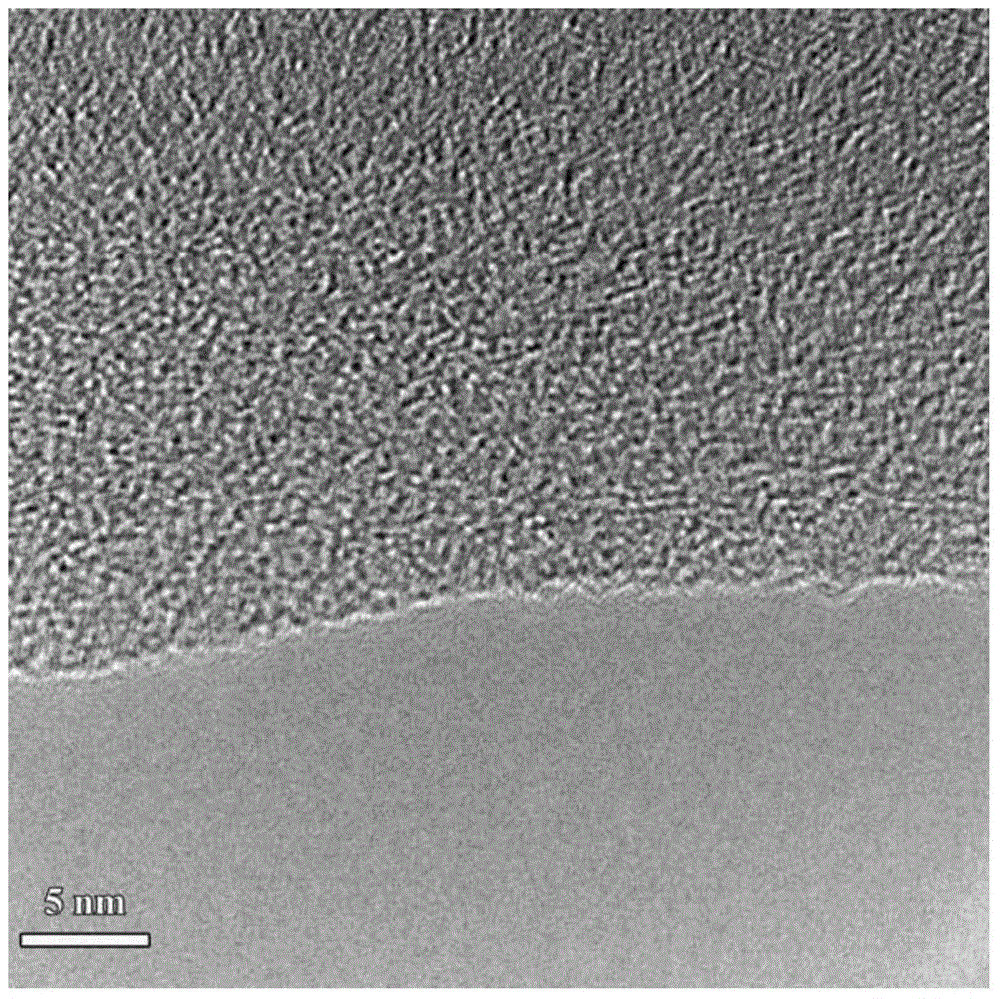

The invention provides a grapheme-coated sulfur / porous carbon composite material and a preparation method thereof, and relates to a grapheme-coated sulfur / porous carbon composite material used as the positive electrode material of a lithium-sulfur secondary battery and a preparation method thereof. The grapheme-coated sulfur / porous carbon composite positive electrode material provided by the invention can be used for solving the technical problem that the existing grapheme-coated sulfur-containing composite material used as the positive electrode material of a lithium-sulfur battery is low in electrochemical properties. The external surface of each of the particles of the grapheme-coated sulfur / porous carbon composite material provided by the invention is evenly covered with a graphene sheet, and a graphene conductive network is formed between the particles; the obtained grapheme-coated sulfur / porous carbon composite material has a hierarchical core-shell structure. The preparation method of the grapheme-coated sulfur / porous carbon composite material is obtained by adding a sulfur / porous carbon composite material to graphene slurry which is stable for a long time and in which graphene sheets are highly dispersed in water for mixing and coating. The positive electrode material has high specific capacity, long cycle life and excellent high-rate performance. Besides, the grapheme-coated sulfur / porous carbon composite material can be used as the positive electrode material of a lithium secondary battery.

Owner:HARBIN INST OF TECH

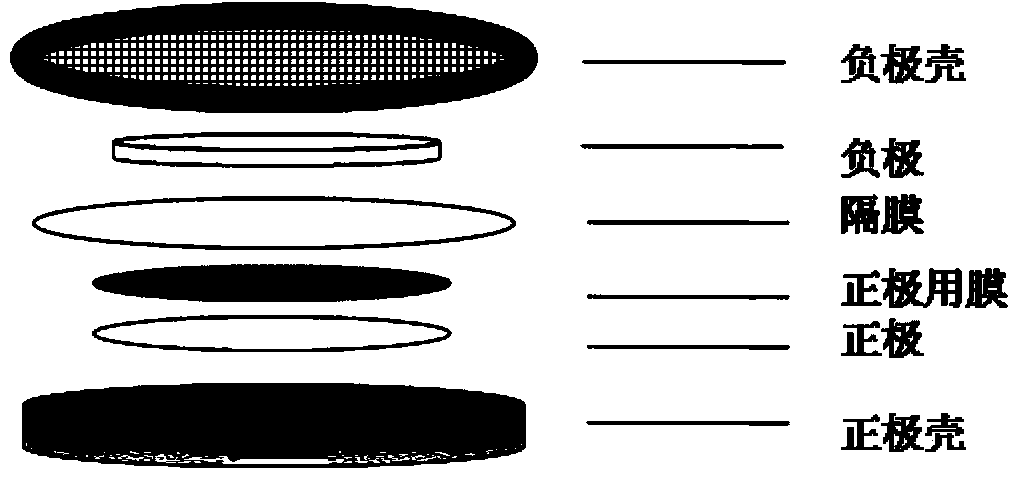

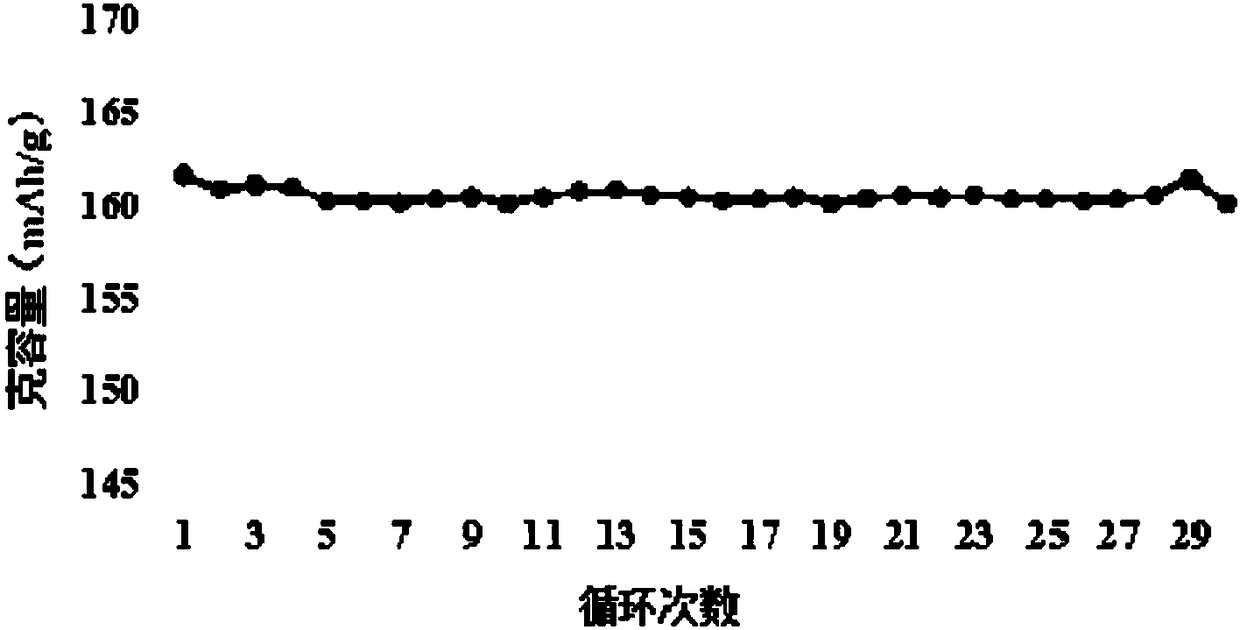

Double-effect composite membrane used for lithium sulphur battery and preparation method thereof

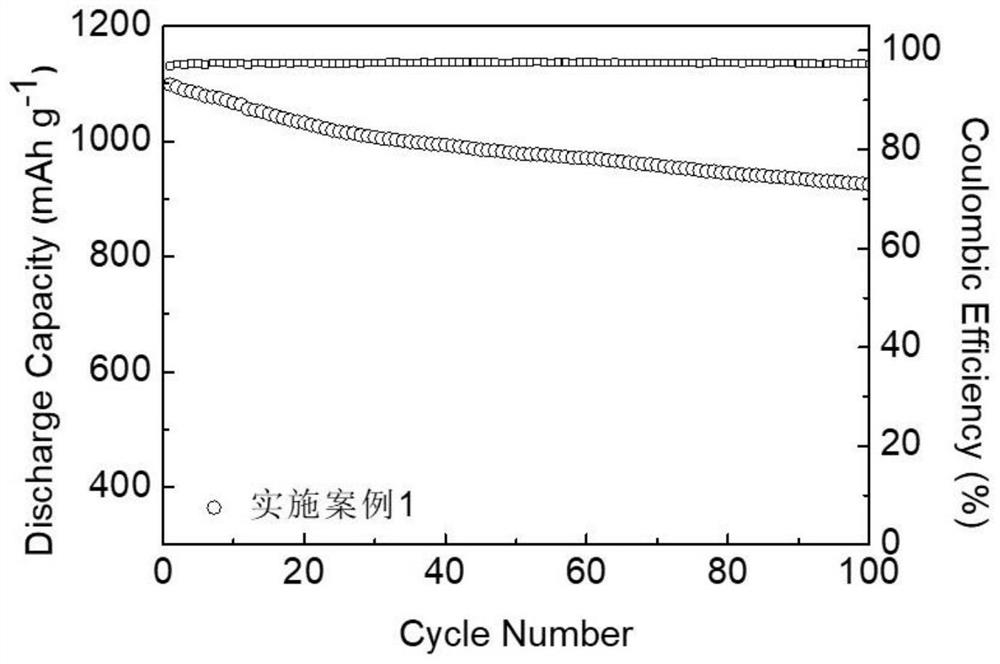

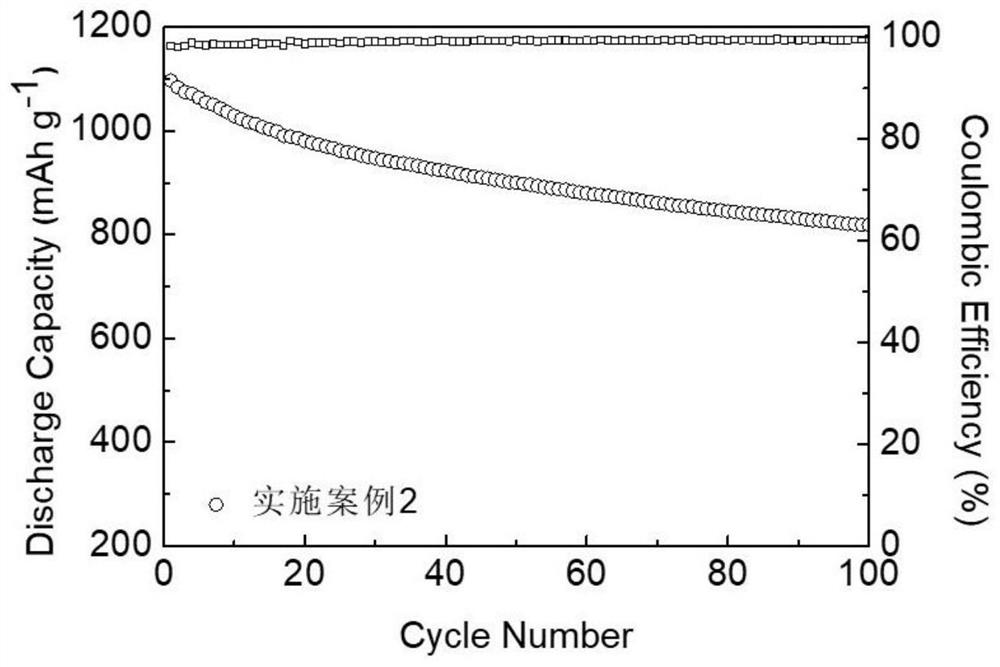

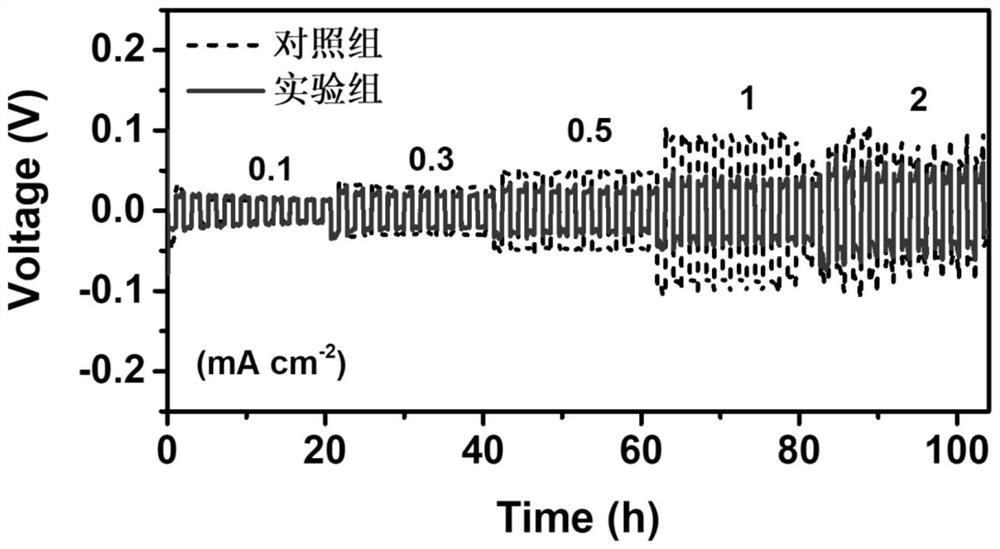

ActiveCN108461694AImprove the utilization rate of active substancesImprove stabilityCell component detailsHigh energyLithium–sulfur battery

The invention provides a double-effect composite membrane used for a lithium sulphur battery and a preparation method thereof. The membrane is composed of a functional composite layer and porous insulating film. The functional composite layer is a composite of conductive carbon base materials, polar materials and a binder, wherein the mass fraction of the conductive carbon base materials and polarmaterials is 5%-90% and 5%-90% respectively. The preparation method comprises the steps that the conductive carbon base materials and the polar materials are used for preparing the functional composite layer, the functional composite layer is loaded on the porous insulating film, and surface loading capacity of the functional composite layer is 0.1-3.0 mg cm-2. The composite membrane in the lithium sulphur battery regulates and controls reaction and deposition behaviors of active substances in different charge-discharge stages and significantly improves the utilization and stability of the active substances of the lithium sulphur battery. Compared with ordinary commercial polymer battery membranes, the composite membrane prolongs the cycle life of the lithium sulphur battery and improvesspecific energy, positive discharge capacity and coulombic efficiency. The method is simple in operation, is beneficial to large-scale preparation, and facilities wide commercial application of the high-energy density lithium sulphur battery.

Owner:TSINGHUA UNIV

Hydrothermal preparation method of graphene-coated sulfur/porous carbon composite positive electrode material

ActiveCN104064738AInhibition of dissolution lossPromote wettingCell electrodesSecondary cellsCvd grapheneGraphite oxide

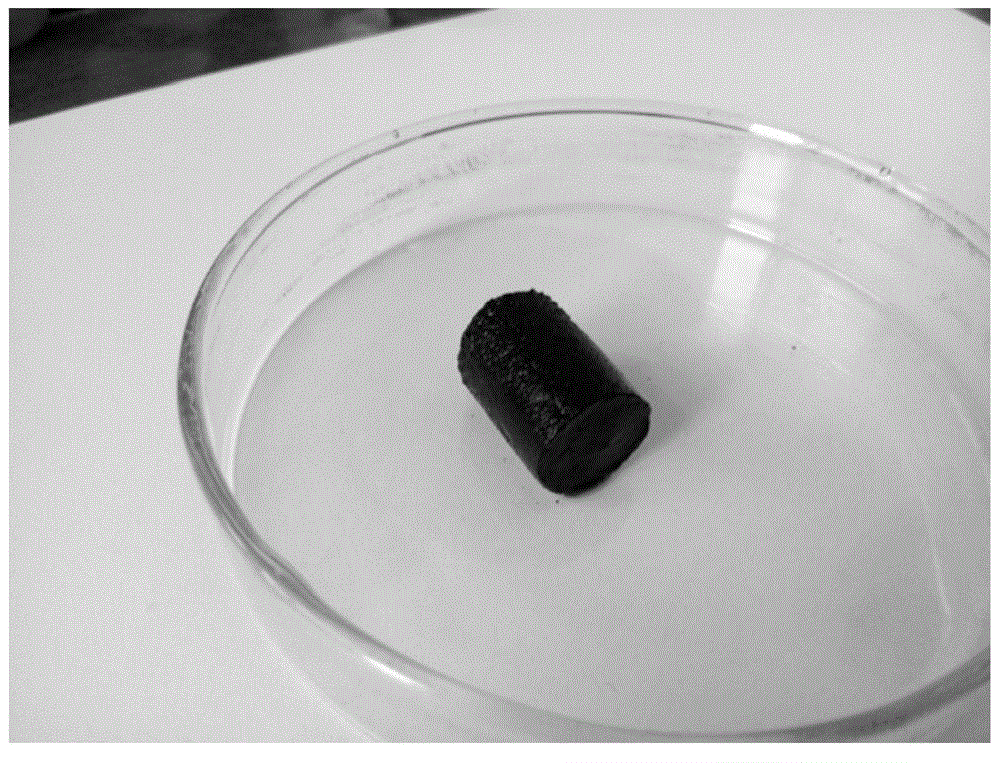

The invention provides a hydrothermal preparation method of a graphene-coated sulfur / porous carbon composite material and relates to a preparation method of the graphene-coated sulfur / porous carbon composite material for a positive electrode material of a lithium-sulfur storage battery. The hydrothermal preparation method is used for solving the technical problem that the electrochemical property of the positive electrode material of an existing lithium-sulfur battery, namely a graphene-coated sulfur-containing composite material, is low. The hydrothermal preparation method comprises the steps of mixing and scattering the sulfur / porous carbon composite material with graphene slurry or oxidized graphene slurry, carrying out hydrothermal synthesis to prepare a hydrogel column, and drying to obtain the graphene-coated sulfur / porous carbon composite material. According to the graphene-coated sulfur / porous carbon composite material prepared by utilizing the hydrothermal preparation method, the outer surfaces of the graphene sheet layers are coated with sulfur / porous carbon composite material particles, a graphene conduction network is generated among the particles, and the obtained graphene-coated sulfur / porous carbon composite material is in a hierarchical core-shell structure; the positive electrode material has the high specific capacity, the long cycle life and the good rate capability; the composite positive electrode material can be used as a positive electrode material in a lithium secondary battery.

Owner:HARBIN INST OF TECH

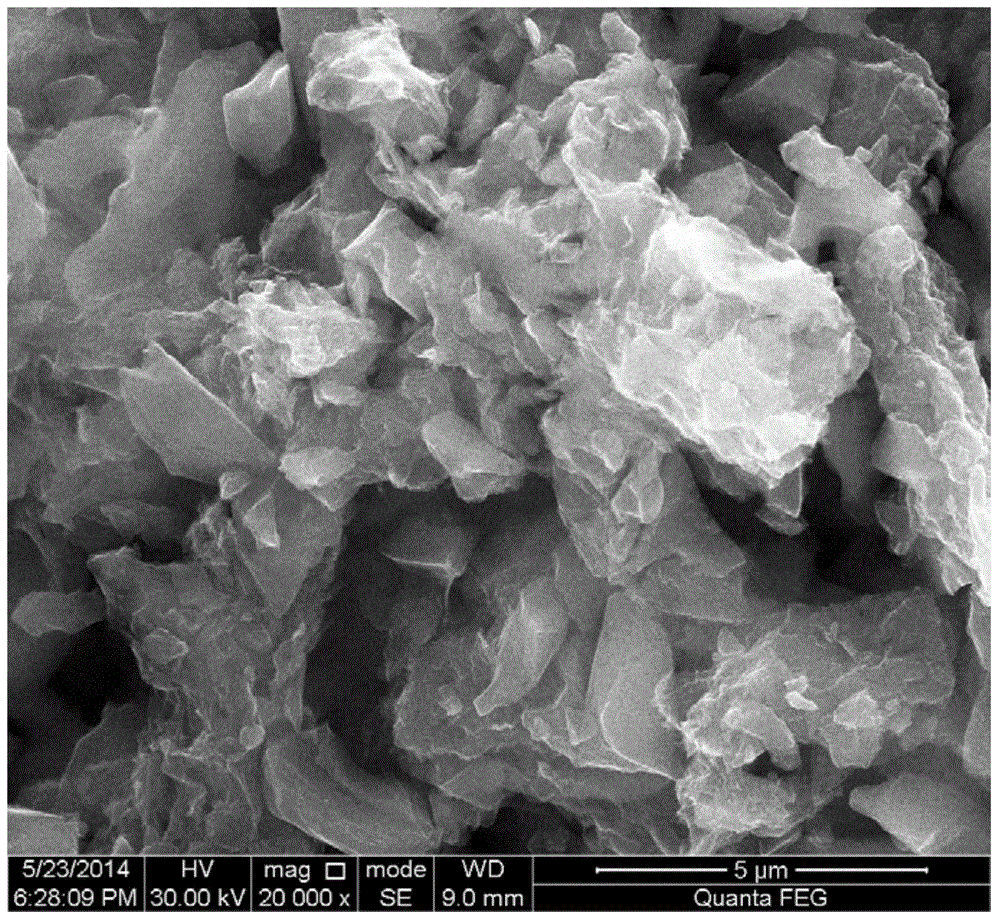

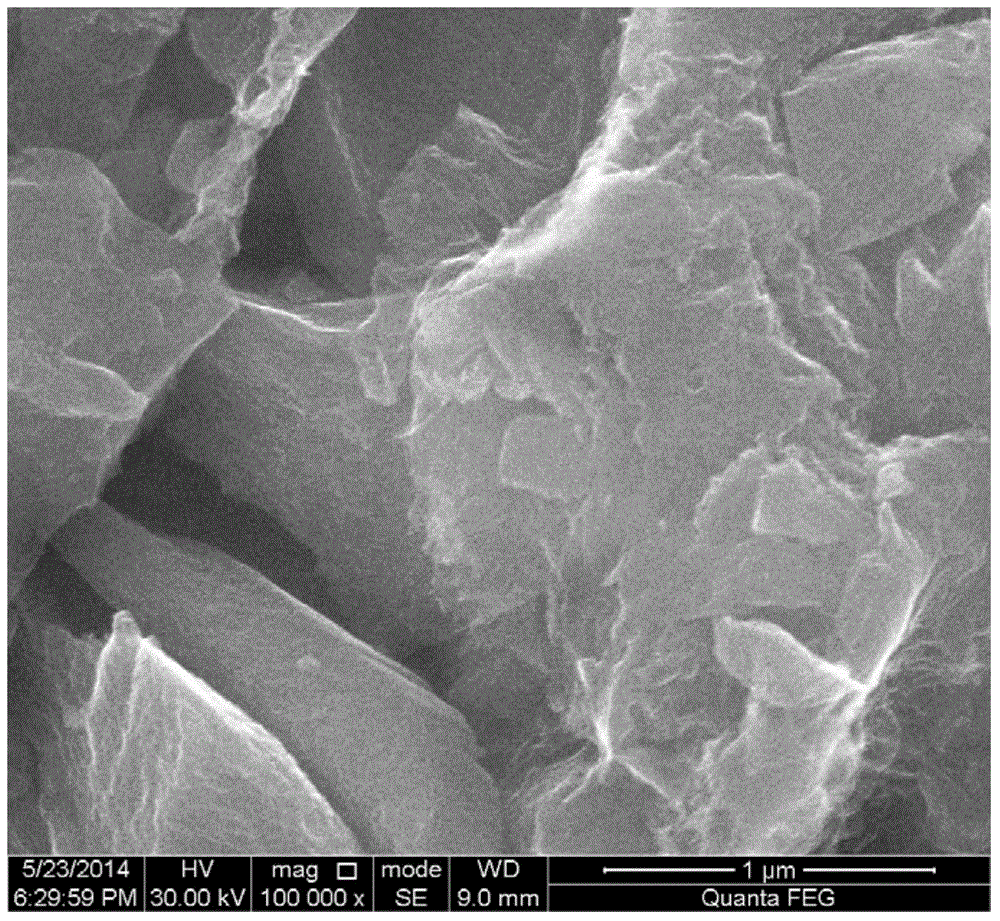

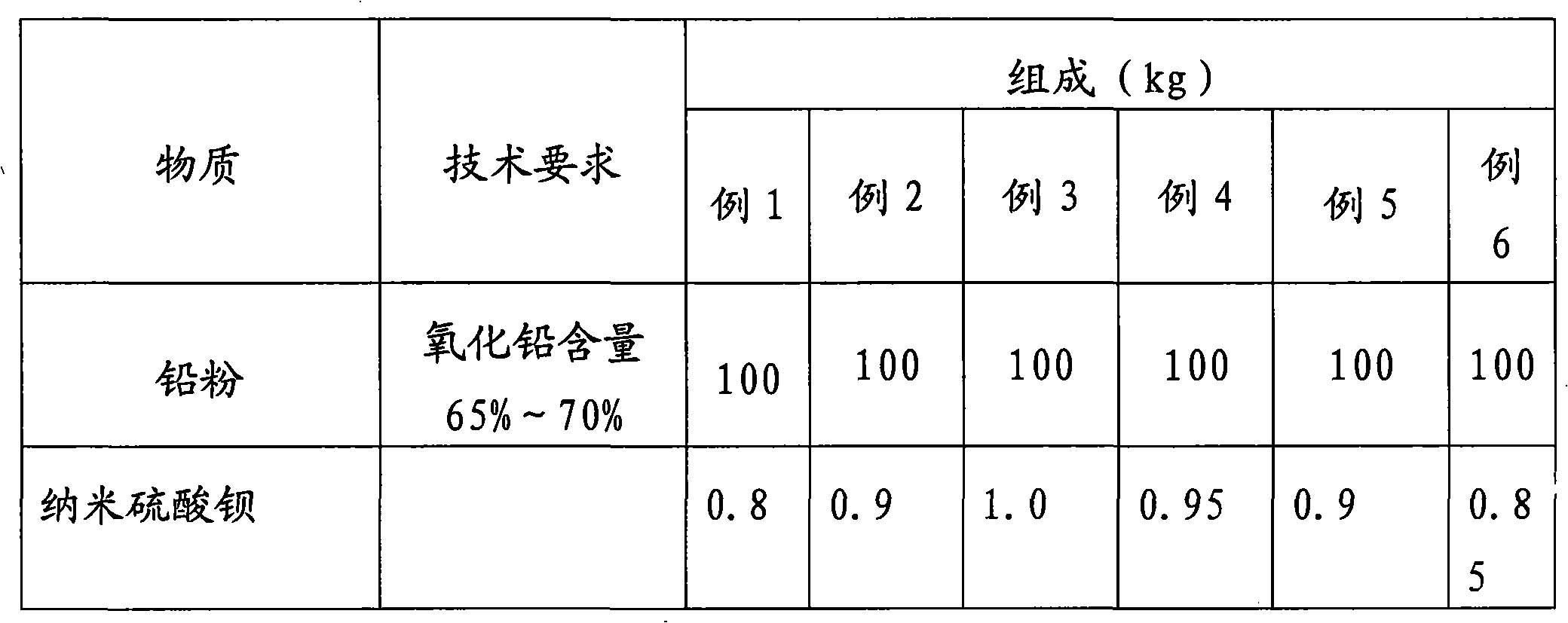

High-energy lead-acid storage battery cathode plate diachylon and preparation method thereof

ActiveCN101937991ALow conductivityImprove the utilization rate of active substancesLead-acid accumulator electrodesPolyesterFiber

The invention provides a high-energy lead-acid storage battery cathode plate diachylon and a preparation method thereof. The diachylon comprises lead powder, pure water, analytical pure sulfuric acid and an auxiliary material, wherein the lead powder comprises 65-70 percent of lead oxide, the density of the analytical pure sulfuric acid is 1.400g / cm<3>, and the pure water has the conductivity of smaller than 0.3 mus / cm; and the auxiliary material comprises the following components based on the weight proportion of the lead powder: 0.8-1 percent of nano barium sulphate, 0.1-0.3 percent of modified sodium lignosulphonate, 0.1-0.3 percent of tannin, 0.08-0.1 percent of polyester short fiber, 0.2-0.3 percent of carbon black and 0.3-1 percent of poly-alpha-olefin base oil. When diachylon is mixed, 10-15kg of water, 8-12kg of analytical pure sulfuric acid and the auxiliary material based on the weight proportion of the lead powder are added into 100kg of lead powder. The invention provides the high-energy lead-acid storage battery cathode plate diachylon and the preparation method thereof.

Owner:张家口保胜新能源科技有限公司

Polyvinylpyrrolidone modified graphene coated sulfur/porous carbon composite anode material and preparation method thereof

ActiveCN104078685AIncrease contentImprove the utilization rate of active substancesCell electrodesLi-accumulatorsCvd grapheneHigh rate

The invention relates to a polyvinylpyrrolidone modified graphene coated sulfur / porous carbon composite anode material and a preparation method thereof, which relates to a sulfur / carbon composite material applied to a lithium-sulfur secondary battery anode material and a preparation method of the composite material, and solves the technical problem of the existing lithium-sulfur battery anode material graphene-coated sulfur-containing composite material that the electrochemical property is low. The polyvinylpyrrolidone modified graphene coated sulfur / porous carbon composite material is characterized in that the outer surface of a sulfur / porous carbon composite material particle is uniformly coated with a polyvinylpyrrolidone modified graphene slab layer, a graphene conductive network is formed between every two adjacent particles, and a grading core-shell structure is formed. The preparation method comprises the steps of adding the sulfur / porous carbon composite material into graphene slurry modified by the polyvinylpyrrolidone, and mixing the sulfur / porous carbon composite material with the graphene slurry, and coating the sulfur / porous carbon composite material with the graphene slurry modified by the polyvinylpyrrolidone. The anode material is high in specific capacity, long in cycle life and good in high-rate performance.

Owner:HARBIN INST OF TECH

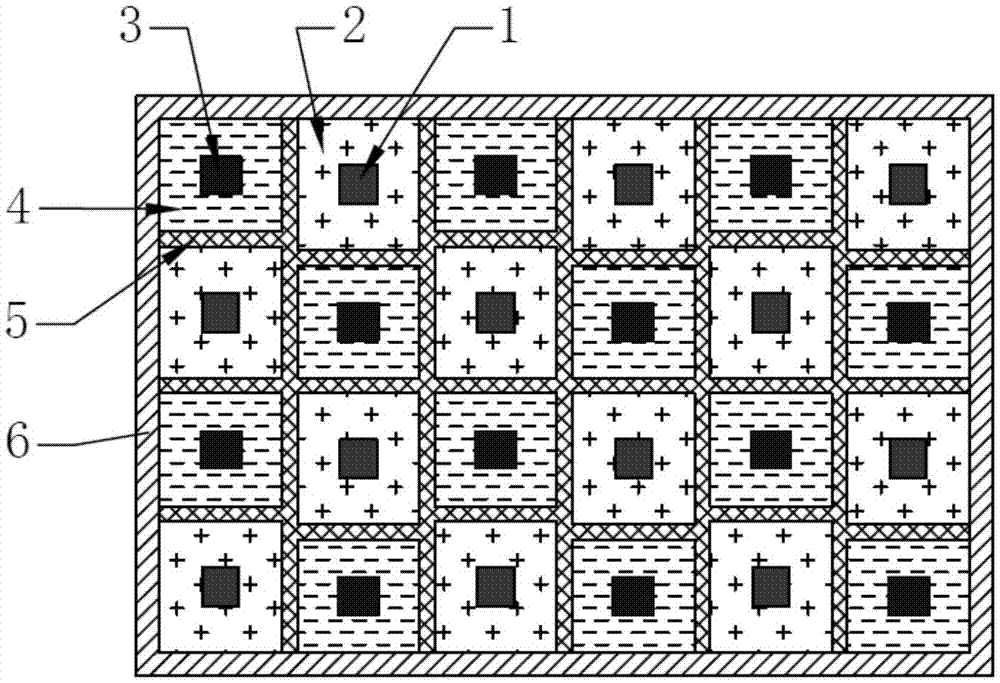

Electrode for lithium secondary battery and lithium secondary battery

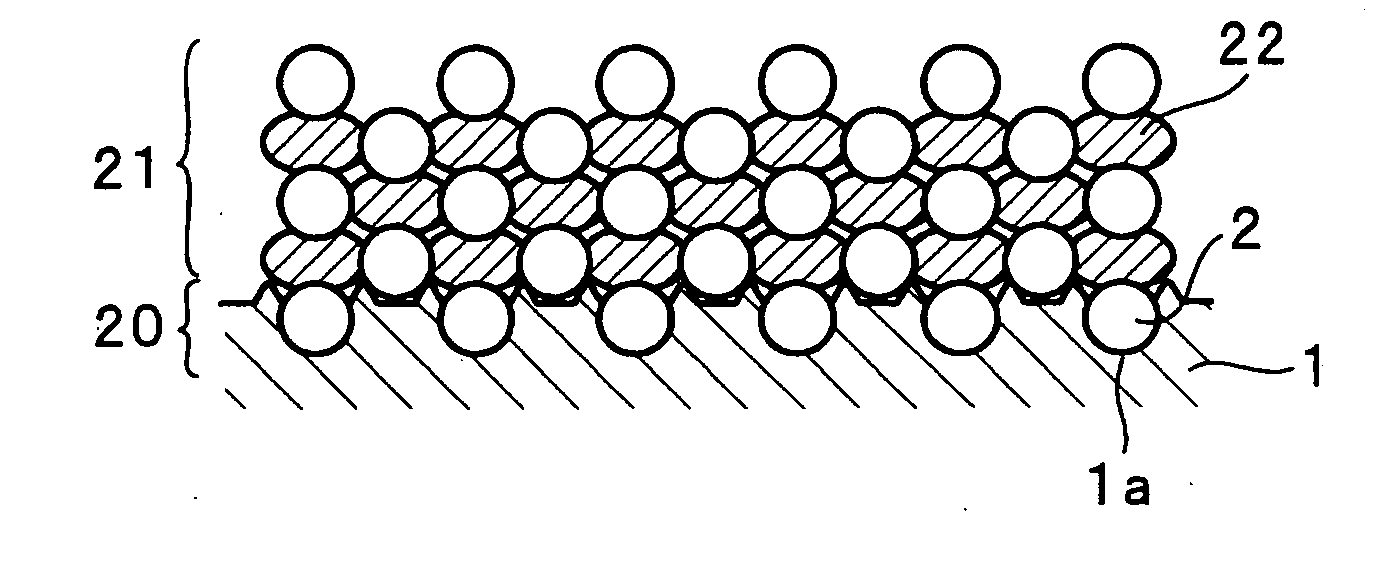

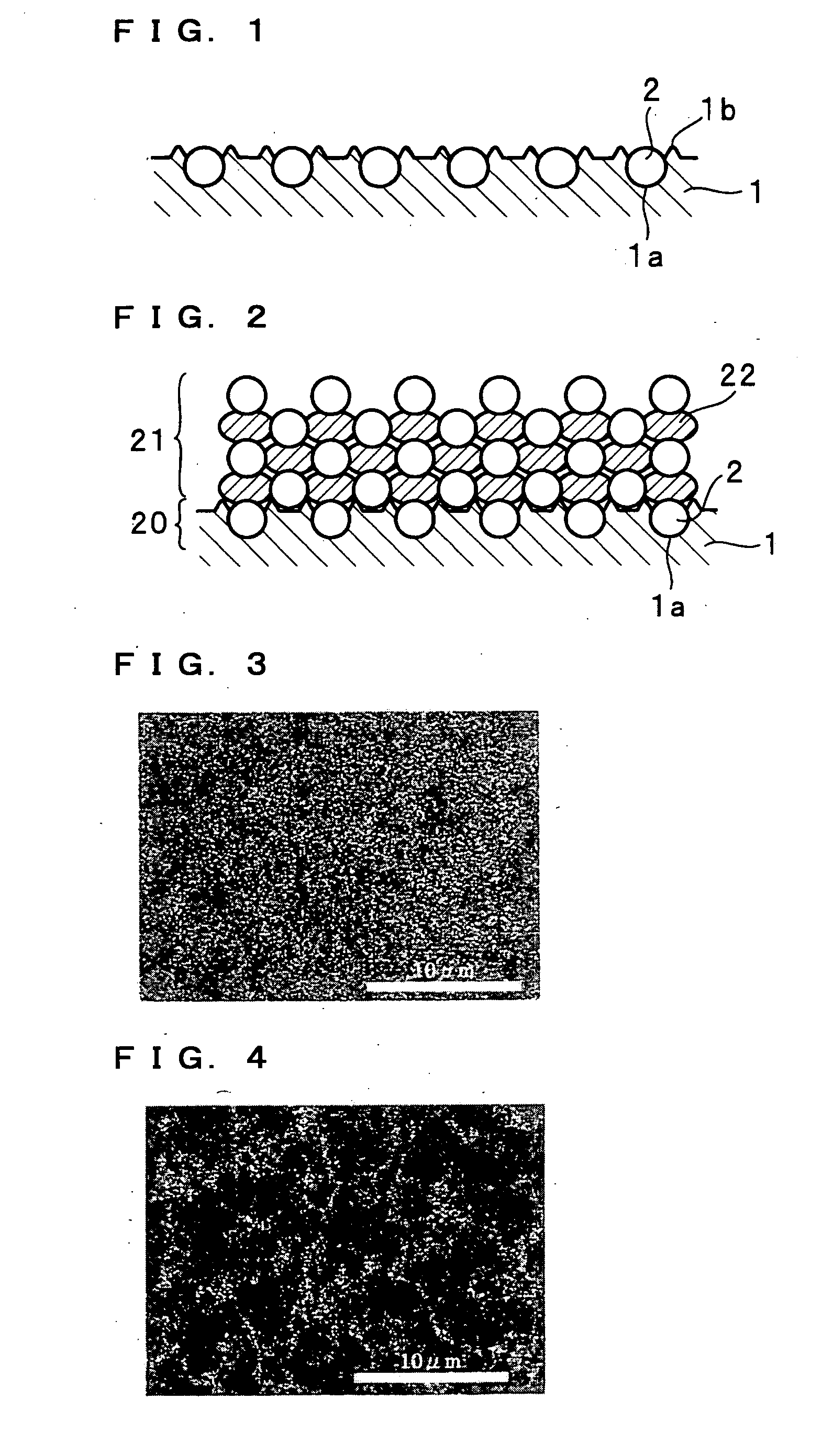

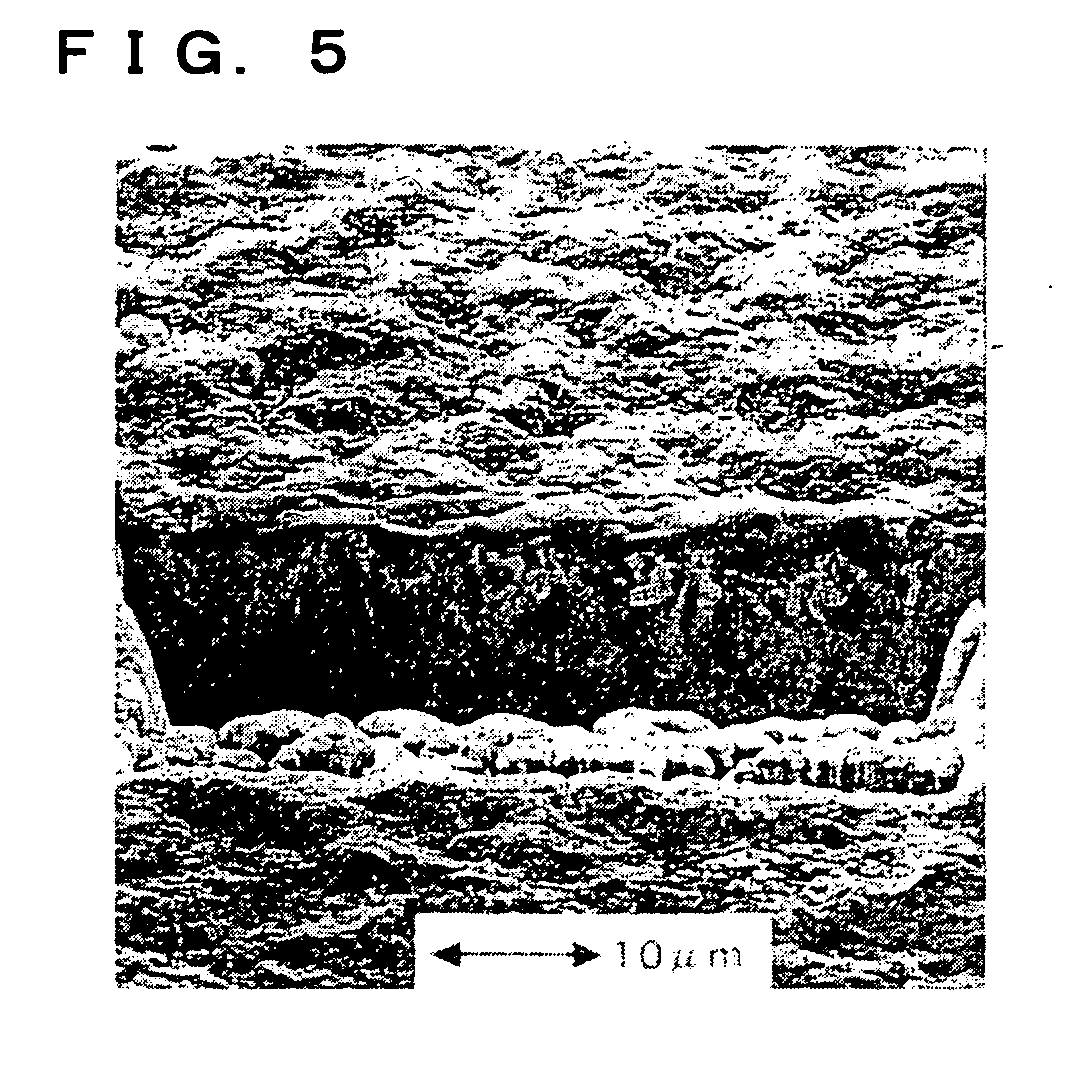

ActiveUS20060159997A1Increase volumetric energy densityImprove charge and discharge cycle characteristicsElectrode carriers/collectorsActive material electrodesLithiumEngineering

There is provided an electrode for a lithium secondary battery where particles, composed of an active material capable of occluding and releasing lithium, are arranged on a current collector, the active material particle being directly bonded to the surface of the current collector in a state where the bottom of the active material particle is imbedded in a concave portion formed on the surface of the current collector. A second particle layer may be provided on a first particle layer comprising the active material particles directly bonded to the surface of the current collector.

Owner:PANASONIC ENERGY CO LTD +1

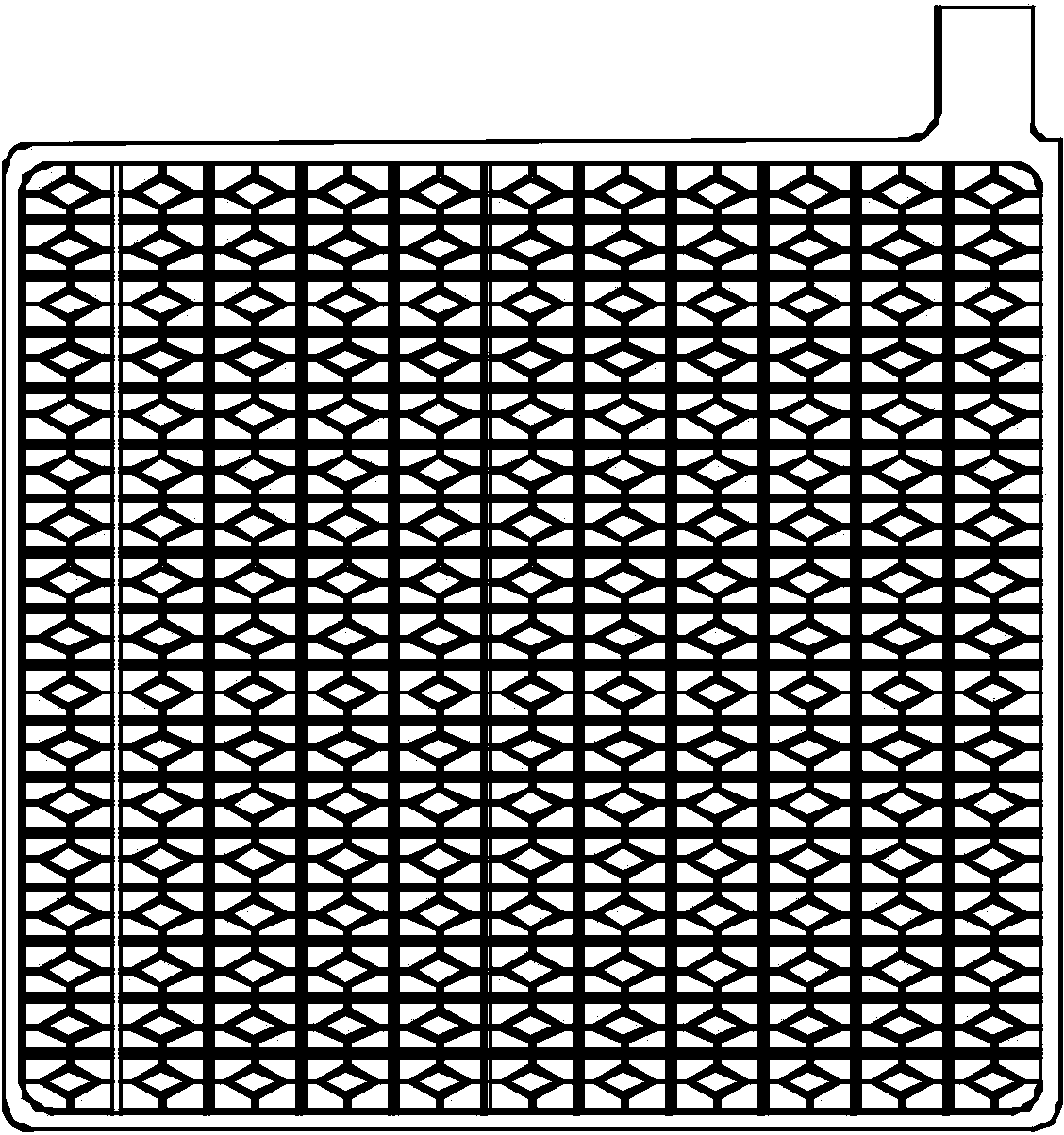

Aluminium-based light-type grid for plumbic acid cells and preparation method thereof

InactiveCN102315455AIncrease profitIncrease specific energyElectrode melt handlingElectrode carriers/collectorsChemical platingInternal resistance

The invention provides an aluminium-based light-type grid for plumbic acid cells and a preparation method thereof. The aluminium-based light-type grid comprises an open-cell porous aluminum or aluminium alloy (Al-Me) matrix with high specific surface area and a lead or lead alloy (Pb-Me') protective layer. The preparation technological flow of the protective layer mainly comprises four operationsof pretreatment, chemical plating of molten salt, metal bath and heat treatment. In comparison with traditional lead and lead alloy grids, the aluminium-based light-type grid prepared in the invention has high mechanical strength, good conductivity, large specific surface area, light weight and the like, and is used for positive and negative electrodes in plumbic acid cells so as to greatly reduce the weight of plumbic acid cells, improve the active substance utilization rate, specific energy, cycle life and seismic performance of plumbic acid cells, and minimize the internal resistance of cells. The preparation method provided by the invention is suitable for industrial application.

Owner:长沙灿能能源科技有限公司 +1

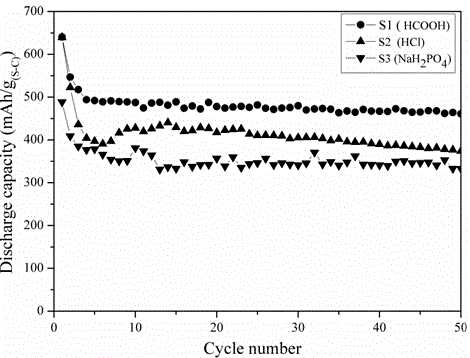

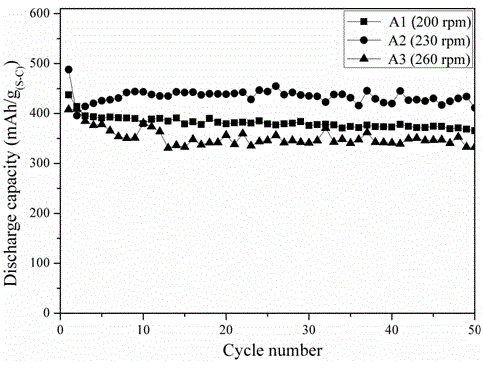

Sulfur-carbon composite positive electrode material for lithium-sulfur battery and preparation method of sulfur-carbon composite positive electrode material

ActiveCN104600247AIncrease contentImprove cycle stabilityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsHigh concentrationCarbon composites

The invention particularly relates to a preparation method of a sulfur-carbon composite positive electrode material for a lithium-sulfur battery. Sodium polysulfide is taken as the raw material, and the nano-scale sulfur particles generated by use of a chemical reaction are promoted to be melted by virtue of high-speed ball milling and go into carbon pores of conductive carbon black, and finally, the sulfur-carbon composite positive electrode material is prepared. The high-performance sulfur-carbon composite material is prepared by use of an in-situ wet ball milling method. According to the preparation method, the operation is simple and easy, the energy consumption is low, the cost is low, an environment-friendly effect is achieved, and the industrial production is easy. The thorough dispersion and fixation of sulfur on a conductive substrate are realized; besides, a high-concentration lithium salt electrolyte is adopted to inhibit the solution of polysulfide, and therefore, the cyclic stability and the active substance utilization rate of the material are improved. As a result, the sulfur-carbon composite material prepared by use of the in-situ wet ball milling method is a positive electrode material which is high in specific capacity, long in cycle life and high in rate performance and can be applied to the field of lithium secondary batteries.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

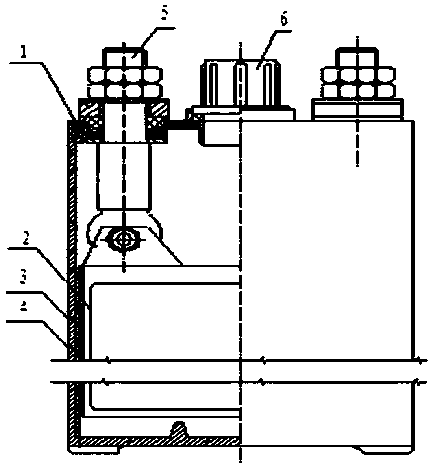

High-temperature valve regulated sealed lead-acid storage battery

ActiveCN103594738AEasy to solveAvoid volume premature agingFinal product manufactureElectrode carriers/collectorsFiberEngineering

The invention relates to a high-temperature valve regulated sealed lead-acid storage battery. The high-temperature valve regulated sealed lead-acid storage battery comprises a battery groove, a positive-electrode plate, a negative-electrode plate, a partition plate and an electrolyte. Each electrode plate comprises grids and an active material layer applied into a grid body of the grids. The active materials in the positive-electrode plate comprise lead powder, sulfuric acid, water, short fibers, graphite, Bi2O3, Sb2O3, SnSO4, polyaniline and 4Pb.PbSO4. The lead-acid storage battery is good in high-temperature performance, can be normally used even on using occasions without air conditioner facilities and is particularly suitable for being used under high-temperature environments.

Owner:HUNAN FENGRI ELECTRIC GROUP

Positive electrode lead plaster of lead acid storage battery and preparation method

InactiveCN109509883AImprove low temperature discharge performanceExtended service lifeCell electrodesFiberGraphite

The invention belongs to the technical field of lead acid storage batteries, and particularly relates to positive electrode lead plaster of a lead acid storage battery. The positive electrode lead plaster of the lead acid storage battery is prepared from the following components in parts by weight: 1000 parts of lead powder, 110 to 120 parts of diluted sulfuric acid, 2.2 to 3.2 parts of graphite,1.2 to 2.2 parts of tetrabasic lead sulfate, 0.6 to 1.2 parts of short fiber, and 135 to 155 parts of water. Compared with the traditional positive electrode lead plaster of the lead acid storage battery, the positive electrode lead plaster of the lead acid storage battery has the advantages that the low-temperature discharge property of the storage battery is improved, the utilization rate of active substances is improved, the curing and formation time of a pole plate is shortened, the service life of the battery is prolonged, the emission of acid mist is reduced, and the environment is protected.

Owner:山东久力新能源集团有限公司

In-situ carbon coating preparation method for secondary lithium ion battery cathode material lithium nickel phosphate

InactiveCN103337633AImprove electrical conductivity and active material utilizationUniform particle size distributionCell electrodesCarbon coatingCarbon source

The invention provides an in-situ carbon coating preparation method for a secondary lithium ion battery cathode material lithium nickel phosphate. The method includes:(1) dissolving a lithium source compound, a divalent nickel source compound, phosphate and a carbon source in a benzyl alcohol water solution; (2) carrying out a hydrothermal reaction at 100DEG C-200DEG C for 4h-10h; (3) performing pumping filtering, conducting washing with distilled water and absolute ethanol; (4) conducting drying at 50DEG C-100 DEG C; (5) fully grinding the dried powder, firstly carrying out a pretreatment, and then performing calcinations at high temperature so as to obtain the final product. The invention makes use of the in-situ carbon coating method to prepare near-spherical nanoscale LiNiPO4 particles, the specific surface area of active particles is increased, the electrochemical contact between active substances and a conductive agent is strengthened, the conductivity of the LiNiPO4 material is enhanced, and the charge and discharge performance of secondary lithium ion batteries is improved. Therefore, the lithium nickel phosphate can be taken as a potential secondary lithium ion battery cathode material.

Owner:HARBIN ENG UNIV

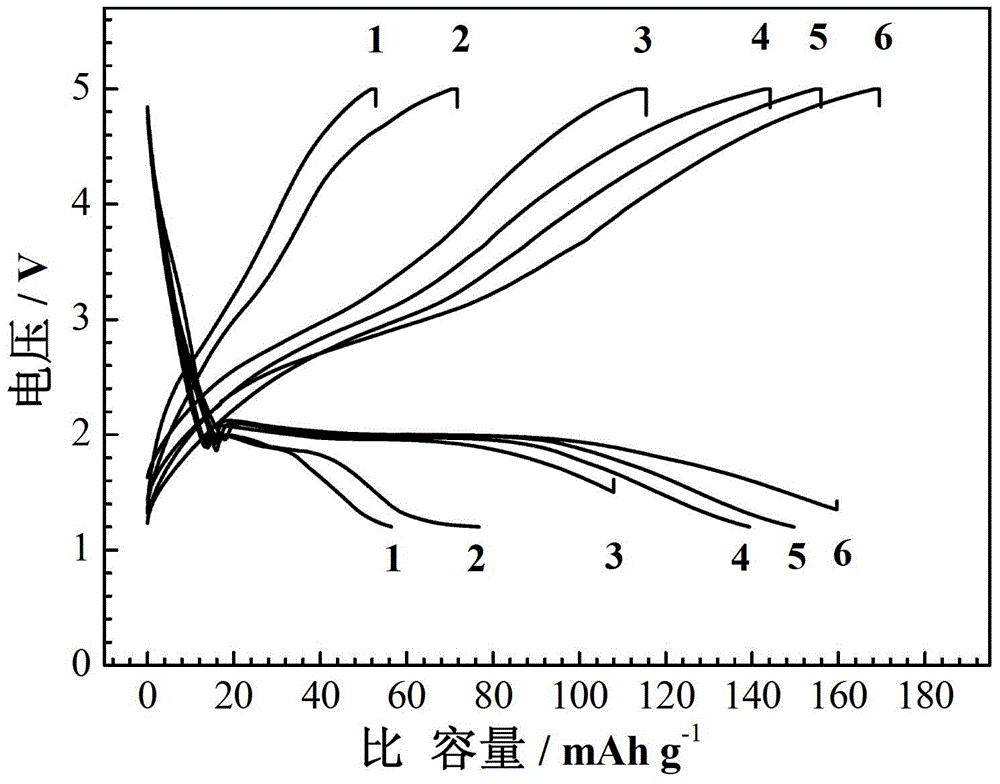

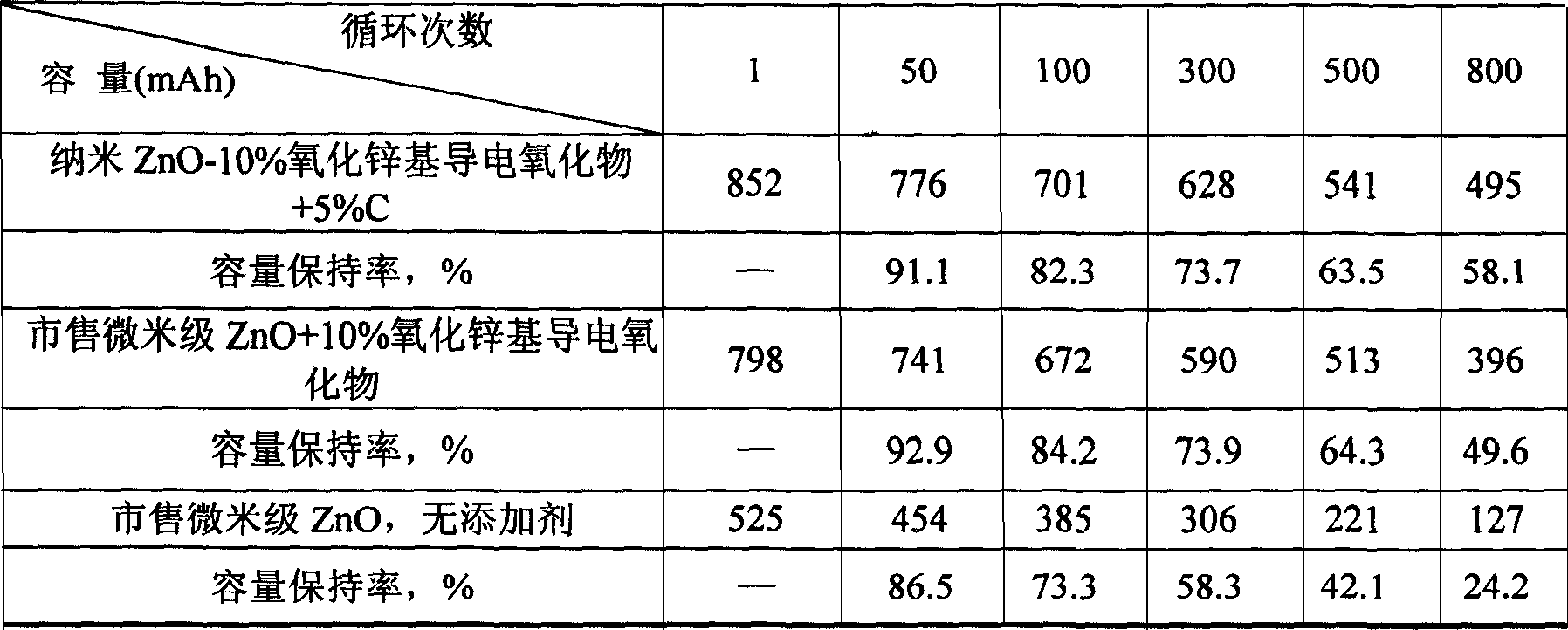

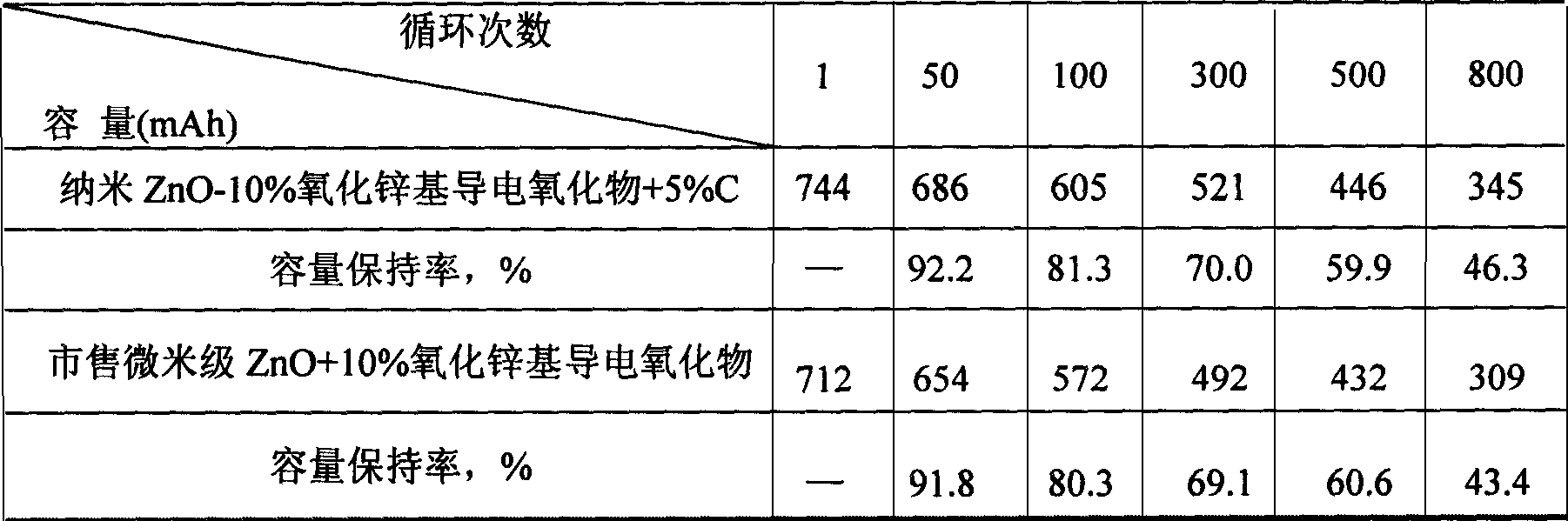

Cathode material for alkaline secondary zinc electrode and its preparing method

InactiveCN1744355AImprove electrochemical performanceReduce and prevent internal resistanceElectrode manufacturing processesAlkaline accumulator electrodesChemical compositionInternal resistance

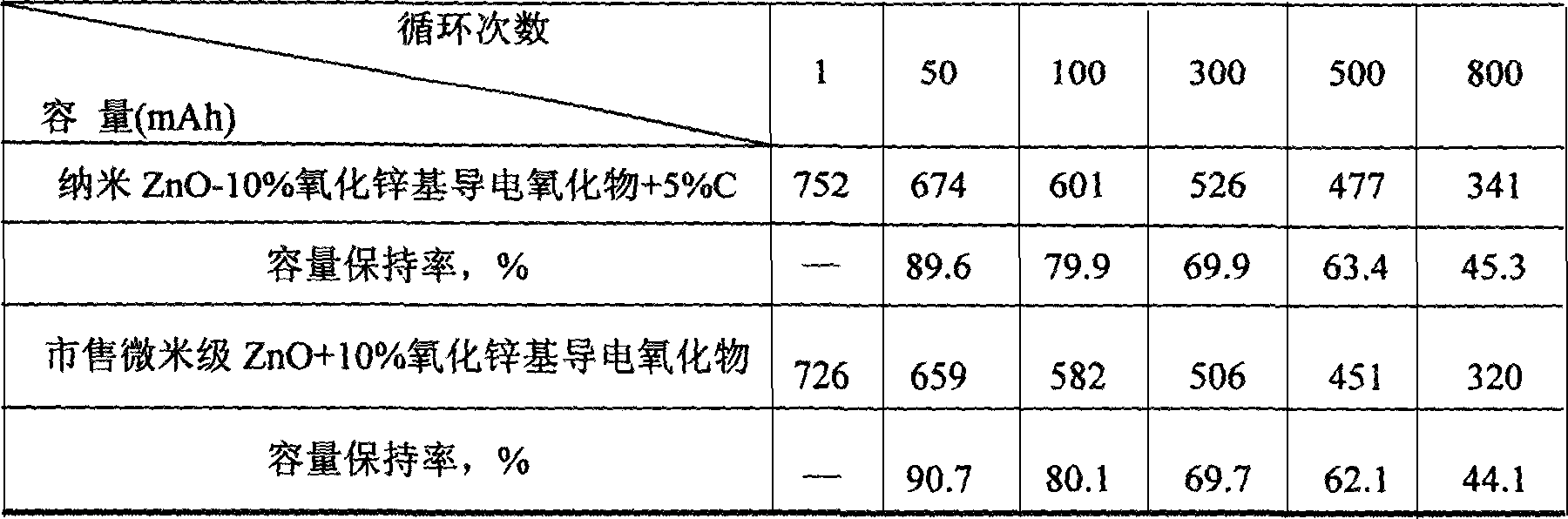

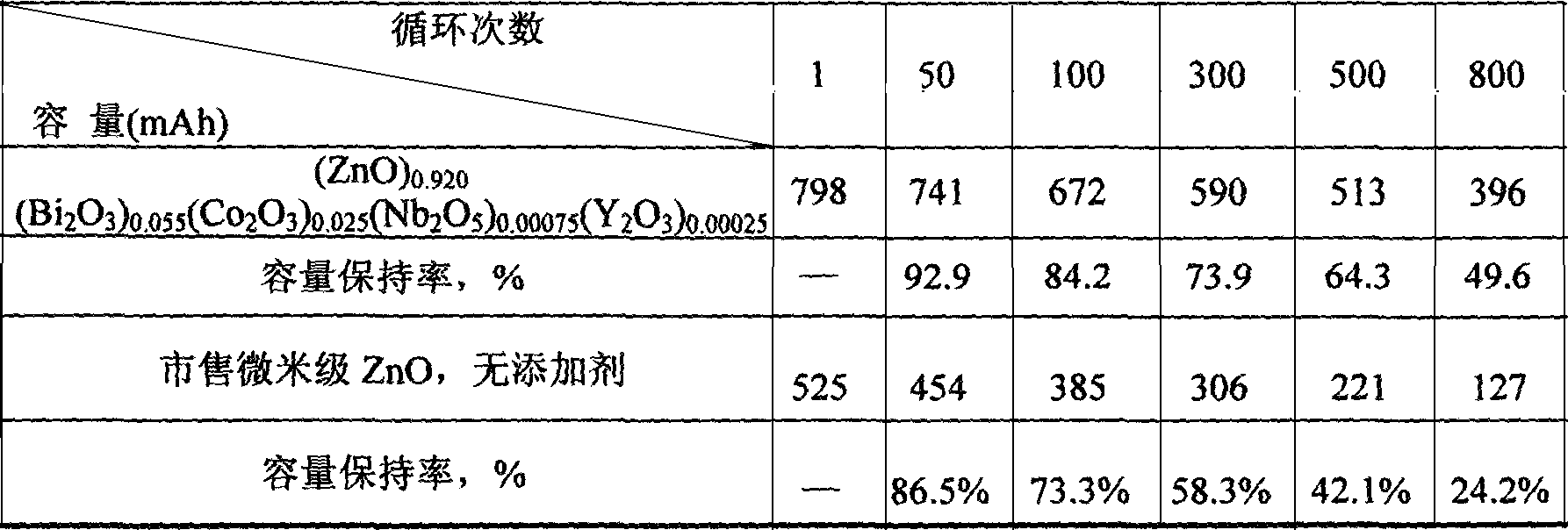

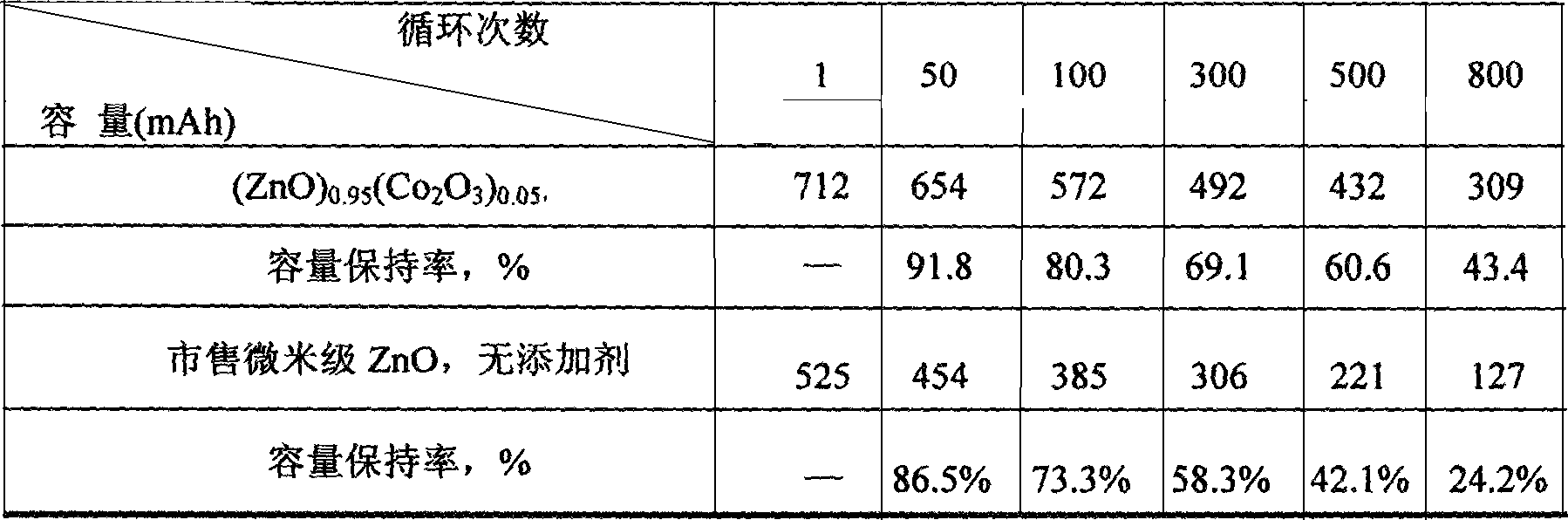

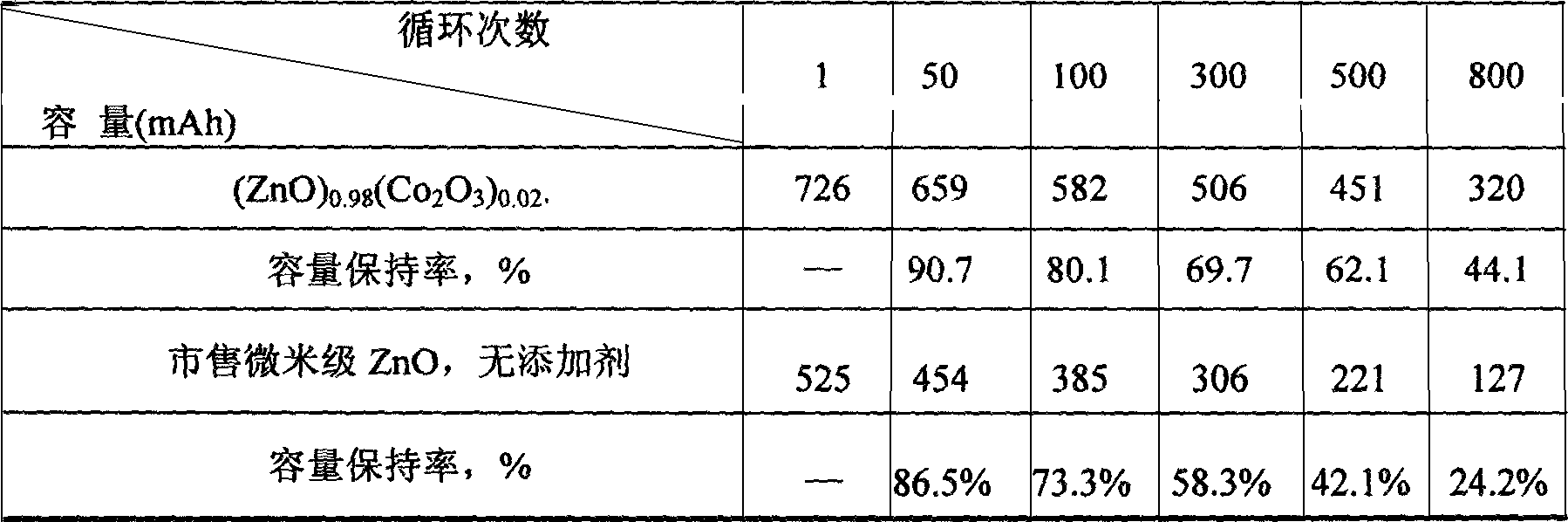

Conducting oxide based on zinc oxide is as kernel. Nano grains of zinc oxide wrap outside kernel evenly. Primary chemical composition of the zinc oxide based conducting oxide is ZnO and CO2O3. The said zinc oxide based conducting oxide can also be conducting oxides of containing Bi2O3, Co2O3, La2O3 etc. Method of deposition in homogeneous phase is adopted to prepare the disclosed material for cathode. Advantages are: (1) being added to zinc electrode, the zinc oxide based conducting oxide can be as center of crystallization; increasing use ratio of active material and discharge capacity, and reducing and preventing generation of tree like crystal of zinc, and raising cycle life of electrode; (2) reducing internal resistance of electrode. The invention possesses favorable effect for improving synthetical electrochemical performance of secondary zinc electrode.

Owner:ZHEJIANG UNIV OF TECH

Chargeable zinc electrode additive, and its preparing method and use

InactiveCN1744358AReduce and prevent internal resistanceImprove the utilization rate of active substancesElectrode manufacturing processesActive material electrodesHydrogenInternal resistance

Main chemistry constitutes of the Additive is ZnO and Co2O3. Conducting oxides such as Bi2O3íóCo2O3, Nb2O5, Y2O3, La2O3 can be added to the additive. Using mode of mixing and grinding solids, the method dopes Bi, Co, Nb elements; and using method of sol, the method leads in adulterants of Y and La elements and tetrabutyl titanate. Advantages are: (1) the zinc oxide based conducting oxide can be as center of crystallization; increasing use ratio of active material and discharge capacity, and reducing and preventing generation of tree like crystal of zinc, and raising cycle life of electrode; (2) reducing internal resistance of electrode as well as preventing zinc from solved in electrolyte, and hydrogen from separating out.

Owner:ZHEJIANG UNIV OF TECH

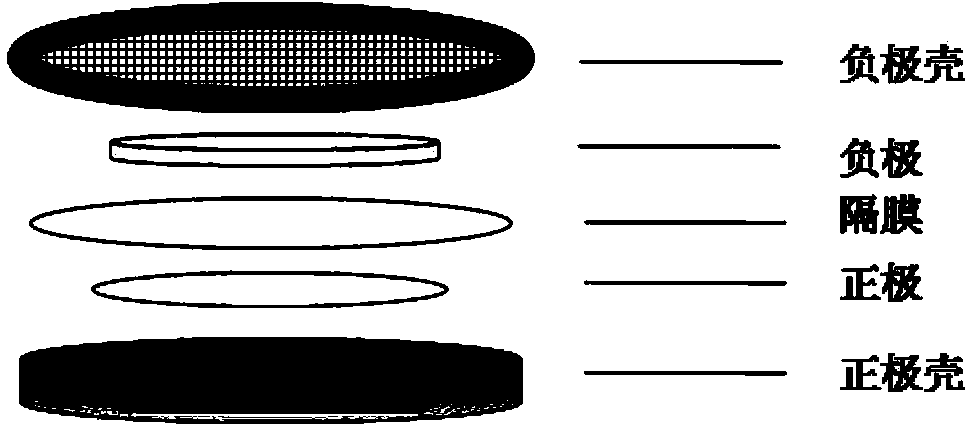

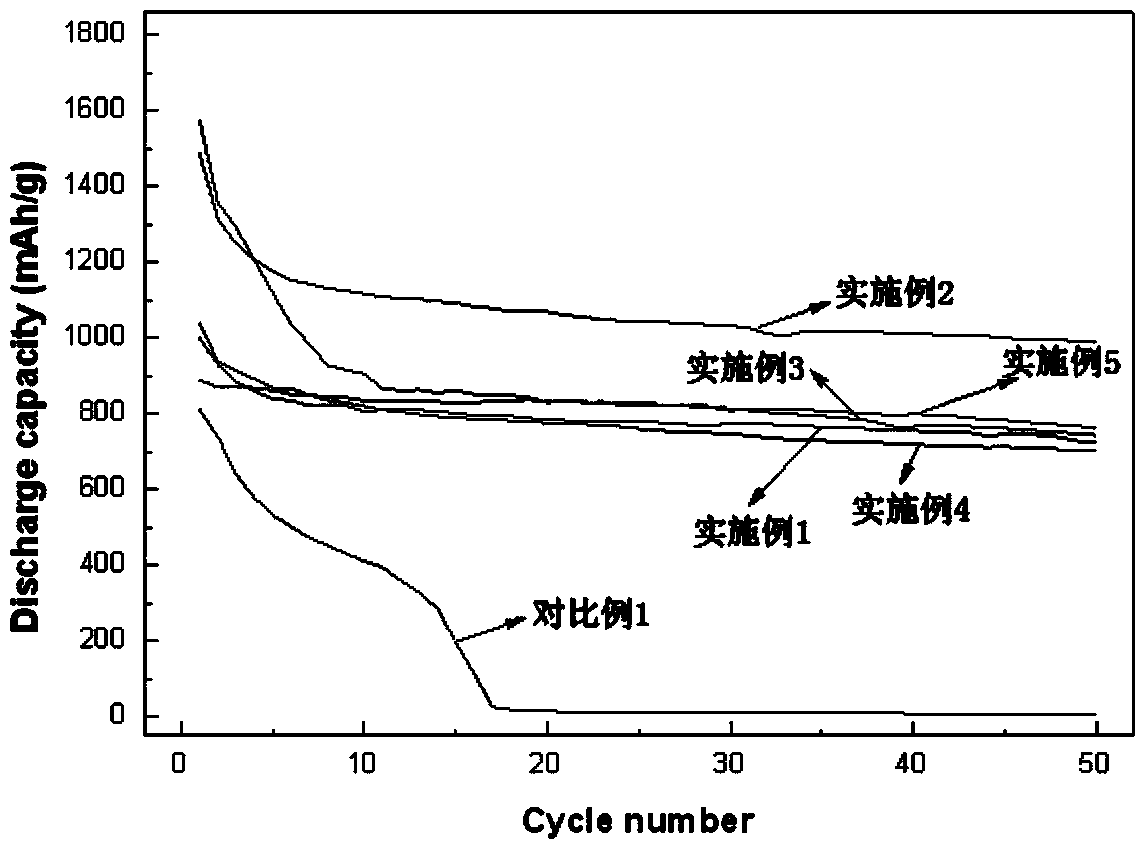

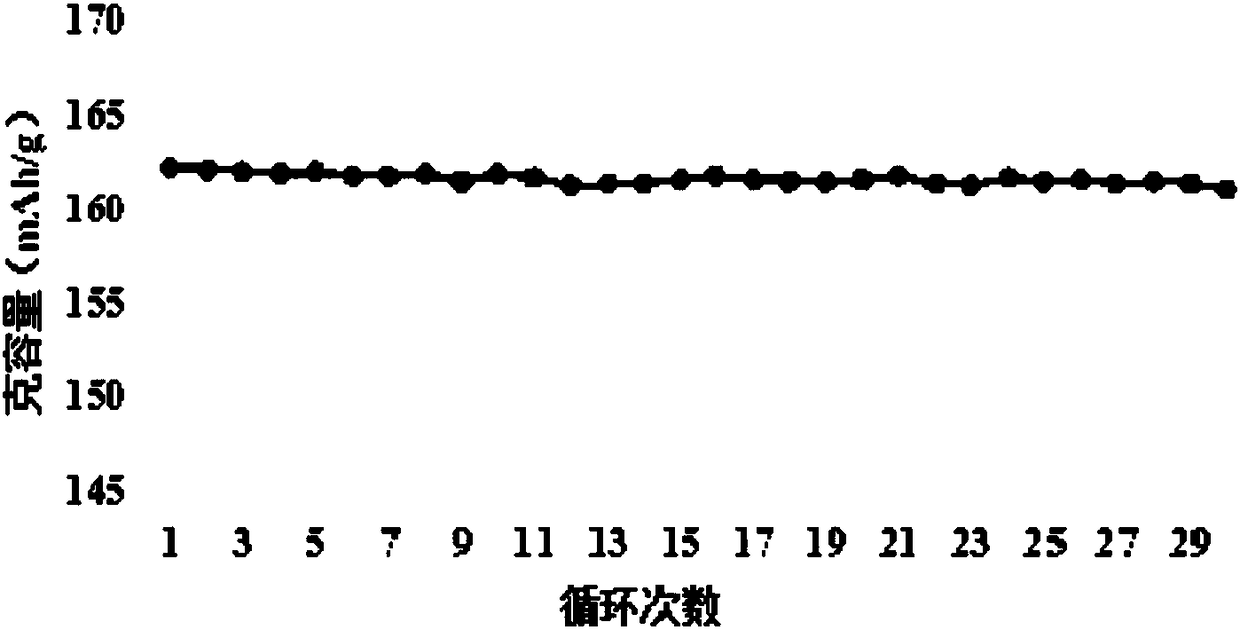

Membrane material for lithium sulfur battery positive electrode

ActiveCN104183820AGap developedImprove electrical conductivityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsCorrosionHigh conductivity

The invention discloses a membrane material for a lithium sulfur battery positive electrode, and belongs to the technical field of electrochemical batteries. The membrane material for making the lithium sulfur battery is designed against the disadvantages of poor conductivity, low active substance utilization rate and the like of traditional lithium sulfur batteries, and has the advantages of multilayer filter screen structure, prosperous gap, high conductivity, simple preparation technology and harmlessness to the environment. The membrane material for the positive electrode is placed between a positive plate and a diaphragm, so the dissolution of the polysulfide in the electrolyte in the charge and discharge process of the battery is effectively inhibited, and the corrosion of the polysulfide to a metallic lithium negative electrode is reduced. The lithium sulfur battery adopting the membrane material has a high active substance utilization rate and stable cycle performances, has an initial discharge specific capacity under a current density of 0.162mA / cm<2>, and still has a discharge specific capacity of above 702mAh / g after 50 times cycle; and compared with traditional lithium sulfur batteries, the lithium sulfur battery adopting the membrane material has the advantages of excellent performances and low cost, and lays a good foundation for the marketization of the lithium sulfur battery.

Owner:HENAN NORMAL UNIV

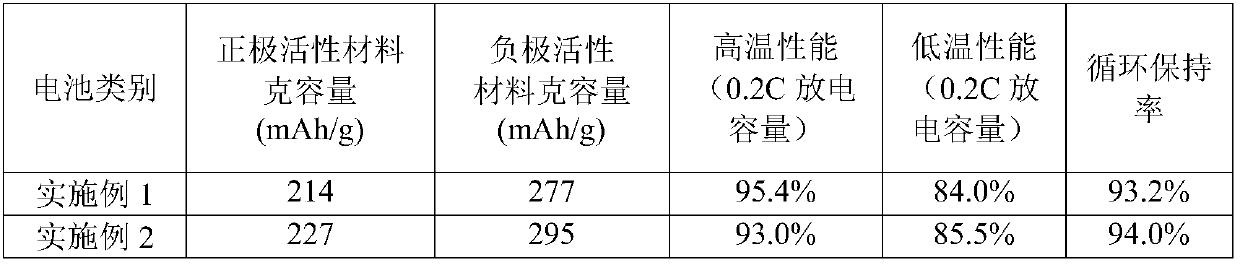

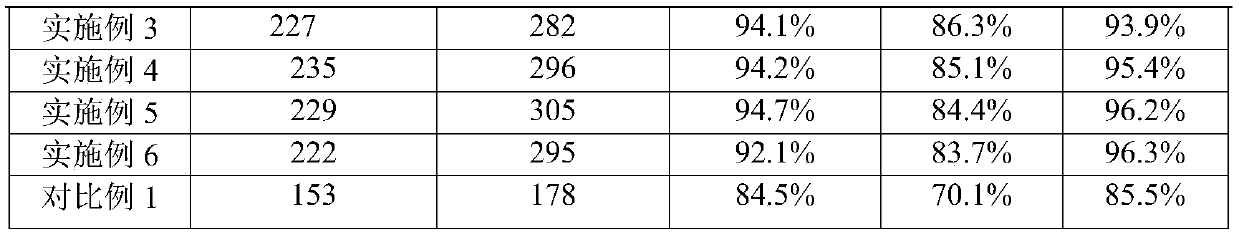

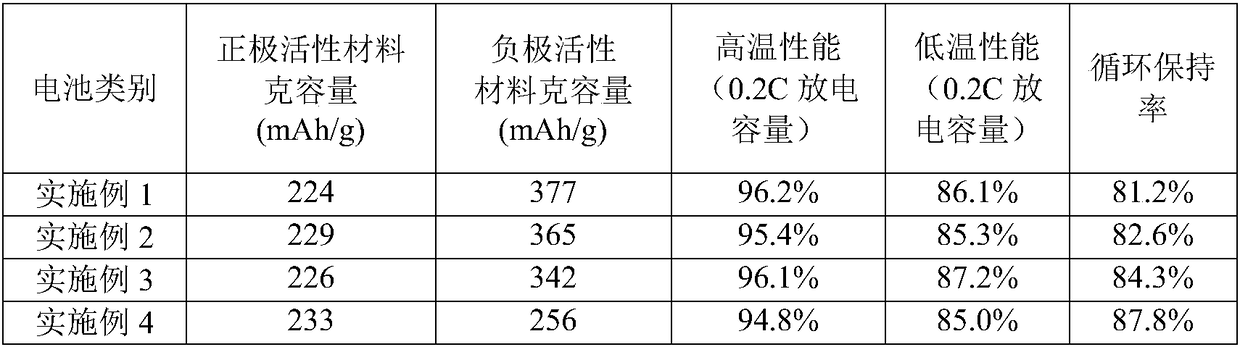

Preparation method for aluminum-coated nickel-cobalt lithium manganite and lithium battery

InactiveCN108598425AImprove electrochemical performanceExtended service lifeCell electrodesSecondary cellsLithium-ion batteryCobalt

The present invention provides a preparation method for aluminum-coated nickel-cobalt lithium manganite and a lithium battery, and relates to the technical field of material preparation methods. The method comprises the steps of wet mixing, wet ball milling, spray drying, first sintering, dry ball milling and second sintering. Aluminum oxide coats a surface of nickel-cobalt lithium manganite obtained by the first sintering through the dry ball milling. Because the dry ball milling is adopted, lithium ions are not prone to form lithium dendrites on the surface of a negative electrode. After thesecond sintering, gram volume is not greatly reduced, and material properties are enhanced to a certain degree. The preparation method for the aluminum-coated nickel-cobalt lithium manganite not onlycan enhance cyclic properties of ternary materials and improve the utilization rate of active substances, but also can obviously improve the gram volume of the materials after the second sintering. The lithium battery provided by the present invention is prepared by the above preparation method for the aluminum-coated nickel-cobalt lithium manganite, and has good electrochemical property and longservice life.

Owner:NORTHERN ALTAIR NANOTECH CO LTD +1

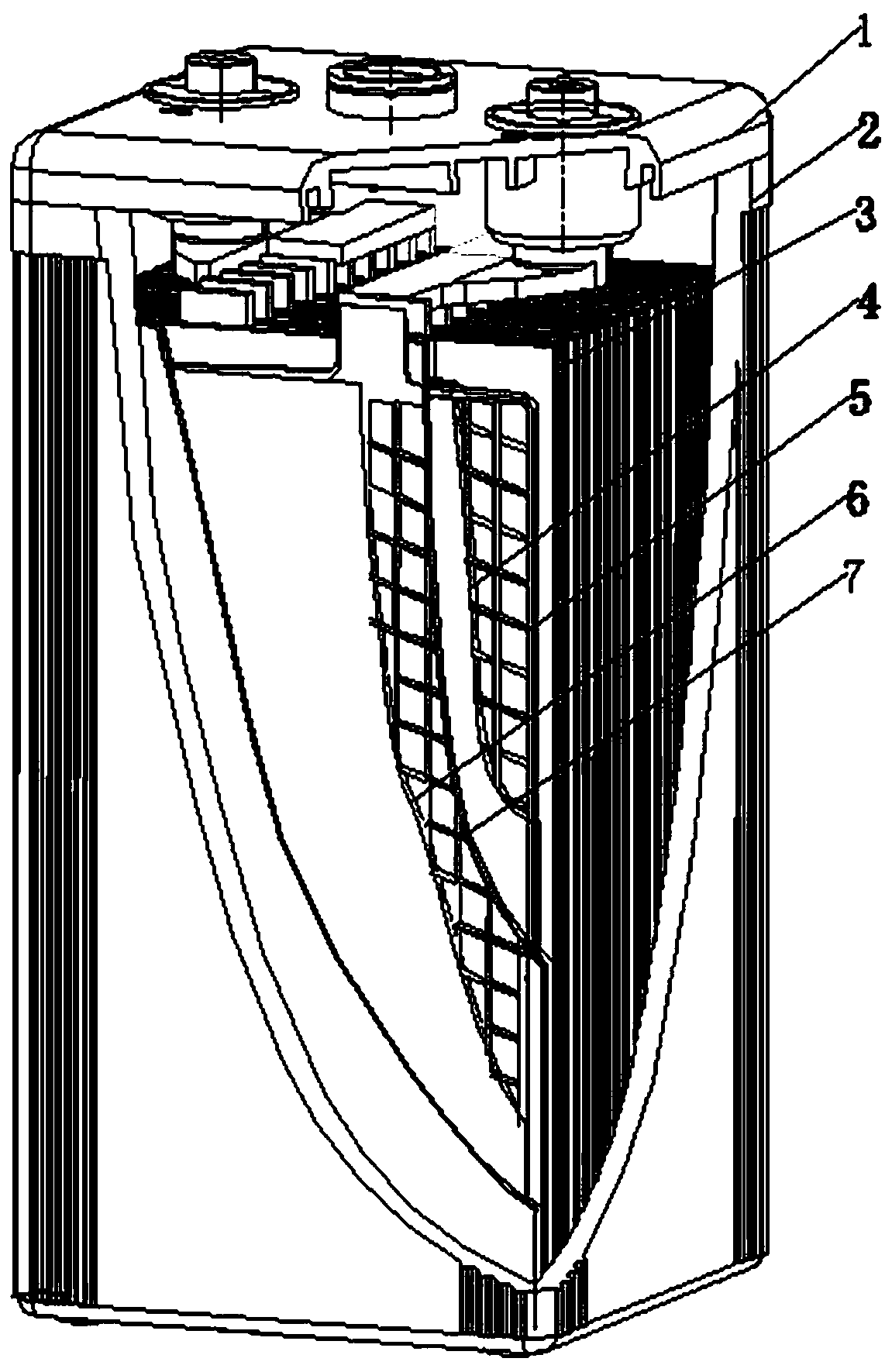

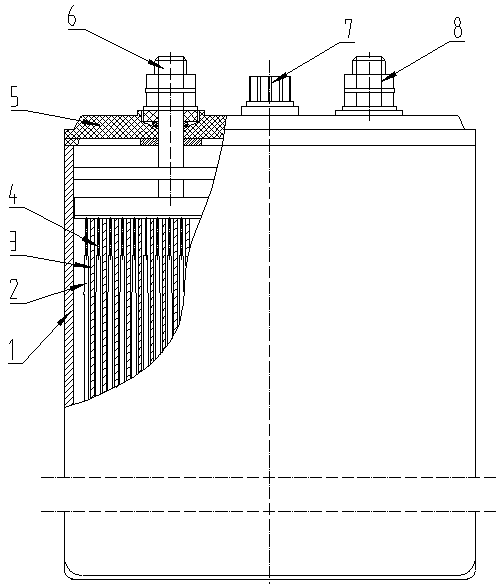

Large-capacity double-bag type iron-nickel battery

ActiveCN108682901AImprove overcharge resistanceExcellent rate performanceFinal product manufactureAlkaline accumulators manufactureEngineeringElectrolyte

The invention discloses a large-capacity double-bag type iron-nickel battery. A battery pole plate is composed of a bag type nickel positive pole plate, a bag type iron negative pole plate and a multilayered composite diaphragm or isolation grid located between the bag type nickel positive pole plate and the bag type iron negative pole plate; an electrode material of the bag type nickel positive pole plate is composed of a positive pole active material, a conducting agent, an additive and a binding agent; an electrode material of the bag type iron negative pole plate is composed of iron-basedoxide powder, a conducting agent, an additive and a binding agent; electrolyte is an alkaline solution which is at a barren liquor state and contains the additive. According to the large-capacity double-bag type iron-nickel battery disclosed by the invention, a formula of positive and negative poles is optimized, a formula of the electrolyte is optimized and a battery structure is adjusted, so that the charging and discharging performance, and circulating performance of the novel iron-nickel battery are improved; furthermore, the battery also has the advantages of high charging and dischargingvoltage platform, good over-charging and over-discharging resisting performance, low cost and the like.

Owner:河南省恒明新能源有限公司

Preparation method of conductive carbon material with hierarchical porous structure, and pole plate for lead acid battery

InactiveCN106784847AReduce concentration polarizationLower internal resistanceLead-acid accumulatorsLead-acid accumulator electrodesMuffle furnaceSurface-active agents

The invention provides a preparation method of a conductive carbon material with a hierarchical porous structure. The method comprises: dissolving phenolic resin into an ethanol solution; dissolving a surface active agent F127 into an HCl-containing ethanol solution; then adding ethyl orthosilicate, silicon dioxide colloidal particles and the phenolic resin ethanol solution; transferring a mixture into a container, volatilizing ethanol, performing thermal polymerization in a reaction furnace of 100 DEG C to obtain a faint-yellow transparent thin film, and grinding the thin film into powder; putting the powder into a tubular muffle furnace, and performing carbonization under the nitrogen atmosphere protection; soaking a hierarchical porous structure carbon / silicon oxide composite material into HF of which the content is 5wt%, removing silicon oxide, only retaining carbon components of the hierarchical porous structure, washing a sample by using deionized water, and then performing drying to obtain the conductive carbon material with the hierarchical porous structure. According to the preparation method of the conductive carbon material with the hierarchical porous structure, the internal resistance of a lead acid battery electrode can be effectively reduced, and the utilization rate of active substances and the charge-discharge rate are improved; meanwhile, the electrode structure can be stabilized, and the recycling life is prolonged.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

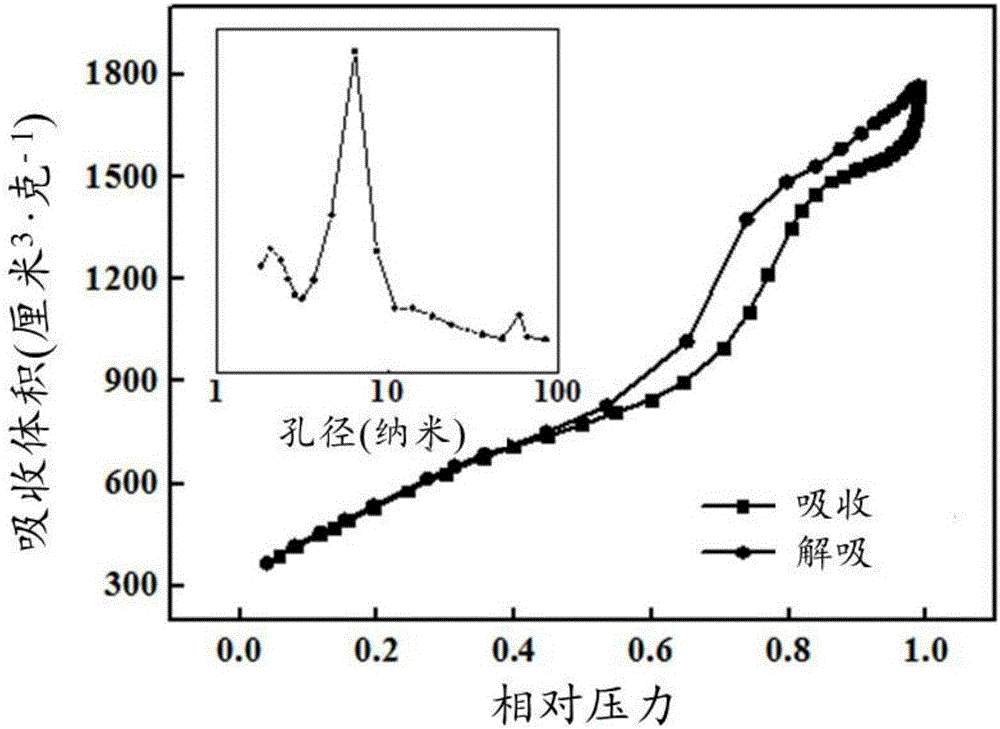

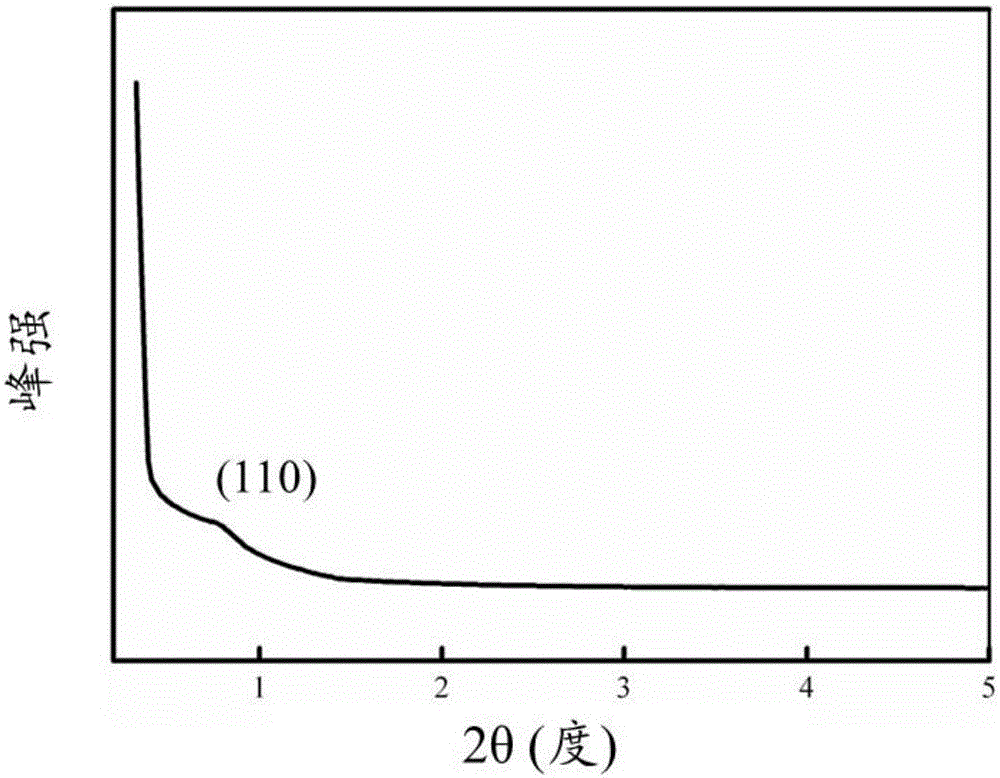

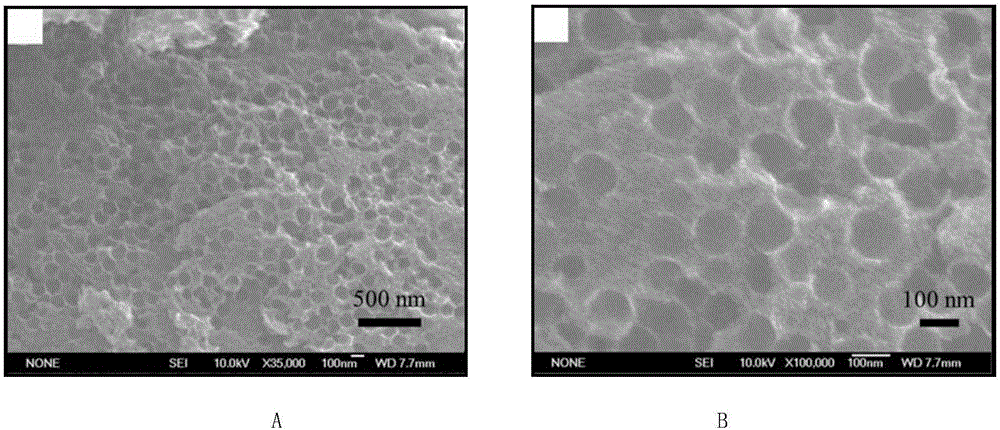

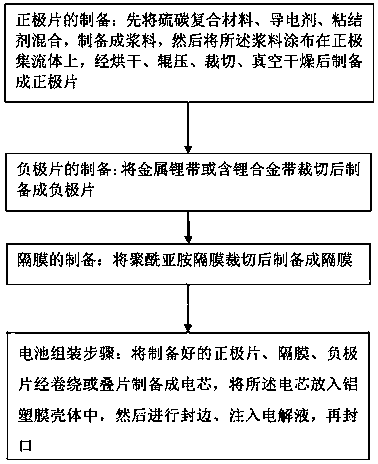

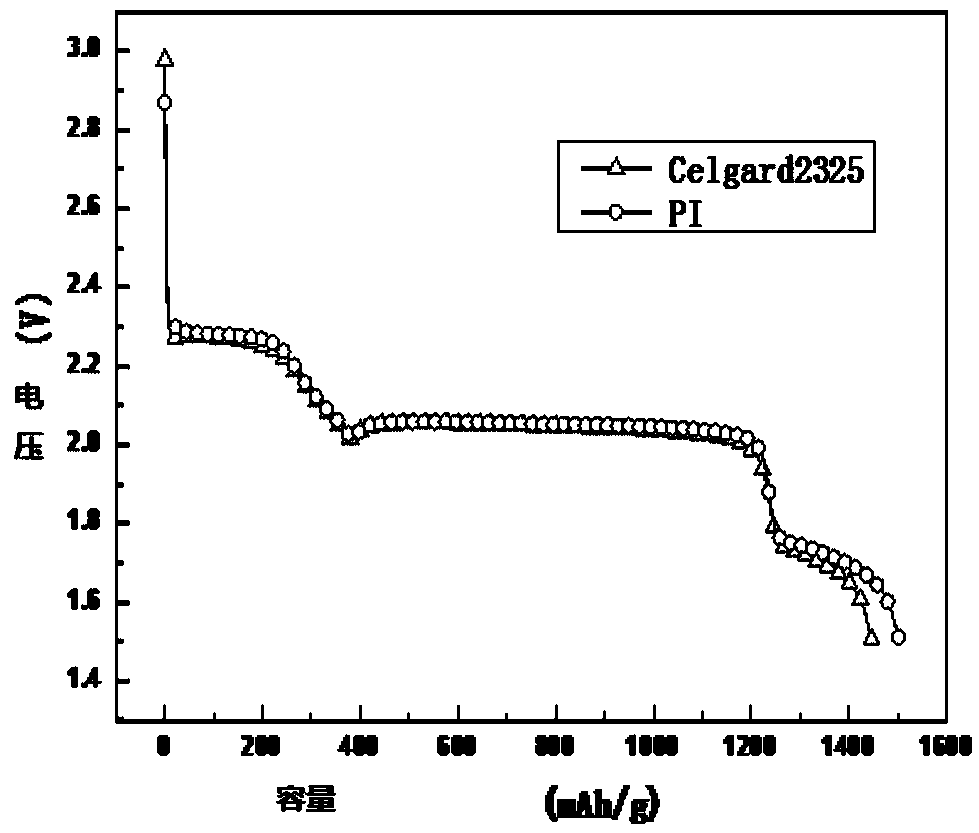

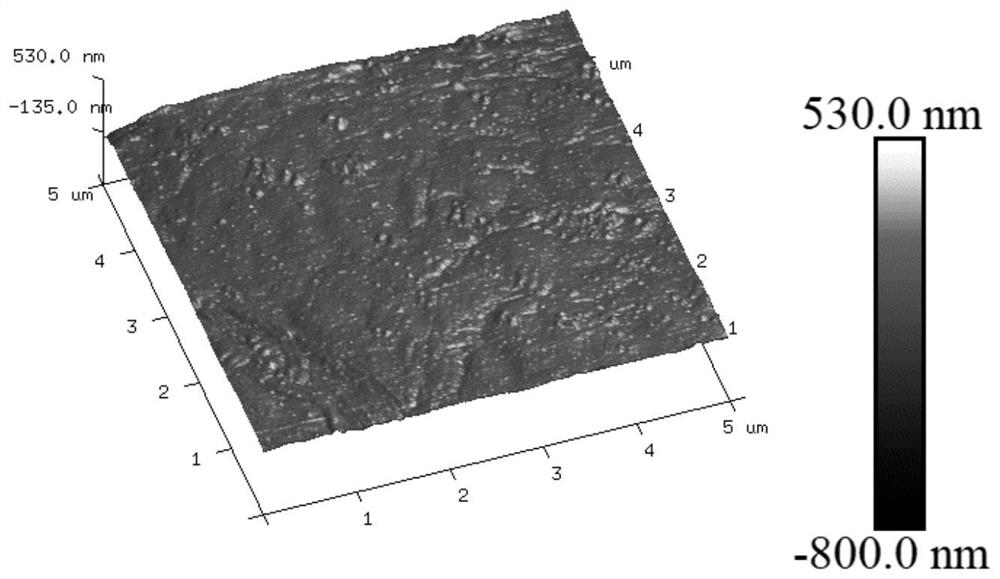

A polyimide separator lithium-sulfur battery and a preparation method thereof

InactiveCN109244335AImprove the utilization rate of active substancesImprove securityCell electrodesSecondary cellsCarbon compositesSlurry

The invention discloses a polyimide separator lithium-sulfur battery and a preparation method thereof. The method comprises the following steps: (1) firstly, a sulfur-carbon composite material, a conductive agent and a binder are mixed to prepare a slurry, and the slurry is coated on a positive electrode current collector to prepare a positive electrode sheet; 2, that metal lithium tape or the lithium-containing alloy tape is cut to prepare a negative electrode sheet; 3) that polyimide diaphragm is cut to prepare a diaphragm; (4) the prepared positive electrode sheet, diaphragm and negative electrode sheet are prepared into a cell, the cell is placed into an aluminum-plastic film shell, the edge is sealed, an electrolyte is injected, and sealing is performed. The invention can effectivelyimprove the utilization rate of the active material of the lithium-sulfur battery, improve the safety performance of the lithium-sulfur battery, broaden the application field of the lithium-sulfur battery, and has a wide application prospect in the fields of portable electronic equipment, electric vehicles, electric tools and the like.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Method of preparing aluminum-substituted alfa-nickel hydroxide coated with beta-nickel hydroxide

InactiveCN104466123AHigh phase stabilityGood electrochemical activityAlkaline accumulator electrodesNickel oxide hydroxideNickel salt

The invention discloses a method of preparing aluminum-substituted alfa-nickel hydroxide coated with beta-nickel hydroxide. The method comprises the steps of: dissolving nickel salt and aluminum salt in a 5:1 molar ratio of nickel to aluminum by using distilled water to prepare a mixture liquid; dissolving potassium hydroxide or sodium hydroxide in the distilled water to prepare alkaline solution of sodium hydroxide or potassium hydroxide; dropwise adding the alkaline solution into the mixture liquid, controlling a pH value, reacting, perform extraction filtration, washing, and drying to obtain aluminum-substituted alfa-nickel hydroxide powder; mixing aluminum-substituted alfa-nickel hydroxide with nickel ions, perform ultrasonic dispersion, dropwise adding the alkaline solution into the nickel salt solution which contains the aluminum-substituted alfa-nickel hydroxide, controlling the pH value, reacting, perform extraction filtration, washing, and drying to obtain the aluminum-substituted alfa-nickel hydroxide coated with the beta-nickel hydroxide. The method is simple in process and easy to control, the cost of raw materials is low, and the utilization rate and cycle performance of the aluminum-substituted alfa-nickel hydroxide coated with the beta-nickel hydroxide serving as an anode material active substance of a nickel-metal hydride battery are excellent.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

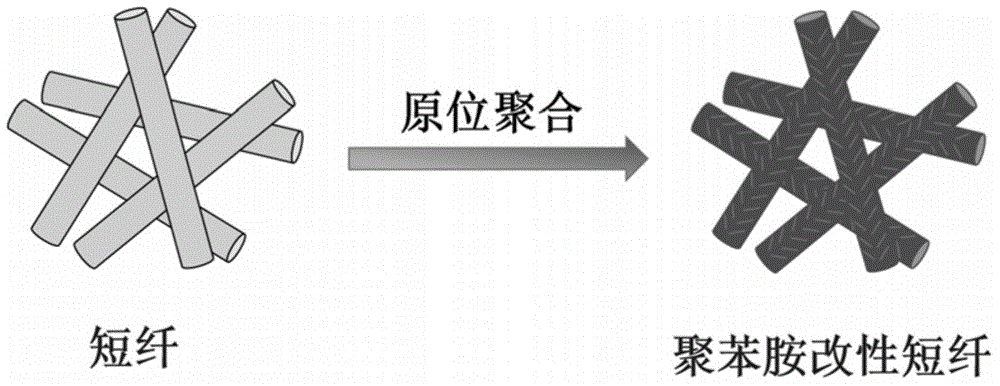

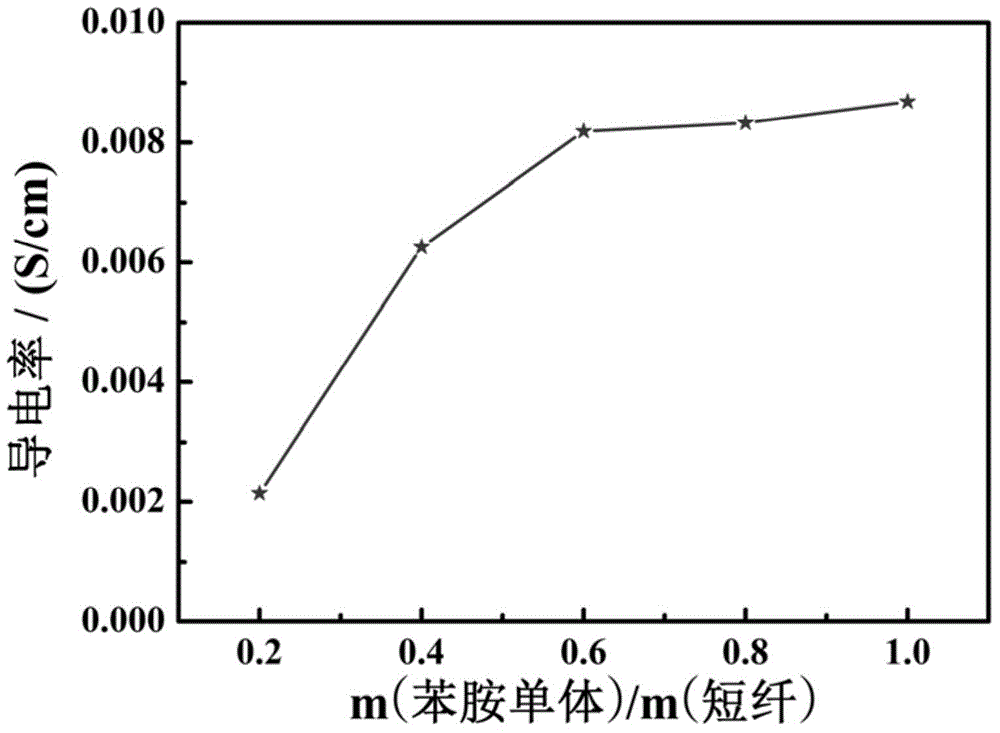

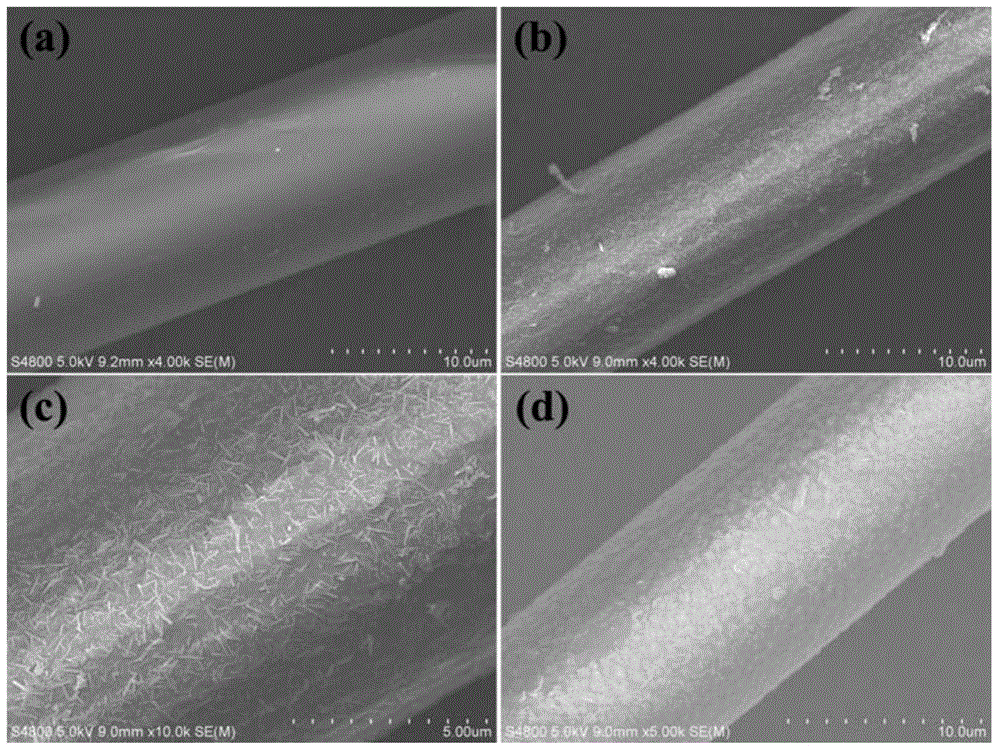

Preparation method of modified short fiber for lead-acid battery and negative plate containing modified short fiber

InactiveCN105047939ASimple preparation processShorten the production cycleElectrode carriers/collectorsFiberHigh rate

The invention provides a preparation method of a modified short fiber for a lead-acid battery and a negative plate containing the modified short fiber. A conductive polymer coats the surface of the short fiber so as to improve the conductivity of the short fiber. By the modified short fiber, the problems of low utilization rate of an active substance of the lead-acid battery and short cycle life in a high-rate partial state of charge are hopefully solved, and meanwhile, the addition proportion of the short fiber in lead paste is increased so as to further enhance the cyclic performance of the lead-acid battery. The short fiber is an important additive in industrial production of the lead-acid battery, and a few additive amount of the short fiber is required in the lead paste due to non-conductivity of the short fiber. An in situ polymerization method is used for coating the surface of the short fiber with the conductive polymer, so that the conductivity of the short fiber is substantially improved. When the modified short fiber is added into the negative electrode lead paste of the lead-acid battery, the capacity of a battery plate and the utilization rate of the active substance can be improved, and moreover, the cyclic service life of the battery in the high-rate partial state of charge (HRPSoC) can be substantially prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

High-capacity double-bag type zinc-nickel secondary battery and preparation method thereof

ActiveCN108878806AEasy to optimizeImprove high temperature performanceFinal product manufactureAlkaline accumulator electrodesAgricultural engineeringZinc

The invention discloses a high-capacity double-bag type zinc-nickel secondary battery and a preparation method thereof, wherein a battery polar plate group consists of a bag type nickel positive plate, a bag type zinc negative plate and a multilayer composite diaphragm positioned between the bag type nickel positive plate and the bag type zinc negative plate; the electrode material of the bag typenickel positive plate is composed of a positive electrode active material, a conductive agent, an additive and a binding agent; the electrode material of the bag type zinc negative plate is composedof a negative active material, a conductive agent, an additive and a binding agent; an electrolyte is an alkaline solution containing additives. According to the secondary battery, the formula of thepositive and negative electrodes and the formula of the electrolyte are optimized and the structure of the battery is adjusted, so that the charge and discharge performance and the cycle performance of the novel zinc-nickel secondary battery are improved, and the application requirements in the industrial field can be further met.

Owner:HENAN NORMAL UNIV

Slurry coating process-based method for preparing thin thermal battery positive electrode and electrolyte combination electrode piece

InactiveCN104681781AAchieve preparationLow costDeferred-action cellsPrimary cell electrodesElectrical batteryCell fabrication

The invention belongs to the field of battery manufacturing, and particularly relates to a slurry coating process-based method for preparing a thin thermal battery positive electrode and electrolyte combination electrode piece. The method comprises the steps: preparing homogeneous thermal battery positive electrode slurry, then coating a conducting substrate with the homogeneous thermal battery positive electrode slurry, drying, solidifying and pressing to obtain a thin thermal battery positive electrode piece; and preparing homogeneous thermal battery fused salt electrolyte slurry, coating the thin thermal battery positive electrode piece with the homogeneous thermal battery fused salt electrolyte slurry in a lamination manner, drying, solidifying and pressing so as to obtain the thin thermal battery positive electrode and electrolyte combination electrode piece. The thin thermal battery positive electrode and electrolyte combination electrode piece prepared by adopting the method has the advantages that the thickness can be reduced by 1 / 3-1 / 2 and is adjustable in the range of tens of micrometers to hundreds of micrometers, and the combination electrode piece has very high values on creating a new way in miniaturizing and thinning thermal batteries and promoting development of national defense industries.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

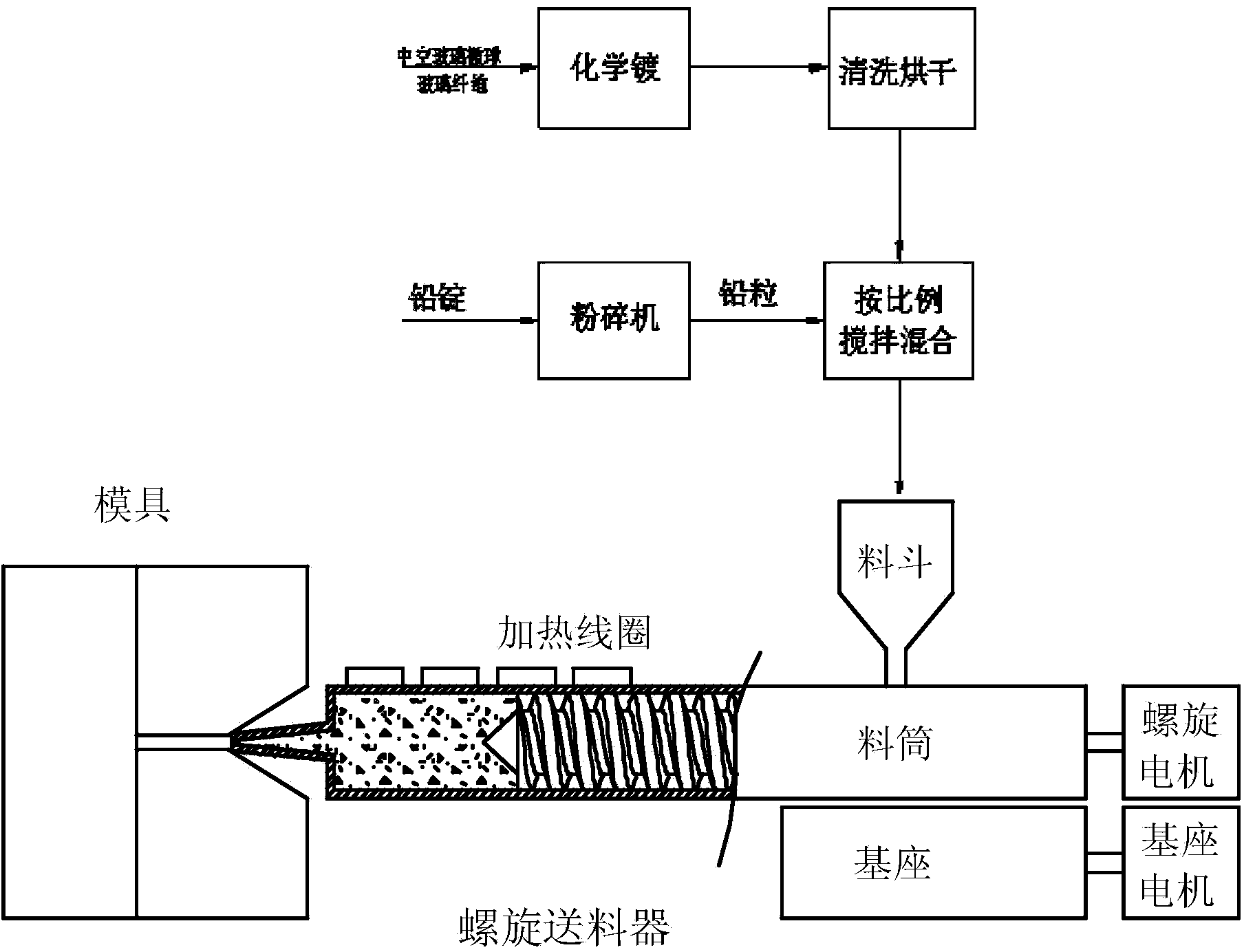

Manufacturing method of current collector of lead-acid storage battery

ActiveCN104241658AThe overall thickness is thinComplex shapeElectrode carriers/collectorsFiberStart stop

The invention provides a manufacturing method of a current collector of a lead-acid storage battery. The manufacturing method comprises the following steps: preprocessing a lead or leaded alloy into particles and uniformly mixing the particles and low-density blended material particles as well as reinforced fibers; heating the uniformly mixed lead or leaded alloy, low-density blended material particles and reinforced fibers to a temperature interval of higher than a melting point of the lead or leaded alloy and lower than melting points of the low-density blended material particles and the reinforced fibers, extruding the mixture into a die to carry out forming processing to form the current collector of the lead-acid storage battery. The current collector manufactured by the technical scheme adopted by the invention has the lowest density of 3g / cm<3>; the largest weight of the current collector can be reduced by 70 percent to the greatest extent; compared with the surface area of a current collector manufactured by a conventional process, the surface area can be increased by 40 percent to the greatest extent; the intensity of the current collector is improved by 200 percent; the current collector manufactured by the manufacturing method can be widely applied to the lead-acid storage battery and is particularly applied to a high-energy-density, high-power and quick-charge start-stop battery.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +1

Preparation method of layered double hydroxide composite material for positive electrode of lithium-sulfur battery

ActiveCN113394381ALarge specific surface areaIncrease loadPositive electrodesLi-accumulatorsLithium–sulfur batteryCation exchange reaction

The invention belongs to the technical field of lithium-sulfur batteries, and particularly relates to a preparation method of a layered double hydroxide composite material for a positive electrode of a lithium-sulfur battery. The preparation method of the layered double hydroxide composite material for the positive electrode of the lithium-sulfur battery comprises the following steps: (1) synthesizing AC-FeCoNi; and (2) synthesizing Cu SAs / AC-FeCoNi. Copper atoms are introduced into AC-FeCoNi through an in-situ cation exchange reaction to prepare the Cu SAs / AC-FeCoNi composite material, and the preparation method is simple, effective and easy to operate; and the prepared composite material has high conductivity and high specific surface area, and has a stable three-dimensional structure.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

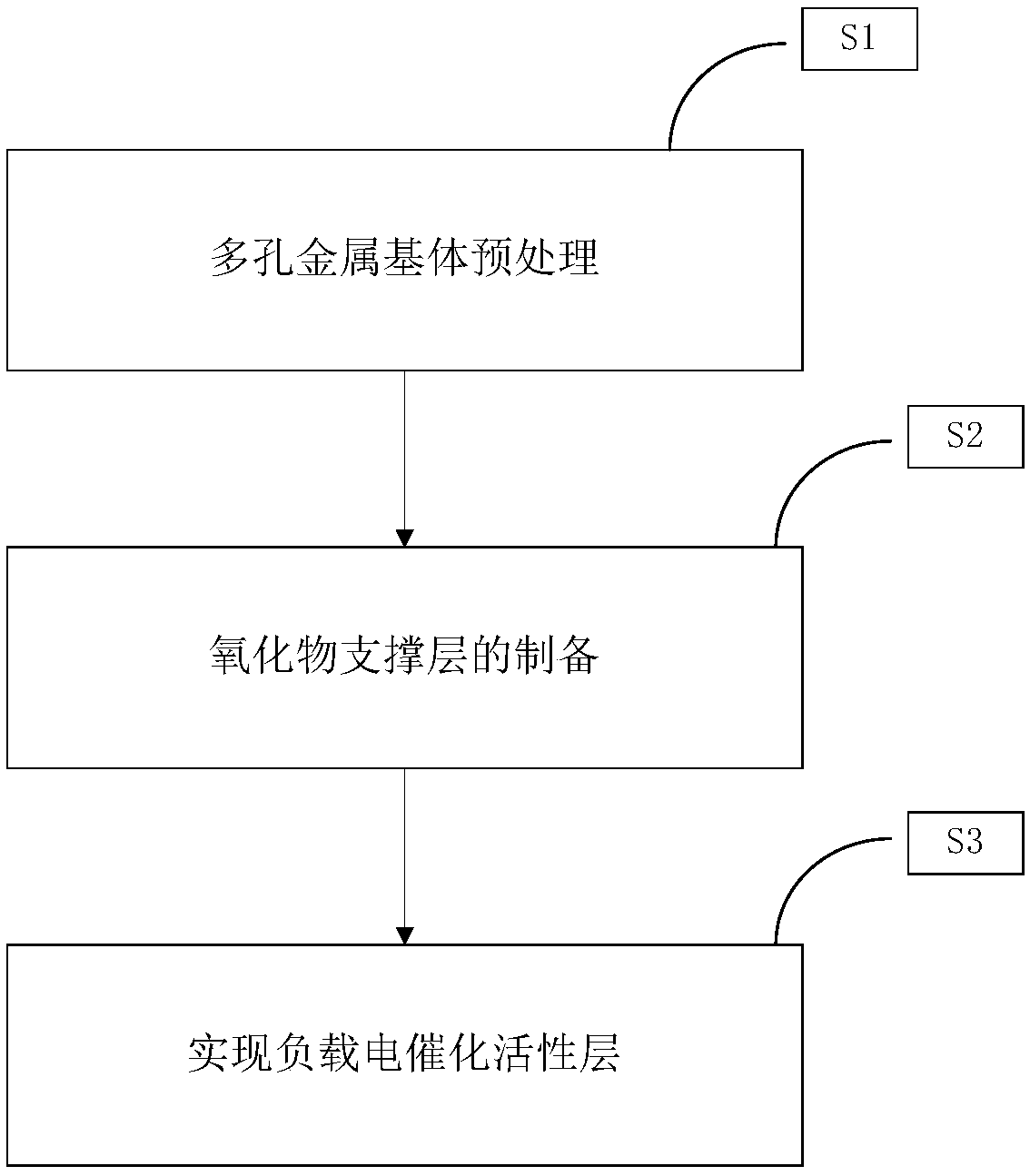

Porous metal aeration electrode capable of producing hydrogen peroxide based on electrocatalysis, and preparation method thereof

ActiveCN109626512AGive full play to the channel effectPromotes poor mass transfer performanceWater/sewage treatment using germicide/oligodynamic-processNano structuringMetal powder

The invention provides a porous metal aeration electrode capable of producing hydrogen peroxide based on electrocatalysis, and a preparation method thereof, wherein the porous metal aeration electrodecomprises a porous metal matrix and an electrocatalytical active layer supported on the porous metal matrix, the porous metal matrix is a porous metal material formed by carrying out pressing sintering on a metal powder material, and the electrocatalytical active layer is a carbon material having a micro / nano structure. According to the present invention, the porous metal aeration electrode has characteristics of high hydrogen peroxide yield, high utilization rate of active material, good mass transfer effect, low energy consumption and long service life; and the preparation method is simple,cannot produce secondary pollution, and can reload and quickly repair the failed aeration electrode.

Owner:BEIJING JIAOTONG UNIV

Preparation method of positive pole piece of high-rate lithium-ion battery

InactiveCN105633353AImprove permeabilityEvenly distributedElectrode carriers/collectorsSecondary cellsHigh rateElectrical battery

The invention provides a preparation method of a positive pole piece of a high-rate lithium-ion battery. The method is characterized by comprising the following steps: firstly, preparing a composite primer liquid; coating the surface of a nickel foam cathode current collector with the composite primer liquid by a gravure printing or spraying technology and drying the nickel foam cathode current collector to obtain a cathode primed piece; and coating the surface with cathode lithium iron phosphate slurry, and carrying out drying and roll-cutting procedures to prepare the positive pole piece. The prepared positive pole piece develops the advantages of high conductivity, high adhesive force and corrosion resistance of a priming coat and the advantage of low volume energy density of a mesh current collector; the cycle performance and the rate capability of the pole piece in the lithium-ion battery are greatly improved; meanwhile, the energy density of the battery is also improved; and the lithium-ion battery prepared from the pole piece is especially suitable for application in a hybrid electric vehicle.

Owner:JIANGSU LENENG BATTERY INC

Rare-earth containing collidal electrolyte solution for accumulator and its preparing method

This invention discloses a colloid electrolyte containing rare earth used in the battery and its preparation method relating to a lead acid battery electrolyte and its method which includes sulfuric acid 34%-37%, sodium silicate 2%-3.5% counted in terms of SiO2, cerous ammonium nitrate 0.05-0.1%, Fe<0.004%. It's difficult for the said electrolyte to become the lean solution since its surface is 10%-15% higher than that of ordinary absorption sulfuric acid electrolyte, the actual capacity is increased, the constant current discharge time is prolonged, its density is high and temperature variance of charge / discharge is small, not easy to form 'heat out-off-control' harm the pole plates.

Owner:谯凤华

Triphenylthiol additive-containing lithium-sulfur battery electrolyte and lithium-sulfur battery

InactiveCN113394460AImprove cycle performanceImprove dynamic performanceLi-accumulatorsElectrolytic agentBenzene

The invention discloses a triphenylthiol additive-containing lithium-sulfur battery electrolyte and a lithium-sulfur battery. The electrolyte comprises an ether solvent, a lithium salt and an additive, and the additive is 1, 3, 5-benzene trithiol. According to the electrolyte of the lithium-sulfur battery, small organic molecule mercaptan 1, 3, 5-triphenylthiol is used as an additive, and triphenylthiol can quickly generate a uniform organic-inorganic SEI layer with a lithium negative electrode in the lithium-sulfur battery, so that the generation of dendritic crystals of the lithium negative electrode is further improved; and meanwhile, a self-binding oligomerization reaction with a sulfur positive electrode in the lithium-sulfur battery can be carried out to generate phenyl polysulfide, so that the generation of polysulfide is reduced, and the dissolution loss of active substances is reduced. The benzene trithiol forms double-layer protection on the positive electrode and the negative electrode of the lithium-sulfur battery, so that the long cycle stability, coulombic efficiency and rate capability of the lithium-sulfur battery are effectively improved, and the lithium-sulfur battery has commercial application potential.

Owner:ZHENGZHOU UNIV

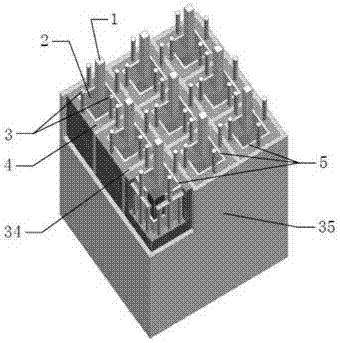

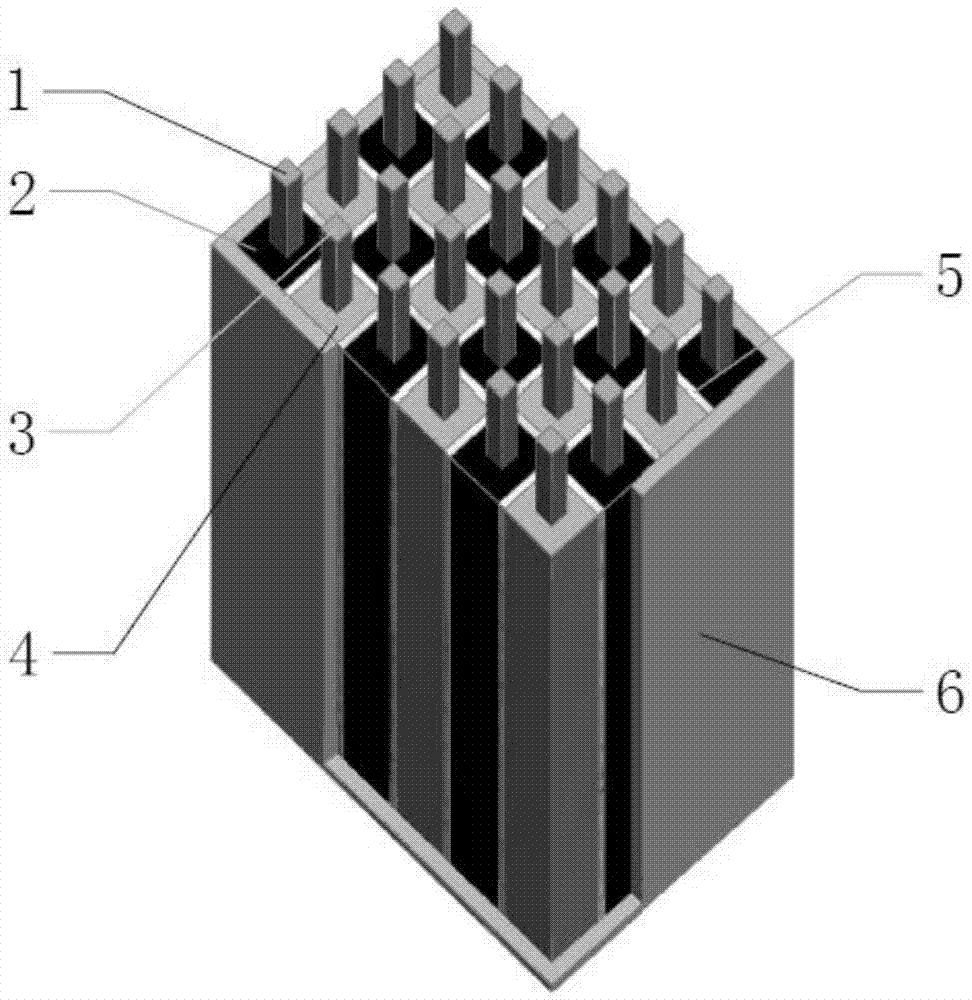

Lead-acid storage battery and lead-acid storage battery pack

InactiveCN107017436AExpand the scope of managementHigh precisionFinal product manufactureLead-acid accumulators constructionPhysical shapeEngineering

The invention discloses a lead-acid storage battery. The storage battery comprises a positive electrode, a negative electrode, a battery shell and a current converging body, wherein the positive electrode and the negative electrode have columnar strip physical shapes; a positive electrode columnar strip and a negative electrode columnar strip are parallel to each other and are arranged in an adjacent or nesting manner; the positive electrode columnar strip and the negative electrode columnar strip are isolated mutually by an isolation plate; each of the positive electrode columnar strip and the negative electrode columnar strip comprises an active material and a current collector; at least one part of each current collector is arranged in the interior or on the surface of the corresponding active material; and one end of each current collector is conductively contacted or combined with the corresponding active material while the other end is conductively connected with at least one kind of the current converging body, a connecting body between batteries or a battery output end point. The invention also discloses a lead-acid storage battery pack formed by the lead-acid storage battery. By means of improving the shapes and the array arrangement structures of the positive electrode and the negative electrode of the lead-acid storage battery, the performance of specific energy, deep discharging, high-current discharging capability, cycling life and the like of the lead-acid storage battery can be greatly improved.

Owner:杨春晓

Method for making thin type silver electrode of silver-zinc battery

InactiveCN1929169AImprove the utilization rate of active substancesLow costAnodisationElectrode manufacturing processesSilver electrodeZinc

This invention discloses one zinc silver battery thin silver electrode process method, which adopts electrochemical oxidation redaction method and uses silver foil as base board and puts it into oxidation liquid then for reduction, clearing and drying and finally in KOH liquid for charging, clearing and drying.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com