High-energy lead-acid storage battery cathode plate diachylon and preparation method thereof

A technology of lead-acid battery and negative plate, which is applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc., and can solve the problems of inability to fully react active substances in lead plaster, poor charging acceptance of sodium lignosulfonate, and problems with auxiliary materials and lead powder. The problem of uneven mixing degree can overcome the premature termination of life, improve the effect of easy precipitation at high temperature, and ensure the anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

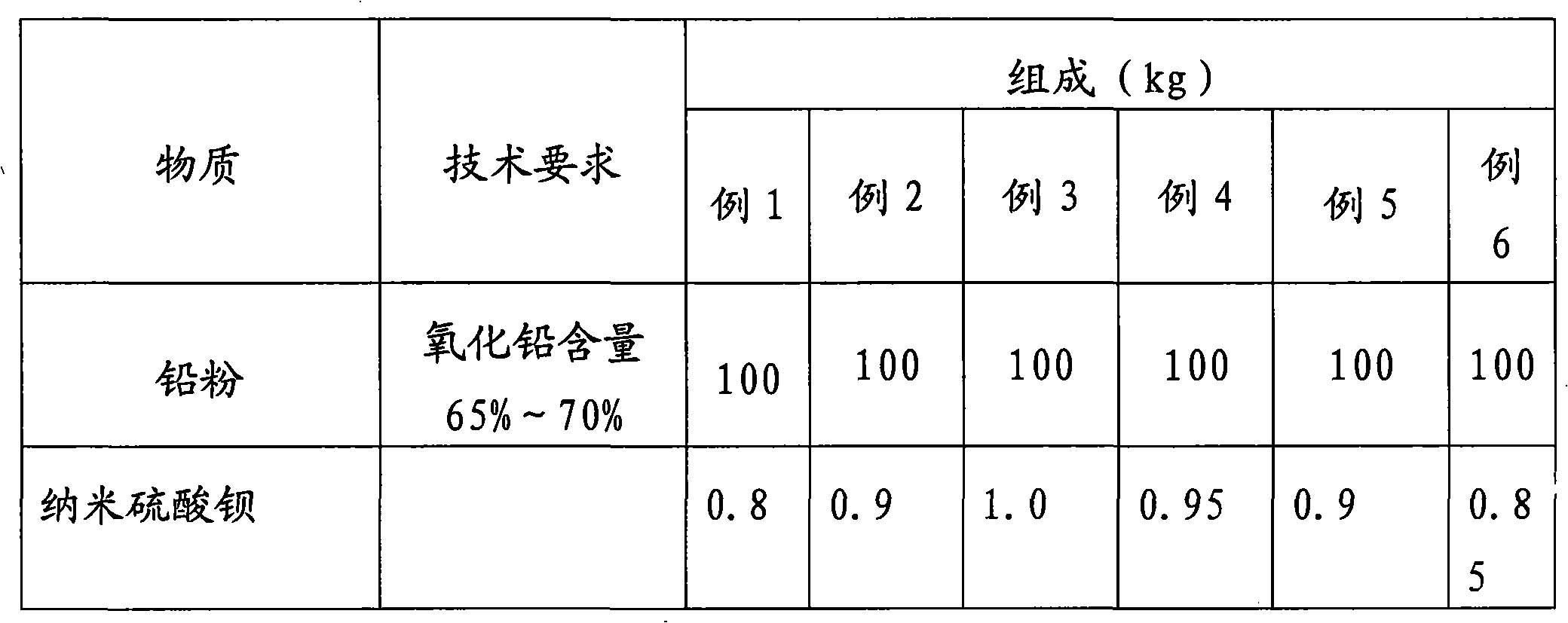

[0032] In order to better understand the technical solution of the present invention, the implementation method of the present invention will be described in detail below in conjunction with examples.

[0033] 1. The composition of the lead paste: as shown in the following table:

[0034]

[0035] Modified Sodium Lignosulfonate

0.1

0.15

0.25

0.2

0.25

0.3

Tannins

0.15

0.1

0.2

0.25

0.3

0.2

Acetylene black

0.2

0.25

0.3

0.25

0.2

0.3

Polyalphaolefin Basics

Oil

0.3

0.5

0.7

0.7

0.9

1.0

0.08

0.09

0.1

0.09

0.085

0.0

95

[0036]

Analytical grade sulfuric acid

Density is

1.400g / cm3

8

9

10

11

10.5

12

pure water

conductivity less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com