Patents

Literature

119results about How to "Do not cause harm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene-coated sulfur/porous carbon composite positive electrode material and preparation method thereof

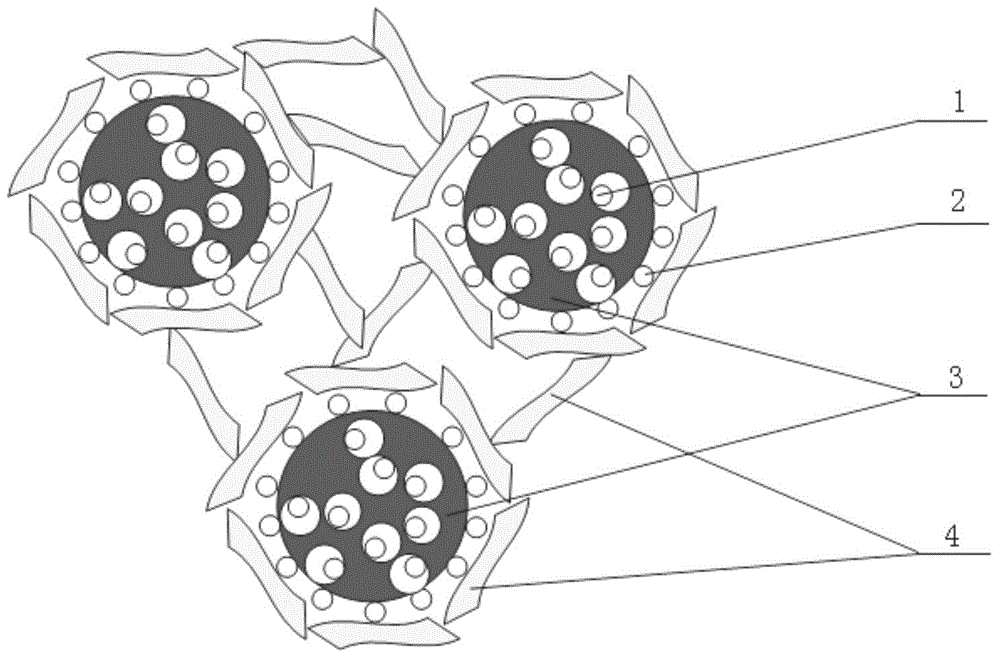

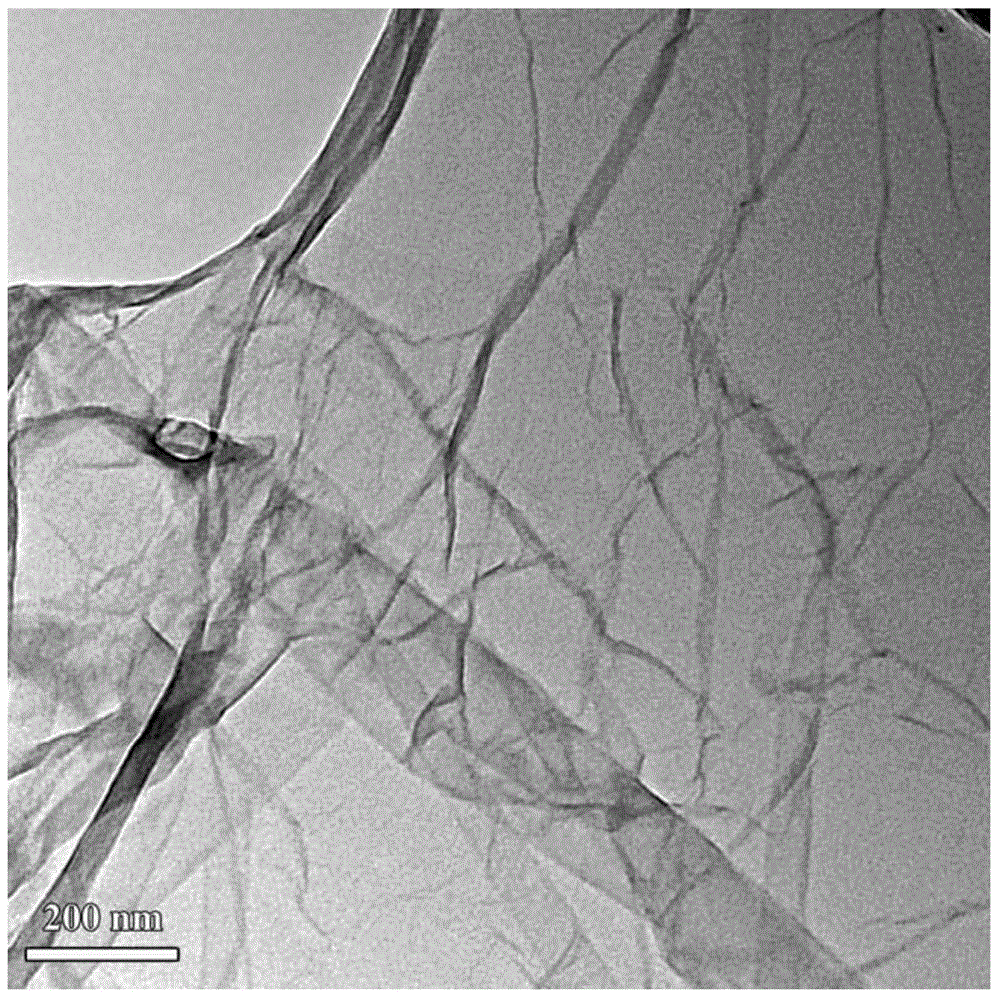

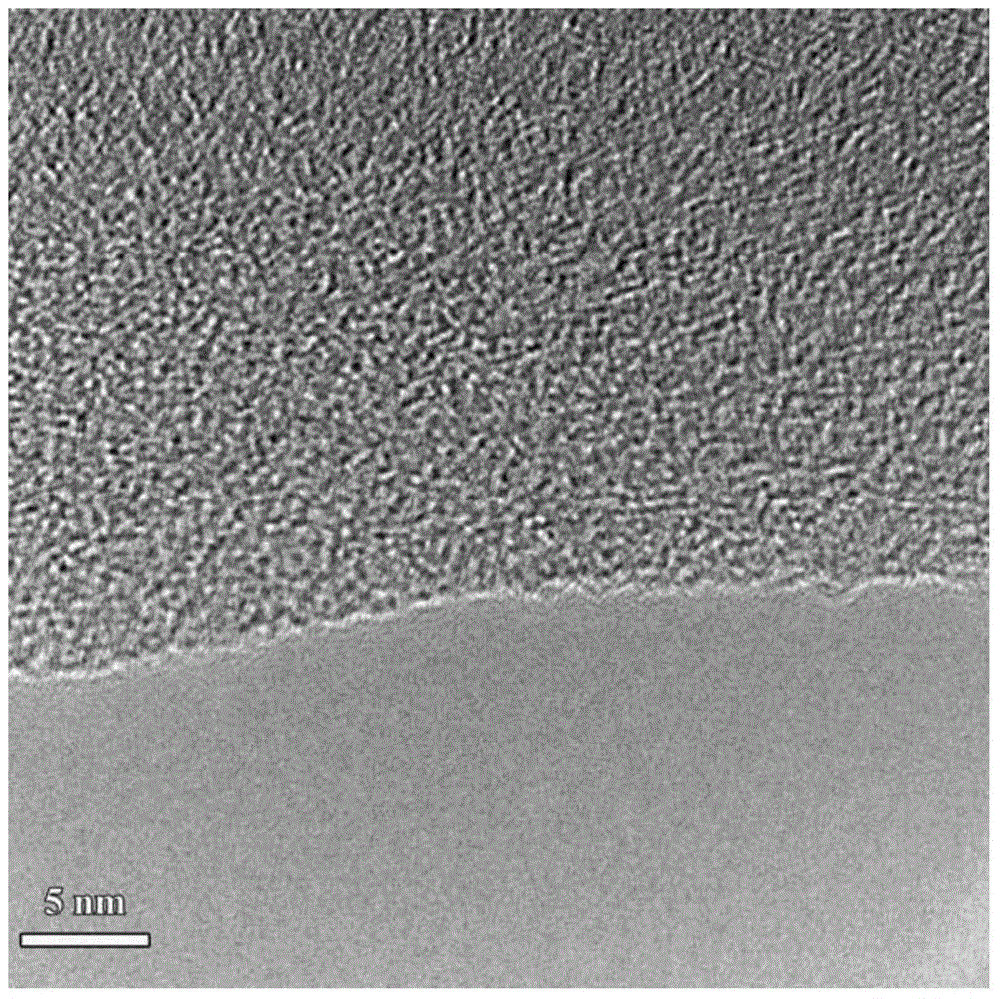

ActiveCN103560235AUnique hierarchical core-shell structureIncrease contentCell electrodesHigh ratePorous carbon

The invention provides a grapheme-coated sulfur / porous carbon composite material and a preparation method thereof, and relates to a grapheme-coated sulfur / porous carbon composite material used as the positive electrode material of a lithium-sulfur secondary battery and a preparation method thereof. The grapheme-coated sulfur / porous carbon composite positive electrode material provided by the invention can be used for solving the technical problem that the existing grapheme-coated sulfur-containing composite material used as the positive electrode material of a lithium-sulfur battery is low in electrochemical properties. The external surface of each of the particles of the grapheme-coated sulfur / porous carbon composite material provided by the invention is evenly covered with a graphene sheet, and a graphene conductive network is formed between the particles; the obtained grapheme-coated sulfur / porous carbon composite material has a hierarchical core-shell structure. The preparation method of the grapheme-coated sulfur / porous carbon composite material is obtained by adding a sulfur / porous carbon composite material to graphene slurry which is stable for a long time and in which graphene sheets are highly dispersed in water for mixing and coating. The positive electrode material has high specific capacity, long cycle life and excellent high-rate performance. Besides, the grapheme-coated sulfur / porous carbon composite material can be used as the positive electrode material of a lithium secondary battery.

Owner:HARBIN INST OF TECH

Polyvinylpyrrolidone modified graphene coated sulfur/porous carbon composite anode material and preparation method thereof

ActiveCN104078685AIncrease contentImprove the utilization rate of active substancesCell electrodesLi-accumulatorsCvd grapheneHigh rate

The invention relates to a polyvinylpyrrolidone modified graphene coated sulfur / porous carbon composite anode material and a preparation method thereof, which relates to a sulfur / carbon composite material applied to a lithium-sulfur secondary battery anode material and a preparation method of the composite material, and solves the technical problem of the existing lithium-sulfur battery anode material graphene-coated sulfur-containing composite material that the electrochemical property is low. The polyvinylpyrrolidone modified graphene coated sulfur / porous carbon composite material is characterized in that the outer surface of a sulfur / porous carbon composite material particle is uniformly coated with a polyvinylpyrrolidone modified graphene slab layer, a graphene conductive network is formed between every two adjacent particles, and a grading core-shell structure is formed. The preparation method comprises the steps of adding the sulfur / porous carbon composite material into graphene slurry modified by the polyvinylpyrrolidone, and mixing the sulfur / porous carbon composite material with the graphene slurry, and coating the sulfur / porous carbon composite material with the graphene slurry modified by the polyvinylpyrrolidone. The anode material is high in specific capacity, long in cycle life and good in high-rate performance.

Owner:HARBIN INST OF TECH

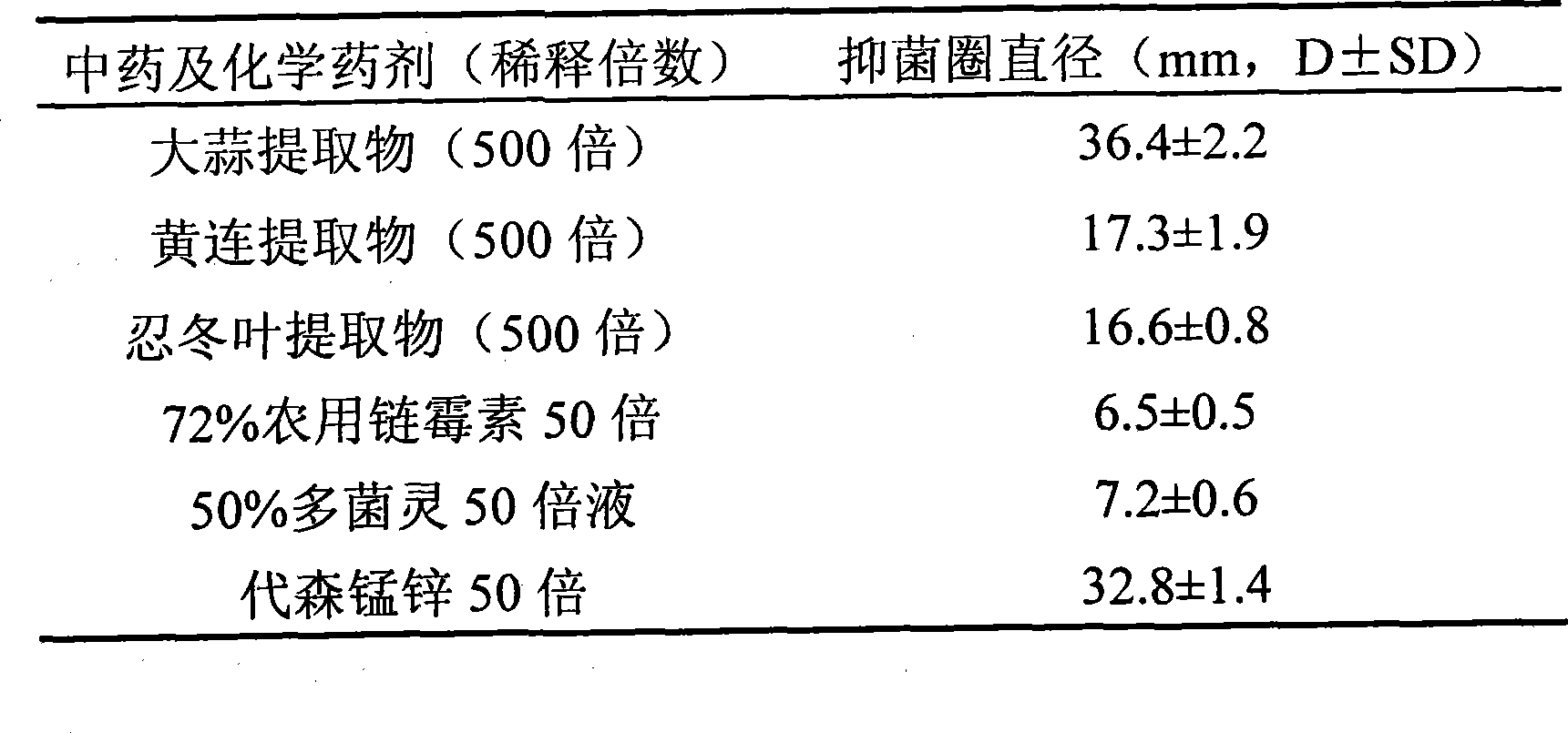

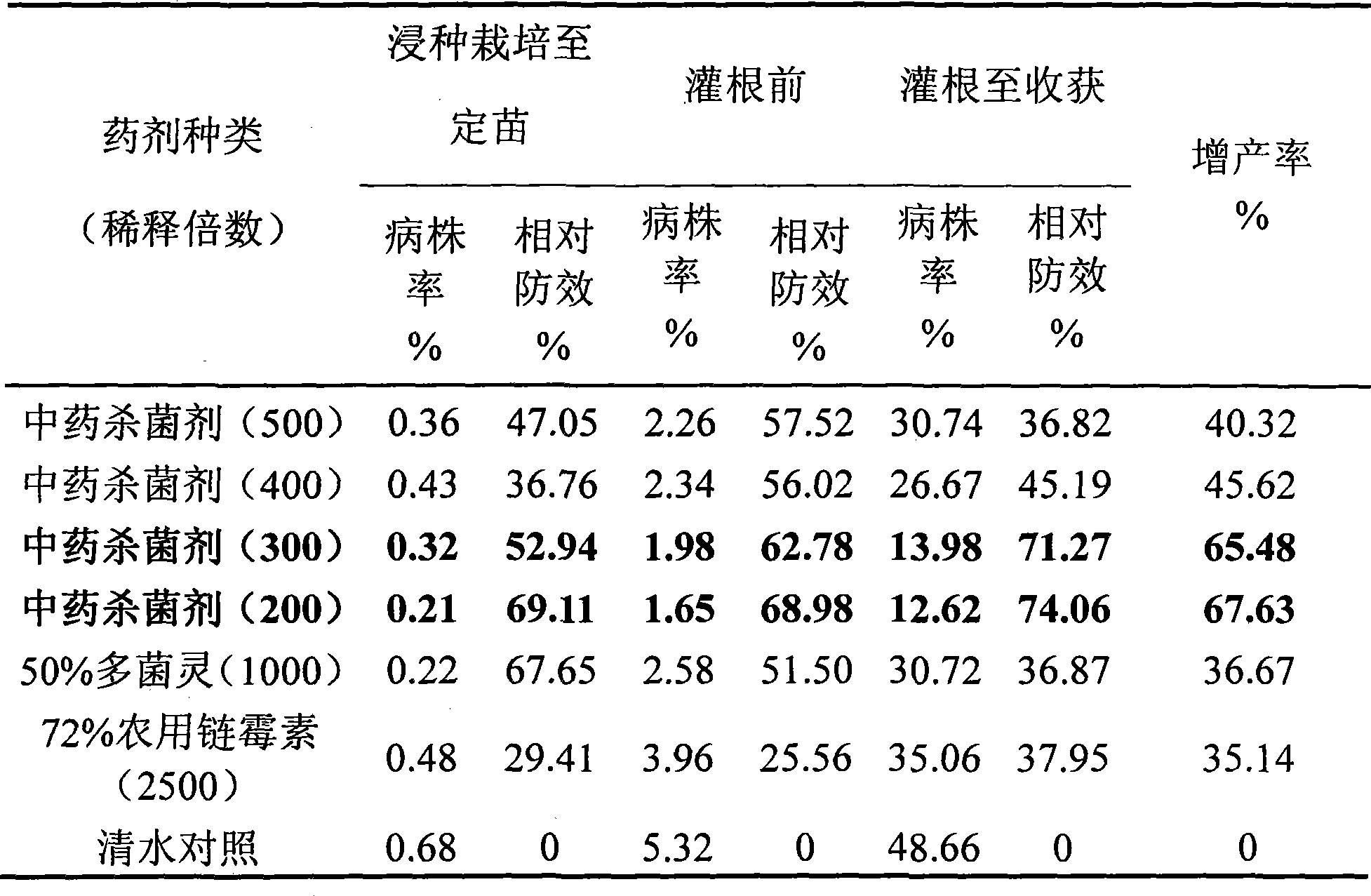

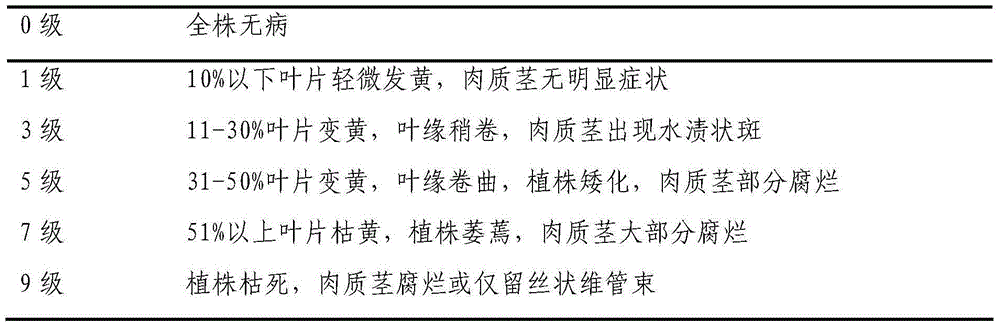

Chinese medicine bactericidal agent for preventing and treating soft rot of konjak

InactiveCN101433221AStrong specificityIncrease drug resistanceBiocideFungicidesPathogenTraditional Chinese medicine

The invention relates to a traditional Chinese medicine bactericide for preventing and controlling soft rot of konjak, and belongs to the filed of insect pests and plant disease prevention and control and biological pesticide. The traditional Chinese medicine bactericide comprises the following components by weight percentage: 12 to 36 percent of garlic extract, 3 to 12 percent of Chinese goldthread rhizome extract, 3 to 10 percent of Flos Lonicerae leave extract, 3 to 5 percent of wettable powder accessory ingredient for farm chemical, and the balance being packing carrier for the farm chemical. The components are compounded into the traditional Chinese medicine bactericide wettable powder which has obvious sterilizing effect on pathogen of the soft rot of konjak, namely Erwinia Aroideae Holland for preventing and controlling the soft rot of konjak. The traditional Chinese medicine bactericide wettable powder is environment-friendly, has strong specificity, is better than chemical agents to prevent and control the soft rot of konjak, has more than 65 percent of relative prevention effect, and can improve the yield of konjak when applied to konjak production, as proved by experiments.

Owner:HUAZHONG UNIV OF SCI & TECH

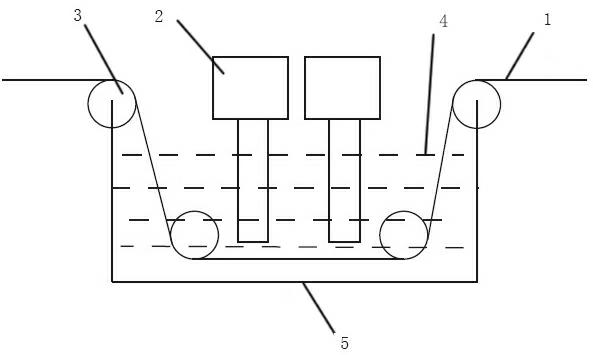

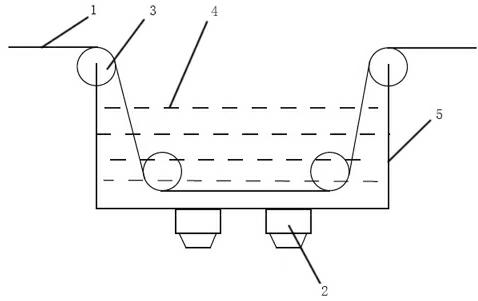

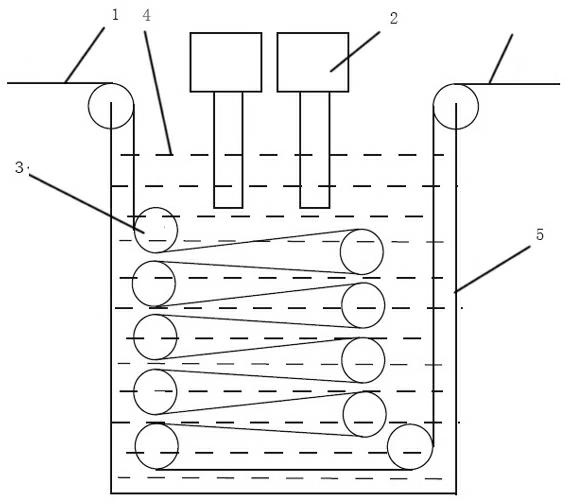

Carbon fiber surface treatment method based on ultrasonic strengthening

InactiveCN102628212AImprove surface morphologyImprove surface roughnessCarbon fibresUltrasonic/sonic fibre treatmentFiberPolymer science

The invention relates to a carbon fiber surface treatment method based on ultrasonic strengthening, comprising the following steps of: soaking carbon fibers into liquid medium in a surface treatment tank, carrying out ultrasonic radiation on the liquid medium by virtue of an ultrasonic generator or an ultrasonic array which is arranged above or below the surface treatment tank, and adjusting ultrasonic processing time according to ultrasonic intensity and frequency, so as to achieve the aim of carrying out the surface treatment on the carbon fibers. The carbon fiber surface treatment method disclosed by the invention has the beneficial effects that: surface morphology, surface roughness and the like of the carbon fibers are improved to improve mechanical properties of carbon fiber composite, and the oil stains produced in the production process of the carbon fiber composite are removed through ultrasonic cleaning at the same time that the carbon fiber is subjected to surface oxidation treatment; and compared with the other traditional methods, the carbon fiber surface treatment method disclosed by the invention has the characteristics of simple treatment equipment, simple and easy operation, no damage to environment, high treatment speed, high treatment efficiency, and easy implementation on assorted online production.

Owner:WUHAN UNIV OF TECH

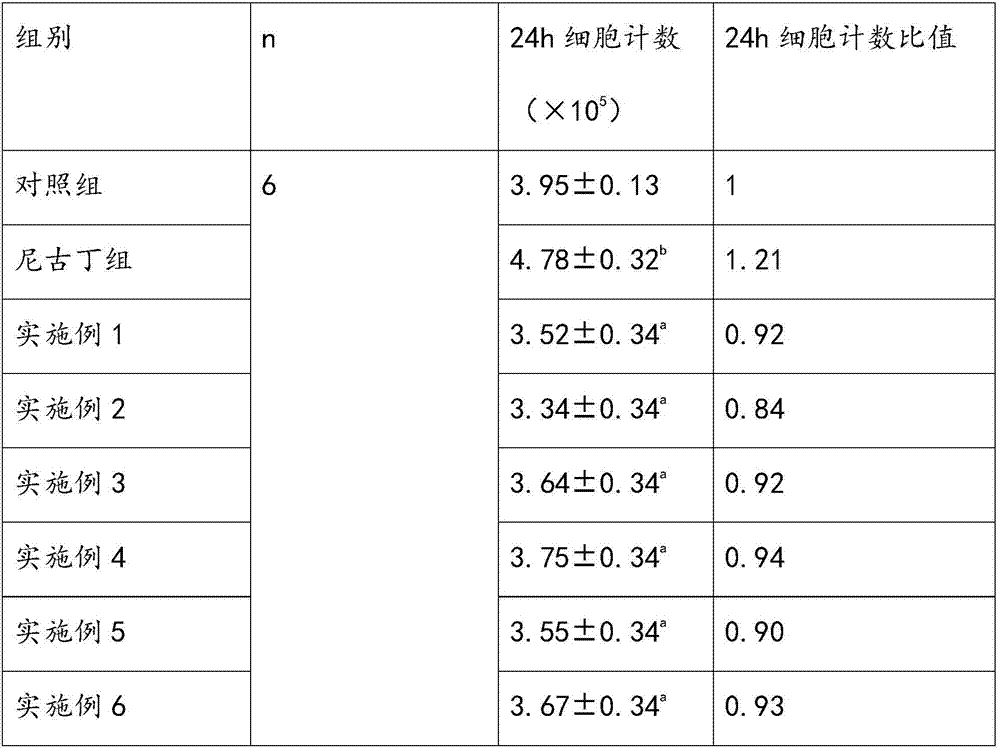

Nicotine ditatrate and preparing method thereof

The invention provides nicotine ditatrate and a preparing method thereof. The method comprises the following step of mixing and stirring organic acid and nicotine to be subjected to a reaction to obtain nicotine ditatrate, wherein nicotine ditatrate is prepared from, by mass, 30-60 parts of organic acid and 40-60 parts of nicotine. Pure nicotine and organic acid are mixed, and the preparing methodhas the advantages of being easy to operate, convenient to manufacture and safe. Prepared nicotine ditatrate is stable in state, the content of nicotine is stable and is not attenuated, the color oftobacco tar is unchanged, the irritation of nicotine is lowered, nicotine is more easily inhaled, the fragrance of electronic tobacco juice is tender, throat hit is comfortable, nicotine ditatrate ismore easily accepted by a user and the production and selling are promoted, nicotine ditatrate is suitable for being widely popularized in the field of electronic cigarettes, and prepared solid nicotine ditatrate does not easily leak in packaging, and is safer and convenient to transport, store and use.

Owner:CHANGNING DEKANG BIOTECH SHENZHEN CO LTD

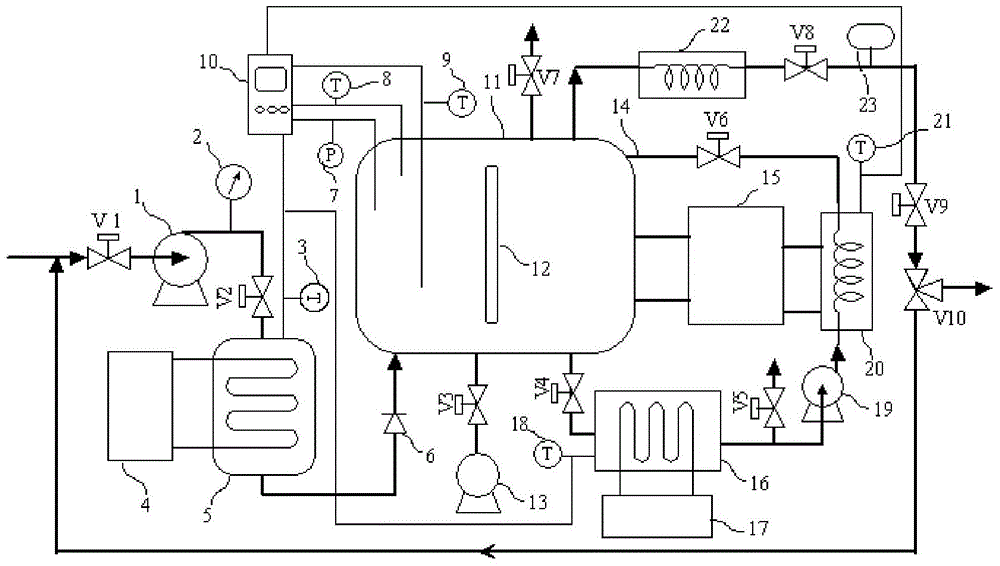

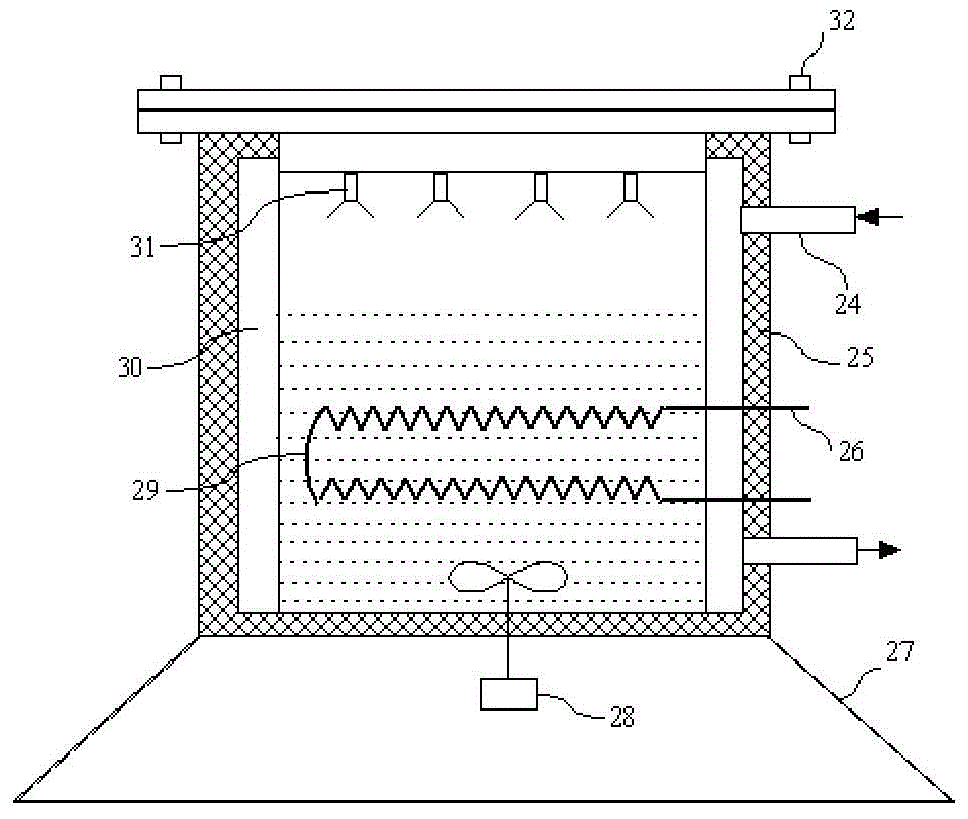

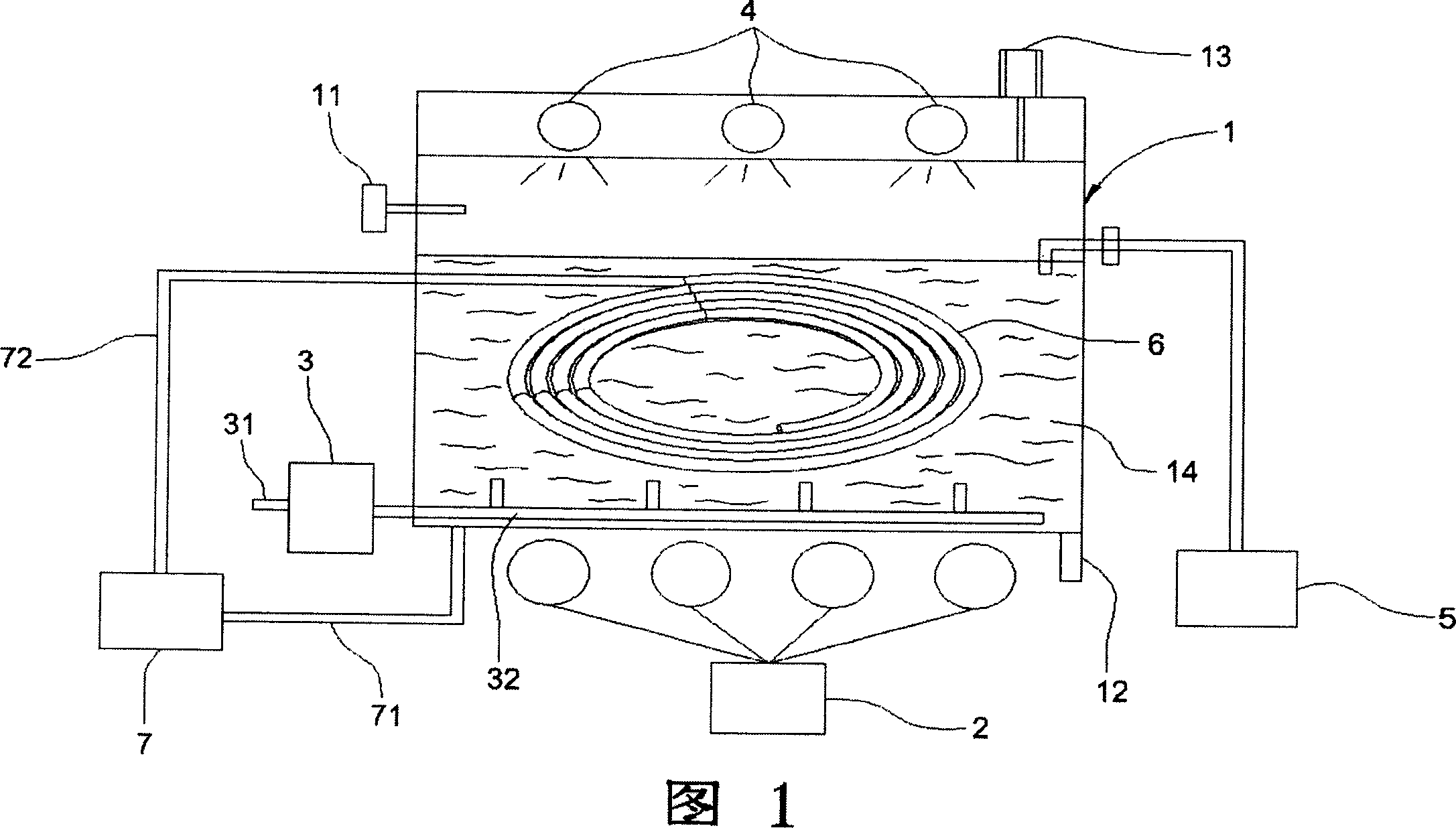

Method and apparatus for separating CO2 in biogas based on hydrate process

The invention discloses a method and an apparatus for separating CO2 in biogas based on a hydrate process. The apparatus comprises a gas booster pump, a gas cooler, a hydrate reaction kettle, a hydrate slurry heater, a liquid booster pump, a liquid cooler, a gas chromatograph, a data acquisition and processing unit, valves and a pipeline; the hydrate reaction kettle is inside plated with a titanium layer for preventing more and more hydrate from being aggregated on the wall of the reaction kettle and solving the problems that a hydrate slurry in a hydrate separation gas is aggregated in the reaction kettle and circulation is not smooth; and the hydrate reaction kettle employs an outer jacket cooling and inner coil pipe cooling method, and also is coated with a thermal-insulation material layer at the outside, so that a large cooling environment in the hydrate reaction process is guaranteed, heat loss is reduced, and also the temperature in the hydrate reaction kettle is uniform. The apparatus structure is simple, the technology is relatively simple, more energy is saved, and the separation effect on biogas is relatively good.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Degradable environment-friendly plant fiber product and manufacturing method thereof

The invention relates to a degradable environment-friendly plant fiber product and a manufacturing method of the degradable environment-friendly plant fiber product, in particular to a flowerpot, tableware, a compressed panel or a tray made of the degradable environment-friendly plant fiber and the manufacturing method of the flowerpot, the tableware, the compressed panel or the tray made of the degradable environment-friendly plant fiber. The raw materials comprise plant fibers from crop straws, food processing wastes, annual wild plant stem parts, bamboos, and woods. The raw materials are added with modified starch and organic pigments to be molded at high temperature to produce the plant fiber product. The degradable environment-friendly plant fiber product has the advantages that the main raw materials can be completely from the wastes of agricultural products; the materials are simple; the cost is low; the product is green and environment-friendly and can be naturally degraded in a natural environment; the production method is simple and high-efficiency; and the product is mild in surface color, high in strength, waterproof and not easy to deform, and can be used for substituting the current products made of plastic, argil and wood, so that the plant fiber product is an ideal degradable environment-friendly plant fiber product.

Owner:李宁

Liquid soap and preparation method thereof

InactiveCN102994279ADo not cause harmSoap detergents with other compounding agentsAlkali/ammonium soap compositionsOrganic chemistryBiomedical engineering

The invention relates to a liquid soap and a preparation method thereof. The liquid soap disclosed by the invention is completely made from natural constituents, does not irritate skin, has no toxic and side effects, and is obvious in skin-cleaning and skin-protecting effects.

Owner:吴妙娴 +1

Organic fertilizer with insect expelling function

InactiveCN104609990ADangerousDo not cause harmBio-organic fraction processingExcrement fertilisersAgricultural residueGleditsia triacanthos

The invention discloses an organic fertilizer with an insect expelling function. The organic fertilizer is prepared from the following raw materials in parts by weight: 5-6 parts of Chinese honey locust, 150-155 parts of fresh sheep manure, 10-15 parts of soybeans, 1-2 parts of garlic, 1-2 parts of clove, 1-2 parts of oil residues, 10-20 parts of waste fruit, melon and vegetable peel, 10-20 parts of fish meal, 5-7 parts of radish peel, 1-2 parts of cassava alcohol residues, 4-6 parts of castor cakes, 5-7 parts of poria cocos, 4-6 parts of astragalus membranaceus, 1-2 parts of pepper leaves, 0.01-0.02 part of trichlorfon, 1-2 parts of red-spotted stonecrop, 2-6 parts of typhonium giganteum, 1-2 parts of radix aconiti agrestis and 0.4-0.5 part of an EM fungicide. The organic fertilizer is prepared through secondary fermentation treatment, is easy in obtaining raw materials, is convenient to use, comprehensive in nutrition, has the functions of yield increase and insect expelling, can do no harm to the soil environment, and is free of pollution or agricultural residues.

Owner:和县宝兰蔬菜种植有限公司

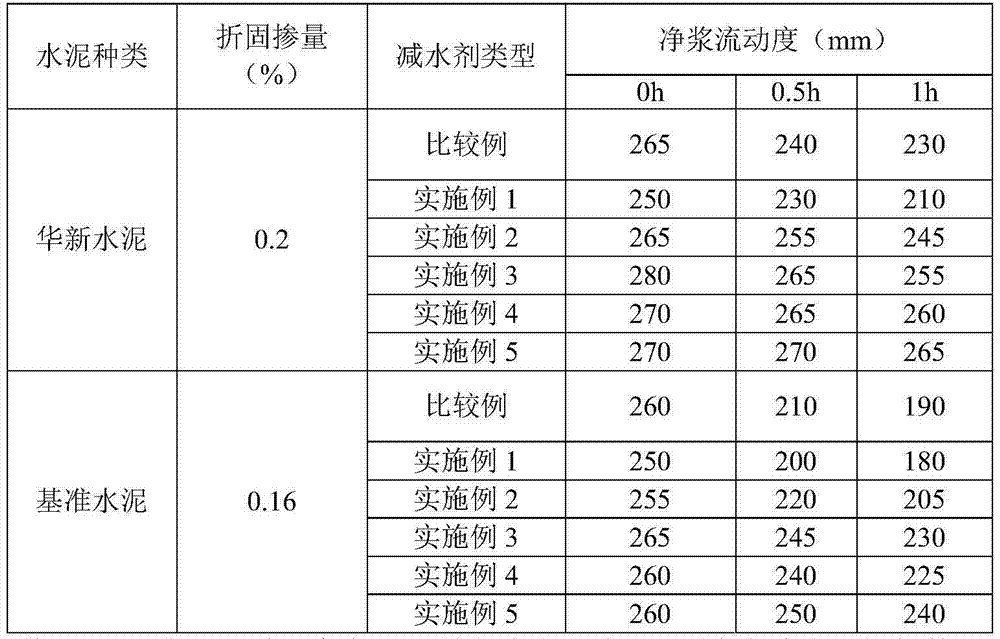

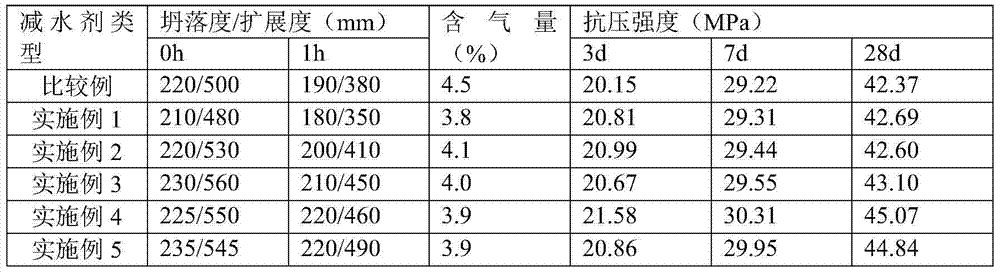

Method for synthesizing solid polyacrylic-series water reducing agents by aid of microwaves at one step

InactiveCN104725574ASimple processReduce production energy consumptionChain transferSaturated carboxylic acid

The invention provides a method for synthesizing solid polyacrylic-series water reducing agents by the aid of microwaves at one step. The method includes adding unsaturated polyoxyethylene ether into a reactor with a stirring device; melting the unsaturated polyoxyethylene ether under microwave conditions, then sequentially adding chain transfer agents, unsaturated carboxylic acid and initiators into the reactor; stirring the unsaturated polyoxyethylene ether, the chain transfer agents, the unsaturated carboxylic acid and the initiators at the temperatures of 20-70 DEG C for 10-30min, and then stopping the polyoxyethylene ether, the chain transfer agents, the unsaturated carboxylic acid and the initiators from reacting with one another; cooling reaction products of the polyoxyethylene ether, the chain transfer agents, the unsaturated carboxylic acid and the initiators until the temperatures of the reaction products reach the room temperature so as to obtain the solid polyacrylic-series water reducing agents. The method has the advantages that microwave equipment with a stirring function is utilized in procedures for preparing the solid polyacrylic-series water reducing agents, so that various materials which participate in reaction can be uniformly mixed with one another without water or other organic solvents, and can completely react with one another, and the solid polyacrylic-series water reducing agents with excellent performance and the content nearly equal to 100% can be obtained under the conditions of specific microwave reaction frequencies, reaction power and reaction time.

Owner:WUHAN UNIV OF TECH

Airplane engine heat exchanger guiding-tube bend filling and technique

InactiveCN101058708AImprove bending qualityStable performance of filling processOther chemical processesHollow article cleaningSodium bicarbonateJet aeroplane

The invention discloses a bending filler and technique of heat exchanger conduit of airplane motor in the machine making domain, which comprises the following steps: allocating raw material proportionally; putting disodium phosphate and sodium bicarbonate in the autoclave; blending 2h; adding stablizier and reinforcer; packing the allocated fill; sealing to reserve. The filling technique of conduit product comprises the following steps: weighing the filler; controlling the temperature after the filler is fused; entering into the working condition; filling the conduit. The cleaning technique is characterized by the following: placing the moulded conduit into cleaning groove; injecting the tap water to heat and stir; controlling the water temperature between 80 and 90 deg. c for 20-30 min; fetching the conduit; draining the solution; repeating 5 times; fetching the conduit to dry; finishing the cleaning process.

Owner:沈阳华铁异型材有限公司 +1

Method for preparing metal material with controllable long and deep through holes

The invention belongs to the field of material preparation and processing, and relates to a method for preparing a metal material with controllable long and deep through holes. The preparation method comprises the steps of selecting fibers, preparing a preform, and melting and pouring the metal material. The method has the advantage of solving the problems of incontrollable hole diameter, hole depth and distribution of the material with long and deep through holes, and can be used for preparing the metal material with controllable position, porosity, diameter and ratio of depth to diameter of long and deep through holes; the diameter of the long and deep through holes of the prepared material is 0.01-10mm, and the ratio of depth to diameter is 1-500. The preparation of the metal material with the long and deep through holes is simple in process and low in cost, and is easy for industrialization.

Owner:SHENYANG POLYTECHNIC UNIV

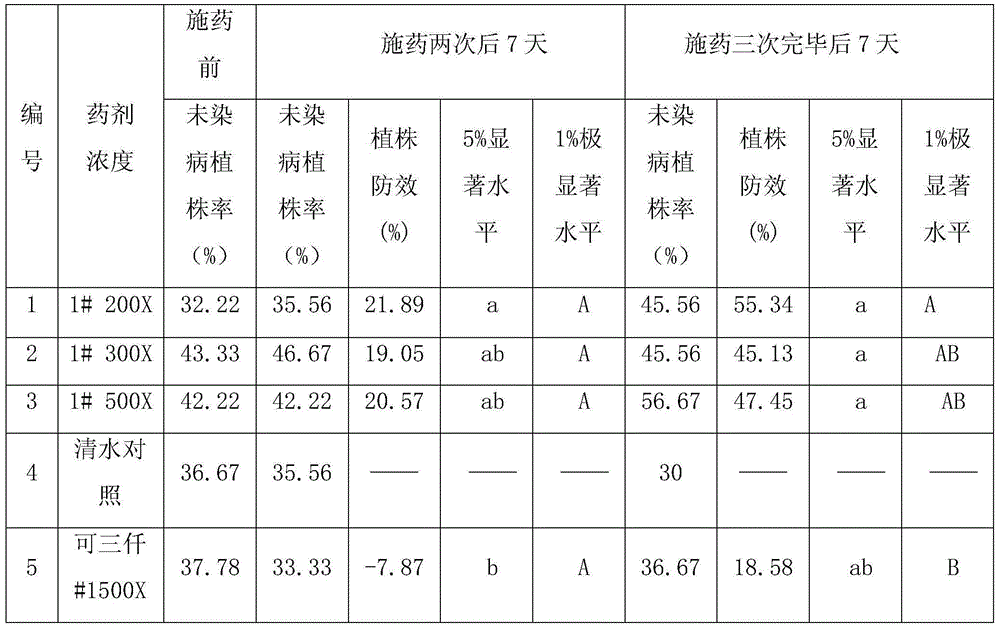

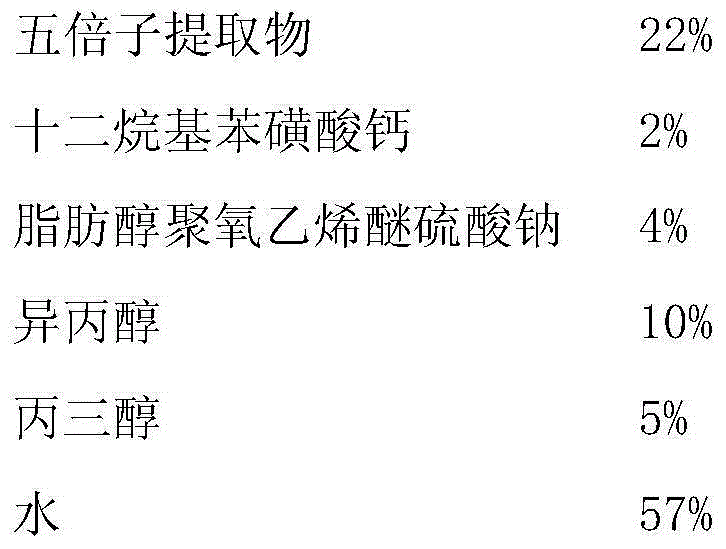

Pesticide for preventing and controlling ginger blast, and preparation method thereof

InactiveCN106561717AEfficient killingEffective controlBiocideFungicidesActive componentRalstonia solanacearum

The present invention relates to a galla chinensis extract-containing pesticide for preventing and controlling ginger blast, and a preparation method thereof, and belongs to the field of pesticides, wherein the galla chinensis extract-containing pesticide comprises the following raw materials by weight: 2-40 parts of an active component, 52-93 parts of a solvent, and 3-8 parts of an auxiliary agent, wherein the active component is a galla chinensis extract. According to the present invention, the galla chinensis extract-containing pesticide can effectively kill Ralstonia solanacearum, effectively prevent and control ginger blast, and has characteristics of rapidness, high efficiency and strong specificity, wherein the field prevention and control effect achieves more than 65%, the raw materials are derived from Chinese herb plants, and the advantages of no residue after use, environmental protection and no toxicity and no harm to human and animals are provided.

Owner:CHENGDU NEWSUN CROPSCI

Traditional Chinese medicine herbicide

InactiveCN105746595AGood weeding effectSuitable for promotionBiocideAnimal repellantsWeedMelia azedarach

The invention discloses a traditional Chinese medicine herbicide.The traditional Chinese medicine herbicide is prepared from the following components in parts by weight: 30-35 parts of Radix Tripterygii Wilfordii, 10-15 parts of Rhizoma Gastrodiae, 25-30 parts of Fructus Cnidii, 18-20 parts of Fructus Quisqualis, 5-12 parts of Cortex Pseudolaricis, 8-10 parts of Melia azedarach L., 5-8 parts of omphalia, 1-3 parts of Semen Abri Precatorii and 2-6 parts of Spina Gleditsiae.The traditional Chinese medicine herbicide has the beneficial effects that the herbicide which is prepared from traditional Chinese medicines can effectively prevent and treat various kinds of weeds, meanwhile does not harm the environment or farmlands, is good in weeding effect, does not harm humans, is suitable for being popularized and meets requirements.

Owner:NANTONG HUIRAN BIOLOGICAL SCI & TECH

Hypothermia sterilization method and apparatus thereof

InactiveCN1961964ATo achieve the effect of decontamination and disinfectionEffectively eliminateLavatory sanitoryChemicalsUltravioletDisinfection methods

The invention relates to a low-temperature disinfection method and relative device, wherein it can disinfect the polluted tools and medical device. It uses ultrasonic wave, ultraviolet and ozone, with the disinfection agent in water solution to clean and disinfect the tools. The invention has wide application.

Owner:丁力行

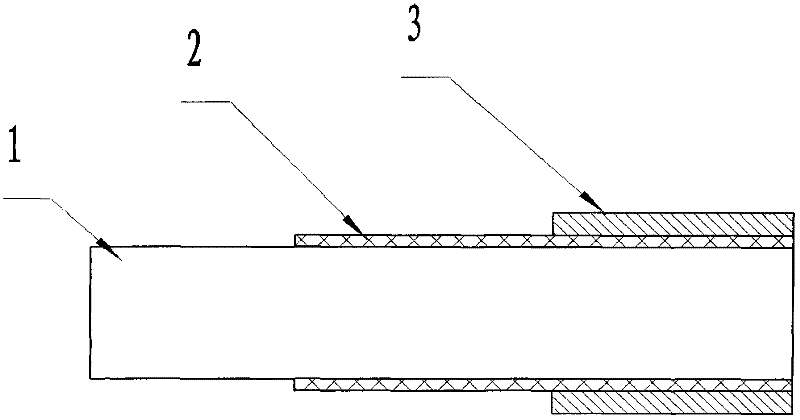

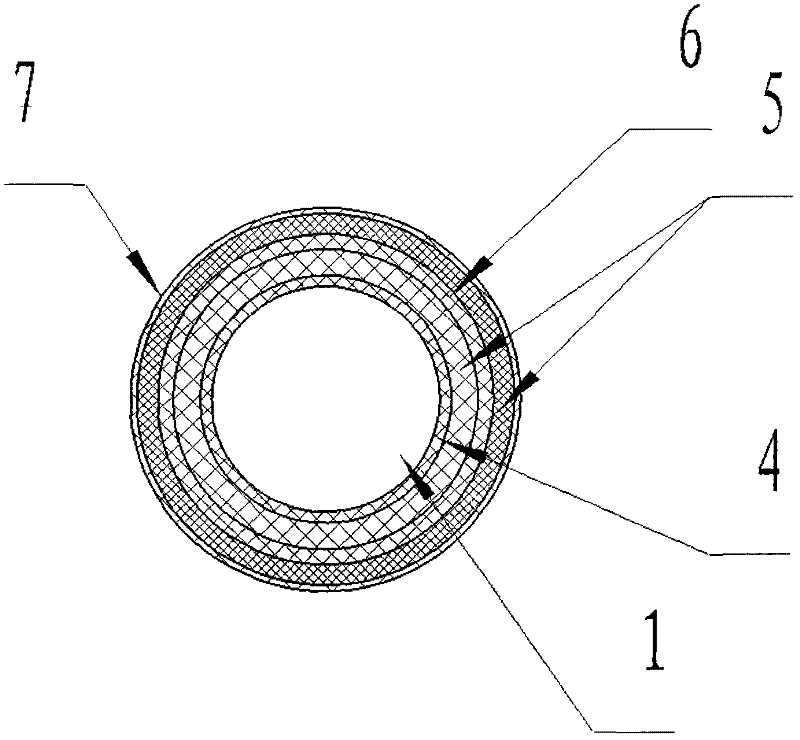

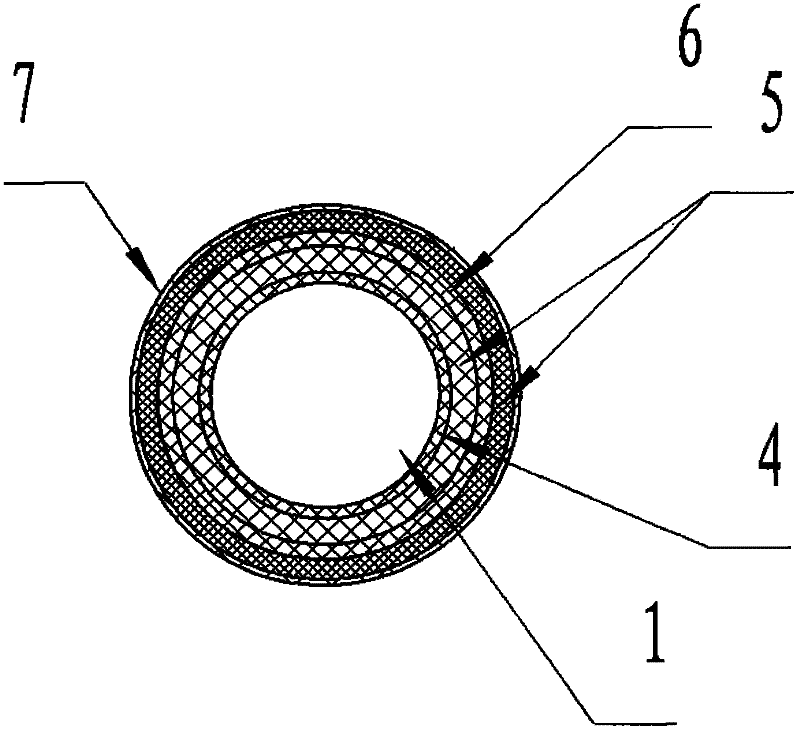

Silicone rubber composite rubber tube lined with polytetrafluoroethylene and manufacturing method thereof

ActiveCN102529181AExpand the scope of useThinLamination ancillary operationsSynthetic resin layered productsPlasma treatmentPolytetrafluoroethylene

The invention provides a silicone rubber composite rubber tube lined with polytetrafluoroethylene, comprising a polytetrafluoroethylene lining tube, a first silicone rubber layer, a reinforced layer and a second silicone rubber layer from inside to outside in sequence. The silicone rubber composite plastic tube solves the problems of low performance of the silicone rubber in oil resistance and solvent resistance, and greatly increases the use range of the silicone rubber tube. Additionally, the invention also provides a manufacturing method of the silicone rubber composite rubber tube, which improves the bonding property of the polytetrafluoroethylene lining tube with the silicone rubber by three methods, and comprises steps of: (1) performing plasma treatment to a polytetrafluoroethylene film belt; (2) tightly winding a layer of glass cloth on the outer surface of the polytetrafluoroethylene film belt after the polytetrafluoroethylene film belt is wound on a mould core so as to make the surface of the polytetrafluoroethylene film belt acquire the same textures to increase the surface area; (3) performing sodium-naphthalene-tetrahydrofuran solution to the outer surface of the shaped polytetrafluoroethylene lining tube to improve the surface polarity and the surface tension of the tube.

Owner:XIAMEN CHUANGXINYUAN RUBBER PROD

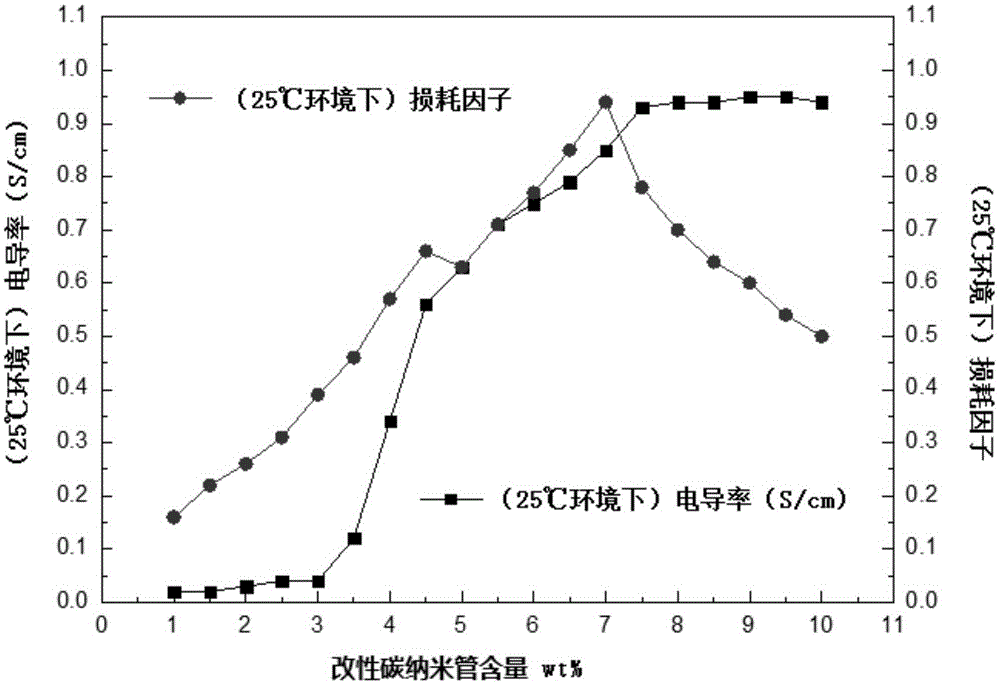

Viscoelastic damping material with good conductivity and preparing method thereof

The invention provides a viscoelastic damping material with good conductivity and a preparing method thereof. The viscoelastic damping material with good performance is obtained by reacting a component A and a component B according to the volume ratio of 1:0.8-1:1.1. The component A is a semi-prepolymer synthesized by 50-70 parts of low-functionality-degree polyisocyanate and 20-50 parts of polyether polyol, the component B is prepared from 25-60 parts of a diamine chain extender, 30-65 parts of amine-terminated polyether and conductive carbon nano tubes, wherein the conductive carbon nano tubes are modified carbon nano tubes, and the weight percent of the conductive carbon nano tubes in the viscoelastic damping material is 5.5-7.0%. The viscoelastic damping material with good performance is capable of accurately controlling conductivity mutation of the conductive damping material in a vadose threshold value region. A conductive phase is capable of forming an intact conductive channel and effectively converting electric charges into heat energy to be dissipated, and can achieve certain self-adaptive damping controlling performance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Leather cleaning agent

InactiveCN101012412ABright and stable colorDo not cause harmNon-ionic surface-active compoundsOrganic detergent compounding agentsGleditsia triacanthosCleansing Agents

The invention discloses an environment-protective leather abluent, which comprises the following parts: 90-97.5% Chinese honey locust and peppertree extract liquid, 1-5% acetate triethanolamine, 1-3% carbowax 6000 and 0.5-2% pingpingjia. The invention makes color fresh on the leather, which protects leather effectively.

Owner:TAIYUAN NORMAL UNIV

High-strength waterproof gypsum board

The invention relates to a high-strength waterproof gypsum board, which is characterized in that the high-strength waterproof gypsum board consists of 100 weigh portions of semi-hydrated gypsum powder, a proper amount of reticulated polypropylene fiber, 10 weight portions of polymer emulsion, 1 weight portion of expanded perlite, 5 weight portions of glass fiber, 2 weight portions of magnesia, 3 weight portions of calcium oxide, and 68 weight portions of industrial water. The high-strength waterproof gypsum board has the following main characteristics that: 1) the gypsum board has high strength and long service life; 2) the gypsum board is dampproof and waterproof, and effectively prevents from loosening and falling; 3) the gypsum board has no toxicity and pollution, and cannot cause the harm to people and environment; and 4) the gypsum board has simple process and convenient operation.

Owner:BEIJING BRIDGECOM SE

Environment-friendly isolation paper and preparation method thereof

The invention discloses an environment-friendly release paper and a preparation method thereof. The environment-friendly release paper includes a base paper layer and a pre-coat layer and a release layer coated on its surface in sequence. The raw materials of the base paper layer include: inorganic powder materials, wood Powder, high molecular polymer, lubricant, foaming agent, active agent, anti-sticking agent; The raw materials of pre-coat paint include water, pigment, dispersant, adhesive, thickener, surfactant according to weight parts; isolation The raw materials of the layer coating according to weight include: water-based high molecular polymer, adhesion promoter, photoinitiator, and leveling agent. The invention has low cost, and the prepared release paper has the characteristics of waterproof, moisture-proof and high strength. It does not use polyolefin materials and solvent-based release agents, is pollution-free, easy to recycle, and does not cause harm to the environment. The used pre-coating paint is solid High content, high viscosity, fast drying speed, high production efficiency, low energy consumption, good film-forming performance of the isolation layer coating used, suitable for advanced curtain coating methods.

Owner:TIANJIN YOUWEI PRINTING PACKAGING

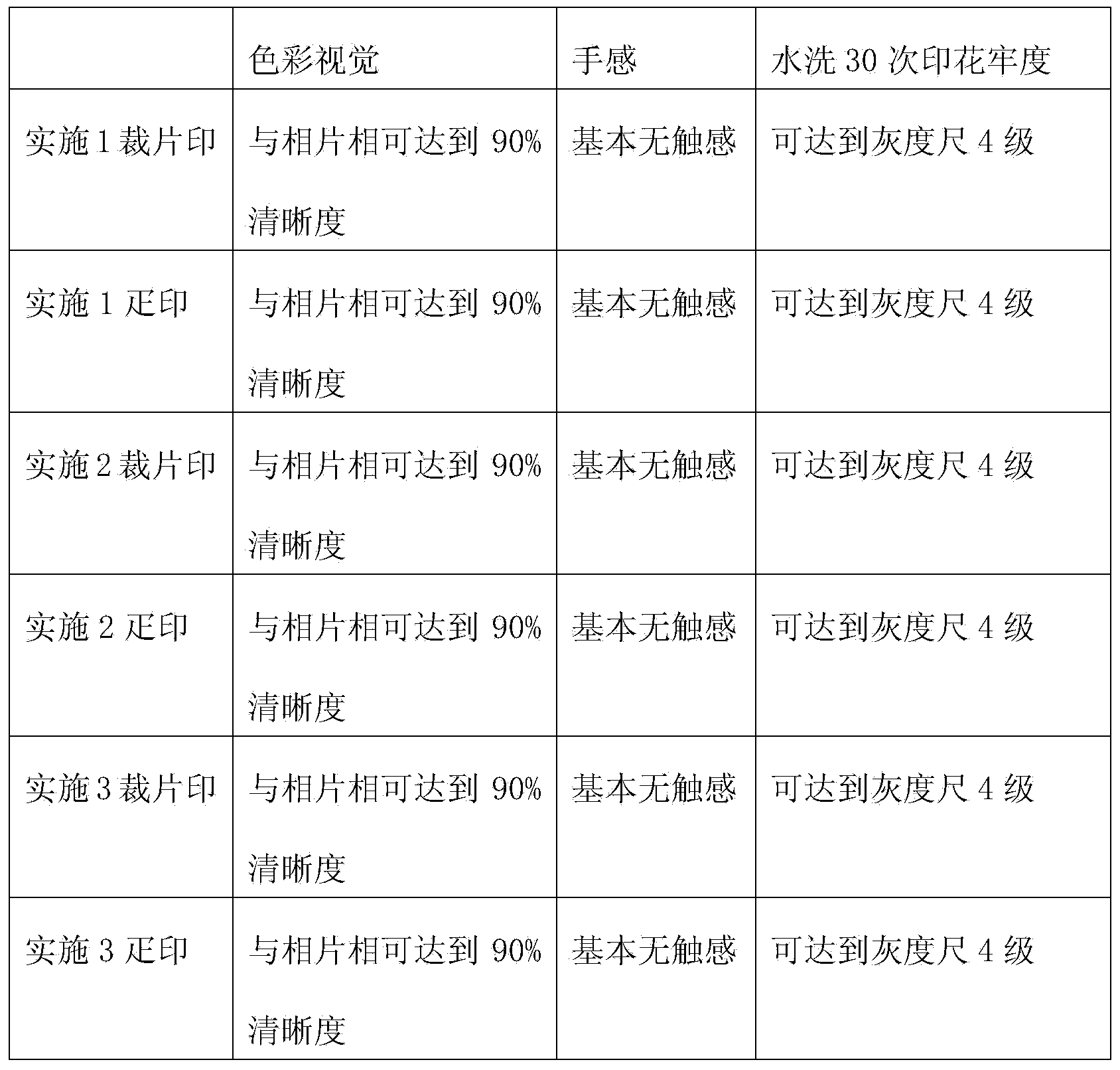

Sublimation transfer printing process for natural fabrics or rayon

InactiveCN103898778ANo touchSoft touchTransfer printing processVegetal fibresPulp and paper industryPre treatment

The invention discloses a sublimation transfer printing process for natural fabrics or rayon. The process comprises the following steps: printing a layer of surface treating agents on cloth, and drying; and printing transfer paper coated with patterns to the cloth printed with the surface treating agents for cooling under the conditions of the temperature of 180-220 DEG C, the pressure of 6-15KG per square inch and the time of 15-20 seconds, and cooling. According to the sublimation transfer printing process, the color and the cloth are totally natural in the process of printing natural fibers, rayon and Leisel cloth, the cloth is non-tactile, is extremely soft in handfeel and vivid in effect, is just like a photo, is almost as vivid as colored rough sketch, is basically not discolored after washing and is also bright and beautiful. In the pretreatment link, only the surface treating agents are sprayed or printed, washing is not needed, only drying is needed, and any damage to the environment is avoided.

Owner:中山市粤漳科技有限公司

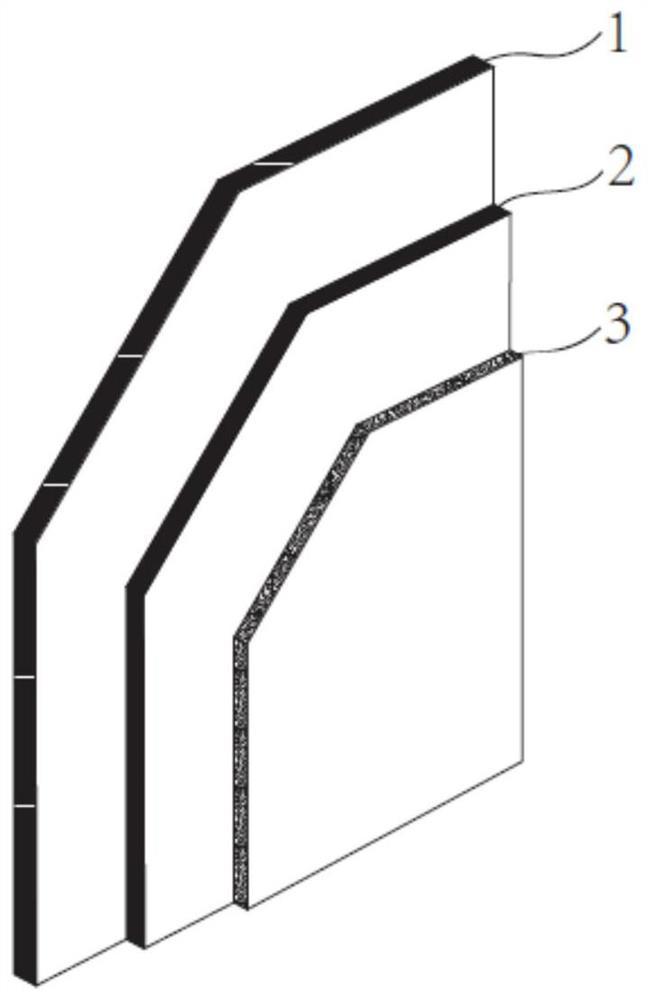

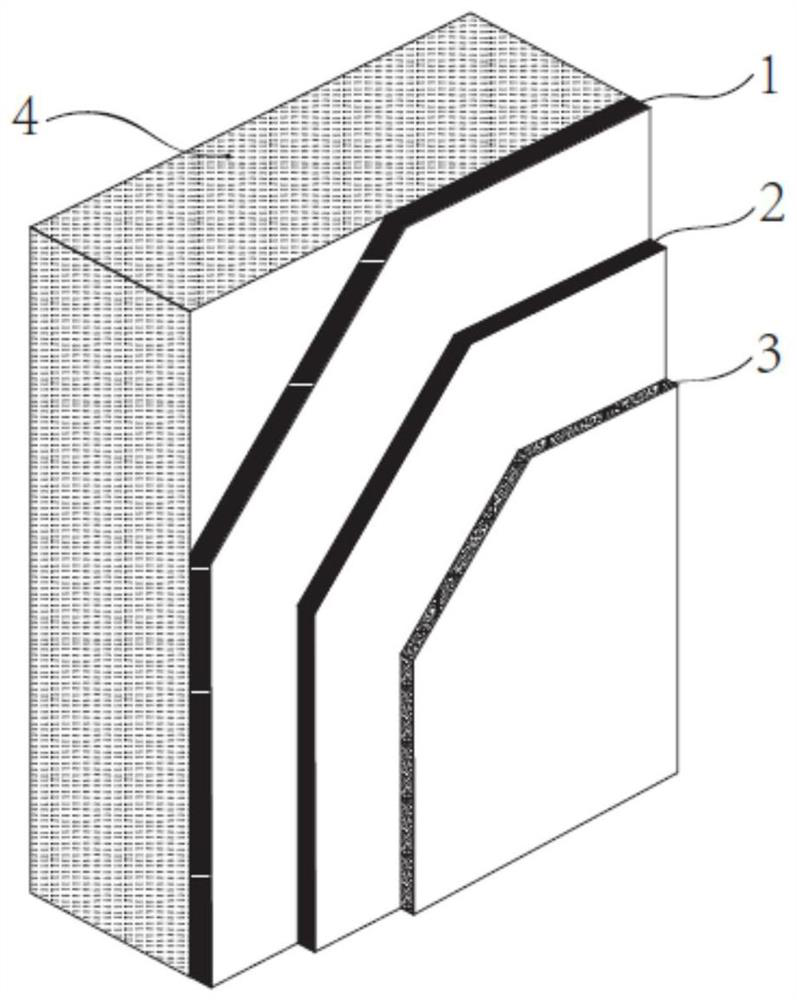

Nano inorganic anti-corrosion, anti-seepage and anti-fouling coating structure for hydraulic concrete

The invention relates to a nano inorganic anti-corrosion, anti-seepage and anti-fouling coating structure for hydraulic concrete, which is characterized by comprising a bi-component high-molecular polymer mortar bonding bottom coating, a bi-component high-strength polymer mortar middle coating and a nano anti-corrosion and anti-fouling protective surface coating, wherein the bi-component high-molecular polymer mortar bonding bottom coating, the bi-component high-strength polymer mortar middle coating and the nano anti-corrosion and anti-pollution protective surface coating are sequentially stacked together. The coating structure has the advantages of corrosion prevention, seepage prevention and pollution resistance, good effect, good stability, easiness in cleaning, lasting effect, good applicability and the like.

Owner:韦尔狄(广州)生物工程科技有限公司

Printing ink with good color fixation and no penetration and production method of printing ink

Owner:HEFEI WANWEI ELECTRICAL EQUIP ENG

Airplane engine fuel oil total pipe bend filling and technique

InactiveCN101054506AStable performance of filling processImprove bending qualityOther chemical processesHollow article cleaningJet aeroplaneSodium bicarbonate

An airplane engine fuel manager bending filling and its craft in machinery manufacturing field are provided. The product preparing craft is correctly weighing material weight by proportion, adding the disodium hydrogen phosphate, trisodium phosphate, sodium bicarbonate by proportion into the material preparing vessel, fully mixing for two hours, adding stabiliser, seal preserving the prepared filling packing. The filling craft of the conduit product is weighing the fillings, enterring the working state after the filling melting achieves the controlling temperature, performing the conduit filling craft. The cleaning craft of the bending conduit product is putting the moulded conduit into the cleaning groove, emitting tap water, heating and stirring, controlling water temperature of 80-90 DEG C for 20-30 minutes, taking out conduit, discharging the water solution, repeating 5 times, taking out conduit and drying. The product and the craft is scientific and novel and has a low cost, a stability to the alloy conduit material non-erosion, alloy conduit bending filling easily being cleaned, and alloy conduit bending filling packing craft.

Owner:沈阳华铁异型材有限公司 +1

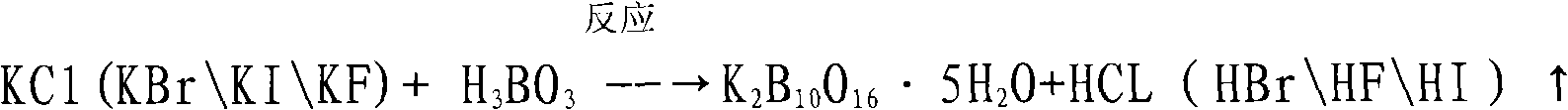

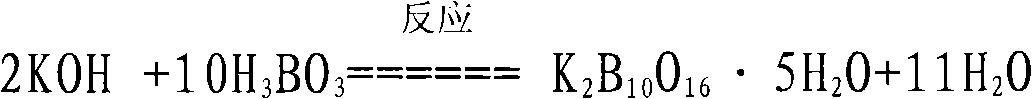

Potassium decaborate fertilizer and method for producing the same

InactiveCN101492311ANo precipitationDissolve fastPotassium fertilisersFertilizer mixturesPotassium fluoridePotassium

The invention relates to a potassium decaborate fertilizer and a preparation method thereof. The method comprises the following steps: a polymerized potassium boron salt potassium decaborate as the main component is prepared by high temperature polyreaction between potassium chloride, potassium bromide, potassium fluoride, potassium iodide or potassium hydroxide and boric acid; the polymerized potassium boron salt is then processed and compounded to prepare the potassium decaborate fertilizer. The product of the invention can be widely applied to various crops.

Owner:安徽省农望农业科技开发有限公司

Method for clearing fouling organisms in saltwater fish aquaculture net cage

InactiveCN102144598AReduce disease riskDocileClimate change adaptationPisciculture and aquariaDiseasePolyculture

The invention discloses a method for clearing fouling organisms in a saltwater fish aquaculture net cage. Fish fry is firstly thrown in the saltwater fish aquaculture net cage, wherein cantherines modestus is polycultured according to according to the ratio of 3-8% of cultured fish fry, preferably 5%, at the beginning of cultivation; the individual size of polycultured cantherines modestus is slightly greater than that of the cultured fish fry; and the overall length accounts for 1.3-1.5 times of the overall length of the cultured fish fry. Through the polyculture of cantherines modestus according to a certain ratio, Cantherines modestus continuously ingests the fouling organisms on a net body of the saltwater fish aquaculture net cage so as to continuously clear the net body; the fouling organisms on the net body can be completely removed basically; therefore, the frequency of replacement of the net body of the net cage is reduced, the injuries and disturbances of the cultured fish are effectively reduced, and the risk of diseases of the cultured fish is decreased.

Owner:MARICULTURE INST OF SHANDONG PROVINCE

Herbicide prepared from pure traditional Chinese medicine materials

InactiveCN106818936AEffective controlDo not cause harmBiocideDead animal preservationWeedMedicinal herbs

The invention relates to the field of pesticide preparations, and discloses herbicide prepared from pure traditional Chinese medicine materials. The herbicide is characterized by being prepared from the following traditional Chinese medicine materials in parts by weight: 20 to 25 parts of leaves of cinnamonum camphora, 4 to 8 parts of saponin, 3 to 6 parts of garlic, 8 to 12 parts of tea-seed cake, 6 to 10 parts of lateral root, fibrous root or leaves and flowers of alangium chinense, 15 to 20 parts of bark of ramulus et folium picrasmae, 12 to 16 parts of rhizoma gastrodiae, 3 to 7 parts of lightyellow sophora root, 1 to 3 parts of orpimentum, 6 to 10 parts of leaves of Chinese toona and 1 to 3 parts of rhizoma coptidis. The herbicide is prepared by adopting the pure traditional Chinese medicine materials and is capable of effectively preventing and treating all kinds of weeds, and meanwhile, the herbicide has no damage to the environment and the farmland; the herbicide is good in weeding effect, has no damage to the environment and the human beings and can be widely promoted and applied.

Owner:陕西绿科生物科技有限公司

Thermal-insulating composite building coating for external wall and preparation method of coating

The invention discloses a thermal-insulating composite building coating for an external wall and a preparation method of the coating. The coating is prepared from components in parts by mass as follows: 40-50 parts of expanded perlite, 8-12 parts of aragonite sand powder, 8-12 parts of liquid sodium silicate, 2-4 parts of liquid potassium silicate, 3-7 parts of silica sol, 3-7 parts of deionized water, 2-4 parts of liquid lithium silicate, 3-7 parts of inorganic acid, 3-5 parts of an expanding agent, 8-12 parts of plant fiber powder and 8-12 parts of water. The thermal-insulating composite building coating for the external wall has the characteristics of low preparation cost, good effect and environment friendliness; tests show that the thermal conduction coefficient of the composite coating is 0.117 W / (m*K), and the density is 700-800 kg / m<3>. The coating is suitable for external thermal-insulation plastering engineering and internal thermal-insulation plastering engineering of walls, built by using reinforced concrete, aerated concrete, laid bricks, sintered bricks, non-sintered bricks and the like, of multistory and high-rise buildings and is also suitable for thermal-insulation improvement engineering of various old buildings currently.

Owner:胡进 +1

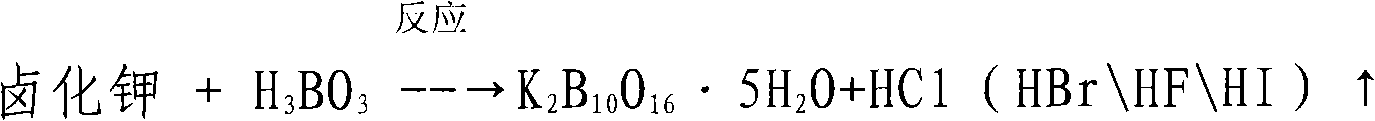

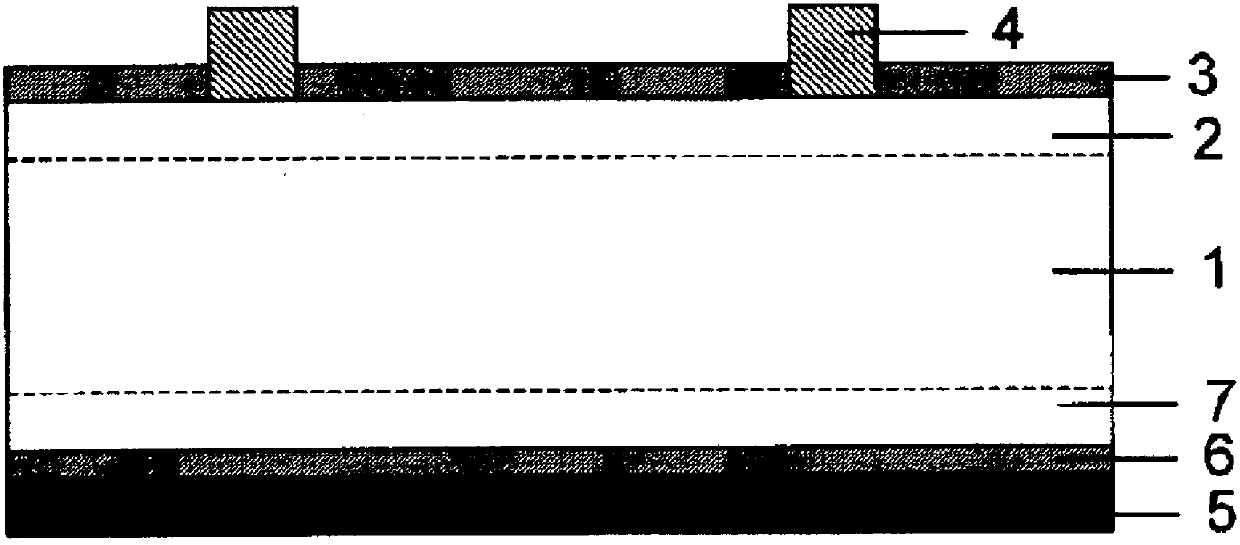

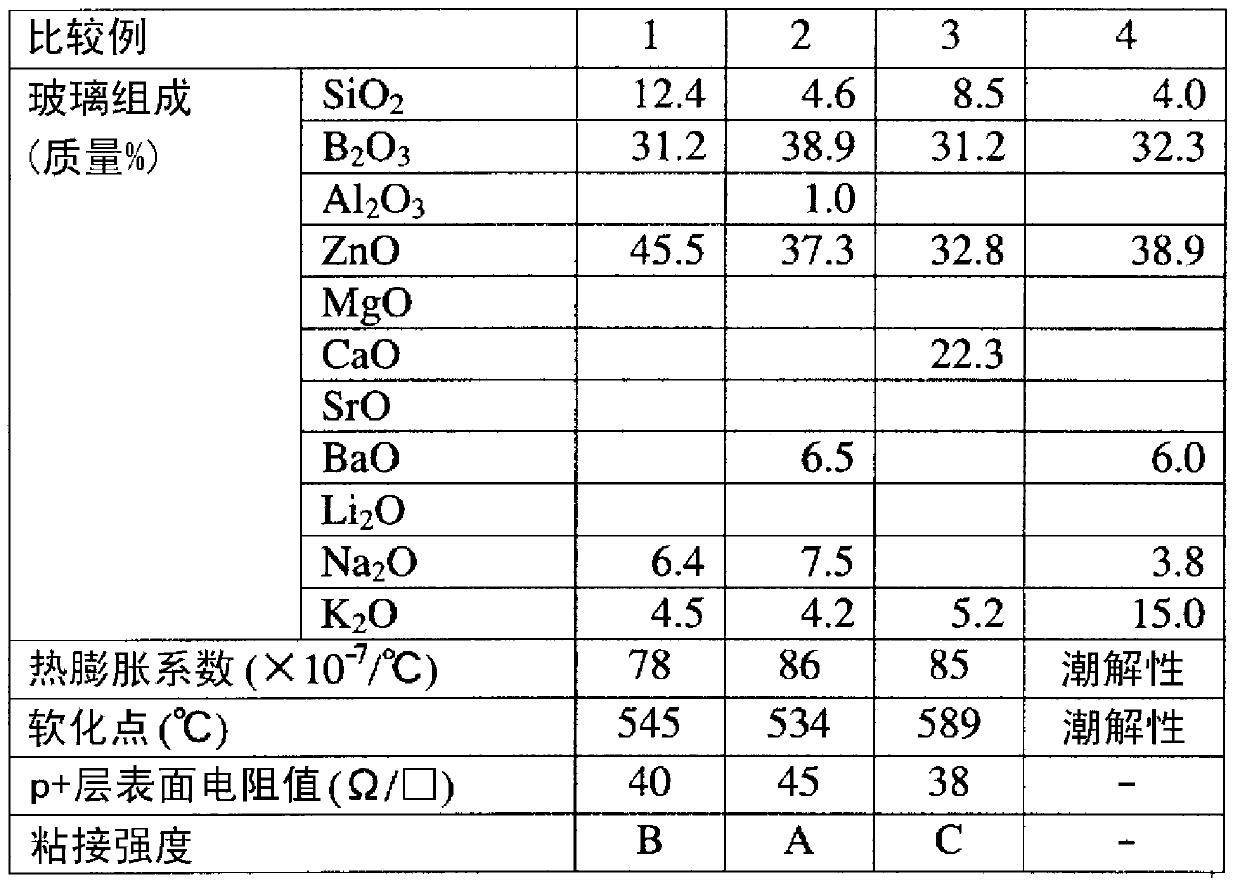

Conductive paste and solar battery cell using said conductive paste

InactiveCN103298759ADo not cause harmHigh BSF effectNon-conductive material with dispersed conductive materialPhotovoltaic energy generationConductive pasteFrit

The objective of the invention is to obtain a non-lead-containing conductive paste which can be used as an electrode formed in a semiconductor silicon solar cell. A conductive paste for a solar cell which uses a semiconductor silicon substrate, the conductive paste characterized in that the composition of the glass frit contained in the conductive paste contains substantially no lead component, and comprises in mass%, 5-15 of SiO2, 20-40 of B2O3, 0-10 of Al2O3, 30-45 of ZnO, 5-30 of RO (total of at least one type selected from the group consisting of MgO, CaO, SrO and BaO), and 0.1-6 of R2O (total of at least one type selected from the group consisting of Li2O, Na2O and K2O).

Owner:CENT GLASS CO LTD

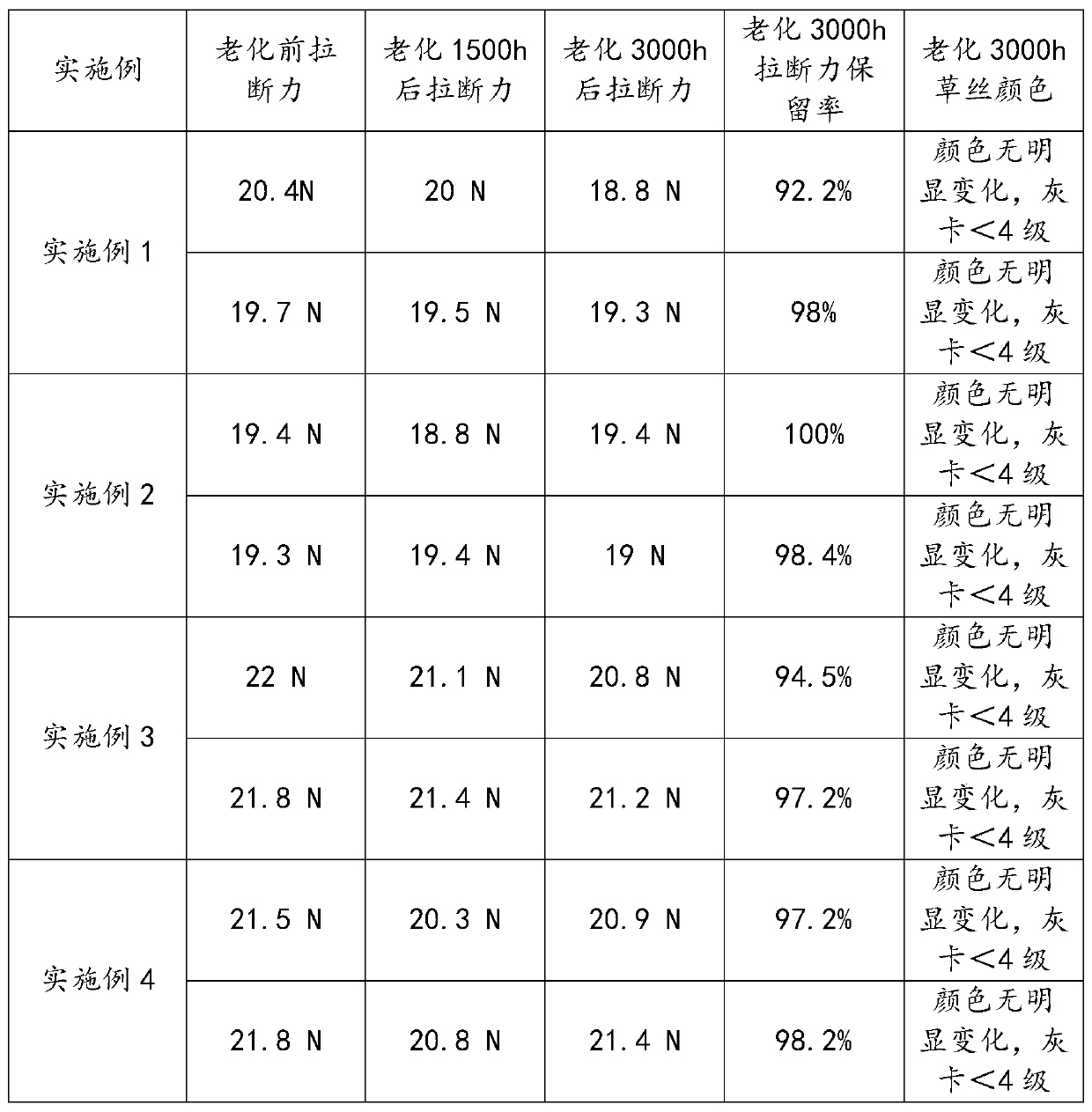

Flame-retardant composition, preparation method thereof, artificial grass yarn, artificial turf backing adhesive and artificial turf

ActiveCN109735913AWith smoke suppressionNon-corrosiveNon-macromolecular adhesive additivesFlame-proof filament manufactureYarnAdhesive

The invention relates to the technical field of an artificial turf and particularly relates to a flame-retardant composition, a preparation method thereof, an artificial grass yarn, an artificial turfbacking adhesive and an artificial turf. The flame-retardant composition contains the following components in parts by mass: 10-30 parts of a nitrogen-containing flame retardant, 40-60 parts of a bromine-containing flame retardant, 5-10 parts of a flame-retardant aid A and 1-3 parts of a flame-retardant aid B, wherein the nitrogen-containing flame retardant is melamine cyanurate, the bromine-containing flame retardant is any one of decabromodiphenyl ethane, octabromoether and ethylene ditetrabromo-o-phenylenimide, the flame-retardant aid A is antimonous oxide or sodium antimonide, and the flame-retardant aid B is 2,3-dimethyl-2,3-diphenylbutane. The flame-retardant composition has a good flame-retardant effect and is applied to the flame retardance of the artificial grass yarn so as to realize an automatic extinguishing effect away from the fire, and the artificial grass yarn has relatively good aging resistance and mechanical property.

Owner:纵横优仪(江苏)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com