Patents

Literature

1338results about How to "Avoid loose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

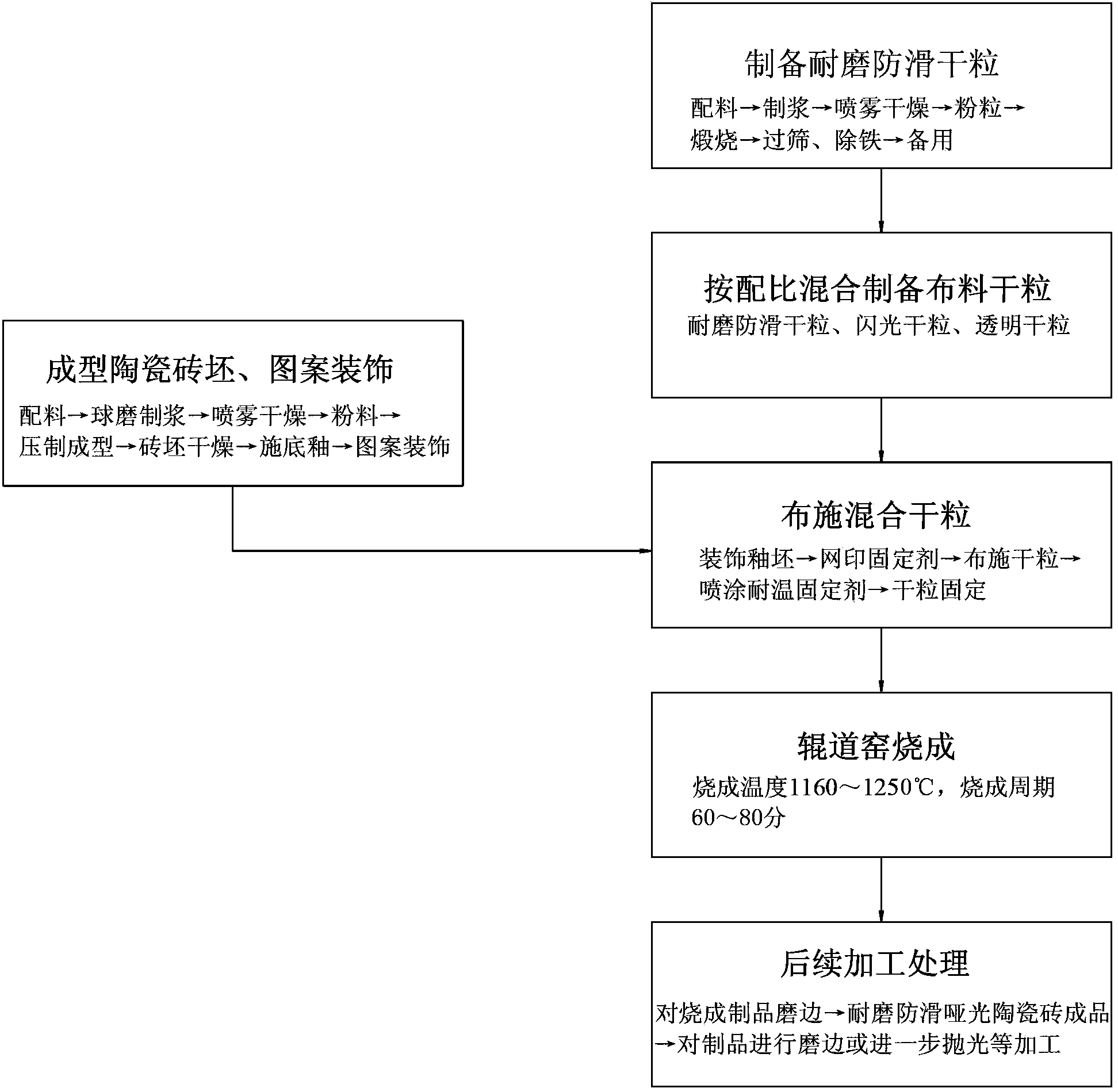

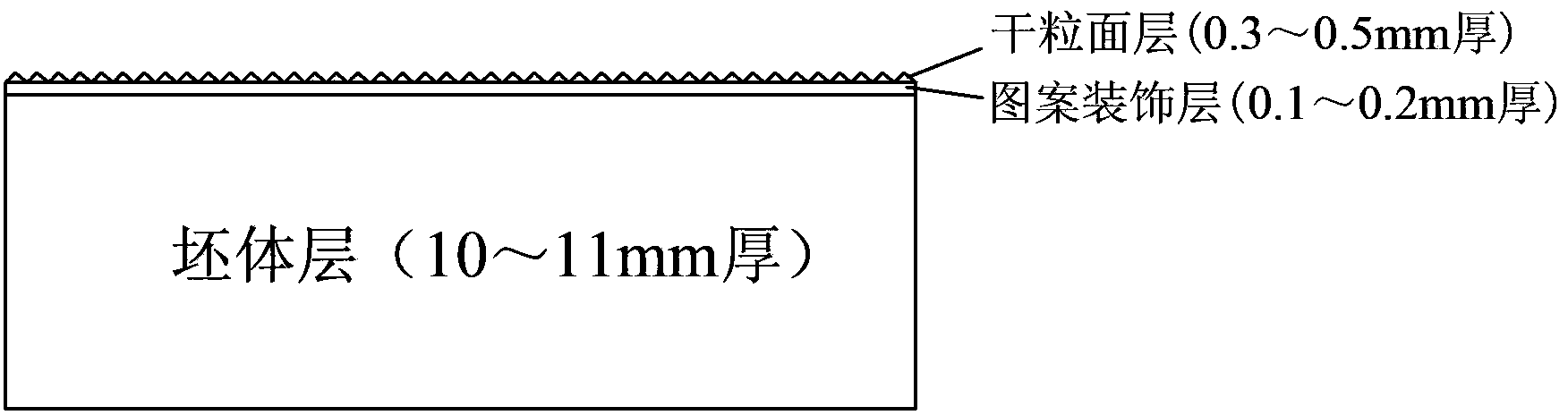

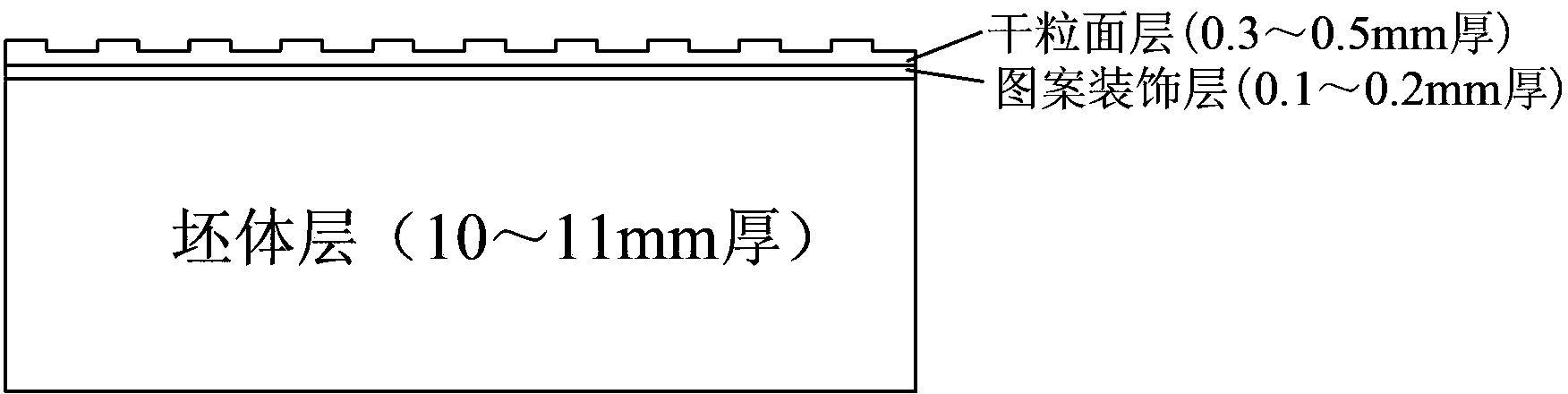

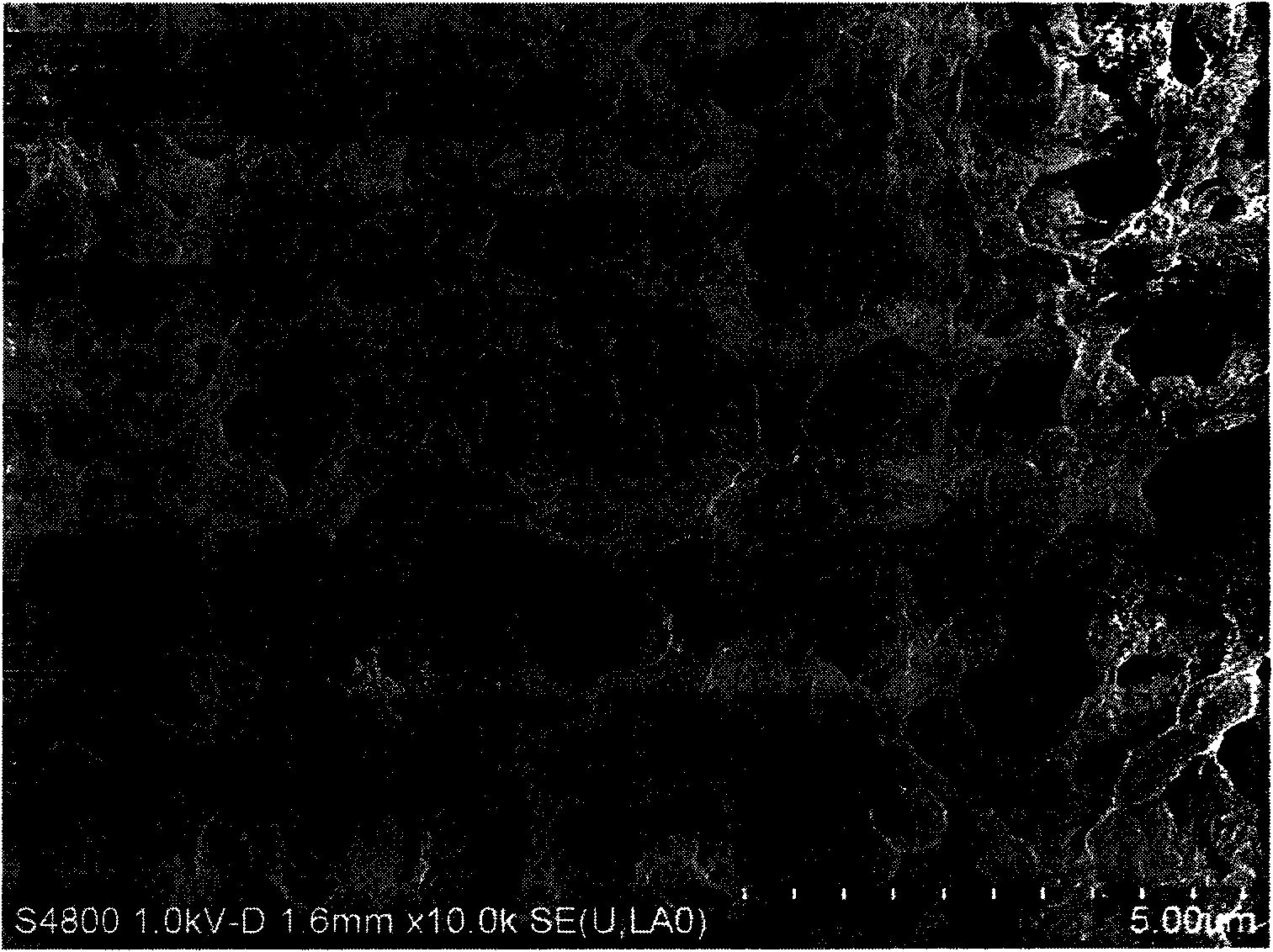

Method for manufacturing wear-resistant antiskid dry-particle ceramic tile

The invention relates to a method for manufacturing a wear-resistant antiskid dry-particle ceramic tile, which comprises the following steps: (1) forming a ceramic tile plane matrix and carrying out pattern decoration; (2) preparing dry particles with wear-resistant and antiskid properties; (3) mixing the wear-resistant antiskid dry particles, flashing dry particles and transparent dry particles according to a certain proportion for distribution; (4) applying the mixed dry particles to the surface of a decorative glazed body and spraying a temperature-resistant fixing agent; (5) conveying the obtained product to a roller kiln for firing and preparing the finished product of the ceramic tile through subsequent processes. According to the method for manufacturing the wear-resistant antiskid dry particle ceramic tile, the dry particles with good wear resistance are mixed with the transparent dry particles and the flashing dry particles, a dry powder distribution mode is adopted and the wear-resistant antiskid dry particles are bulged due to different melting performance of various dry particles in the firing process, so that the problems of wear resistance of the surface and thickness of a wear-resistant layer are solved; by distributing the transparent dry particles, a decorative pattern has a stereoscopic decorating effect under the covering of a glass layer, so that unification of wear-resistant and antiskid properties and decoration of the ceramic tile is achieved.

Owner:JIANGXI HEMEI CERAMICS

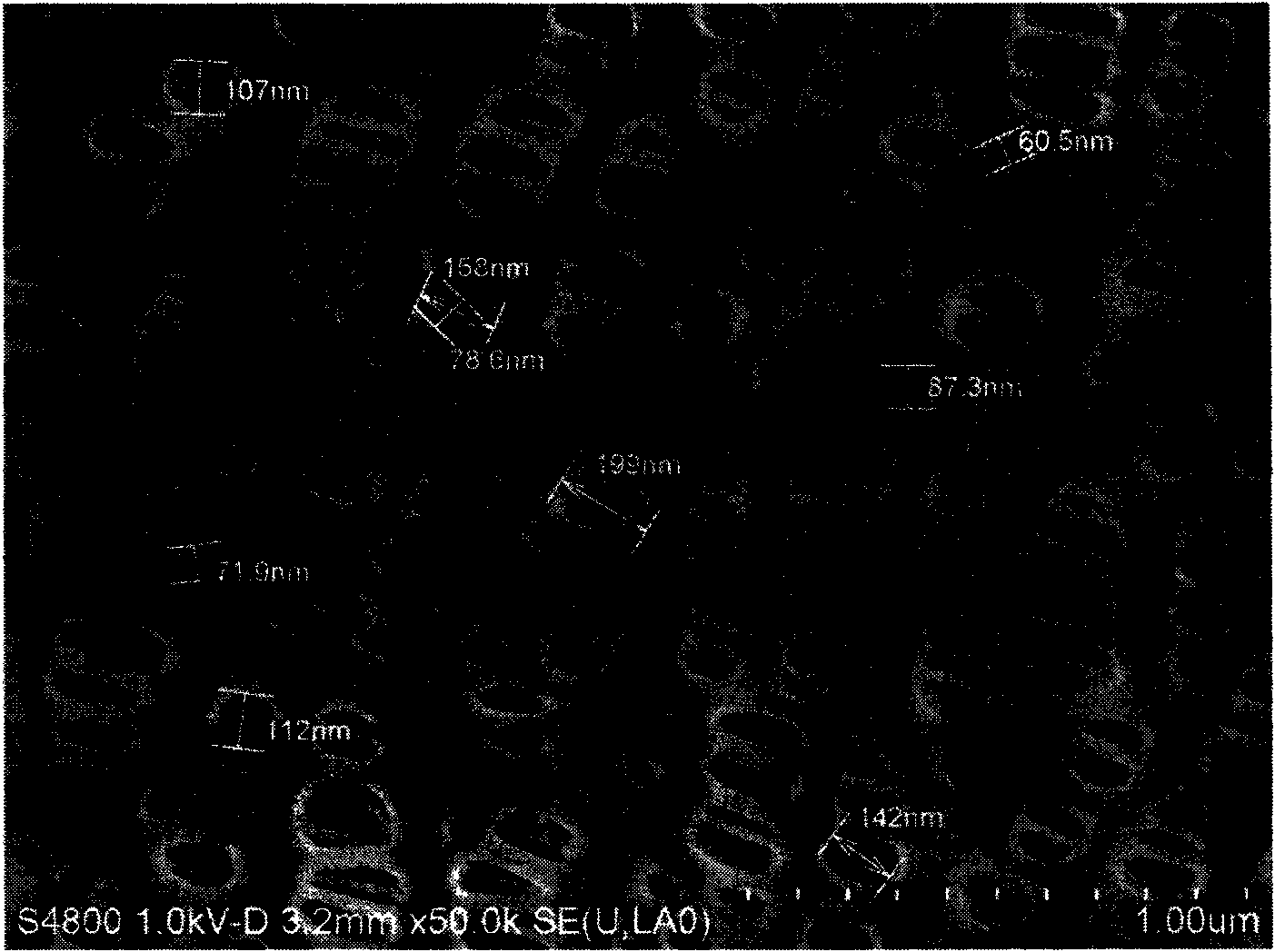

High-liquid absorbing rate micro-nano structure polymer electrolyte membrane and preparation method thereof

InactiveCN101626097AHigh liquid absorptionPromote absorptionSecondary cellsMicro nanoPolymer science

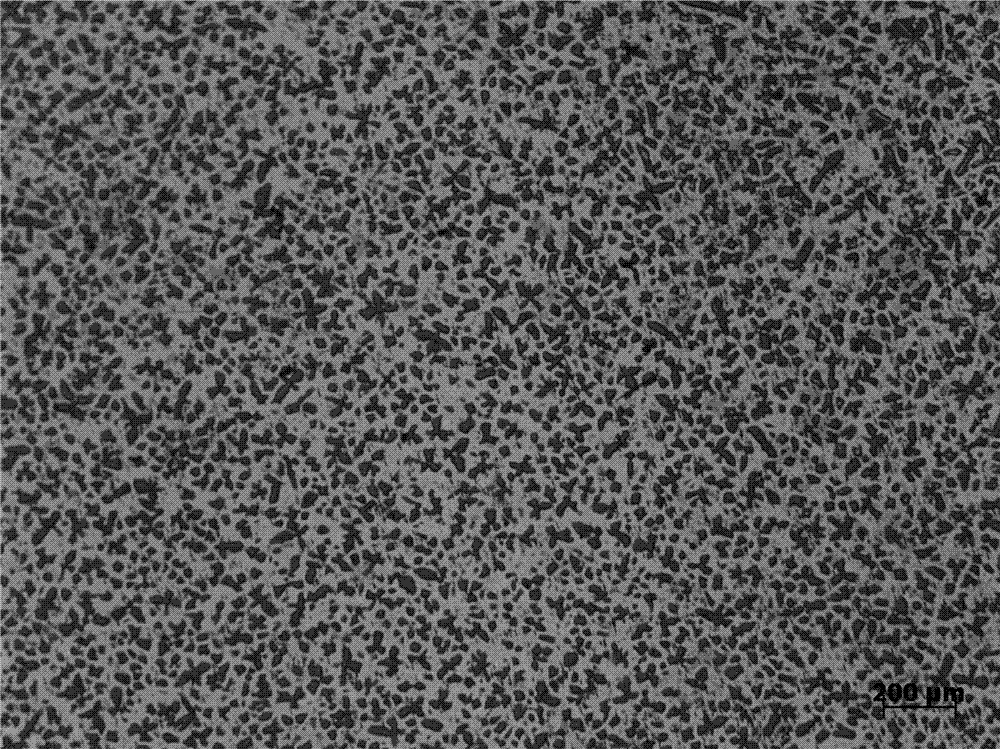

The invention discloses a preparation method of a high-liquid absorbing rate micro-nano structure polymer electrolyte membrane, wherein the membrane is prepared by polymer material being packed on a support frame. The method comprises the following steps of: by being processed, the polymer membrane has a micro-nano structure, forms holes with micron level and nanometer level, and forms a netty distribution hole structure with the nanometer holes of the support frame; and the polymer which is crossly linked layer by layer is packed on the special support frame to form a special netty micro-nano structure polymer electrolyte membrane. The polymer membrane of the micro-nano structure can absorb large numbers of electrolyte, greatly increase liquid-absorption rate, and improve the affinity of diaphragm to the electrolyte; the netty micro-nano structure leads the electrolyte to be kept in the membrane well, leads lithium ion in the polymer electrolyte membrane to be evenly distributed, leads the concentration to be to balanced, and lead the current density in the battery to be evenly when discharging electricity; and the special support frame guarantees the mechanical capability of the membrane. The preparation technology of the polymer electrolyte membrane has simple route and easily obtained raw material, can be operated under a normal condition, and does not need harsh production environment. The polymer lithium ion battery prepared by the membrane has good electrochemistry capability.

Owner:CHANGSHA HIGH TECH INDAL DEV ZONE CAISHENG NEW ENERGY TECH

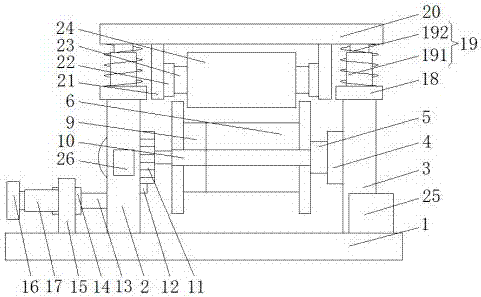

Control wire winding device with function of preventing wire coil from loosening

InactiveCN107444977ASqueeze wellIncrease the binding speedFilament handlingPackagingEngineeringConductor Coil

The invention discloses a control wire winding device with a function of preventing a wire coil from loosening. The control wire winding device comprises a bottom plate, wherein two first supporting legs and a second supporting leg are arranged on the left side and the right side of the upper surface of the bottom plate respectively; a first bearing is clamped on the left side surface of the second supporting leg; a first rotating shaft is connected into the first bearing in a sleeving manner; one end of the first rotating shaft is fixedly connected with the right side surface of a first wire winding wheel; two clamp slots are formed in the left side surface of the first wire winding wheel. According to the control wire winding device with the function of preventing the wire coil from loosening, the first wire winding wheel, a second wire winding wheel, sliding chutes, a motor, a slide bar, electric push rods, telescopic devices and an extrusion roll are arranged, so that when the device is used for bundling and fixing a control wire, the control wire can be prevented from loosening; meanwhile, the control wire after being bundled and fixed can be taken down from the first wire winding wheel and the second wire winding wheel, therefore, the bundling and fixing speed of a worker for the control wire is increased, the bundling and fixing efficiency of the control wire is improved, and production efficiency of the control wire is guaranteed.

Owner:JIANGYIN YONGCHANG TRAFFIC MACHINERY PARTS

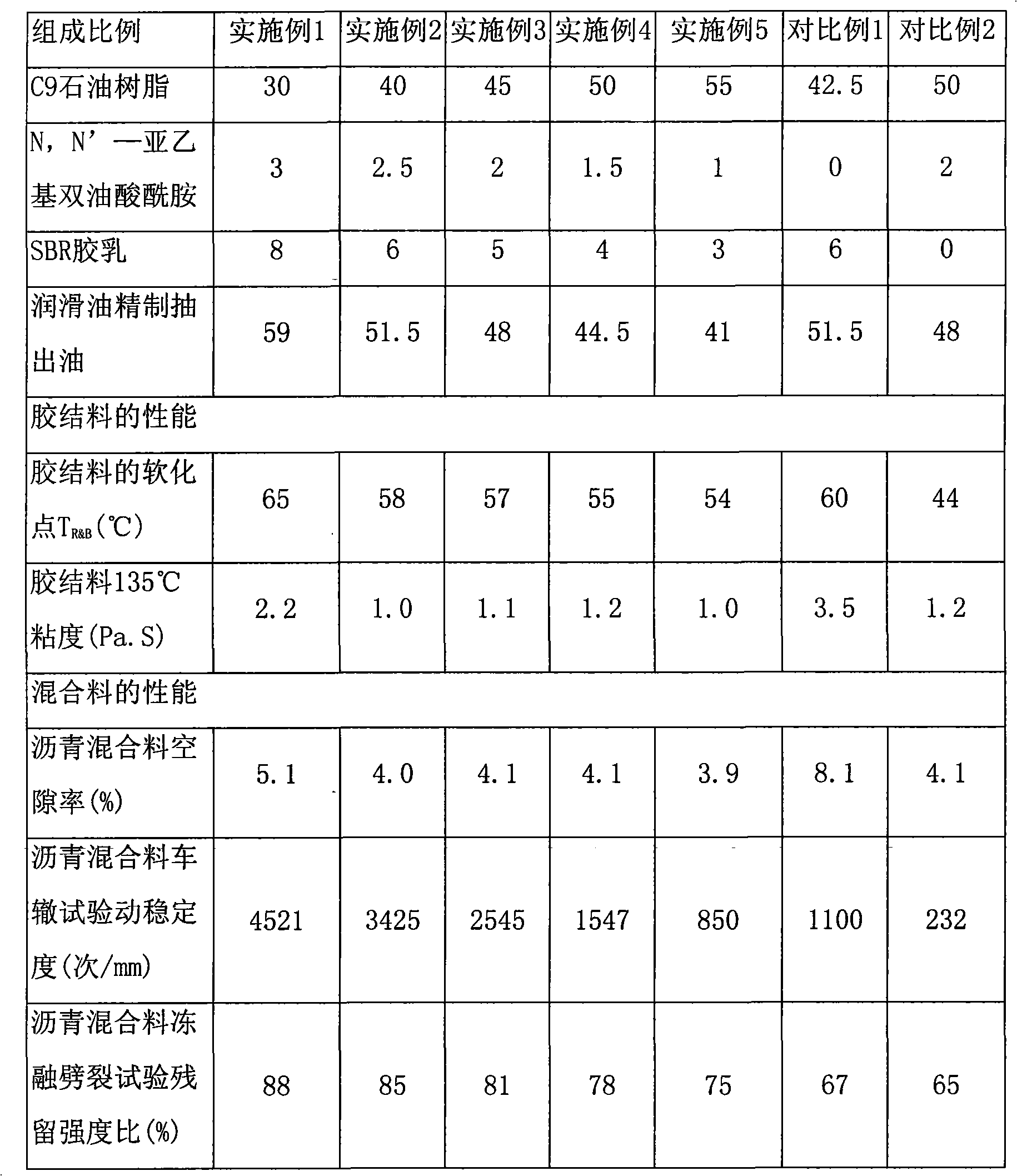

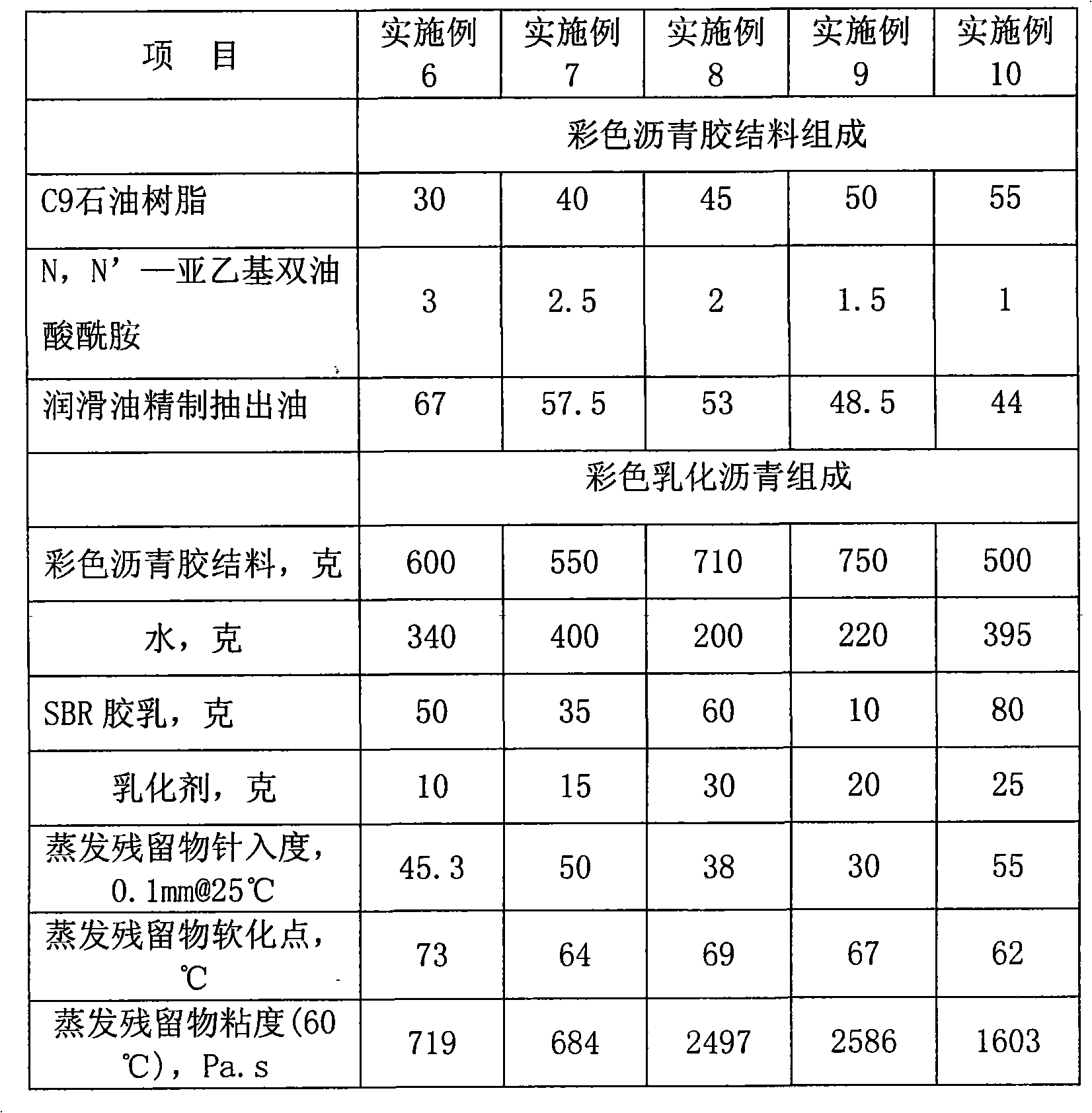

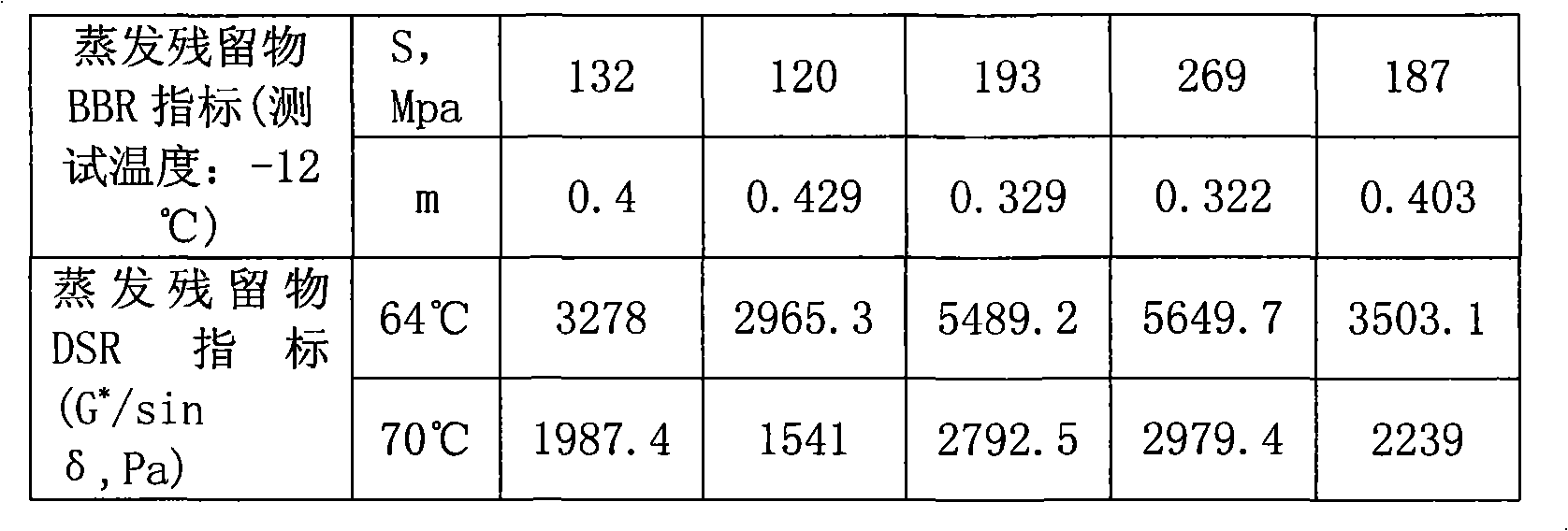

Color emulsified asphalt and preparation method thereof

InactiveCN101585952AImprove adhesionImproved high temperature stability and low temperature crack resistanceWater damageLubricant

The invention discloses a color emulsified asphalt and preparation method thereof, characterized in that color bituminous cements, emulsifier, water and modifying SBR rubber latex are included. According to proportioning by weight, parts of components are: 50.0 to 75.0 of color bituminous cements, 0.5 to 3.0 of emulsifier, 1.0 to 10.0 of modifying SBR rubber latex; 20 to 40 of water. The component and weight percent of the color bituminous cements comprise 30% to 65% of petropols, 1% to 3% of N,N'ethylidene bioleoylamido; lubricant or extract oil residual of lubricant. By selection of bituminous cements, in particular small amount of N,N'ethylidene bioleoylamido and SBR rubber latex, compared with other bituminous cements formulation, the formulation has better adhesiveness, which can prevent damages such as water damage, loose and peeling off of color path surface paved as well as tracks.

Owner:上海梁韵实业有限公司

Plastic plating method for automobile component

The invention discloses a plastic plating method for an automobile component. The plastic plating method for the automobile component is characterized by comprising the steps of chemical degreasing, coarsening, restoring, presoaking, palladium exciting, peptizing, chemical nickel-plating, copper pre-plating, acid-copper-plating, si-bright nickel plating, bright nickel plating, nickel sealing, and chromium plating. The adhesive force of the plastic surface substrate and the plating layer of the automobile component is high, the thickness of the penetration is up to 0.003-0.12 mm, and 0.003-0.12 mm of thicker metal layer is embedded in the plastic surface layer, so that the metal layer is tightly adhered to the plastic substrate, and the phenomenon of loosening, bubbling, peeling and the link of the plating layer is avoided after plating, the surface durability of the product is prolonged, and the product is smooth and has the metallic texture.

Owner:南通创源电化学科技有限公司

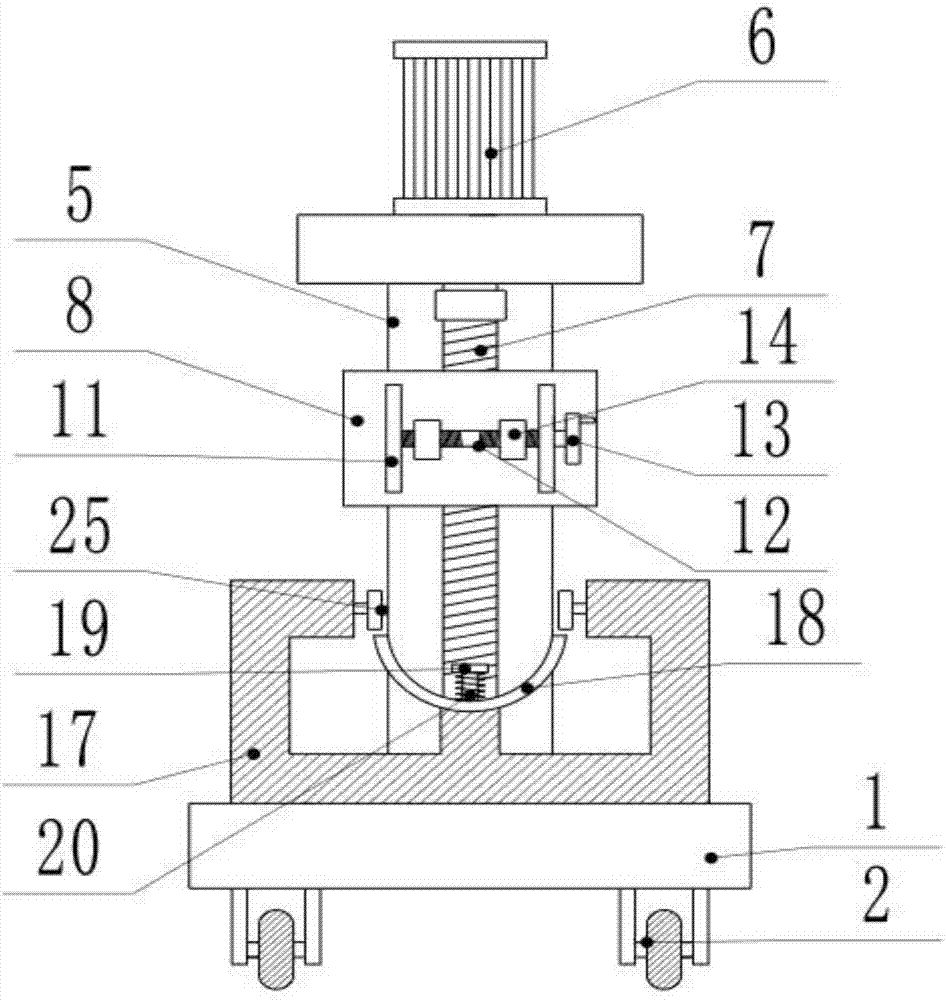

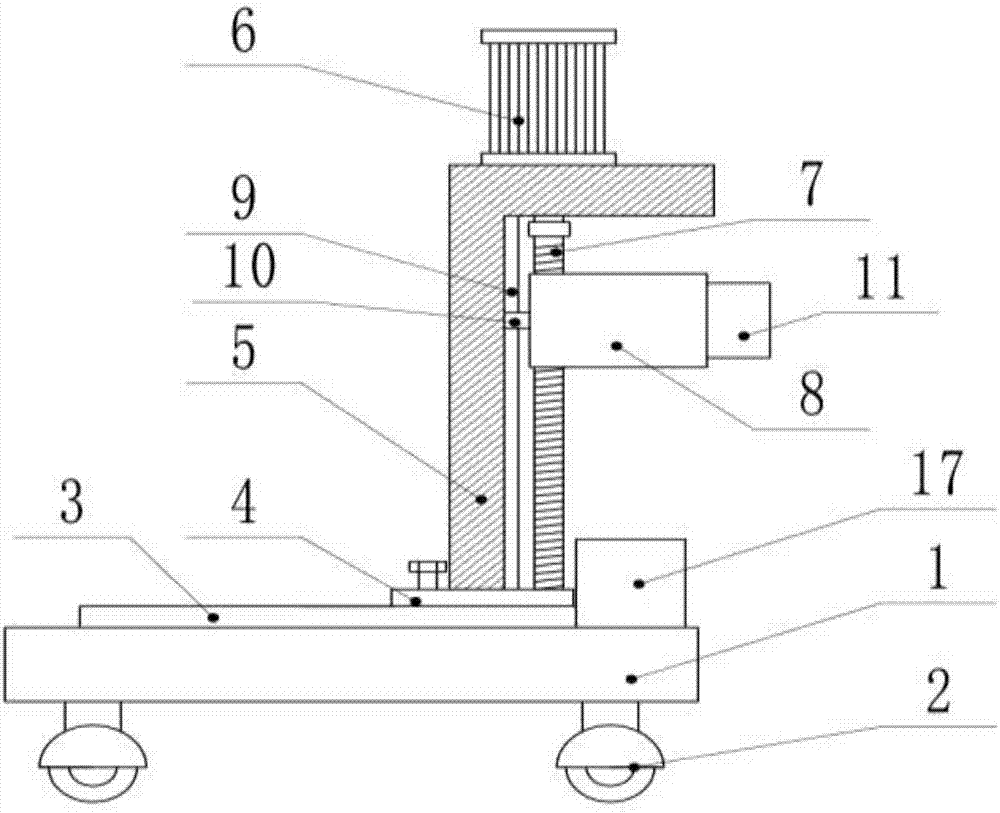

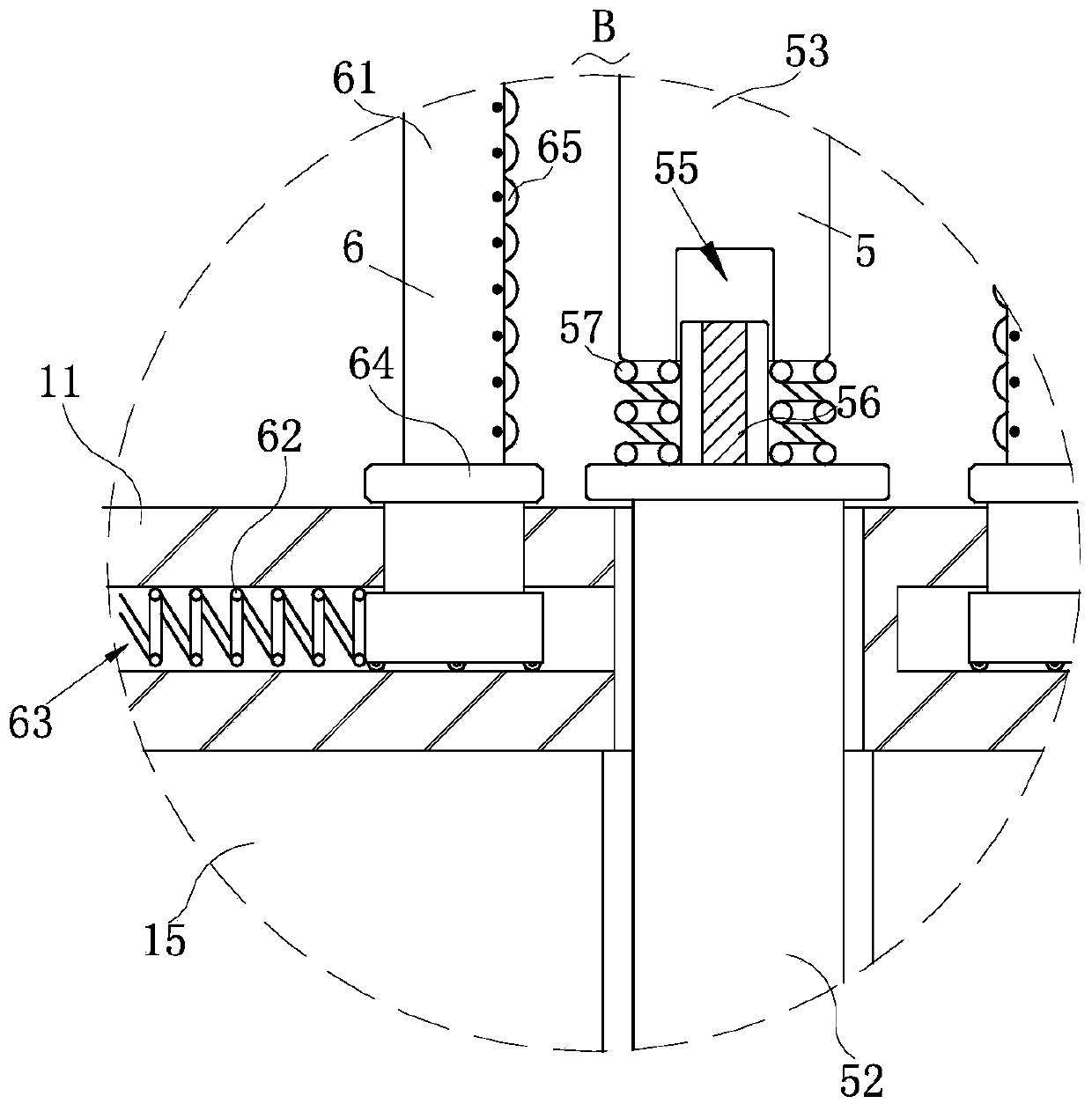

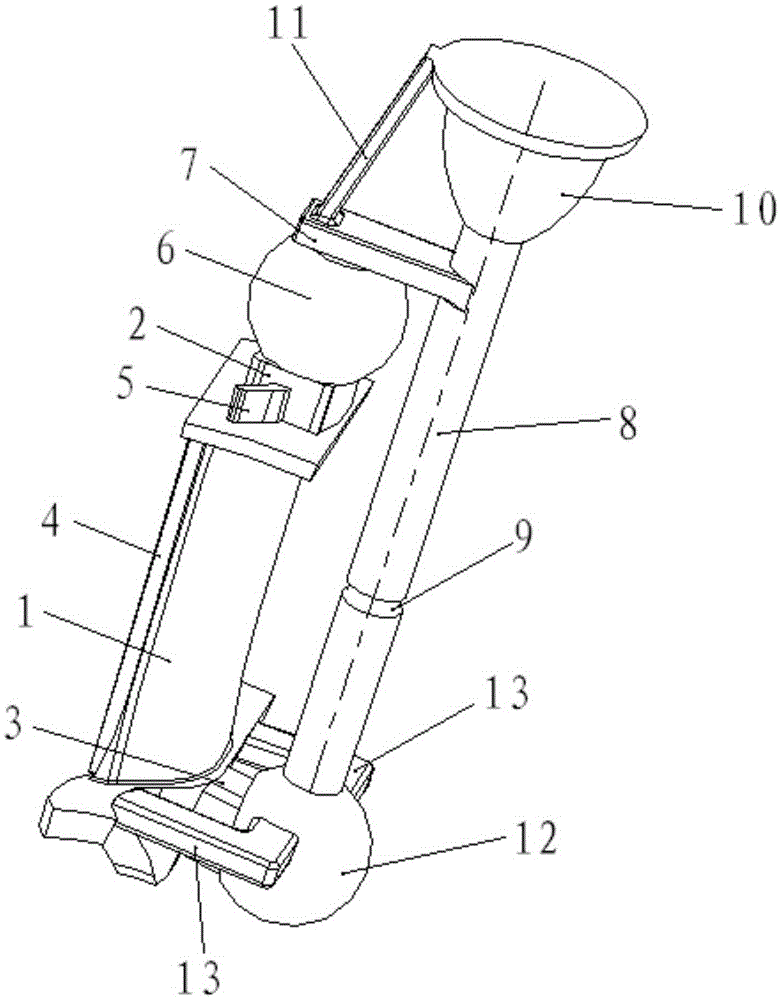

Green seedling transplanting device for garden construction

The invention discloses a green seedling transplanting device for garden construction, which comprises a base, a T-shaped slide rail, a slide plate, a main support plate, a lifting motor, a first screw rod, a second screw rod, clamping claws and an anti-shake device. A lifting motor is fixedly installed on the top plate, and the lower end of the output shaft of the lifting motor is connected with a first screw rod through a coupling, and a movable plate is threaded on the first screw rod; the connecting plates on the left and right sides rotate A second screw rod is installed, and clamping claws are also installed on the threads of the left and right parts of the second screw rod; the upper surface of the right side of the base is also fixedly installed with an anti-shake device. Use the clamping claws to clamp the trunk and then use the principle of screw lifting to lift the seedlings out of the pit. Compared with manual lifting, it saves time and effort. The anti-shake device can effectively prevent the soil ball from shaking during transportation. Avoid bumping soil balls during transportation and cause loosening, thereby improving the survival rate of seedlings.

Owner:广西综改咨询服务有限公司

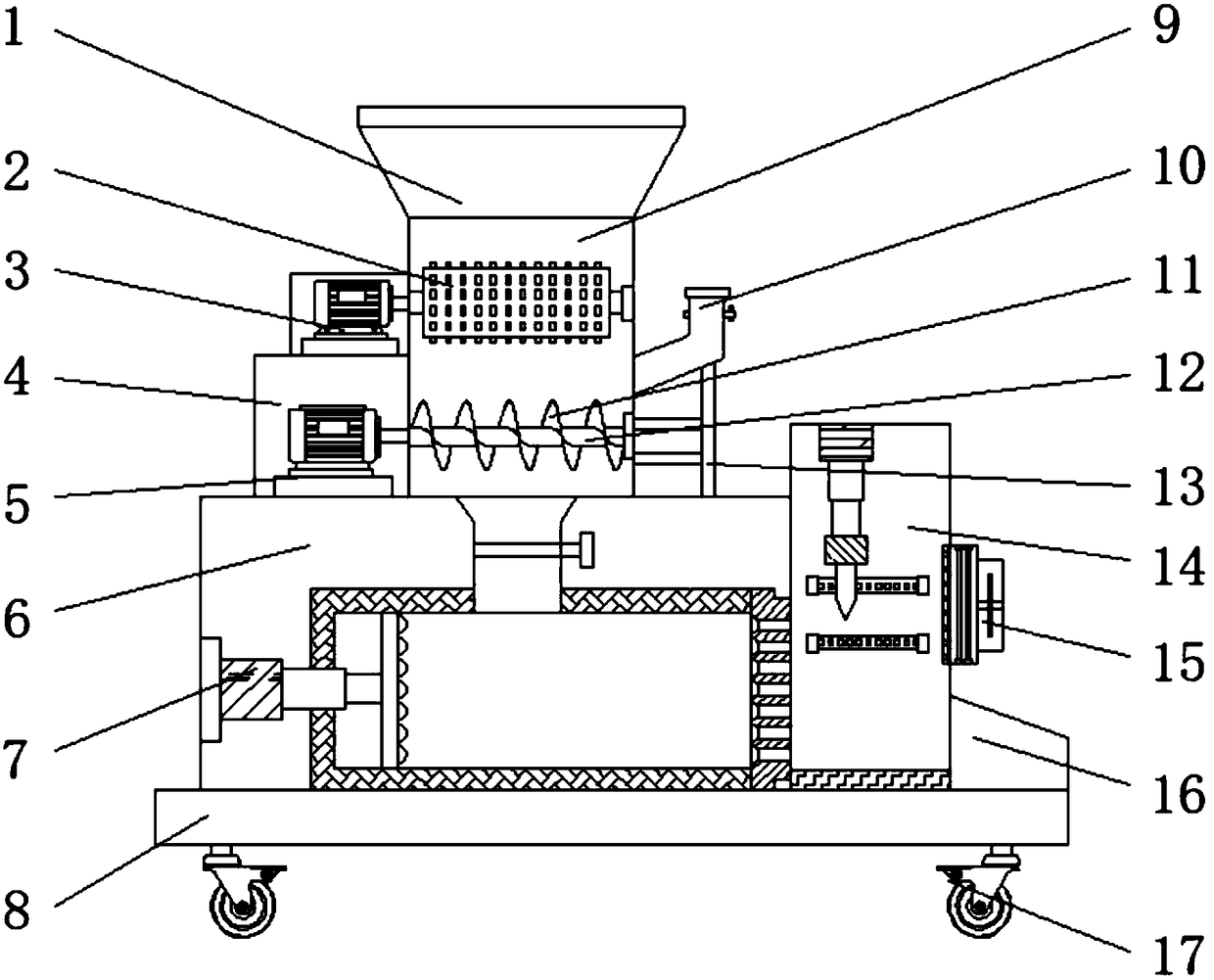

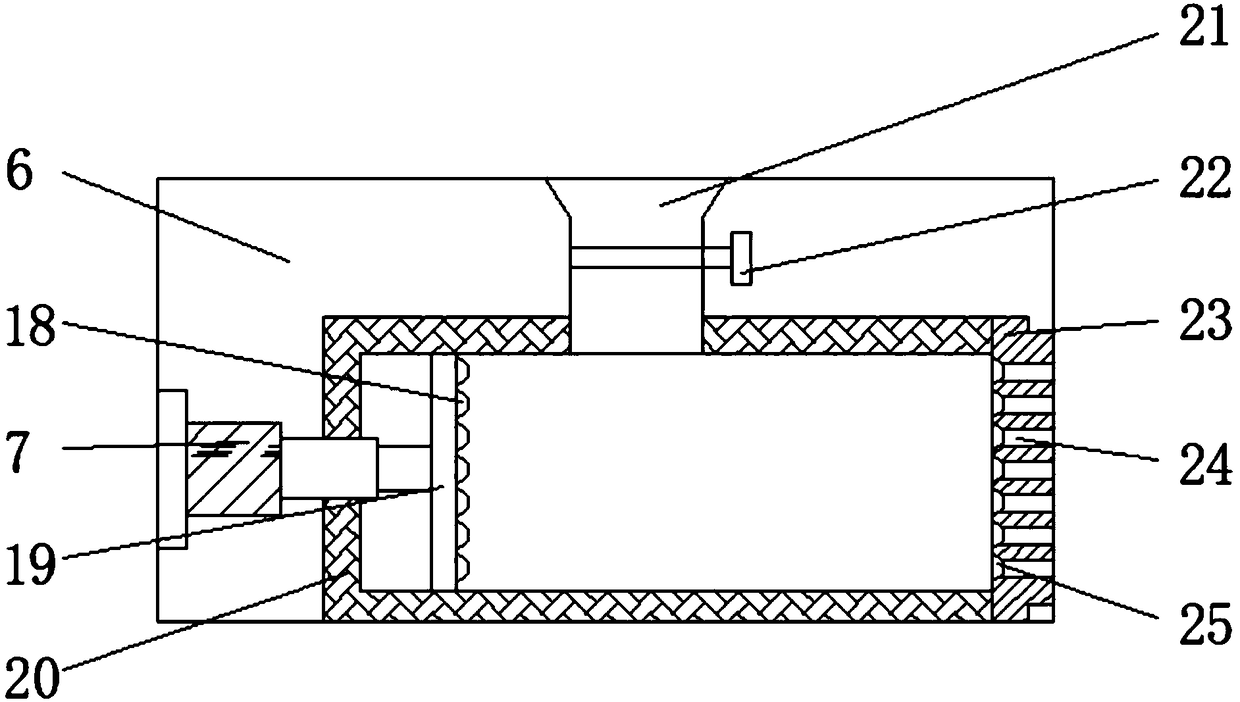

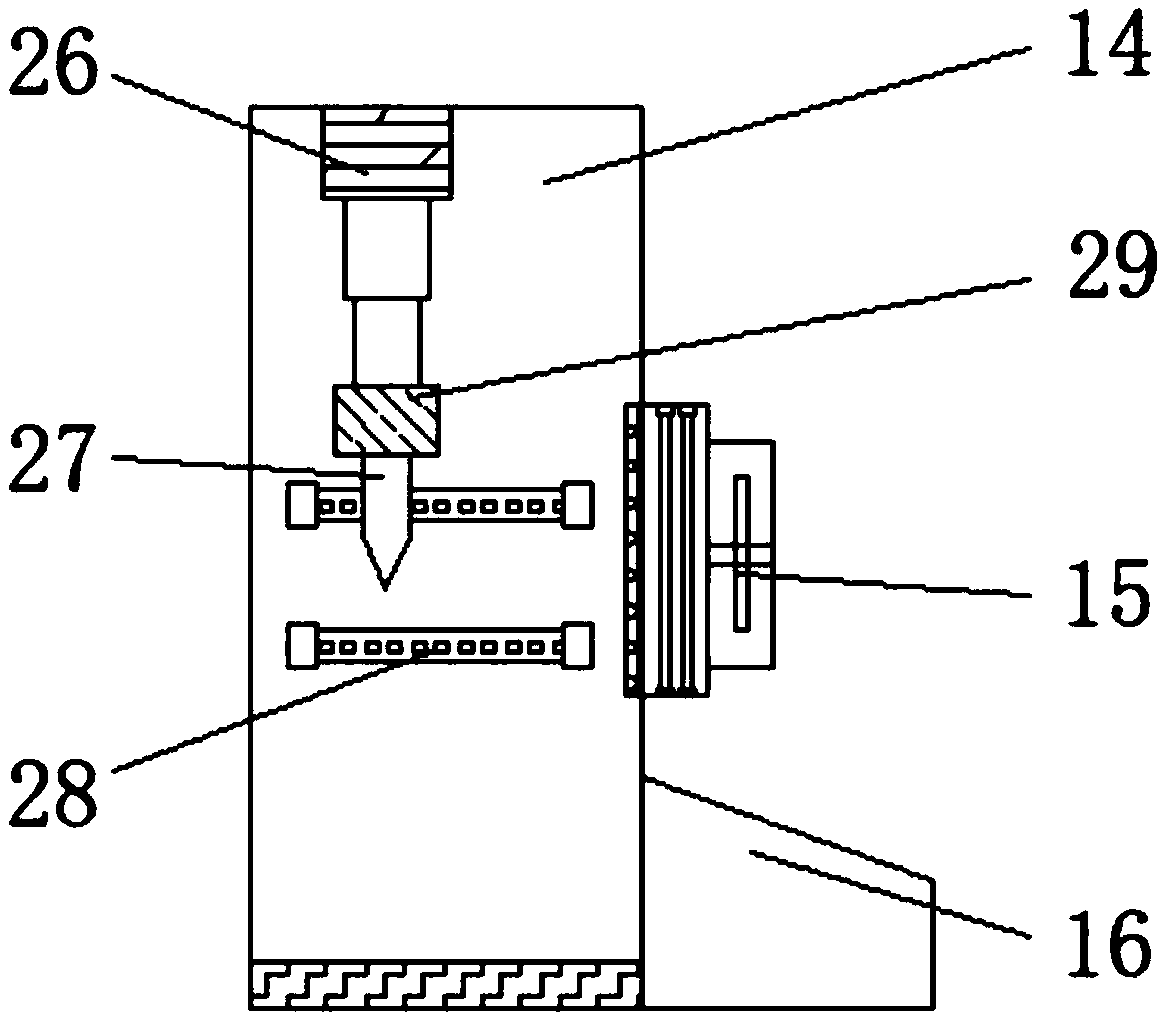

Aquatic feed processing device

PendingCN108095173AIncreased efficiency of impact extrusionImprove the bactericidal effectFeeding-stuffRotary stirring mixersPunchingAquatic product

The invention discloses an aquatic feed processing device. The device comprises a processing box, a base, a crushing box and a cut-off box; the processing box is installed on the top of the base, a punching tube is installed at the bottom inside the processing box, a feed delivery pipe is installed on the top of the punching tube, a solenoid electric valve is installed on the feed delivery pipe, aforming die is installed on one side of the punching tube, and die holes are uniformly formed in the forming die. Accordingly, by installing the crushing box, a crushing roll is installed in the crushing box, the crushing roll is driven by a motor to rotate at a high speed, raw materials such as fish bones are ground and crushed, and processing and shaping are facilitated; by arranging a feedingpipe, other organic matter is added into the crushed materials conveniently; meanwhile, by installing a stirring shaft, stirring blades are uniformly installed on the stirring shaft, and different rawmaterials are fully stirred and mixed conveniently.

Owner:GUIZHOU UNIV

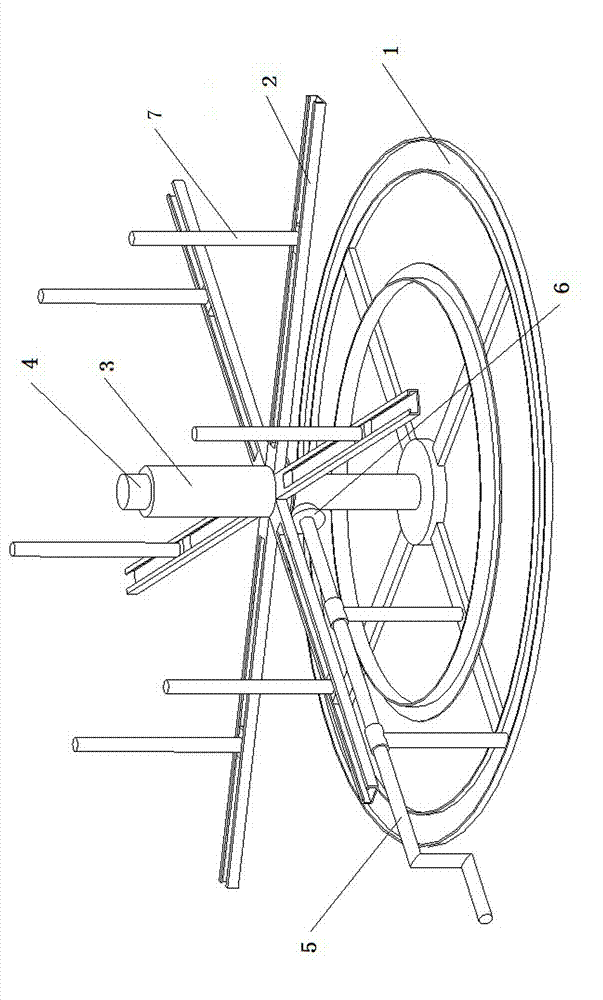

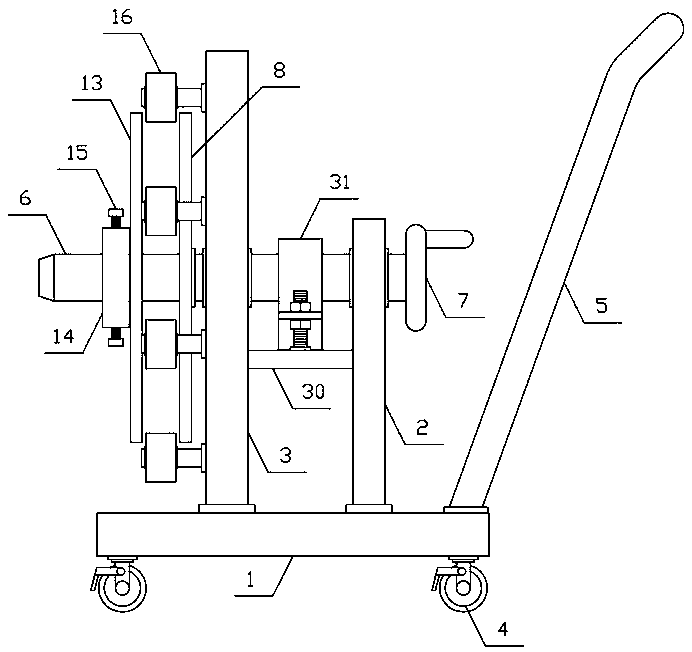

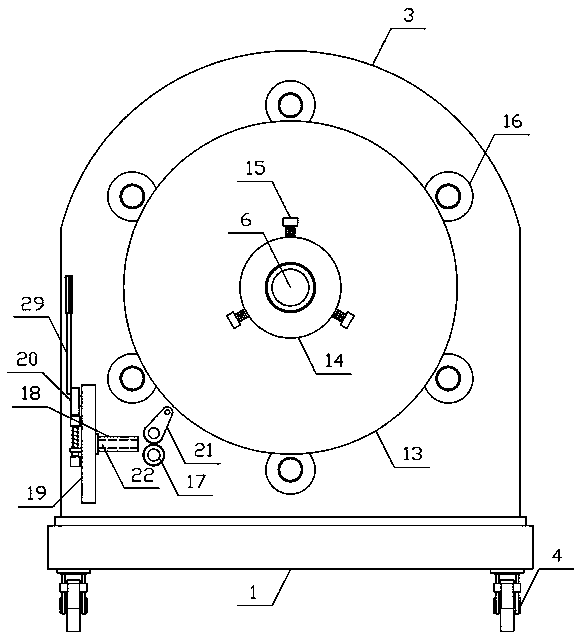

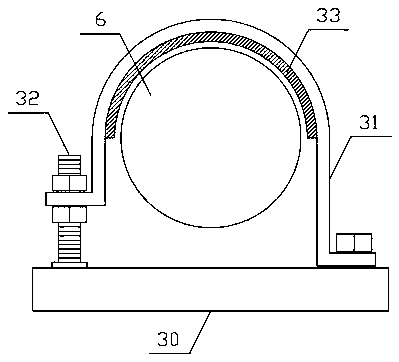

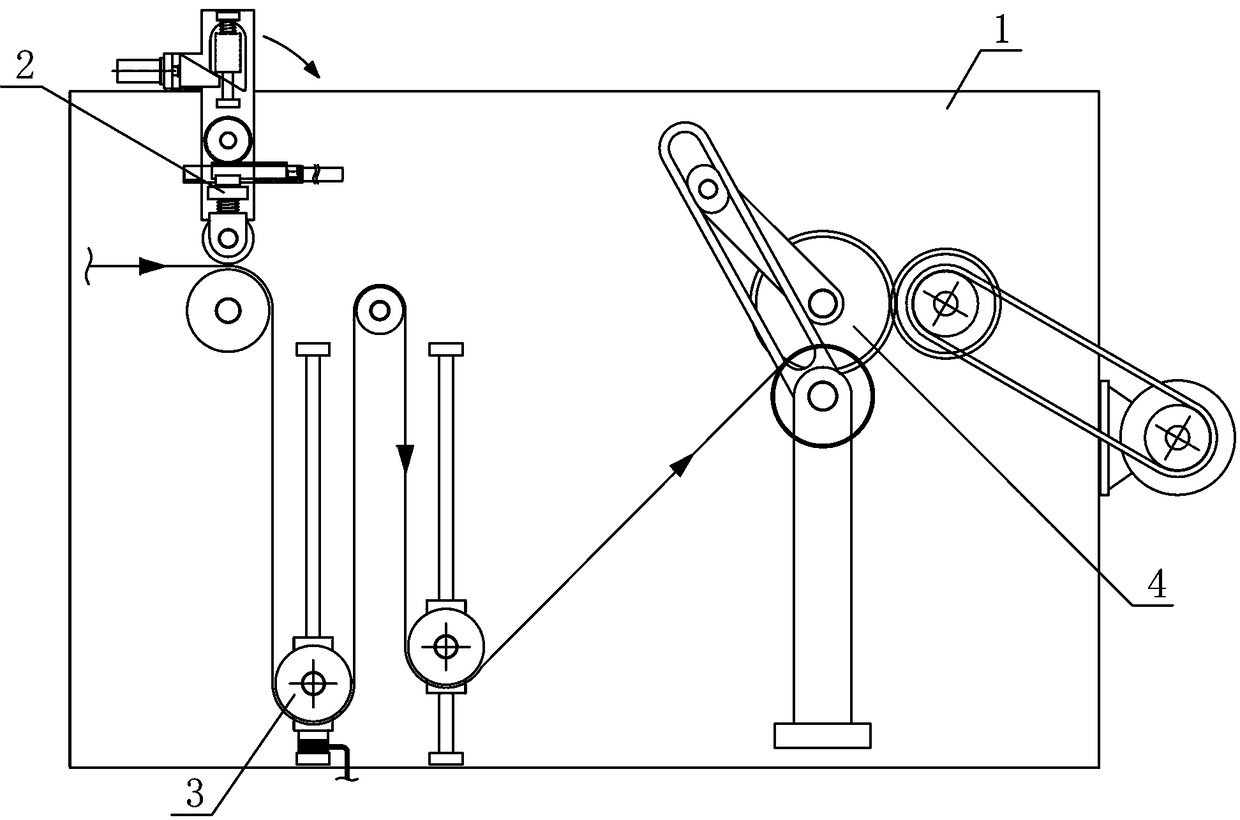

Scattered wire winding and unwinding device

The invention discloses a scattered wire winding and unwinding device and relates to the technical field of power engineering construction auxiliary devices. The scattered wire winding and unwinding device comprises a base and a main shaft which is fixedly arranged on the base. The main shaft is rotatably connected with a sleeve. A wire winding bracket is arranged on the sleeve. The sleeve is additionally connected with a hand-operated driving mechanism. The scattered wire winding and unwinding device has the advantages that since the wire winding bracket is rotatably arranged on the base and certain resistance exists between the sleeve and the main shaft during wire unwinding, the problem that wires are buckled can be avoided, adjustment by auxiliary personnel is not needed and the labor intensity is reduced; and during winding, the situation that the wires are loose by adopting a manual wire winding method is avoided, the labor intensity is further reduced and the production efficiency is improved.

Owner:STATE GRID CORP OF CHINA +2

External fixation rack elasticity device

The invention discloses a resilient device of an external fixator in the clinical application of orthopaedics. The resilient device consists of a cylinder, a sliding axle in the cylinder, a flexible apparatus, a sliding nail body and a sliding axle stopper. An anti-spin rivet, a pressure regulation rivet, a pressure regulation nut, a tightening jack bolt, a hollow screw on the cylinder wall and a pressurization hole are arranged in the radial direction on the cylinder wall, wherein, the sliding axle stopper can be provided with a stop jack bolt in the radial direction on the cylinder wall, or a stop nut or a stop fixture block can be arranged on the sliding axle; the cylinder wall can be designed to have equal inner diameters at the upper and lower parts or have the inner diameter of the upper part at the corresponding position of the sliding axle larger than that of the lower part; the flexible device can be made into a flexible capsule or a spring; and the sliding nail body is connected with the cylinder in a sliding manner. The resilient device can match with external fixators of different shapes and structures to form external flexible fixators. When a limb with a fracture suffers axial pressure, the external flexible fixator can have a slight axial movement so that an interaction force can be generated due to the slight movement at the end of fracture so as to stimulate callus to grow at the end of fracture. The resilient device can avoid osteoporosis due to stress shielding of the external fixator, quicken the fracture healing, increase the strength of healed bone and effectively prevent delayed fracture healing or nonunion.

Owner:河南科科生物科技有限公司

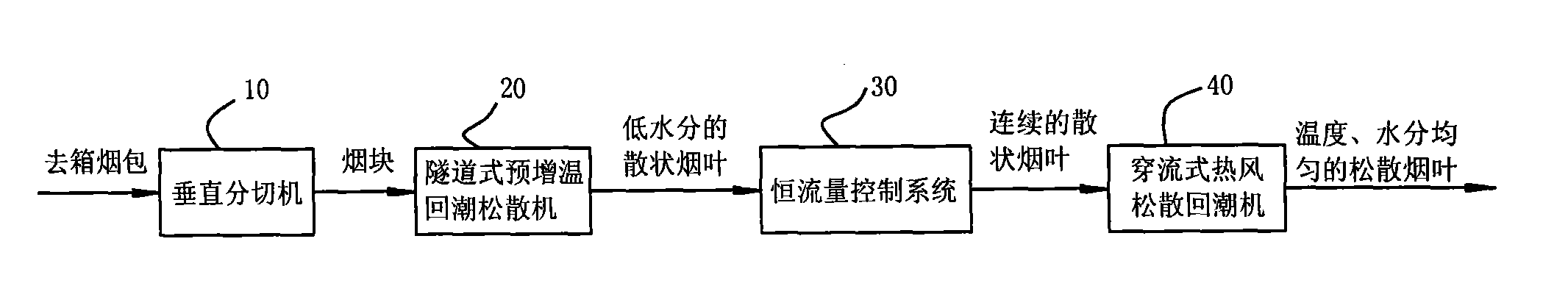

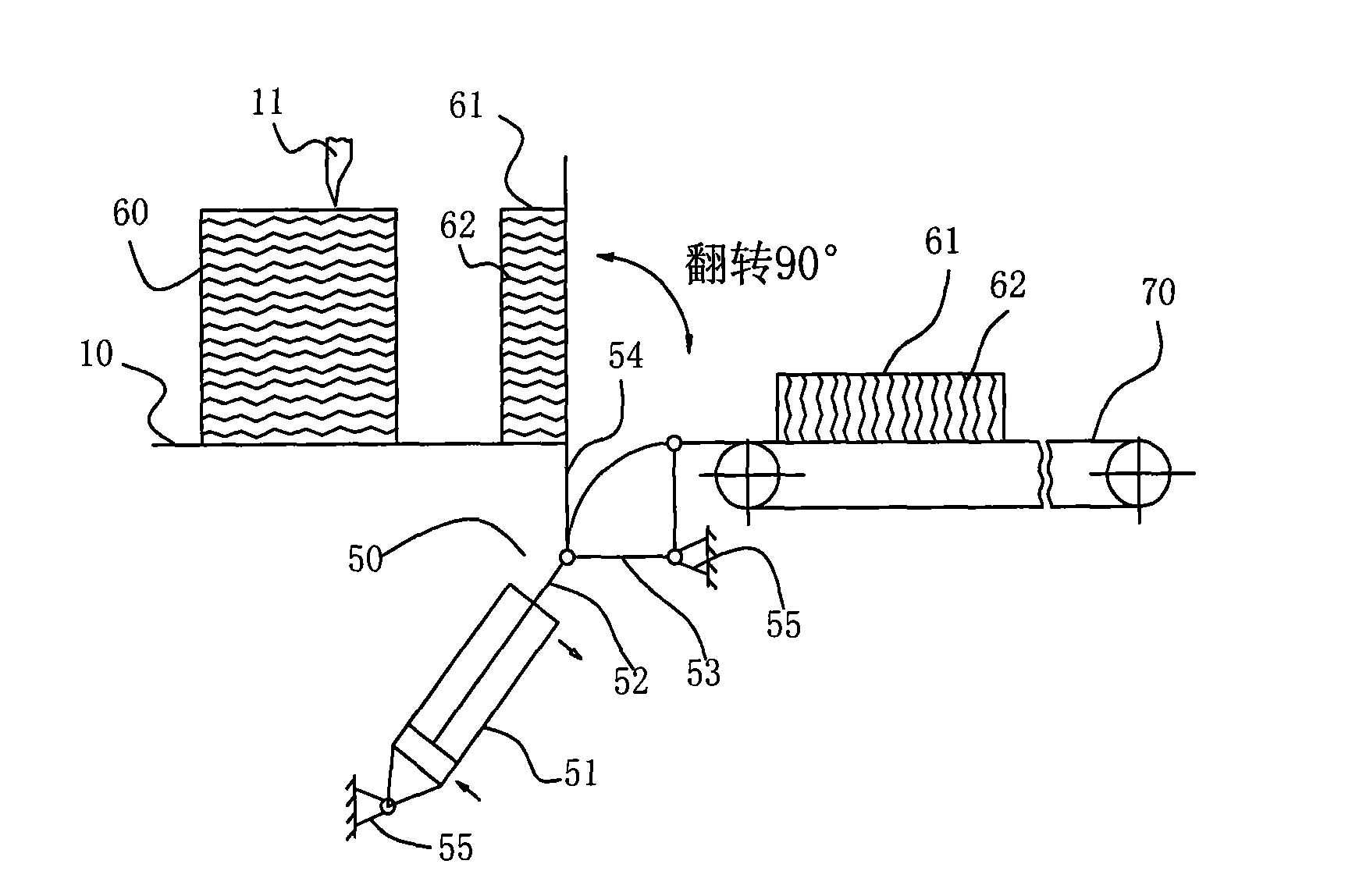

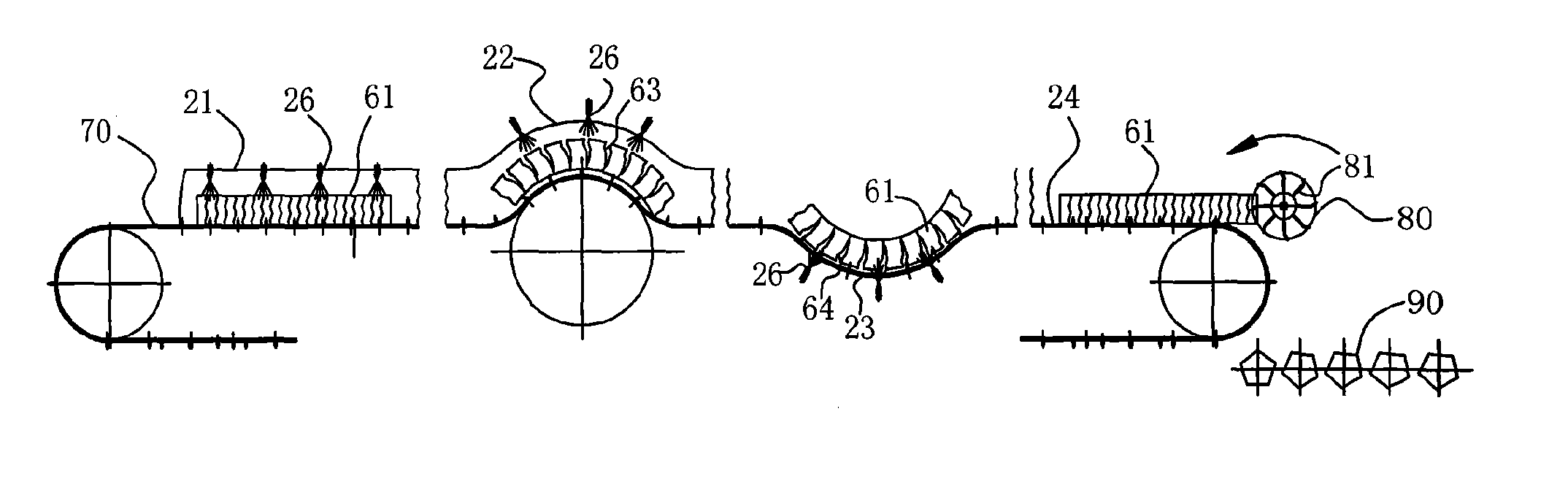

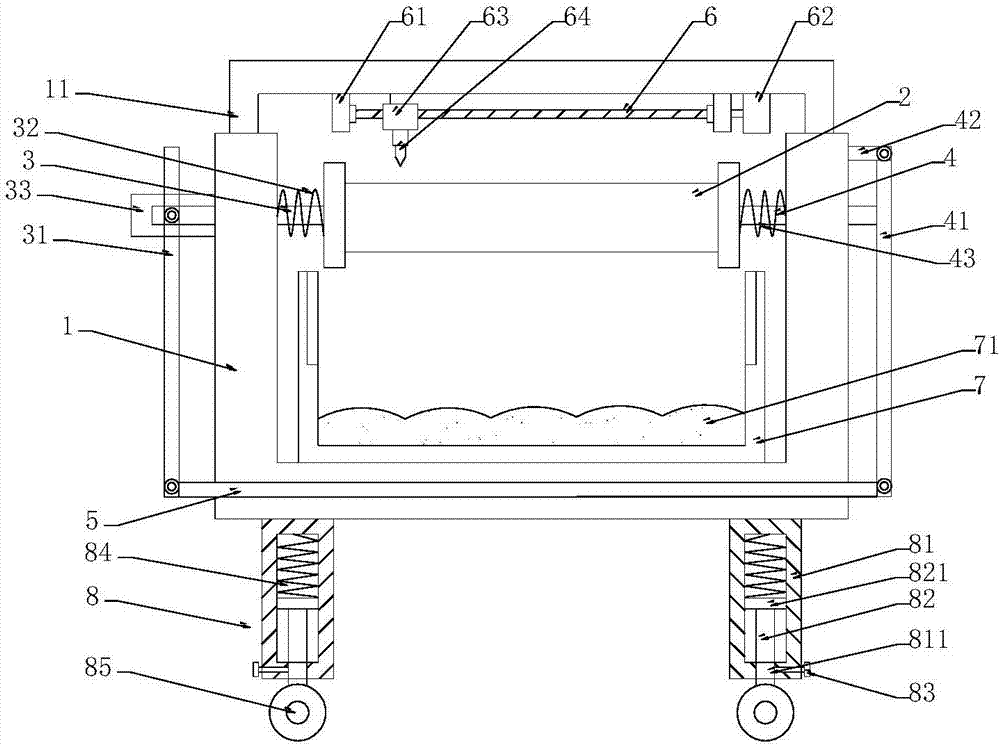

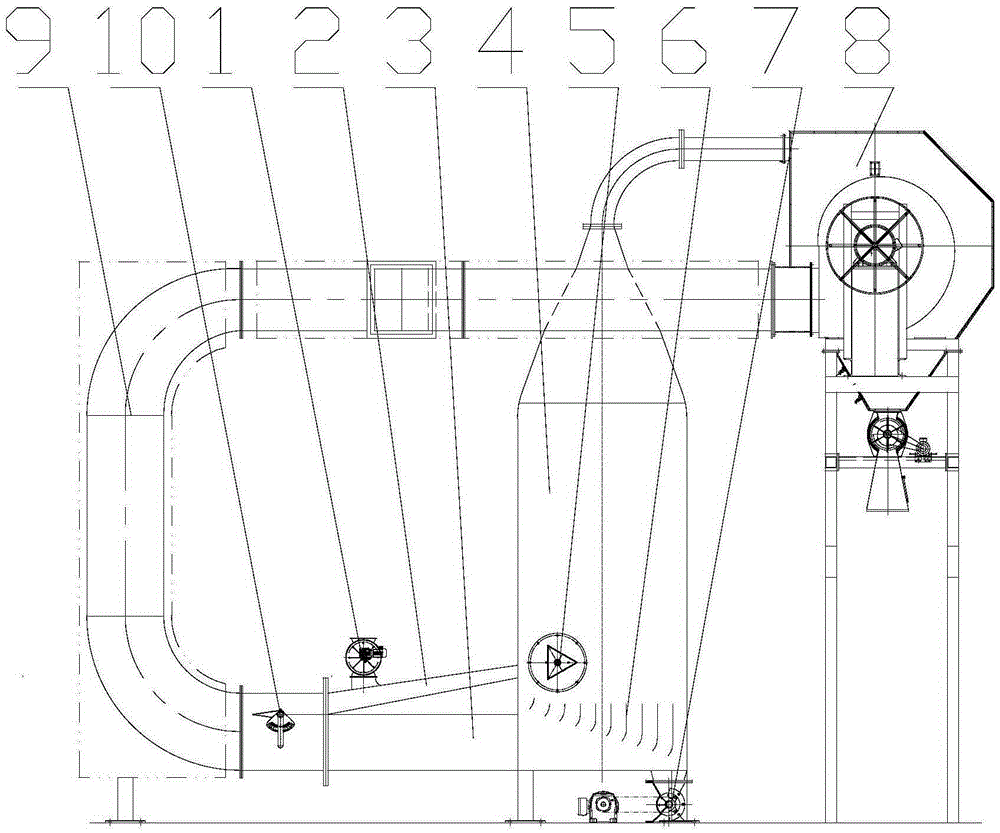

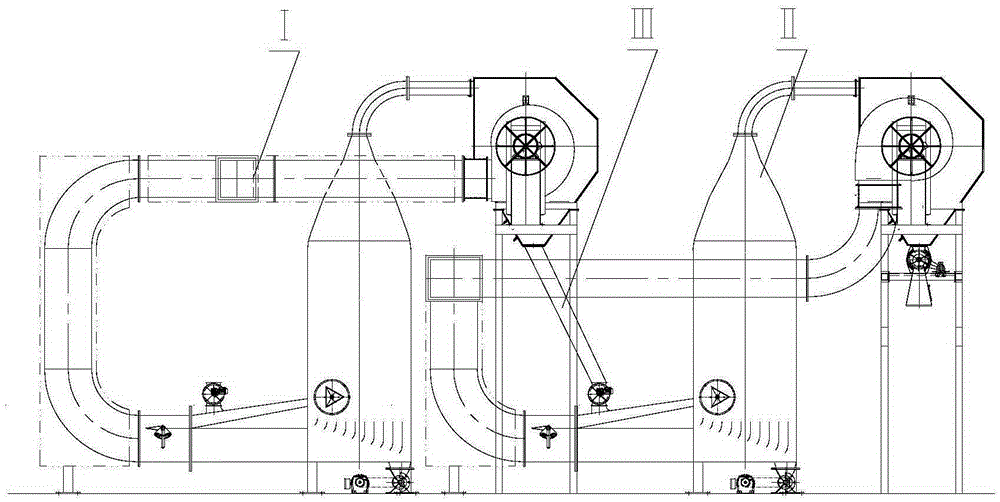

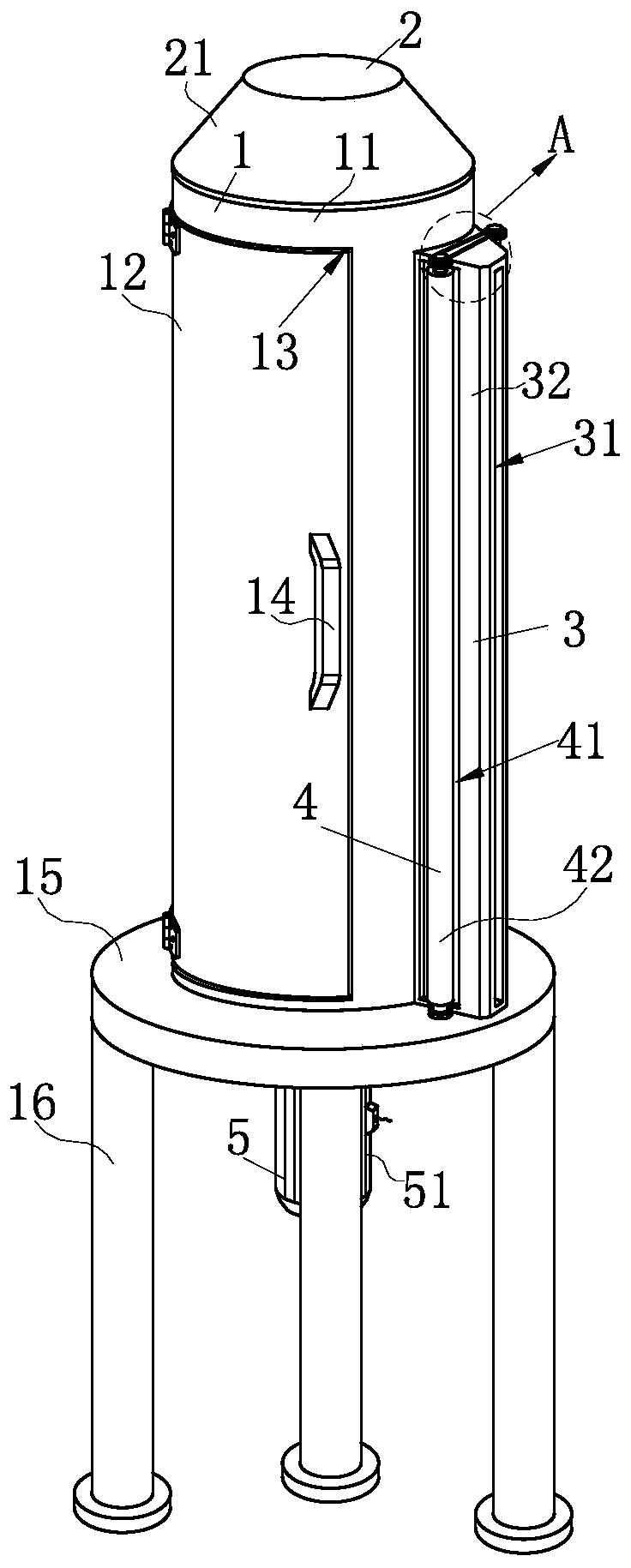

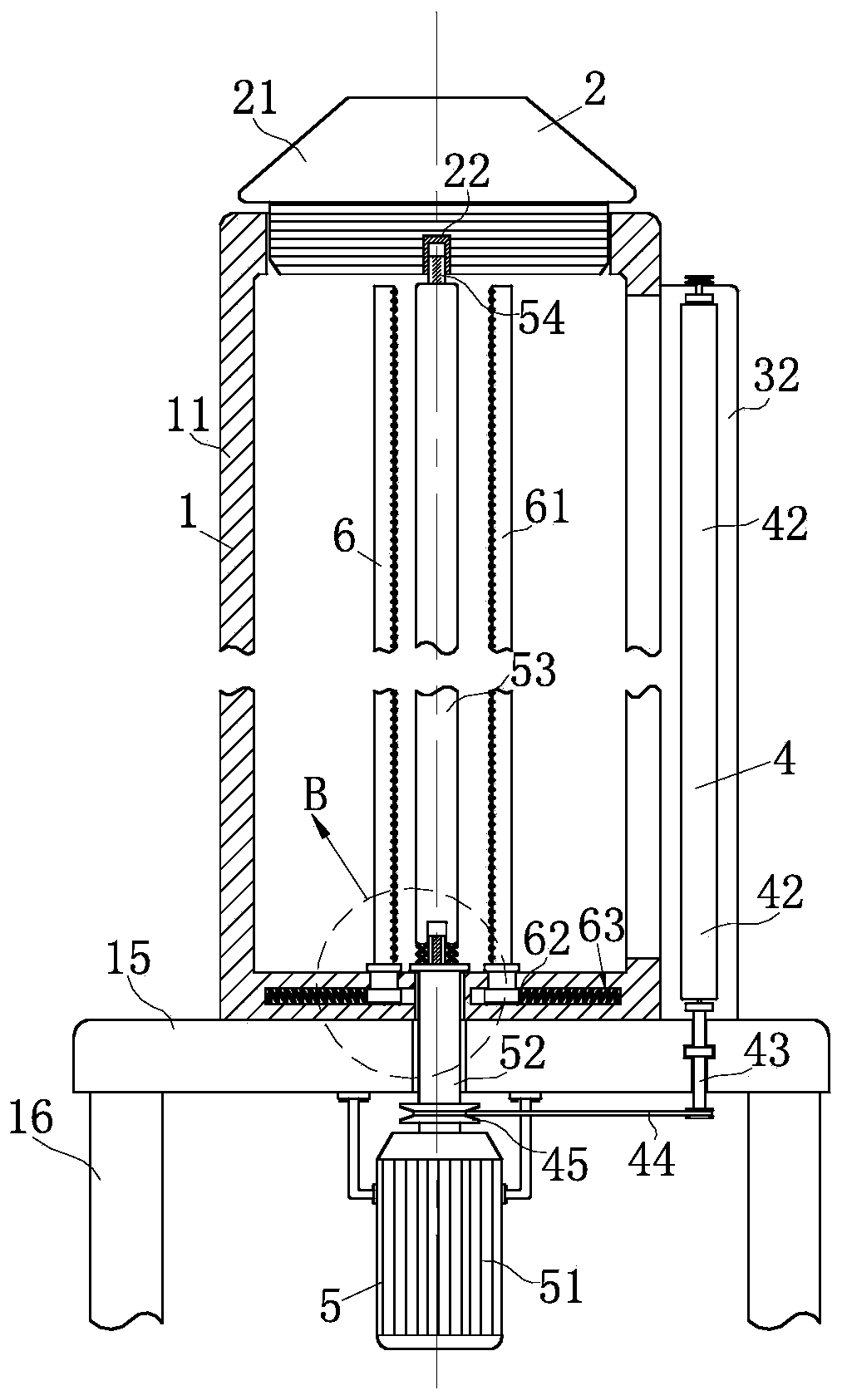

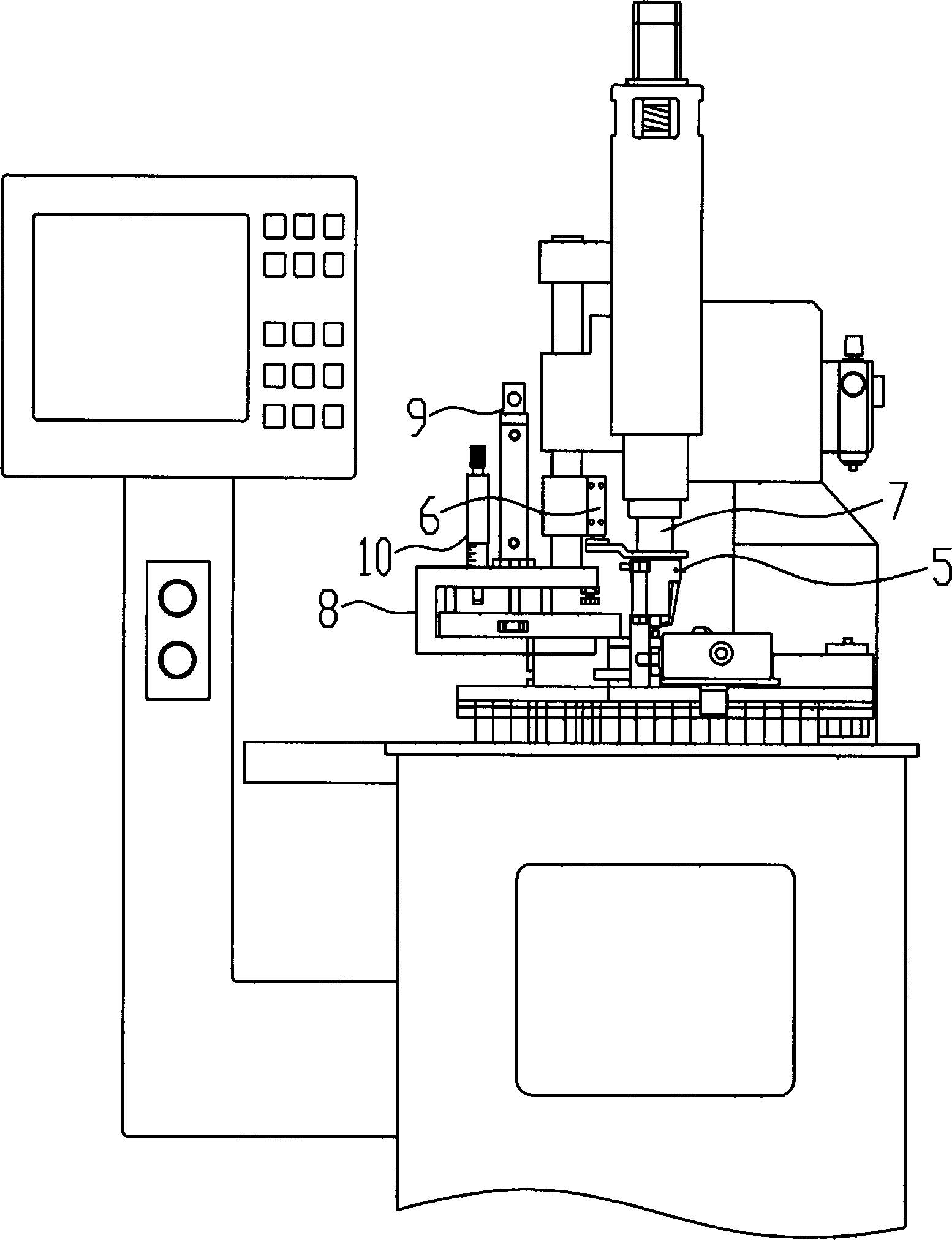

Tobacco piece loosening and conditioning system

ActiveCN101637297AReduce breakage rateAvoid breakingTobacco preparationControl systemPulp and paper industry

The invention discloses a tobacco piece loosening and conditioning system. The system comprises a vertical splitting machine, a tunnel type preheating conditioning loosening machine and a percolationtype hot-air loosening conditioning machine which are arranged in accordance with a pipeline method in turn. A constant flow control system is arranged between the tunnel type preheating conditioningloosening machine and the percolation type hot-air loosening conditioning machine. A turning and slow releasing device is arranged between the vertical splitting machine and the tunnel type preheatingconditioning loosening machine. The tunnel type preheating conditioning loosening machine is equipped with a bending delivery tunnel. The tobacco piece loosening and conditioning system has a combination of the tunnel type preheating conditioning loosening machine and the percolation type hot-air loosening conditioning machine, causes more even heating, improves loosening rate of tobacco flakes and reduces fragment generation ratio. The tobacco piece can be loosened and conditioned under low strength condition, and the raw materials of the tobacco can be subject to maximal flexible looseningto keep original fragrant of the tobacco, and realize coordination of sensor quality and material loosening.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Protective film rolling device with conveniently detached and mounted drum

Owner:FOSHAN ZHENGLUE INFORMATION TECH CO LTD

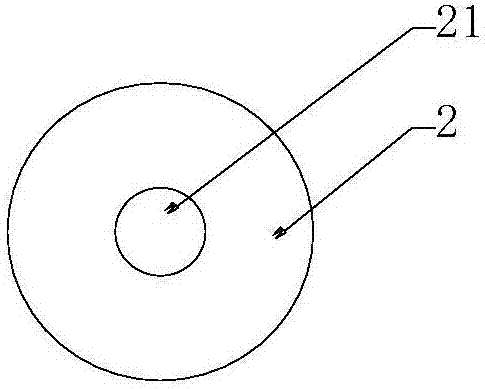

Gold base alloy casting blank melting and casting integrated device and utilization method thereof

ActiveCN103691912AReduce the number of oxide inclusionsEliminate severe oxidationIntegrated devicesCrucible

The invention discloses a gold base alloy casting blank melting and casting integrated device and a utilization method thereof. The gold base alloy casting blank melting and casting integrated device comprises a melting pot, a fireproof material cylinder, a cooling base, an outer cylinder, a heating induction coil and a magnetic stirring device. The utilization method of the gold base alloy casting blank melting and casting integrated device comprises putting gold into the melting pot and inserting the melting pot into the fireproof material cylinder; piping inert gas or reducing gas into the outer cylinder; heating the metal inside the melting pot to be melted through magnetic fields, adding other metal or alloy and performing alloying; enabling the melting pot with the fusant to descend to an annual boss of the cooling base and cooling the fusant to cast the fusant which is gradually solidified from bottom to upper during the cooling process. The gold base alloy casting blank melting and casting integrated device has the advantages of being simple in structure, convenient to operate and low in integral cost and enabling prepared gold base alloy to be uniform in ingredient and less in internal defect. The gold base alloy casting blank melting and casting integrated device and the utilization method thereof have good application prospects.

Owner:NORTHEASTERN UNIV

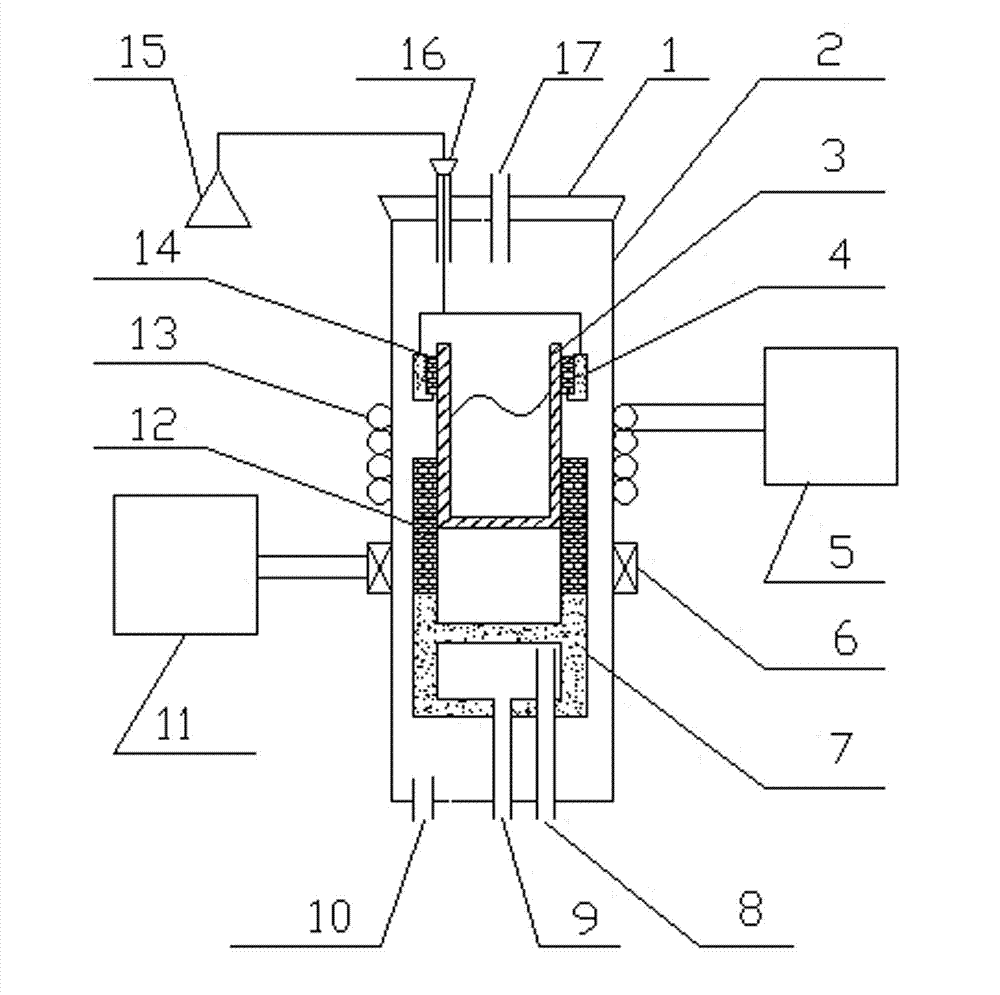

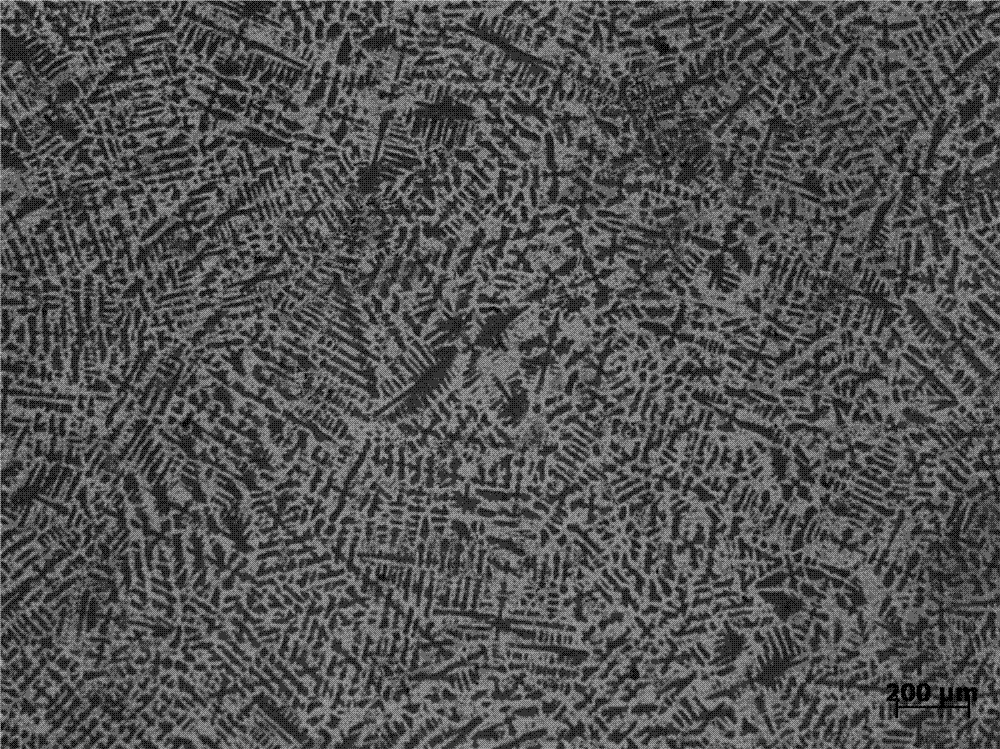

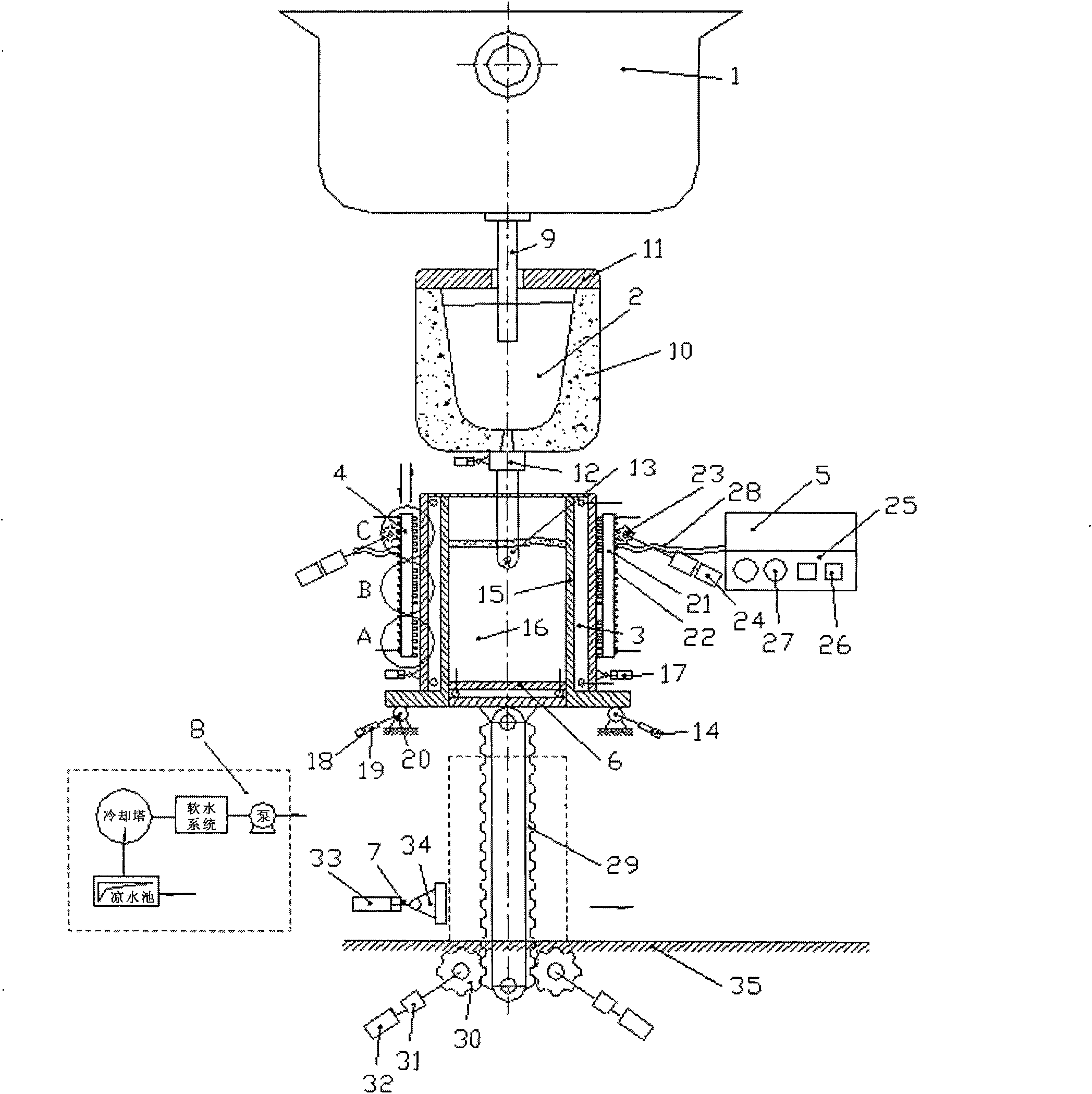

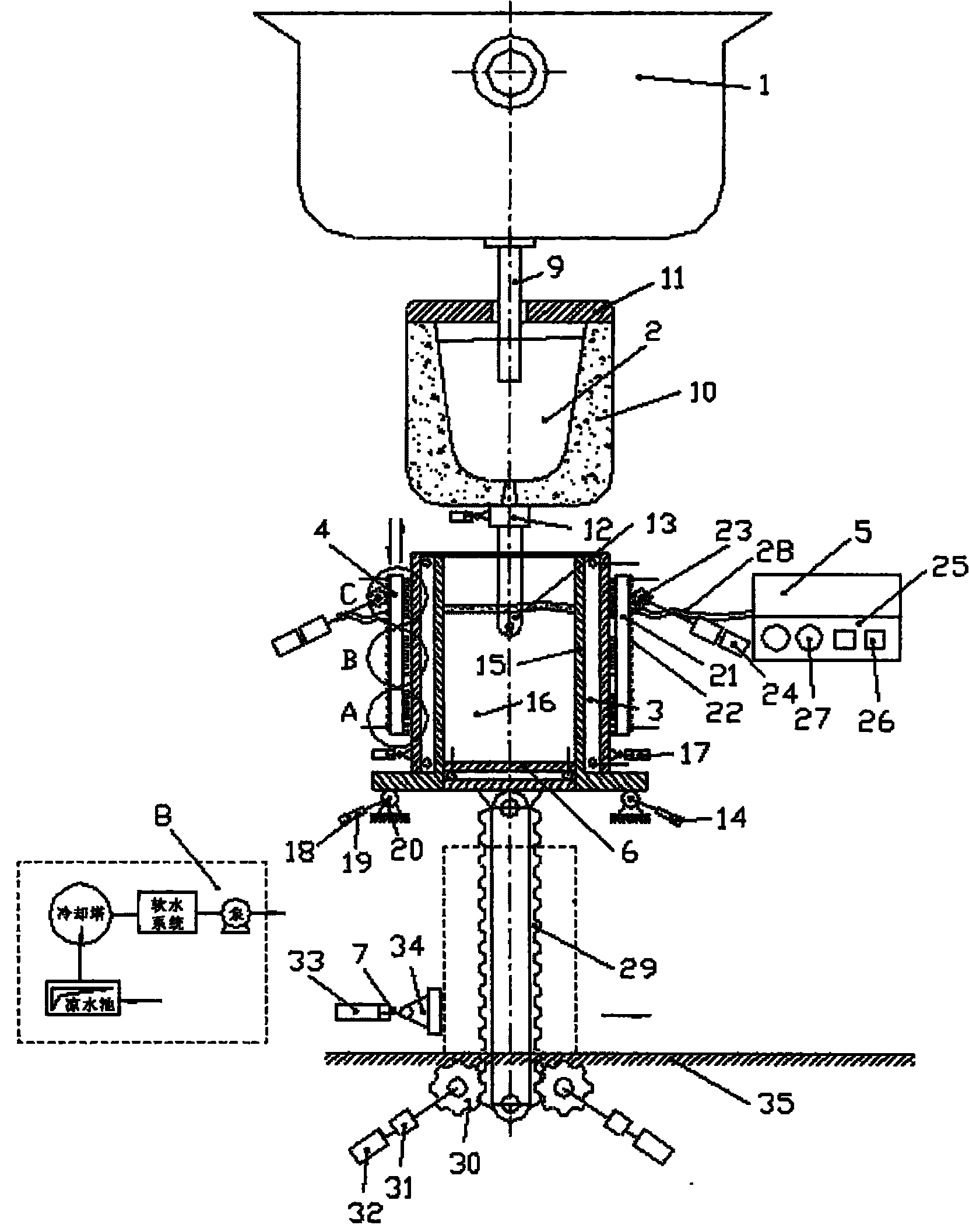

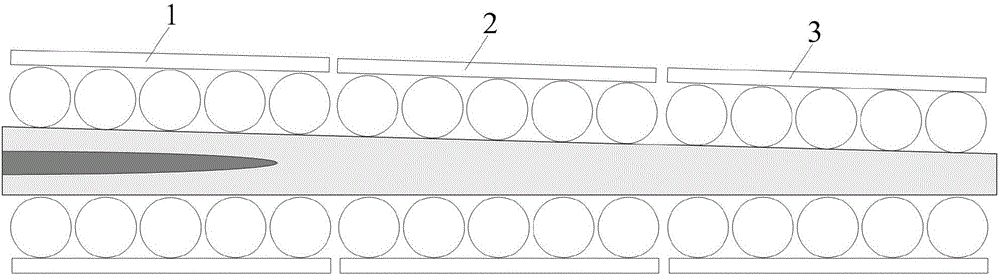

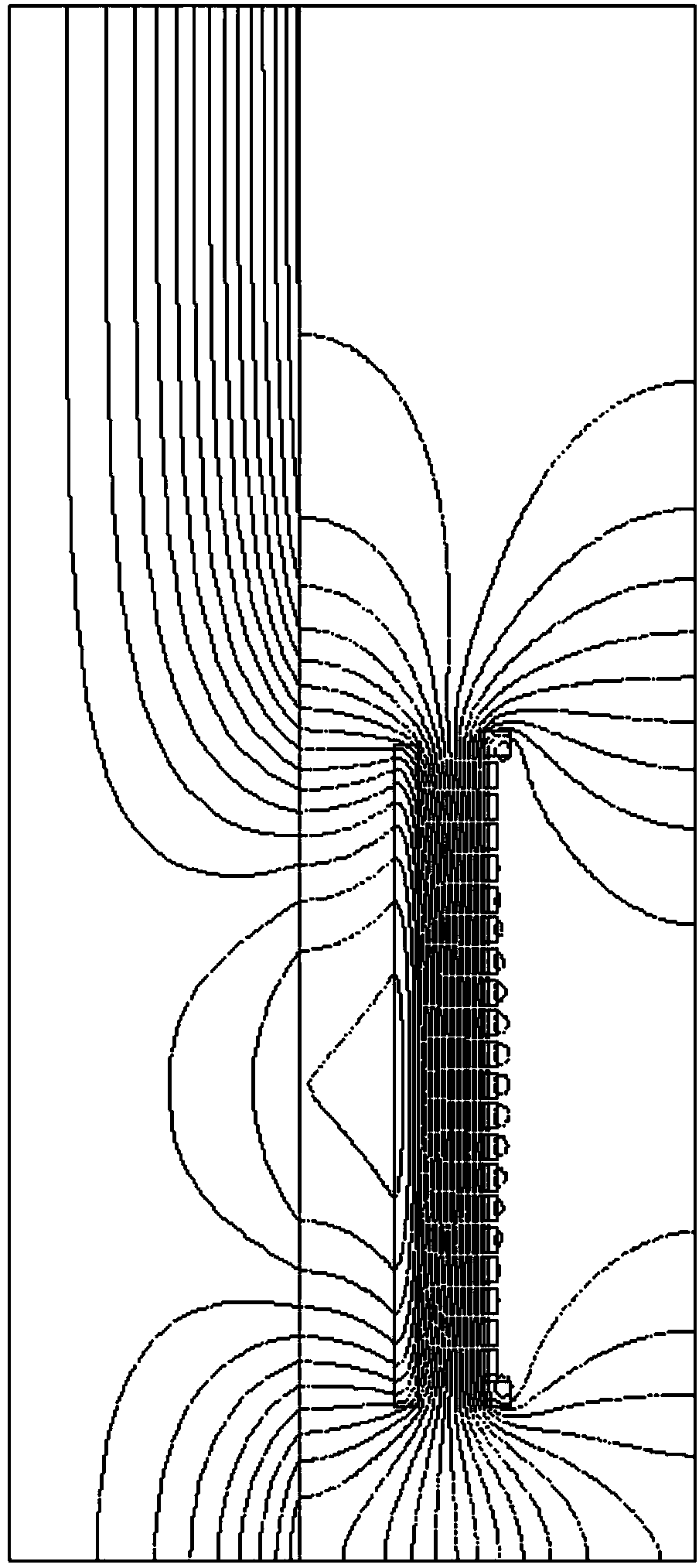

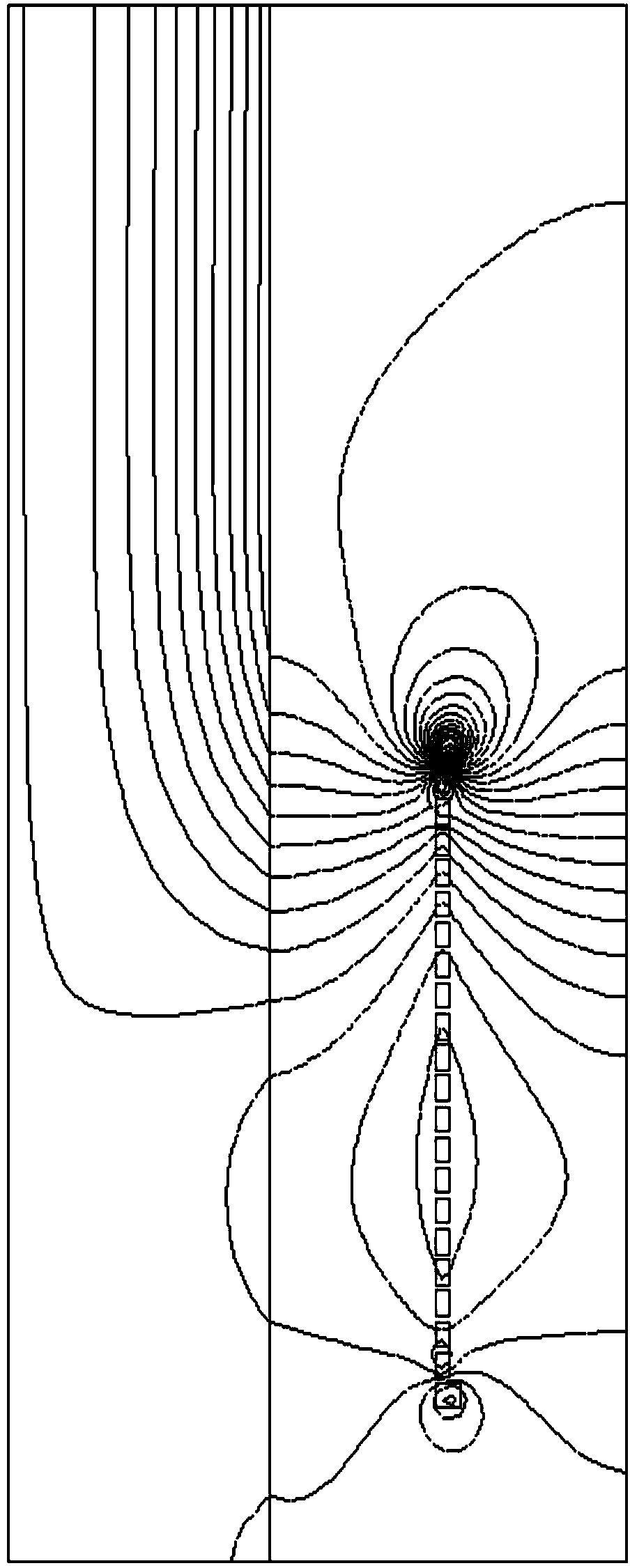

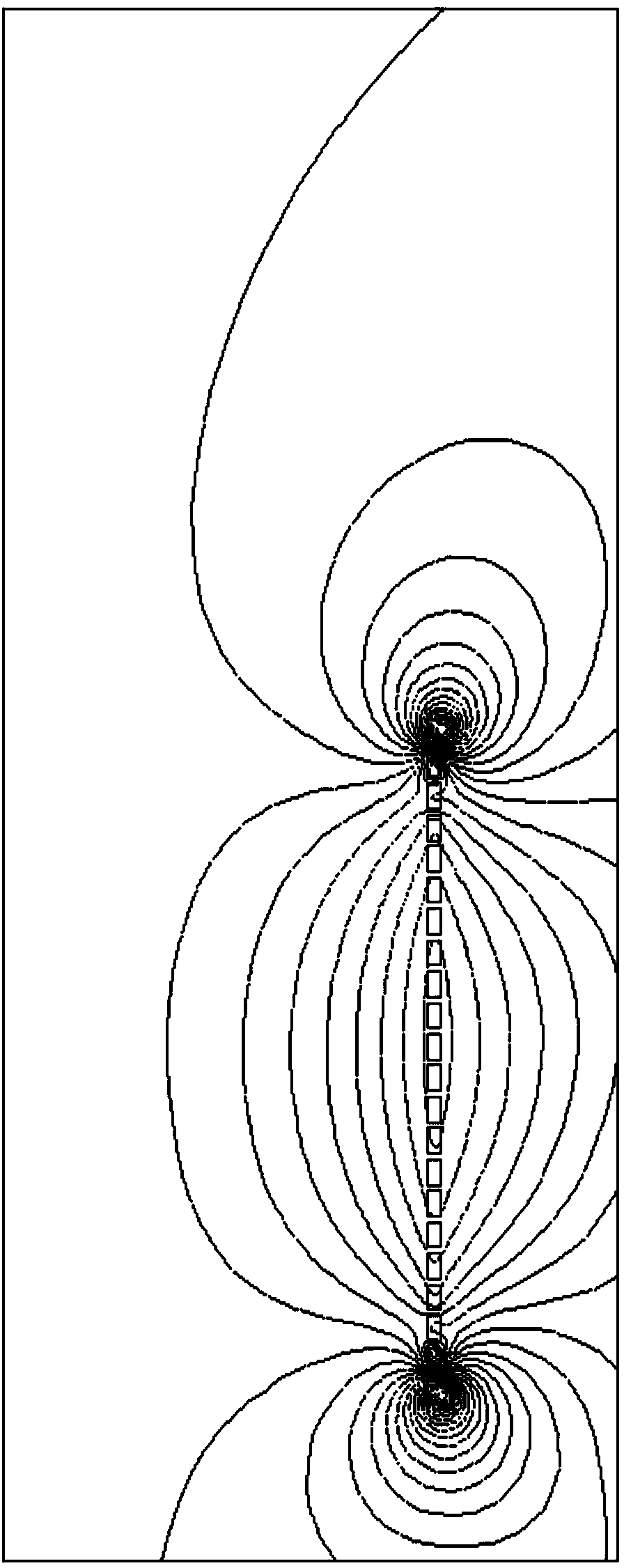

Intermediate-frequency induction and directional solidification ingot casting process and equipment utilizing same

The invention discloses an intermediate-frequency induction and directional solidification ingot casting process and equipment utilizing the same, which are used for producing extra-thick plates capable of guaranteeing internal quality of ingots and meeting requirements of the compression ratio. The intermediate-frequency induction and directional solidification ingot casting process includes that after being subjected to external refining, molten steel is delivered to an ingot casting platform by the aid of steel ladles and then used for casting, is poured into tundish through a long nozzle,and then is poured into a water-cooled crystallizer in a protected manner after flowing through a slide nozzle and an embedded nozzle; a vibration device of the crystallizer vibrates to start intermediate-frequency coils arranged outside the water-cooled crystallizer, heating of induction current and electromagnetic stirring effect are realized to control stop time, power and frequency of the induction coils at different positions of steel ingots so as to control internal quality of the steel ingots; a drawing device of a water-cooled underpan is started to draw the steel ingots from the water-cooled crystallizer, and finally the steel ingots are sent to be rolled. According to the distribution characters of an induced magnetic field in an intermediate-frequency electric induction furnace, inverted-V type segregation of the steel ingot is avoided. Gas impurity can be removed according to the electromagnetic stirring principle. Excellent feeding capacity of steel ingots is guaranteed, and the steel ingots casted by the process have compact insides and are free of segregation and low in impurity by the aid of an upper heat center utilizing induction heating. Due to better head feeding, the yield and production efficiency of steel ingots are improved.

Owner:UNIV OF SCI & TECH LIAONING

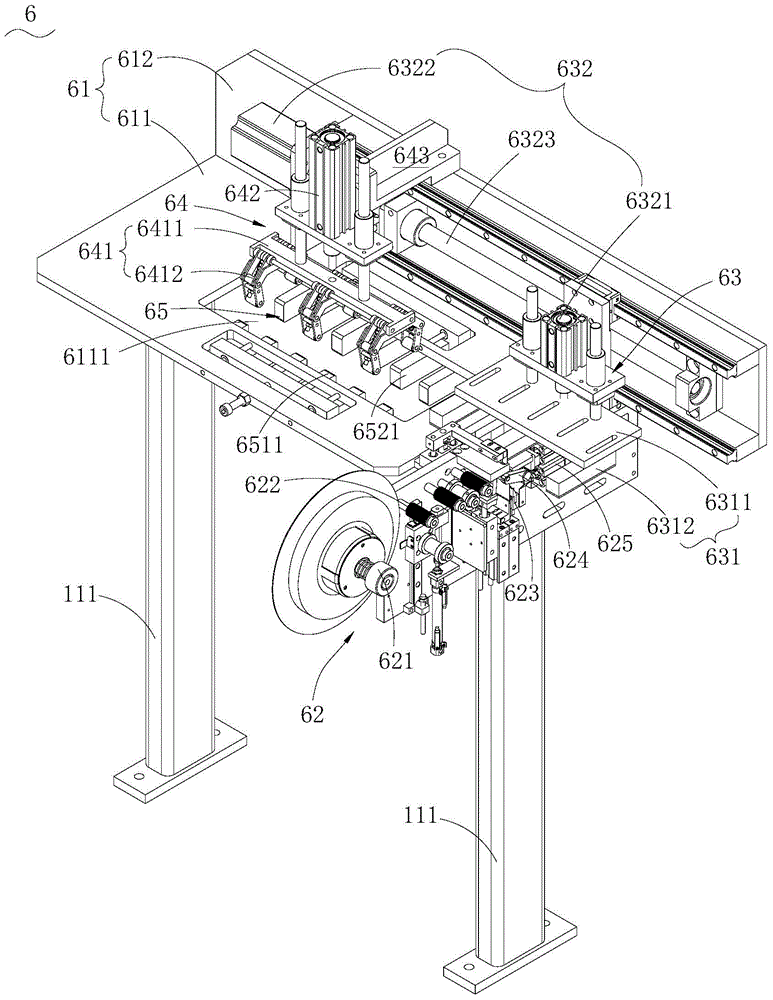

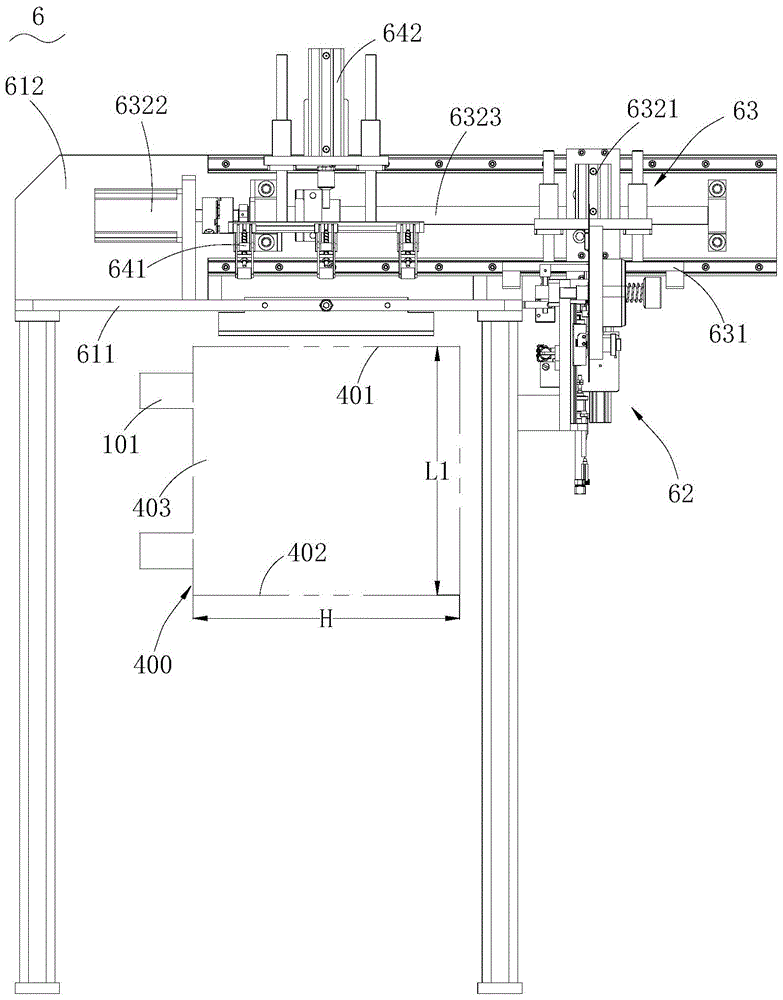

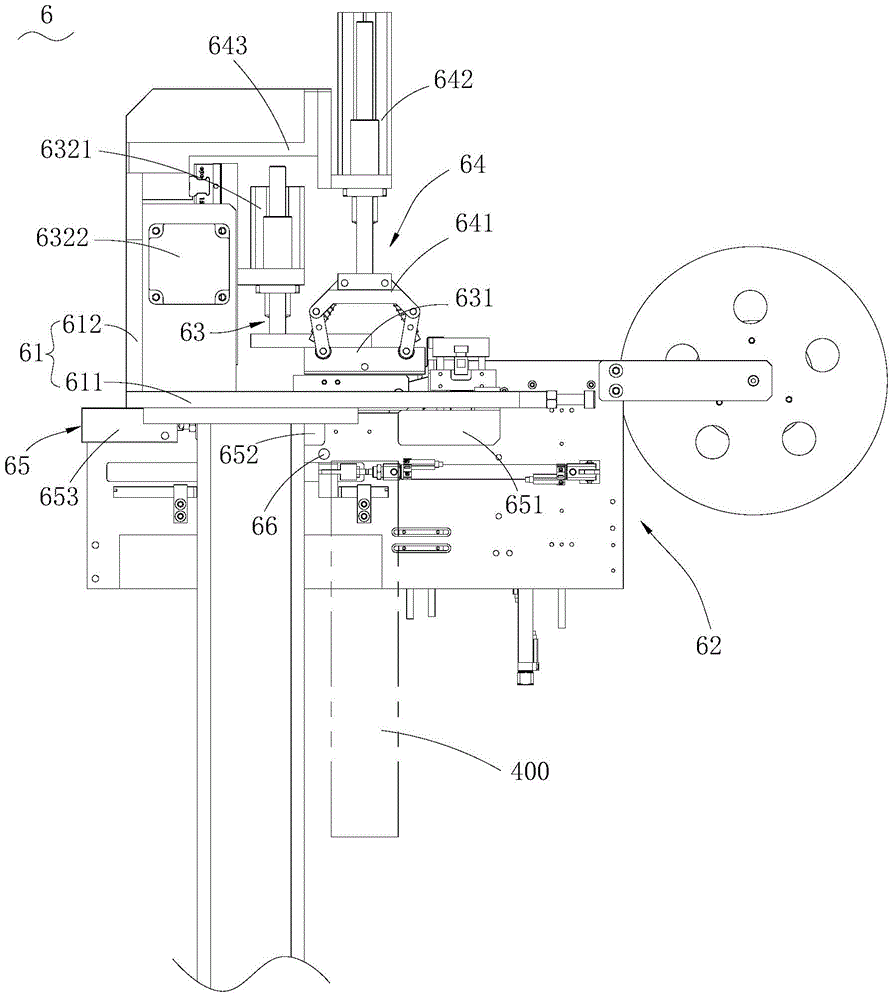

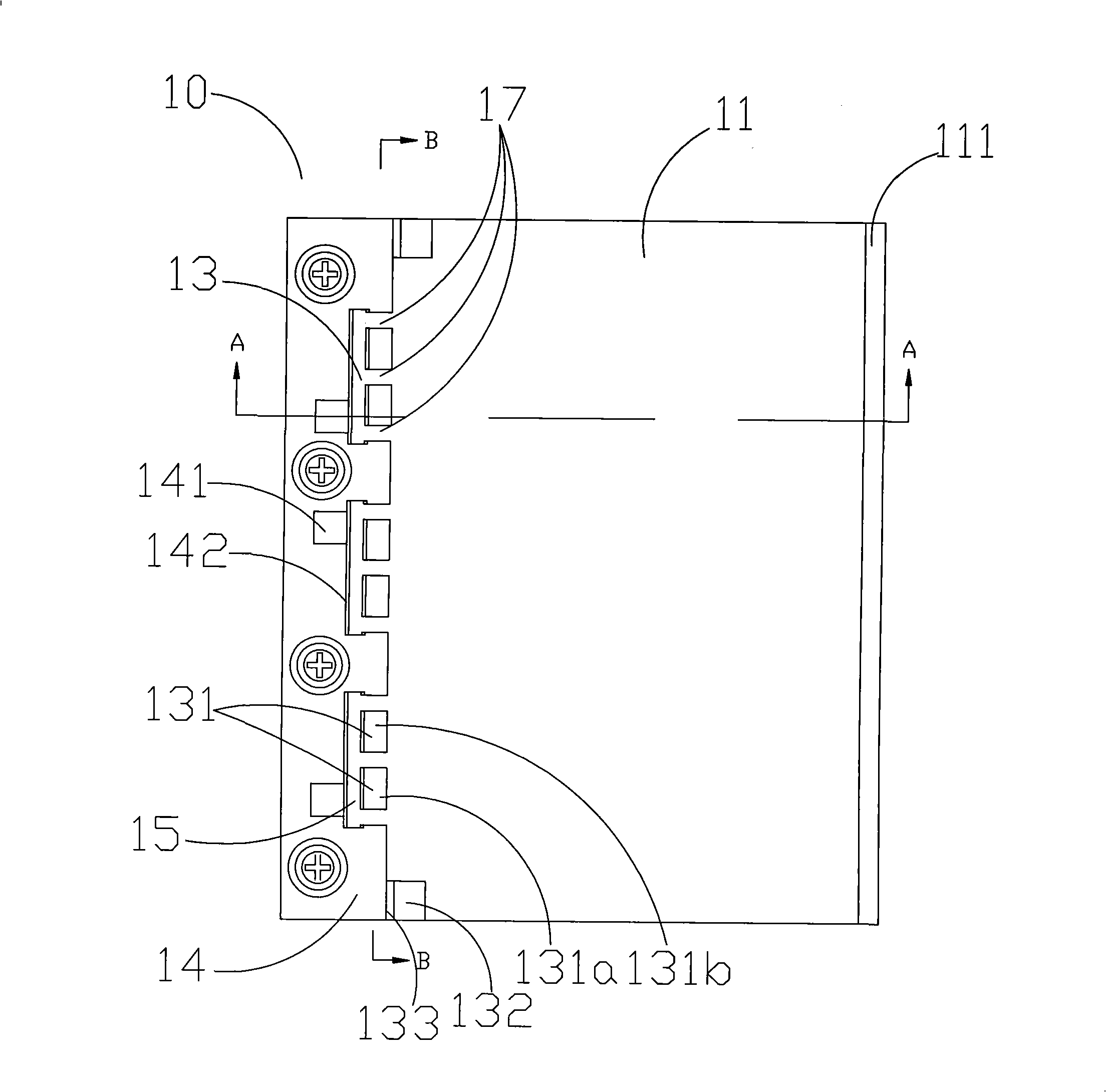

Laminating machine and cell rubberizing structure and cell rubberizing method therefor

ActiveCN105633446APacked tightlyQuality improvementFinal product manufacturePrimary cellsEngineeringCoating

The invention provides a laminating machine and a cell rubberizing structure and a cell rubberizing method therefor. The cell rubberizing structure comprises a rubberizing mounting base, a rubber feeding mechanism, a rubberizing mechanism, a rubber coating mechanism, a cell pressing mechanism and a membrane attachment rod, wherein the rubberizing mounting base is provided with a rubber feeding station and a rubberizing station; the rubberizing mechanism comprises a rubberizing suction cup and a suction cup drive component; the rubberizing suction cup adsorbs gummed paper provided by the rubber feeding mechanism on the rubber feeding station, is driven by the suction cup drive component to move on the rubberizing station to attach the gummed paper to the cell; the rubber coating mechanism comprises a rubber coating wheel component and a rubber coating drive component; the rubber coating wheel component is arranged corresponding to the rubberizing station and can press the gummed paper into a U shape to coat the cell when driven by the rubber coating drive component to move downwards; the cell pressing mechanism is arranged corresponding to the rubberizing station and is used for clamping two surfaces of the cell; and the membrane attachment rod is arranged at the lower part of the rubberizing station and is used for stopping the tail part of the membrane, so that the tail part of the membrane is attached to the surface of the cell. The laminating machine can coat the cell relatively tightly, and improves the cell quality.

Owner:DONGGUAN ARECONN PRECISION MACHINERY

Method and device for efficiently winnowing tobacco shreds

ActiveCN105396782AAchieve uniform distributionGood dispersionGas current separationEngineeringEqualization

The invention provides a method and device for efficiently winnowing tobacco shreds. Tobacco materials are fed into a winnowing chamber through conveying air, and the tobacco materials are loosened by a material equalization roll in the winnowing chamber and evenly distributed in the winnowing chamber; winnowing air is fed into the winnowing chamber, suspension winnowing is carried out on the tobacco materials in the winnowing chamber, and sundries are separated out; and meanwhile, the caked tobacco materials are suspended on air equalization plates in the winnowing chamber and are repeatedly jolted to be loosened under the action of upward blown winnowing air and gravity. A multilevel winnowing scheme is further designed, the amount of the materials subjected to secondary winnowing is greatly reduced, and therefore the purity of the tobacco shreds is improved, and energy consumption for winnowing is effectively reduced. According to the method and device, the winnowing efficiency is high, the purity of the tobacco shreds is high, and crushing is greatly reduced.

Owner:ZHISI HLDG GRP

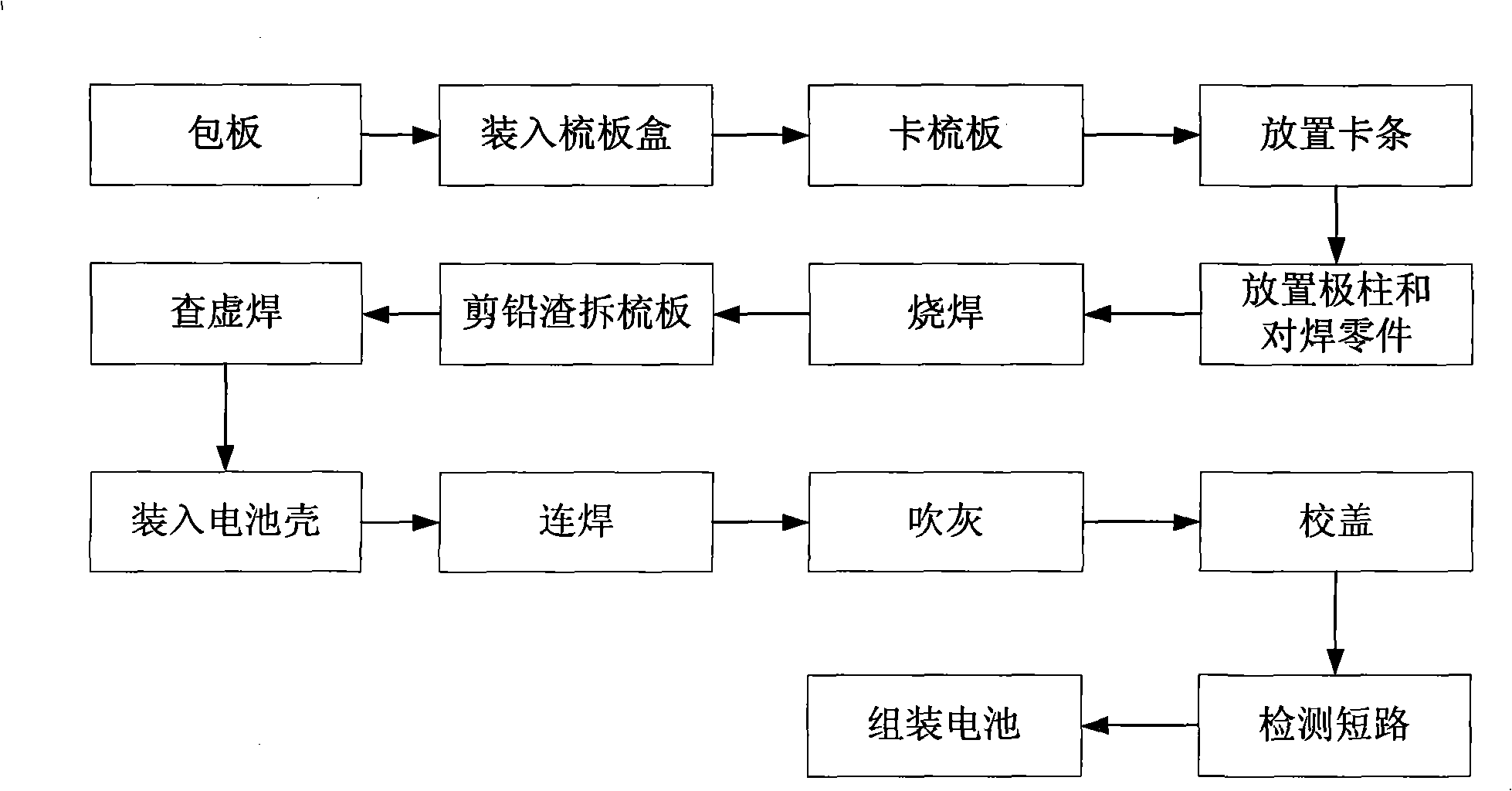

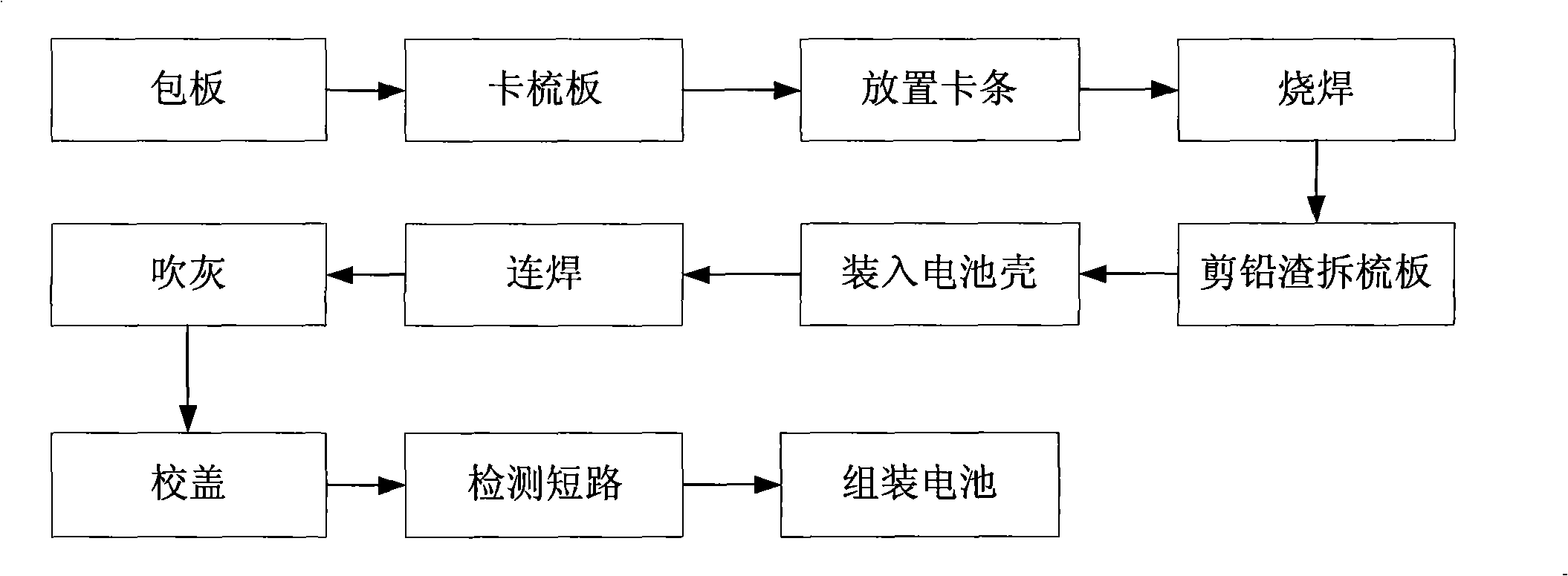

Sealed lead sour accumulator welding clamp and welding process thereof

InactiveCN101342652AThickness is easy to controlReduce processWelding/cutting auxillary devicesAuxillary welding devicesButt weldingBusbar

The invention discloses a sealed lead acid battery welding fixture and a welding process; the welding fixture comprises two welding comb plates, a positive welding comb plate and a negative welding comb plate, which comprise a vacant comb plate groove, a vacant comb plate tooth, a column and a locating plate. The vacant comb plate groove is arranged on the vacant comb plate tooth. The vacant comb plate is connected with the locating plate through the column. A busbar, a designed detail part and a tab seam matched with the tab of the plate are formed between the comb plate groove and the vacant comb plate tooth. The sealed lead acid battery welding fixture also comprises a locking strip. The locking strip is provided with a bayonet which is corresponding to the tab seam of the two welding comb plates. The welding process comprises plate wrapping, comb plate locking, locking strip arranging, flow welding, lead ash cutting and comb plate disassembling, battery shell setting, joint welding, soot blowing, cap checking, short circuit checking and battery assembling. The traditional processe of comb plat box setting, polar post arranging and parts butt welding, and the step of false welding checking are avoided. The production efficiency is improved.

Owner:SHENZHEN SUNNYWAY BATTERY TECH

Packing steel belt unwinding and cutting device

ActiveCN105364158APrevent proliferationEasy to moveShearing machinesShearing toolsRubber materialCam

The invention discloses a packing steel belt unwinding and cutting device and belongs to the field of packaging machines and equipment. The packing steel belt unwinding and cutting device comprises a horizontal movement base, a rotary supporting frame, an unwinding support and a discharging and cutting mechanism. A rotary shaft is horizontally and rotatably connected to the middle of the unwinding support. A braking mechanism is arranged on the outer side of the portion, between the unwinding support and the rotary supporting frame, of the rotary shaft. A material supporting baffle is vertically and fixedly arranged on the portion, at one side of the unwinding support, of the rotary shaft. A limiting baffle is vertically arranged on the portion, at one side of the material supporting baffle, of the rotary shaft. A limiting sleeve is arranged at the outer end of the rotary shaft. The discharging and cutting mechanism comprises a rubber material guiding roller, a discharging plate, a cutting supporting frame and a cutting cam. The discharging plate is horizontally arranged at one side of the cutting supporting frame. An upper cutting knife and a lower cutting knife are arranged on the portions, at the upper side and the lower side of a discharge outlet, of the cutting supporting frame respectively. The packing steel belt unwinding and cutting device is simple in structure and convenient to use; a packing steel belt can be rapidly and efficiently unwound and cut stably and accurately, the working efficiency of workers is improved, and the use requirements are met.

Owner:ZHEJIANG HUASHUN METAL MATERIAL CO LTD

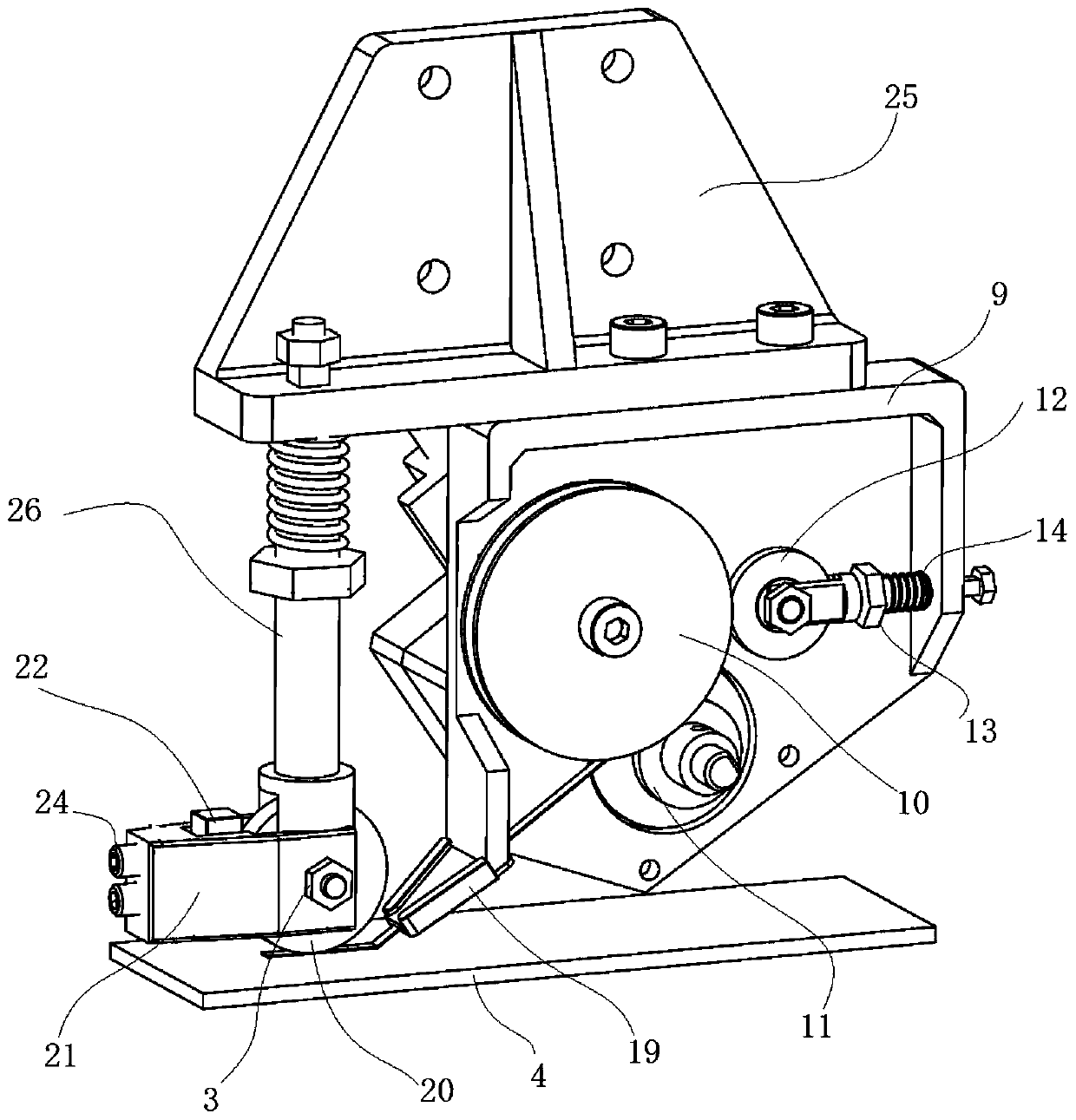

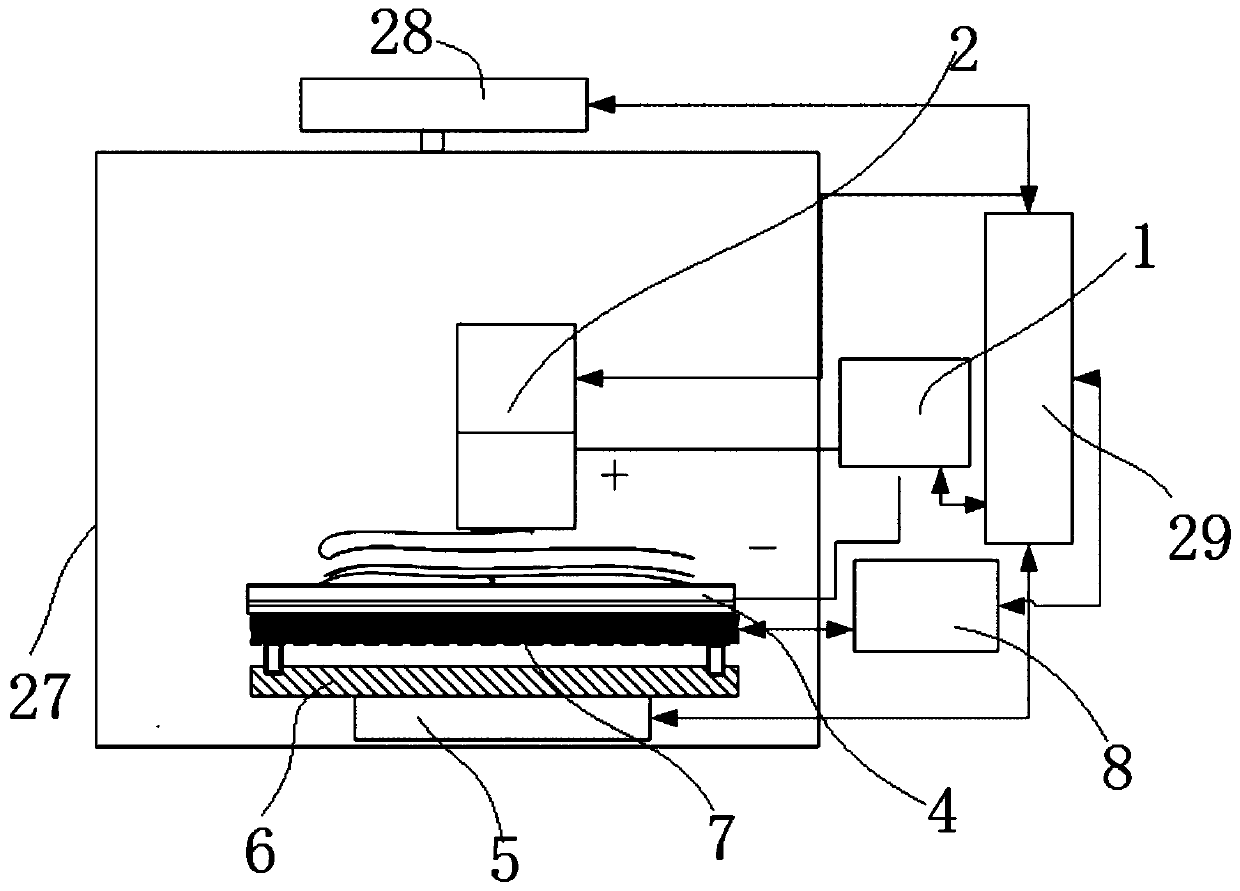

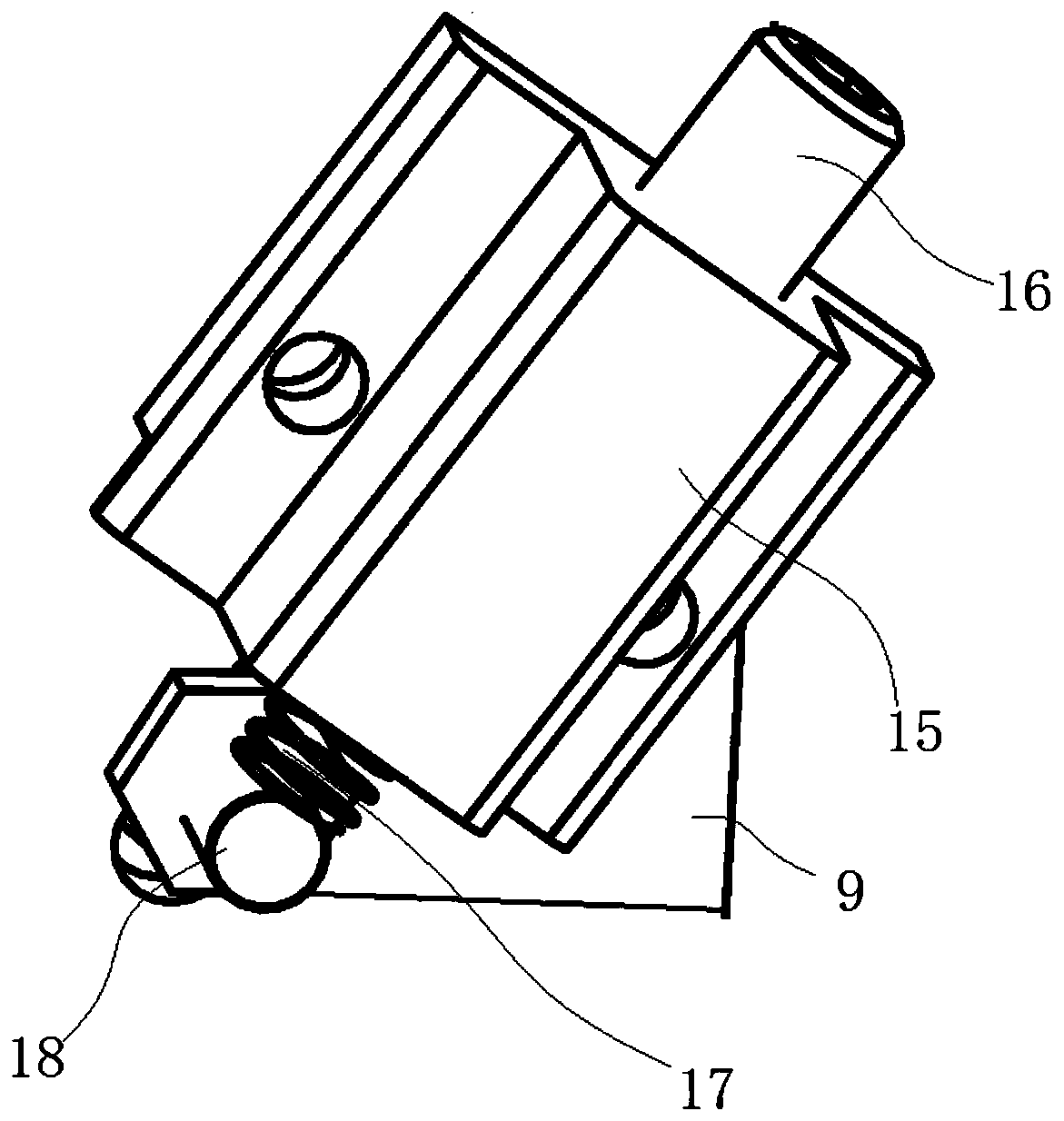

3D printing system based on Joule heat and used for thermoplastic alloy

PendingCN110899482ARealize temperature controlSolve crackingShaping toolsMetal working apparatusInformation processingThermoplastic

The invention discloses a 3D printing system based on Joule heat and used for a thermoplastic alloy. A wire feeding device and a hot rolling wheel are oppositely fixed in position; a wire feeding portof the wire feeding device is located in one side of the hot rolling wheel; the hot rolling wheel and a forming base plate are connected to a negative pole and a positive pole of a Joule heat power supply separately; the wire feeding device and the forming base plate are capable of relatively moving; printing wires are conveyed to the forming base plate by virtue of the wire feeding device, and then the wires to be printed are tightly pressed onto the forming base plate through the hot rolling wheel; the hot rolling wheel and the forming base plate form a loop; and the conductive wires are instantaneously softened at the contact ends of the hot rolling wheel and the forming base plate. The device is simple in structure, capable of realizing high-utilization-rate, high-quality, low-cost, green and environment-friendly additive manufacturing for metal parts, and is metal additive manufacturing method integrating materials, machinery, measurement and control technology, and information processing; and moreover, high compactness in a formed sample piece is realized through rolling at the moment of melting the wires to be printed by the hot rolling wheel.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Yarn rolling device capable of preventing yarn from loosening

The invention relates to the field of cloth rolling, and in particular to a cloth rolling device capable of preventing cloth from loosening. The cloth rolling device comprises a support mechanism, a positioning mechanism, a guide mechanism, a cleaning mechanism, a rolling mechanism and a protection mechanism; the rolling mechanism is installed on a surface of the support mechanism; after the rolling mechanism is connected with a power supply, rolling of a cloth is realized; the protection mechanism positioned on the surface of the support mechanism is slidably connected with a surface of the support mechanism in an annular array manner at equal intervals, wherein the cloth is protected from loosening during rolling; one end of the rolling mechanism is rotationally connected with the cleaning mechanism on a side wall of the guide mechanism, wherein the rolling mechanism rotates to drive the cleaning mechanism to clean the cloth, so that dust is prevented from adhering to a surface of the cloth when the cloth is rolled, and production quality of the cloth is improved; and the positioning mechanism is in threaded connection with the top of the support mechanism, so that the rolling mechanism can be positioned conveniently during rolling, and the rolling mechanism is prevented from shaking. After rolling is finished, the positioning mechanism is detached to be matched with the rolling mechanism for ejecting the cloth, so that the rolled cloth is convenient to take.

Owner:ANHUI HANLIAN TEXTILE CO LTD

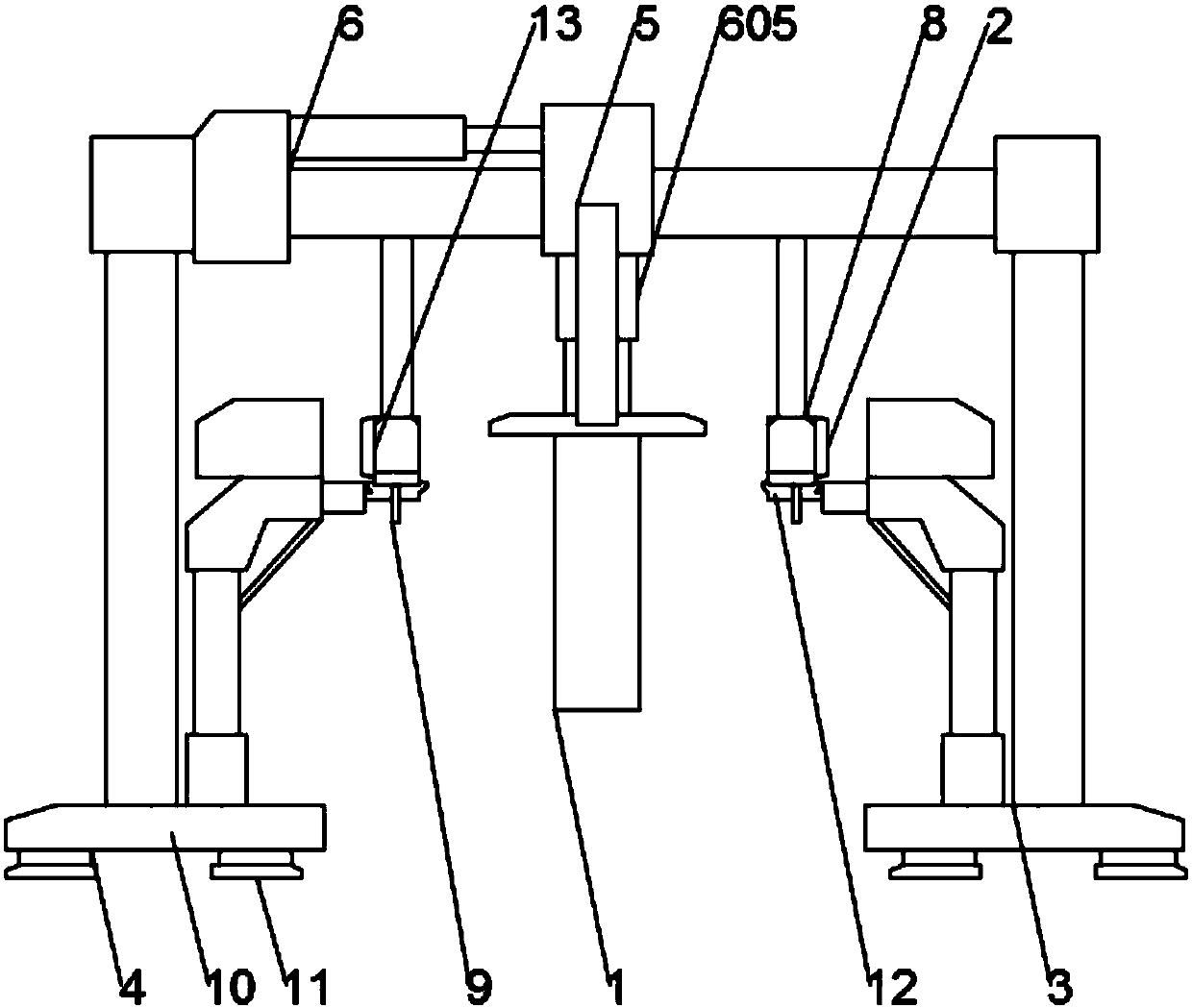

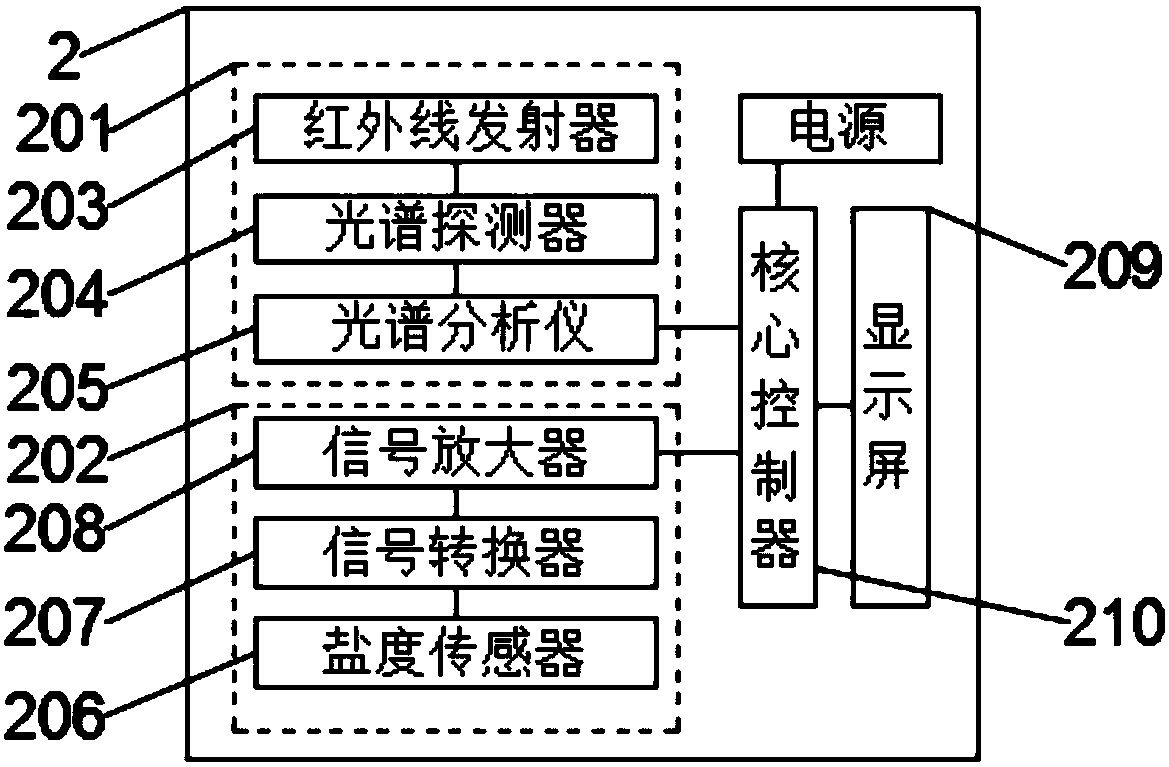

Seawater sampling and detecting device

ActiveCN108051391APrevent deviationReduce vibrationWithdrawing sample devicesMaterial analysis by electric/magnetic meansEngineeringSeawater

The invention discloses a seawater sampling and detecting device, comprising a movable base, a main body frame and a sampling unit, wherein the main body frame is fixedly connected with the movable base through an adjustment bracket; a fixed seat is arranged on the surface of the adjustment bracket; the surface of the fixed seat is loaded with a charging barrel; a dual detecting unit is installedon the side surface of the charging barrel; the movable base is fixed by a positioning frame located at the bottom; the main body frame comprises a central column and an electric push rod; one end ofthe electric push rod is mounted on one end of the central column through a metal seat, and the other end of the electric push rod is connected with a sliding seat sleeved on the surface of the central column; a fixed plate is connected with one side of the sliding seat and is fixedly connected with the sampling unit; and the sampling unit is fixed by an anti-shake unit. The whole seawater sampling and detecting device can rapidly sample and detect seawater from different regions and at different depths, is hardly to shake and more stable during sampling, can be quickly cleaned after detectionand avoids generation of residues or corrosion.

Owner:SHANGHAI BRAVO TESTING TECH CO LTD

Casting technology of wear-resistant and low-porosity steel casting

InactiveCN104325073AStrong ability to resist sand inclusionImprove thermal stabilityFoundry mouldsFoundry coresWear resistanceHot blast

The invention discloses a casting technology of a wear-resistant and low-porosity steel casting. The casting technology takes silica sand, bentonite, an additive and water as molding materials, and comprises the steps of preparing a casting mould by mixing the molding materials; drying the prepared casting mould with hot air at the temperature of 130-140 DEG C; injecting the dissolved metallic solution into the casting mould, and pouring a semi-finished product; carrying out heat treatment on the semi-finished product, polishing and machining to obtain the finished product; checking and putting into a storage. After the casting technology is adopted, the wear resistance and the toughness of the casting are greatly improved, the pores in the casting are reduced, and the service life of the casting is prolonged; furthermore, the casting technology is simple in operation and low in cost.

Owner:DAFENG HONGLIAN CAST STEEL

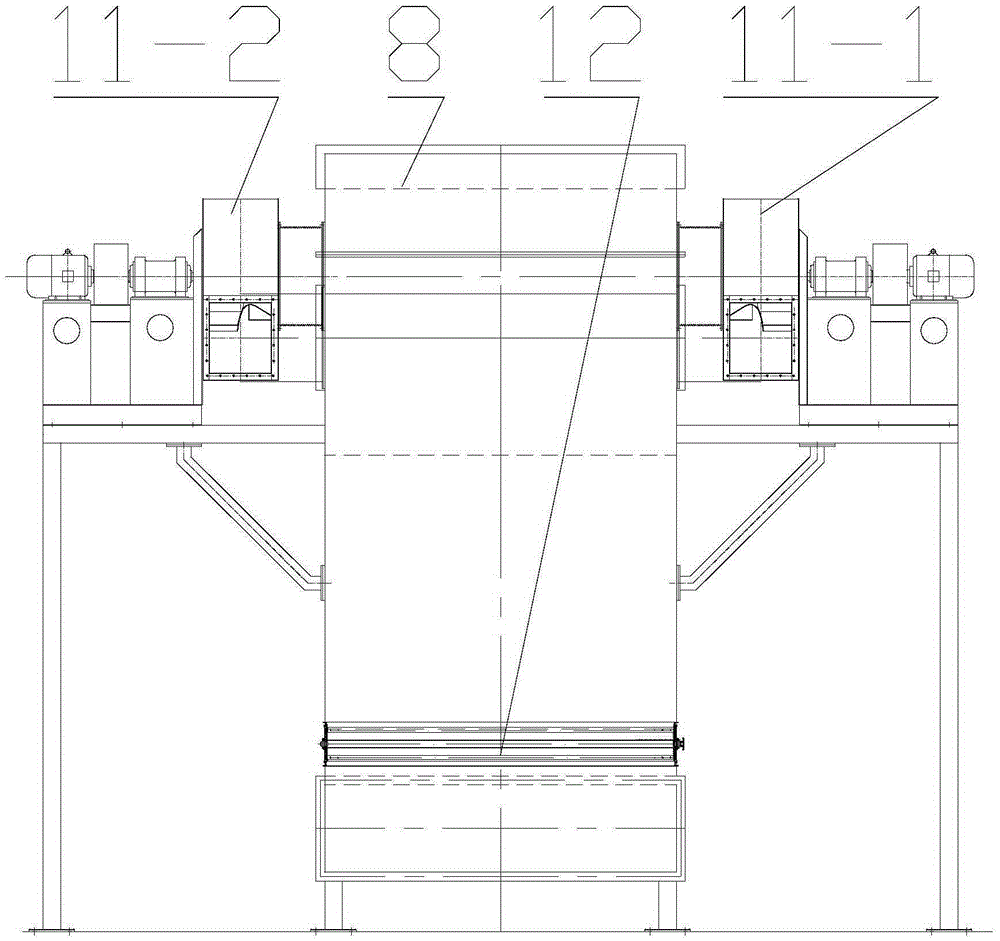

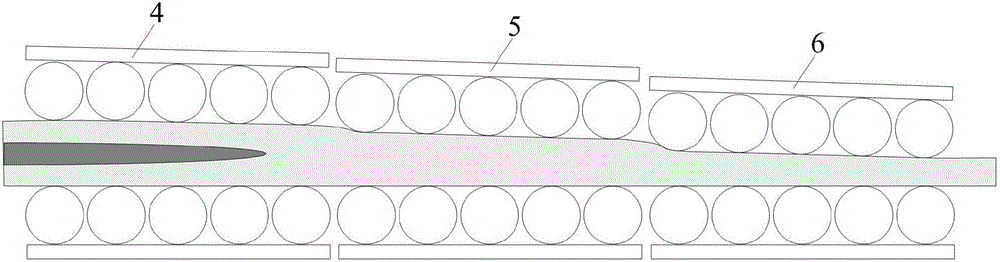

Continuous casting billet solidification end single-point and continuous heavy reduction technology

The invention provides a continuous casting billet solidification end single-point and continuous heavy reduction technology and belongs to the field of continuous casting production. The heavy reduction technology is completed through 1-3 fan-shaped sections. Each fan-shaped section comprises 5-7 pairs of pinch rolls, wherein each pair of pinch rolls comprises an upper supporting roll and a lower supporting roll. The single-point reduction of 3-20 mm is exerted on the upper supporting roller at an inlet of each fan-shaped section, so that the single roll reduction effect is achieved; and in this way, the strain rate of the heart portion of a casting billet can be effectively improved, and welding of a central pipe and the improvement on the density of the heart portion of the casting billet are facilitated. Meanwhile, the billet is continuously rolled by the follow-up upper supporting rolls of each fan-shaped section at the reduction rate of 1.5-5.0 mm / m, and it is guaranteed that the casting billet cannot rebound after rolling is conducted. Besides, a billet shell of the casting billet is forced to continuously shrink, and therefore the looseness caused by the difference between the inner shrinkage rate and the outer shrinkage rate of the casting billet is relieved.

Owner:NORTHEASTERN UNIV LIAONING

Wax mold of large-size hollow shrouded blade casting pouring system and manufacturing method of wax mold

The invention provides a wax mold of a large-size hollow shrouded blade casting pouring system and a manufacturing method of the wax mold. The wax mold comprises a casting wax mold and a runner wax mold; a core is arranged in the casting wax mold; a shroud inner gate is formed in the top of the casting wax mold, while a tenon inner gate is formed in the bottom of the casting wax mold; the runner wax mold comprises a first spherical riser of which the bottom is bonded to the top of the shroud inner gate and the top is connected to one end of a first horizontal runner; the other end of the first horizontal runner is connected to a straight runner; the top of the straight runner is bonded to a gate cup, while the bottom of the straight runner is connected to a second spherical riser; the second spherical riser is bonded to the tenon inner gate; the second spherical riser is connected to one end of a second horizontal runner, and the other end of the second horizontal runner is connected to the casting wax mold. According to the wax mold of the large-size hollow shrouded blade casting pouring system, the spherical risers and the corresponding runners are designed reasonably, such that smooth filling and effective feeding to a casting can be realized and the stress can be reduced; hence, the wax mold is applicable to produce large-size, hollow shrouded and complex-structure blades; the pouring difficulty can be reduced, such defects as core breakage, looseness and cracks of the casting can be avoided, and the product qualification rate can be increased.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

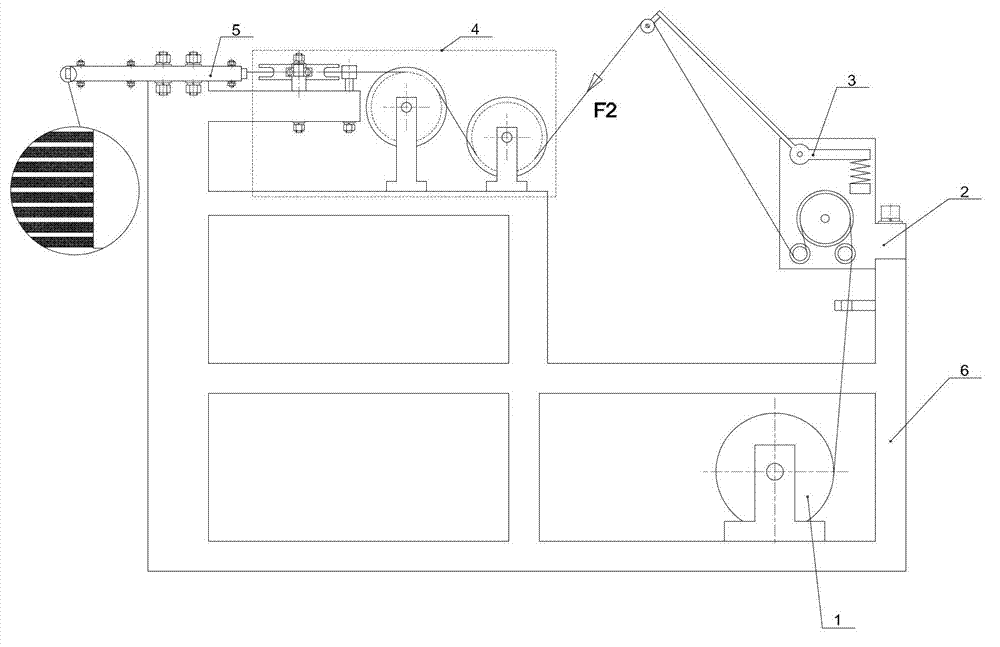

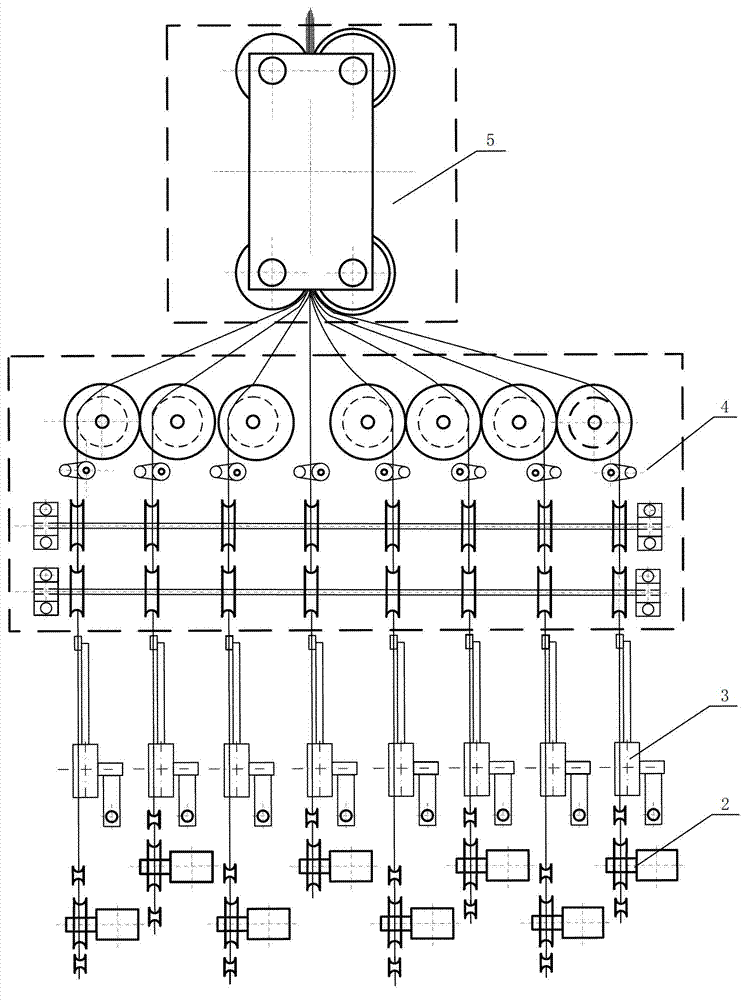

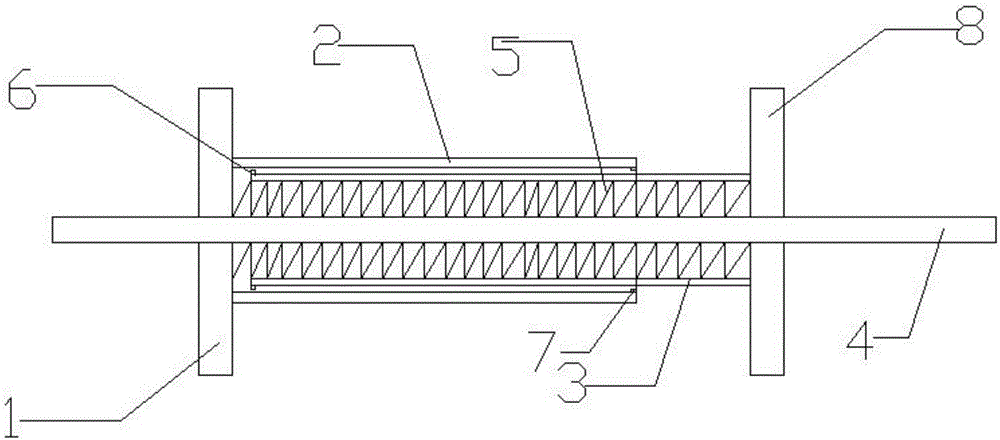

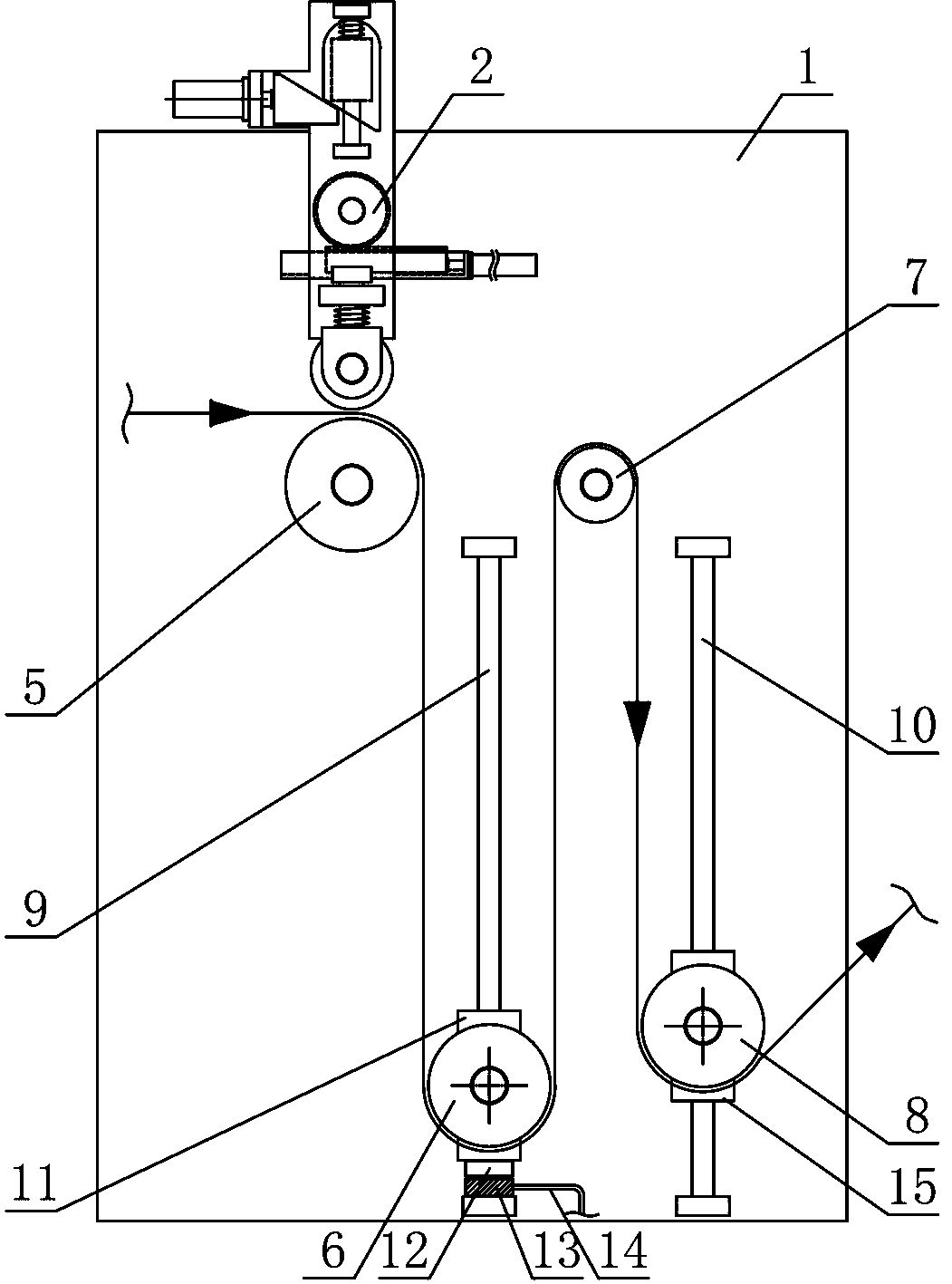

Wire arranging device of winding machine

InactiveCN103296840AImprove work efficiencyAvoid loose threadsManufacturing dynamo-electric machinesWinding machineWire tension

The invention discloses a wire arranging device of a winding machine. The wire arranging device comprises a wire concentrating and arranging device, a rack and a wire arranging unit, wherein the wire concentrating and arranging device and the wire arranging unit are connected to the rack, respectively; the wire arranging unit comprises a wire supply drum, a passive tension controller, a positive tension controller and a wire direction converter; an enameled wire to be twisted is wound on the wire supply drum; the wire supply drum is located below the passive tension controller; the passive tension controller is located below the positive tension controller; and the enameled wire to be twisted passes through the passive wire tension controller, the positive wire tension controller, the wire direction converter and the wire concentrating and arranging device sequentially. The wire arranging device provides the enameled wire with uniform tension for a winding end of the winding machine, so that the wire arranging device of the winding machine improves the winding quality of the coil, increases work efficiency of the winding machine, and guarantees the motor product quality at the later stage.

Owner:SOUTHEAST UNIV

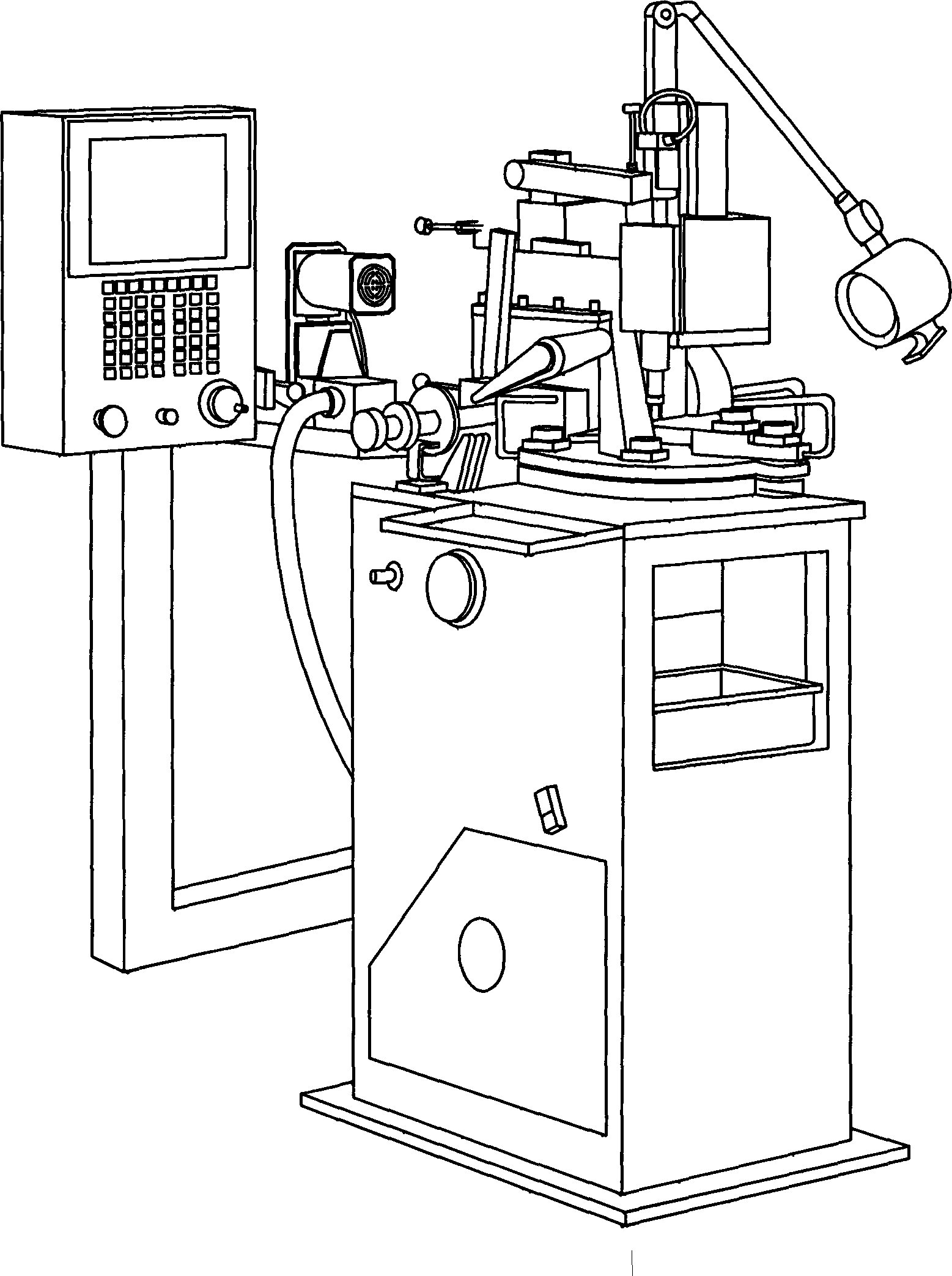

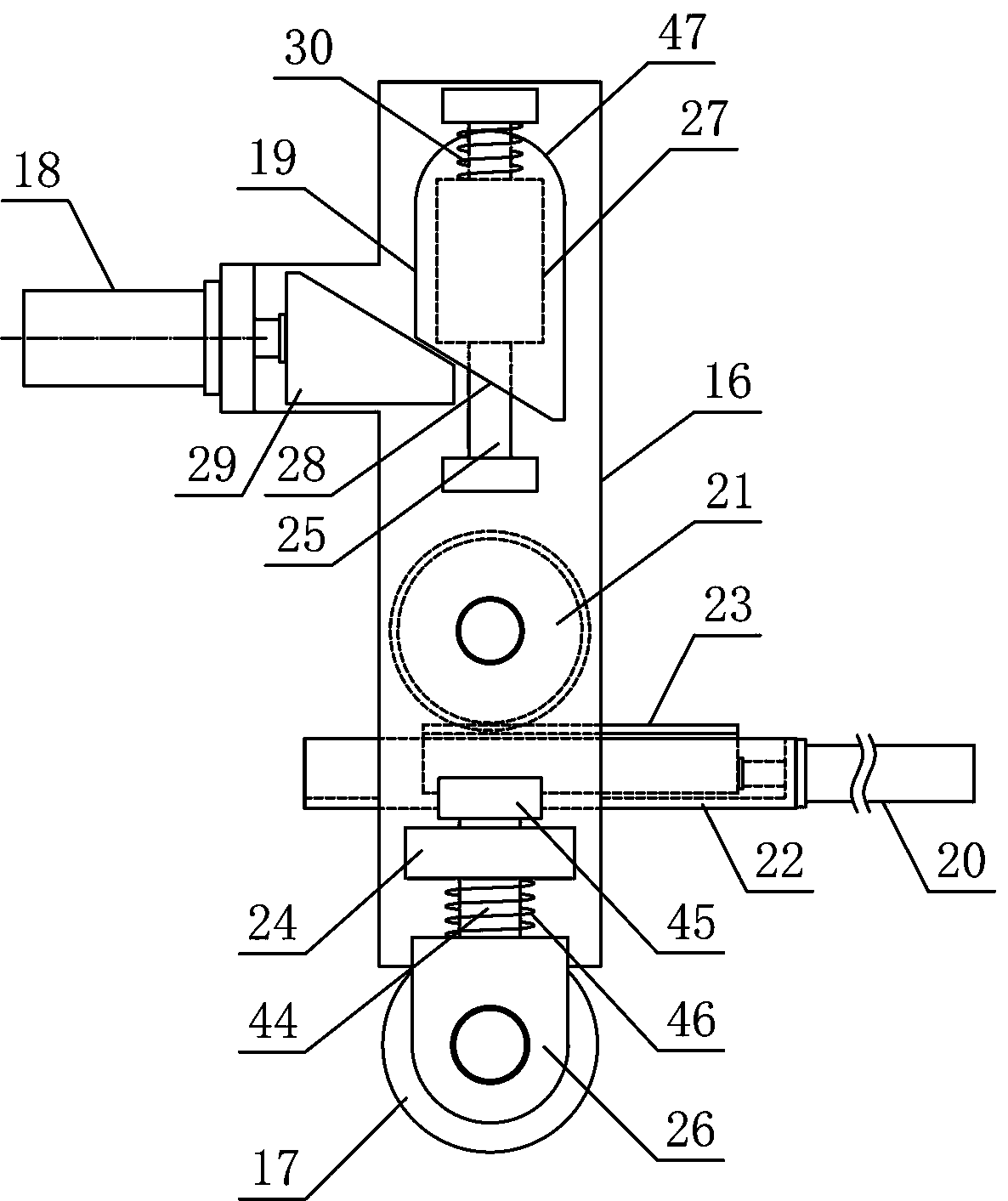

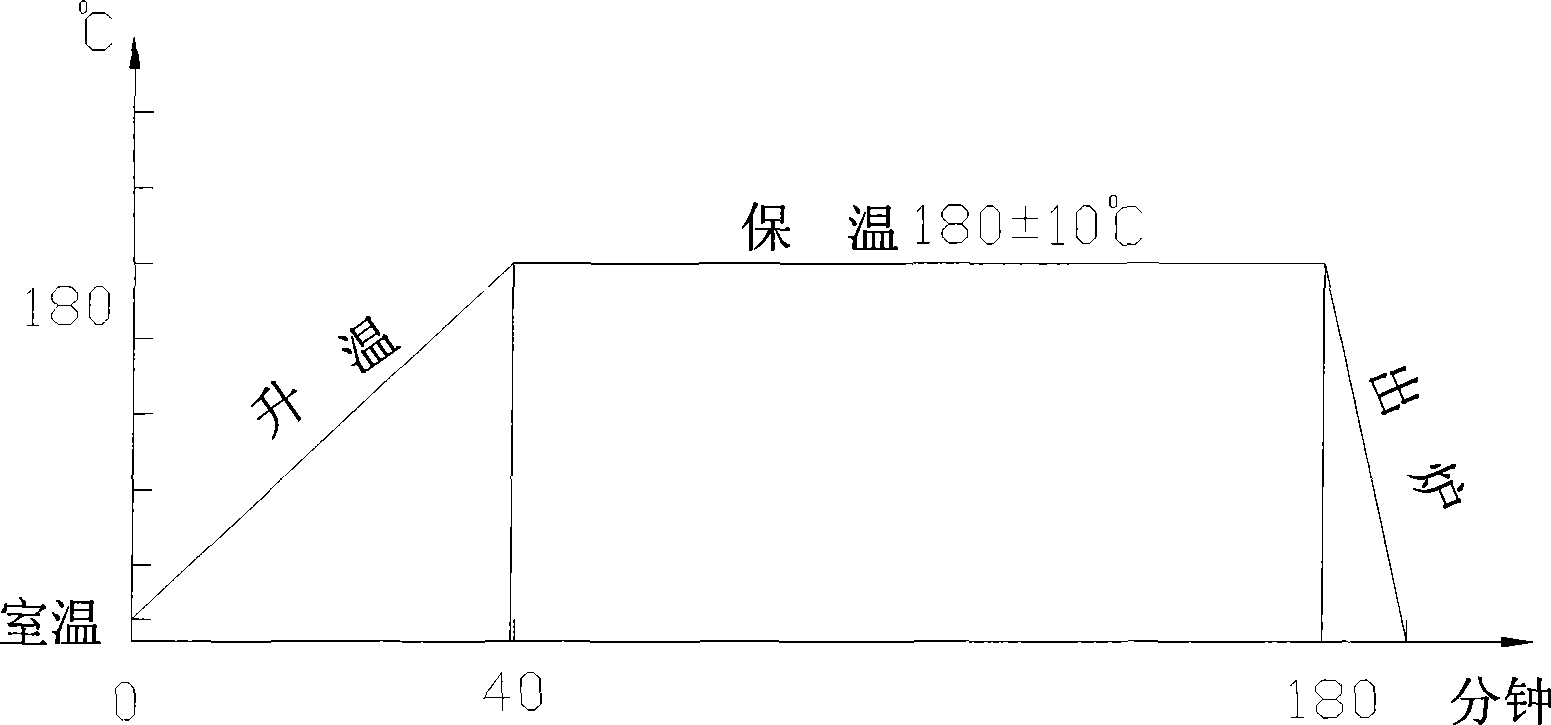

Self-bonded coil forming machine and process

InactiveCN102709047ASimple production processShort time consumptionFluid heatersCoils manufactureWork in processConductor Coil

The invention discloses a self-bonded coil forming machine and a self-bonded coil forming process. A winding mechanism is arranged on the forming machine and comprises a winding shaft and a winding chuck which can rotate along with the winding shaft; the self-bonded coil forming machine also comprises a coil heating system; and the heat spray opening of the coil heating system is opposite to a semi-finished self-bonded coil wound on the winding chuck. The coil heating system is arranged on the self-bonded coil forming machine, so that the semi-finished self-bonded coil can be heated and baked after being wound; a self-bonded layer on the outer layer of an enamelled wire is softened and formed through bonding, namely one set of equipment can be used for winding and baking; the production process is simple; a small amount of equipment is involved; the time consumption is low; the production efficiency is high; resources are saved; furthermore, the self-bonded coil is wound and baked on the same equipment, so that the self-bonded coil is not required to be transferred to an oven and heated after being wound; phenomena of rebounding and loosening of the coil during transferring are avoided; and the qualified rate of a product is increased.

Owner:昆山广辉精密五金有限公司

Telescopic cable winding device

The invention discloses a telescopic cable winding device. The telescopic cable winding device comprises a disc-like base. A rotary shaft is fixedly arranged in the center of the disc-like base. A clamping plate is arranged on the rotary shaft. A metal tube A is arranged on the disc-like base. A metal tube B is arranged on the clamping plate and sleeved with the metal tube A. A plurality of springs surrounding the rotary shaft are horizontally arranged in the metal tube B. One end of each spring is fixed to the disc-like base, and the other end of each spring is fixed to the clamping plate. When the telescopic cable winding device is used for winding cables, the rotary shaft is rotated to drive the disc-like base to rotate, then the metal tube A and the metal tube B are driven to rotate, along with increase of the collection amount of the cables, the cables push the clamping plate to move rightwards, and the metal tube B is driven to stretch rightwards, so that the winding amount of the cables is increased; and the multiple springs surrounding the rotary shaft are horizontally arranged in the metal tube B, the effect that the clamping plate makes close contact with the cables all the time can be ensured, and the cables are prevented from loosening.

Owner:安庆市汉久电子科技有限公司

Yarn variable speed winding mechanism

The invention discloses a yarn variable speed winding mechanism, and belongs to the field of textile machining mechanical equipment. A yarn guide mechanism and a rolling mechanism are sequentially arranged on a conveying support in the horizontal direction, yarn is sequentially connected to a yarn inlet rotating roller, a yarn storage rotating roller, a yarn guide rotating roller and a lifting rotating roller in a wound manner, a yarn compressing mechanism is vertically arranged on at the position, on the upper side of the yarn inlet rotating roller, of the conveying support, a rolling motor is in transmission connection with an output gear, a rotating crank is arranged on one side of a rolling gear in the radial direction of the rolling gear, a crank sliding block of the outer end of therotating crank is in rotatable connection to the end of one side of the rotating crank, a rolling rotating shaft is horizontally and rotatably connected to the upper side of a rolling support, a rotating rocker arm is fixedly arranged on one side of the rolling rotating shaft in the radial direction of the rolling rotating shaft, and the crank sliding block is arranged in a rolling guide groove inthe rotating rocker arm in a sliding manner. The yarn variable speed winding mechanism is reasonable in structural design, yarn can be continuously rolled efficiently and compactly, the yarn conveying and rolling automation degree is improved, and the production use needs are met.

Owner:浙江云飞扬羊绒有限公司

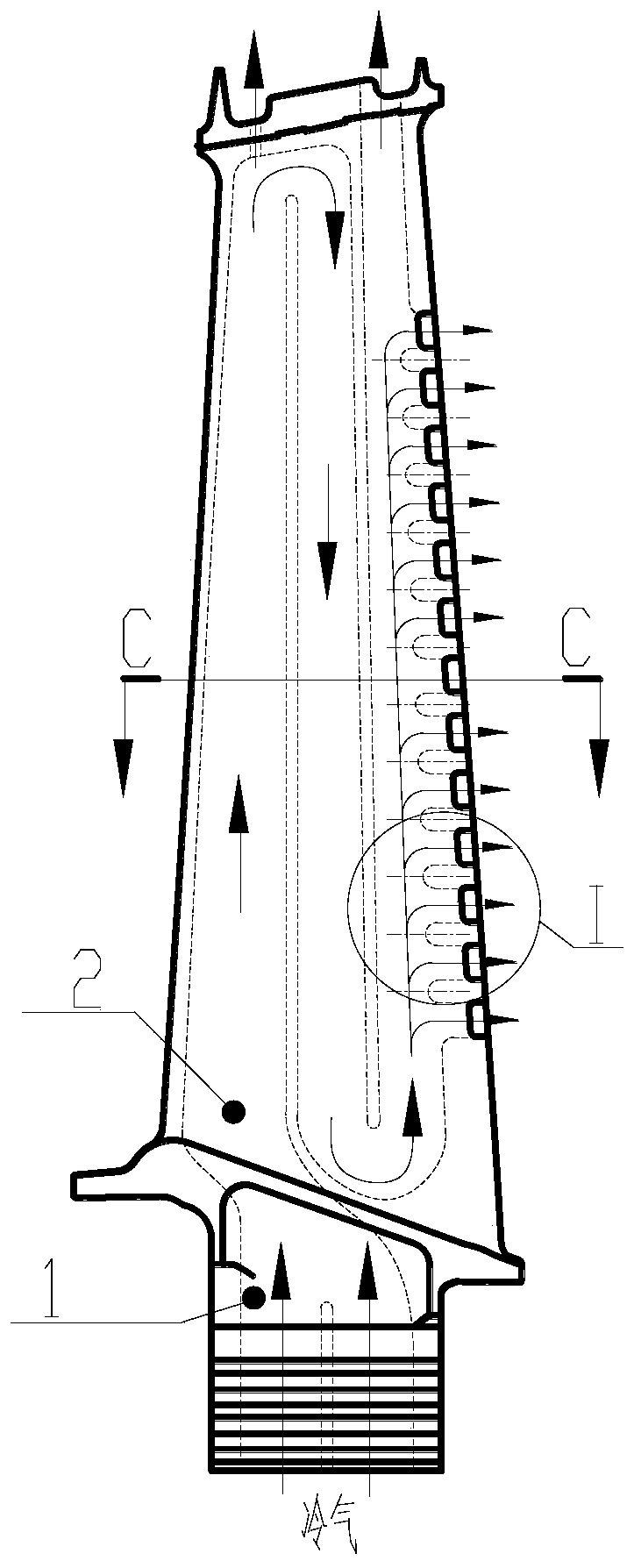

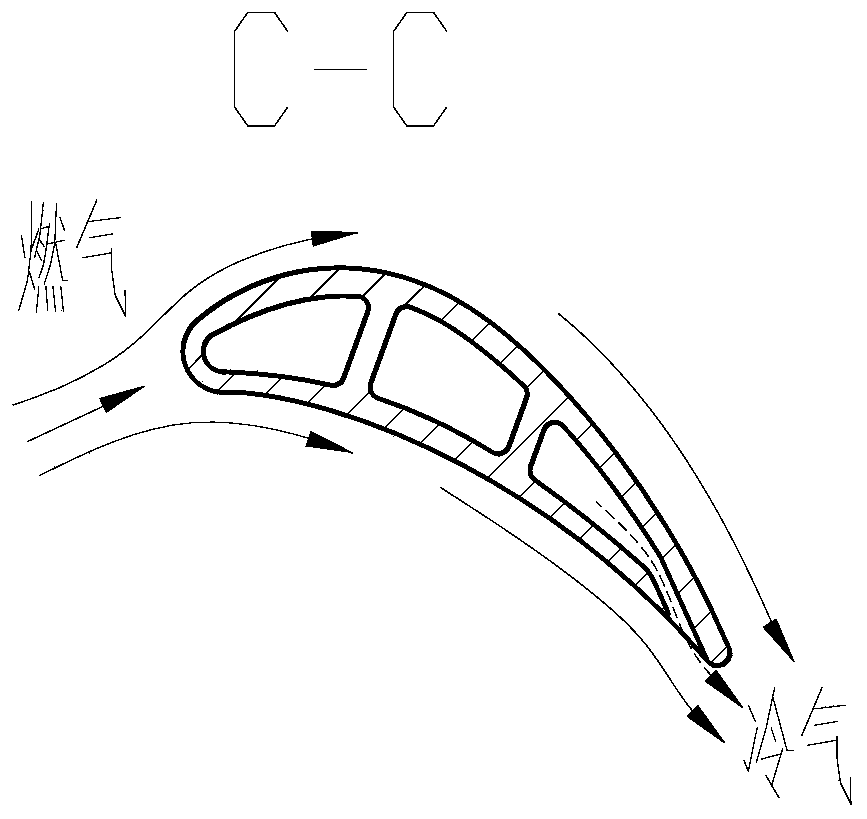

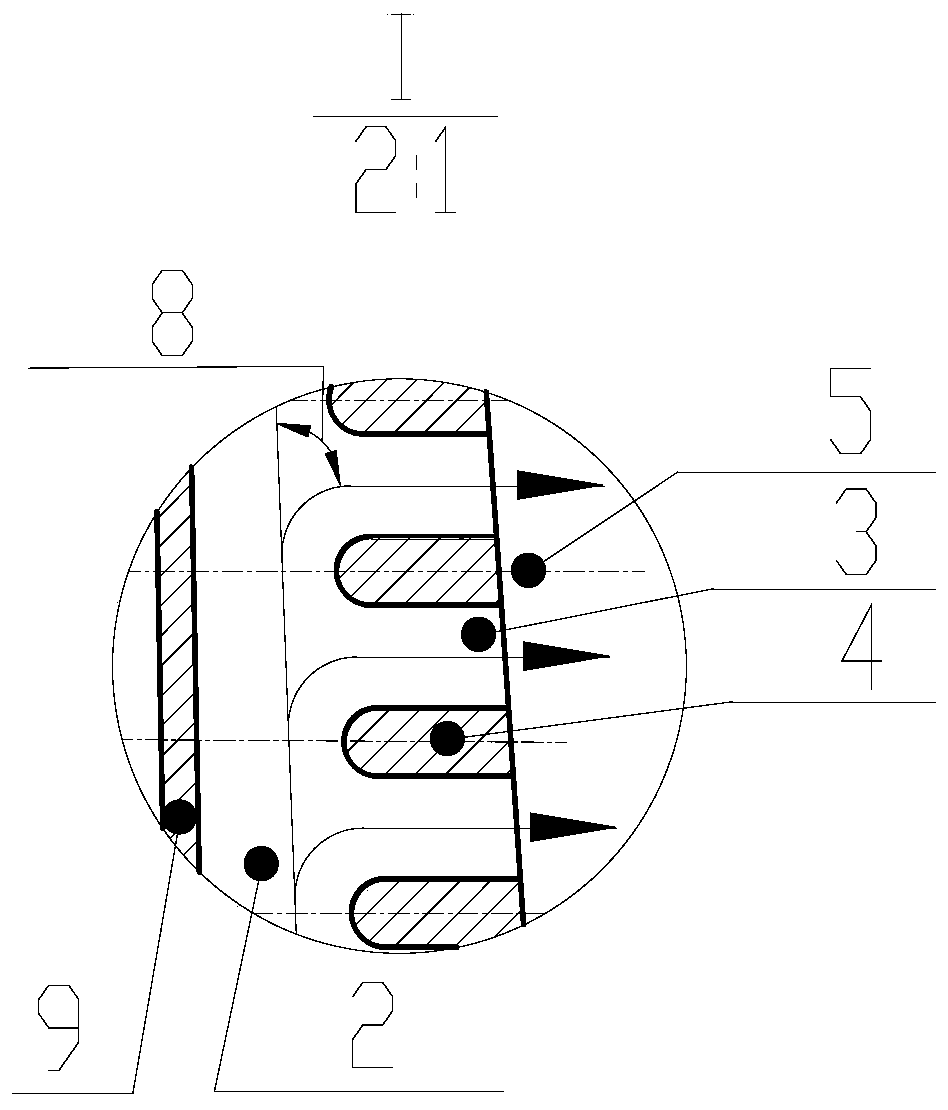

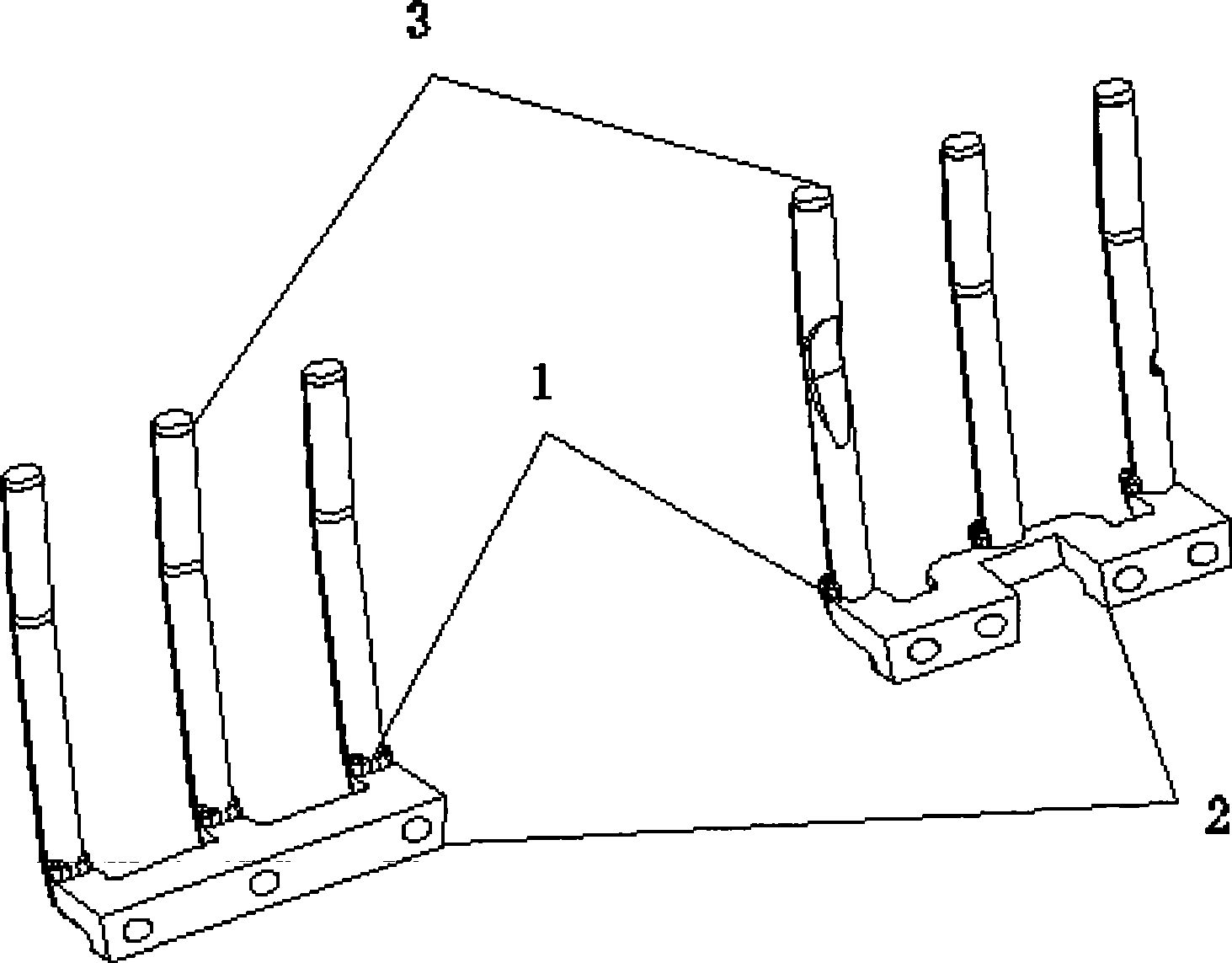

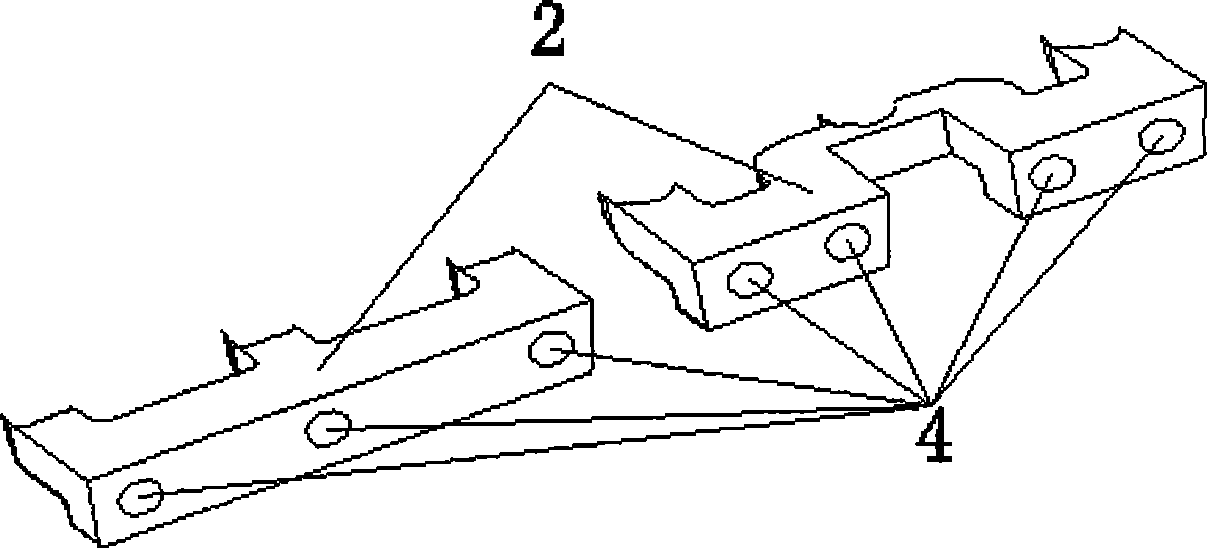

Tapered inclined exhaust splitting seam structure for turbine blade trailing edge

InactiveCN110925027AIncrease flow rateReduce blending lossBlade accessoriesMachines/enginesTurbine bladeCooling effect

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a tapered inclined exhaust splitting seam structure for a turbine blade trailing edge. The inclined exhaustsplitting seam structure comprises a hollow turbine blade, an inner cavity cool air channel, a trailing edge exhaust splitting channel and trailing edge splitting seam partition ribs, wherein the inner cavity cool air channel is formed inside the hollow turbine blade, the trailing edge of the hollow turbine blade is provided with the trailing edge splitting seam partition ribs arranged side by side, and the trailing edge exhaust splitting seam channel is formed between the trailing edge splitting seam partition ribs arranged side by side for allowing cooling air to be discharged out of the blade and meanwhile carrying out air film coverage cooling on the blade trailing edge. According to tapered inclined exhaust splitting seam structure for the turbine blade trailing edge, the cool air canflow much smoothly, so that flow resistance and loss of the cool air in an cavity of the blade is reduced, and the flow resistance can be reduced by about 16%; and through designing an inclined exhaust trailing edge splitting seam into a tapered structure, the outflow speed of the cool air can be improved, internal convection heat exchange is strengthened, an air film coverage dead zone is reduced, in this way, comprehensive cooling effects of the blade trailing edge is further improved while blending loss is reduced, and heat exchange can be enhanced by about 8%.

Owner:DALIAN UNIV OF TECH

Processing method of sand core in engine aluminum alloy cylinder metal mould low-pressure casting

ActiveCN101497109AReduce moisture contentLack of angerFoundry mouldsFoundry coresPressure castingMetal mold

The invention relates to a casting technique, in particular to a method for processing a metal mold low-pressure casting medium sand core for an aluminum alloy cylinder of an engine, wherein a method for coating a coating layer, removing water content and drilling vent holes is adopted to process the sand core so as to achieve the aim of preventing phenomena of sand inclusion, air holes, looseness, cracks, and the like.

Owner:SHANGHAI AISHIDA AUTOMOTIVE COMPONENTS

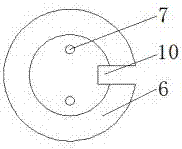

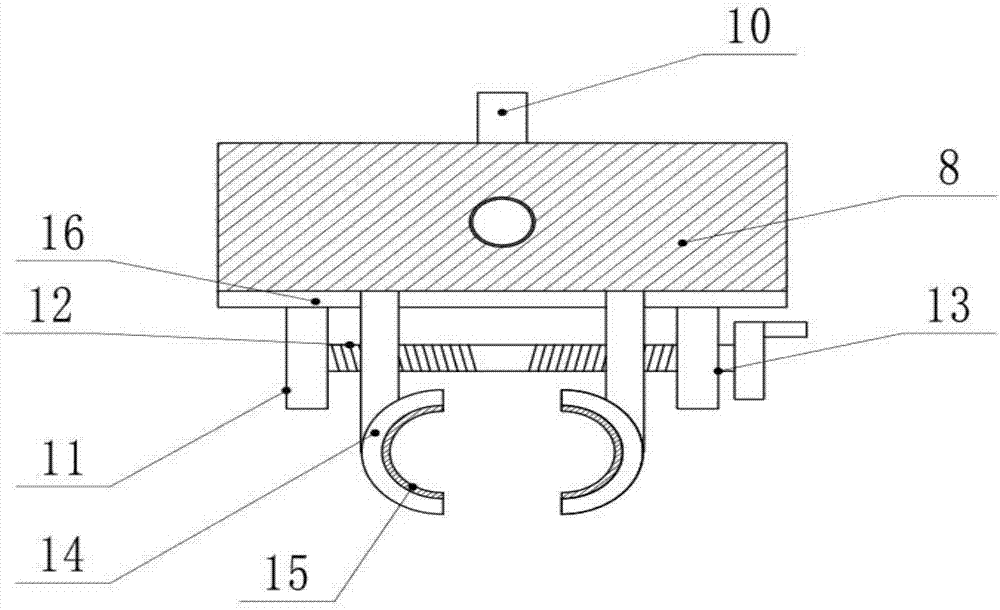

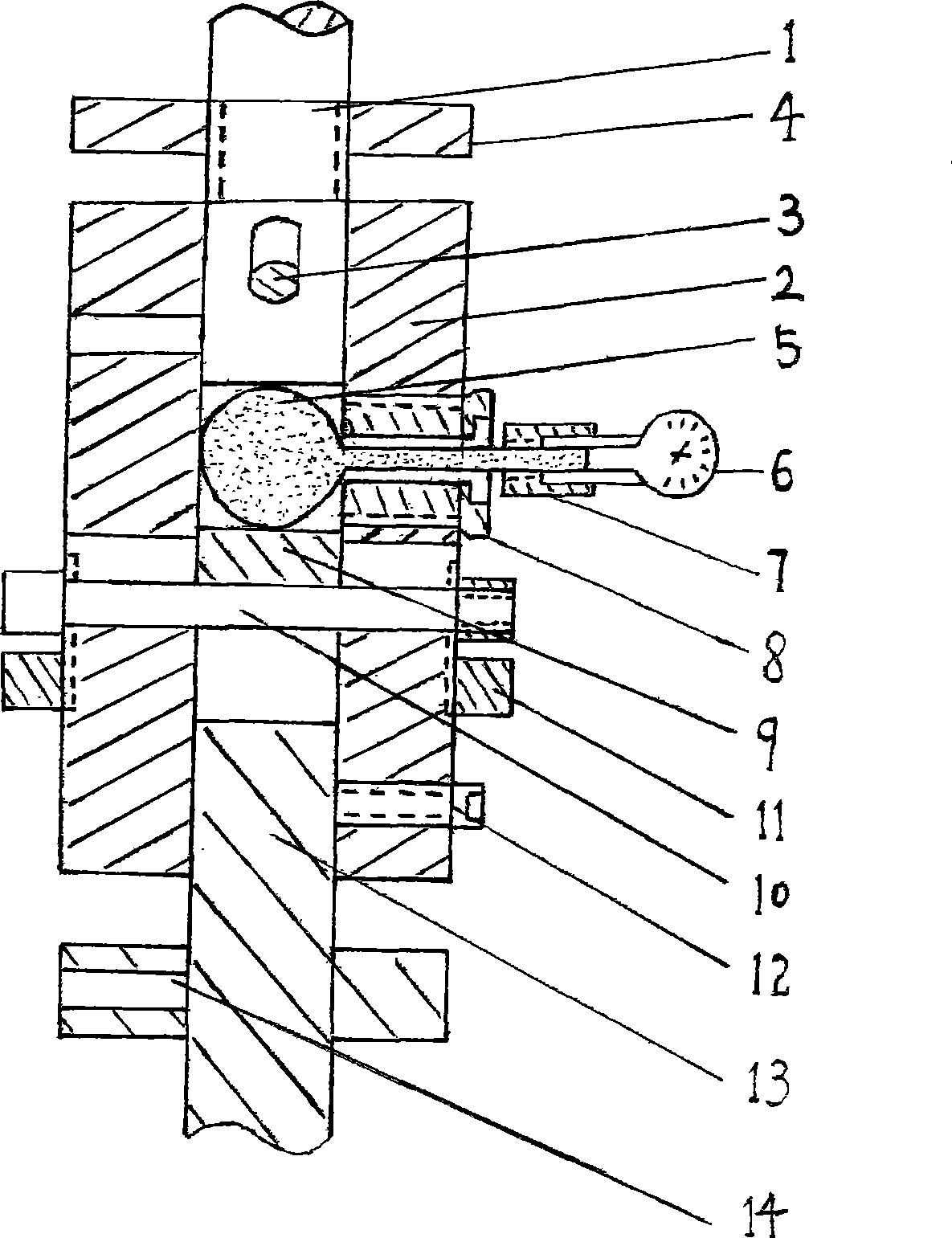

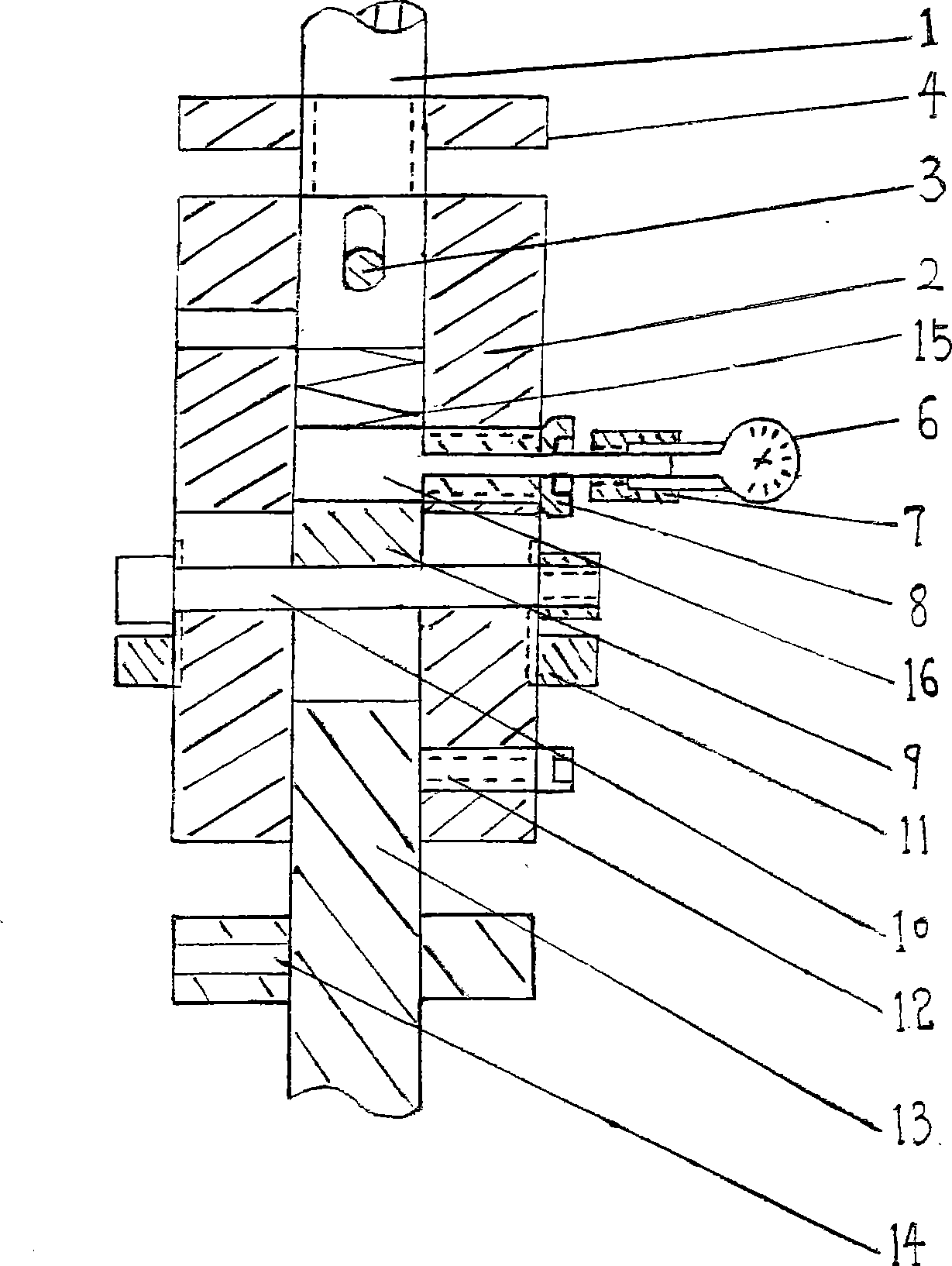

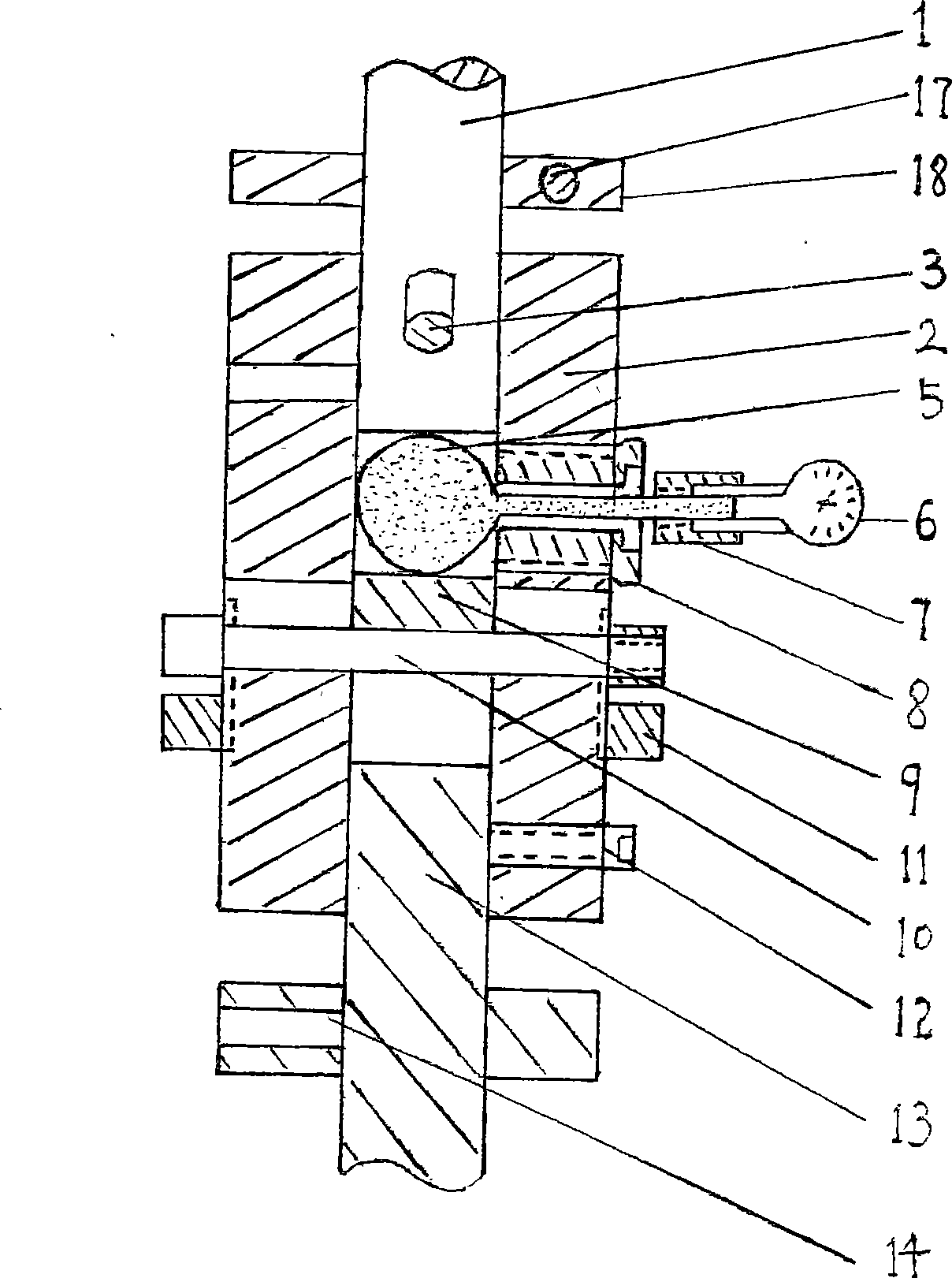

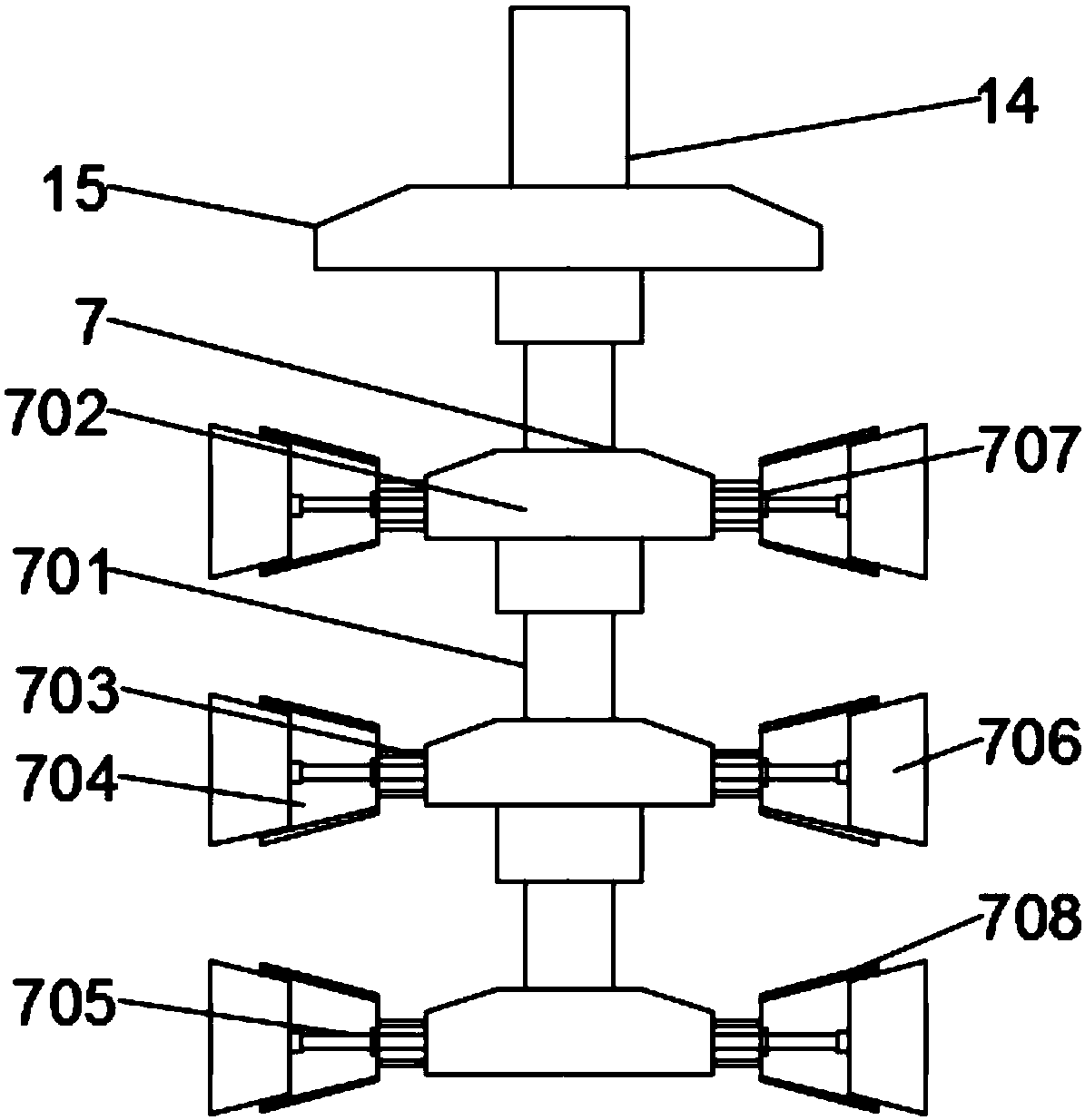

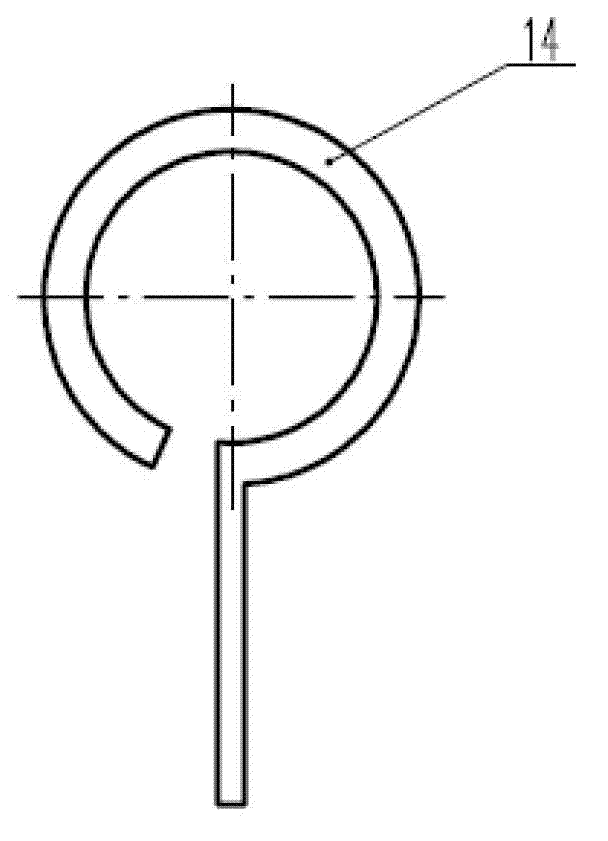

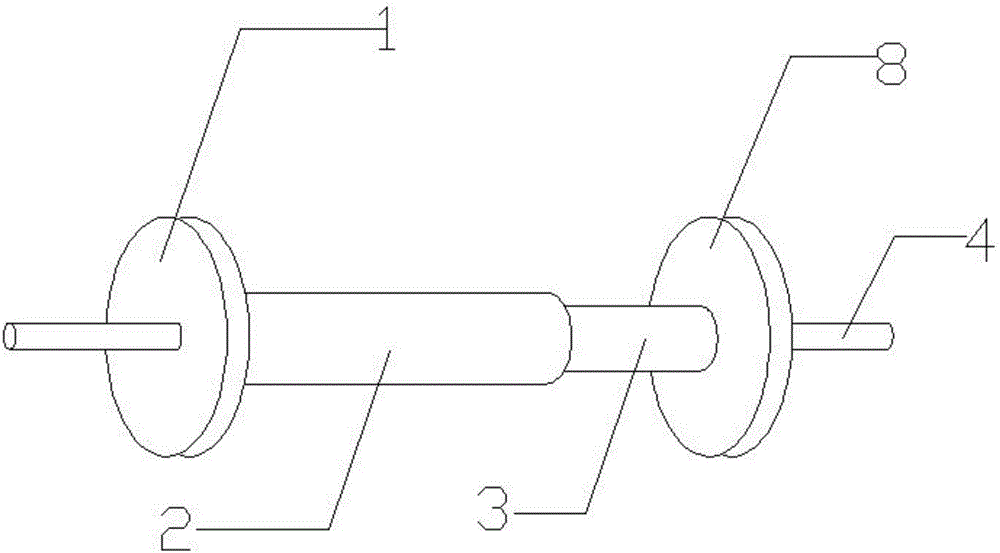

Four-band shunt-wound high-temperature superconducting double-pie coil and winding die and winding method thereof

InactiveCN103632801ALarge carrying capacityEvenly distributedSuperconducting magnets/coilsCoils manufactureHigh temperature superconductingConductor Coil

The invention discloses a four-band shunt-wound high-temperature superconducting double-pie coil and a winding die and a winding method thereof. The four-band shunt-wound high-temperature superconducting double-pie coil consists two sets of coils and a pie-to-pie support gasket (5), wherein each set of coils comprises a positive pie and a negative pie which are wound by four shunt-wound superconducting bands (1-4); the high-temperature superconducting double-pie coil is divided into the positive pie and the negative pie by the pie-to-pie support gasket (5). Two transposition ports are formed in a position of 0 degree and a position of 180 degrees along the peripheral direction of the pie-to-pie support gasket (5); transposition is performed on the positive-pie coils and the negative-pie coils for two times at the two transposition ports. The winding die for the coil consists of a main shaft (6), a first template (7), a second template (8), a positioning bolt (9), a first pressing plate (10), a second pressing plate (11), a first locknut (12), a second locknut (13) and temporary separation blades (14). The outer side of the first template (6) and the outer side of the second template (7) are respectively provided with a small groove along the peripheral direction to clamp the pie-to-pie support gasket (5) in the middle; the first template (7) and the second template (8) are pressed by the first pressing plate (10) and the second pressing plate (11).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com