Intermediate-frequency induction and directional solidification ingot casting process and equipment utilizing same

A technology of directional solidification and intermediate frequency, which is applied in the field of intermediate frequency induction directional solidification ingot and its device, which can solve the problems of low production efficiency, many processes, high power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

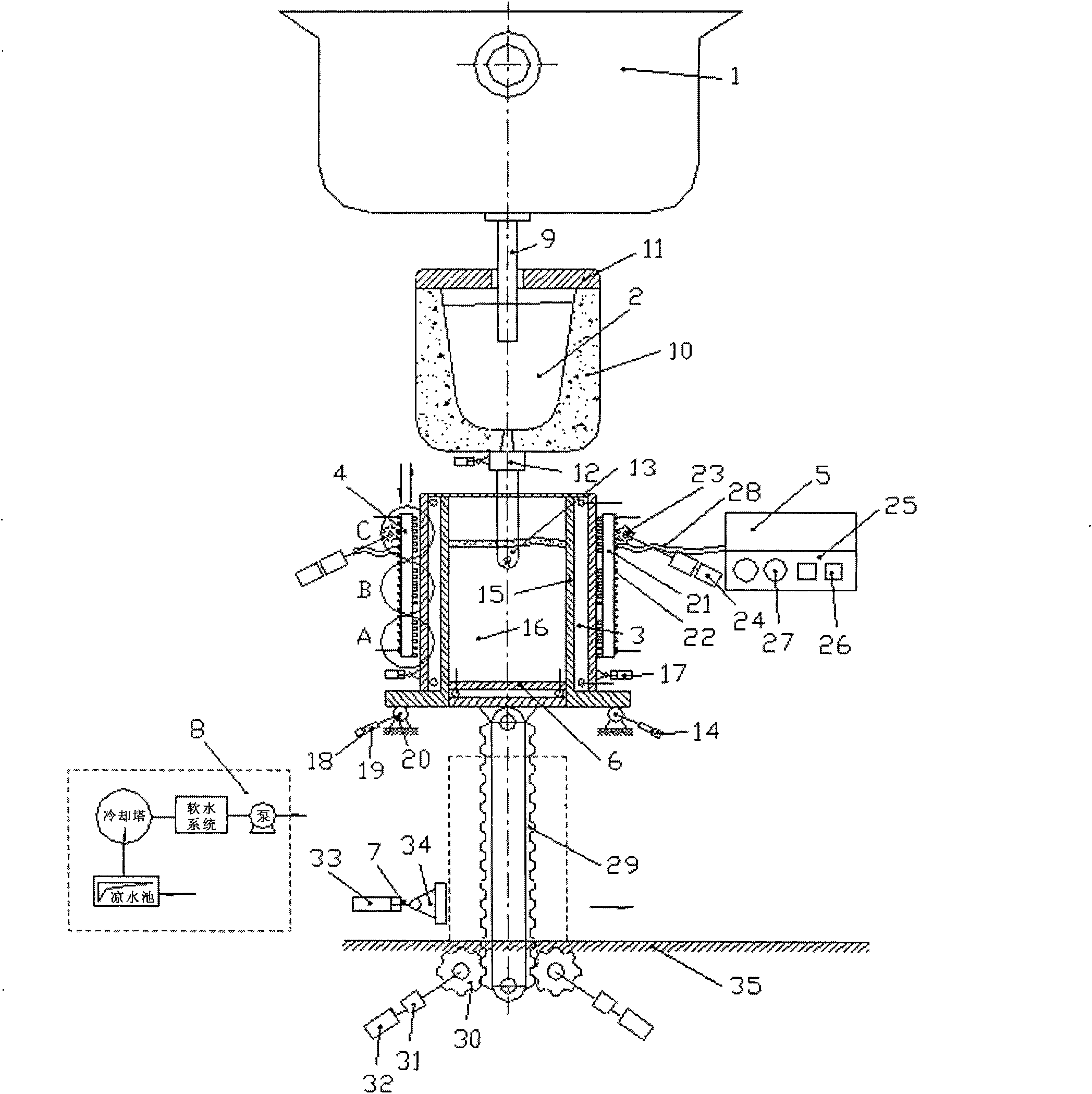

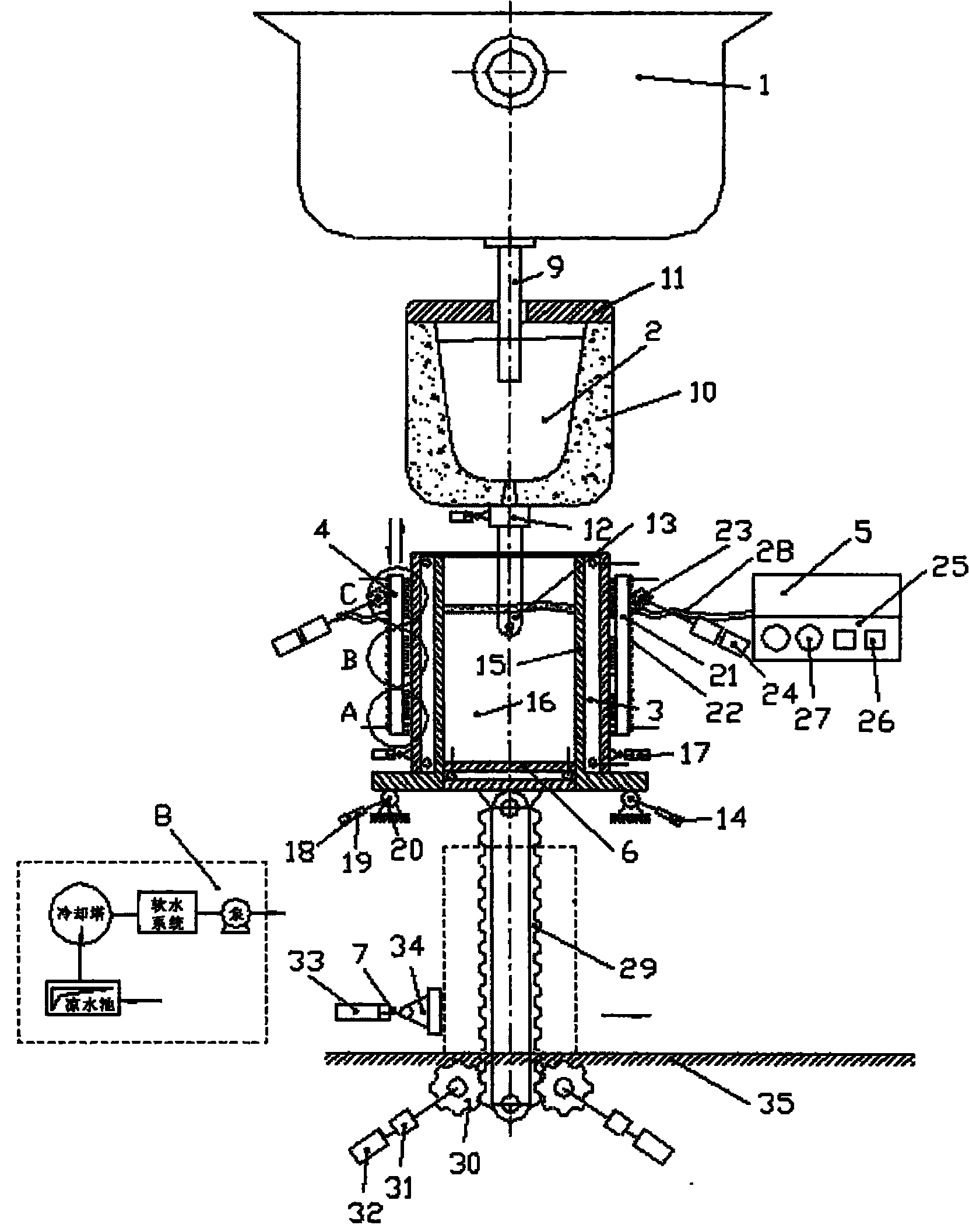

[0022] use as figure 1 The medium-frequency induction directional solidification ingot casting device shown in the figure, according to the need to cast a 40t steel ingot for a wide and thick plate rolling mill, the steel ingot size determined by the finished product specification and equipment capacity is 700mm thick, 2300mm wide, and 3600mm high, from which the inner cavity of the water-cooled crystallizer can be obtained The size is 700mm thick, 2300mm wide, and 4000mm high. The medium-frequency induction coils use three sets of A, B, and C, with powers of 200, 260, and 320kW and frequencies of 200, 350, and 500HZ. 150mm.

[0023]Molten steel with a degree of superheat of 40 degrees is injected into the water-cooled crystallizer system 3 with a vibration device through the ladle 1, the tundish system 2 with protective casting, and at the same time, protective slag is added to the molten steel surface. The water-cooled chassis and its lifting device 6 control the water-cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com