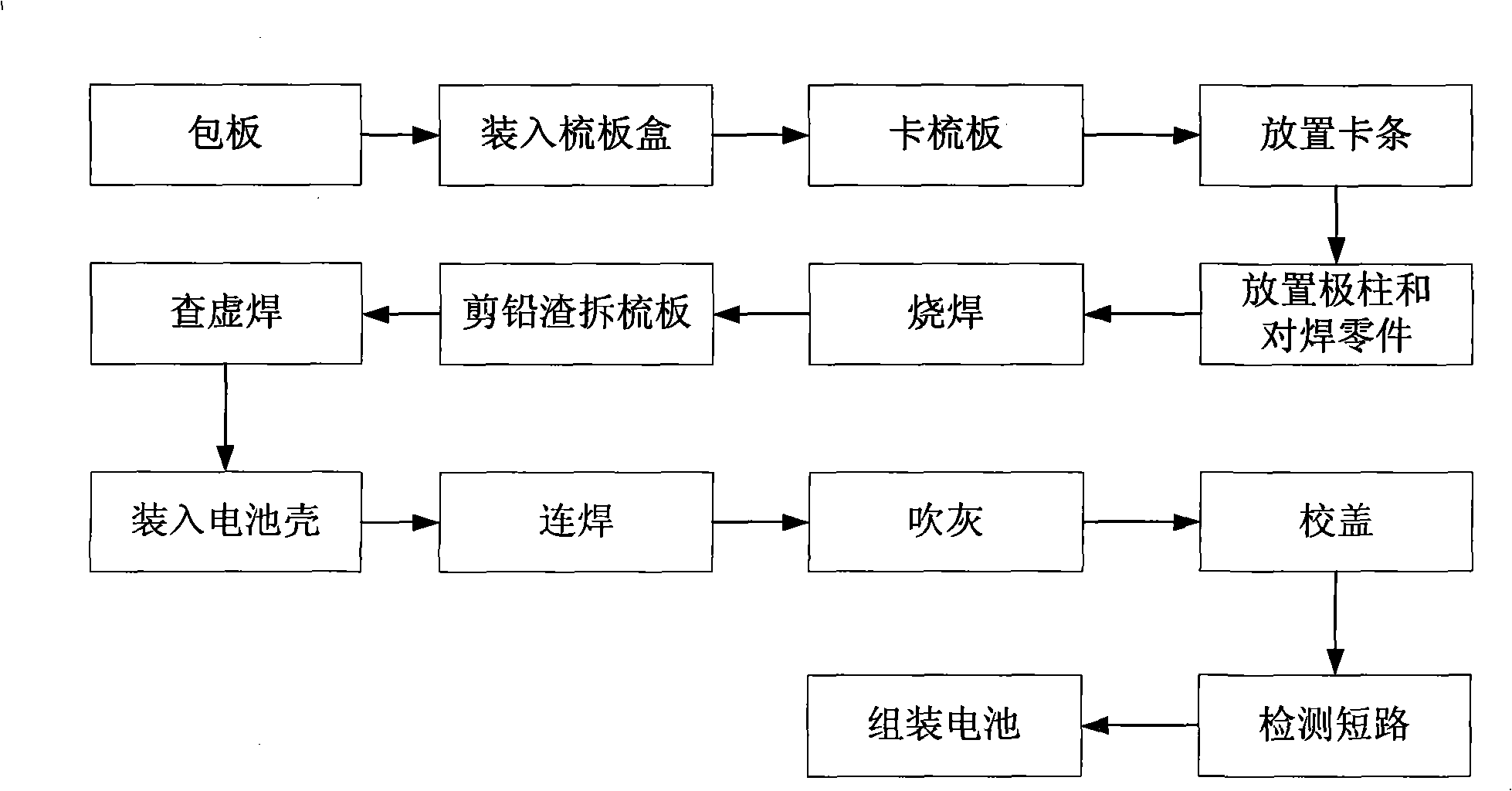

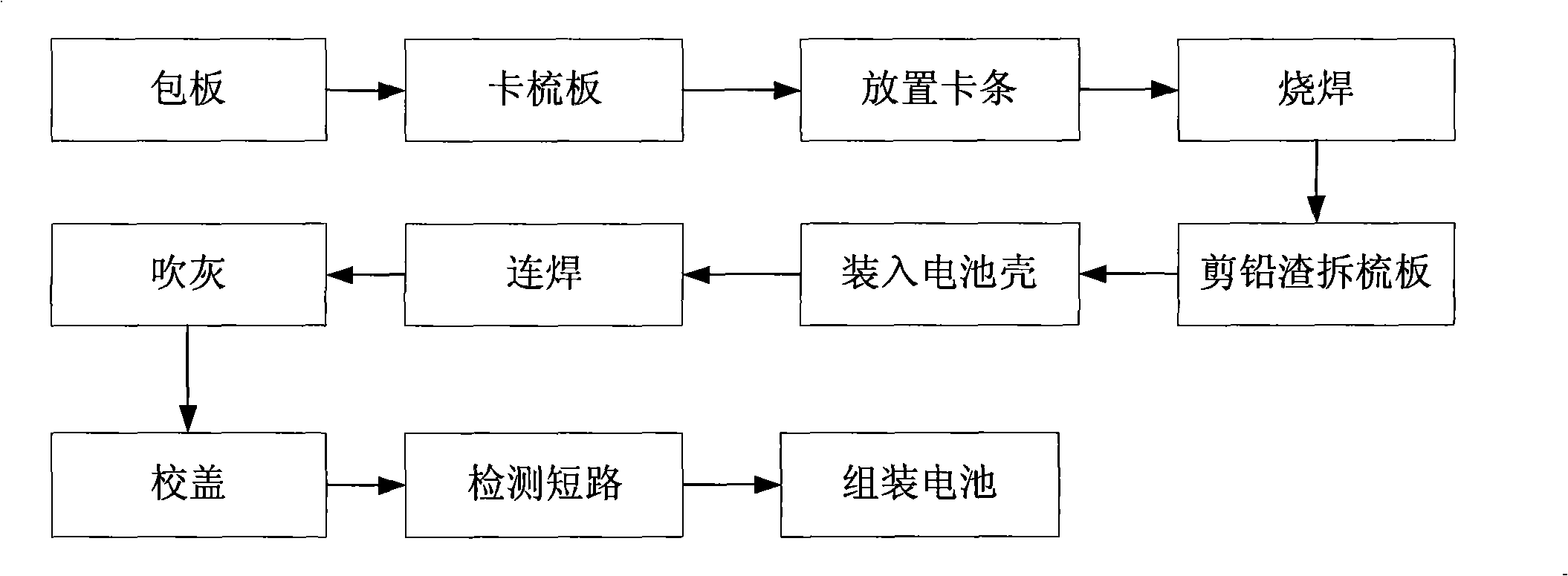

Sealed lead sour accumulator welding clamp and welding process thereof

A lead-acid battery, welding fixture technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of low production efficiency, increased battery connection resistance, low battery capacity, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

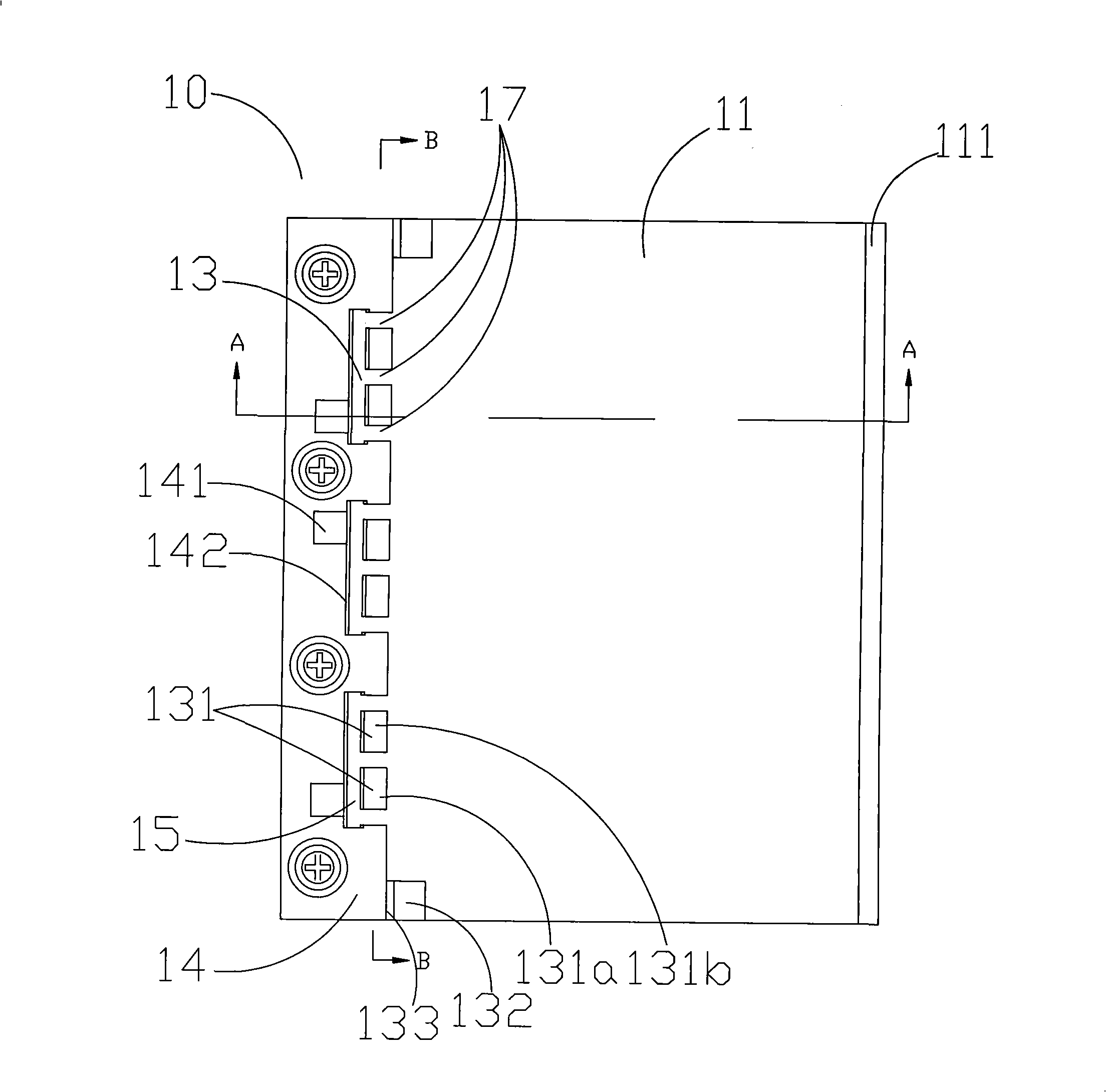

[0052] A sealed lead-acid battery welding fixture, such as image 3 As shown, the welding comb plate 10 is included. The welding comb plate 10 further includes a positioning plate 11. The positioning plate 11 includes a bottom plate. The bottom plate can be a horizontal plate. At one end of the bottom plate, a protrusion 111 perpendicular to the bottom plate is set.

[0053] The vacancy comb teeth 13 include a vacancy comb tooth main board, which can be a horizontal plate, and a comb tooth group 131 protrudes from the top surface of the vacancy comb tooth main board, and the comb tooth group 131 can be positioned along the vacancy comb. The first edge of the tooth main board is arranged at equal intervals in sequence; each comb plate tooth group 131 includes at least one comb plate tooth (such as image 3 The comb tooth group 131 shown comprises two comb teeth, respectively a comb tooth 131a and a comb tooth 131b), and each comb tooth group 131 comprises the same number of com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com