Four-band shunt-wound high-temperature superconducting double-pie coil and winding die and winding method thereof

A double-cake coil and high-temperature superconducting technology, which is applied in superconducting magnet/coil, coil manufacturing, inductor/transformer/magnet manufacturing, etc., can solve the problem that the double-cake coil winding device cannot be directly applied, and the current of multiple series and parallel windings Uneven distribution and other problems, to achieve the effect of uniform distribution of carrying current and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, the transposition method and the winding mold of the four-tape parallel-wound high-temperature superconducting double cake coil will be described in conjunction with a preferred embodiment of the present invention.

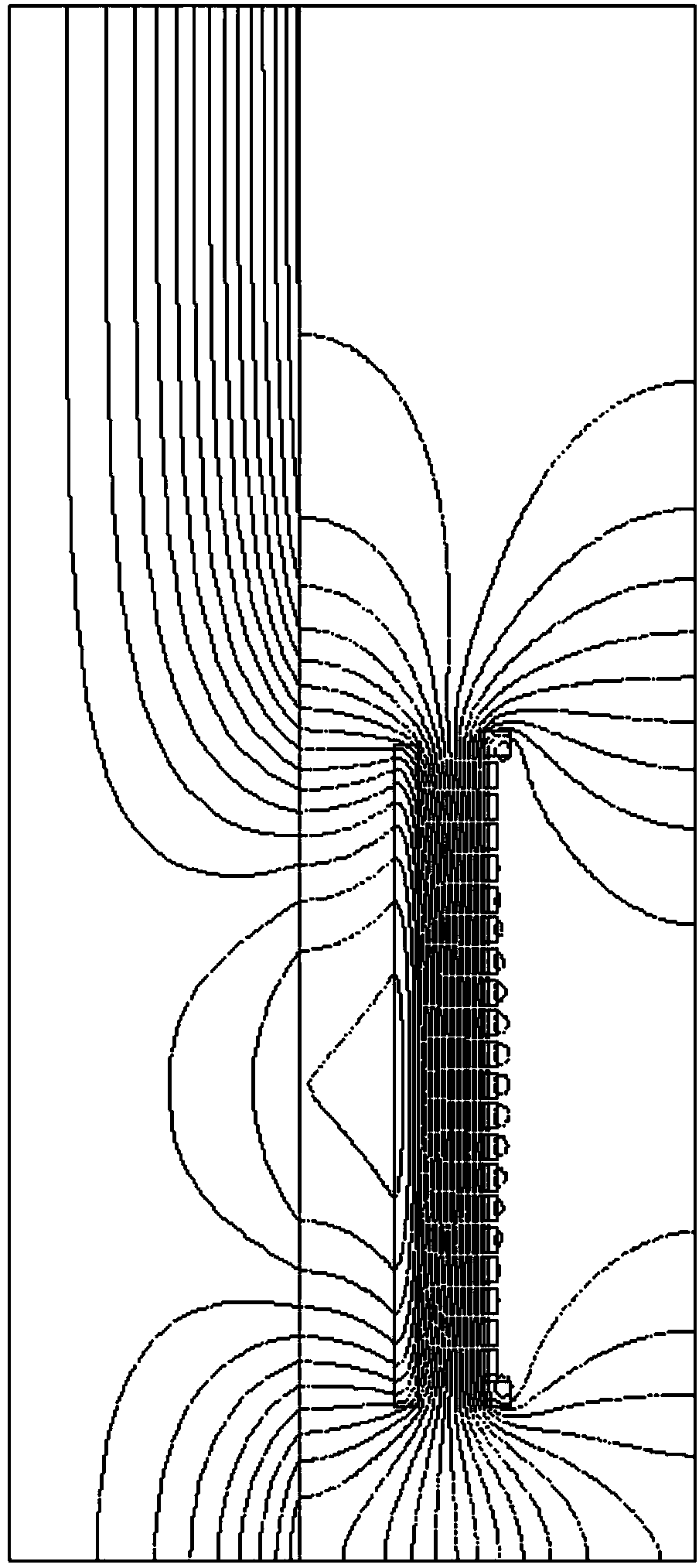

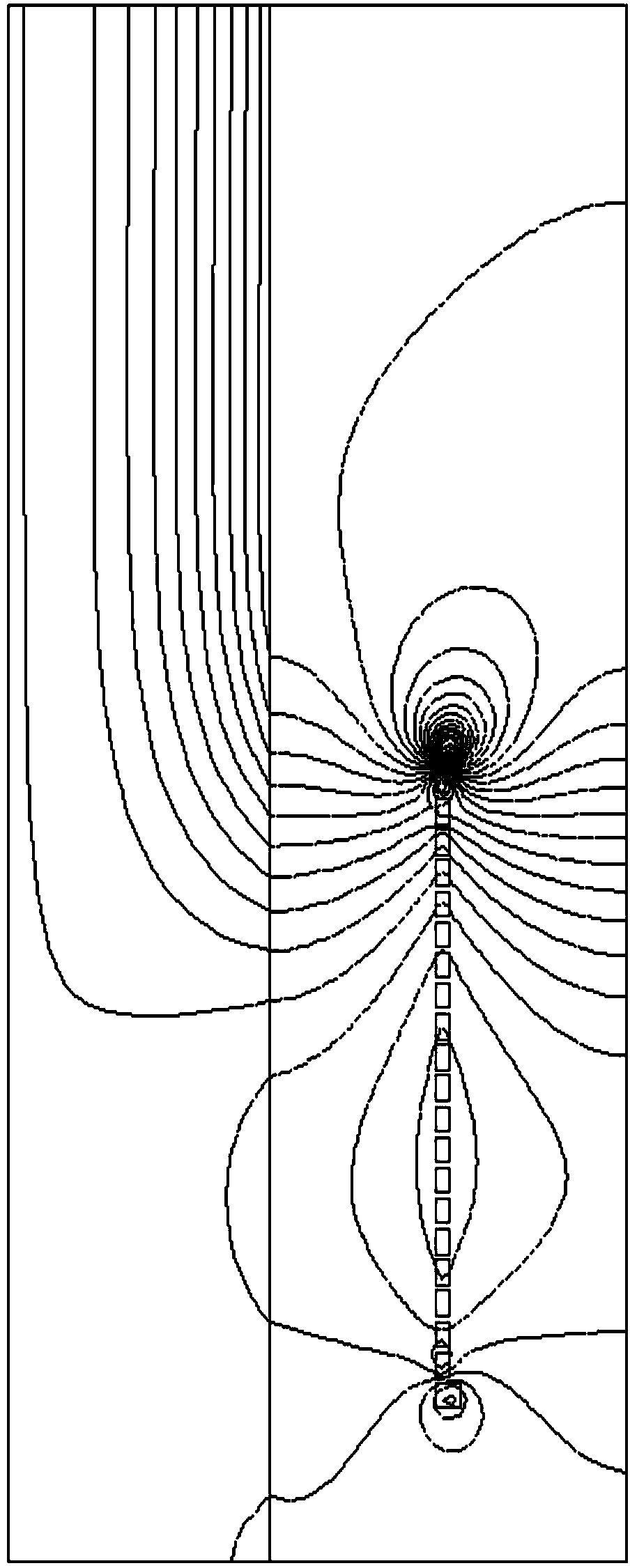

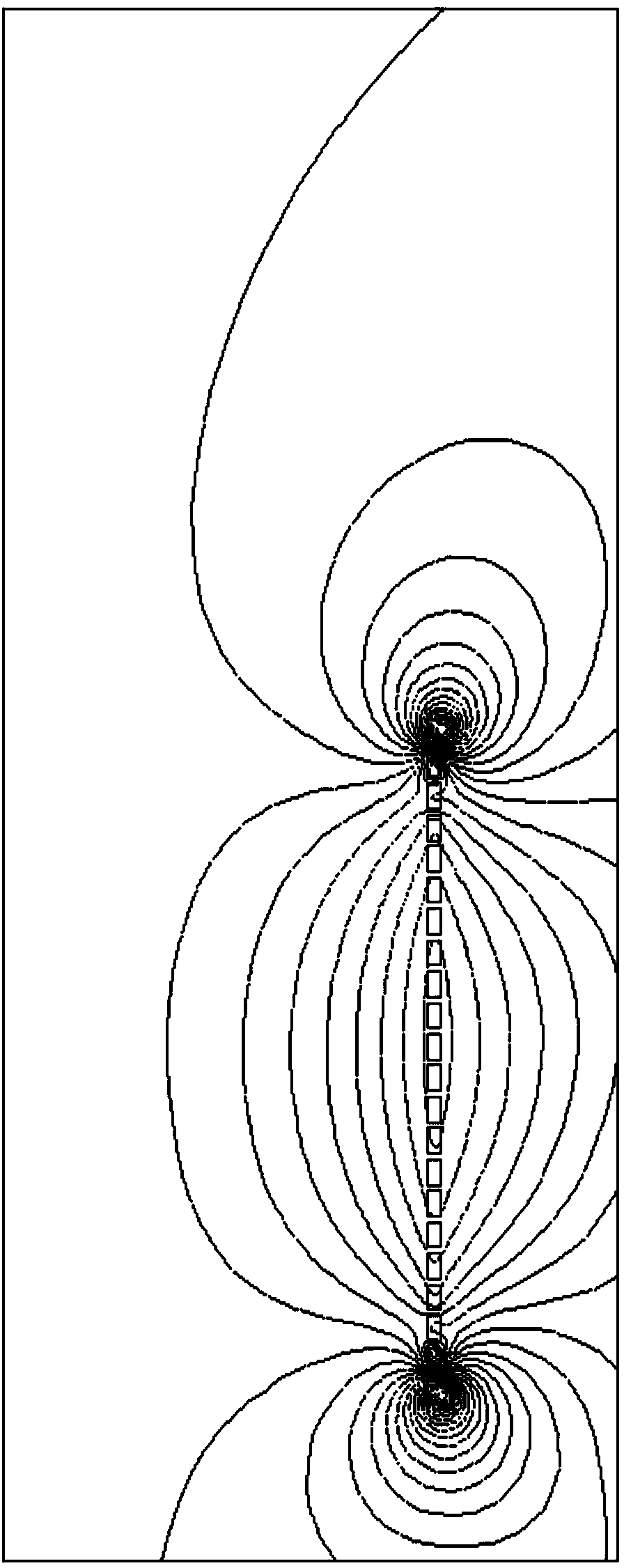

[0024] The four-belt parallel-wound high-temperature superconducting double-cake coil is composed of a regular cake, a reverse cake and a support spacer 5 between the cakes. The regular cake and the reverse cake are wound by four parallel-wound superconducting ribbons 1-4. The inter-cake support gasket 5 separates the high-temperature superconducting double-cake coils into two groups of positive and reverse cake coils, and the inter-cake support gasket 5 is used as insulation between the two groups of positive and reverse cake coils. In the pancake coil, the arrangement order of the four superconducting strips 1-4 is the first superconducting strip 1, the second superconducting strip 2, the third superconducting strip 3, and the fourth supe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com