Self-bonded coil forming machine and process

A technology of forming machine and coil, which is applied in the field of self-adhesive coil forming machine and self-adhesive coil forming process and self-adhesive coil forming process, can solve the problems that the coil volume cannot meet the design requirements, the production process is complicated, the production efficiency is low, etc. Avoid self-rebound and loose, simple production process, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

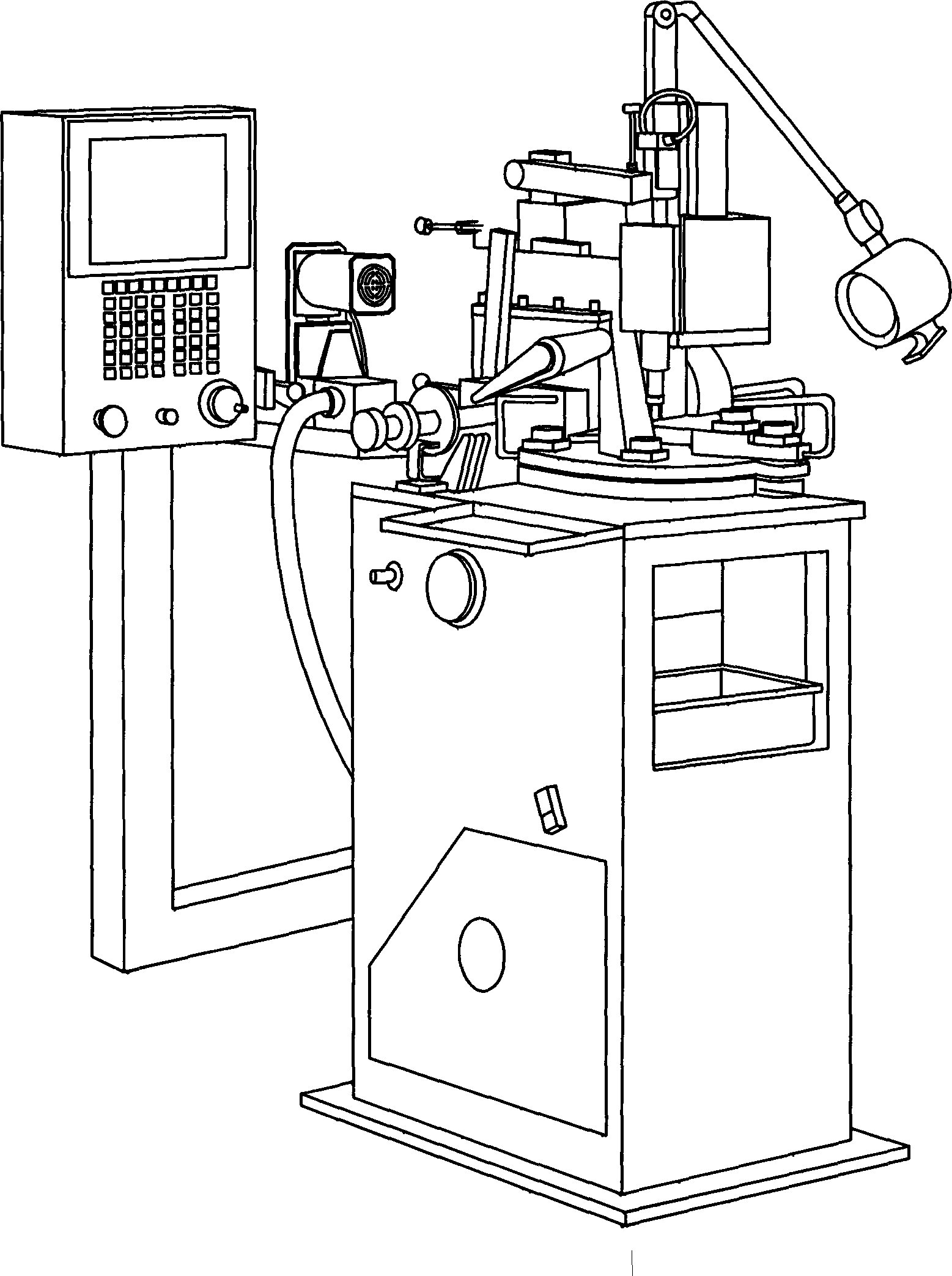

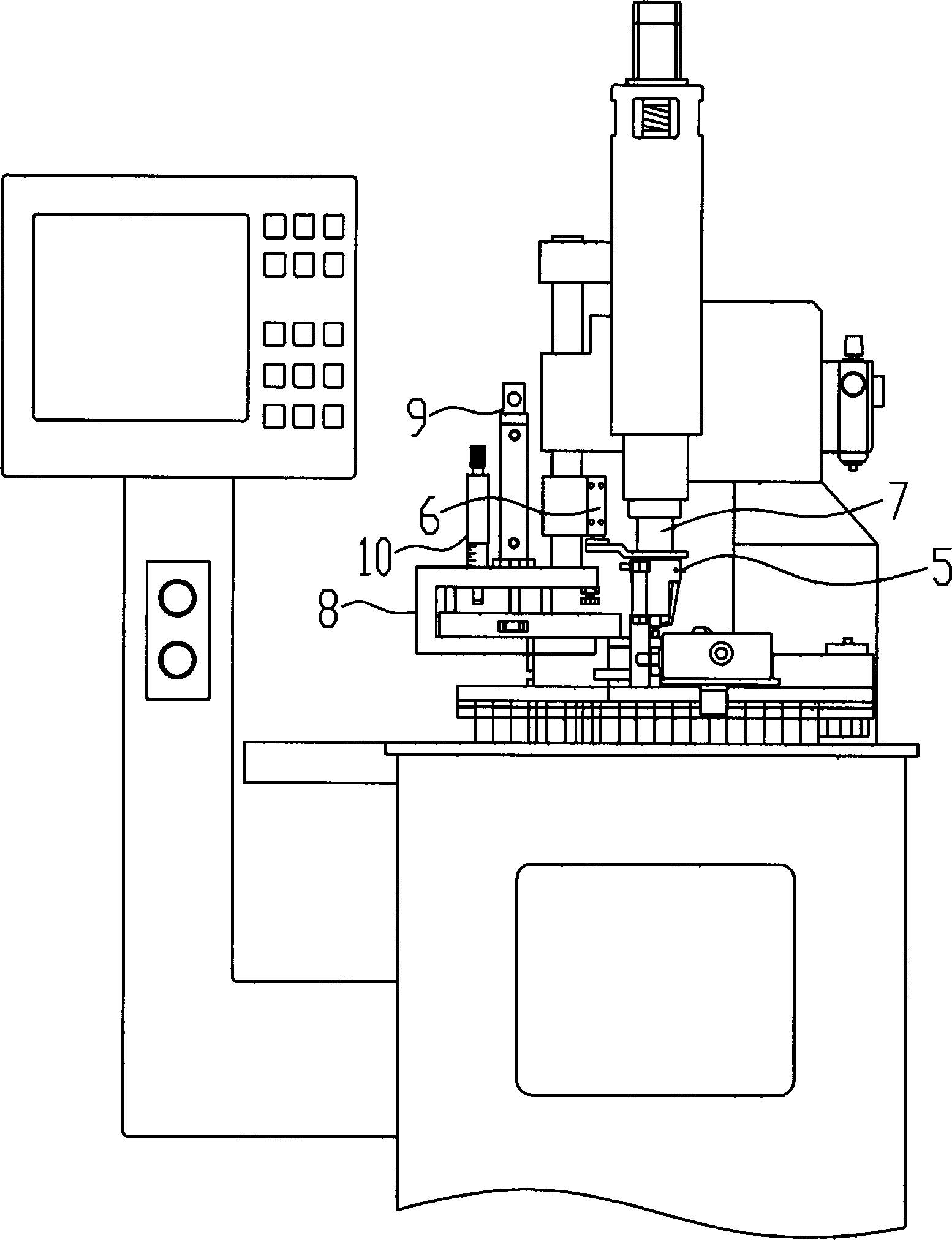

[0038] Embodiment one: see Figure 3 ~ Figure 5 As shown, a self-adhesive coil forming machine is provided with a winding mechanism, and the winding mechanism includes a winding shaft 7 and a winding chuck 5 rotating with the winding shaft 7 .

[0039] The self-adhesive coil forming machine also includes a coil heating system, and the heat outlet of the coil heating system is facing the semi-finished self-adhesive coil 14 wound on the winding chuck 5 .

[0040] The coil heating system is composed of a heat gun 13 and a control device for controlling hot air on and off. The air outlet of the heat gun 13 faces the semi-finished self-adhesive coil 14 wound on the winding chuck 5 .

[0041] In this embodiment, the air delivery pipe of the heat gun 13 has a two-stage structure, and the control device is composed of a heating switching cylinder 11 and an airflow switching jig 12 inserted at the junction of the two sections of the air delivery pipe. The airflow switching jig 12 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com