Yarn rolling device capable of preventing yarn from loosening

A winding device and yarn technology, applied in the field of yarn winding, can solve the problems of affecting the quality of yarn production, insufficient winding of yarn, single yarn protection point, etc., and achieve the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

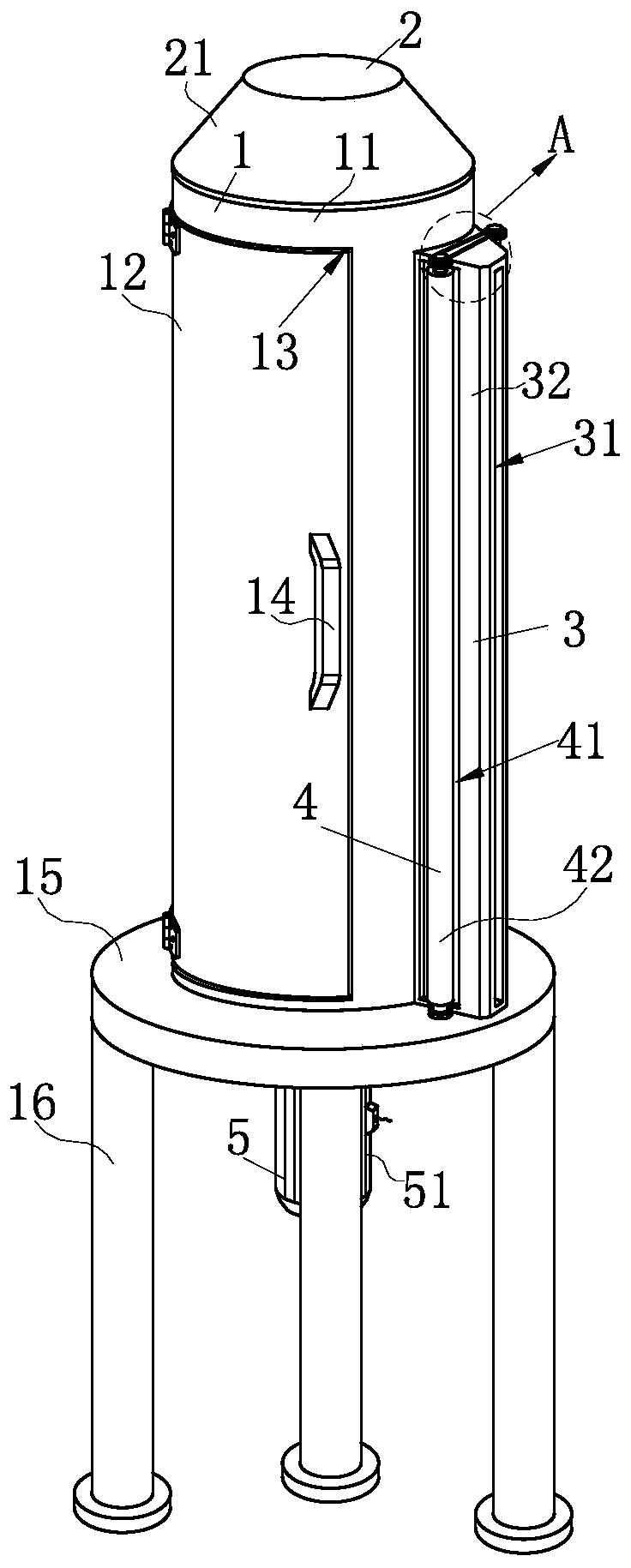

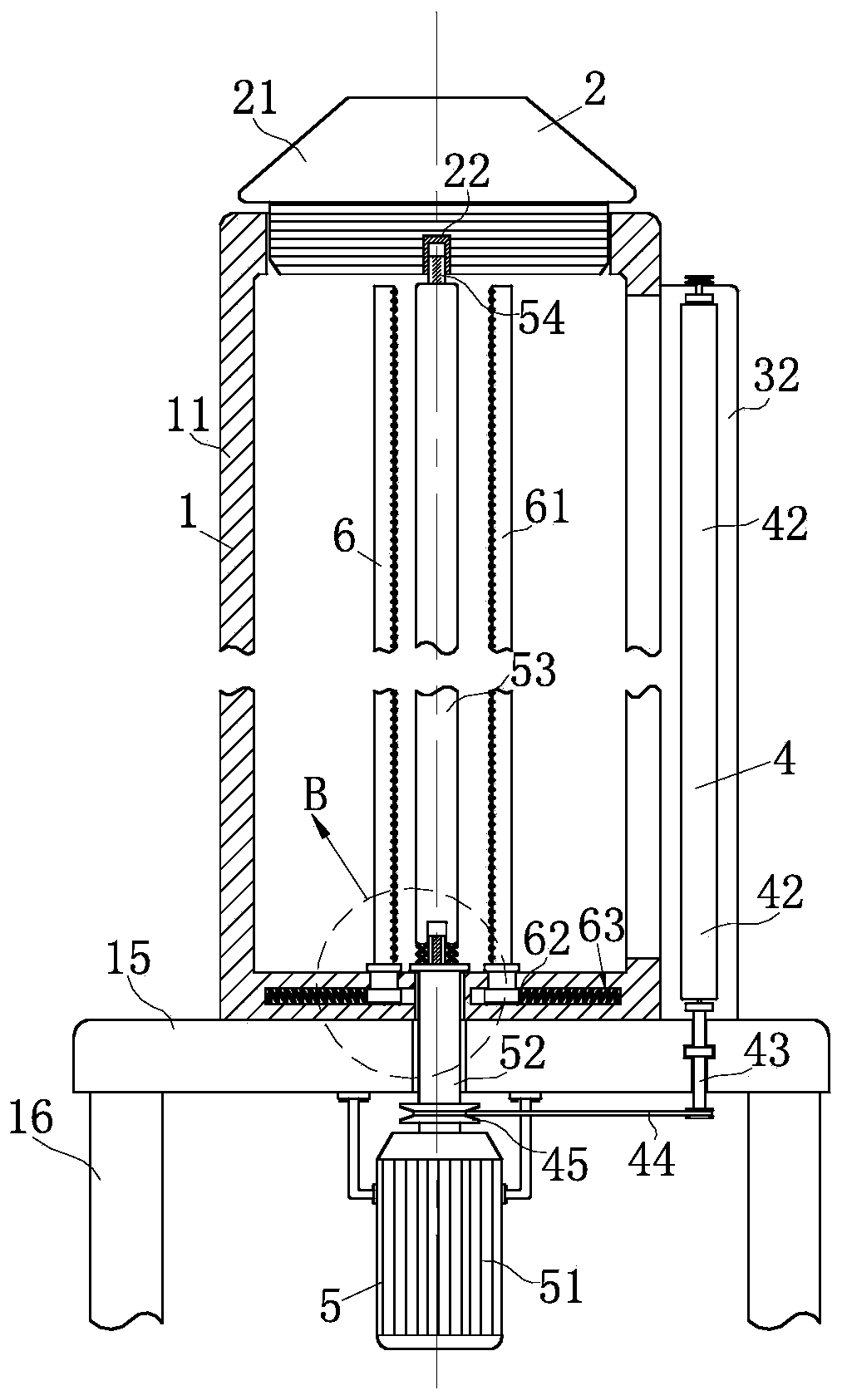

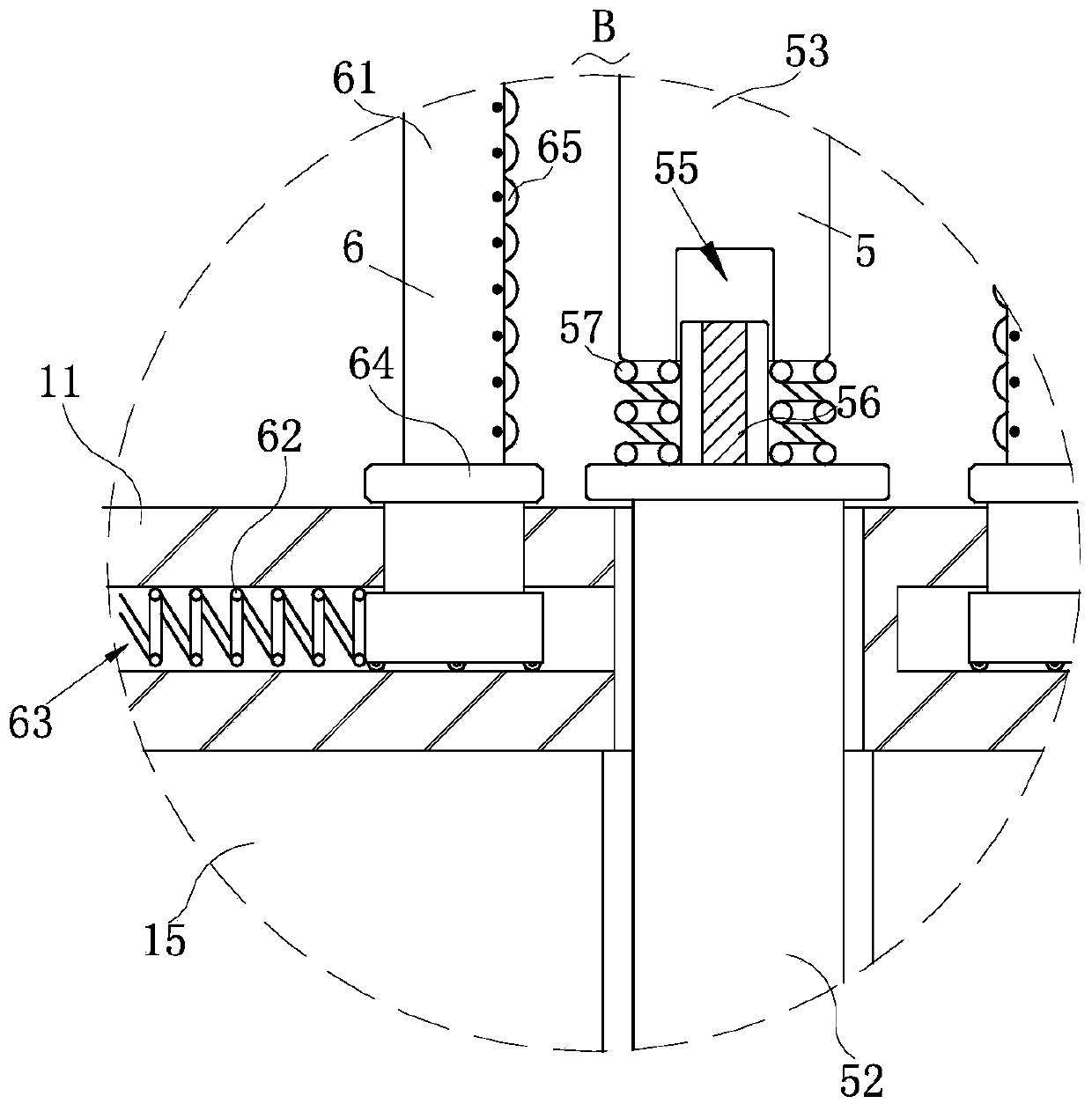

[0024] like Figure 1-Figure 6 As shown, a yarn winding device capable of preventing loose yarns according to the present invention includes a supporting mechanism 1, a positioning mechanism 2, a guiding mechanism 3, a cleaning mechanism 4, a winding mechanism 5 and a protection mechanism 6; The inside of the support mechanism 1 that supports the overall mechanism is installed with the winding mechanism 5 for winding the yarn, and the top of the support mechanism 1 is screwed with the winding mechanism 5. The positioning mechanism 2 is rotationally connected, and the inside of the support mechanism 1 is equidistant and slidingly connected in a circular array with several groups of the protection mechanisms 6 for protecting the wound yarn. The supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com