Laminating machine and cell rubberizing structure and cell rubberizing method therefor

A cell and glue technology, applied in the field of battery manufacturing equipment, can solve the problems affecting the quality of the cell and the glue is not tight, and achieve the effect of improving the quality of the cell and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

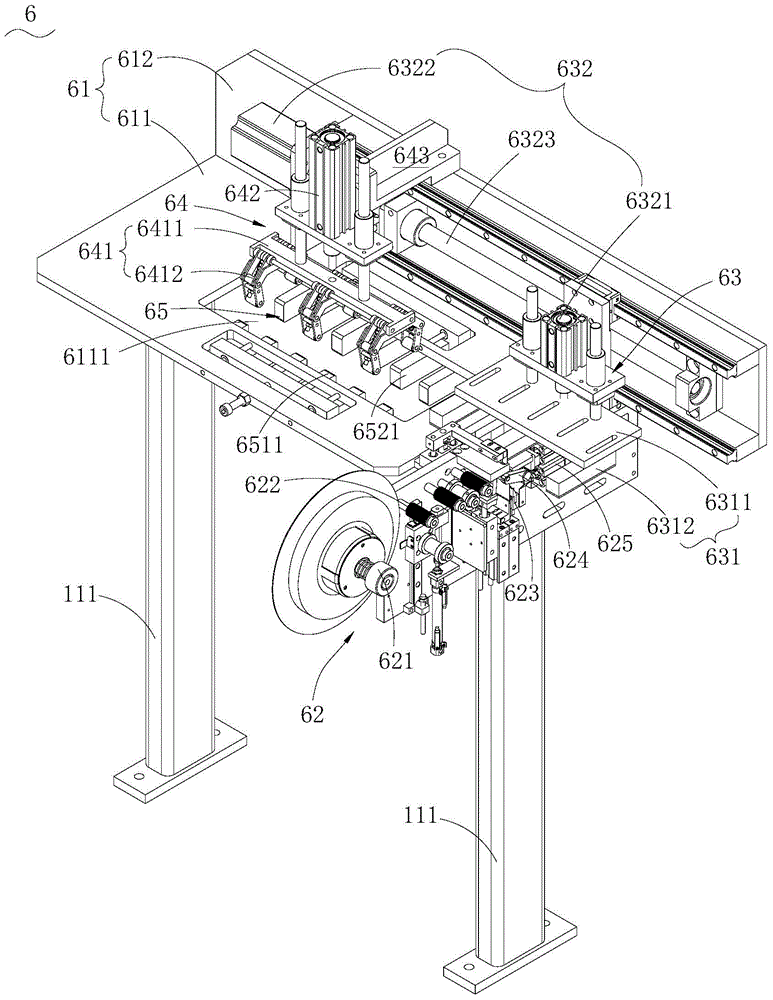

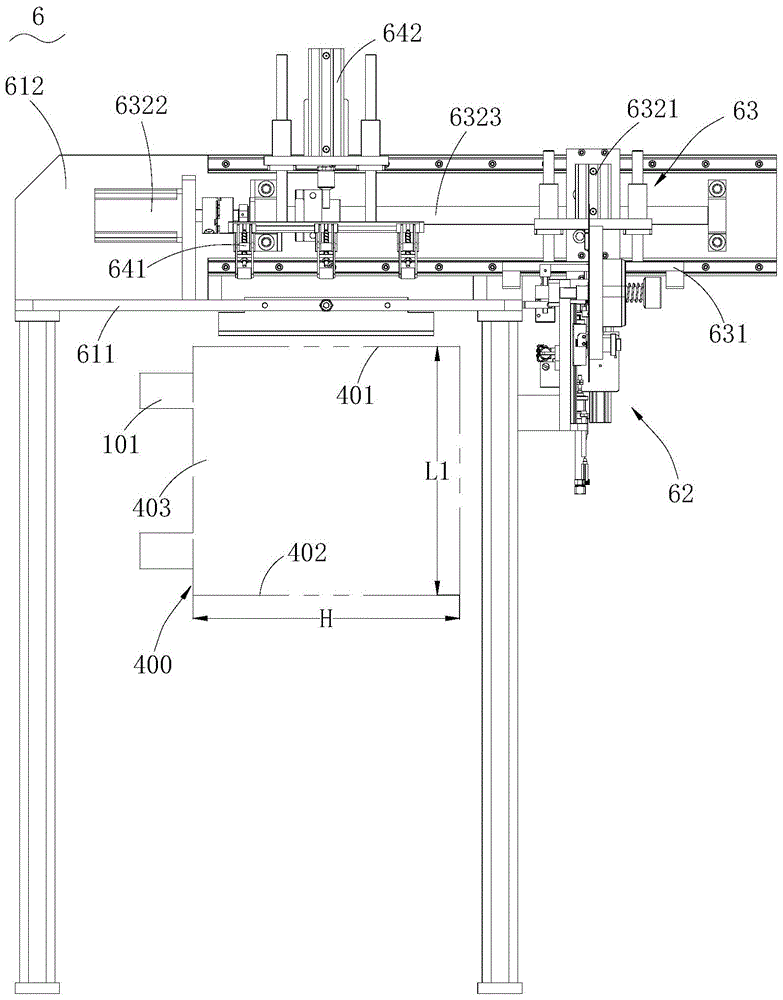

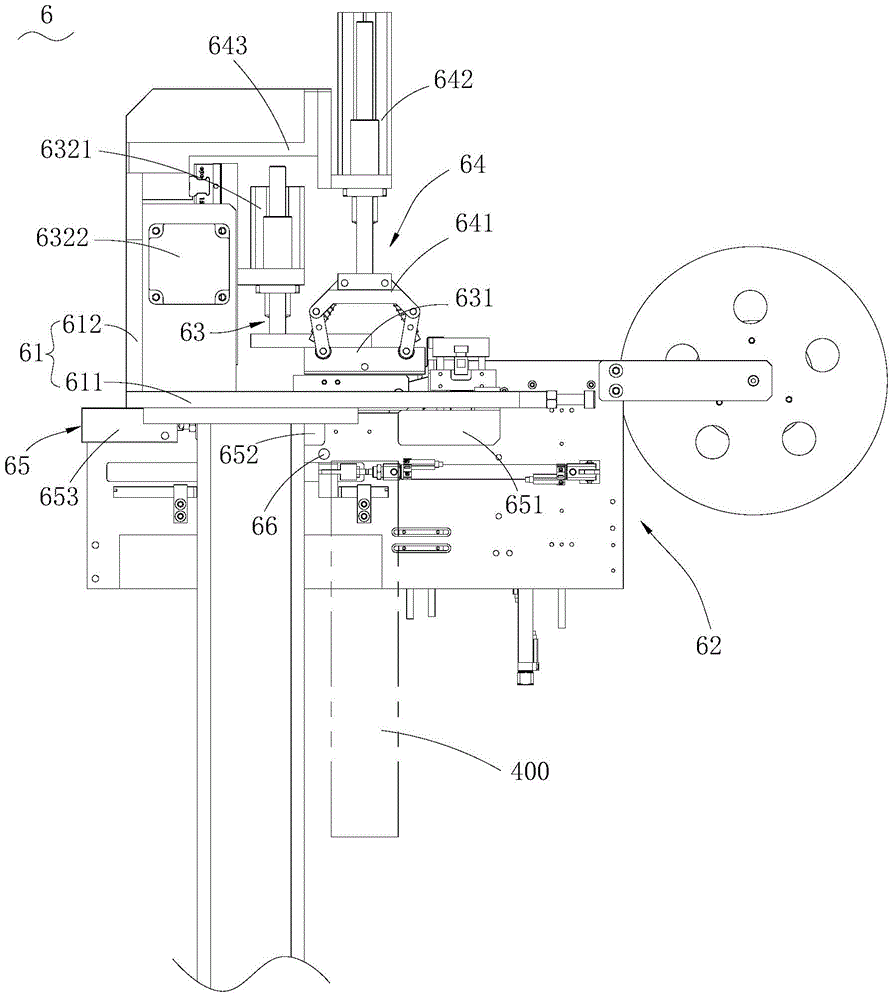

[0029] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0030] The cell gluing method and cell gluing structure provided by the present invention are suitable for rectangular cells. The outer layer is also wrapped with a diaphragm. The cell adhesive method and the cell adhesive structure of the present invention are to apply adhesive to the cell wrapped with the diaphragm to prevent the cell from loosening.

[0031] The shape of the electric core 400 can refer to figure 2 , one end of the battery cell 400 has two tabs 101, and there are four faces adjacent to this end of the battery cell, and the height H of the four faces is the same, and the two faces with the larger width L1 are called the face of the battery cell The surface 403 and the other two sides with a smaller width are called side surfaces of the cell, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com