Processing method of sand core in engine aluminum alloy cylinder metal mould low-pressure casting

A technology of low pressure casting and processing method, applied in the direction of core, casting molding equipment, metal processing equipment, etc., can solve problems such as looseness and cracks, and achieve the effect of low moisture content, simple steps, and prevention of pores and looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further described below in combination with specific illustrations, taking the sand core of the oil channel as an example.

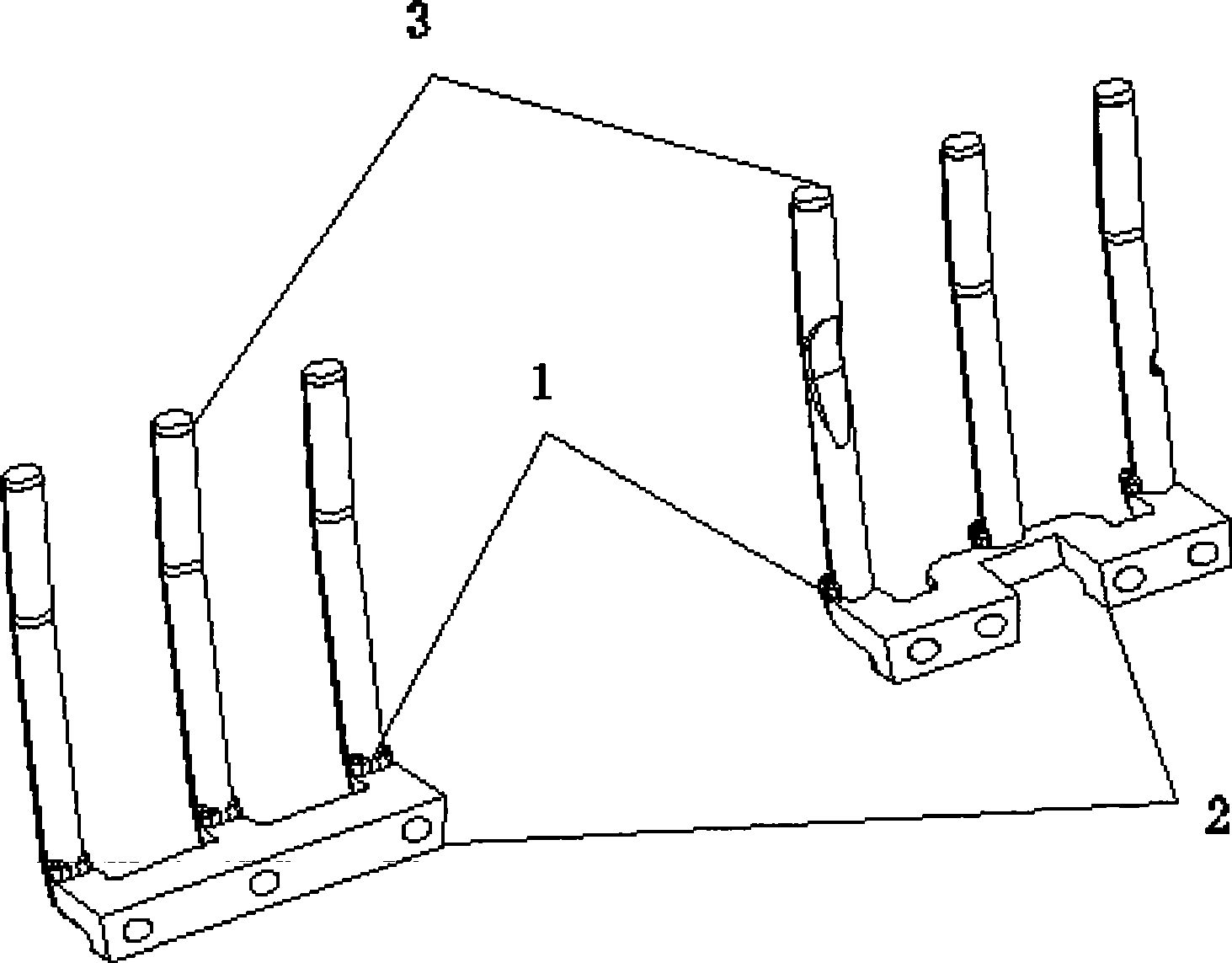

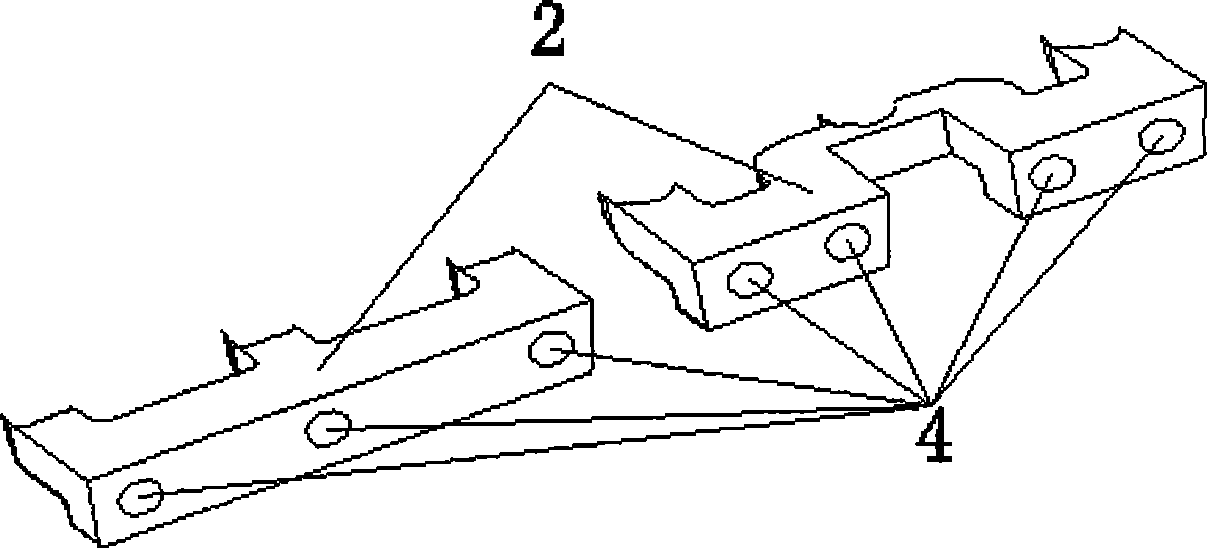

[0019] refer to figure 1 , the oil passage sand core 1 (coated sand hot core) in the metal mold low-pressure casting of the engine aluminum alloy cylinder body is divided into a large core head 2 and a sand core rod 3. Before the oil passage sand core 1 is used for casting, the following method is used: To process:

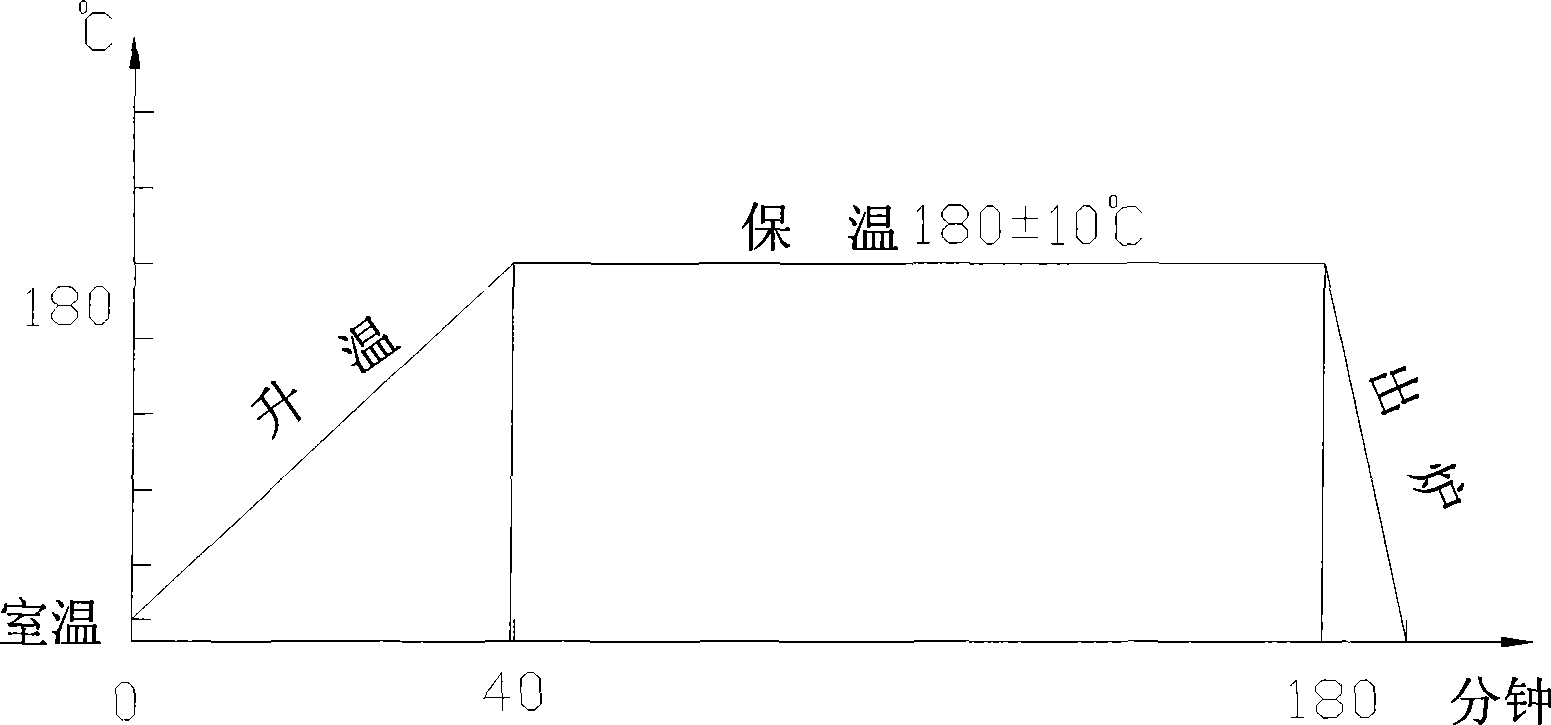

[0020] Firstly, the surface of the sand core 1 in the oil channel should be dip-coated with an alcohol-based paint with a Baume degree of 30-50 to prevent mechanical sand sticking when the low-pressure cast aluminum alloy is filled and solidified under pressure, and can also effectively prevent sand inclusions. .

[0021] The alcohol-based paint used was Voseco Alcohol-Based Paint 460....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com