Patents

Literature

146results about How to "Avoid crack phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

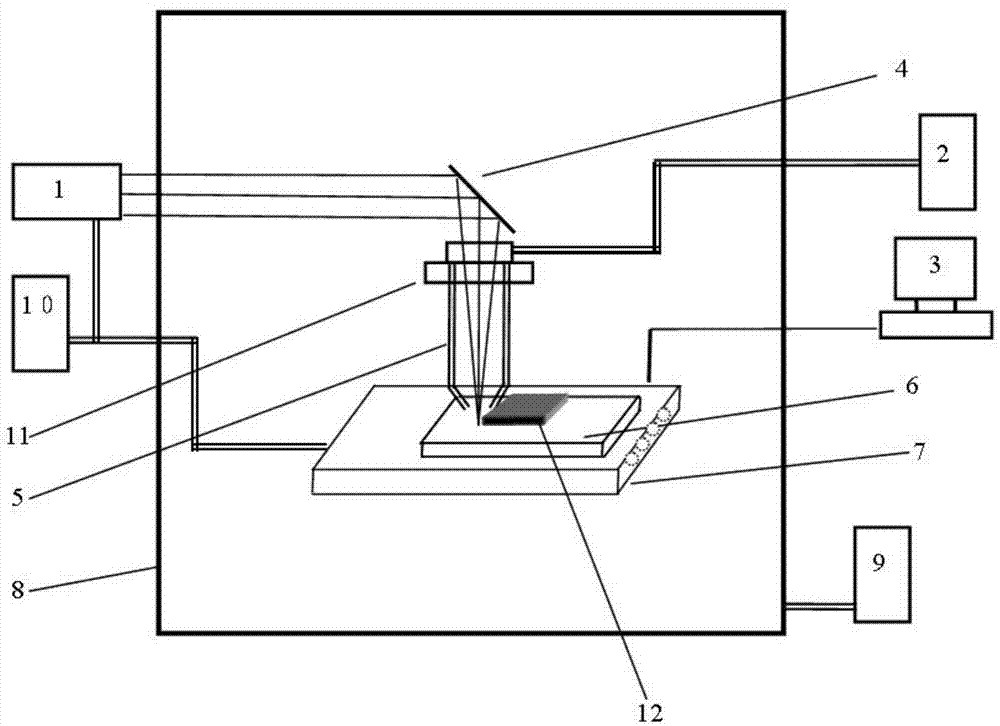

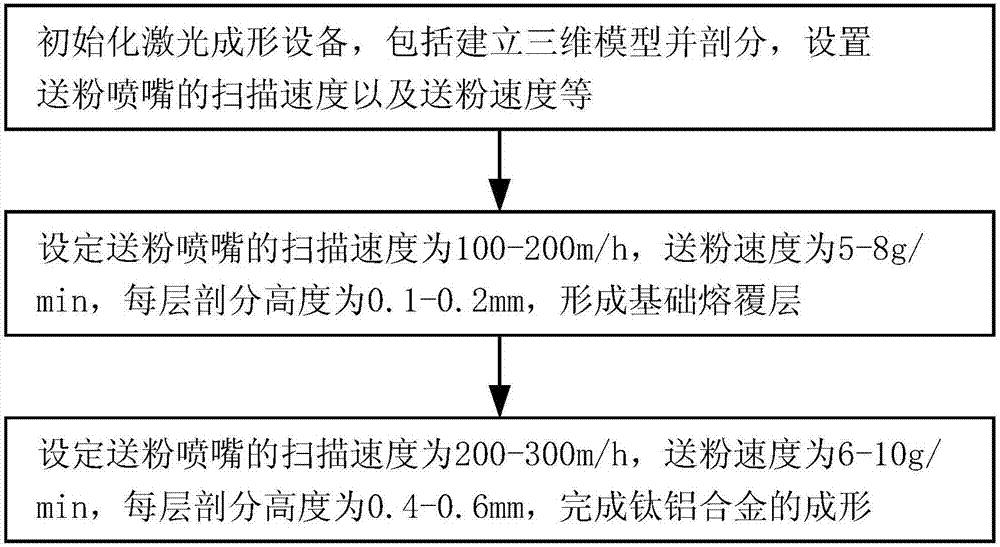

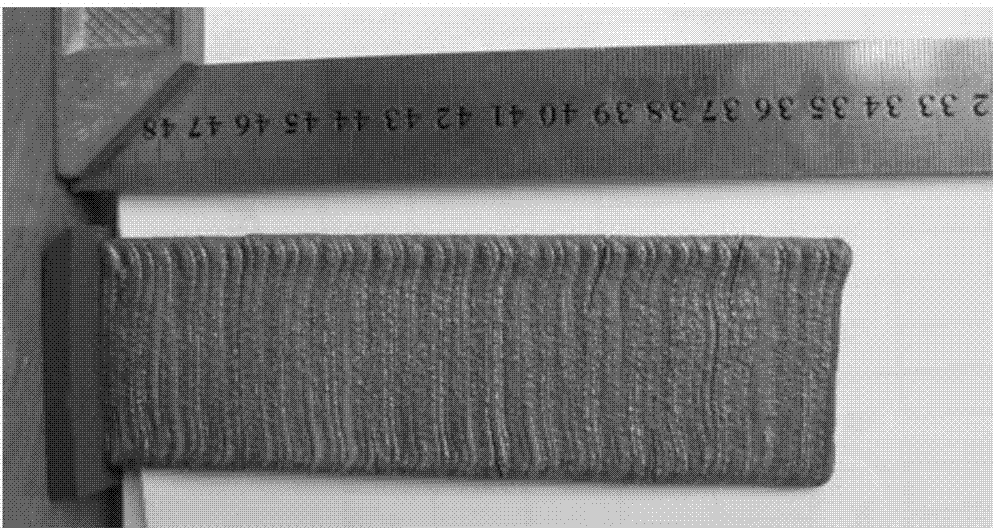

Laser three-dimensional forming method of large-size titanium-aluminum-based alloy

The invention relates to a laser three-dimensional forming method of large-size titanium-aluminum-based alloy. According to the method, a three-dimensional model of the titanium-aluminum-based alloy is established first, subdivision is carried out, then a fusion covering control program is compiled; the scanning speed of a powder feeding nozzle is controlled to be 100-200m / h, powder feeding speed is set to be 5-8g / min, the subdivision height of each layer is 0.1-0.2mm, 5-10 layers cover a base plate in a fusion mode, a base fusion covering layer is formed; the scanning speed of the powder feeding nozzle is adjusted to be 200-300m / h, the powder feeding speed of a powder feeding system is adjusted to be 6-10g / min, the subdivision height of each layer is adjusted to be 0.4-0.6mm, and even and stable forming is carried out until the forming process is over. The method can solve the problem that cracks can be generated easily during a titanium-aluminum-based alloy fusion covering process, and large-size crack-less titanium-aluminum-based alloy materials can be manufactured.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

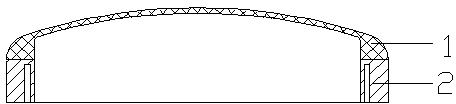

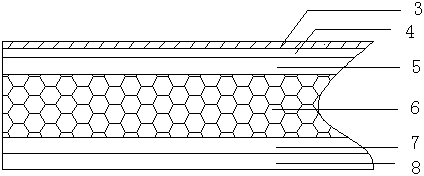

Combined antenna housing

The invention relates to an antenna housing and provided a combined antenna housing. The combined antenna housing comprises an arc-shaped housing body (1) and a steel base (2) in a hollow cylindrical structure, wherein the steel base (2) is located on the lower portion of the arc-shaped housing body (1), and the arc-shaped housing body is in a sandwiched composite structure. Compared with existing products, the combined antenna housing has the advantages of being good in electromagnetic permeability and high and low temperature shock resistance and capable of protecting antennas to be used in severe weather such as sand, high wind and humid rainy climate and in regions with large temperature differences.

Owner:洛阳双瑞橡塑科技有限公司

Continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel

The invention discloses continuous casting crystallizer casting powder for large circular blank abrasion resisting high manganese steel. According to the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel, cracks are reduced by adopting low carbon amount and high viscosity, reducing thermal stress inside blank shells and increasing powder consumption amount. The alkalinity of the casting powder is 0.8-1.1, the cracks caused by uneven heat transmission are avoided; through the adoption of 8-12% of Na2O, 6-8% of F- and 3-4.5% of Li2O, weak coldness and even heat transmission of the upper portion in a crystallizer are achieved, inclusion absorbing effects are improved, and the cracks are reduced; through the adoption of 2-8% of MnO, lattice vibration and conduction heat transmission are weakened, and the crystallization properties of the casting powder and the casting blank quality are improved. Raw materials of the continuous casting crystallizer casting powder for the large circular blank abrasion resisting high manganese steel are easy to obtain, and production cost is low. Through field testing, the casting power is good in spreadability and good in air permeability and can be smelted stably and be free of caking, the consumption amount of the casting powder is around 0.3-0.42kg per ton of steel, the consumption cost is relatively low, and the qualified rate of the first grate casting blanks is improved significantly.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

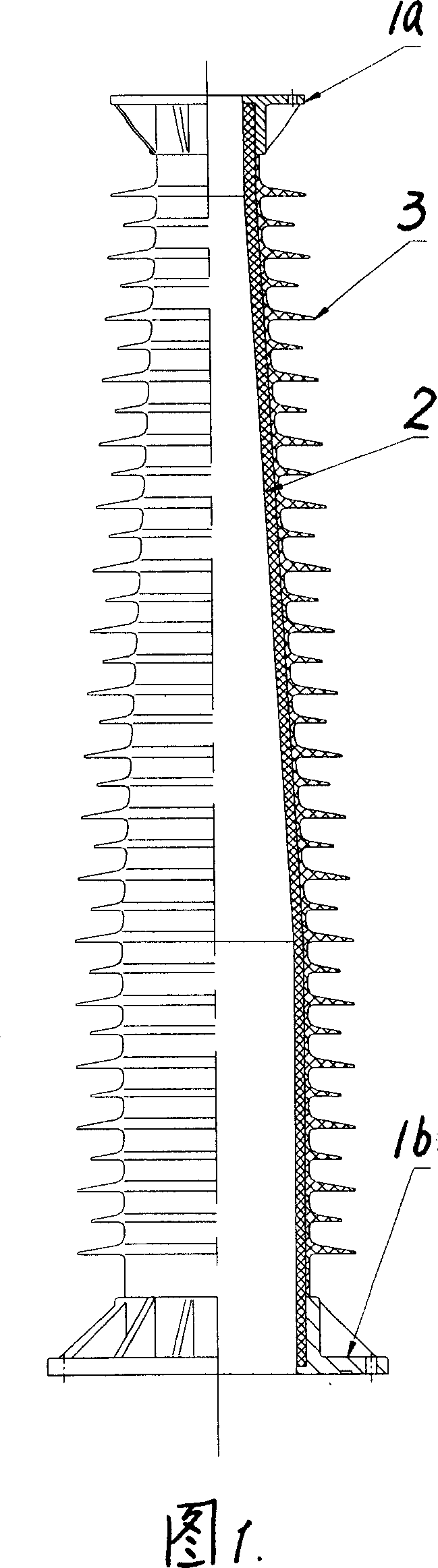

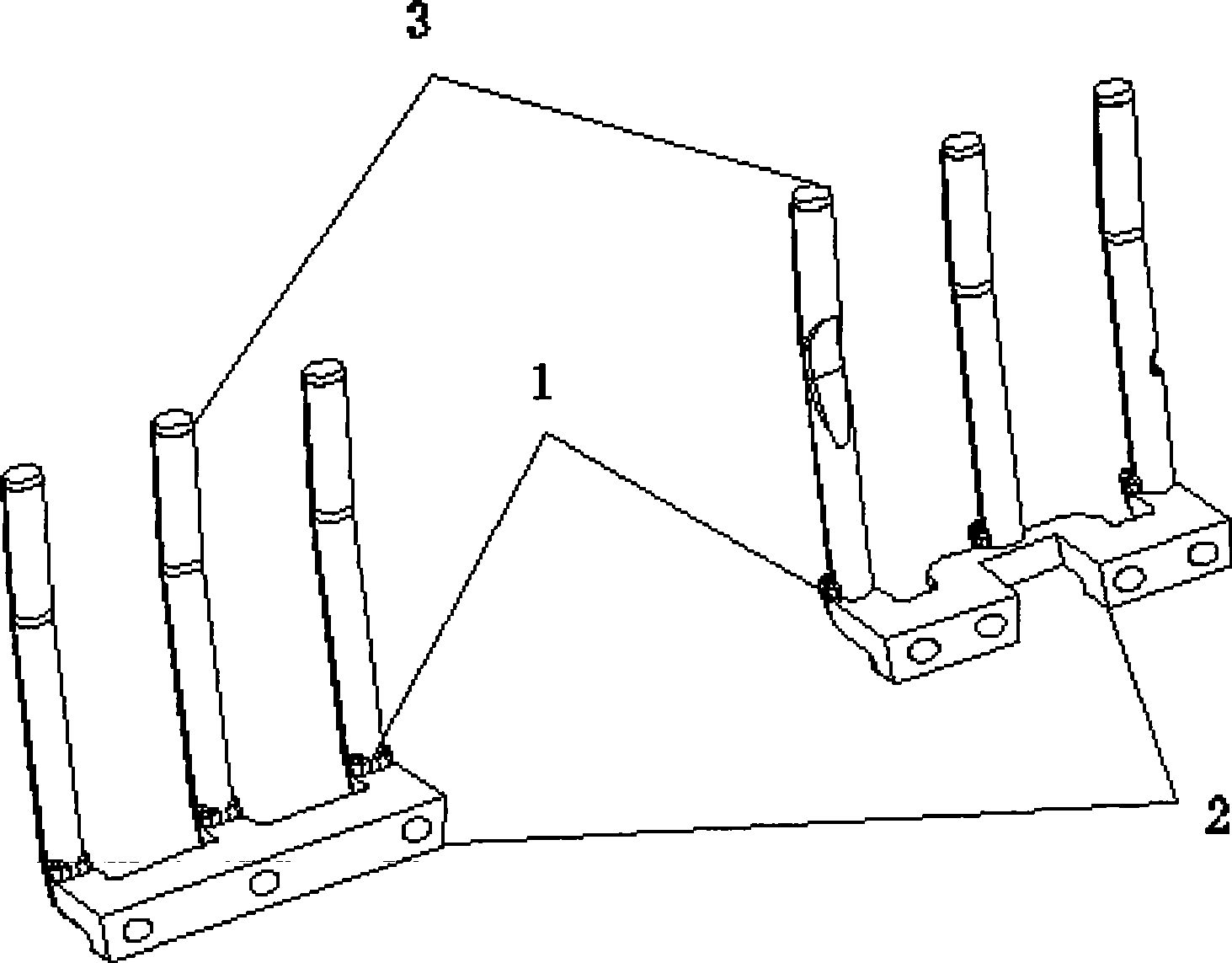

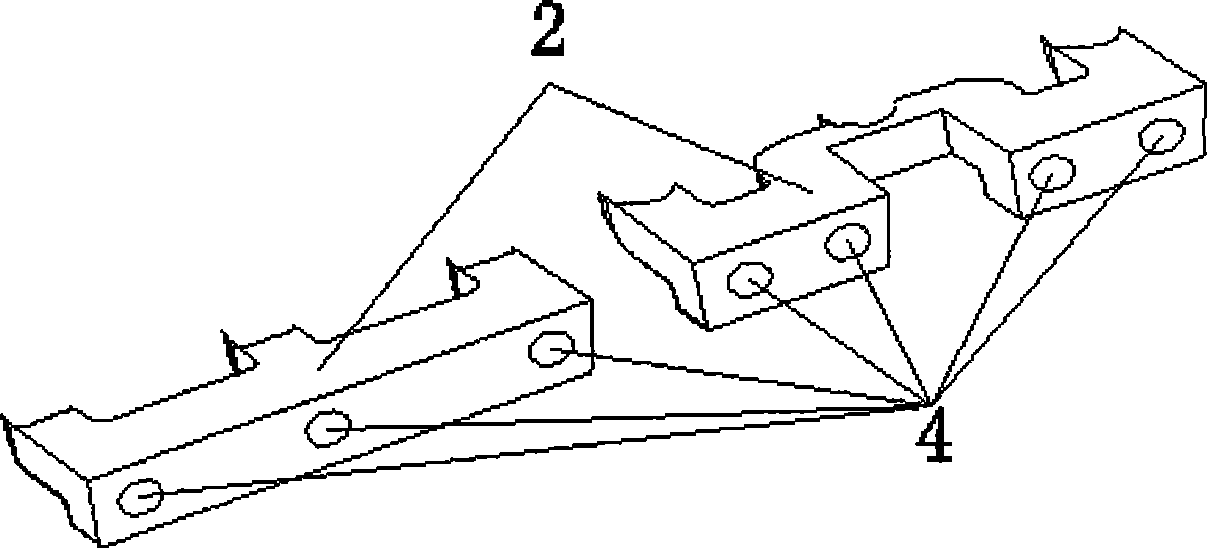

Reducing diameter high voltage hollow composite insulator and its manufacturing method

InactiveCN101000816ALower center of gravity and frontal areaIncreased bending load requirementsInsulatorsEngineeringSilicon disulfide

A high voltage hollow composite insulator of diameter variable type is prepared as sticking end connection pieces firmly at two ends of winding tube, setting a unified structure of umbrella body at external of winding tube, setting said winding tube to be tube body in variable diameter, using high temperature silicon sulfide rubber to form a unified structure of umbrella body by injection forming process.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

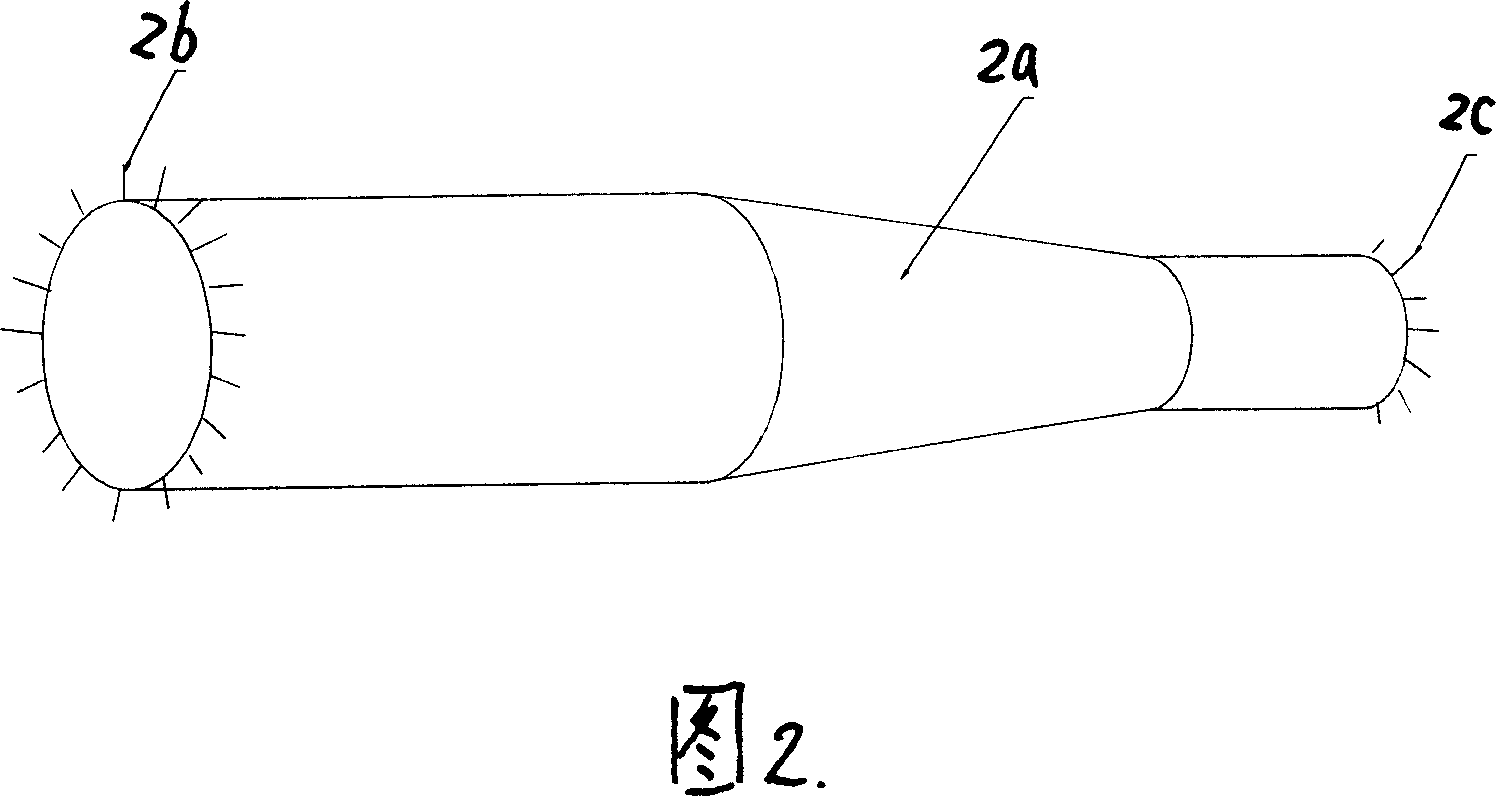

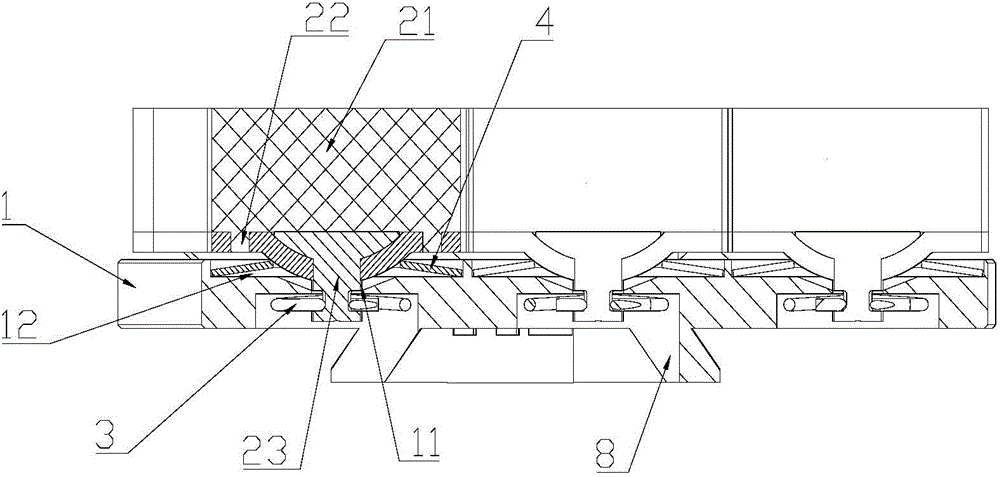

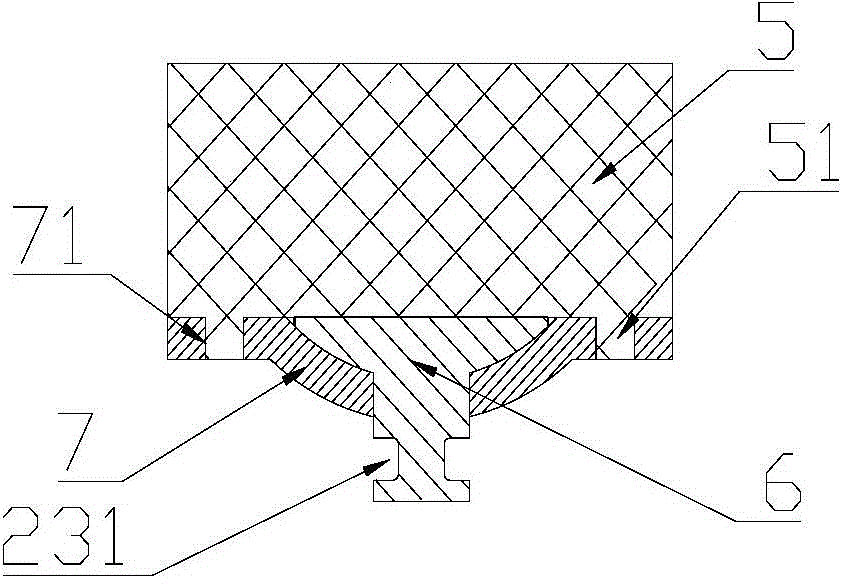

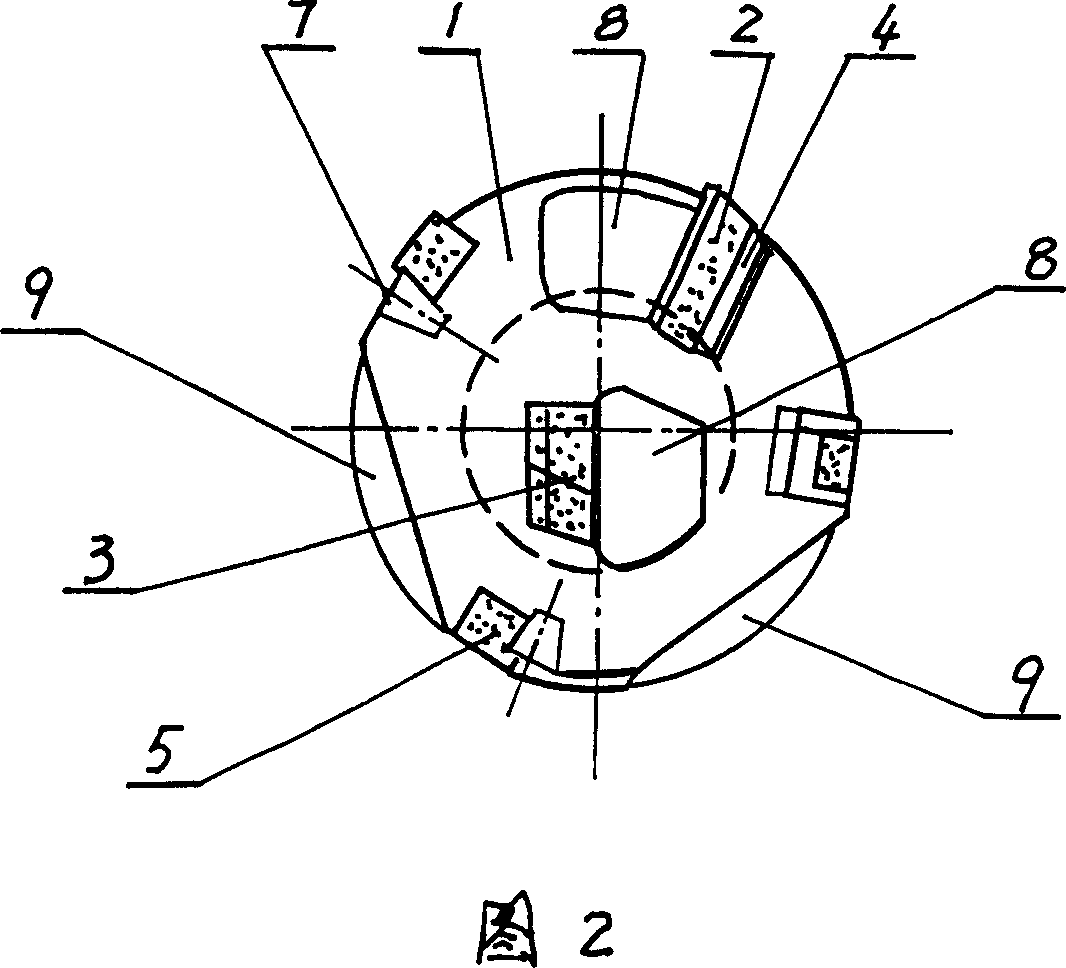

Floating type brake pad

InactiveCN104455105AConsistent heat fluxExtended service lifeBraking membersFriction liningStress concentrationEngineering

The invention discloses a floating type brake pad. The floating type brake pad comprises a back plate, a plurality of friction blocks, disc springs and clamping springs, wherein the friction blocks are arranged on the back plate, the disc springs are arranged between the friction blocks and the back plate, and the friction blocks are connected to the first back plate in a floating mode through the clamping springs. Positioning grooves are formed in the back plate, and the disc springs are arranged inside the positioning grooves. The back plate is divided into a plurality of concentric circular rings by using the circle center of a brake disc matched with the brake pad as the circle center. The circular rings are equal in radial length. The friction area of the friction block inside each circular ring is not larger than 15% of the standard average friction area compared with the standard average friction area. According to the floating type brake pad, the problem of fatigue cracks caused by instantaneous stress concentration during braking of existing disc springs is solved, meanwhile, gaps between the back plate and the friction blocks are reduced, oscillation of the friction blocks is small, meanwhile, the problem of eccentric abrasion of the friction blocks is avoided, and the brake stability is greatly improved.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Method for processing rectangular-tooth spline sleeve using 42CrMoE high-quality alloy steel as material

InactiveCN102534374AImprove wear resistanceImprove bending abilityCouplings for rigid shaftsPhosphorylationThermal treatment

The invention discloses a method for processing a rectangular-tooth spline sleeve using 42CrMoE high-quality alloy steel as a material, belonging to the technical field of thermal treatment. The method comprises the steps of: free forging of a blank, normalizing treatment, rough turning, hardening and tempering thermal treatment, finish turning, spline drawing, drilling, burr gripping, carburization treatment, surface deposition treatment, phosphorylation treatment, electroplating, drying and detection. In the invention, due to the new material and new technology, the wear resistance of the produced rectangular-tooth spline sleeve is greatly enhanced, the phenomenon of crack of the rectangular-tooth spline sleeve is avoided, the surface is smooth, the friction is low, the heat dissipation is good, and the service life is prolonged, thus the processing technology is widely applied.

Owner:无锡市万邦机械制造厂

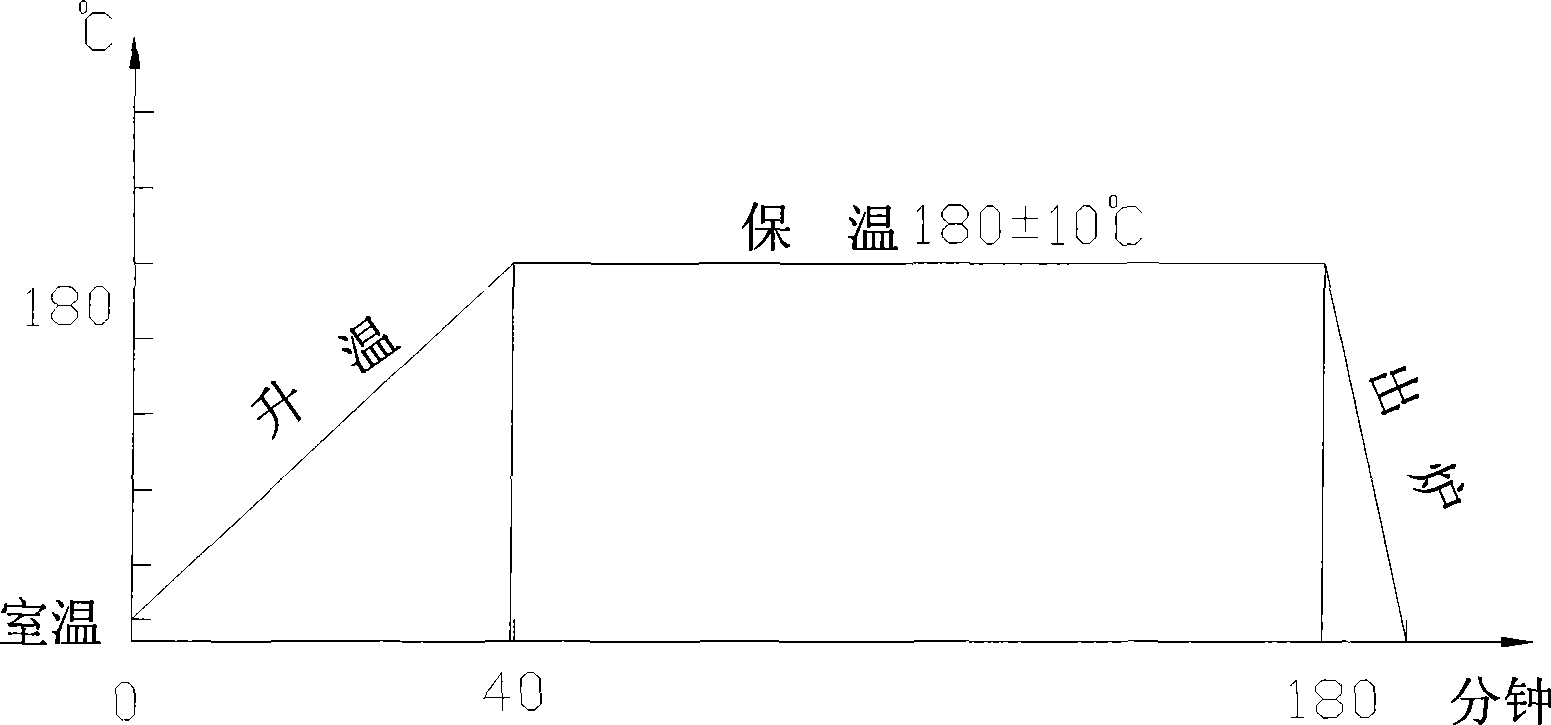

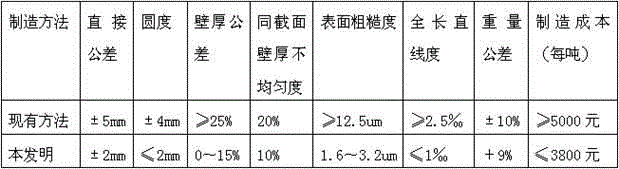

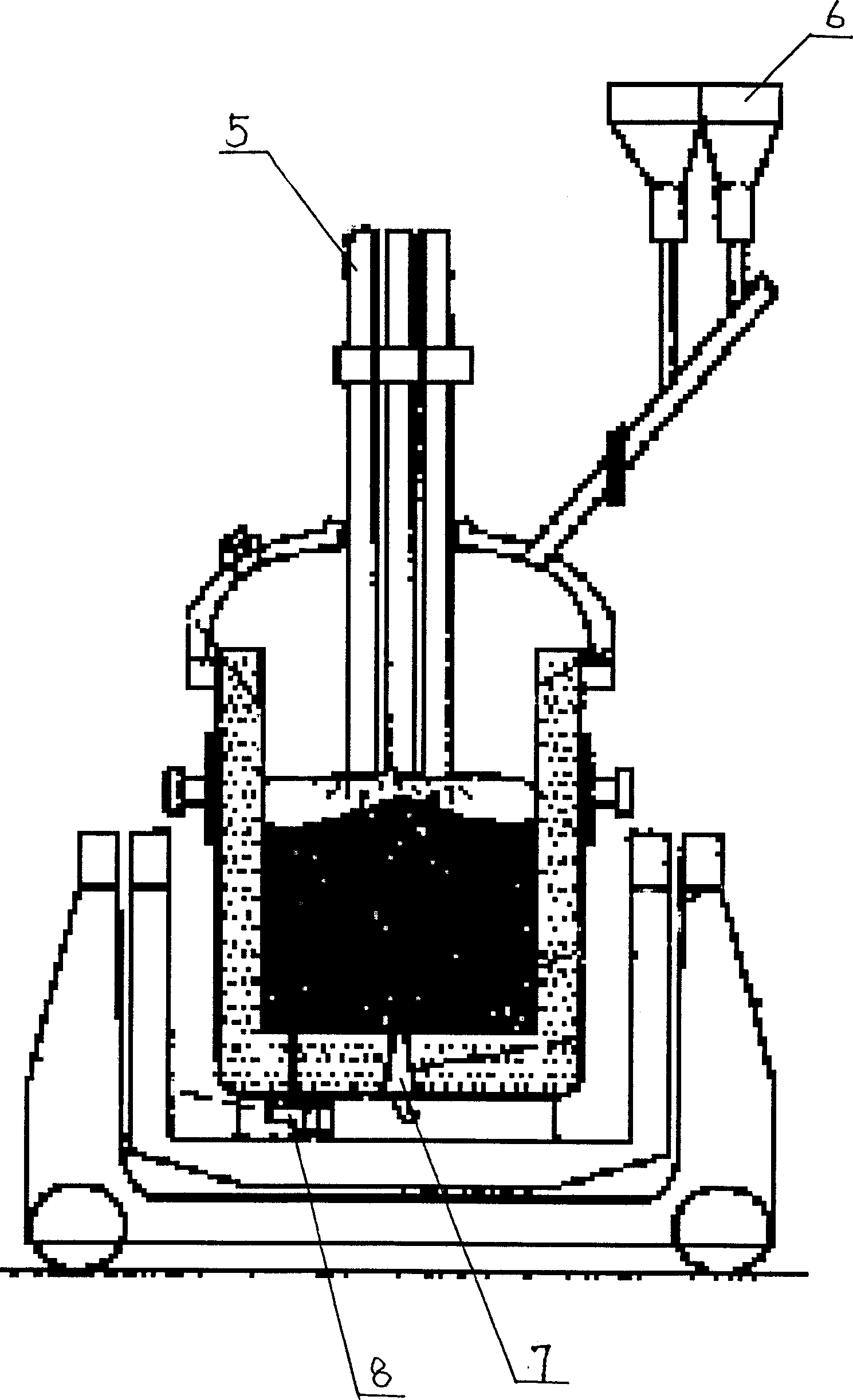

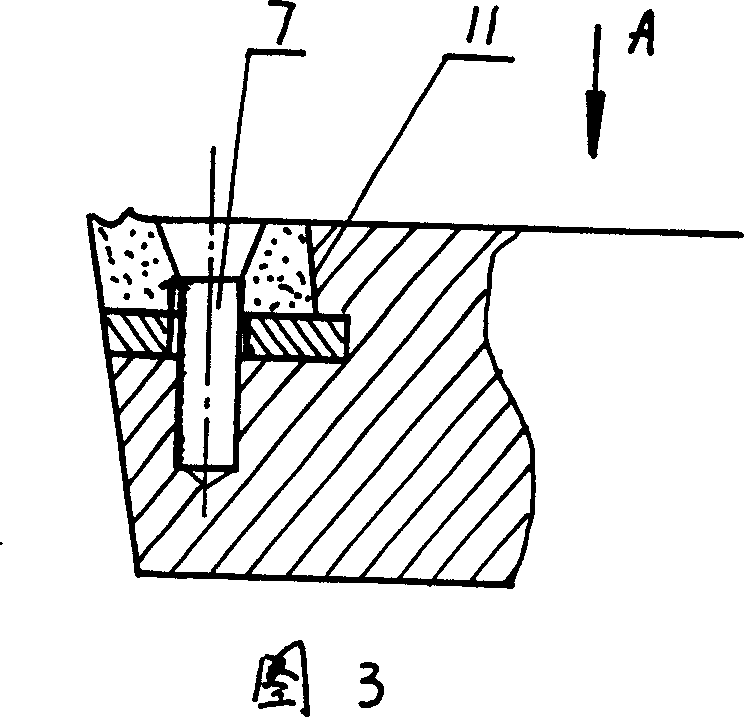

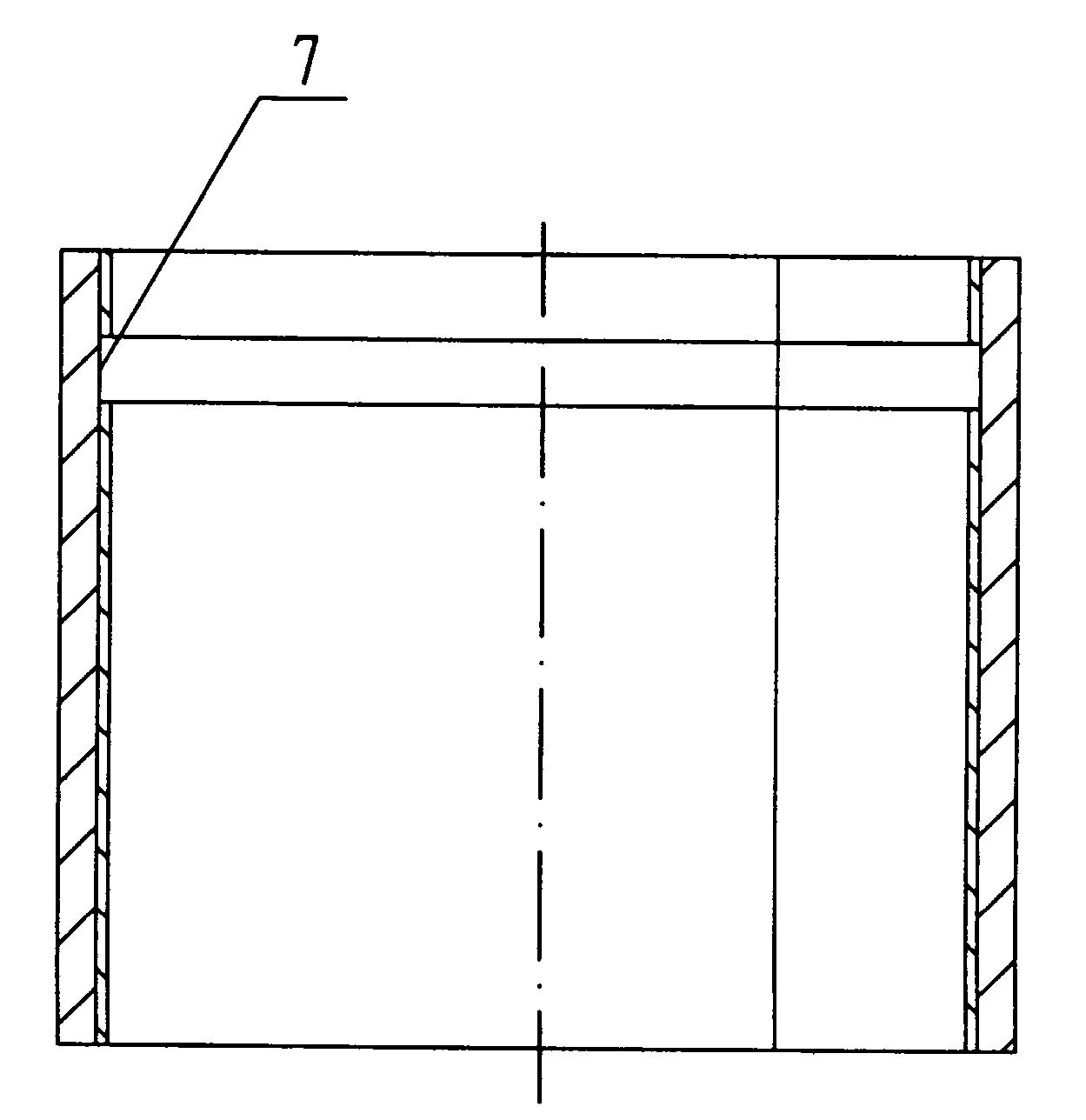

Control method for hot forging structure property of Mn18Cr18N steel retaining ring

InactiveCN102350474AAvoid crack phenomenonQuality improvementMetal-working apparatusStructure propertyHeating furnace

The invention relates to a control method for the hot forging structure property of a Mn18Cr18N steel retaining ring, belongs to the technical field of a metal pressure machining. The operation method of the invention comprises the following steps: (1) sheathing a soft steel sleeve outside blanks and putting the soft steel sleeve and the blanks together into a heating furnace to be heated to 1180-1220 DEG C; (2) putting the heated blanks wrapped with the sleeve externally into a cylinder die and punching the blanks by utilizing a plunger chip; when the plunger chip load is increased to the load allowed by a press machine, replacing a chassis by a drain cap to carry out extrusion and losing the gross weight; (3) putting the annular blanks which is extruded into the heating furnace to be heated to 1100-1150 DEG C and keeping the temperature for 1-3 hours; (4) carrying out the broaching on a mandrel at the first circle and controlling the deformation amount between 13-18%; (5) when the temperature in the broaching process is reduced below the final forging temperature, putting into the heating furnace and heating to 1100 DEG C as well as keeping the temperature for 1 hour; (6) carrying out the broaching on a mandrel at the second circle and controlling the deformation amount between 9-13%; (7) when the temperature in the broaching process is reduced below the final forging temperature, putting into the heating furnace again and heating to 1100 DEG C as well as keeping the temperature for 1 hour; and (8) continuously carrying out the broaching on the mandrel until the dimension requirements are met. The method has the advantages that the phenomenon of generating cracks on the surface of a forge piece in the deformation process in the prior art can be prevented; and the deformation on the external surface of the forge piece is increased in the multiple broaching processes of the mandrel, thereby refining grains more uniformly and improving the quality of the forge piece.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Light-cured resin based ceramic composite material capable of providing bright and clean contour and blank degreasing method

ActiveCN108249930AIncrease penetration depthImprove the finishAdditive manufacturing apparatusCeramic compositeSlurry

The invention discloses a light-cured resin based ceramic composite material capable of providing the bright and clean contour of a formed part and a blank degreasing method of a ceramic blank. By optimally designing the resin system, the transmission depth of the ceramic slurry system can be improved and the dimension errors of the formed part are reduced while the reaction activity of the systemis maintained; the interlayer binding force of the ceramic blank and the adhesive property between the ceramic blank and a printing platform are increased, and the distance between the ceramic blankand the platform and cracks on the surface of the ceramic blank are reduced; moreover, the regularity of powder particles arranged along a model surface is improved, so that the material can be made into a model with improved brightness and cleanness of the contour.

Owner:深圳长朗智能科技有限公司

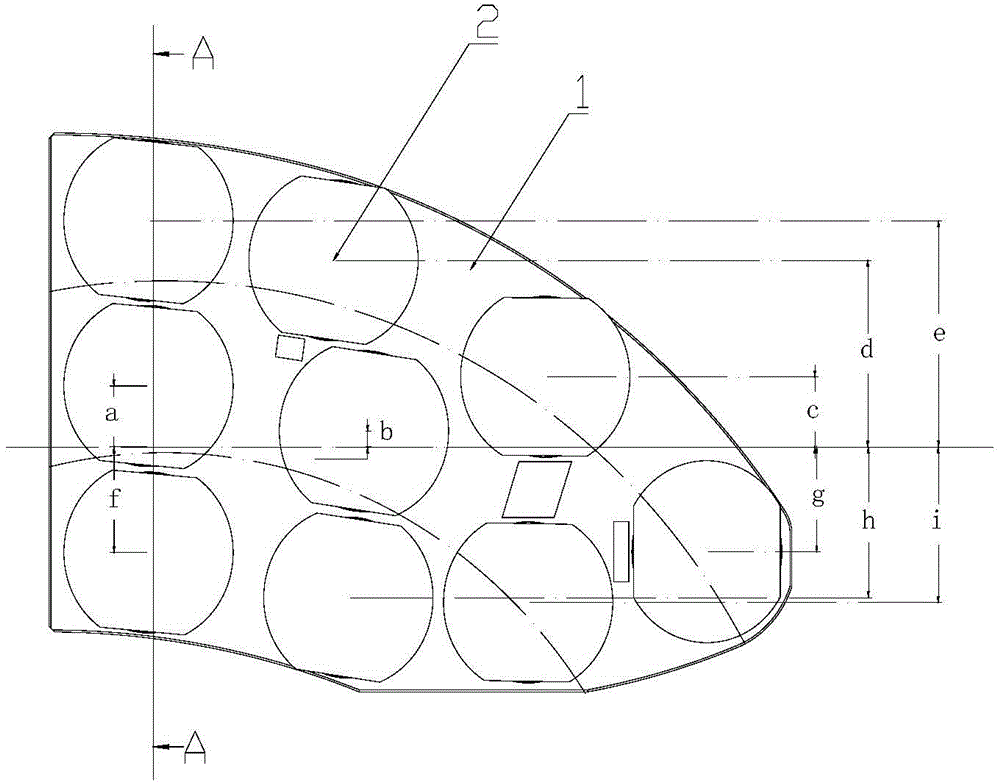

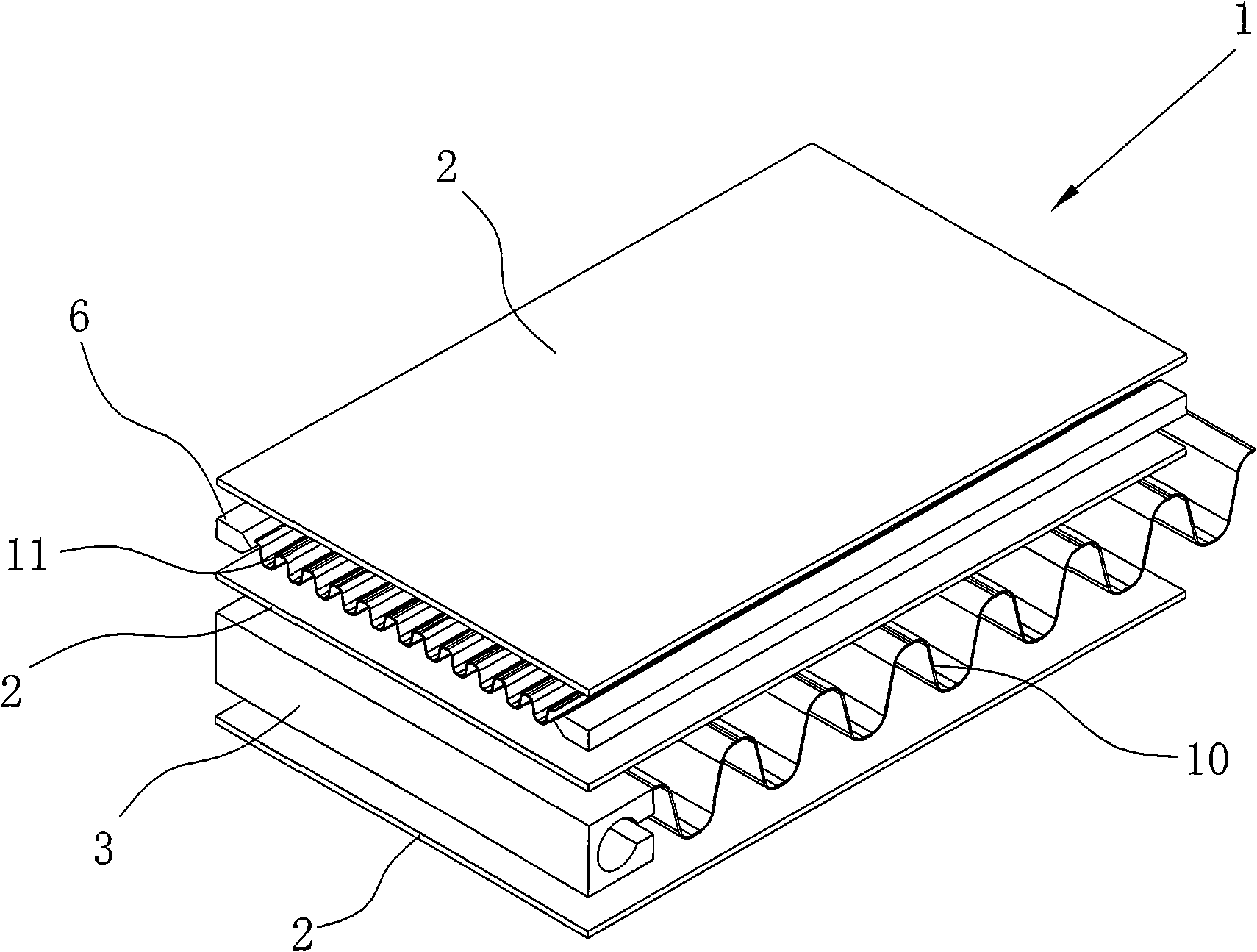

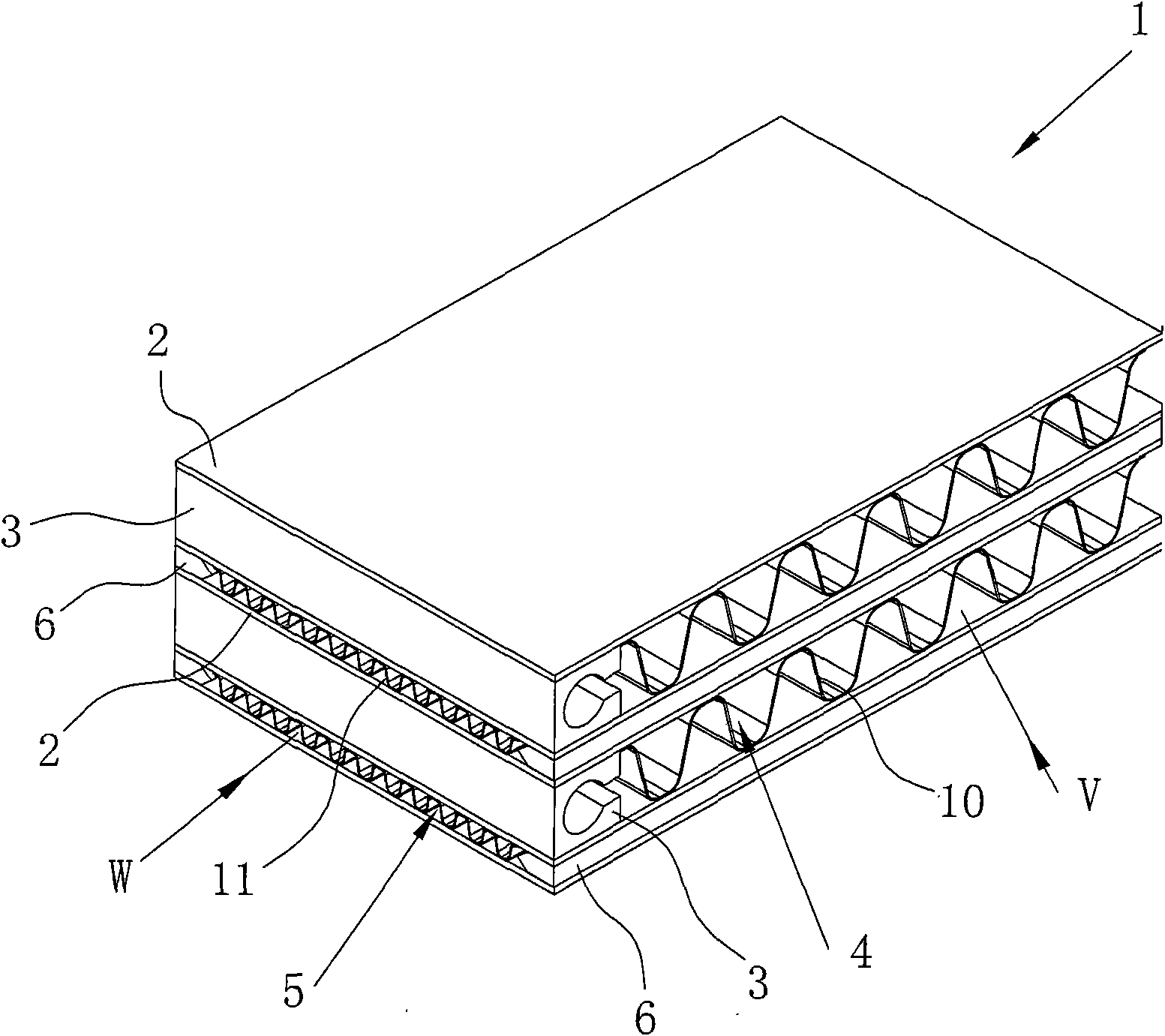

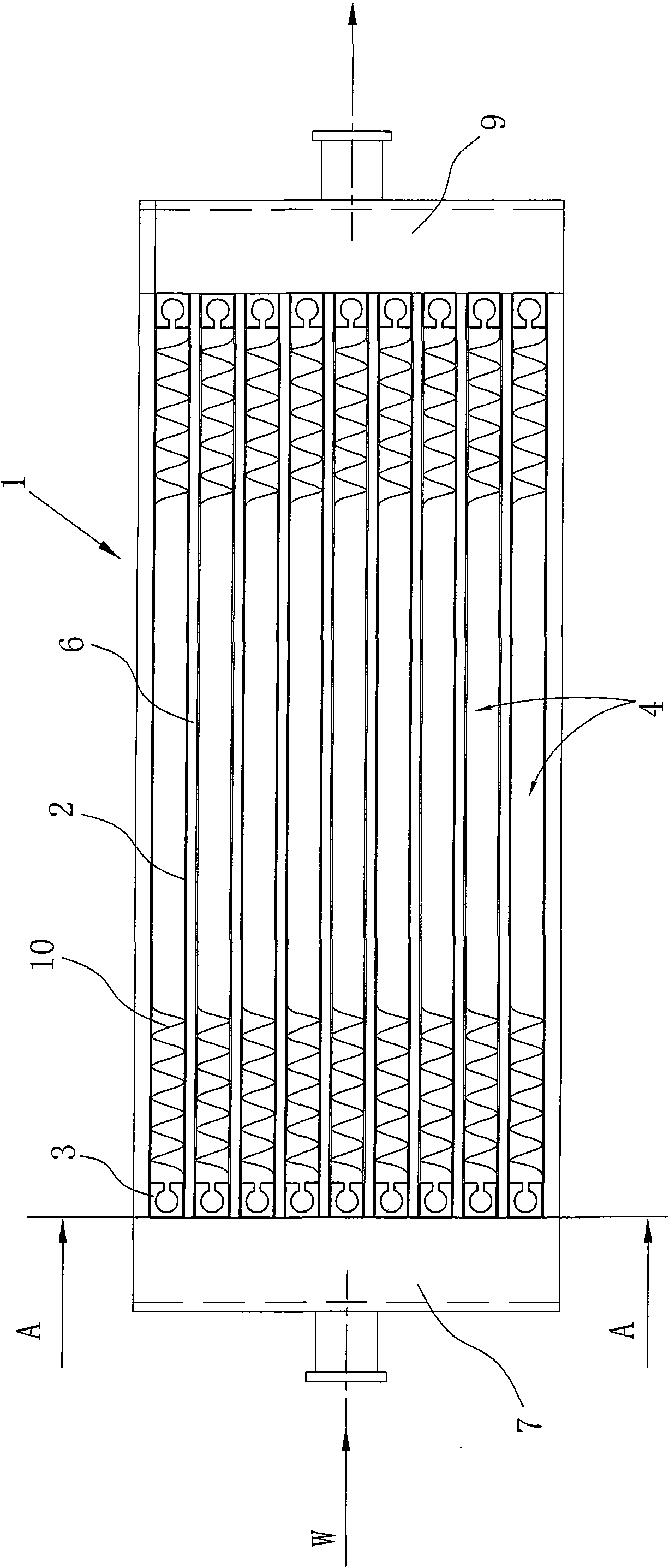

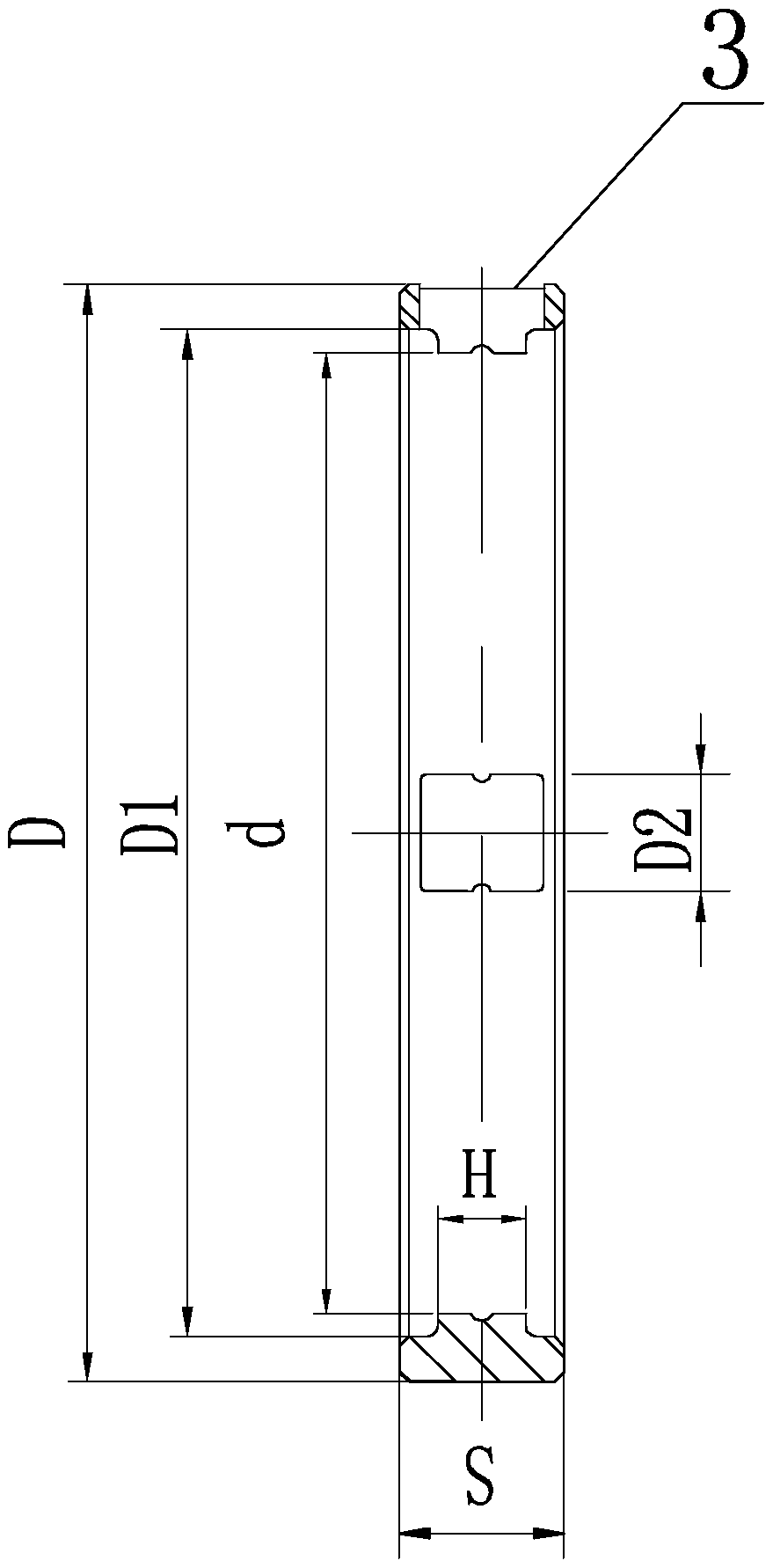

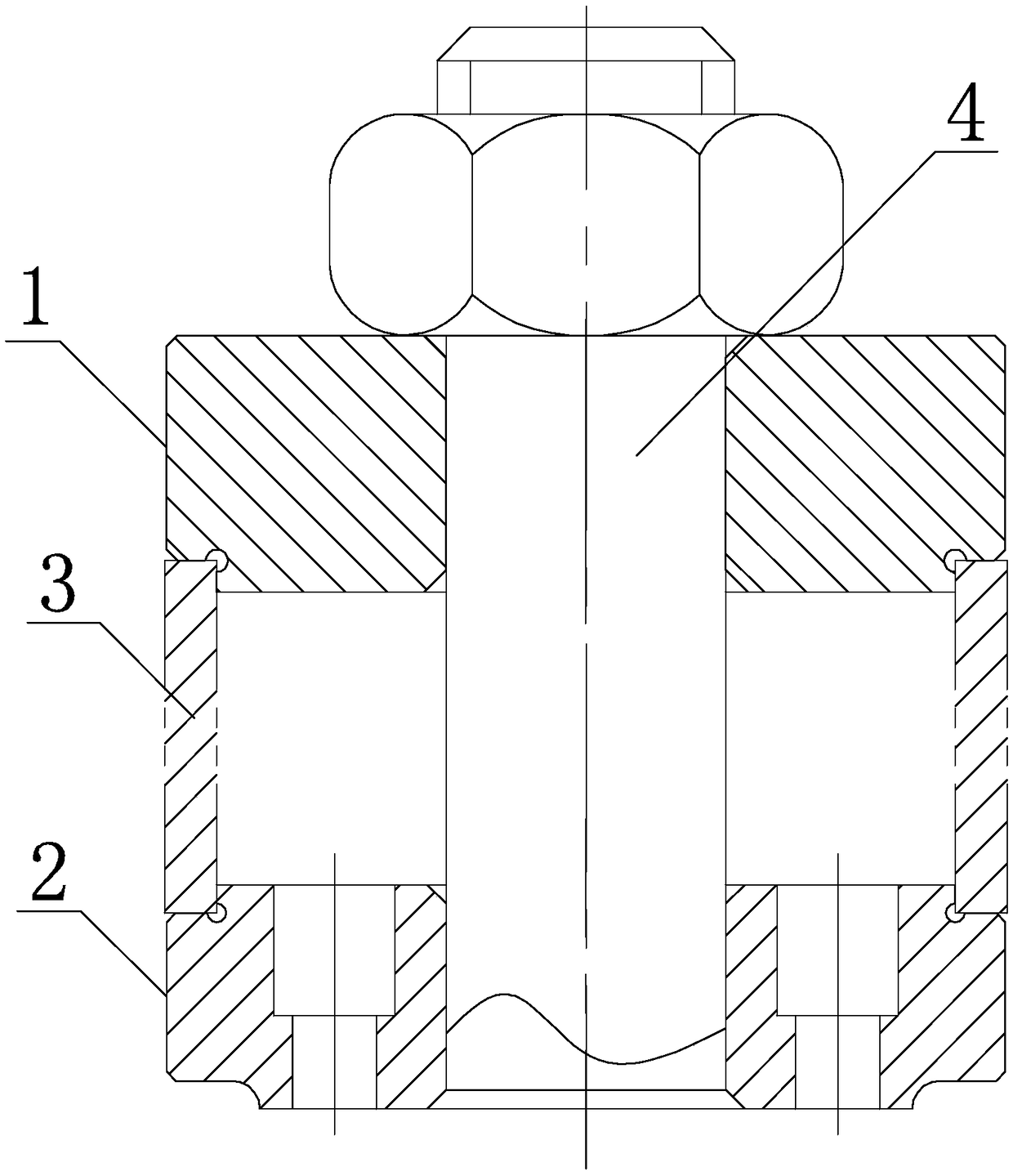

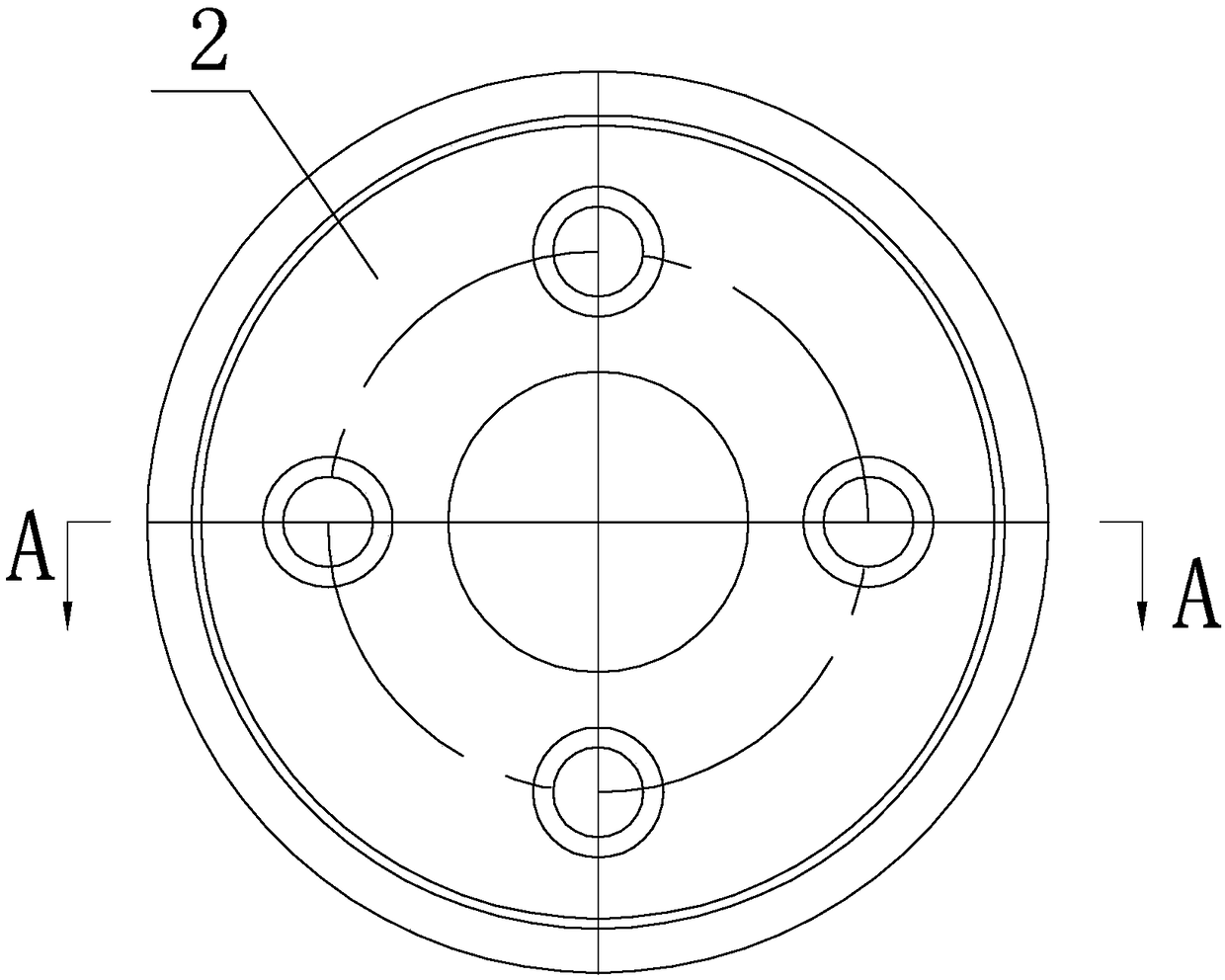

Core of heat exchanger

ActiveCN101672597AReduce the impact of impactReduce the speed of sudden temperature changesLaminated elementsEngineeringMechanical engineering

The invention relates to a core of a heat exchanger, comprising a cold fluid channel and a hot fluid channels. The cold fluid channel and the hot fluid channel are distributed in an overlapping way, are partitioned by partition boards and are crossed in the extension direction. The edges of the two sides of the cold fluid channel are provided with cold fluid channel seal strips. The cold fluid channel comprises the two cold fluid channel seal strips and partition boards arranged above and below the cold fluid channel seal strips; the two cold fluid channel seal strips are respectively arrangedat the inlet and the outlet of the hot fluid channel, and the cold fluid channel seal strip which is arranged at the inlet of the cold fluid channel is provided with a hole lengthwise. Because the cold fluid channel seal strip which is arranged at the inlet of the hot fluid channel is provided with the hole and is hollow, the flexibility of the hot fluid channel seal strip is improved, and the flexibility of the inlet of the whole hot fluid channel is improved accordingly. Therefore, the thermal stress impact to the core of the heat exchanger can be reduced, and the part of core of the heat exchanger, where the hot fluid flows past, can not crack due to the sudden change of temperature.

Owner:爱克奇换热技术(太仓)有限公司

Method for preparing grinding wheel according to wet method

The invention belongs to the technical field of grinding wheel preparation and particularly relates to a method for preparing a grinding wheel according to a wet method. The method comprises the following steps: respectively adding powder glue, water, starch, binder, foaming agent and curing agent in proportion at different time, and then controlling the stirring speed, temperature and pouring speed in different preparing steps. The method provided by the invention has the advantages of simple technology and production equipment; the prepared grinding wheel is uniform in pore size and distribution; the mechanical strength, the abrasive resistance and the grinding property of the grinding wheel are greatly increased; and especially, the maximum porosity can reach 75%.

Owner:东莞市脉拓表面处理科技有限公司 +1

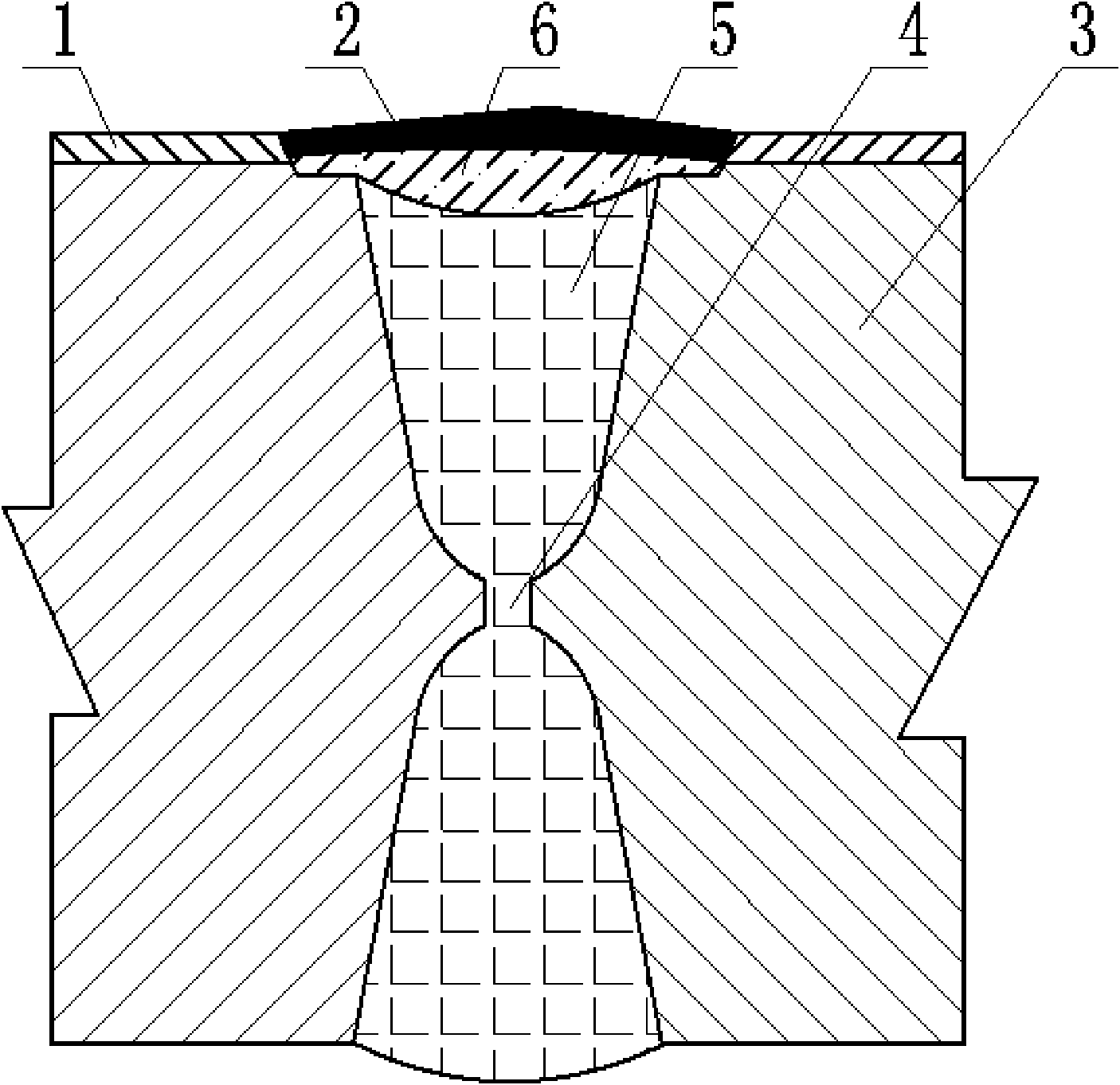

Processing method for inner-ring-free cylindrical roller bearing alloy steel solid retainer

InactiveCN109500549AImprove mutual differenceSmall machining allowanceSurface roughnessStress relief

The invention discloses a processing method for an inner-ring-free cylindrical roller bearing alloy steel solid retainer, and relates to the technological field of bearings. The problems that after anexisting bearing retainer processing process, the working accuracy of a pocket hole of the bearing retainer and the surface roughness of the pocket hole do not reach the standard, and rolling surfacecan generate cracks in the lock opening rolling process are solved. The processing method comprises the following processes of lathe forming, hardening and tempering, rough grinding of the outer diameter, fine lathing of the two end faces, fine lathing of the inner diameter, even grinding of the two end faces, final grinding of the outer diameter, final grinding of the inner diameter, turning ofinner steps, marking, drilling, milling of square holes, pulling of the square holes, deburring, cleaning, stress relief annealing, glazing, lock opening rolling, dynamic balancing, magnetic powder inspection, silver plating, final inspection and packaging. According to the processing method, stress relief annealing is carried out before lock opening rolling is carried out, and the cracks generated by machining stress superposition and a surface cold hardening layer on the rolling surface are avoided. The processing method is suitable for processing the inner-ring-free cylindrical roller bearing alloy steel solid retainer.

Owner:AVIC HARBIN BEARING

Processing method of sand core in engine aluminum alloy cylinder metal mould low-pressure casting

ActiveCN101497109AReduce moisture contentLack of angerFoundry mouldsFoundry coresPressure castingMetal mold

The invention relates to a casting technique, in particular to a method for processing a metal mold low-pressure casting medium sand core for an aluminum alloy cylinder of an engine, wherein a method for coating a coating layer, removing water content and drilling vent holes is adopted to process the sand core so as to achieve the aim of preventing phenomena of sand inclusion, air holes, looseness, cracks, and the like.

Owner:SHANGHAI AISHIDA AUTOMOTIVE COMPONENTS

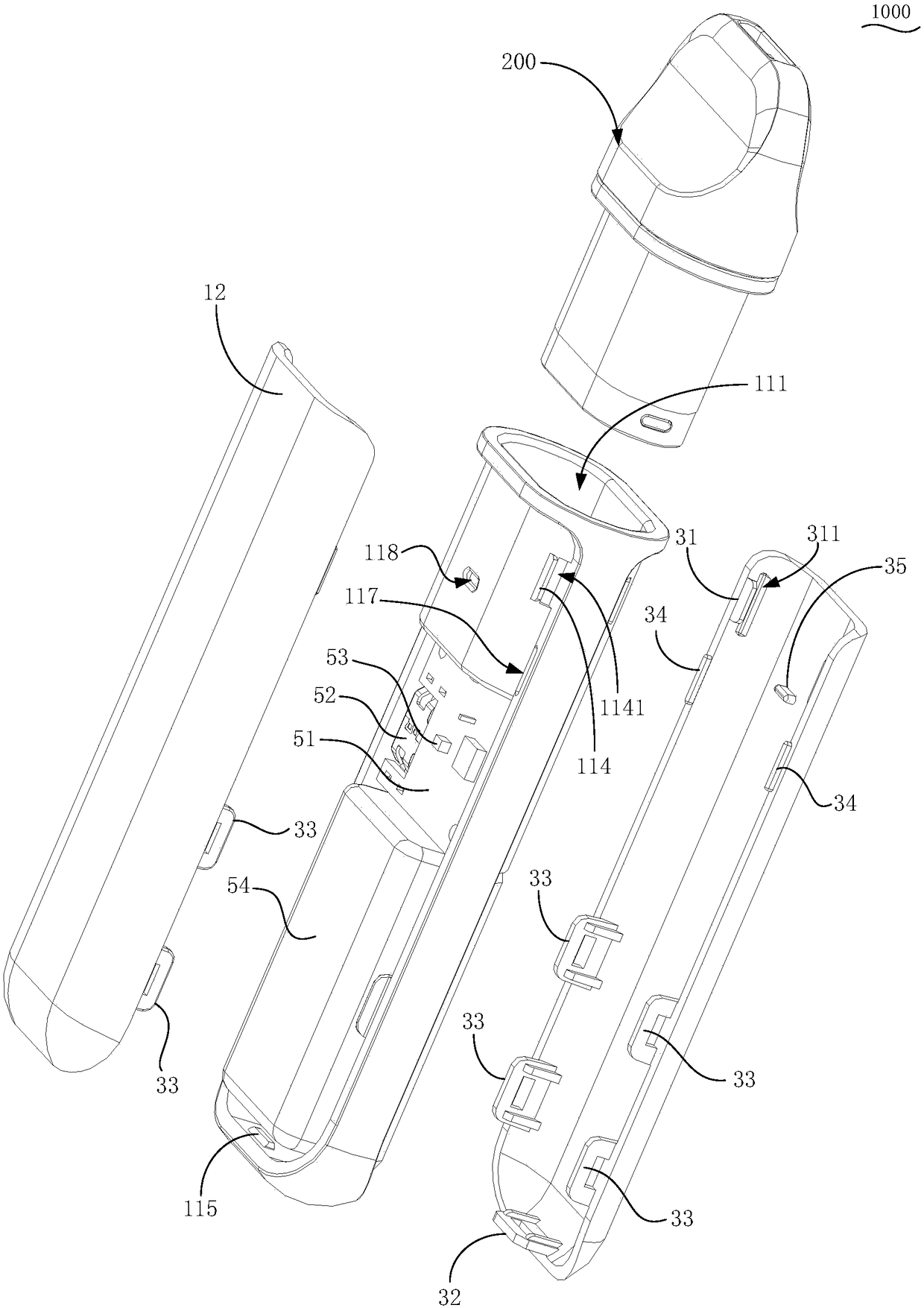

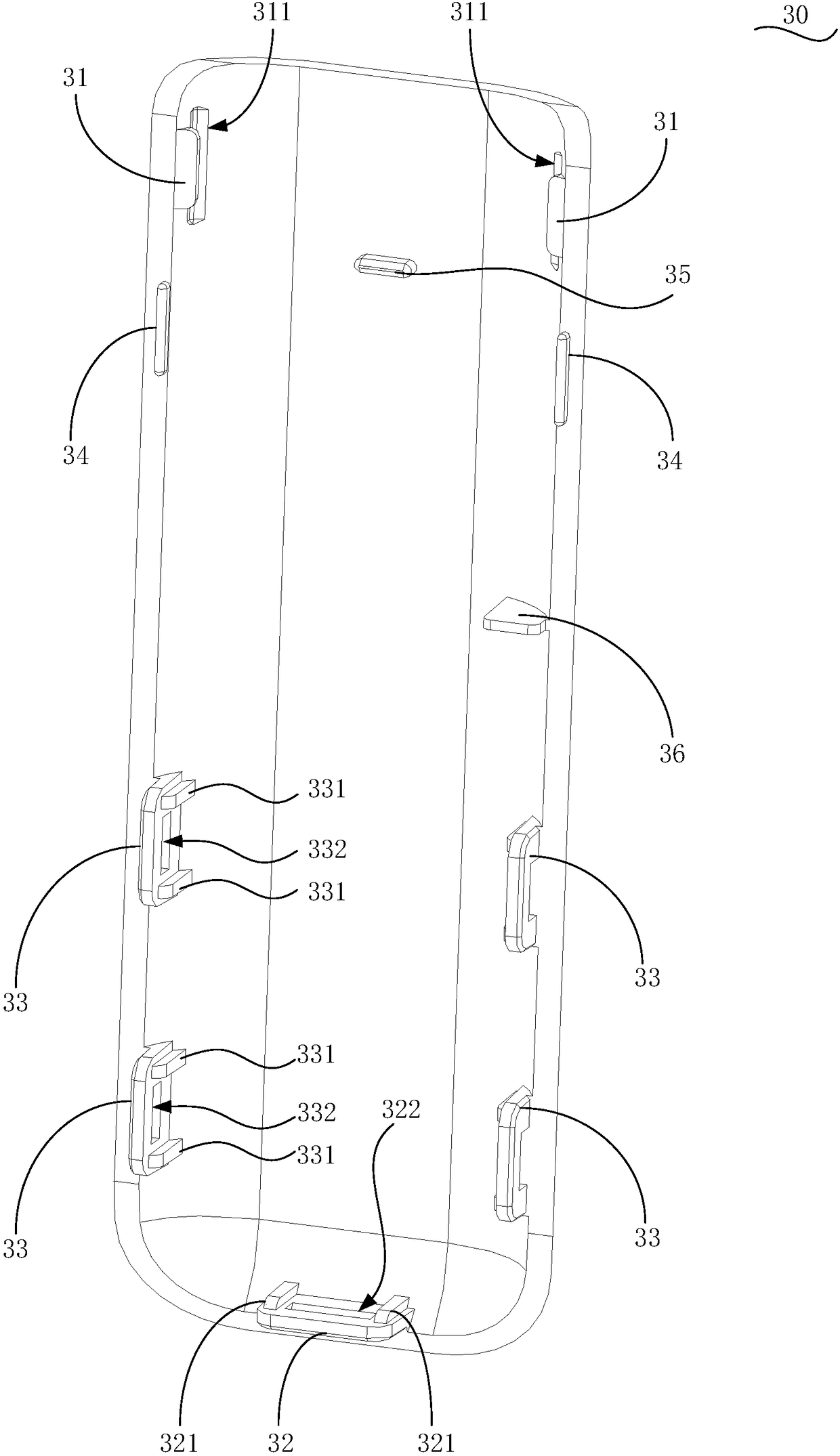

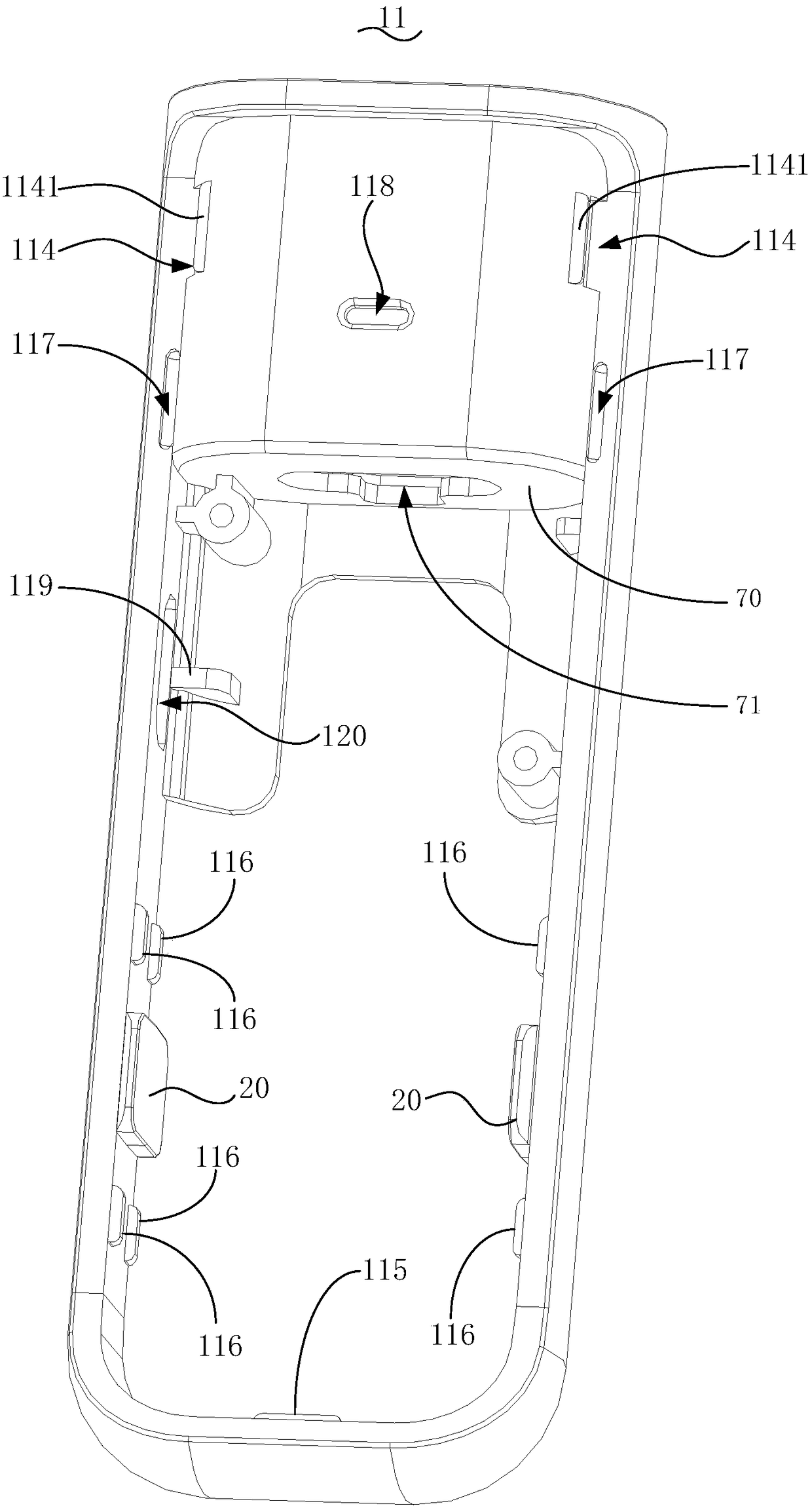

Power supply component and electronic cigarette

The invention discloses a power supply component and an electronic cigarette with the same. The power supply component comprises a body and a rear cover fixedly mounted on the body, one end of the body is provided with a connection portion which is fixedly and electrically connected with an external load, the other end of the body is provided with an inner cavity for storage of electronic elements, the rear cover is fixedly mounted on the body and covers the inner cavity, and one end, away from the connection portion, of the body is provided with an extending portion facing the rear cover. Theextending portion covers the end, away from the connection portion, of the rear cover. Damages of an outer shell away from the end of a smoking port due to hitting in falling of the electronic cigarette can be effectively avoided.

Owner:SHENZHEN IVPS TECH

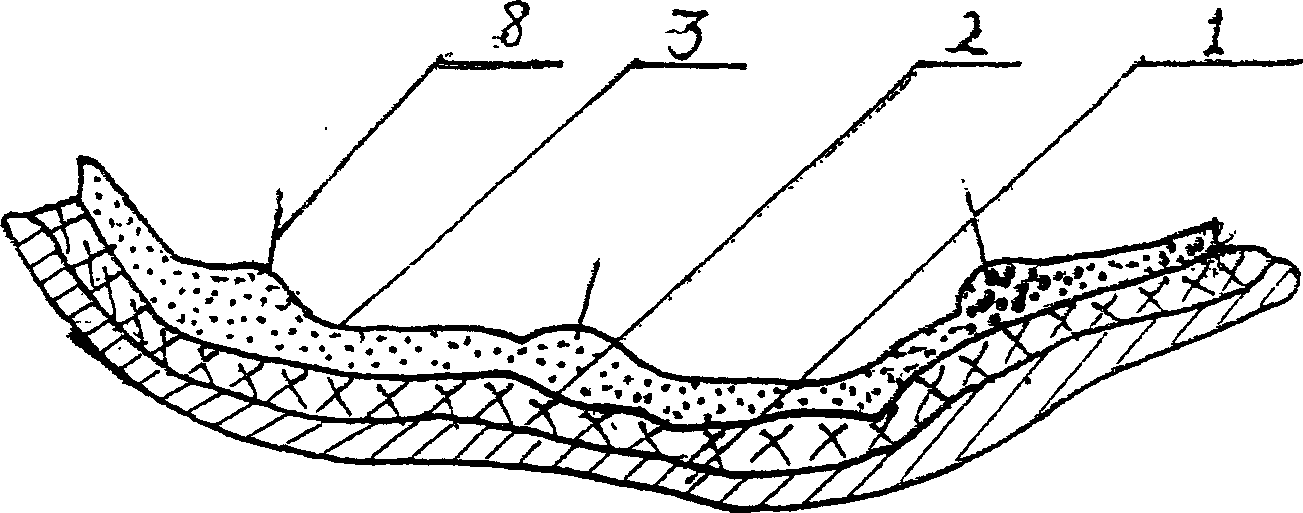

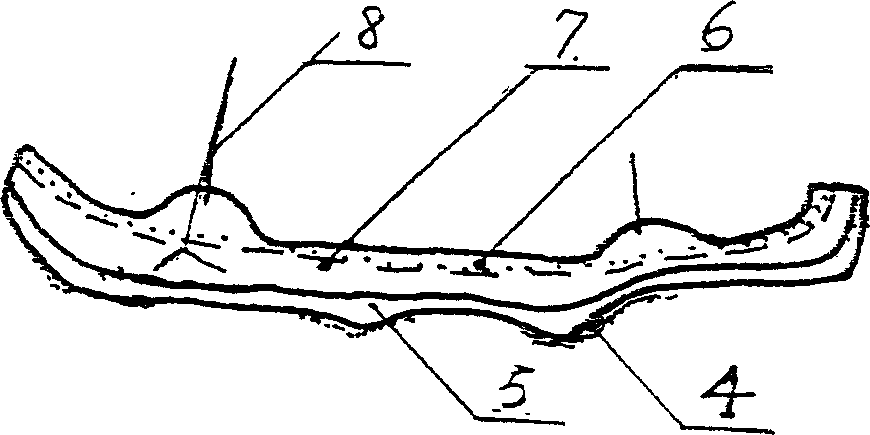

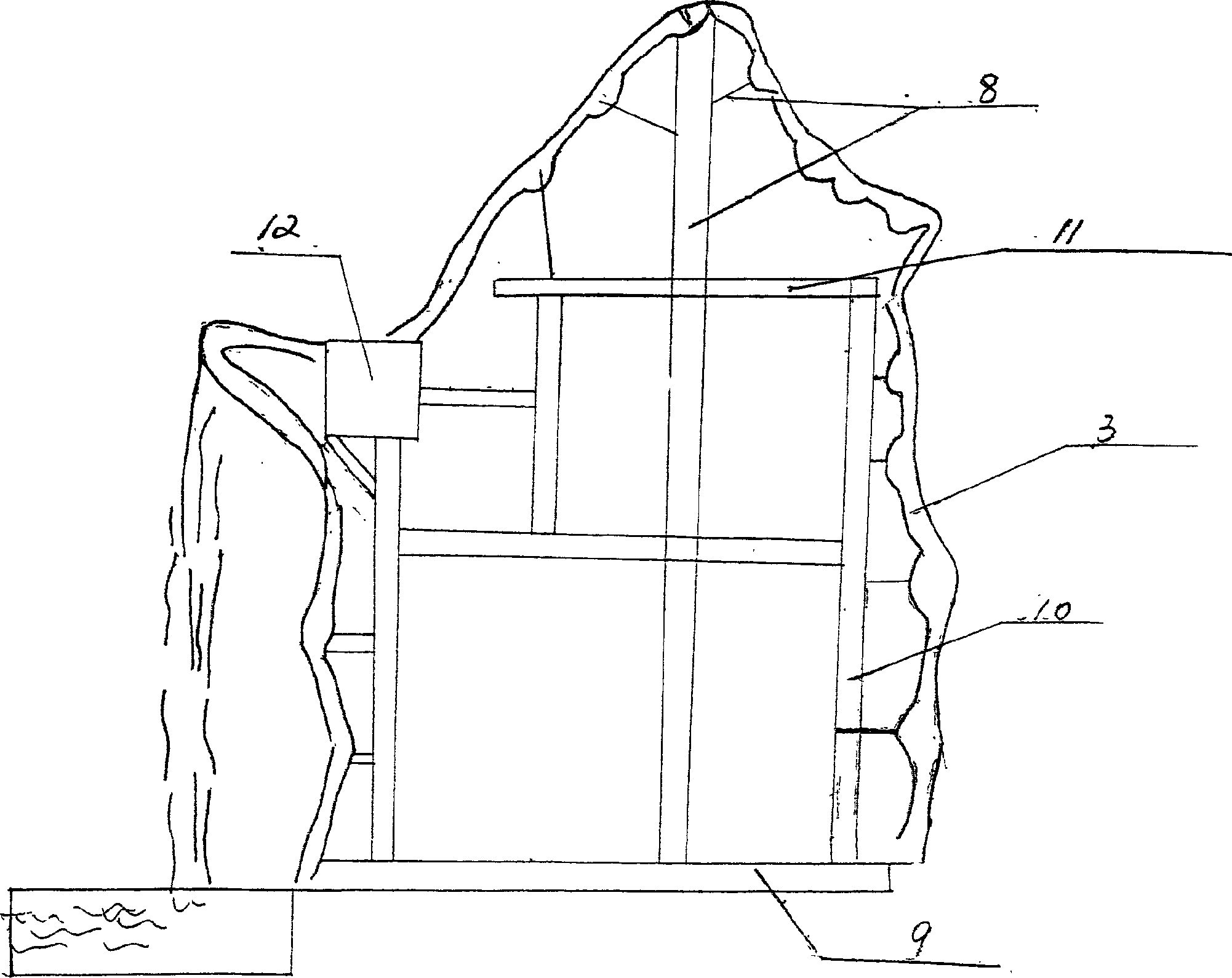

Prefabricated regenerated stone block for rockery, its fabrication process, regenerated stone rockery and its piling up method

InactiveCN1486861ARich surface color and textureRealistic stone-like effectDecorative surface effectsThree-dimensional effectsWaddingCorrosion resistant

The present invention is th technological scheme of prefabricated regenerated stone block for rockery, its fabrication process, regenerated stone rockery and its piling up method. Structurally, the prefabricated rockery block includes molded inner layer, middle layer and outer layer and structural layer, which is set on the molded layers and includes support frame, netted layer and stuffing. The rockery piling up process includes connecting shaped ground shaped steel with foundation to make ground rib of rockery; welding support shaped steel with the ground shaped steel to make skeleton of rockery; welding the skeleton to the support frame of the prefabricated fockery block to form the outer appearance of rockery. The present invention can reproduce grains of stone and has realistic artistic effect and simple piling up process. The rockery is corrosion resistant, environment friendly and low in cost.

Owner:北京宝贵石艺科技有限公司

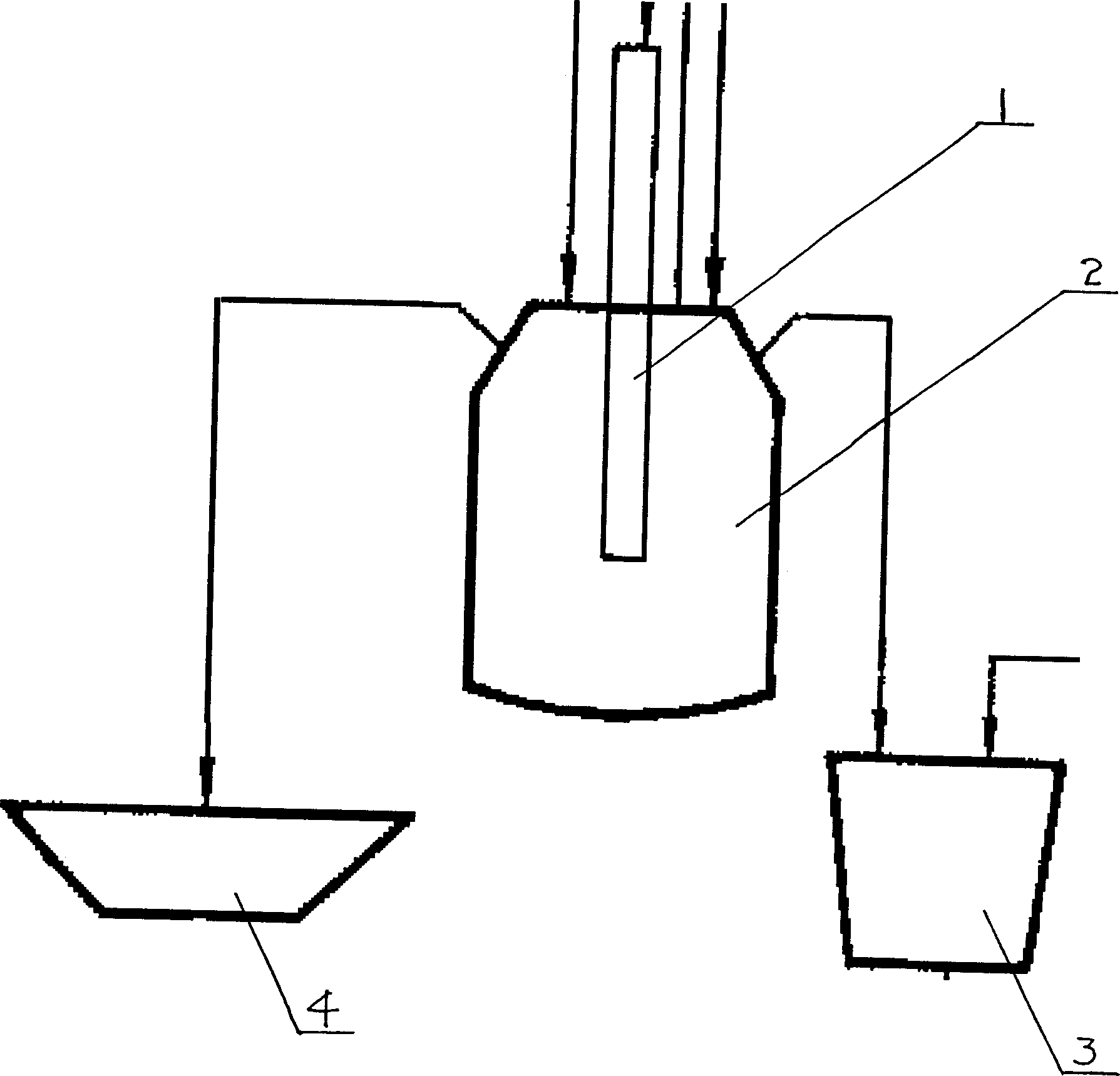

Seamless steel pipe for long pipe trailer and manufacturing method for seamless steel pipe

InactiveCN102720943ATo satisfy the market's needsIncrease storage capacityElongated constructional elementsAbrasion apparatusPipeMechanical engineering

The invention discloses a seamless steel pipe for a long pipe trailer and a manufacturing method for the seamless steel pipe. The outer diameter of the seamless steel pipe is 630 to 720mm, the wall thickness is 18 to 30mm, and the length is 10,000 to 12,500mm. The manufacturing method comprises the following steps of: 1) rechecking a pipe blank, and turning a chuck; 2) performing shot blasting treatment on the pipe blank by using an outer shot blasting machine and an inner shot blasting machine respectively; 3) performing surface quality inspection, and polishing; 4) washing the pipe blank, and performing phosphate treatment; 5) saponifying the pipe blank for a first time; 6) performing cold drawing on the pipe blank for a first time; 7) polishing the inner and outer surfaces of a cold drawing pipe, and saponifying the cold drawing pipe for a second time; 8) performing cold drawing on the cold drawing pipe for a second time; and 9) performing dimensional inspection, alignment, defect polishing, surface quality inspection and non-destructive inspection on the cold drawing pipe respectively to form a finished seamless steel pipe, and cropping the top. The seamless steel pipe and the manufacturing method have the characteristics that the seamless steel pipe and the manufacturing method are economical, environment-friendly, low in metal consumption, high in quality and yield of finished products, efficient in processing, easy to operate, and the like, and completely meet the market requirement of seamless steel pipes for long pipe trailers.

Owner:DEYANG YUXIN MACHINERY MFG

Welding process of hydrogenation reaction kettle cylinder body

InactiveCN101579783AImprove fusion qualityAvoid Weld CrackingNon-electric welding apparatusHydrogenation reactionCarbon steel

The invention discloses a welding process of a hydrogenation reaction kettle cylinder body which is used for producing various chemical raw materials with a method of continuous hydrogenation. A plate resulted from compounding common carbon steel and stainless steel with the explosive technology is welded and processed into a cylinder shape, thereby overcoming phenomena such as easily-occurring welding cracks, and the like, which are caused by different material properties of the carbon steel and the stainless steel and by the welding among great-thickness carbon steels; and the production cost of the reaction kettle is greatly reduced. The hydrogenation reaction kettle cylinder body produced according to the welding process is widely applied in chemical engineering, pharmaceutical and other industries for producing sorbierite, xylitol, maltose, furfuryl alcohol, and the like.

Owner:倪加明

Technological process of making flat spring steel for automobile

The flat spring steel for automobile is produced via converter smelting process. Compared with available technology, the present invention has the following advantages and positive effects: utilizing molten iron with less harmful elements as material to result in high flat spring steel quality; higher finished product rate and lower power consumption to result in lower cost than production in electric furnace; casting molten steel into small square billet to omit the billet cutting step and lower cost; and high size precision of the continuously cast small square billet to ensure high size precision of flat spring steel.

Owner:青岛钢铁控股集团有限责任公司

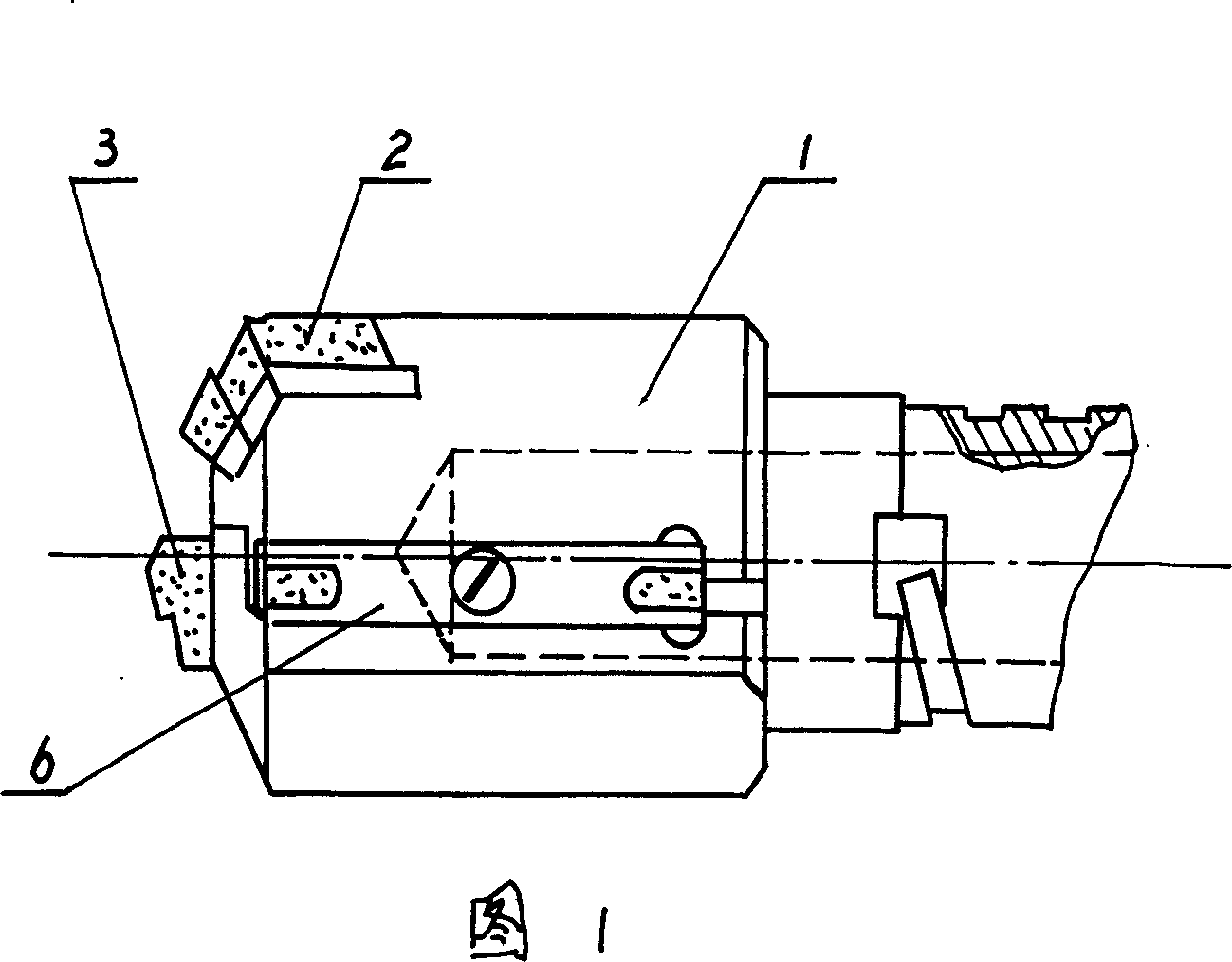

Deep hole drilling bit and blade

InactiveCN1974089AAvoid crack phenomenonImprove machining accuracyTransportation and packagingBoring/drilling machinesKnife bladesDeep hole

The present invention is one kind of deep hole drilling bit and blade on eccentric chuck. The drill chuck includes a cutter body, an outer cutter, an inner cutter, a guide piece, a movable key, a conic screw, two rows of clearance holes, an oil feeding interval, an axial datum plane, etc. The blade with conic through hole may be re-sharpened. The present invention has simple structure, convenient assembling and disassembling, adjustable cutting angle and other features.

Owner:田清安

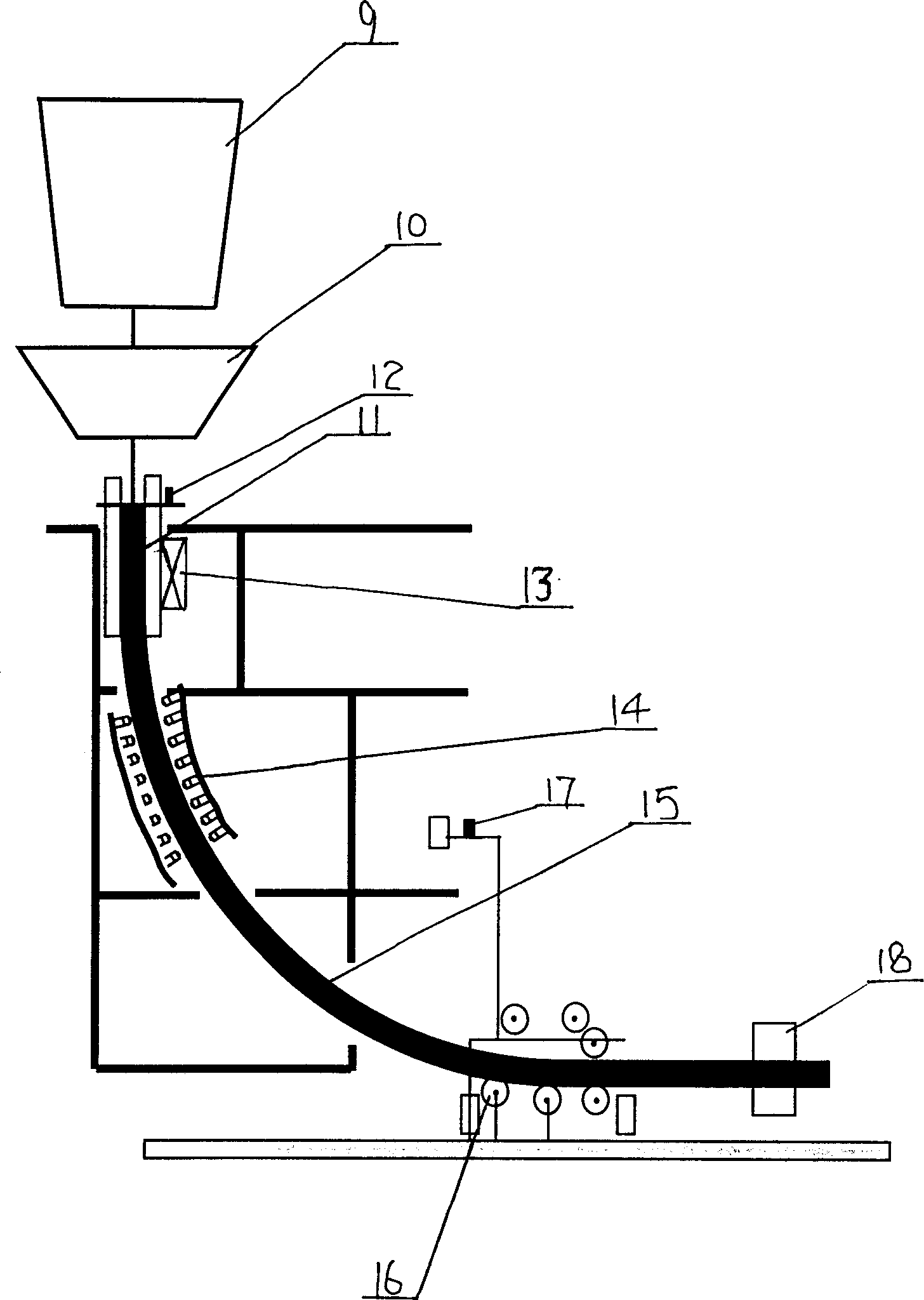

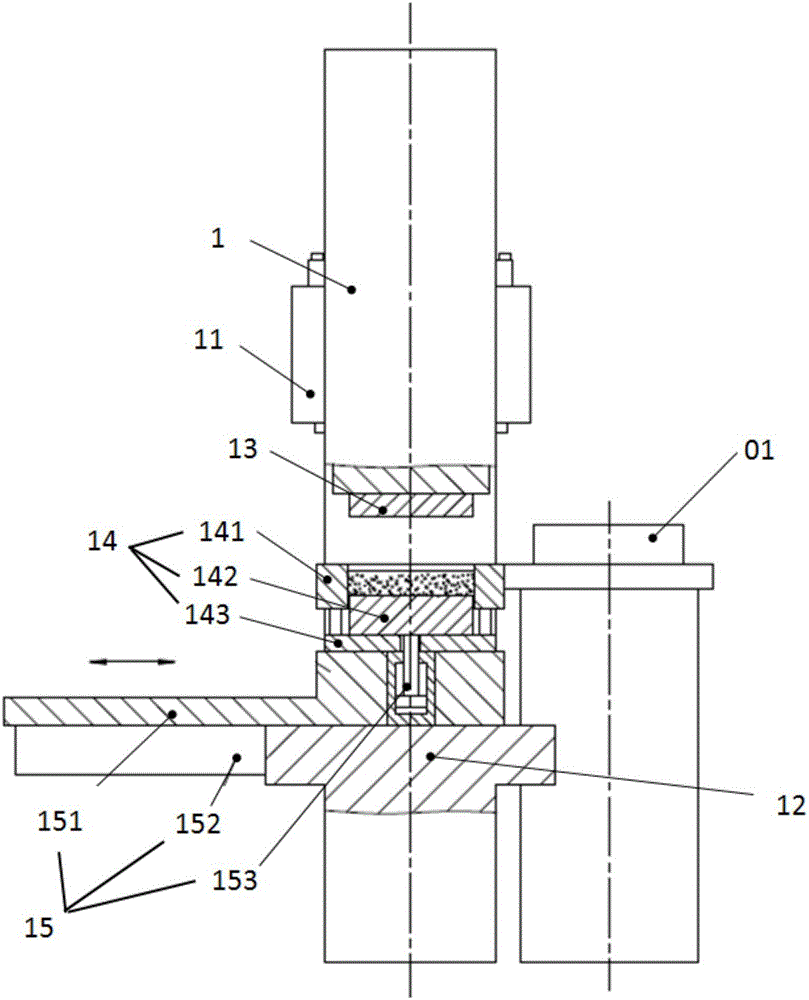

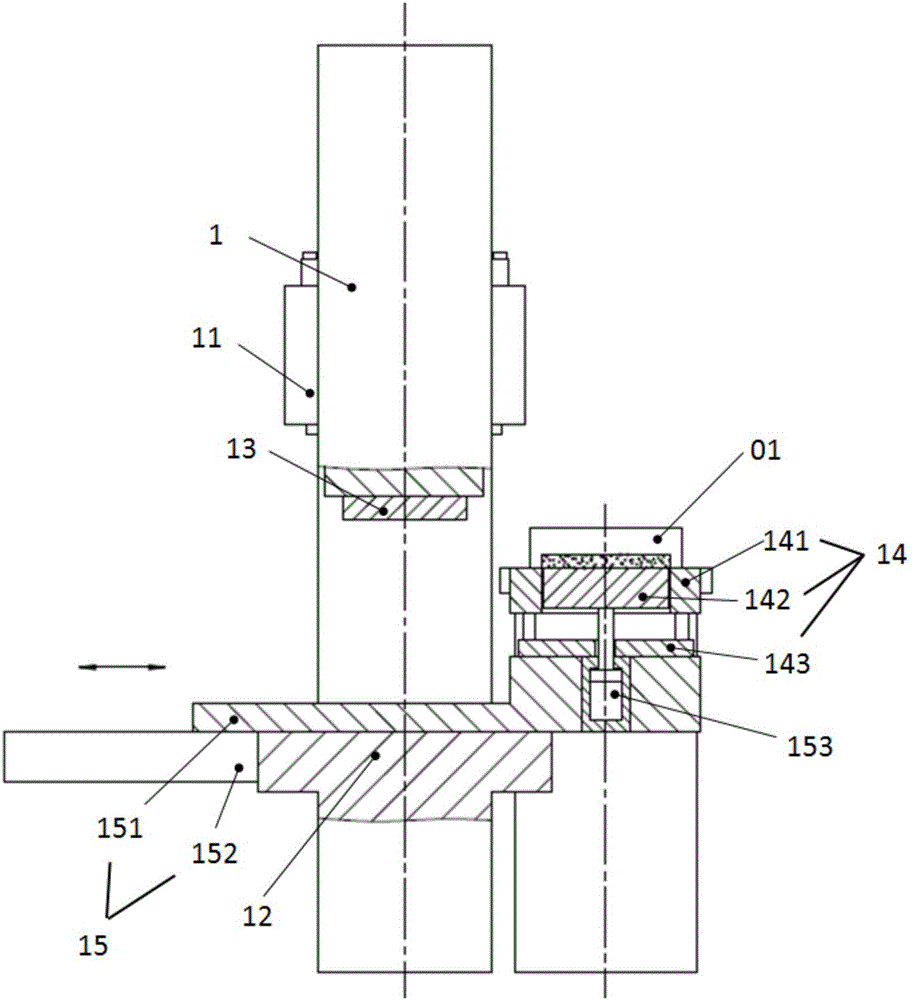

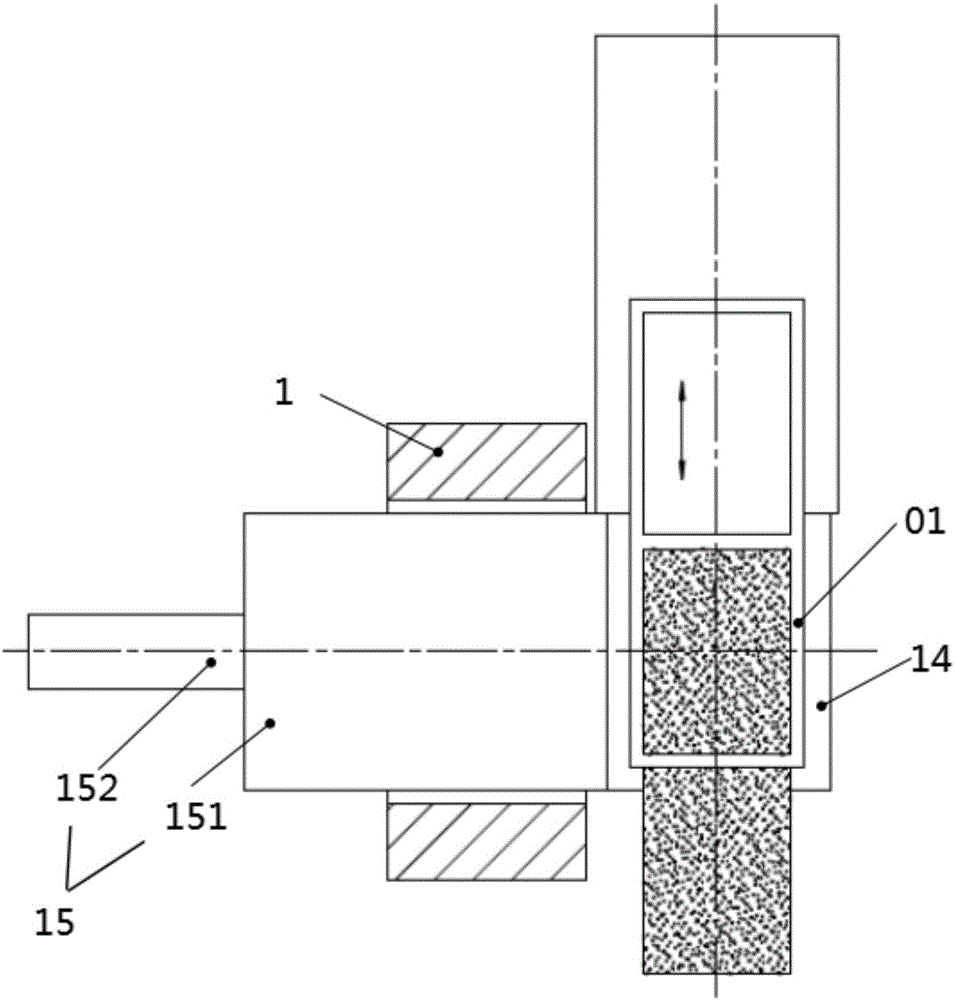

Technological method, pressing machine equipment and system for ceramic tile formation

ActiveCN105946096AShorten the timeImprove molding efficiencyDischarging arrangementShaping press ramProduction lineMaterial distribution

The invention discloses a technological method, pressing machine equipment and system for ceramic tile formation. The technological method for ceramic tile formation comprises the following steps that 1, materials are distributed outside a pressing machine, wherein a die cavity of a lower die located outside the pressing machine is filled with the materials, and the die cavity is filled with powder through limitation of material distribution equipment; 2, pressing is conducted inside the pressing machine, wherein the lower die is moved under an upper die, and the upper die moves downwards to conduct stamping, so that a green tile is obtained; 3, a tile is discharged out of the pressing machine, wherein the lower die is moved out of the pressing machine, the green tile is ejected out of the die cavity through an ejection device at the bottom of the die cavity, and the pressed green tile is pushed to a transfer line through the material distribution equipment. By means of the technological method for ceramic tile formation, idle-hour-free linkage among different procedures is achieved, ceramic tile formation efficiency is effectively improved, and the method is applicable to formation of thin tiles of the large specification. The invention further provides the pressing machine equipment and system for ceramic tile formation. By means of the pressing machine equipment and system for ceramic tile formation, material distribution and tile discharging can be conducted outside the pressing machine, and tile discharging efficiency of a production line of the system is improved by one time or more.

Owner:FOSHAN HENGLITAI MACHINERY

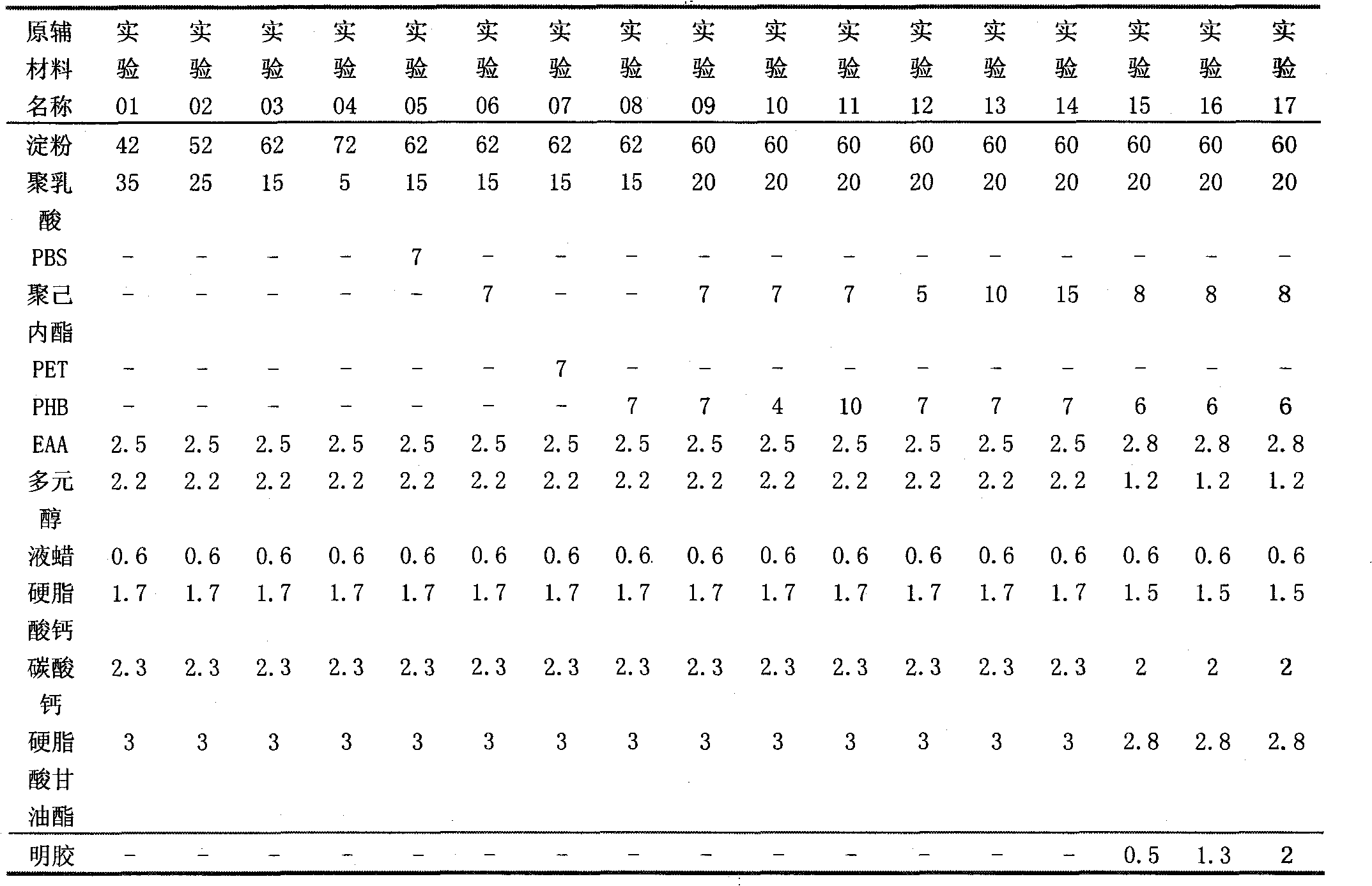

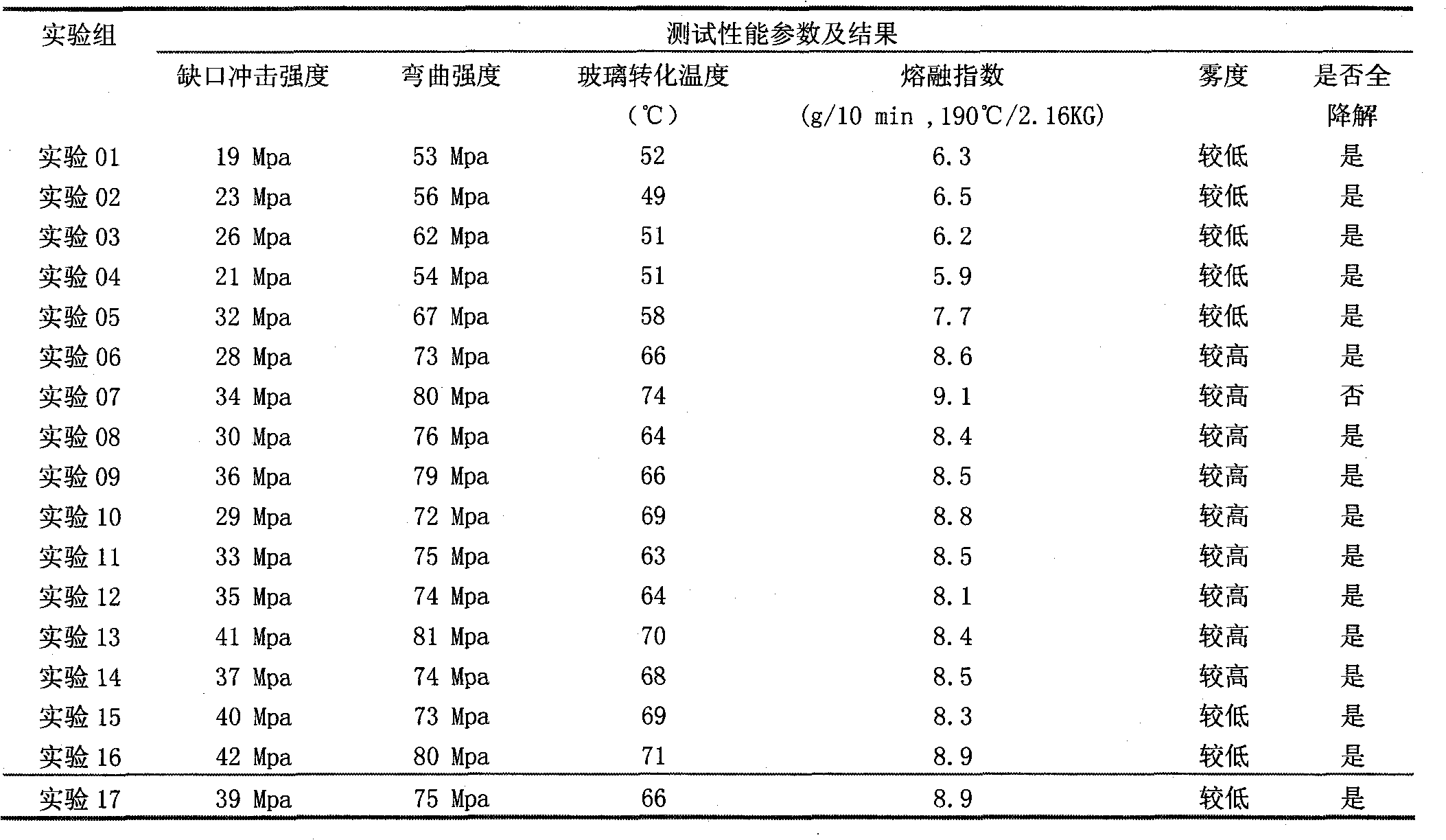

Full-degradable injection molding composite material and preparation method thereof

The invention discloses a full-degradable injection molding composite material, which is mainly prepared by blending starch, polylactic acid and polyester. In the full-degradable injection molding composite material, factors such as degradability, processability, usability, cost performance and the like are considered fully, the problems of chromatic aberration and texture are solved, and the composite material is suitable to be processed into various injection molding devices.

Owner:任伟

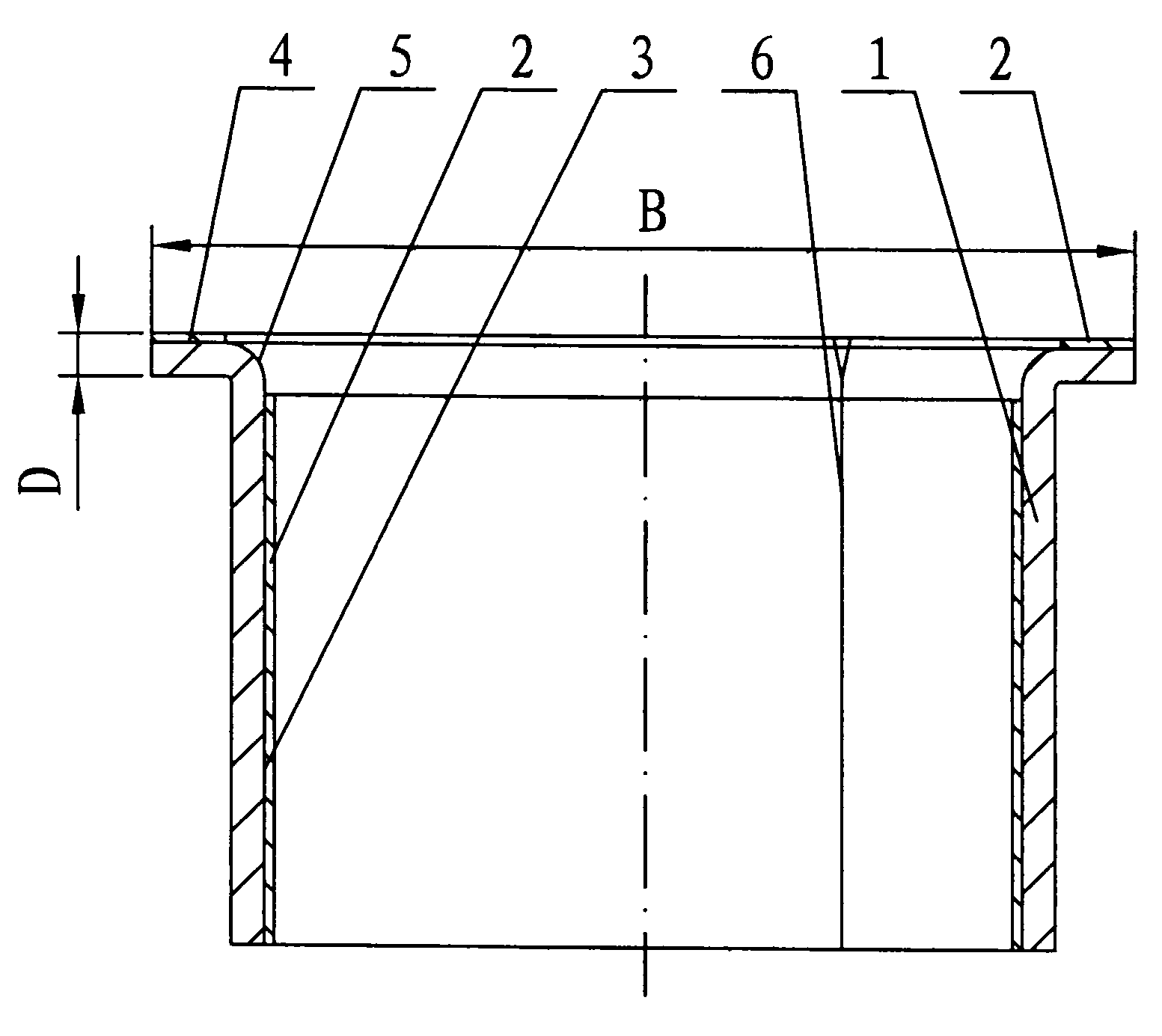

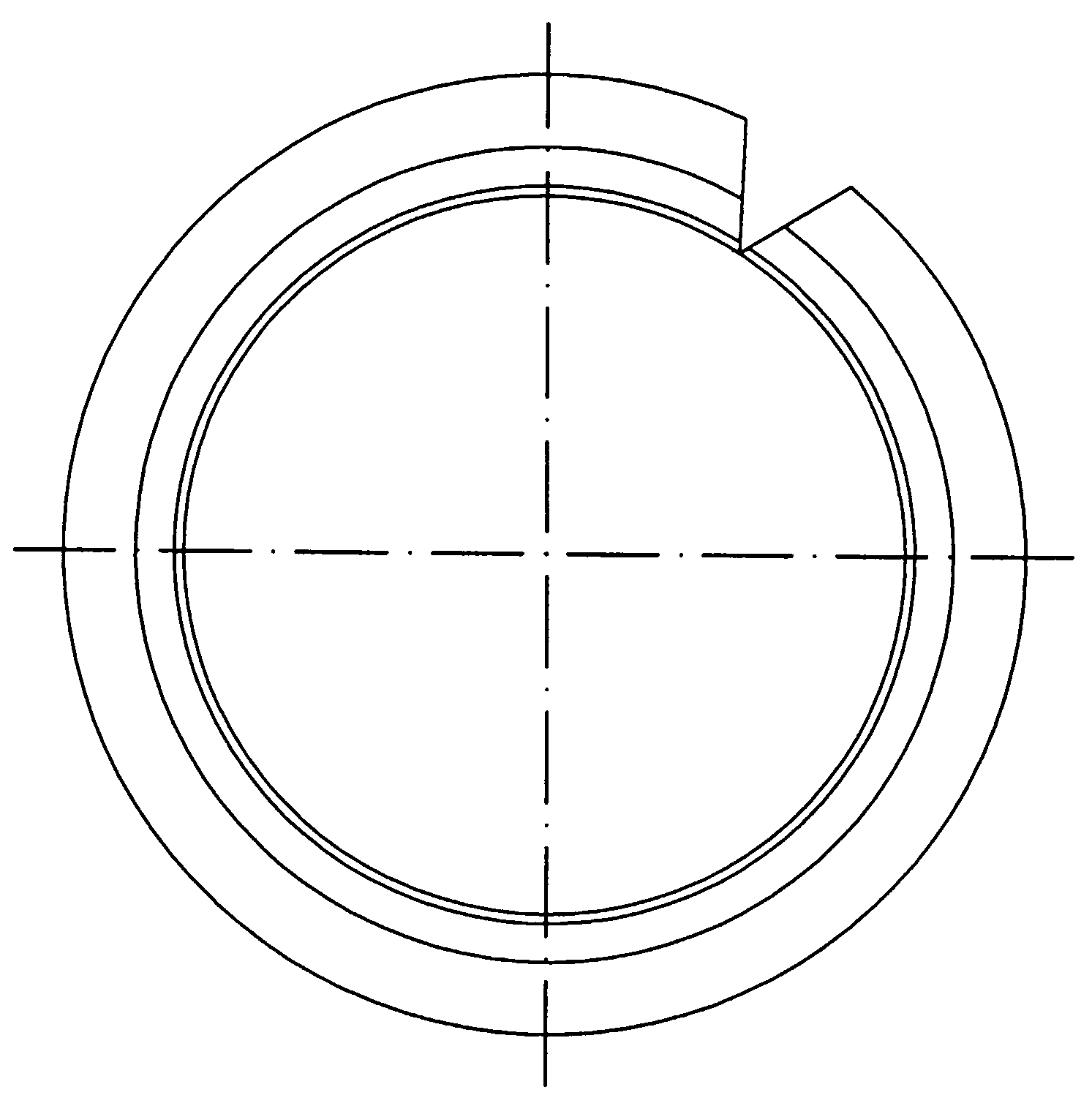

Bimetal liner with flanged flange and manufacturing method of bimetal liner

The invention discloses a bimetal liner with a flanged flange and a manufacturing method of the bimetal liner. The bimetal liner with the flanged flange and the manufacturing method of the flanged flange have the advantages that the structure is simple, the process performance is good, the self-lubricating property is excellent, a copper alloy layer of a flange face cannot crack, and the production efficiency is high. The bimetal liner with the flanged flange comprises a shaft-sleeve-shaped bimetal liner, wherein an outer layer of the bimetal liner is made of steel material, and an inside lining of the bimetal liner is a copper alloy layer; and an outward-flanged flange side is arranged at one end of the bimetal liner and is also in a bimetal structure consisting of the steel material and the copper alloy layer. The bimetal liner is characterized in that the copper alloy layer is not arranged at an outer arc face at a bending part between the bimetal liner and the flange side. As the copper alloy layer is not arranged at the bending part, a situation that the copper alloy layer cracks is avoided in a flanging process. According to a flanging die used in the manufacturing method, the outward-flanged flange side is located in a pit of an upper die, and the outer edge of the flange side is limited by the edge of the pit and cannot extend and deform outwards without limit, so that a phenomenon that the copper alloy layer on the flange side cracks is avoided.

Owner:ZHEJIANG SF OILLESS BEARING +1

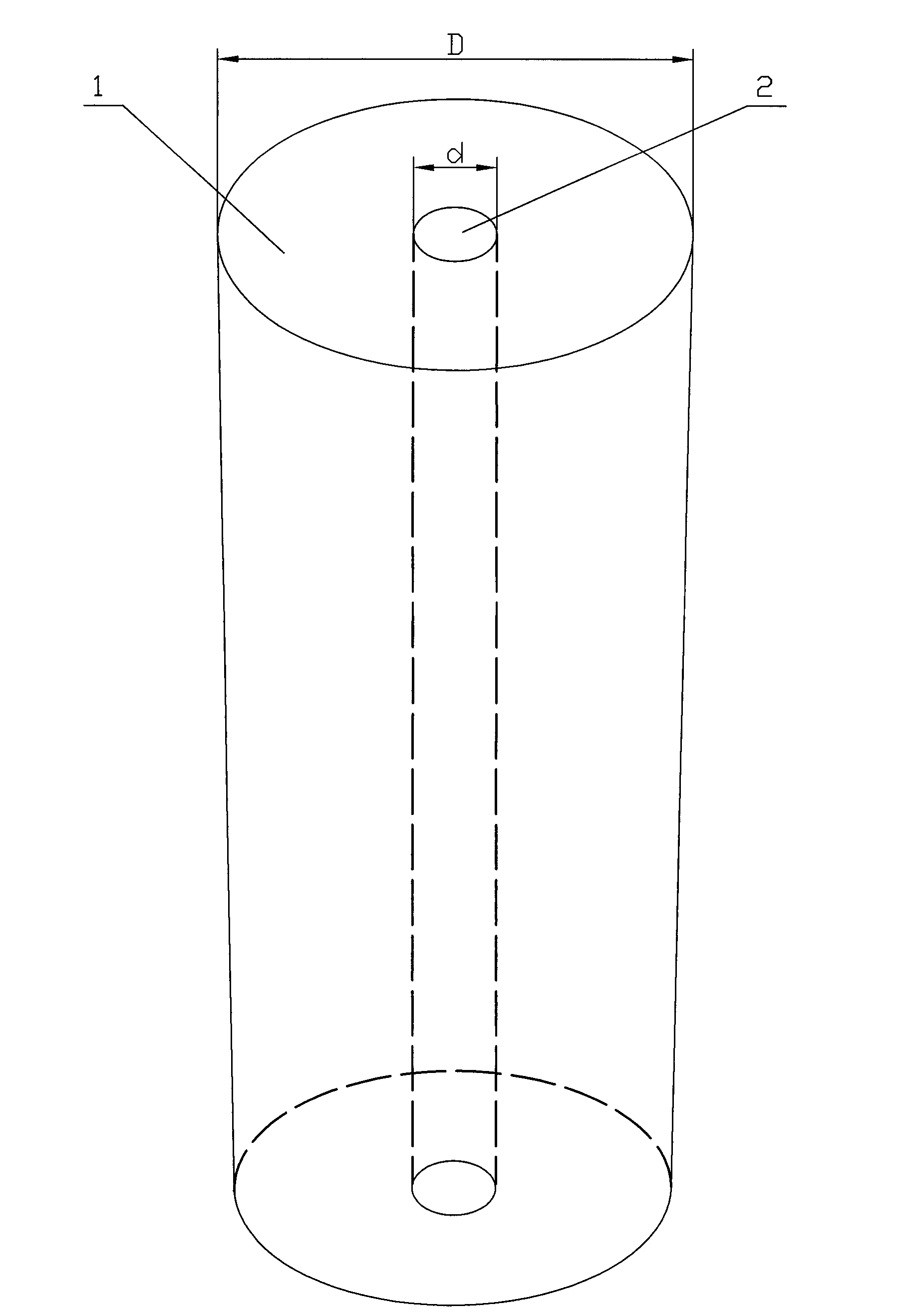

Log cracking prevention method

InactiveCN103009447AGood shrinkage inside and outsideAvoid crack phenomenonWood dampingComputer science

The invention discloses a simple log cracking prevention method with obvious effects. The log cracking prevention method is characterized in that a cylindrical pressure-reducing through hole is drilled in the axial center of a log. According to the log cracking prevention method provided by the invention, by virtue of the pressure-reducing through hole drilled in the center of the log, water of the log is released through the pressure-reducing through hole in the center of the log and an outer circumference surface of the log simultaneously. Therefore, the center and the outer surface of the log are more uniformly dried, the inner and outer contraction consistency of the log is good, and cracks are difficult to generate. Particularly, in a log drying and contraction process, the middle of the log is hollow, so that relative tension disappears when the former outward surrounding tension loses a center object supplying center counter-acting force (or supporting force) according to a principle of acting force and counter acting force. Therefore, the cracks are prevented on the four sides of the log, and the yield and the use rate of timber can be greatly improved.

Owner:嘉善县魏塘镇永兴工艺品厂

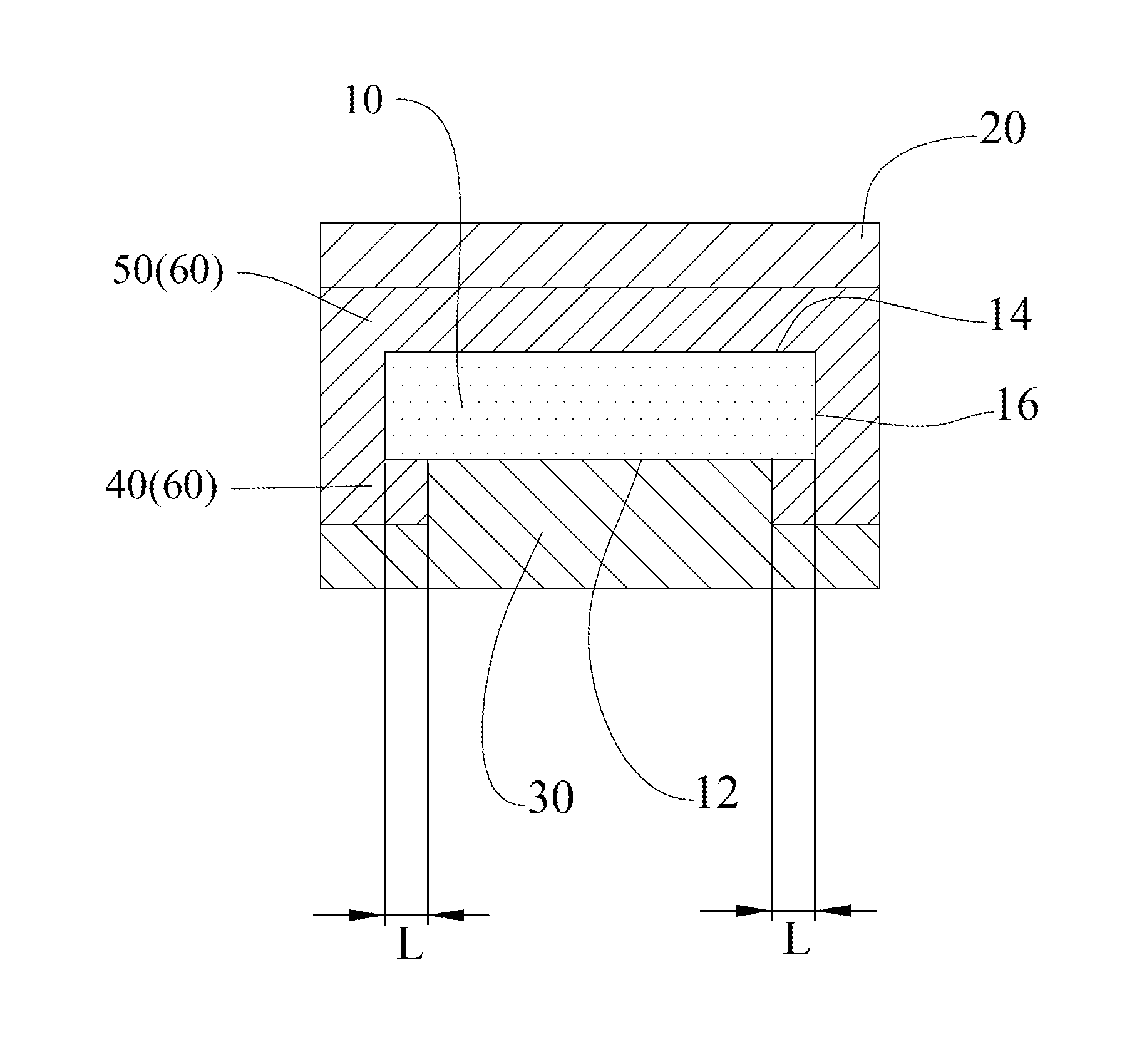

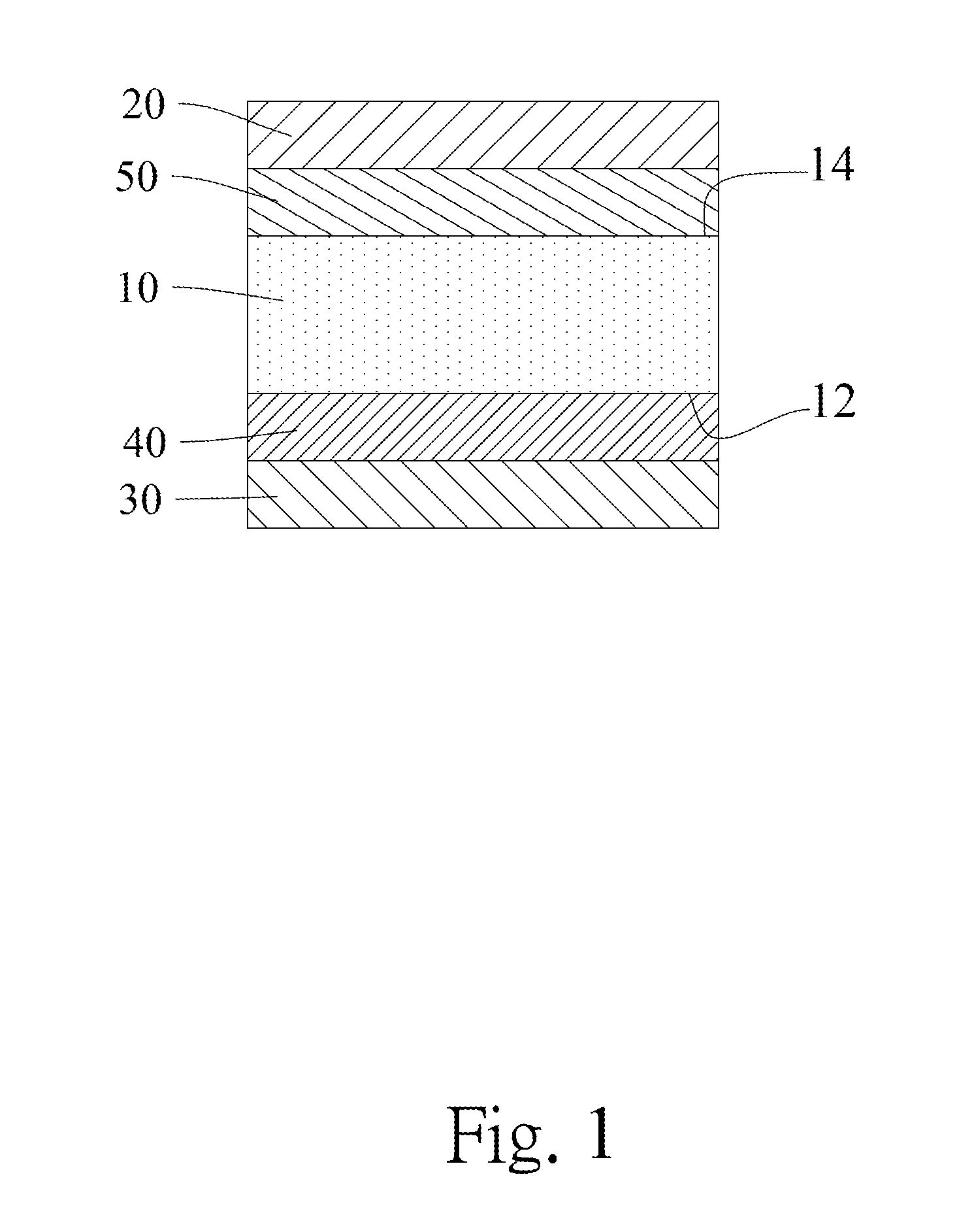

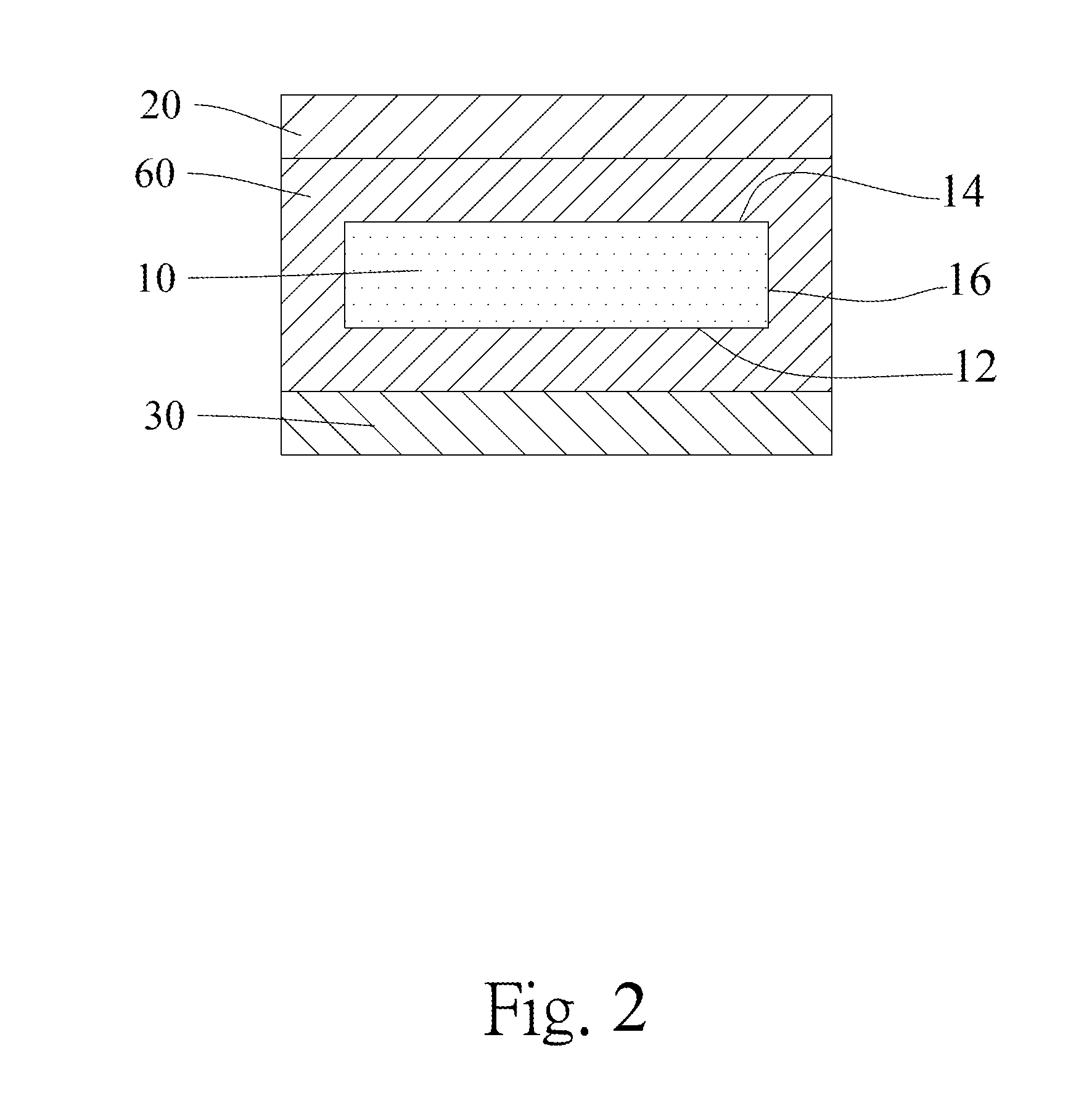

Laminar structure of semiconductor and manufacturing method thereof

ActiveUS20150357290A1Reduce the effects of stressAvoid crack phenomenonSemiconductor/solid-state device detailsSolid-state devicesThermal expansionProtection layer

A laminar structure of semiconductors comprises a substrate, an epitaxial layer, a protective layer, a first layer and a second layer. The epitaxial layer is arranged above the substrate and the protective layer is arranged below the substrate. Thermal expansion coefficients of the epitaxial layer and the protective layer are simultaneously greater than or less than that of the substrate. The first layer is arranged between the substrate and the protective layer; and the second layer is arranged between the substrate and the epitaxial layer, wherein the band gap of the first layer and the second layer are both greater than 3 eV. By a protective layer arranged below the substrate, stress generated between the substrate and the epitaxial layer can be reduced to prevent occurrence of bending or crack. Therefore, yield can be promoted and costs can be reduced. A manufacturing method thereof is also herein provided.

Owner:GLOBALWAFERS CO LTD

Heat treatment of cam shaft for diesel engine

InactiveCN1940095AAvoid pollutionImprove distributionFurnace typesIncreasing energy efficiencyInductorEngineering

Treatment of diesel engine cam shaft is carried out by high-frequency heating for cam gear, bearing gear and gear, spraying cooling liquid, quenching, taking water as cooling liquid, coating magnetic-conductive powder onto surface of inductor, stopping cooling at 160degree, controlling temper temperature and time and eliminating heat stress. It's cheap, has no crack and environmental pollution.

Owner:YANGDONG CO LTD

Environmental-friendly calcium silicate board and production process thereof

InactiveCN104016628AAvoid layeringAvoid crack phenomenonSolid waste managementCalcium silicateWollastonite

The invention relates to a calcium silicate board, and particularly relates to an environmental-friendly calcium silicate board and a production process thereof. The calcium silicate board comprises the following components in percentage by weight: 6%-7% of slaked lime, 9%-11% of wollastonite, 37%-39% of quartz powder, 36%-38% of cement and 6%-7.5% of paper pulp. According to the production process, because the temperature and water content of slurry are controlled in a pallet board preparation process, the pallet adhesion and the pallet dropping are prevented, and the temperature change and the water content during steam curing can prevent the phenomena of lamination and cracking of the pallet board; the finished product ratio of products is enhanced, and the cost is reduced.

Owner:LUOFEIER BUILDING MATERIAL SHENYANG GRP

Salt-bath furnace quenching method for teeth of chain wheel

InactiveCN103820624AImprove reliabilityLow equipment investment costFurnace typesHeat treatment bathsQuenchingHeating time

The invention relates to a salt-bath furnace quenching method for teeth of a chain wheel. The method comprises the following steps of (1) placing a mixture containing BaCl2 and KCl in an intermediate-temperature salt-bath furnace for heating, wherein based on the total amount of 100 parts, the mixture contains 65 to 75 parts by weight of BaCl2 and 25 to 35 parts by weight of KCl, the mixture is heated to be completely melted at the heating temperature of 720 to 940 DEG C, and the melted mixture is the melt of a salt bath; (2) placing the teeth of the chain wheel in the salt bath for heating, wherein the heating temperature of the salt bath is 900 to 920 DEG C, and the heating time is set to be 26 to 30 seconds per millimeter of the tooth thickness of the chain wheel; (3) performing rapid quenching by utilizing a quenching medium after heating and heat preservation; (4) performing tempering heat preservation for 3.5 to 4.5 hours after quenching, and after heat preservation, discharging the teeth of the chain wheel out of the furnace, and air-cooling the teeth. According to the method, a salt-bath furnace quenching process for the teeth of the chain wheel is adopted, so that the hardened layer depth can reach more than 12mm; moreover, hardened layers with different depths can be obtained by regulating the heating time of the salt-bath furnace; the salt-bath furnace quenching process is high in the heating speed and convenient to operate, a workpiece is difficult to oxidize and decarburize, and the temperature is easy to control.

Owner:LINZHOU HEAVY MACHINERY GROUP

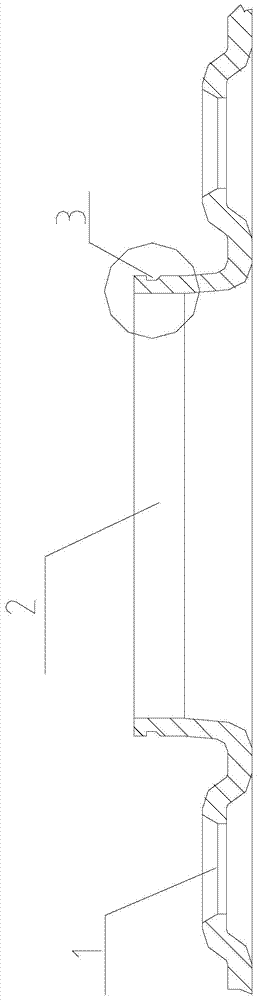

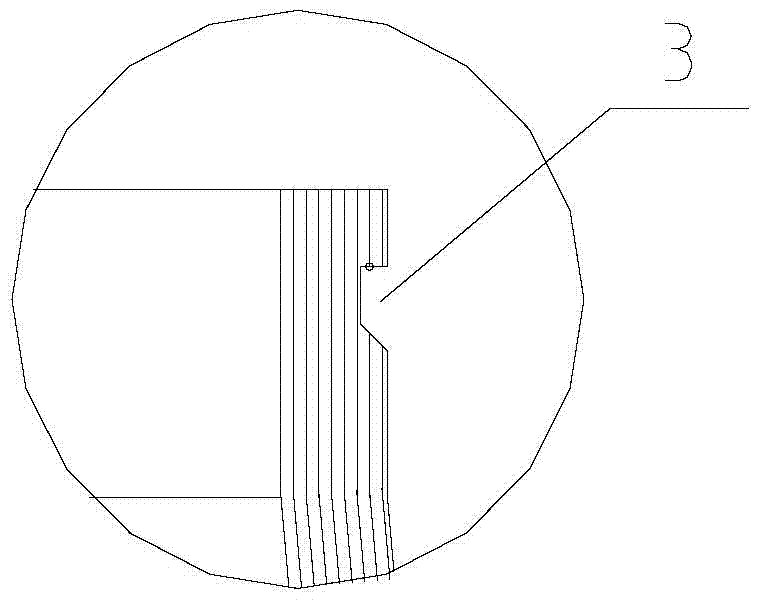

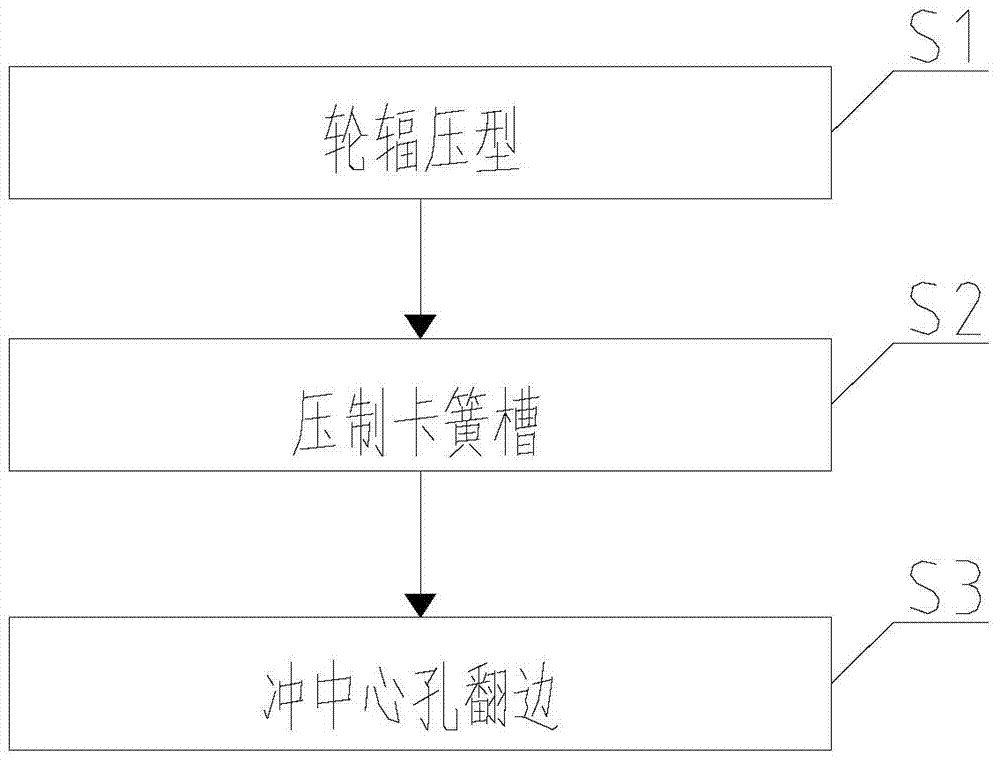

Vehicle wheel spoke machining technique

The invention provides a vehicle wheel spoke machining technique which is characterized in that a turned clamping spring groove is replaced with a pressed clamping spring groove. Specifically, the technique can comprise the steps of S1) spoke compressing, S2) clamping spring groove pressing and S3) center hole flange punching or the first step and the second step can be conducted at the same time. According to the vehicle wheel spoke machining technique, due to the fact that clamping spring groove pressing is conducted after spoke compressing or clamping spring groove pressing and spoke compressing are conducted at the same time before center hole flanging punching, the process of clamping spring groove turning is omitted, and damage to the internal structure and surface shape of a steel plate material is avoided; furthermore, through clamping spring groove pressing, the density of materials at the position of a clamping spring groove is improved, and as a result, the overall strength of a spoke is effectively improved, and cracking at the position of the clamping spring groove is avoided; meanwhile, the process design enables production efficiency to be improved greatly.

Owner:山东英顿车轮科技有限公司

Wood drying treatment method

ActiveCN107449224ALow shrinkageAlleviate shrinkageDrying solid materials with heatHearth type furnacesMicrowaveMaterials science

The invention discloses a wood drying treatment method, and relates to the technical field of wood treatment. The wood drying treatment method comprises the steps of (1) degreasing, (2) alkali liquor dipping, (3) pre-drying, (4) buffer treatment, and (5) microwave drying. Through treatment with the wood drying treatment method, the cracking condition after wood drying can be obviously reduced, and the quality of dried wood is guaranteed.

Owner:FUNAN TENGBO ARTS & CRAFTS CO LTD

Welding process of alloy steel and trough type steel rail

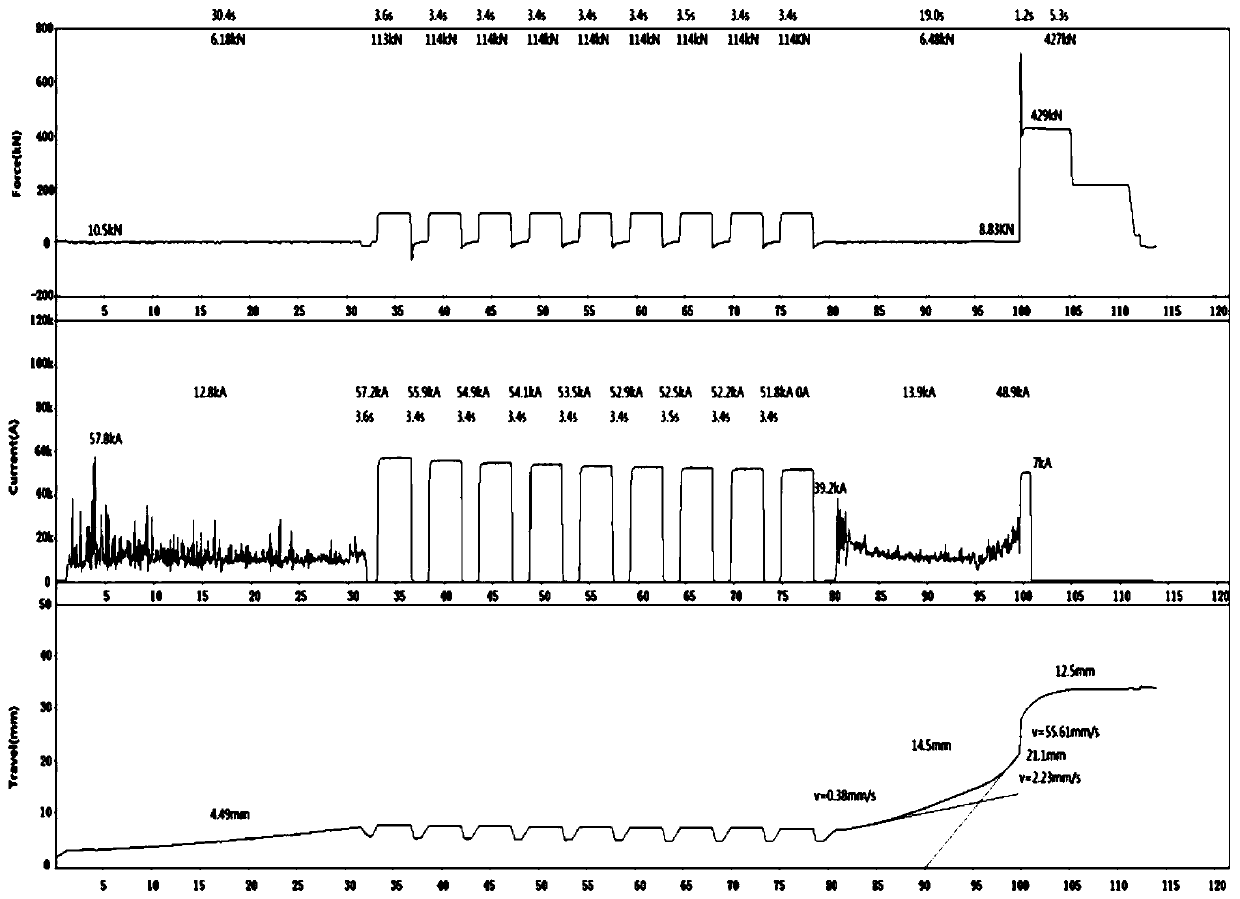

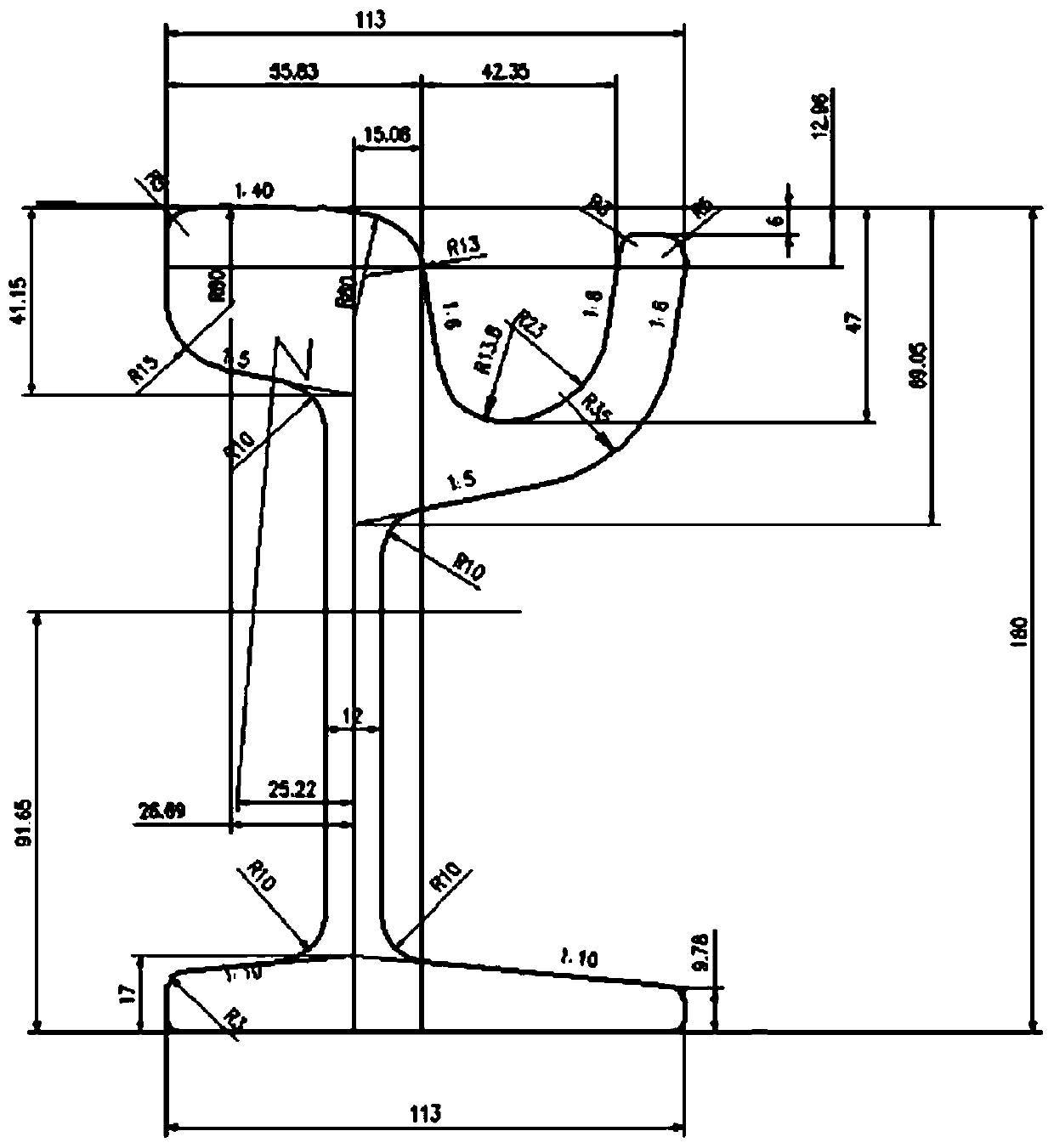

ActiveCN110102864AStress reliefEnhanced breaking loadResistance welding apparatusUpset forgingAlloy steel

The invention relates to the technical field of tracked trolley bus frog welding, in particular to a welding process of alloy steel and a trough type steel rail. According to the welding process of the alloy steel and the trough type steel rail, the alloy steel and the trough type steel rail are welded together through a flash welding method; the welding process comprises a flash levelling stage,a preheating stage, a burning stage, an upset forging stage and a postheating stage; the total duration time of the welding process is 114s to 115s; the upset forging amount of the welding process is12mm to 12.8mm; and the total consumption amount of the steel rail of the welding process is 30 to 31.8mm. According to the welding process of the alloy steel and the trough type steel rail provided by the invention, the flash welding of the alloy steel and the trough type steel rail is realized successfully, the mechanical property of a formed welding joint is good, and the welding quality is stable.

Owner:CNR BEIJING RAIL EQUIP +1

Photocurable photochromic material and preparation method thereof

ActiveCN105670602AShorten production timeImprove impact resistanceTenebresent compositionsOptical partsWeather resistanceDiacrylate ester

The invention discloses a photocurable photochromic material and a preparation method thereof. The photocurable photochromic material is composed of 30%-70% of bisphenol A dimethacrylate, 10%-60% of poly(ethylene glycol) diacrylate, 10%-30% of polyfunctional acrylate monomer and the balance modifying additives, wherein the sum of weight percentages is 100%. The photocurable photochromic material and the preparation method thereof have the advantages that lens production time is shortened from 20 hours to 15 minutes, impact resistance of lenses is improved to prevent breakage in use, and weather resistance of the lenses can be improved as well to avoid cracks in a fierce cold-hot change process.

Owner:JIANGSU MAAT OPTICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com