Core of heat exchanger

A technology of heat exchangers and cores, applied in heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve the problem of reducing cooling power and product service life, cracks, especially in places where brazing connections are more serious etc. to achieve the effects of reducing thermal stress, avoiding cracks, and reducing the impact of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, embodiments of the present invention will be described with reference to attached drawings, and the parts that are the same as those in the prior art will be given the same reference symbols, and detailed description will be omitted.

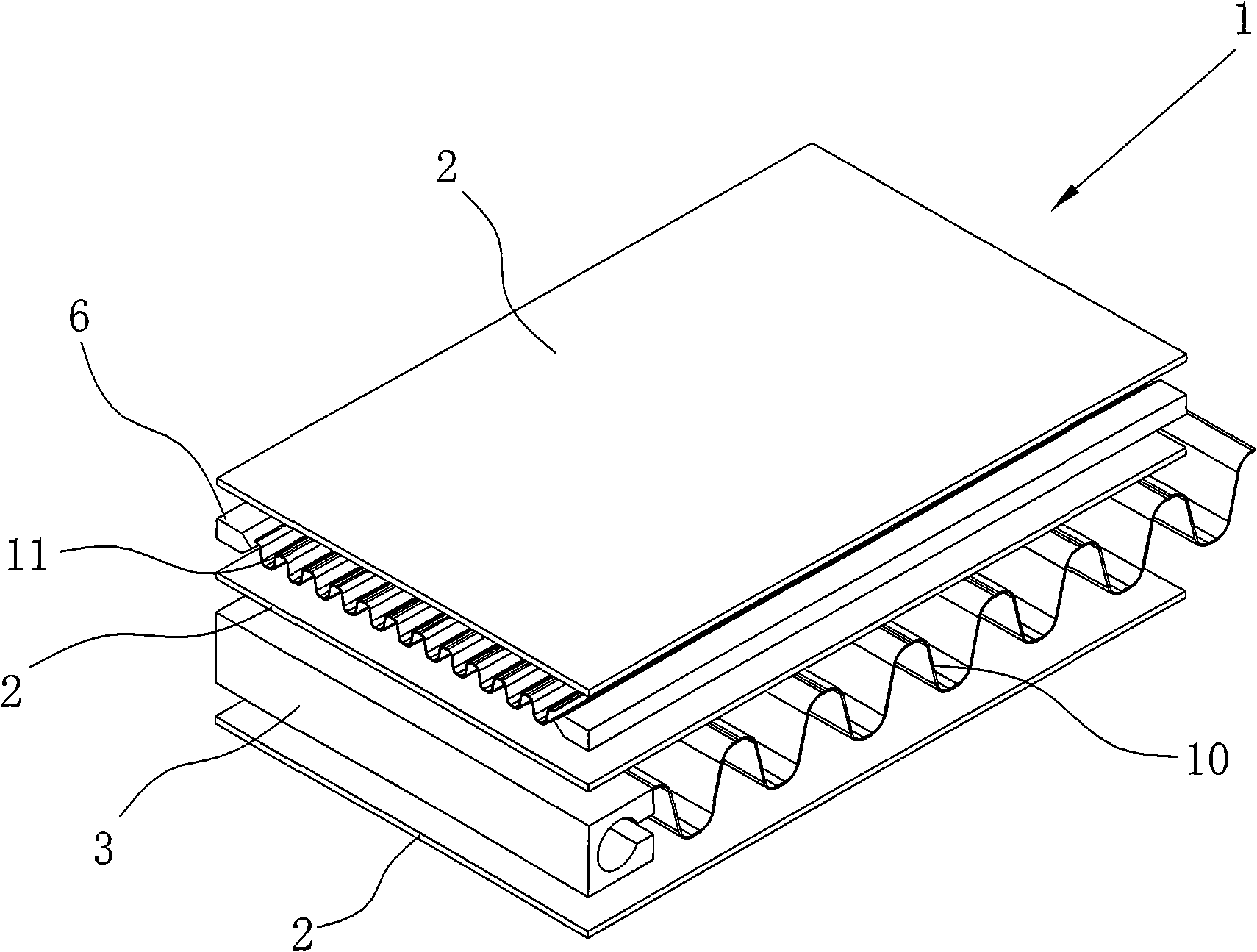

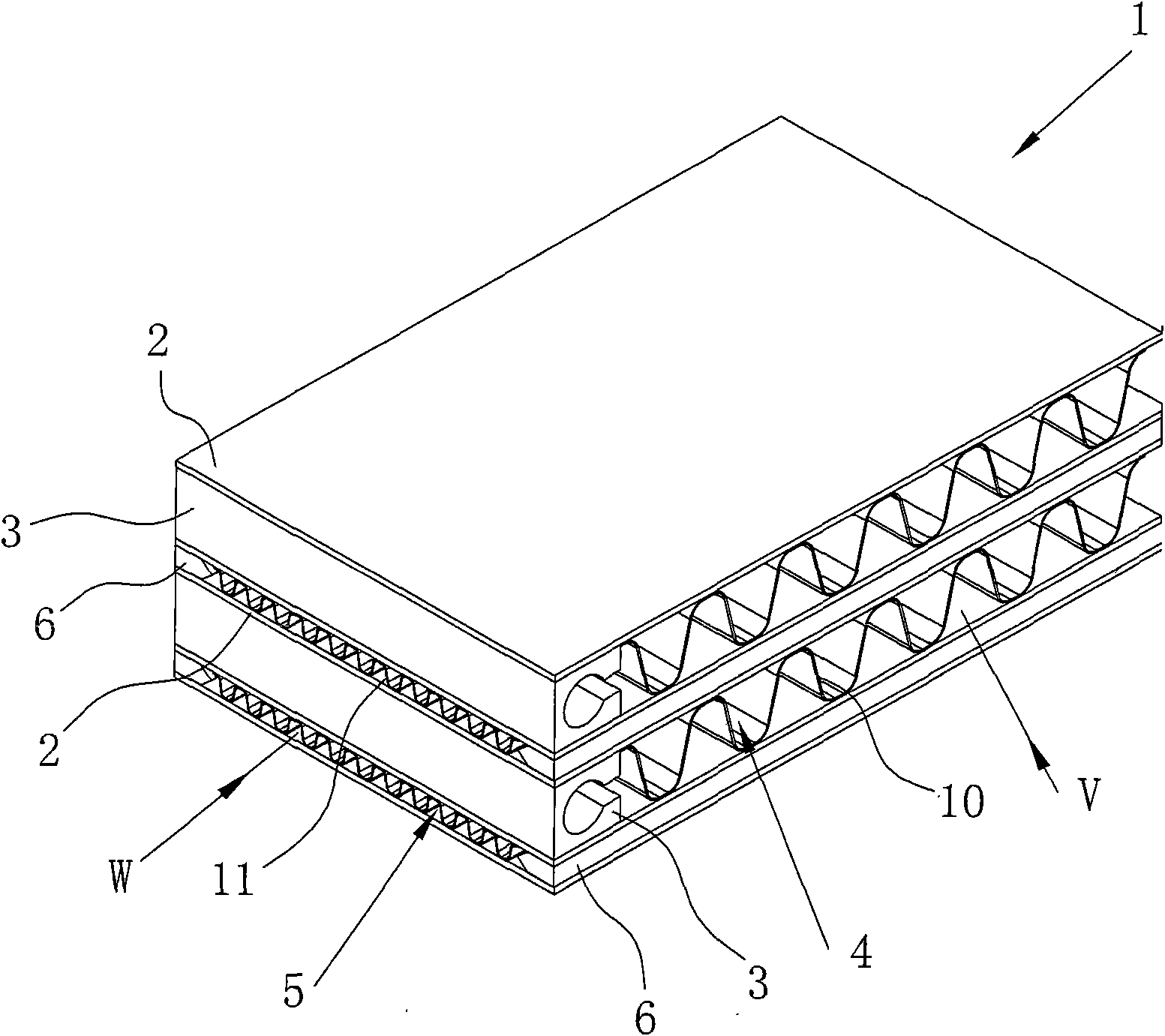

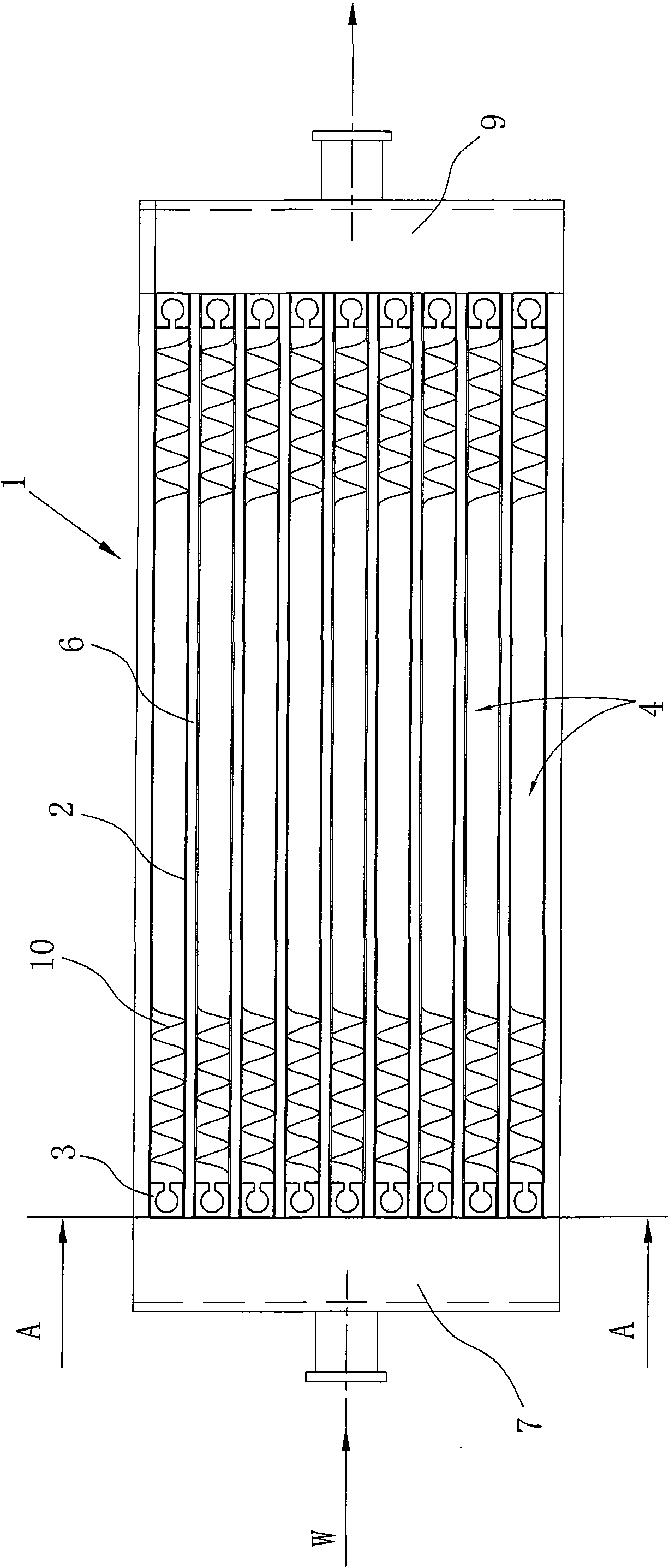

[0033] See Figure 1-8 The structure diagram of a heat exchanger core 1 shown is consistent with the traditional technology in that the cold fluid passage 4 and the hot fluid passage 5 are arranged at intervals, intersecting and stacked, between the cold fluid passage 4 and the hot fluid passage 5 The rooms are separated by partitions 2. Such as Figure 2-4 As shown, the two cold fluid channel seals 3 arranged on the left and right and the two partitions 2 above and below form a front and rear cold fluid channel 4, and the two hot fluid channel seals 6 arranged at the front and back and the two spacers above and below The block partitions 2 form left and right thermal fluid passages 5 . From Figure 5 It can be seen from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com