Patents

Literature

322results about "Heat treatment baths" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel sheet for hot press forming having low-temperature heat treatment property, method of manufacturing the same, method of manufacturing parts using the same, and parts manufactured by the same

ActiveUS20090238715A1Reduced strengthHigh yield strengthMetal rolling stand detailsFurnace typesManganeseHeat treated

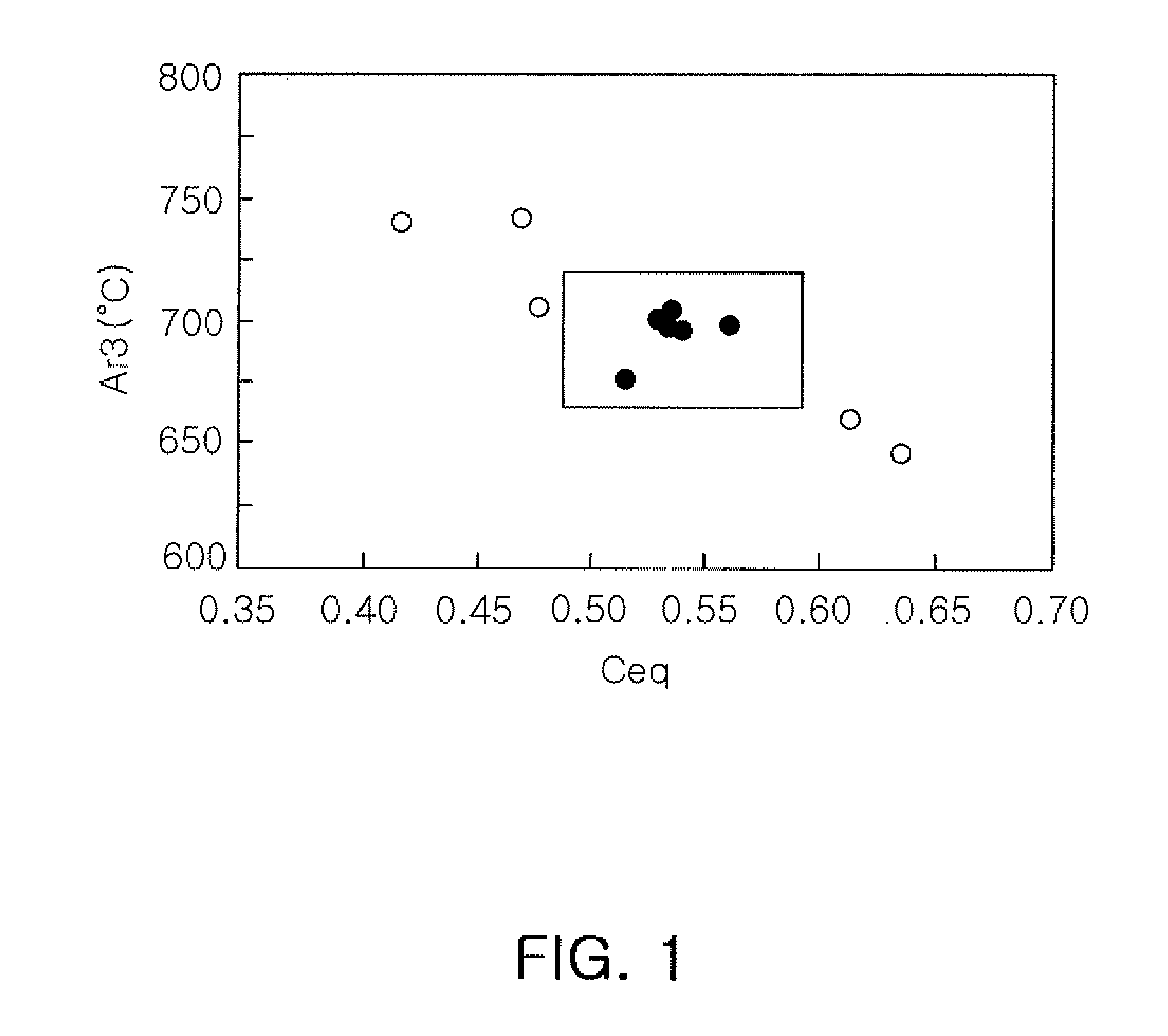

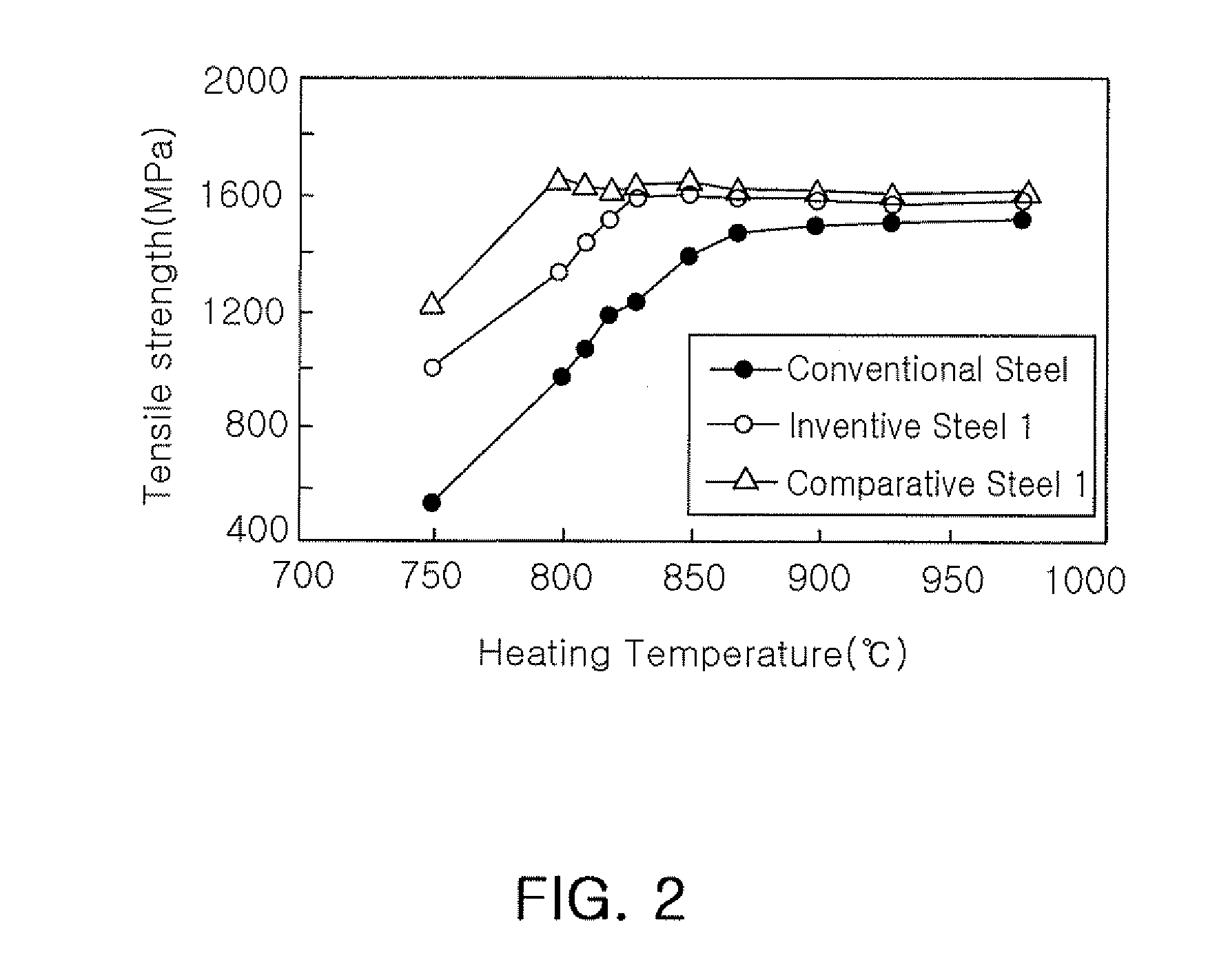

A steel sheet for forming having low-temperature heat treatment property, in which heat treatment is performed within a range of lower temperature than a conventional steel sheet in the event of hot press forming or post-heat treatment after cold forming, a method of manufacturing the same, and a method of manufacturing parts using the same. The steel sheet has a composition of, by weight, carbon (C): 0.15 to 0.35%, silicon (Si): 0.5% or less, manganese (Mn): 1.5 to 2.2%, phosphorus (P): 0.025% or less, sulfur (S): 0.01% or less, aluminum (Al): 0.01 to 0.05%, nitrogen (N): 50 to 200 ppm, titanium (Ti): 0.005 to 0.05%, tungsten (W): 0.005 to 0.1%, and boron (B): 1 to 50 ppm, wherein Ti / N: less than 3.4, where Ti / N is the atomic ratio of the corresponding elements, Ceq expressed by the following formula ranges from 0.48 to 0.58, and temperature Ar3 ranges from 670° C. to 725° C. Wherein Ceq=C+Si / 24+Mn / 6+Ni / 40+Cr / 5+V / 14 where C, Si, Mn, Ni, Cr and V indicate the contents (wt %) of the respective elements.

Owner:POHANG IRON & STEEL CO LTD

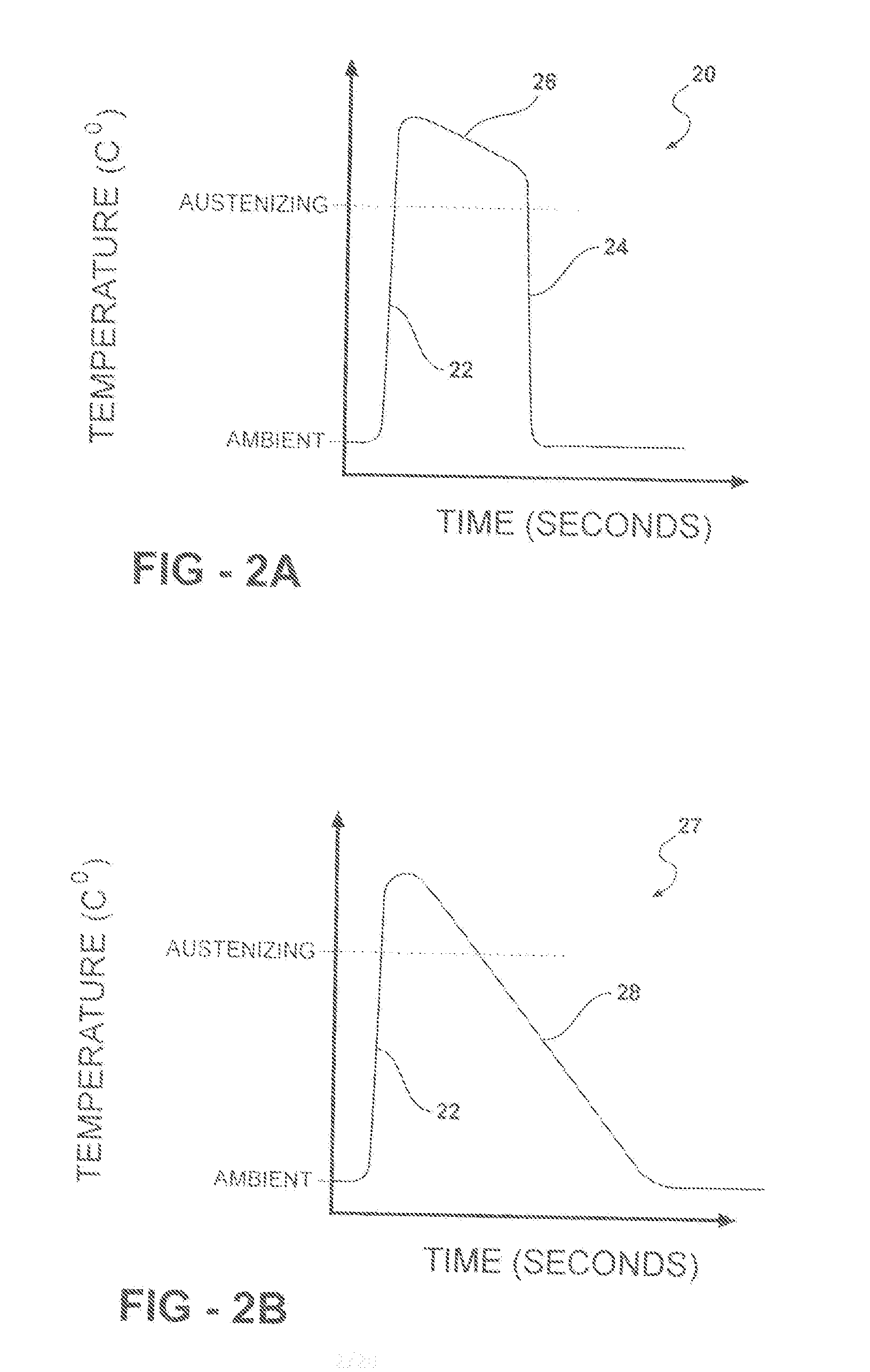

Microtreatment of Iron-Based Alloy, Apparatus and Method Therefor, and Articles Resulting Therefrom

ActiveUS20100132854A1Minimum of costMinimum of timeFurnace typesIncreasing energy efficiencyHigh carbonQuenching

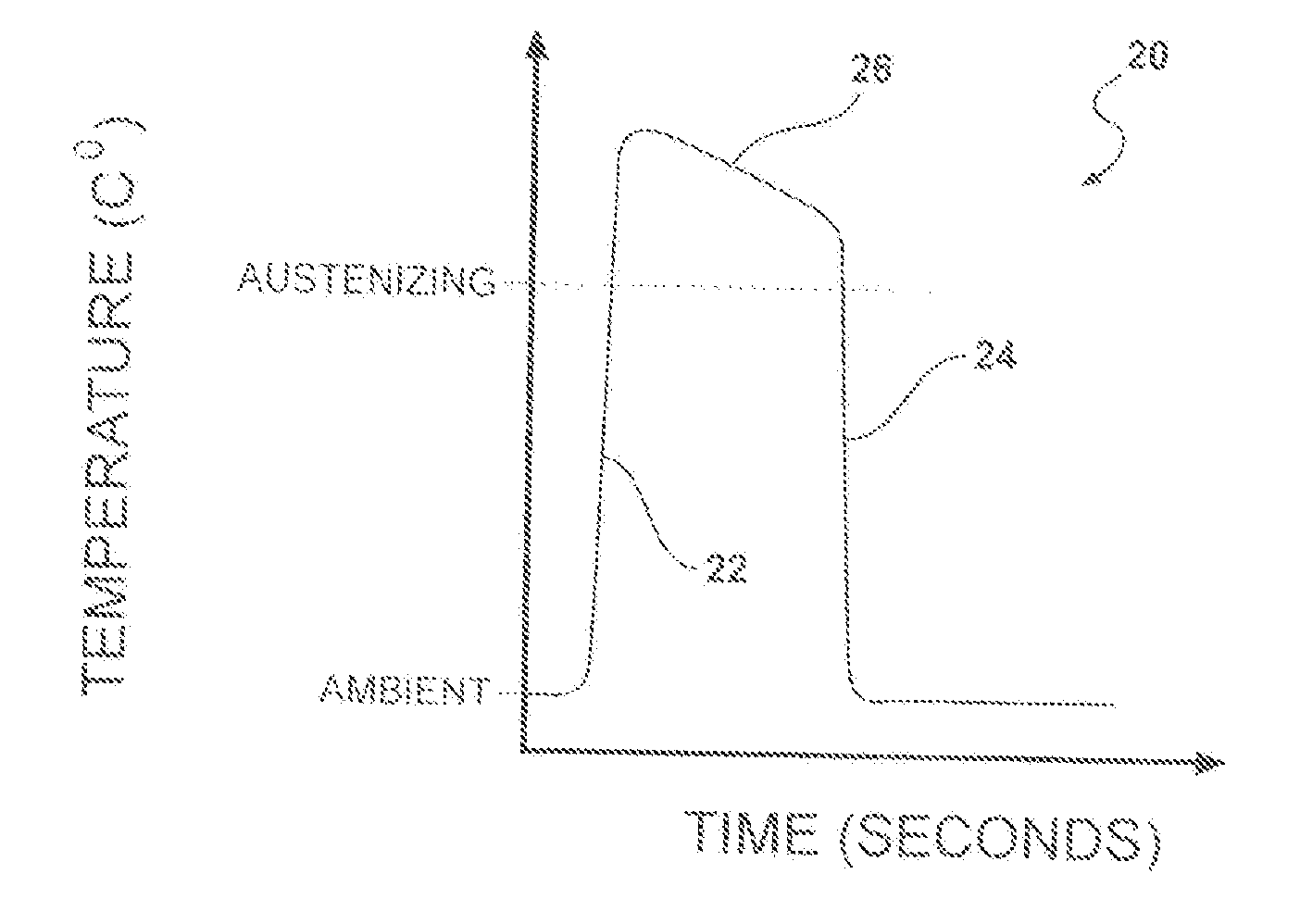

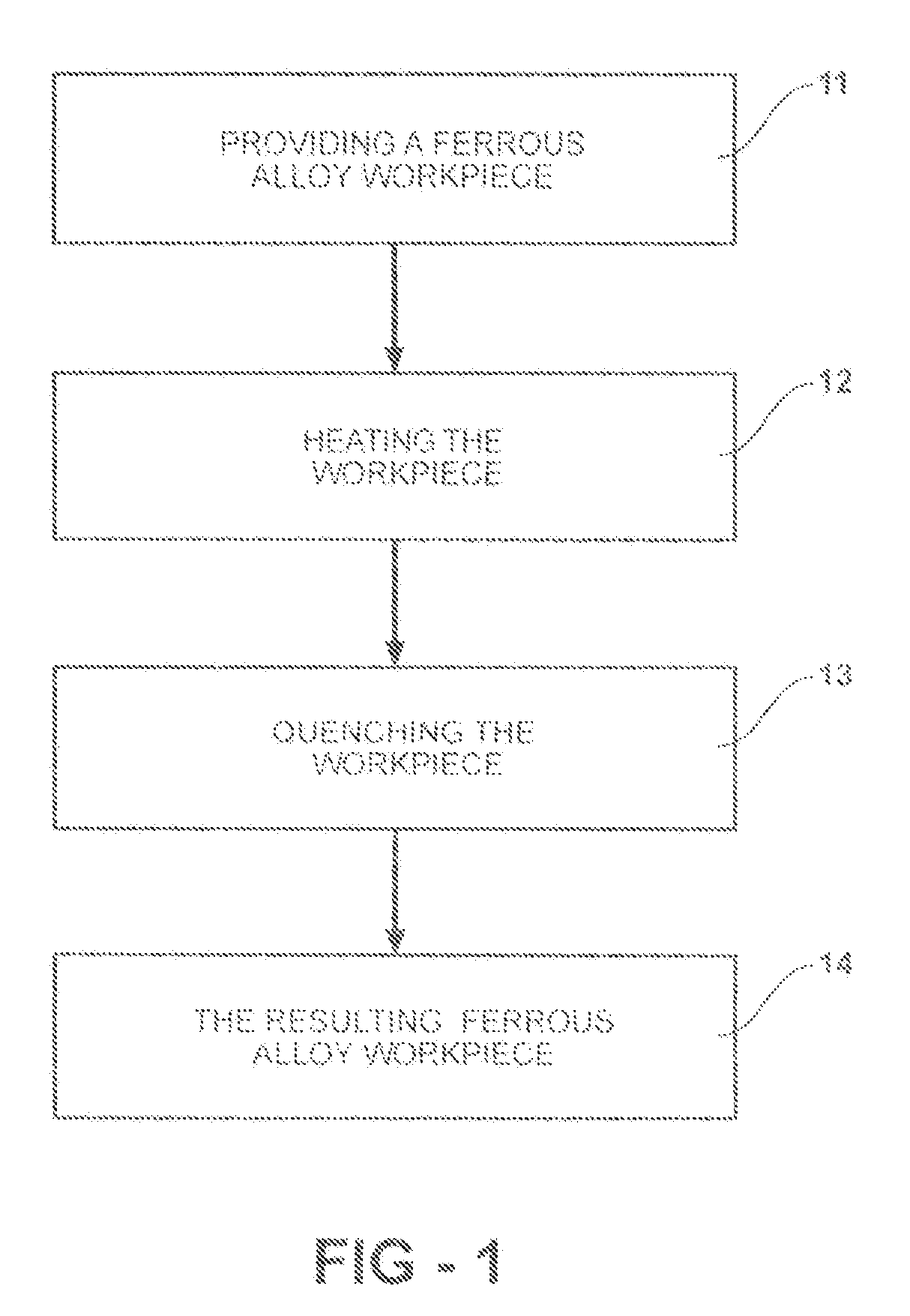

Iron-based alloys and articles in strips, sheets, workpieces and the like are converted into high strength steel with a minimum of cost, time and effort, including producing dual phase materials. This is achievable by extremely rapid micro-treating of low, medium, and high carbon iron-based alloys and articles by rapid heating and rapid cooling at least a portion of the alloy / article. This heating step involves nearly immediately heating the iron-based alloy to a selected temperature above its austenite conversion temperature. Then, the alloy is immediately quenched, also at an extremely fast rate, on at least a portion of the iron-based alloy in a quenching unit adjacent the heating unit. This procedure forms high strength alloy in a desired area, depending upon where the treatment was performed.

Owner:COLA JR GARY M

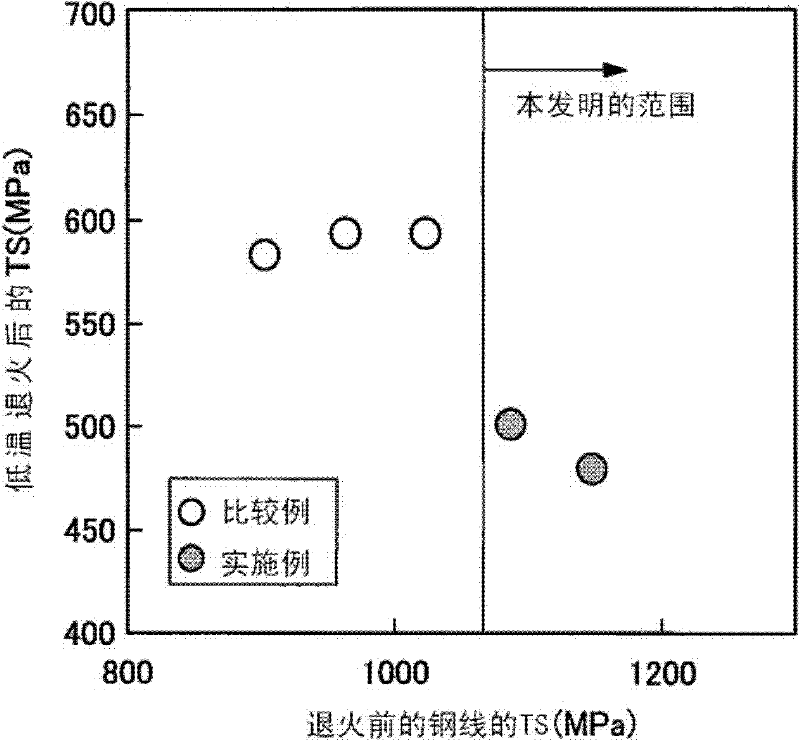

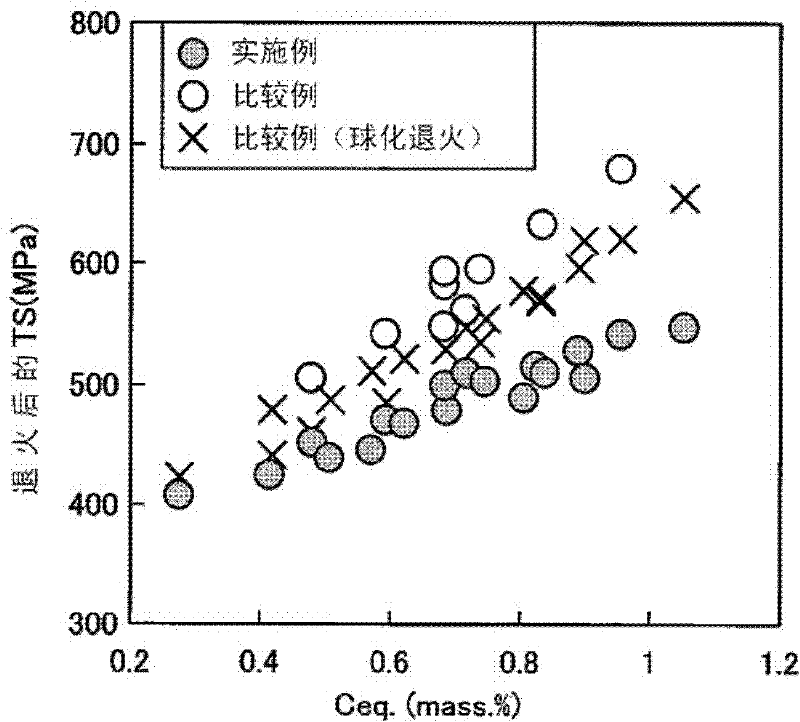

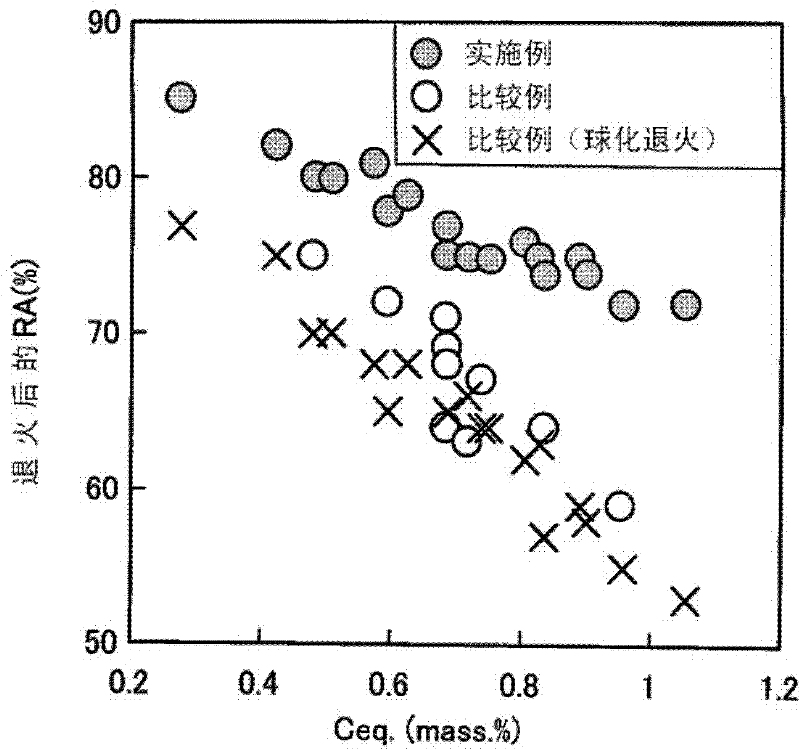

Steel wire for low-temperature annealing and method for producing same

ActiveCN102227512AImprove yieldImprove productivityFurnace typesHeat treatment bathsImpurityVolume percent

Provided is a steel wire for low-temperature annealing which comprises, by mass%, C: 0.10% to 0.60%, Si: 0.01% to 0.40%, Mn: 0.20% to 1.50%, P: 0% to 0.040%, S: 0% to 0.050%, and N: 0.0005% to 0.0300%, and further comprises one or more selected from Cr: 0.03% to 0.4%, V: 0.03% to 0.2%, and Mo: 0.03% to 0.2%, with Fe and inevitable impurities as the remainder. The volume percent of pearlite structure is between 1.40*(C%)*100% and 100%, the volume percent of proeutectoid ferrite is between 0% and (1 - 1.25*(C%))*50%, and the volume percent of bainite structure is between 0% and 40%. The tensile strength is between 480 + 850*Ceq. MPa and 580 + 1130 Ceq. MPa.

Owner:NIPPON STEEL CORP

Wire rod, steel wire and their manufacturing method

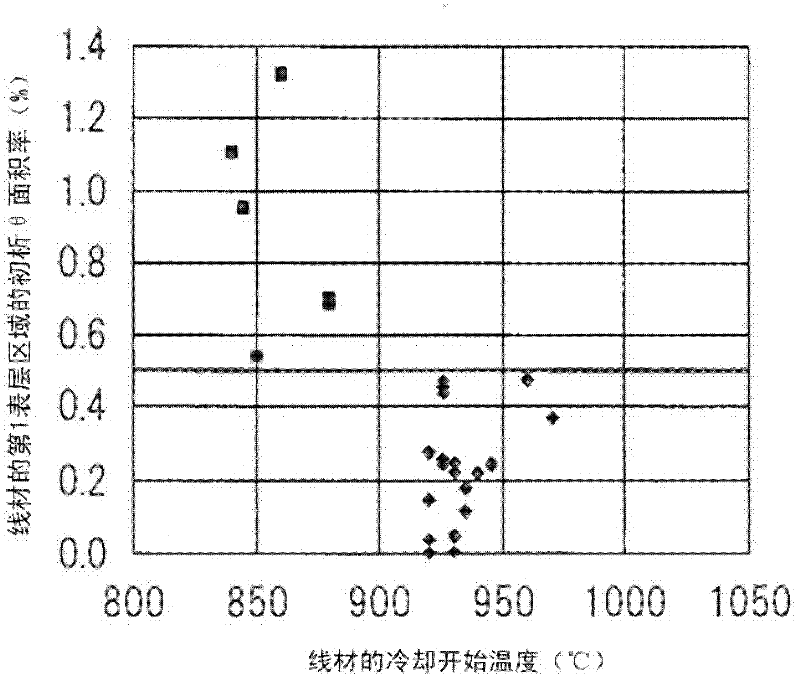

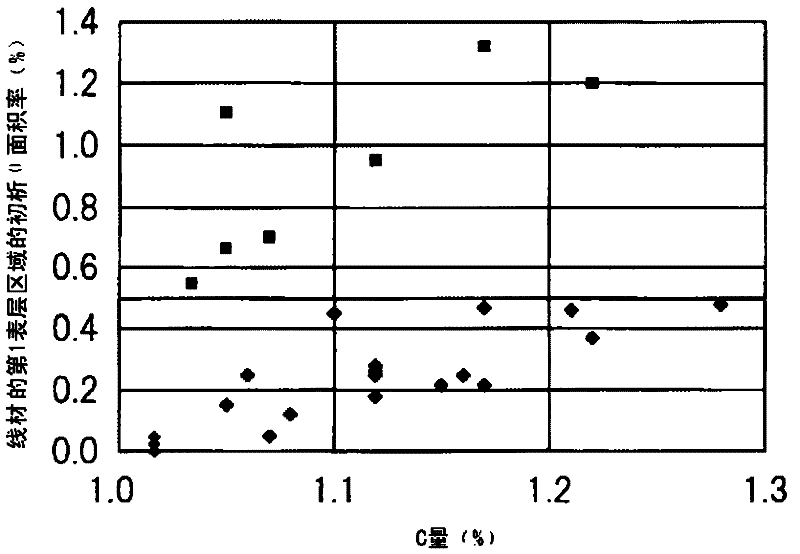

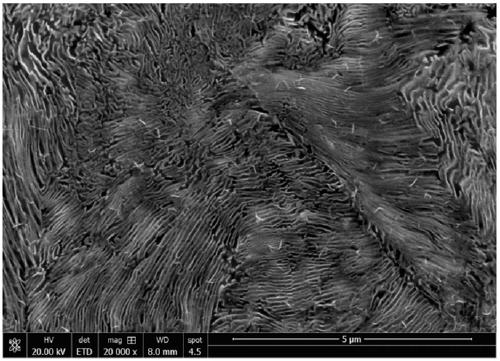

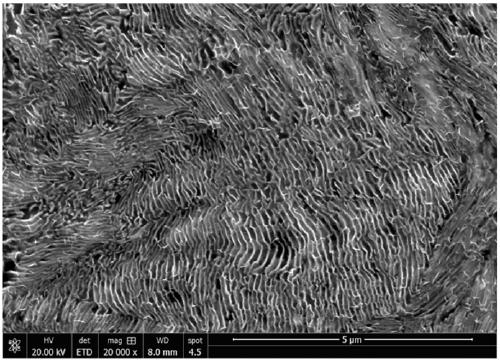

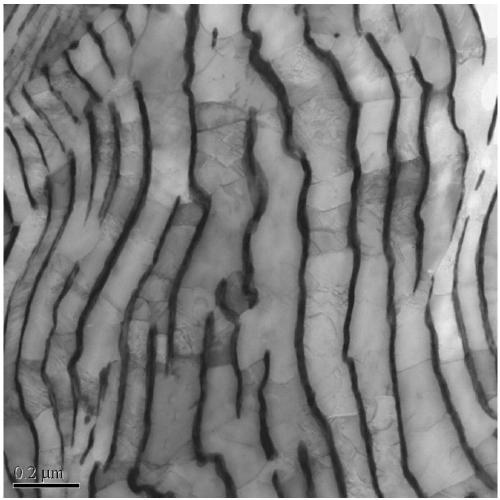

ActiveCN102301024AExcellent stringinessImprove productivityFurnace typesHeat treatment bathsMetallurgyImpurity

The present invention relates to a wire material comprising 0.95 to 1.30 mass% of C, 0.1 to 1.5 mass% of Si, 0.1 to 1.0 mass% of Mn, 0 to 0.1 mass% of Al, 0 to 0.1 mass% of Ti, 0 to 0.02 mass% of P, 0 to 0.02 mass% of S, 10 to 50 ppm of N, 10 to 40 ppm of O, and the remainder containing at least Fe and unavoidable impurities, wherein 97% or more of the area of a cross-sectional surface perpendicular to the length-wise direction of the wire material is occupied by a pearlite structure, and wherein both a 0.5% or less of the area of the center region of the cross-sectional surface and 0.5% or less of the area of a first surface layer region of the cross-sectional surface are occupied by a pro-eitectoid cementite structure.

Owner:NIPPON STEEL CORP

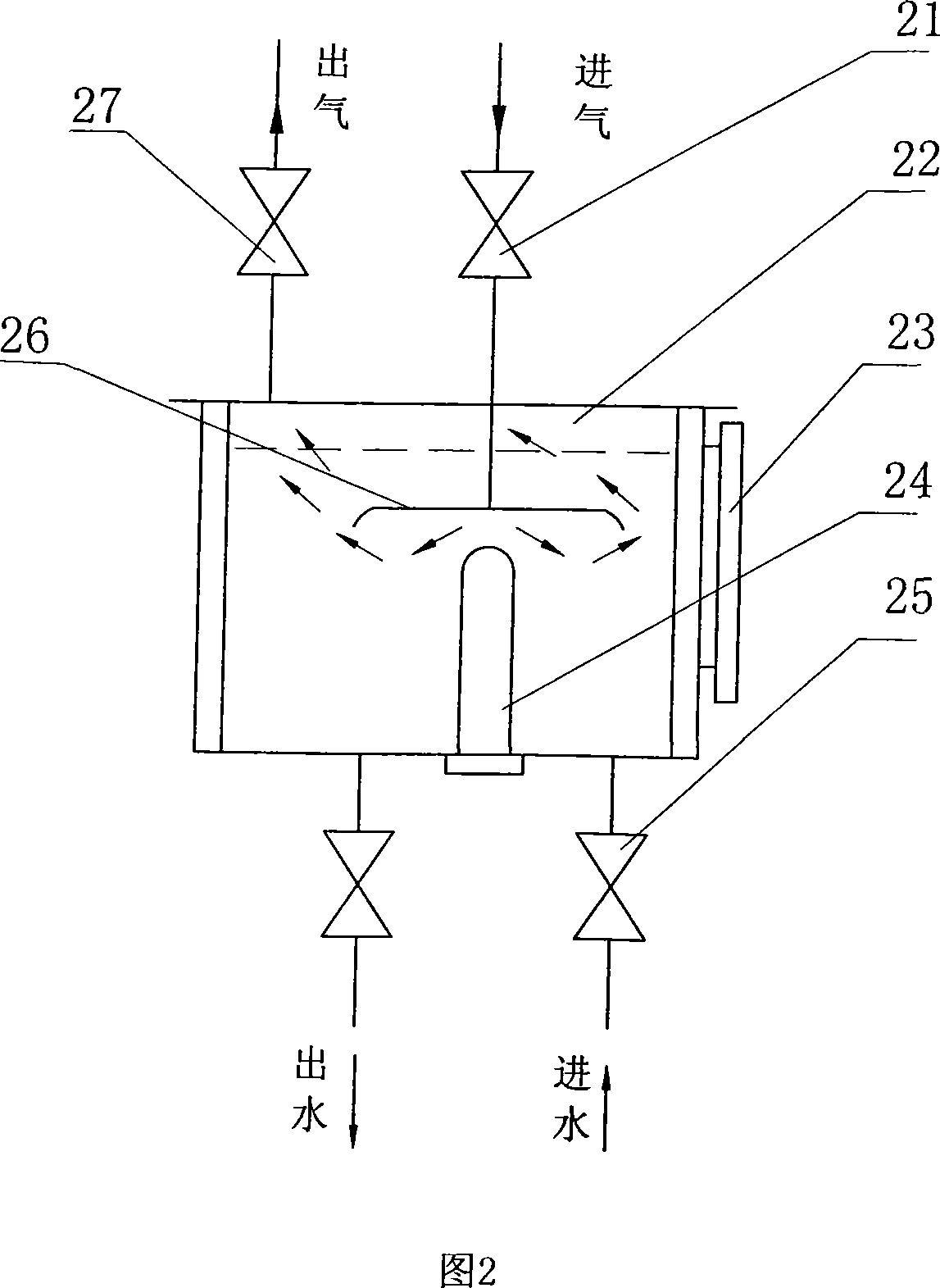

Method for manufacturing high chromium white wear-resistant cast iron

InactiveCN101104196AHigh hardnessImprove impact toughnessHeat treatment bathsIntermediate frequencyWear resistant

The invention discloses a manufacturing method of high chromium white mouth wear resistance cast iron, which adopts a wet casting; pig iron, scrap steel and partial ferroalloy are added in an intermediate frequency induction electric furnace in proportion to smelt qualified liquid iron; and then re modification is carried out; the modified processed liquid iron is cast into a sand mould to be cast and molded; finally isothermal salt bathing heat treatment is carried out. The stiffness, the impacting toughness and the wear resistance of the cast iron manufactured by the method are obviously improved with lower cost , and thus the invention is convenient for the industrial production.

Owner:安徽省安工机械制造有限公司

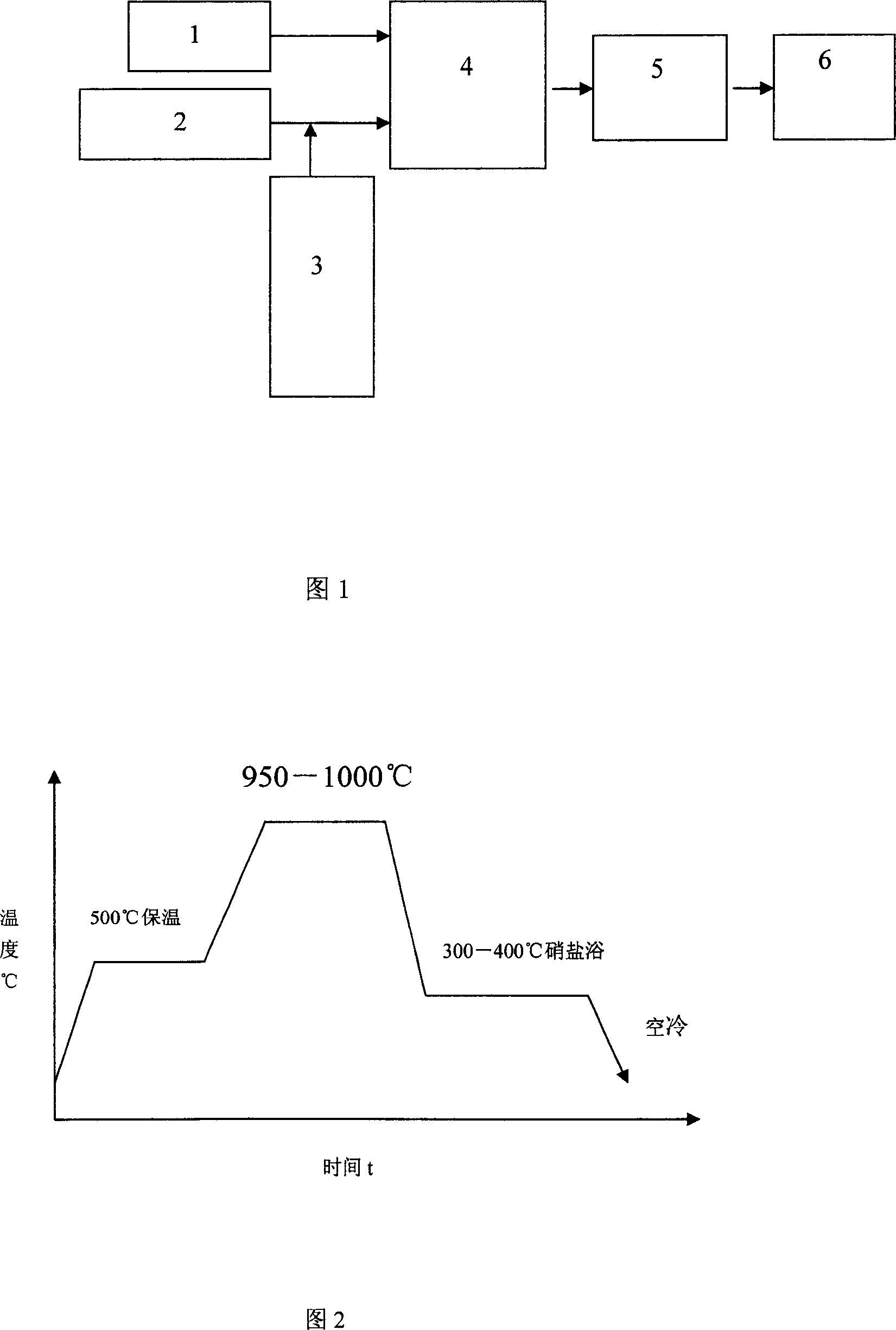

Method for preparing bainite wear-resistant cast steel

InactiveCN102877008AReduce manufacturing costSimple casting processProcess efficiency improvementHeat treatment bathsWear resistantManganese

The invention discloses a method for preparing bainite wear-resistant cast steel. The method includes the steps: taking steel scrap, (manganese, silicon, molybdenum, chromium, titanium and vanadium), ferrum, rare earth and RE as smelting raw materials; distributing the materials according to the weight percent of 0.2-0.6% of C, 0.7-2.5% of S, 0.3-3.0% of Mn, 0.1-1.5% of Mo, 0.2-3.0% of Cr, less than or equal to 0.5% of Ti, less than or equal to 0.5% of V, less than or equal to 0.5% of RE, less than or equal to 0.06% of S and P and the balance of Fe; completely melting down and then deoxidizing the steel scrap, (manganese, silicon, molybdenum and ferrochromium) and the like and pouring liquid steel into a ladle simultaneously holding ferrotitanium, ferrovanadium, rare earth and RE; casting the liquid steel at the temperature of 1500-1550 DEG C; placing a casting into a heat treatment furnace, increasing the temperature to 850-1000 DEG C and keeping the temperature; and placing the casting into a salt-bath furnace with the temperature of 200-350 DEG C, keeping the temperature and finally discharging the casting to be air-cooled to obtain the bainite wear-resistant cast steel.

Owner:XI AN JIAOTONG UNIV

Method for manufacturing drilling bit

InactiveCN101653905AImprove surface roughnessFree from destructionDrilling accessoriesSolid state diffusion coatingEngineeringSharpening

The invention belongs to the manufacturing field drilling bits, in particular a method for manufacturing a drilling bit. The method for manufacturing the drilling bit comprises the steps of snagging,slot rolling, cutting and sharpening, coarse grinding before heat treatment, heat treatment, coarse grinding of excircle, handle flat head chamfering, opening, fine grinding of excircle, edge finishing and cleaning. The invention has the advantages of low cost, excellent performance and longer service life.

Owner:常州市万绥工具厂

Surface treatment technique for coal winning machine cutting bit

InactiveCN101191230AExtended service lifeImprove work efficiencySolid state diffusion coatingHeat treatment bathsHardnessCoal

The invention discloses a surface treatment technology for a cutting bit of a coal winning machine. The cutting bit is made of the 35 chrome molybdenum vanadium alloy structural steel; the surface treatment technology includes the carburizing treatment, the boronizing, molybdenum permeating and chromizing treatment in which the optimal proportioning of the ingredients in a permeating box is that the boronizing agent is 80.6 percent, the molybdenum powder is 3 percent and the chrome powder is 16.4 percent, the salt bath treatment in which the optimization proportioning of the ingredients in a salt bath furnace is that the baryta is 73 percent, the non-iodized refined salt is 22 percent and the salt bath deoxidizing agent is 5 percent and the annealing and tempering treatment. The cutting bit which is treated according to the technology of the invention has the Rockwell hardness higher than HRC62 and the service life more than 400 hours.

Owner:李明

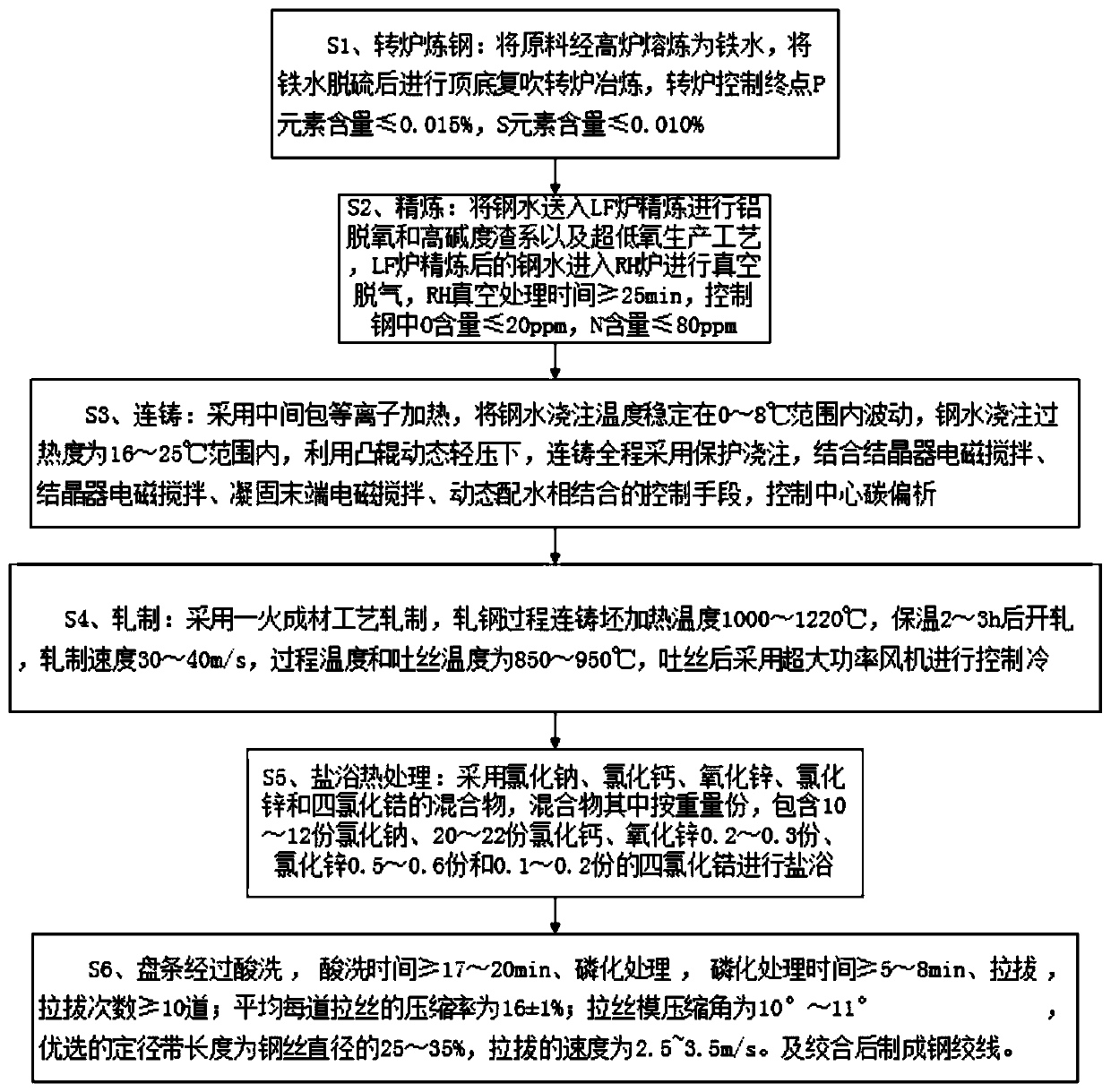

2400-MPa-strength prestressed steel strand and production process thereof

InactiveCN111321352AImprove uniformityHigh strengthTemperature control deviceManufacturing convertersWire rodPre stress

The invention provides a 2400-MPa-strength prestressed steel strand and a production process thereof. The 2400-MPa-strength prestressed steel strand comprises the following chemical components in percentage by mass: 0.88-1.02% of C, 0.10-1.30% of Si, 0.30-0.90% of Mn, 0.10-0.50% of Cr, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.01-0.08% of Al, 0.01-0.10% of V, and thebalance Fe and inevitable impurities. Through processes such as slat bath, the problems that a bad structure and large difference in property of a whole wire rod due to the fact that the cooling rateof the air-blown wire rod is low and uneven are solved, rapid cooling and isothermal phase change of the wire rod are achieved, and the strength and uniformity of the structure property are greatly improved; segregation is at a low level, the structure property is more uniform, no quenching structures influencing use, such as a network carbide and a martensite, exists, and good plasticity is stillmaintained while high strength is ensured; and after the wire rods is subjected to drawing, pulling, stranding, and stabilizing treatment, the strength of the strand reaches 2300 MPa or above and 2400 MPa or above, and can be used for producing the superstrength prestressed steel strands of 2300 MPa and 2400 MPa.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +5

Heat processing technology of high-carbon carbon steel coil rod for steel wire rope

InactiveCN102719643AImprove plasticityImprove toughnessFurnace typesHeat treatment bathsCarbon steelHeat processing

The invention discloses a heat processing technology of a high-carbon carbon steel coil rod for a steel wire rope. The heat processing technology is characterized by comprising the following steps of: carrying out hot rolling, water passing and cooling and coiling on the high-carbon carbon steel coil rod with the diameter of 6mm-16.5mm so as to obtain coil rod; when the prepared coil rod reaches the temperature range of 820 DEG C-900 DEG C, rapidly throwing the coil rod in a salt groove to keep for 2 seconds-40 seconds in salt bath lower than sorbite temperature at constant temperature; and then putting the coil rod into salt bath or lead bath with the sorbite temperature range to keep at constant temperature for 5 minutes-15 minutes, taking out and cooling naturally, thereby completing the heat processing technology of the high-carbon carbon steel coil rod for the steel wire rope. The heat processing technology of the high-carbon carbon steel coil rod for the steel wire rope can effectively refine the sorbite clique size and interlayer spacing and can improve the uniformity of interlayer spacing; and the product has the advantages of high intensity plasticity, excellent fatigue resistance, long service and the like. The heat processing technology of the high-carbon carbon steel coil rod for the steel wire rope has an obvious effect of improving the high plasticity of a coil rod wire material.

Owner:GUIZHOU UNIV

Low carbon silicon cold rolling phase variable plastic steel and production thereof

The invention was involved in the method of preparation of cold roll phase changing plastic steel that has a low ratio of C and Si. The mass ratio of ingredient was: C 0.1-0.2%, Si 0.1-0.5%, Mn 0.5-2.0%, Al 0.5-1.5%, V 0.05-0.5%, microcontent of S, P, N, the residue is Fe. Process: cold rolling billet steel was made up steel plate that has a thickness of 0.05-1.5mm, the steel plate was heated at 700-800 deg.C for 2-10 min, then quickly cooled in to 350-500 deg.C and thermal retardation for 2-10 min; It was immersed nito the oil and cooled it to room-temperature. Its advantages include a good plastic nature; the value motor than 20000 MPa%, the strength of extension was 650-670 Mpa, extensibility 32.5-34%.

Owner:SHANGHAI UNIV

Method for prolonging service life of key parts and components of production equipment of chain cage machine - rotary kiln ball lumps

InactiveCN101092658ARestore GeometryRestoration of Surface StrengtheningHeat treatment bathsAnti stressThermal effect

This invention relates to a method for prolonging the service life of key components of long-chain grate machine-rotary kiln pellet production apparatus. The method comprises: performing laser cladding / hardening treatment on the surfaces of the components by using laser thermal effect to improve surface hardness, performing salt bath treatment on the surfaces of the components by using QPQ process to form a compact bath treatment hardening layer with high friction resistance, and performing laser shock reinforcement on the surfaces of the components by using laser shock technique to form a stress layer with high amplitude residual pressure, which can effectively improve the surface mechanical properties of the components, and largely improve the anti-fatigue service life and anti-stress corrosion performance of the component. The method can improve the mechanical strength of key components so that they are hard at the surface and tough inside.

Owner:江苏宏大特种钢机械厂有限公司 +1

Alloy cast iron and manufacturing method of vane using the same

InactiveUS20130118651A1Improve productivityReduce manufacturing costRotary piston pumpsRotary piston liquid enginesManganeseAlloy

An alloy cast iron, a method of manufacturing a vane for a rotary compressor, and a vane for a rotary compressor using the alloy cast iron are disclosed. The alloy cast iron according to one exemplary embodiment includes, by weight, 3.2 to 3.8% carbon, 2.0 to 2.6% silicon, 0.5 to 1.0% Manganese, 0.2 to 0.6% chrome, 0.1 to 0.6% molybdenum, 0.04 to 0.15% titanium, less than 0.3% phosphorus, less than 0.1% sulphur, and the rest percentage of iron and foreign materials, wherein the alloy cast iron includes a martensitic matrix structure, flake graphite, and 15 to 30% carbide in volume ratio.

Owner:LG ELECTRONICS INC

Steel wire for springs, and spring

ActiveCN108350537AExcellent resistance to weakening of elasticityEasy to processFurnace typesHeat treatment bathsMetallurgyMaterials science

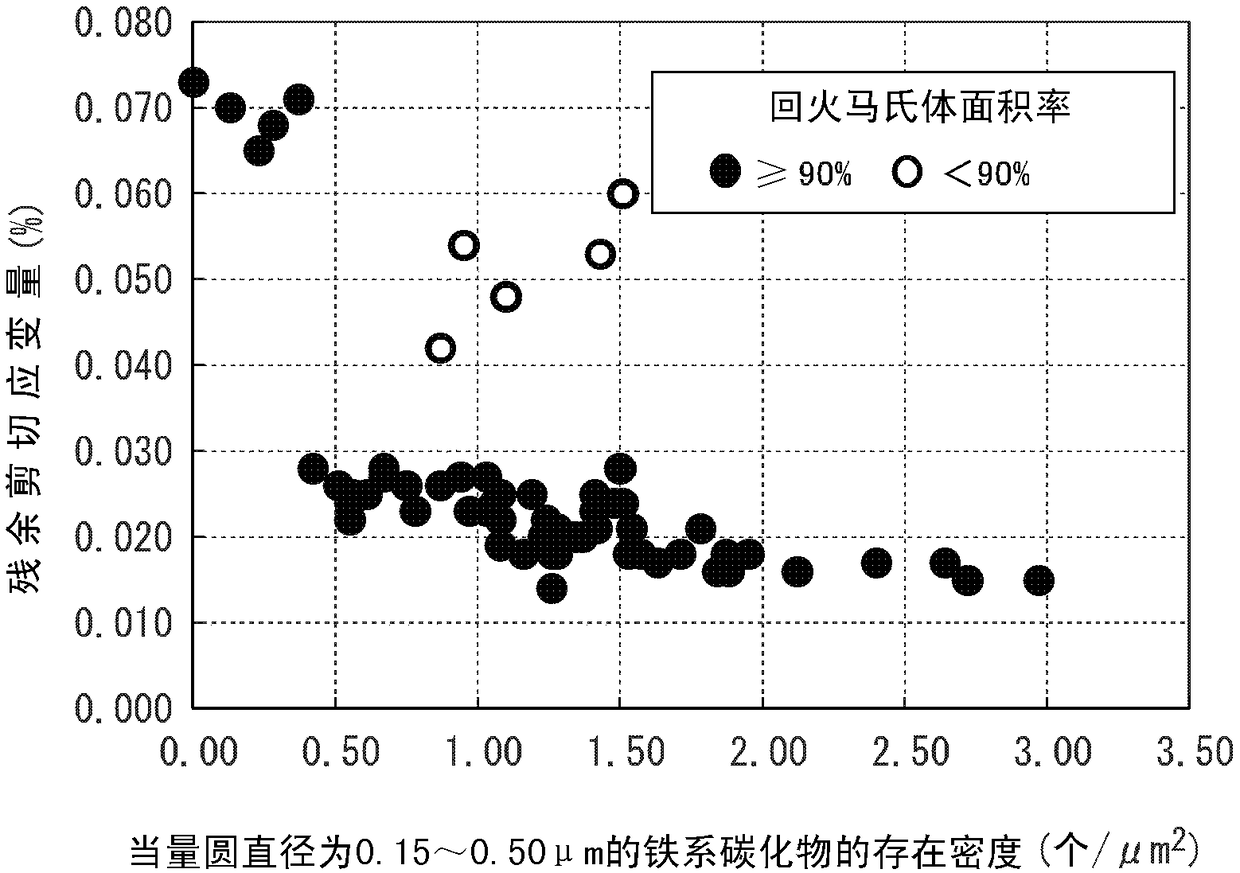

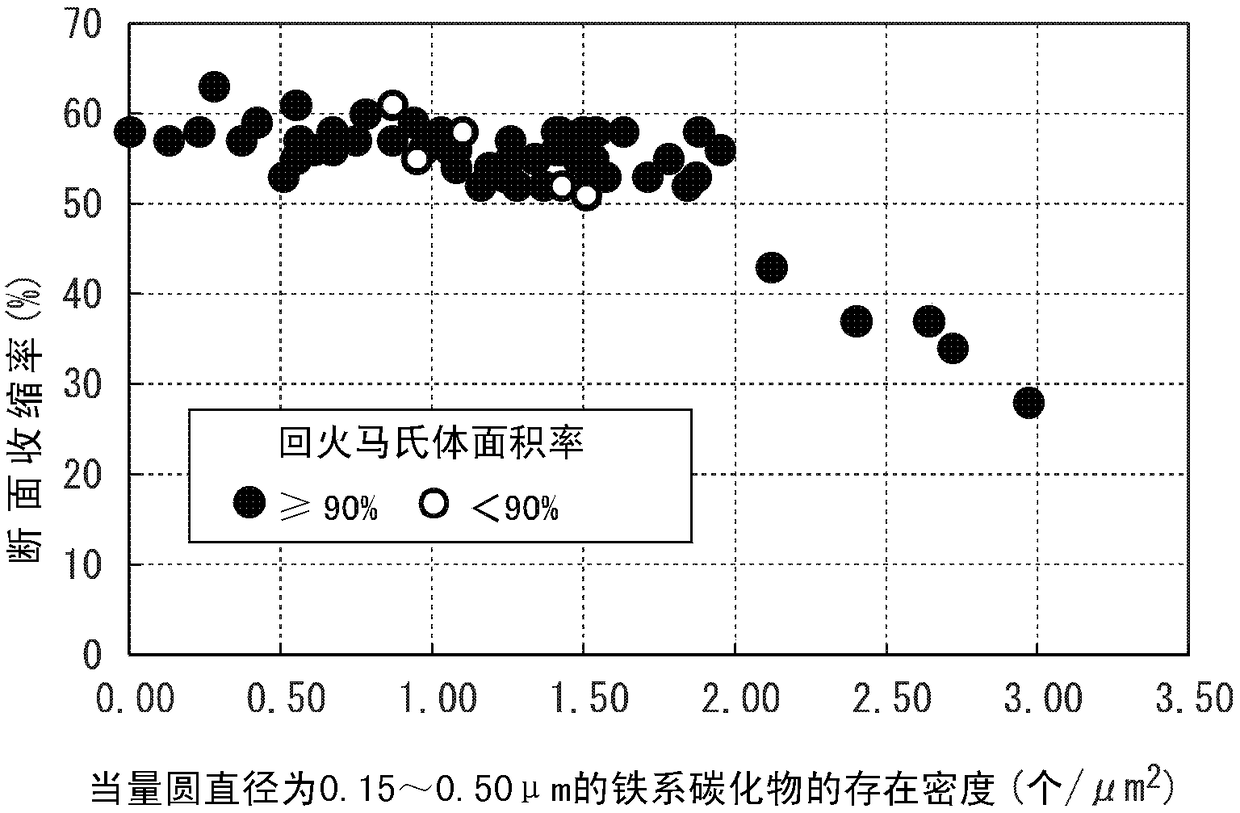

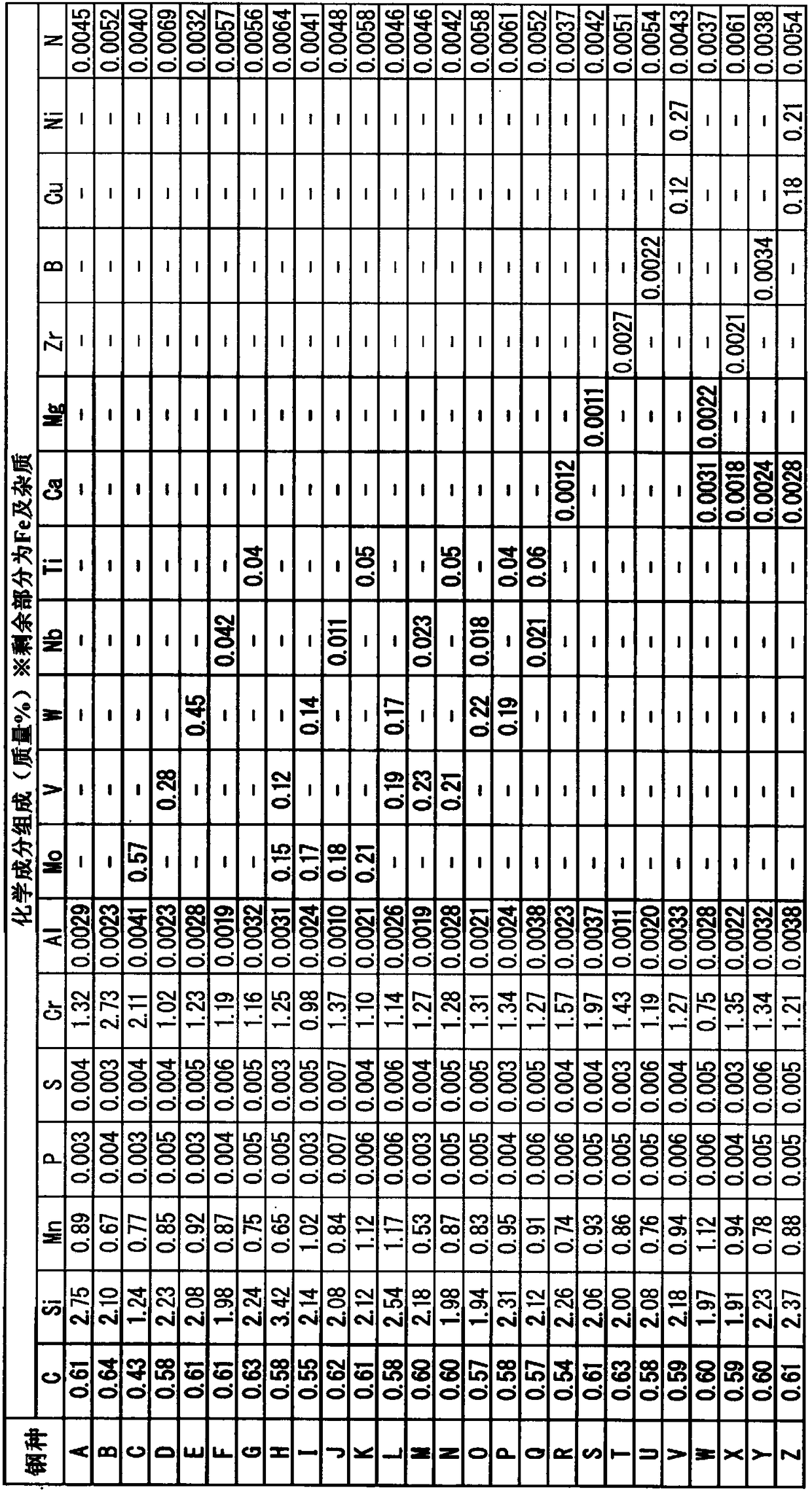

A steel wire for springs contains C: 0.40-0.75% by mass, Si: 1.00-5.00% by mass, Mn: 0.20-2.00% by mass, P: 0.0001-0.0500% by mass, S: 0.0001-0.0500% by mass, Cr: 0.50-3.50% by mass, Al: 0.0005-0.0500% by mass, N: 0.0020-0.0100%% by mass, Mo: 0-2.00% by mass, V: 0-0.50% by mass, W: 0-0.50% by mass, Nb: 0-0.100% by mass, Ti: 0-0.100% by mass, Ca: 0-0.0100% by mass, Mg: 0-0.0100% by mass, Zr: 0-0.1000% by mass, B: 0-0.0100% by mass, Cu: 0-1.00% by mass, and Ni: 0-3.00% by mass, the remainder being Fe and inevitable impurities. The structure includes tempered martensite having an area ratio of 90% or greater. The old austenite grain size number is 12.5 or higher. The concentration of iron carbide having an equivalent circle diameter of 0.15-0.50 um is 0.40 units / um2 to 2.00 units / um2 inclusive.

Owner:NIPPON STEEL CORP

Thermal processing technology for bolts

InactiveCN103643018ALow shrinkageImprove match rateFurnace typesQuenching agentsPotassium nitrateCyanide

A disclosed thermal processing technology for bolts comprises the following steps: 1) pre-heating to-be-processed bolts for 4-5 h, pre-heating a furnace to a temperature of 360-370 DEG C; 2) performing carburization processing; 3) keeping the bolts in a salt bath furnace with a temperature of 600-620 DEG C for 5-6 h and quenching; 4) performing first-stage quenching, employing a nitrate quenching agent and quenching to 500-510 DEG C with a constant velocity of 50-55 DEG C / min, wherein the nitrate quenching agent is a quenching agent prepared by mixing potassium nitrate and sodium nitrate with a mass ratio of 2:1; 5) performing second-state quenching, employing a nitrate quenching agent and quenching to 100-110 DEG C, wherein the nitrate quenching agent is a quenching agent prepared by mixing potassium nitrate and sodium nitrate with a mass ratio of 1:2; 6) performing third-stage quenching, employing hot water with a temperature of 200-205 DEG C and quenching to 230-235 DEG C; and 7) keeping the bolts in a tempering furnace with a temperature of 300-305 DEG C for 8-10 h, and cooling in air to room temperature. By employing the thermal processing technology for the bolts, the prepared bolts are small in cross-section shrinkage, improved in match rate and reduced in rejection rate, and cyanide penetrating agents harmful to human body and environment are avoided.

Owner:常熟市福熙机械零部件制造有限公司

Bimetallic bainite-martensite complex phase steel wear-resistant liner and preparation method thereof

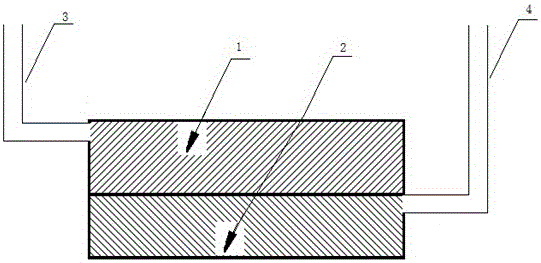

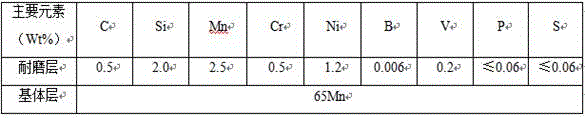

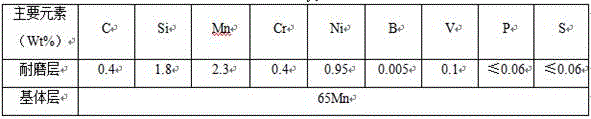

ActiveCN105856725AImprove mechanical propertiesAvoid crackingHeat treatment bathsMetal layered productsWear resistantMetallic materials

The present invention discloses a bimetallic composite bainite-martensite complex phase steel wear-resistant liner and a preparation method thereof, and belongs to the technical field of metal material casting. The method is as below: two liquids and two metals cast low-carbon alloy bainite-martensite complex phase alloy steel with different components in silicon manganese system; an inner layer is a high-hardness bainite-martensite wear-resistant layer; an outer layer is a high-toughness impact resistant base layer; after heat treatment, the inner and outer layers acquire different tissues, so as to obtain different properties. The method optimizes the alloy composition ratio of the inner liner and outer material, uses reasonable double-liquid bimetal casting process, employs a conventional salt bath austempering heat treatment to endow the inner and outer layers with different tissues. The inner layer of the liner has hardness of 55-57 HRC, and impact toughness of 11-14J / cm<2>; the outer layer has hardness of 45-50 HRC and impact toughness of 19-21J / cm<2>, thereby obtaining the wear-resistant liner with superior hardness and toughness and low cost.

Owner:KUNMING UNIV OF SCI & TECH

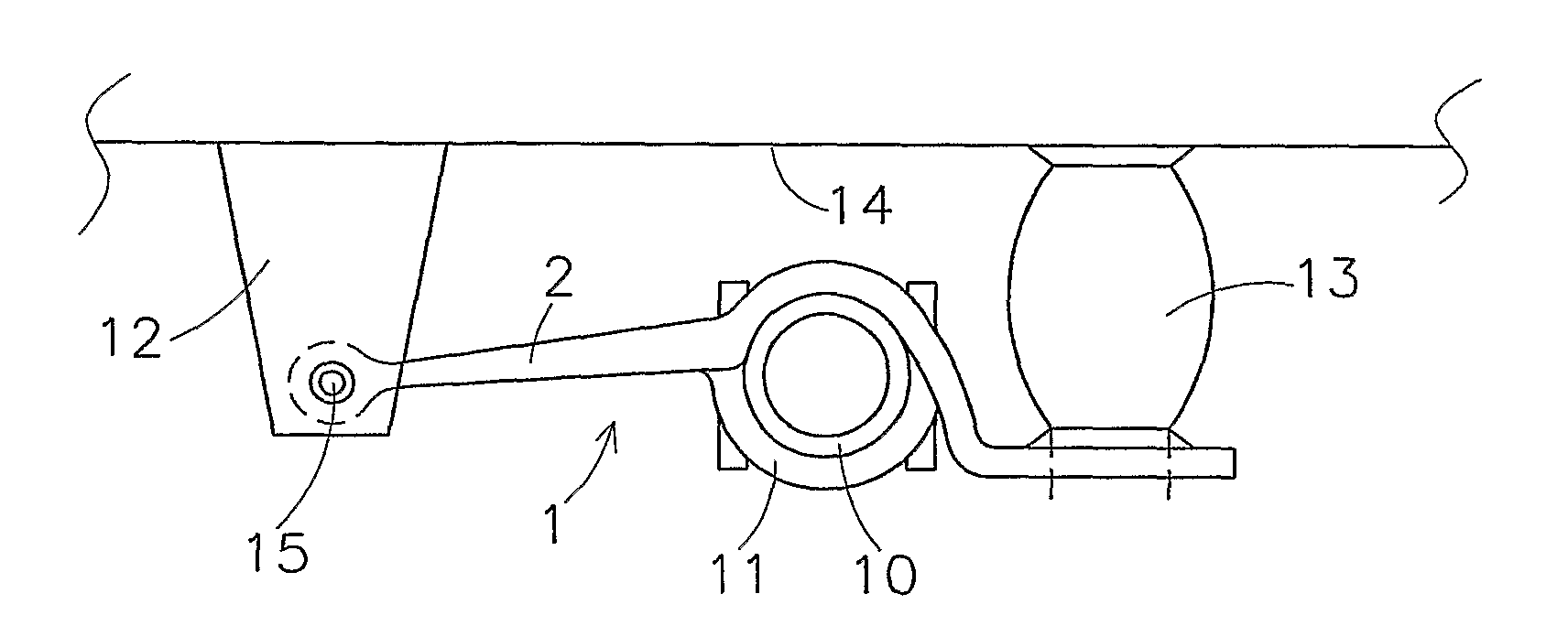

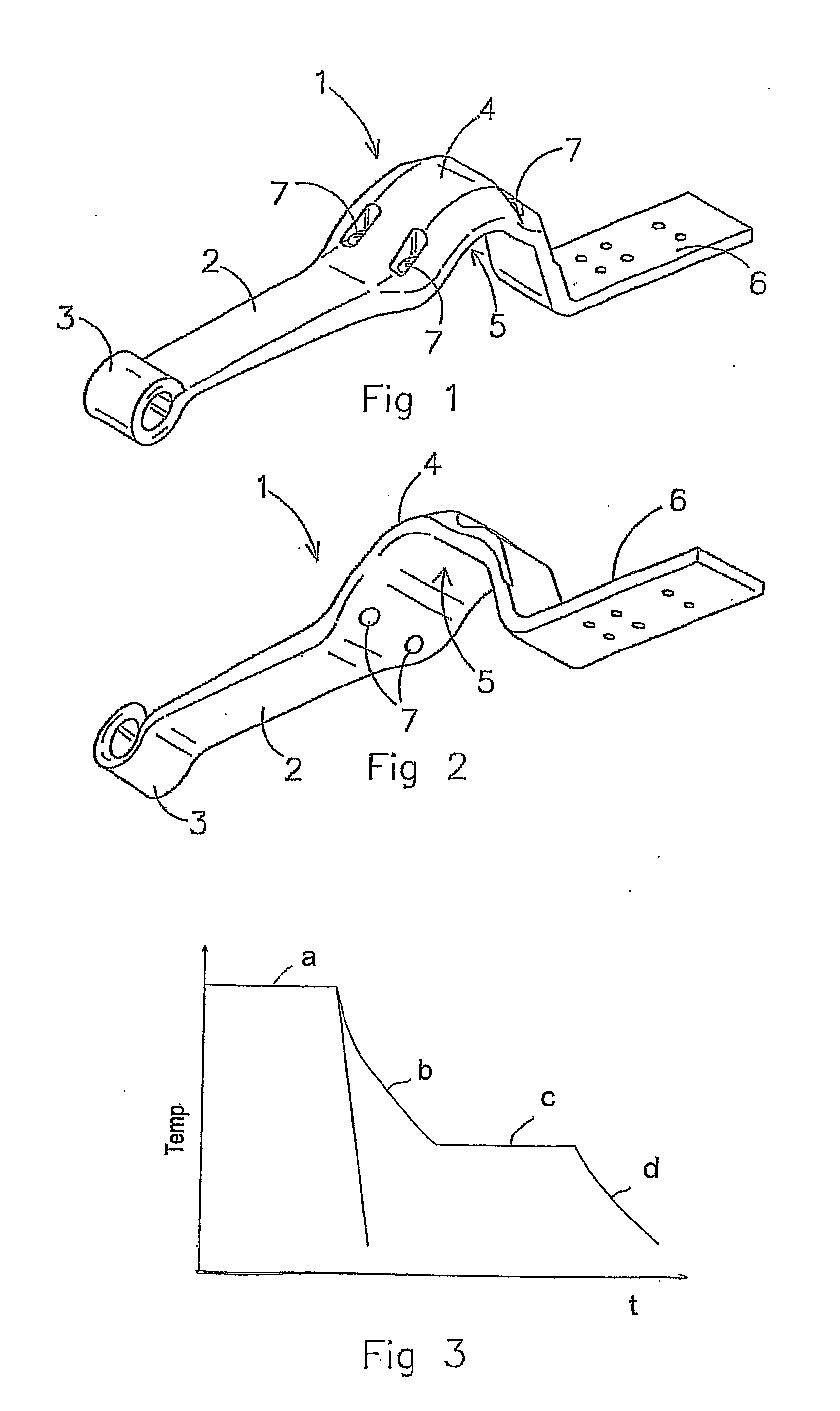

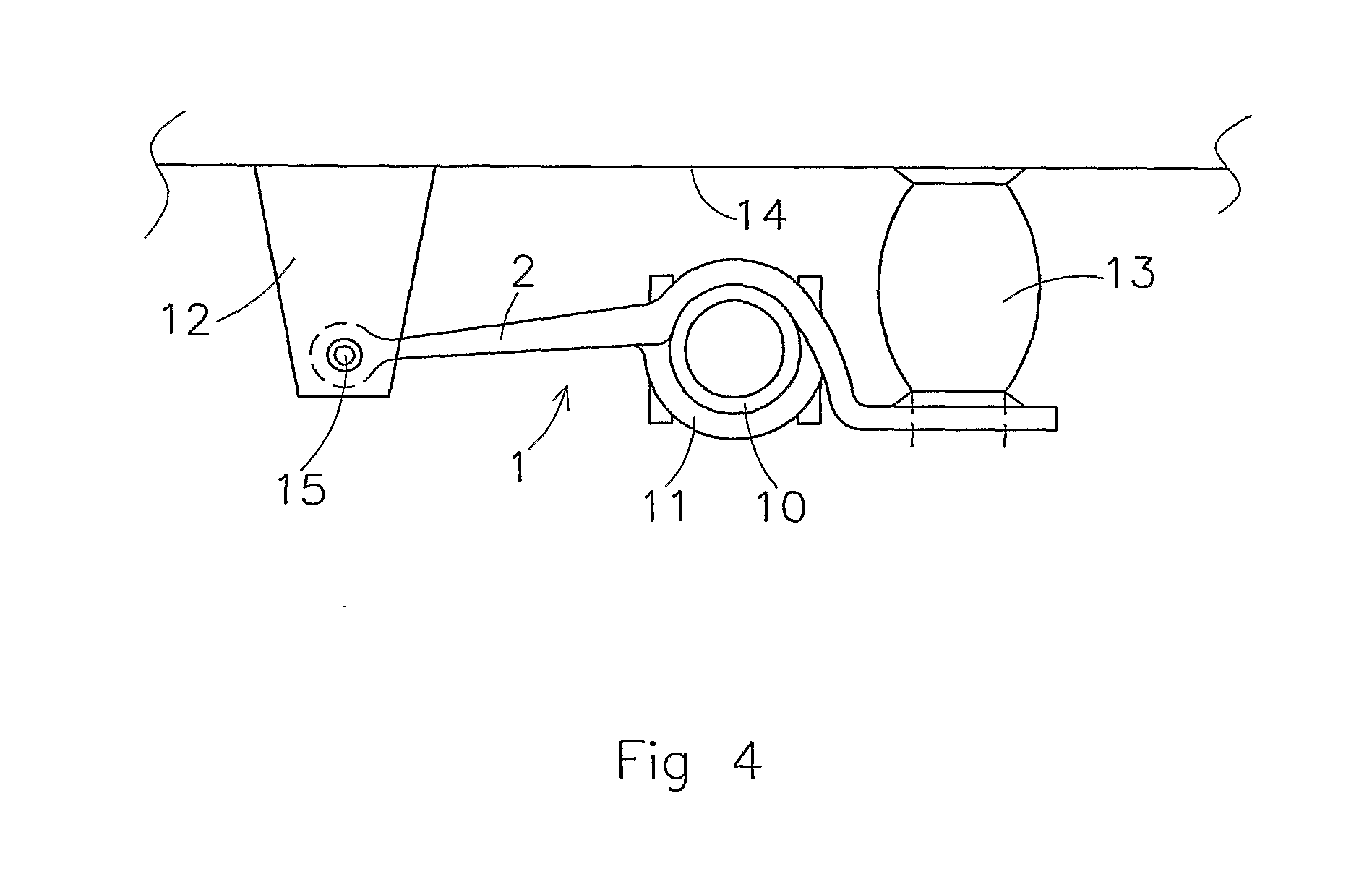

Hardening of flexible trailing arms

InactiveUS20110254243A1Quality improvementSave energyFurnace typesInterconnection systemsTrailing armEngineering

The invention relates to a method for manufacturing of a flexible trailing arm for a wheel axle suspension of a vehicle such as a lorry or a trailer. In the method a steel blank is heated. Next, the blank is formed into the desired shape of the trailing arm by means of a suitable forming process. Following that the trailing arm is austempered by cooling it in a warm fluid medium.

Owner:WEWELER NEDERLAND BV

Improved method for producing steel cords

ActiveCN107442596AIncreased micro-roughnessGuaranteed cleanlinessHeat treatment bathsVulcanizationConductor Coil

The invention discloses an improved method for producing steel cords. The improved method for producing the steel cords comprises the following steps that step 1, a high-strength steel cord coil rod serves as a raw material coil rod, the carbon content is 0.85%, the manganese content is 0.4%, the sulfur content is 0.01%, the phosphorus content is 0.01%, and the diameter phi of the steel cord coil rod is 5.5mm; step 2, the coil rod is pre-treated, specifically, descaling, washing, electrolytic pickling, washing, hot water washing, boron coating and drying are conducted; step 3, coarse wire drawing is conducted; step 4, middle wire is heat-treated; step 5, middle drawing is conducted; step 6, a finished product is subjected to heat treatment and heat-diffusion brass plating; step 7, detecting is conducted, mechanical performance which comprises tensile strength, extension, bending, torsion and the strength declining rate after diffusion is detected; step 8, fine drawing is conducted; step 9, single twisting forming and double twisting forming and outer winding are conducted; and step 10, packaging and encasing are conducted. According to the improved method for producing the steel cords, improving of the adhesion and the gumming rate of the steel wire and rubber after vulcanization are facilitated, and the quality of a tire is improved.

Owner:SHANDONG DAYE

Annealing furnace

InactiveCN106544478APrevent oxidationPrevent decarbonizationFurnace typesHeat treatment bathsThermal insulationHearth

The invention provides an annealing furnace which comprises a furnace shell, a hearth, a furnace door, heating elements, a temperature thermocouple and an intelligent temperature controller. The annealing furnace is characterized in that the furnace door is of a side opening type structure and is arranged on a panel of the furnace shell through multiple sets of hinges, the hearth is closed and is provided with a furnace opening, a protruding block matched with the furnace opening is arranged on the furnace door, and the protruding block tightly presses and is tightly attached to the interior of the furnace opening; a handle is arranged on the furnace door, the position between the furnace shell and the hearth is filled with a thermal insulation layer, and the heating elements surround the four walls of the hearth; a containing support and a rail are arranged inside the annealing furnace, and therefore materials can be continuously pushed into and ejected out of the annealing furnace, the automatic degree is high, and the labor amount is reduced; and the temperature in the hearth is even, the machining efficiency is greatly improved, and the energy resource using rate can be effectively improved.

Owner:丹阳市丹力展览用品有限公司

Heat treatment process of welded type weighted drill rod joint

InactiveCN103233113AReduce crackingImprove organizational structureFurnace typesHeat treatment bathsWater channelOil temperature

The invention discloses a heat treatment process of a welded type weighted drill rod joint. The heat treatment process comprises the following steps of: sequentially placing workpieces into a box type quenching furnace, vertically placing in a large-space mode, heating the furnace to 860 to 890 DEG C, preserving heat for at least 60 minutes, and stirring quenching oil before discharging the workpieces out of the furnace, wherein the oil temperature is controlled to be 80+ / -1 DEG C; taking the workpieces out of the furnace, throwing the workpieces into the quenching oil at once, quenching, and cooling the workpieces in the quenching oil for at least 10 minutes; performing tempering treatment on the workpieces within 3.5 hours after the workpieces are quenched, heating a tempering furnace to 600 to 630 DEG C, preserving heat for at least 120 minutes, taking the workpieces out of the tempering furnace, throwing the workpieces into a water channel at once, and cooling to normal temperature. By adopting the heat treatment process, the quenching quality is improved mainly by taking a series of technology measures of reducing the quenching upper limit temperature, increasing the heat-preserving time and the like, so that the cracking phenomenon is avoided.

Owner:JIANGSU SHUGUANG OIL DRILLING EQUIP CO LTD

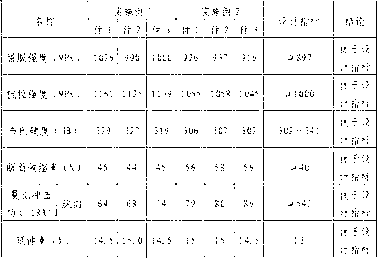

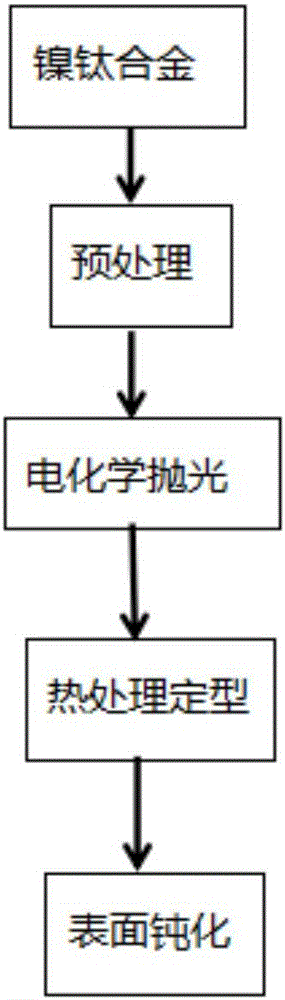

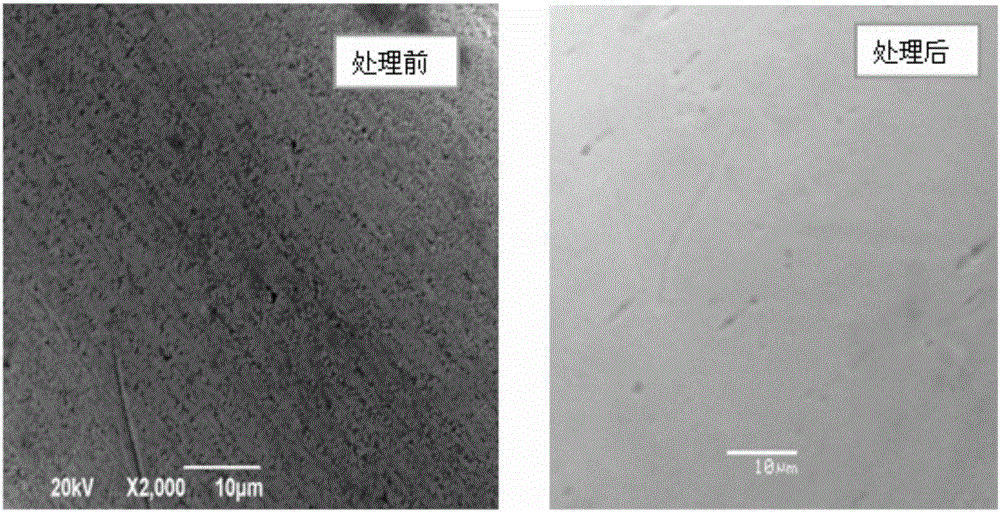

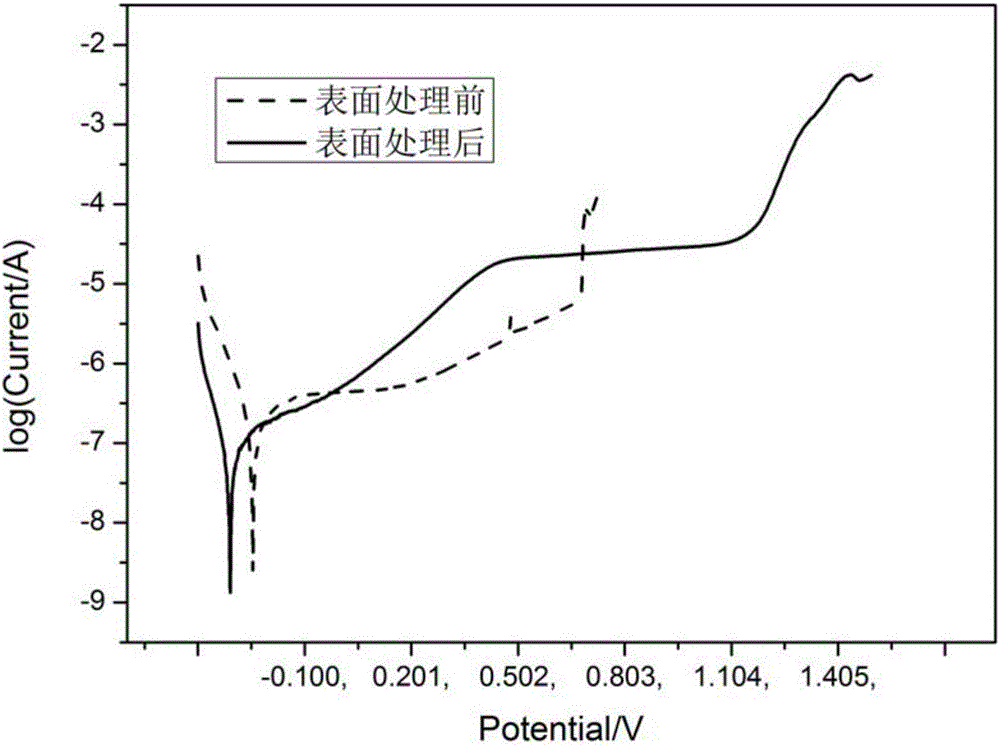

Surface treatment method for material nickel-titanium alloy for left aurcle plugging device

InactiveCN106811753AReduce surface roughnessEasy to useSurgeryPharmaceutical delivery mechanismTitaniumPre treatment

The invention discloses a method for surface treatment of a nickel-titanium alloy, a material used for a left atrial appendage occlusion device, and belongs to the technical field of medical metal surface treatment; the invention relates to a method for surface treatment of a biomedical nickel-titanium alloy, comprising the following steps and process conditions: (1) Substrate pretreatment; (2) Electrochemical polishing; (3) Product heat treatment setting; (4) Surface passivation process. Compared with the prior art, the process can significantly improve the surface treatment quality, improve the corrosion resistance of the nickel-titanium plug, and can expand the scope of the process treatment, especially suitable for the surface treatment of small pieces and complex-structured nickel-titanium products, with low cost and low cost. Simple and convenient for factory production and use of nickel-titanium products.

Owner:XIANGTAN UNIV

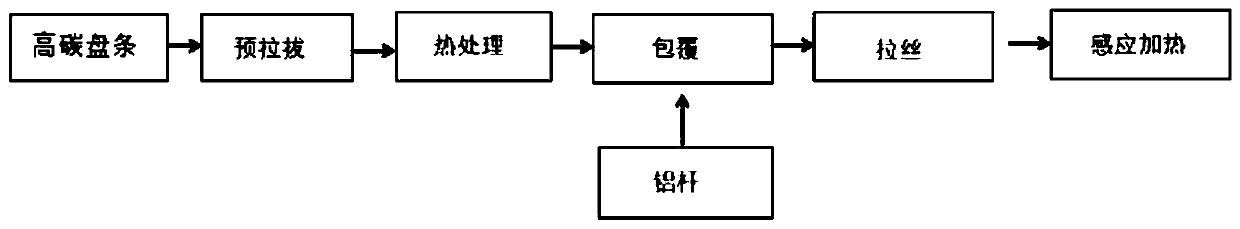

Production method of large-elongation aluminum clad steel wire

InactiveCN110125211AIncrease productivityHigh elongationApparatus for heat treatmentReduction of cables/conductors sizeWire rodSurface layer

The invention provides a production method of a large-elongation aluminum clad steel wire. The production process comprises the following steps of (1) derusting and drawing a high-carbon hot rolled wire rod to form a steel wire with the required wire diameter; (2) conducting austenitizing on the steel wire and conducting isothermal transformation through a lead bath to obtain the steel wire with the sorbite structure; (3) conducting online acid pickling on the steel wire with the sorbite structure to remove lead slag and oxide skin on the surface layer to obtain the steel wire with the clean surface; (4) cladding an aluminum layer on the surface layer of the steel wire with the clean surface through continuous extrusion cladding treatment to obtain a clad blank; (5) drawing the clad blankto be deformed to form the aluminum clad steel wire; and (6) conducing ageing treatment on the aluminum clad steel wire through an induction heating device. Through the production method, the production efficiency is high; and the problem that the hardness of an aluminum layer of the aluminum clad steel wire subjected to ageing treatment is reduced, and the aluminum clad steel wire is scratched inthe subsequent stranding process is solved. Compared with a traditional method that it needs to take 4-24 h of conduct heating and heat preservation during low-temperature long-time ageing treatment,the production method provided by the invention has the advantage that the induction heating device only needs 0.1-2.0 min to conduct online ageing treatment.

Owner:SOUTHEAST UNIV

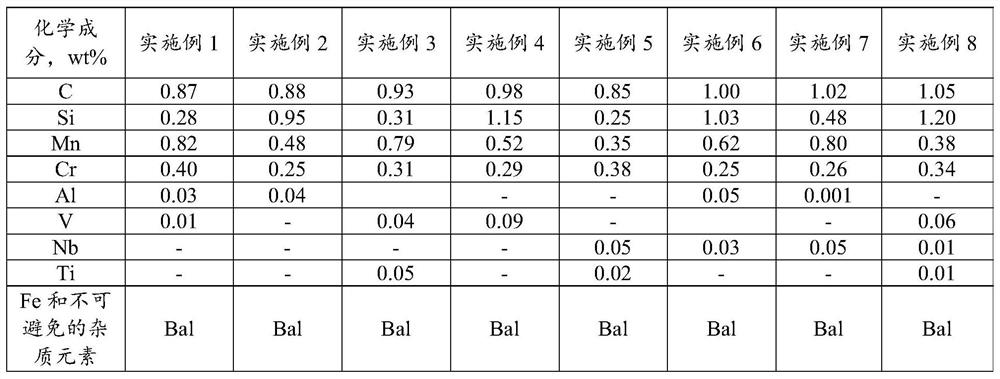

High-carbon steel wire rod and production method thereof

InactiveCN113088798AStrong enoughSufficient tissue homogeneityFurnace typesHeat treatment process controlWire rodChemical composition

The invention discloses a high-carbon steel wire rod and a production method thereof. The production method comprises the processes of molten steel smelting, continuous casting, cogging, high-speed wire rolling, temperature-controlled cooling and salt bath heat treatment which are carried out in sequence, wherein in the cogging process, the temperature of a soaking zone is 1200-1250 DEG C, and the soaking time is longer than or equal to 6 hours; in the temperature-controlled cooling process, the wire rod is subjected to temperature-controlled cooling on a Stelmor cooling line; and in the salt bath heat treatment process, the wire rod subjected to temperature-controlled cooling is firstly heated after being paid off, the heating temperature is 920-980 DEG C, then the wire rod is sent into a salt bath pot to be subjected to isothermal phase change, and the cooling rate before isothermal phase change is larger than or equal to 30 DEG C / s. The prepared high-carbon steel wire rod comprises the following chemical components in percentage by mass: at least one of 0.001 to 0.050 percent of Al, 0.01 to 0.09 percent of V, 0.01 to 0.05 percent of Nb and 0.01 to 0.05 percent of Ti, 0.85 to 1.05 percent of C, 0.25 to 1.20 percent of Si, 0.30 to 0.90 percent of Mn, 0.25 to 0.40 percent of Cr and the balance of Fe and inevitable impurity elements; and the high-carbon steel wire rod is high in strength, good in plasticity and toughness, and good in same-circle mechanical property uniformity.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Steel wire for non-thermal-refined machine component, and non-thermal-refined machine component

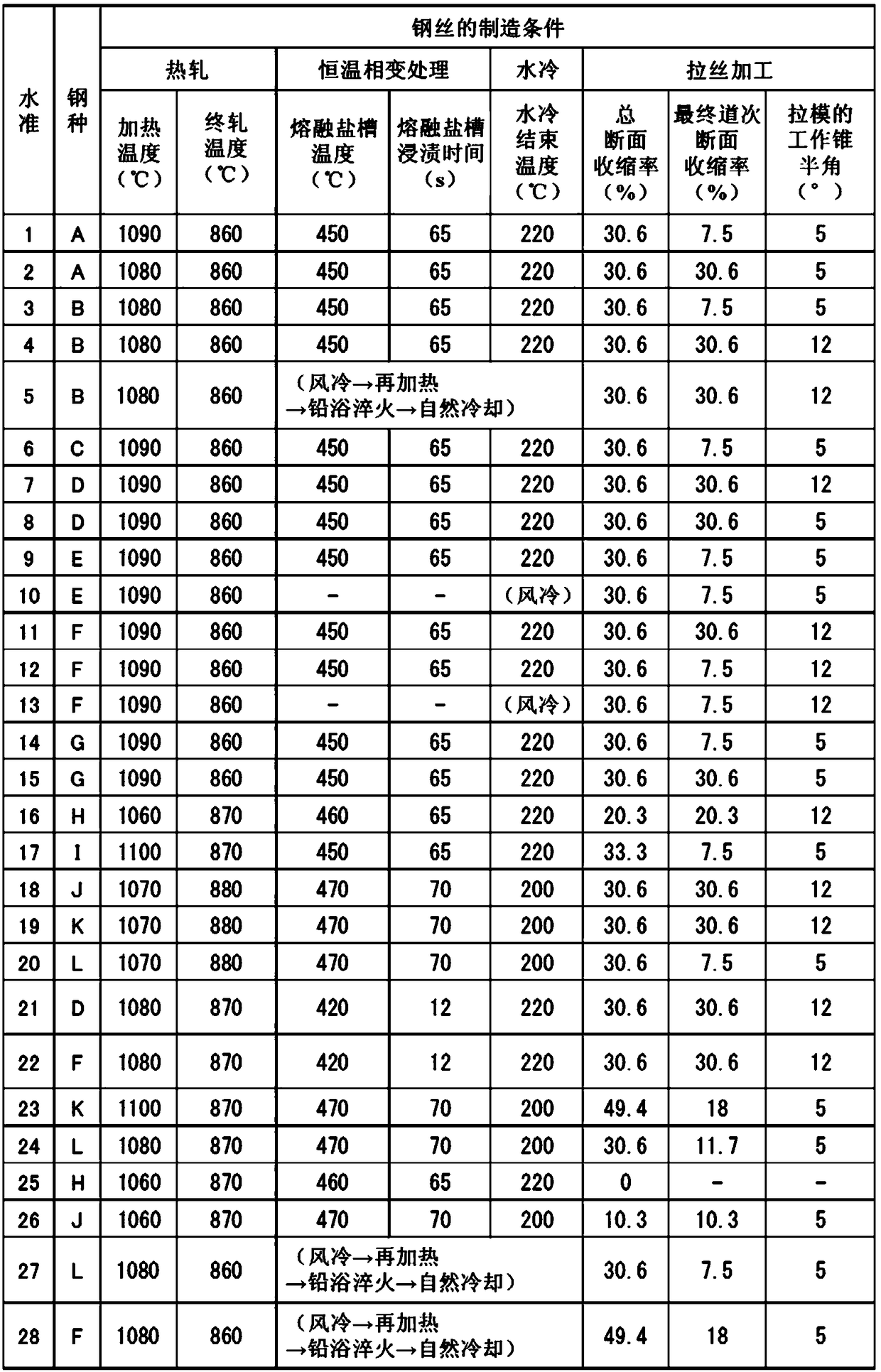

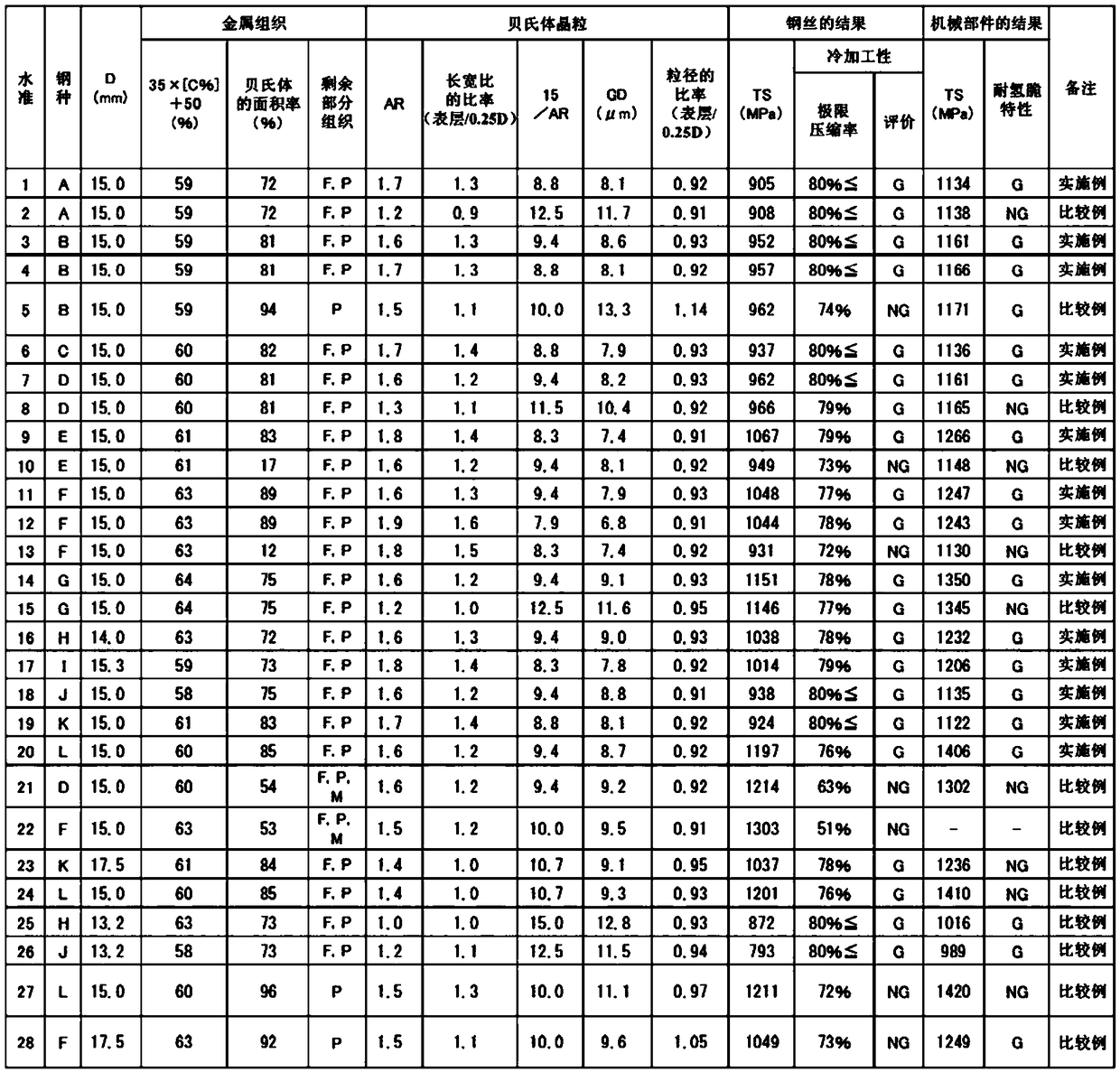

ActiveCN108474073AImproved cold working propertiesExcellent resistance to hydrogen embrittlementNutsBoltsImpurityMetal

A steel wire for a non-thermal-refined machine component, the steel wire including, in terms of mass%, 0.20-0.40% C, 0.05-0.50% Si, 0.50-2.00% Mn, and 0.005-0.050% Al, the remainder including Fe and impurities, the metallographic structure including (35 x [C%] + 50)% or more of bainite, and AR being 1.4 or greater, (AR) / (average aspect ratio of bainite particles at a position a depth of 0.25 D inthe L cross-section) being 1.1 or greater, GD being (15 / AR) [mu]m or less, and (GD) / (average particle diameter of bainite particles at a position a depth of 0.25 D in the C cross-section) being less than 1.0, where D is the diameter of the steel wire, AR is the average aspect ratio of bainite particles at a position a depth of 50 [mu]m in the L cross-section, and GD is the average particle diameter of bainite particles at a position a depth of 50 [mu]m in the C cross-section.

Owner:NIPPON STEEL CORP

Zinc-coated steel wire for bridge cable with high-strength and high-torsion and preparation technology thereof

ActiveCN109055679AMeet the development requirementsSolve the tensile strengthFurnace typesHeat treatment bathsReduction rateZinc

The invention discloses a zinc-coated steel wire for bridge cable with high-strength and high-torsion and preparation technology thereof, and belongs to the technical field of wire rods for bridge cables. The preparation technology comprises the steps that (1) rolled steel wires with high quality are selected; (2) single-pass or multi-pass pre-drawing is carried out, specifically the reduction rate of the single-pass pre-drawing is less than or equal to 20%, and the front-pass reduction rate of the multi-pass pre-drawing is larger than the rear-pass reduction rate of the multi-pass pre-drawing; (3) off-line heat treatment is carried out, specifically heat treatment is carried out on the obtained rolled steel wires of the step (2) by adopting one kind of salt bath, lead bath or water bath;and (4) the finished product zinc-coated steel wire is obtained by throwing. Compared with an existing preparation technology of general rolled steel wires, the designed preparation technology does not change technology parameters of off-line heat treatment and throwing, the operation is simple, and the feasibility is higher; and the tensile strength of the obtained zinc-coated steel wire is not less than 1860 MPa, the number of torsions is not less than 18 times in the torsion performance, and the service requirement of the bridge cables is met.

Owner:武汉钢铁有限公司

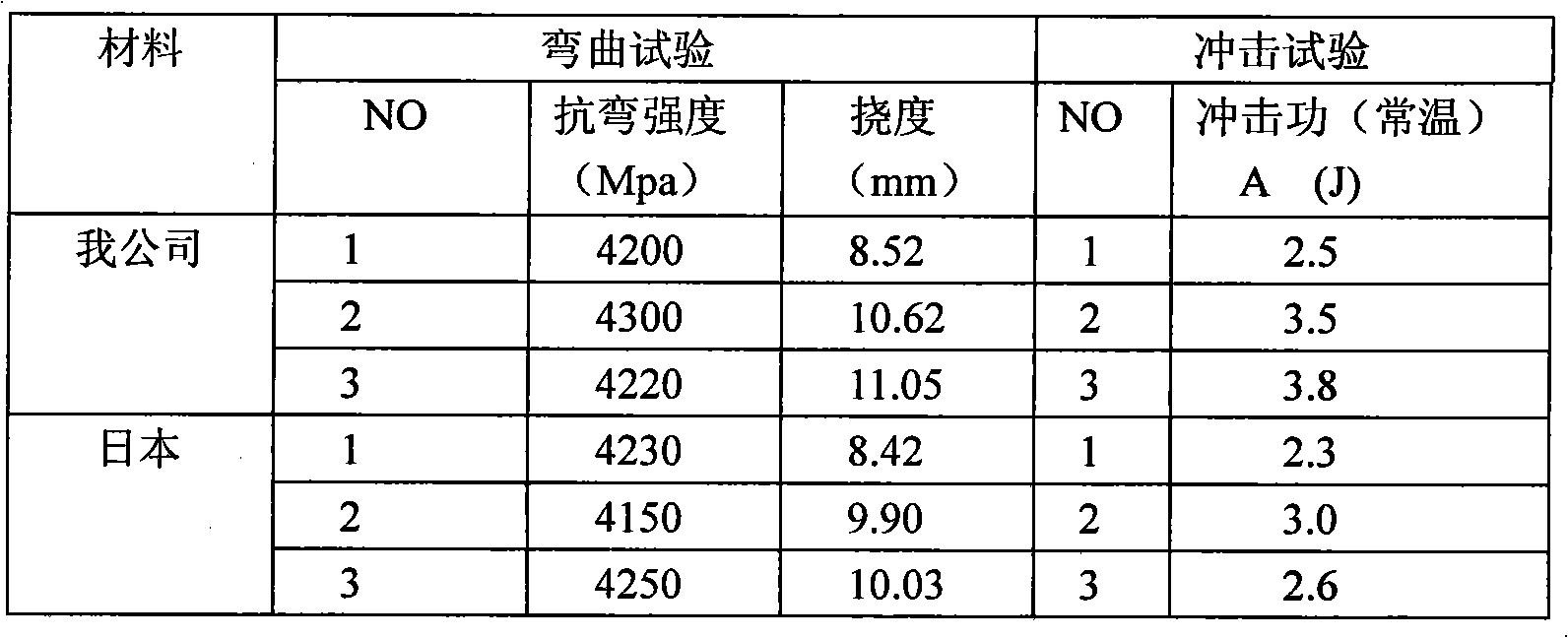

Alloy ball iron guide disc for precision tube grimper

The invention discloses a new-typed alloy ball-iron guide disc of fine rolling machine, which comprises the following parts: 3.0-3.6% C, 1.5-2.2% Si, 0.4-0.8% Mn, not more than 0.04% P, not more than 0.04% S, 0.1-0.3%Cr, 2.0-3.5% Ni, 0.5-1.0% Mo, not less than 0.04% Mg and Fe and inevitable impurity. The material tissue uniforms interior and exterior to improve abrasion resistance and flexibility, which improves manufacturing efficiency obviously.

Owner:SHANDONG SIFANG STEEL PIPE EQUIP MFG

Bolt heat treatment process

InactiveCN106119472AHigh surface hardnessFurnace typesHeat treatment bathsUltrasound deviceRoom temperature

The invention discloses a bolt heat treatment process which comprises the following steps: 1) carrying out ultrasonic cleaning on a bolt by adopting ultrasonic equipment to remove oil pollution on the surface, and then drying the bolt after oil pollution removal; 2) putting the bolt in a preheating furnace, and preheating for 4-6h, wherein the temperature of the preheating furnace is 500-750 DEG C; 3) placing the bolt obtained in the second step into a salt bath furnace with the temperature to be 700-720 DEG C, carrying out heat insulation for 3-5h, and quenching; 4) carrying out tempering on the bolt obtained in the third step at the temperature of 190-220 DEG C, then carrying out heat insulation for 30-50min, then carrying out heat insulation for 10-12h in a tempering furnace with the temperature to be 350-400 DEG C, and air cooling to the room temperature; and 5) carrying out surface phosphating treatment on the bolt obtained in the fourth step. According to the bolt heat treatment process, the bolt after being treated is very high in surface hardness.

Owner:NINGBO JINDING FASTENING PIECE

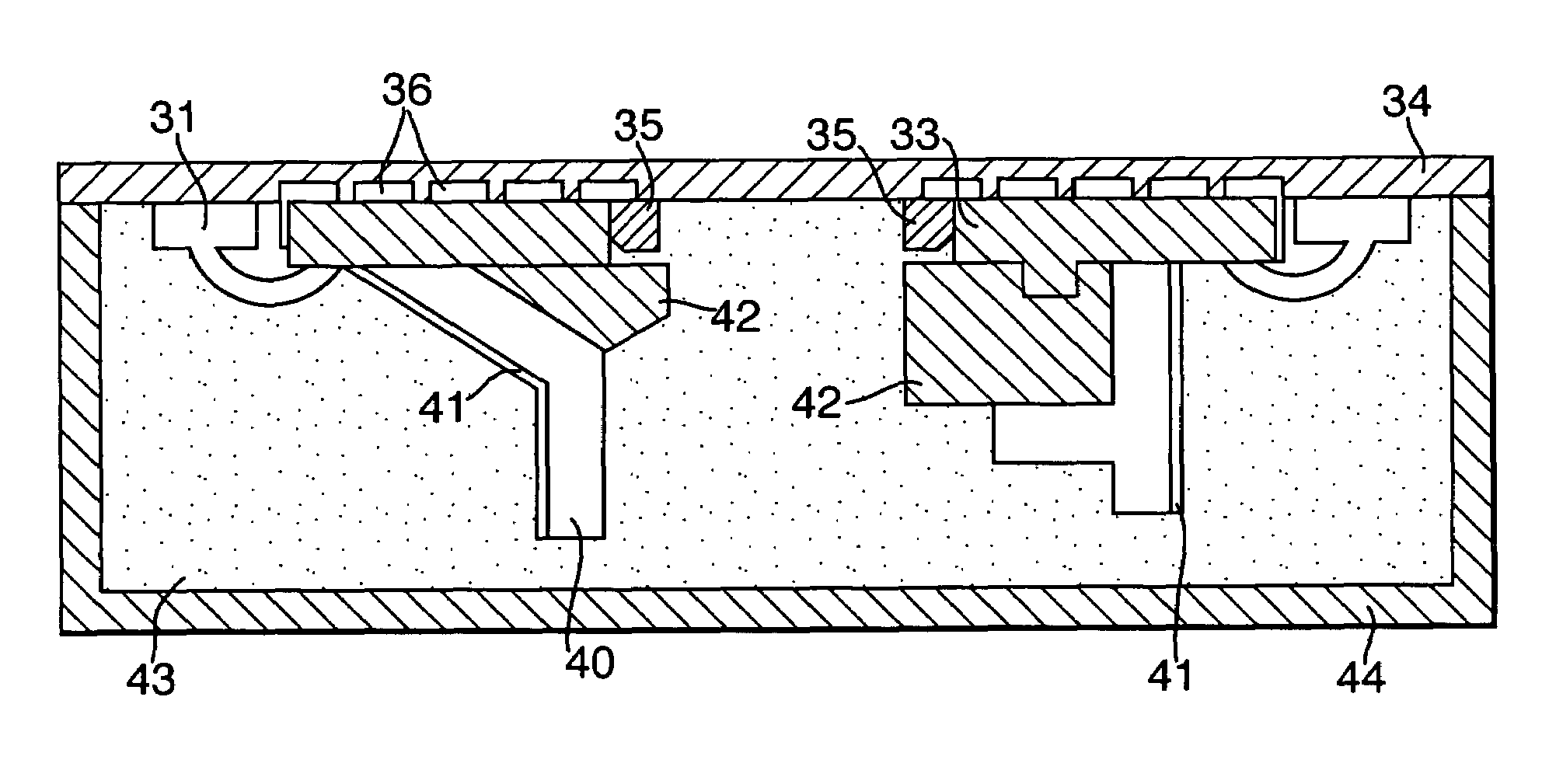

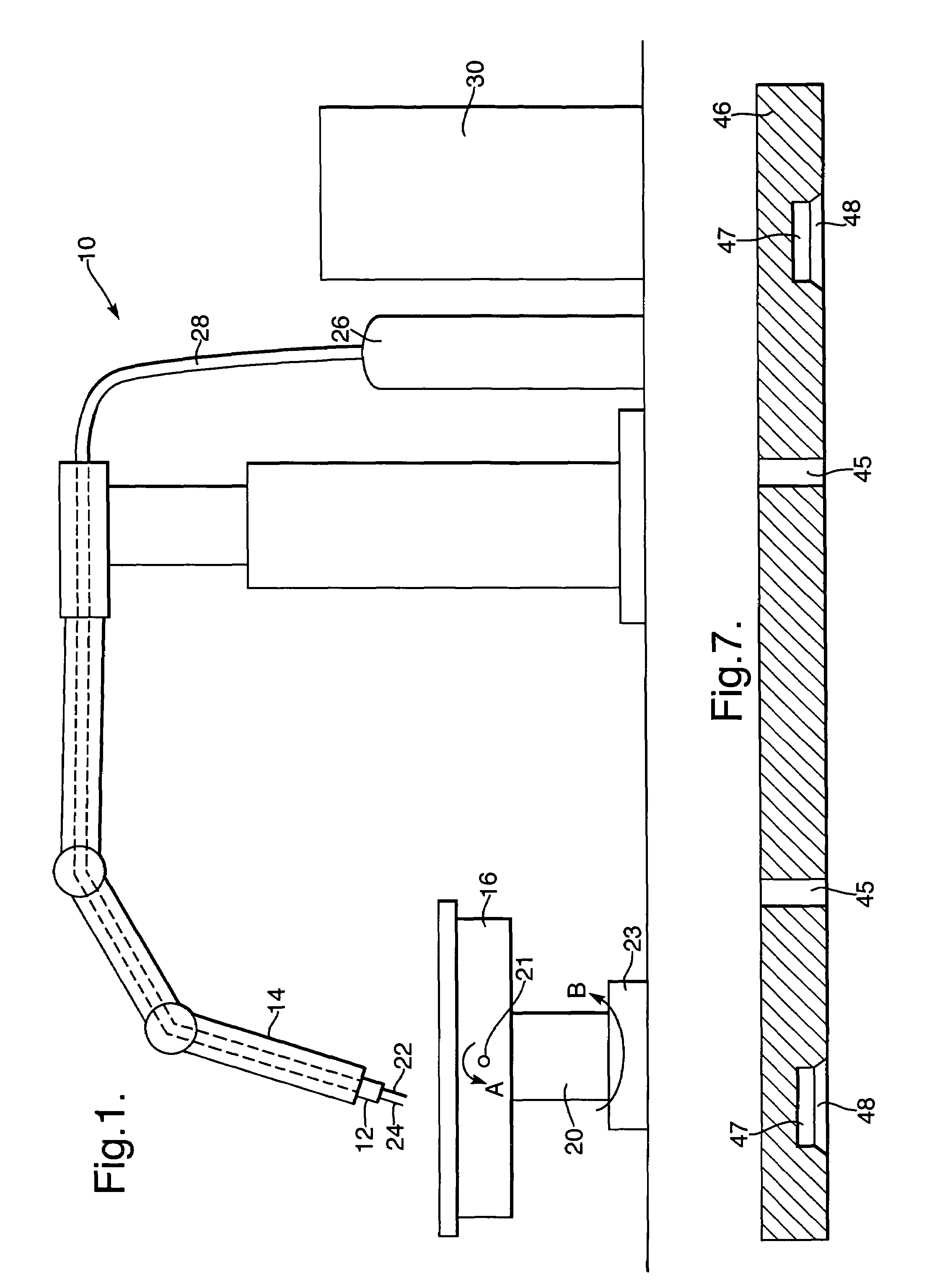

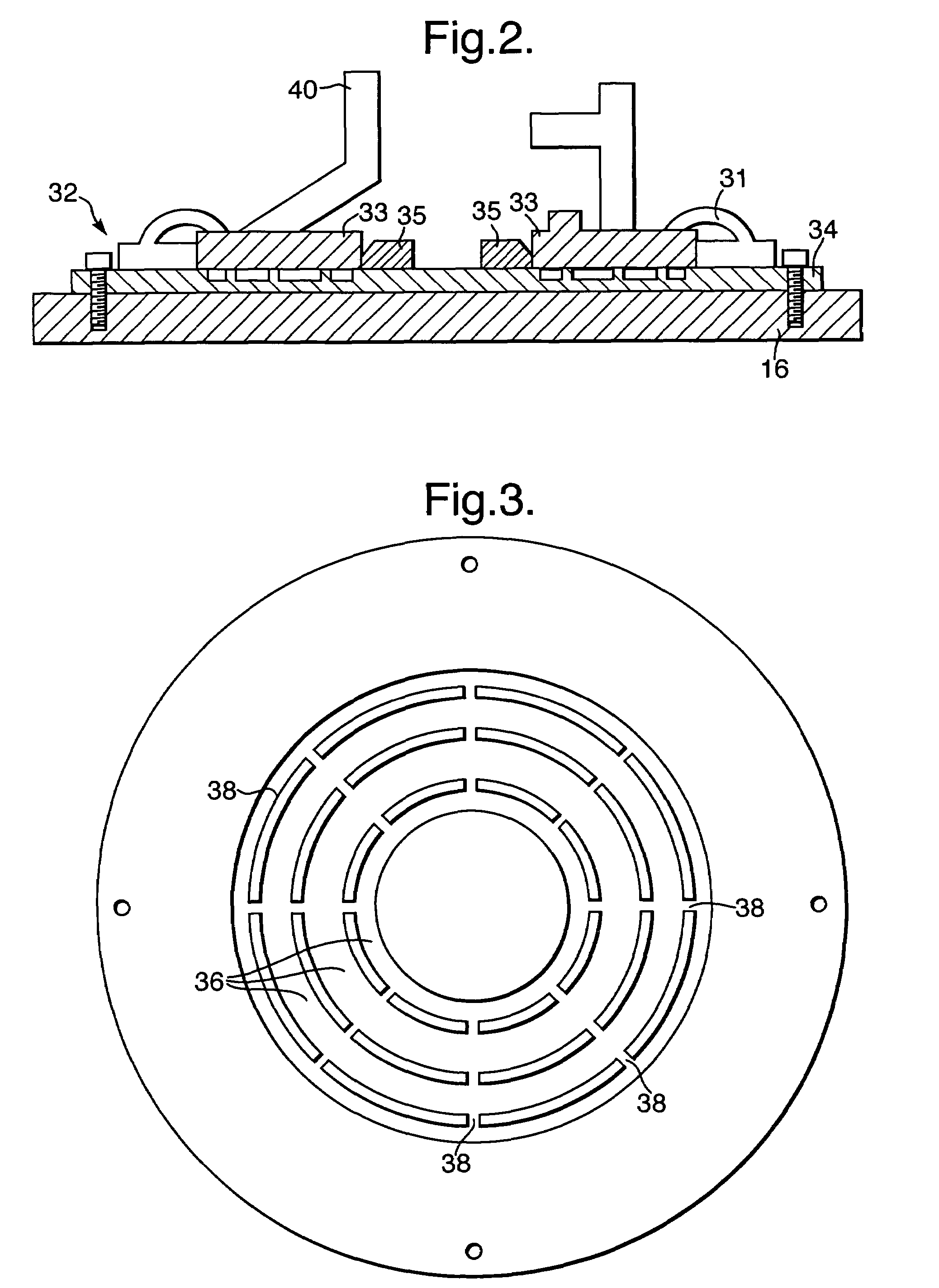

Method and apparatus for heat-treating an article and a fixture for use in the same

InactiveUS7344608B2Speed up the processWelding/cutting auxillary devicesArc welding apparatusEngineeringHeat treating

A substrate (33) is clamped into a fixture (32) and material is deposited thereon to form a complex article (40). The article (40) produced is packed, using ceramic inserts (42) and a coating (41). The packing (42) ensures that the article (40) maintains its true shape and allows for expansion during the subsequent heat treatment process. The packed article (40), mounted on the fixture (32), is then placed in a box (44), encased in a granular material (43) and heated. It is heated to a temperature sufficient to relieve stresses and is maintained at this temperature for a time period such that the stresses in the article (40) are relieved.

Owner:ROLLS ROYCE PLC

Production method of high speed steel prehardening materials

ActiveCN101665864ARealize online productionDecrease stockFurnace typesIncreasing energy efficiencyWire rodQuenching

The invention discloses a production method of high speed steel prehardening materials, which comprises the following steps: using a high speed steel wire as a raw material, prestraightening the raw material, quenching and heating the prestraightened raw material; carrying out small deformation and quenching straightening for the quenched high speed steel wire by a wire drawing die; tempering, straightening, tempering, straightening and cooling the high speed steel wire in a tempering furnace; forming a product through the traction of a tractor and carrying out dimensioning cut-off for the product. The production method of the high speed steel prehardening materials has the characteristics that quenching, tempering and straightening are combined for continuous production, the online production of the prehardening high speed steel wire is realized, the product has identical organization and performance as well as realizable and stable quality, and various high speed steel prehardening materials with the length of more than 2m and good straightness can be produced.

Owner:烟台百特合金材料制造有限公司

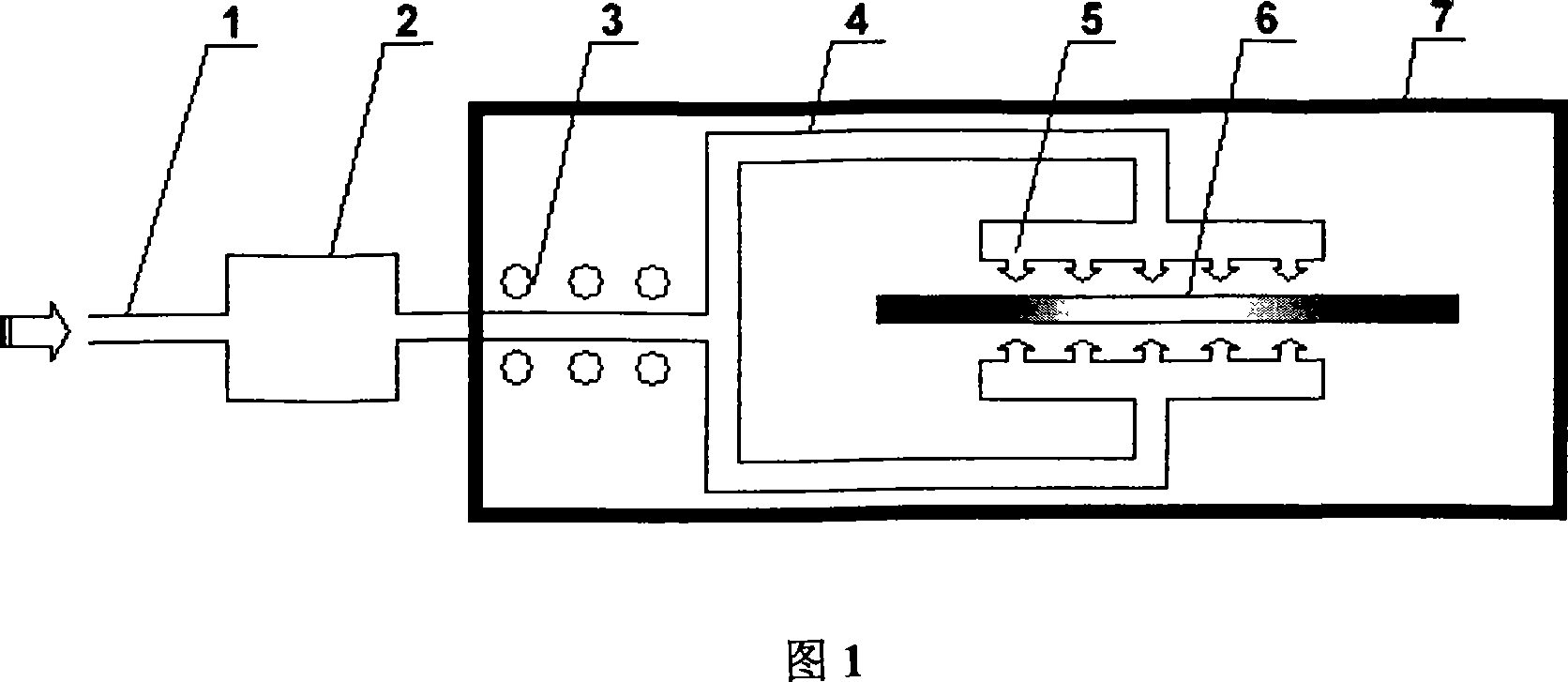

Steel belt lead-bath quenching and backfire product line decarburization technique and device thereof

InactiveCN101054620AImprove plasticityReduce plasticityFurnace typesHeat treatment bathsProduction lineSurface layer

A surface decarburation technology in the process of metal strip plumbum quenching-tempering and apparatus are provided. The process comprises humidifying the protective gas to make the protective gas contain a certain vapor in the process of metal strip continuous quenching and heating, doing an oxidation reaction of oxygen in the hot vapor and carbon in the metal strip surface layer to obtain the objective of metal strip surface decarburation and the ecarburation layer about 5 mum thickness on the metal strip surface and improve the metal strip plastic nature obviously. Meanwhile, there has no distinct oxidation on the metal strip surface. The metal strip by decarburation treatment will not breakdown or appears crack by 180 DEG bending so as to effectively improve the rate of finished products and quality of the metal strip.

Owner:奉化市光亮热处理电炉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com