Heat treatment process of welded type weighted drill rod joint

A drill pipe joint and welding technology, applied in heat treatment baths, heat treatment furnaces, heat treatment equipment, etc., can solve problems such as cracking, achieve the effects of preventing cracking, controlling quenching and cooling speed, and improving stability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

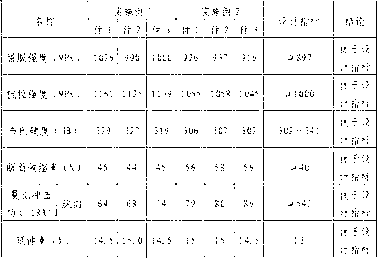

Embodiment 1

[0014] In this embodiment, the diameter of the welded heavy drill pipe joint is φ170mm, and the material is AISI4145. The supporting heat treatment process is carried out according to the following steps: a. The end is facing down, and the distance between the periphery and the upper layer is 40 mm. b. Quenching: b1. After the furnace temperature rises to 875°C, keep it warm for 80 minutes. b2. Stir the prepared KR218 quenching oil 10 minutes before the workpiece is released from the furnace, and the oil temperature is controlled at 80°C±1°C. b3. The workpiece is taken out from the back chamber of the furnace and put into the quenching oil for quenching, and the workpiece is cooled in the quenching oil for 12 minutes. c. Tempering: c1. The workpiece is tempered within 3.5 hours after quenching. The temperature of the tempering furnace is raised to 615°C and kept for 140 minutes; c2. The workpiece is taken out of the tempering furnace and put into a water tank to cool to room ...

Embodiment 2

[0016] In this embodiment, the diameter of the welded heavy drill pipe joint is φ130mm, and the material is AISI4145. The matching heat treatment process is carried out according to the following steps: a. The end is facing down, and the distance between the periphery and the upper layer is 26mm. b. Quenching: b1. Heat the temperature of the furnace to 865°C for 60 minutes. b2. Stir the prepared KR218 quenching oil 5 minutes before the workpiece comes out of the furnace, and the oil temperature is controlled at 80°C±1°C. b3. The workpiece is taken out from the back chamber of the furnace and put into the quenching oil for quenching, and the workpiece is cooled in the quenching oil for 10 minutes. c. Tempering: c1. The workpiece is tempered within 3.5 hours after quenching. The temperature of the tempering furnace is raised to 605°C and kept for 120 minutes; c2. The workpiece is taken out of the tempering furnace and put into a water tank to cool to room temperature.

[0017]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com