Steel wire for springs, and spring

A steel wire quality technology, applied in the field of spring steel wire and high-strength spring steel wire, can solve the problems of low elastic weakening resistance, spring recovery force reduction, insufficient elastic weakening resistance technology, etc., to achieve durability Excellent elastic weakening property and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

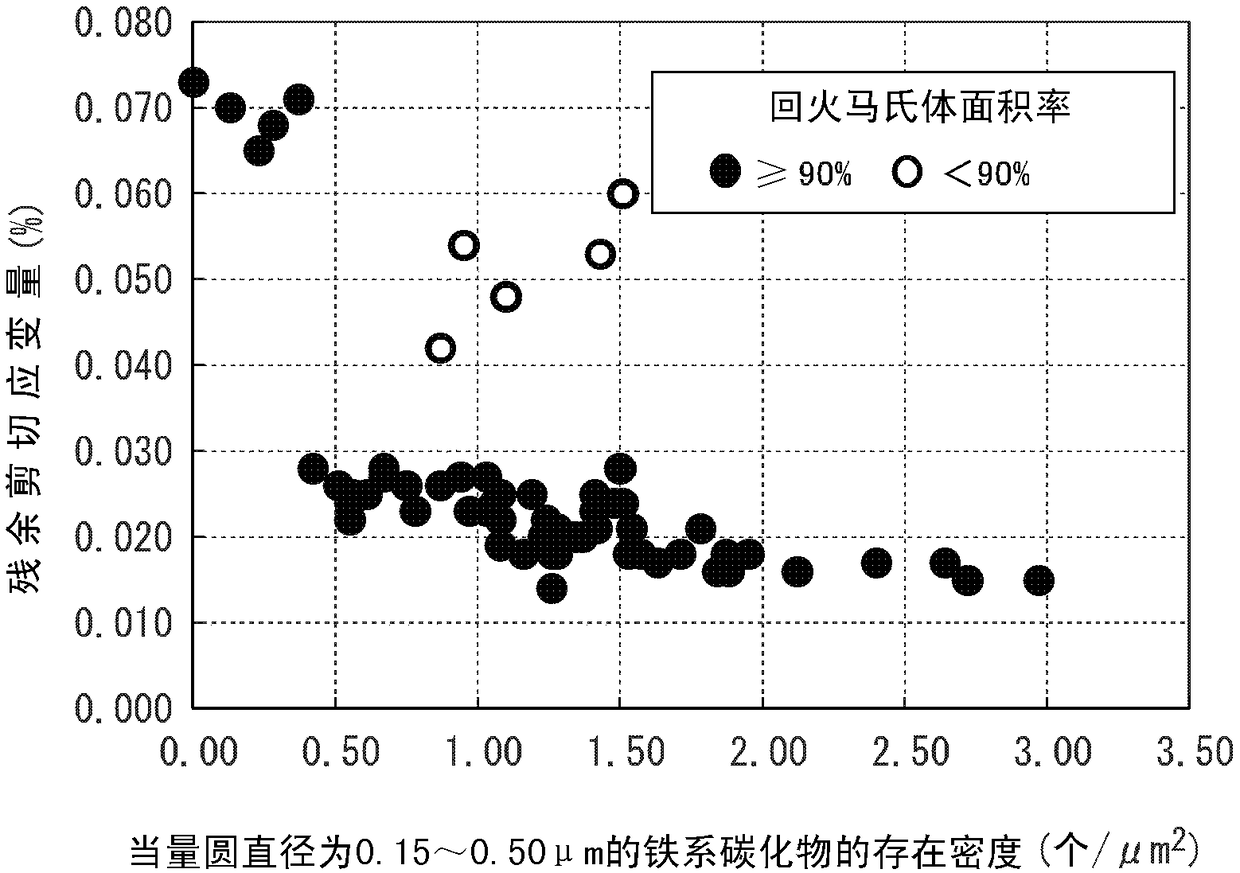

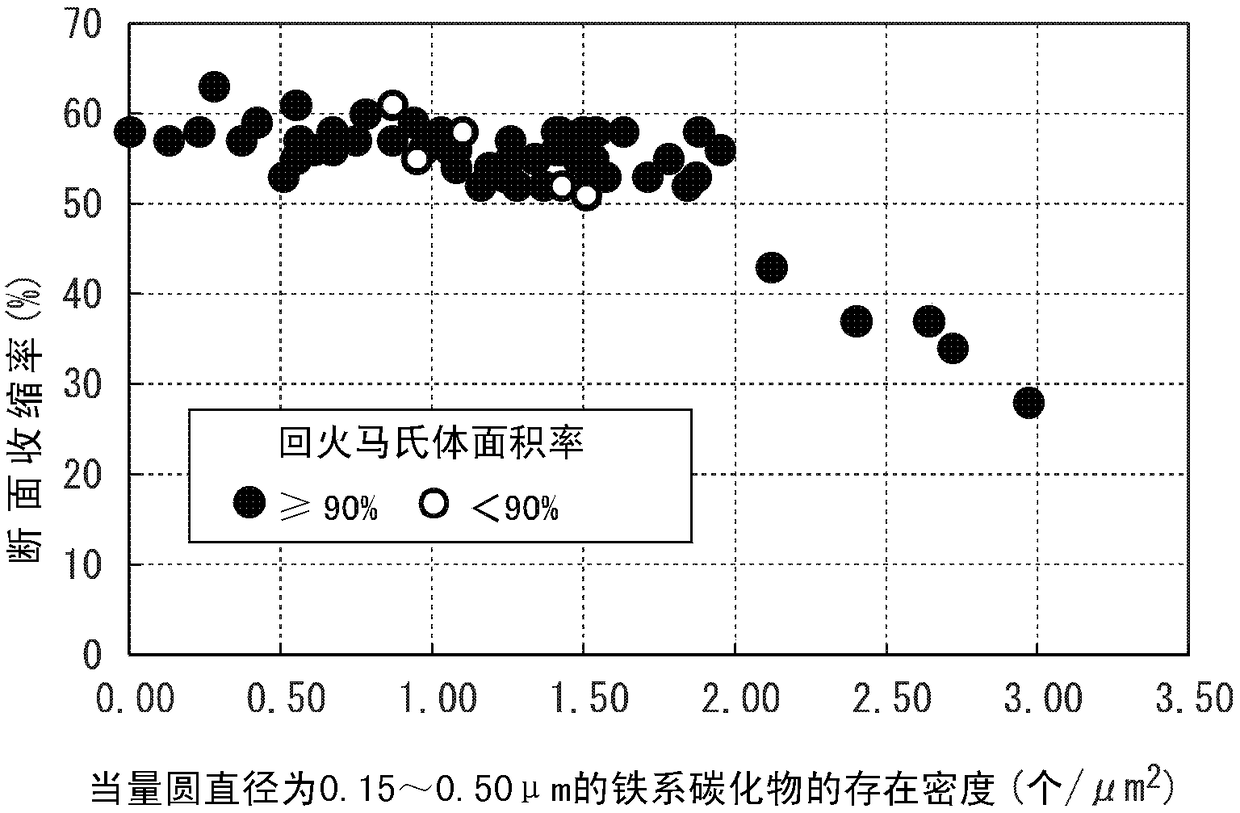

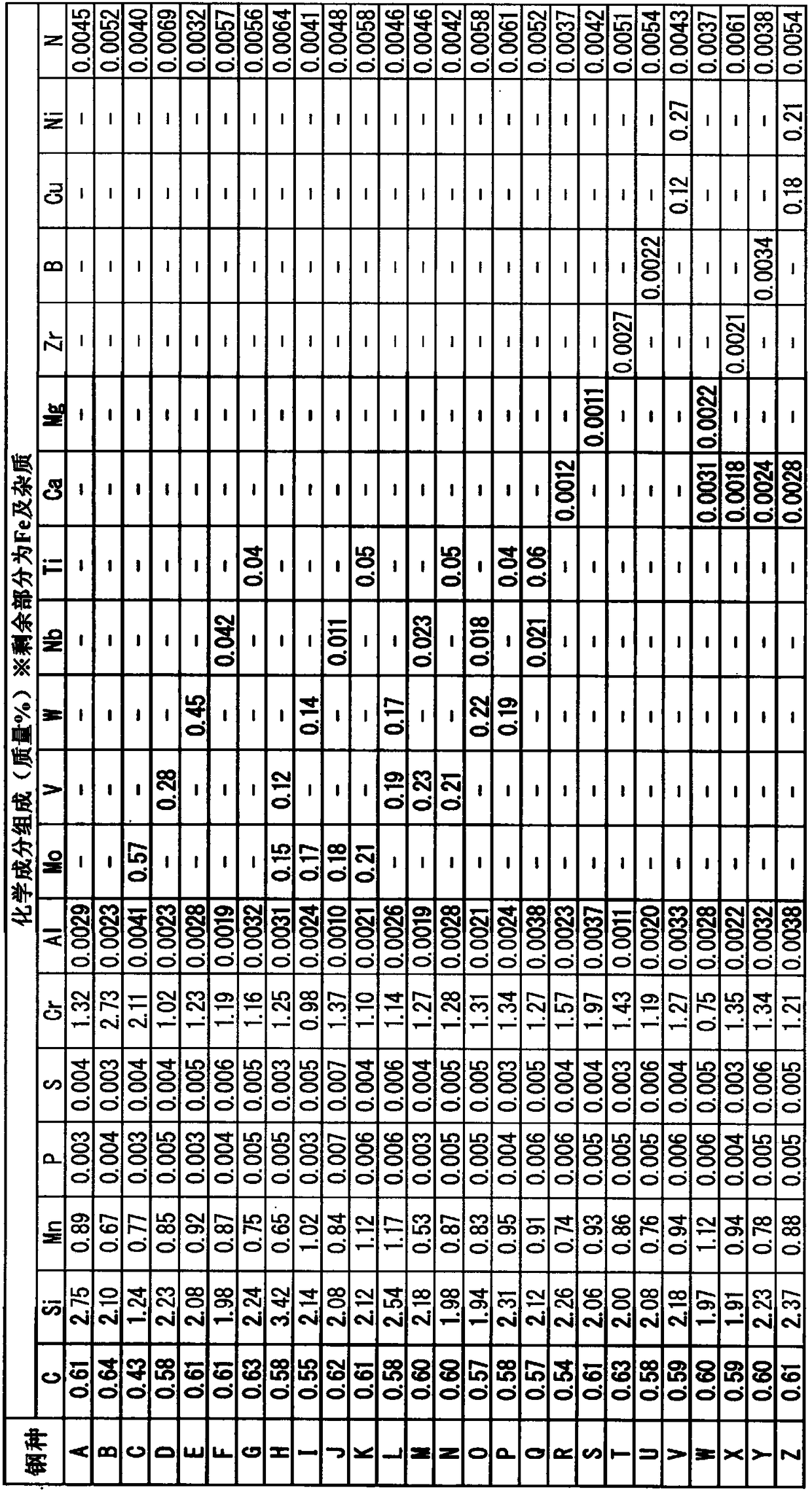

[0093] Converter cast steels having the compositions shown in steel grades A to Z in Table 1 and steel grades AA to AV in Table 2 were continuously cast, and if necessary, passed through a soaking diffusion treatment process and a billet rolling process to produce 162 mm Square rolled raw material. Thereafter, it was heated to 1150° C. and hot rolled to form a φ8.0 mm steel wire rod. The surface of the steel wire rod was peeled to φ7.4 mm, heated to 950° C., and then lead quenching was performed at the temperatures shown in Tables 3 and 4. After cold drawing to φ4.0mm, quenching and tempering were performed, and the heating temperature before quenching was changed within the range shown in Tables 3 to 4, thereby manufacturing the size of the iron-based carbides in each steel wire and density of existence. In addition, by using a water-soluble quenching liquid (liquid temperature: 40° C.), adjusting the degree of stirring (0 to 50 cm / sec), and changing the cooling rate, each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com