Bimetallic bainite-martensite complex phase steel wear-resistant liner and preparation method thereof

A wear-resistant liner and bainite technology, which is applied in the field of metal material casting, can solve the problems that the hardness of the wear layer is difficult to control, the toughness of the matrix layer is difficult to control, the liner is not easy to control, and the composition of the liner is single, so as to achieve excellent comprehensive mechanical properties, good The effect of comprehensive mechanical properties and simple heat treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

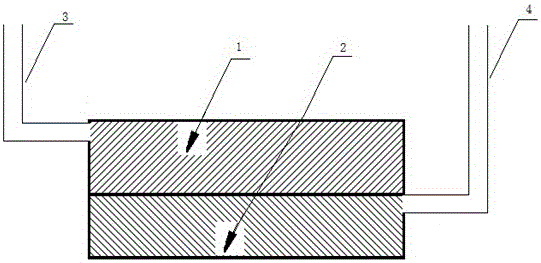

Image

Examples

Embodiment 1

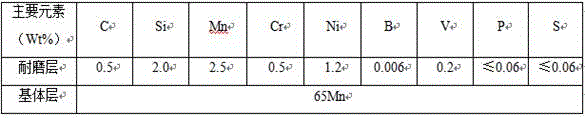

[0022] In this example, a bimetallic bainite-martensite composite phase wear-resistant lining plate with a thickness of 300mm was prepared, the wall thickness of the wear-resistant layer was 100mm, and the wall thickness of the matrix layer was 200mm; the chemical composition of the two-layer materials is shown in Table 1

[0023] Table 1

[0024]

[0025] The preparation method of the bimetallic bainite-martensite composite phase wear-resistant lining plate described in this embodiment specifically includes the following steps:

[0026] (1) Melting: According to the composition of the outer layer and the inner layer, the ingredients are mixed, and the intermediate frequency induction furnace is used for melting respectively.

[0027] (2) Layered casting: First, pour the inner molten steel through the inner sprue into the cavity with the chilled layer installed at the bottom, the casting temperature is 1480°C; when cooled to 1300°C, pour the outer layer of molten steel, Th...

Embodiment 2

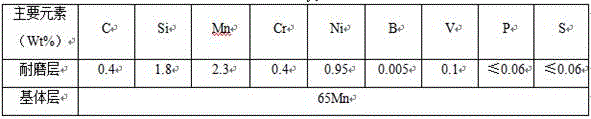

[0032] In this example, a bimetallic bainite-martensite composite phase wear-resistant lining plate with a thickness of 300 mm was prepared, the wall thickness of the wear-resistant layer was 150 mm, and the wall thickness of the matrix layer was 150 mm; the chemical composition of the two layers of materials is shown in Table 2

[0033] Table 2

[0034]

[0035] The preparation method of the bimetallic bainite-martensite composite phase wear-resistant lining plate described in this embodiment specifically includes the following steps:

[0036] (1) Melting: According to the composition of the outer layer and the inner layer, the ingredients are mixed, and the intermediate frequency induction furnace is used for melting respectively.

[0037] (2) Layered casting: firstly pour the inner molten steel through the inner sprue into the cavity where the cooling layer is installed at the bottom, the casting temperature is 1500°C; when cooled to 1325°C, then pour the outer layer of ...

Embodiment 3

[0042] In this example, a bimetallic bainite-martensite composite wear-resistant lining plate with a thickness of 300 mm was prepared, the wall thickness of the wear-resistant layer was 125 mm, and the wall thickness of the matrix layer was 175 mm; the chemical composition of the two layers of materials is shown in Table 3

[0043] table 3

[0044]

[0045] The preparation method of the bimetallic bainite-martensite composite phase wear-resistant lining plate described in this embodiment specifically includes the following steps:

[0046] (1) Melting: According to the composition of the outer layer and the inner layer, the ingredients are mixed, and the intermediate frequency induction furnace is used for melting respectively.

[0047] (2) Layered casting molding: First, pour the inner molten steel through the inner sprue into the cavity with the chilling layer installed at the bottom, the casting temperature is 1520°C; when cooled to 1350°C, pour the outer layer of molten ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com