2400-MPa-strength prestressed steel strand and production process thereof

A technology of prestressed steel strand and production process, which is applied in metal material coating process, manufacturing tools, temperature control, etc., can solve problems such as difficult production, and achieve the effect of improving tissue uniformity and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A prestressed steel strand with a strength of 2400MPa, its chemical composition includes C0.92%, Si1.20%, Mn0.80%, Cr0.010%, P0.003%, S0.33%, Al0. 0.011%, V0.032%, and the rest are Fe and unavoidable impurities. The diameter of the steel strand is 13 or 14mm.

[0047] The preferred raw material for steel strand production is air-cooled and hot-rolled wire rod with a diameter of Φ14mm and a strength of not less than 1400MPa; the preferred grade of wire rod used is QS92Si-HT, and the C content is 0.9% to 0.95%.

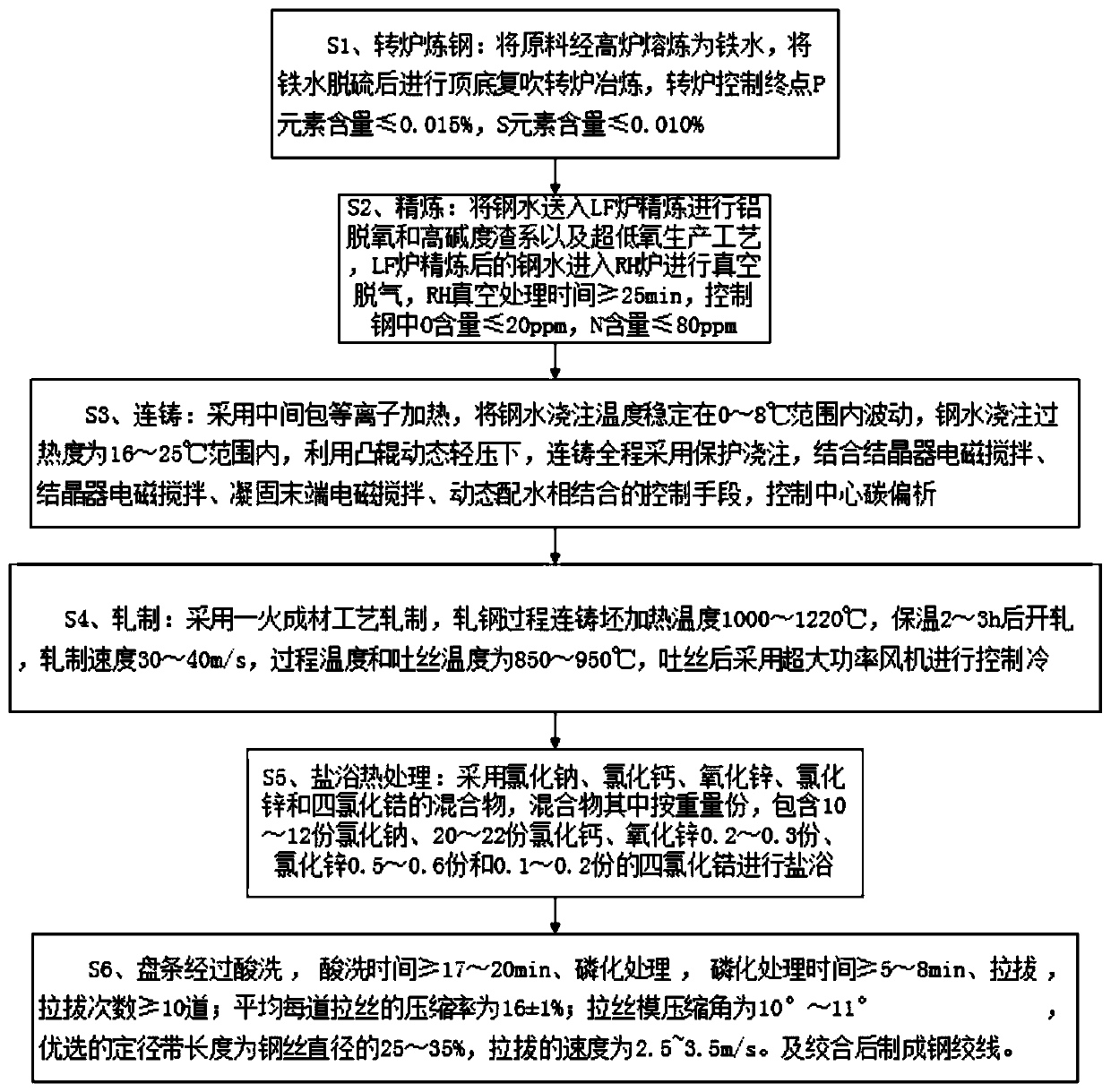

[0048] Such as figure 1 As shown, the production process of 2400MPa grade prestressed steel strand includes the following steps:

[0049] S1. Converter steelmaking: The raw materials are smelted into molten iron by blast furnace, and the molten iron is desulfurized and then smelted in the top-bottom combined blowing converter.

[0050] The raw materials are smelted through blast furnace molten iron→KR or granular magnesium desulfurization→top-bottom combined bl...

Embodiment 2

[0085] A prestressed steel strand with a strength of 2400MPa, its chemical composition includes C0.97%, Si0.80%, Mn0.70%, Cr0.011%, P0.003%, S0.26%, Al0. 0.040%, V0.053%, and the rest are Fe and unavoidable impurities. The diameter of the steel strand is 13 or 14mm.

[0086] The preferred raw material for the production of steel strands is salt bath heat-treated wire rod with a diameter of Φ14mm and a strength of not less than 1500MPa; the preferred grade of wire rod used is PQS92Si-HT and QS92Si after lead bath treatment, and the C content is 0.9%-0.95 %.

[0087] Such as figure 1 As shown, the production process of 2400MPa grade prestressed steel strand includes the following steps:

[0088] S1. Converter steelmaking: The raw materials are smelted into molten iron by blast furnace, and the molten iron is desulfurized and then smelted in the top-bottom combined blowing converter.

[0089]The raw materials are smelted through blast furnace molten iron→KR or granular magnesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com