Production method of large-elongation aluminum clad steel wire

A technology of aluminum-clad steel wire and production method, which is applied in the direction of improving process efficiency, improving energy efficiency, reducing the size of conductors/cables, etc. problems, to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

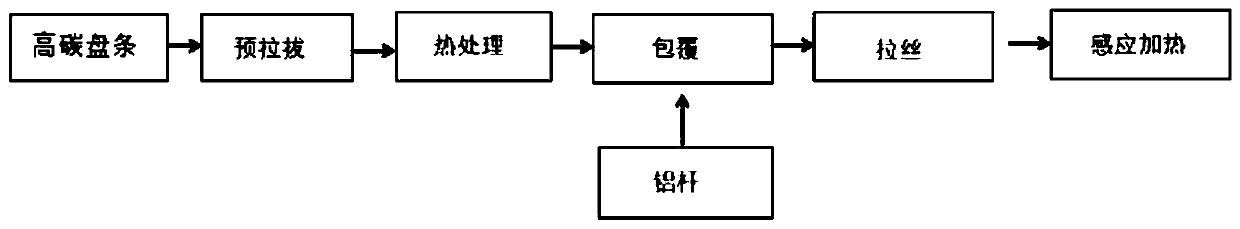

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Production Aluminum-clad steel wire with high strength and large elongation, the specific steps are as follows:

[0029] 1) Derusting and pre-drawing of raw materials: The SWRH87B high-carbon hot-rolled wire rod with a diameter of 5.5mm is mechanically derusted on the surface of the wire rod by repeated bending, and drawn into a diameter by cold drawing abrasive tools. 4.7mm steel wire;

[0030] 2) Heat treatment: the pre-drawn steel wire is austenitized through a coal-fired muffle furnace, the temperature is set at 960°C, and the austenitization holding time is 120s; and isothermally quenched in a lead bath at a temperature of 550°C. The holding time is 65s, and the obtained steel wire has a volume fraction of sorbite structure above 90%;

[0031] 3) pickling: the steel wire with sorbite structure obtained in step 2) is pickled with an industrial synthetic hydrochloric acid solution with a mass concentration of 18% to 25%, to remove the residual lead slag...

Embodiment 2

[0035] Example 2: Production Aluminum-clad steel wire with high strength and large elongation, the specific steps are as follows:

[0036] 1) Derusting and pre-drawing of raw materials: The SWRH87B high-carbon hot-rolled wire rod with a diameter of 5.5mm is mechanically derusted on the surface of the wire rod by repeated bending, and drawn into a diameter by cold drawing abrasive tools. 4.8mm steel wire;

[0037] 2) Heat treatment: the pre-drawn steel wire is austenitized through a coal-fired muffle furnace, the temperature is set at 980°C, and the austenitization holding time is 90s; and isothermally quenched in a lead bath at a temperature of 550°C. The holding time is 70s, and the obtained steel wire has a volume fraction of sorbite structure above 90%;

[0038] 3) pickling: the steel wire with sorbite structure obtained in step 2) is pickled with an industrial synthetic hydrochloric acid solution with a mass concentration of 18% to 25%, to remove the residual lead slag ...

Embodiment 3

[0042] Embodiment 3: As a comparative example of Embodiment 1, it is prepared by low temperature and long time aging treatment Aluminum-clad steel wire, the specific steps are as follows:

[0043] 1) Derusting and pre-drawing of raw materials: The SWRH87B high-carbon hot-rolled wire rod with a diameter of 5.5mm is mechanically derusted on the surface of the wire rod by repeated bending, and drawn into a diameter by cold drawing abrasive tools. 4.7mm steel wire;

[0044]2) Heat treatment: the pre-drawn steel wire is austenitized through a coal-fired muffle furnace, the temperature is set at 970°C, and the austenitization holding time is 100s; and it is austenitized through a lead bath at a temperature of 550°C. The holding time is 65s, and the obtained steel wire has a volume fraction of sorbite structure above 90%;

[0045] 3) pickling: the steel wire with sorbite structure obtained in step 2) is pickled with an industrial synthetic hydrochloric acid solution with a mass co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com