Steel wire for non-thermal-refined machine component, and non-thermal-refined machine component

A non-quenched and tempered technology for mechanical parts, applied in the direction of mechanical equipment, connecting components, threaded fasteners, etc., can solve problems such as fracture and easy decline in hydrogen embrittlement resistance, and achieve excellent tensile strength and hydrogen embrittlement resistance, Excellent cold workability and excellent hydrogen embrittlement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0293] Examples of the present application are shown below, but the present application is not limited to the following examples.

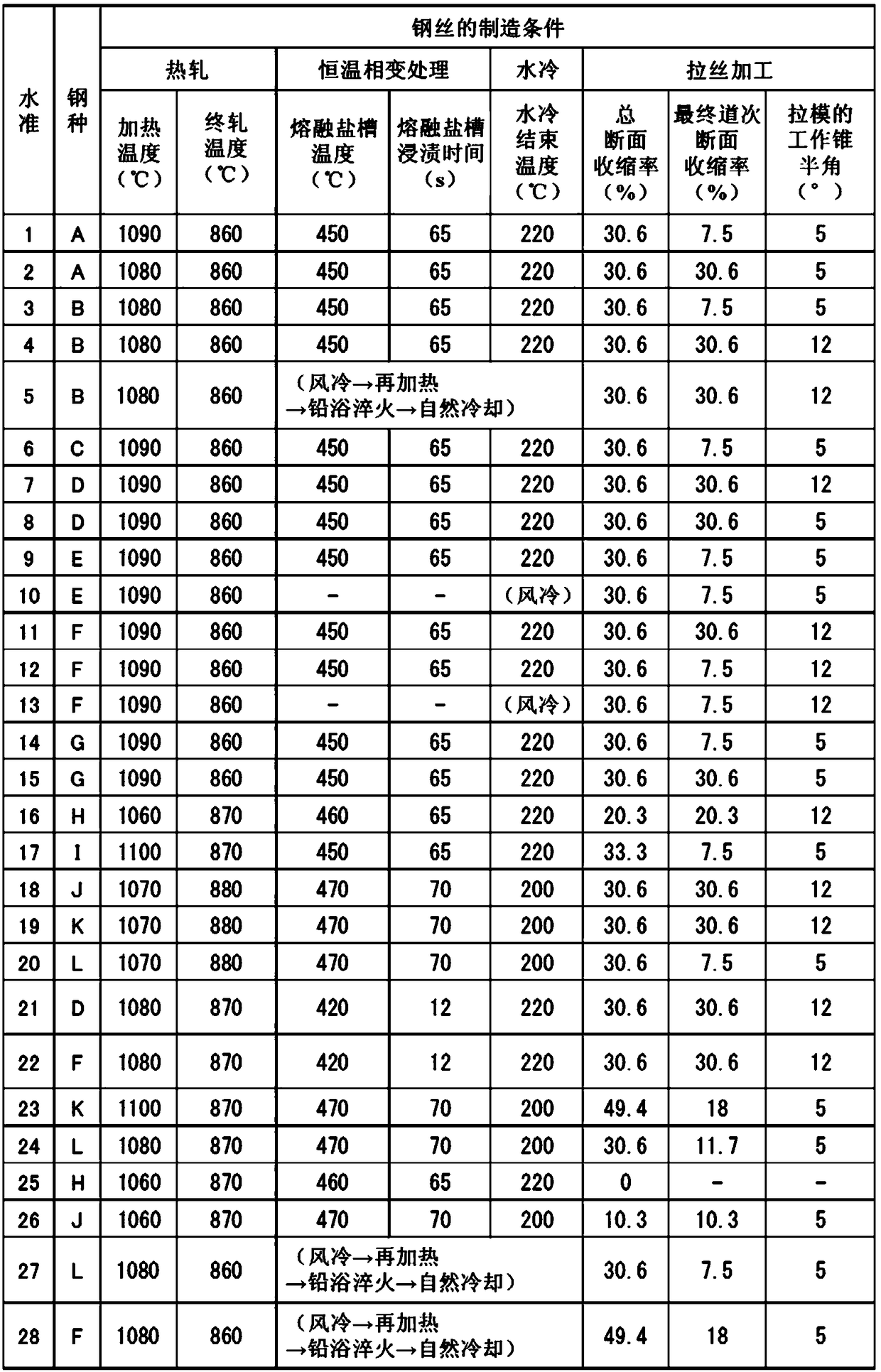

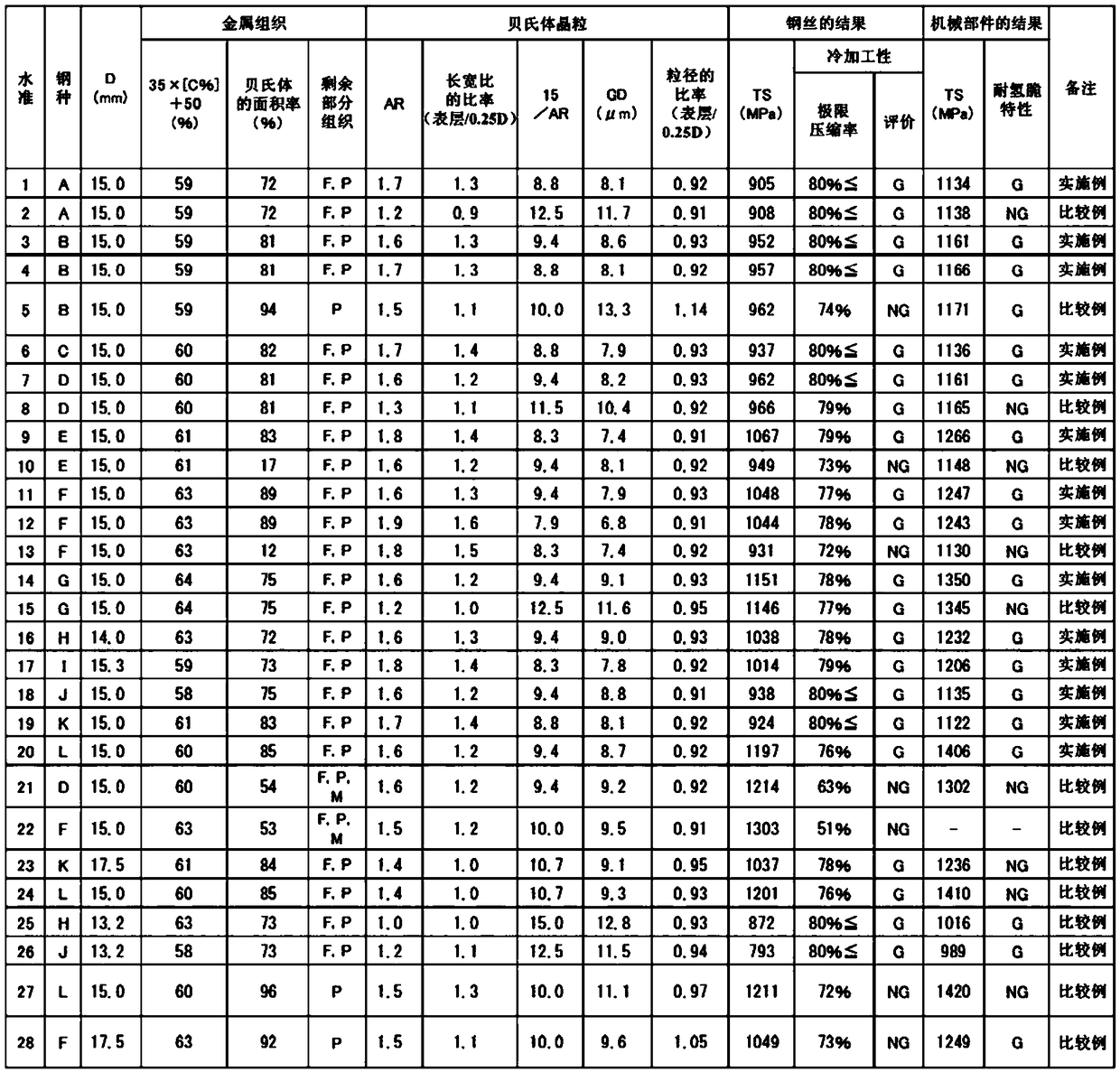

[0294] 〔Level (condition) 1~28〕

[0295]

[0296] Using billets with the chemical compositions shown in Table 1, steel wires with diameters (D) shown in Table 3 were produced.

[0297] In the chemical composition of each steel type in Table 1, the balance other than the elements shown in Table 1 is Fe and impurities.

[0298] For levels 1-4, 6-9, 11, 12 and 14-26, the diameter (D ) Steel wires as shown in Table 3.

[0299] For levels 5, 27, and 28, hot rolling under the conditions shown in Table 2 is carried out on the billet, followed by air cooling, reheating at a heating temperature of 950°C, and lead bathing at a lead bath temperature of 580°C. Quenching and natural cooling, followed by wire drawing under the conditions shown in Table 2, gave steel wires with diameters (D) shown in Table 3.

[0300] For levels 10 and 13, the diameter (D)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com