Beta type titanium alloy and manufacturing method thereof

a titanium alloy and manufacturing method technology, applied in the field of beta type titanium alloy, can solve the problems of inability to always stably obtain cold workability and age strengthen ability, and no remarkable influence of the variation of the main elements of this alloy, and achieves excellent cold workability, high strength, and easy and stably realizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

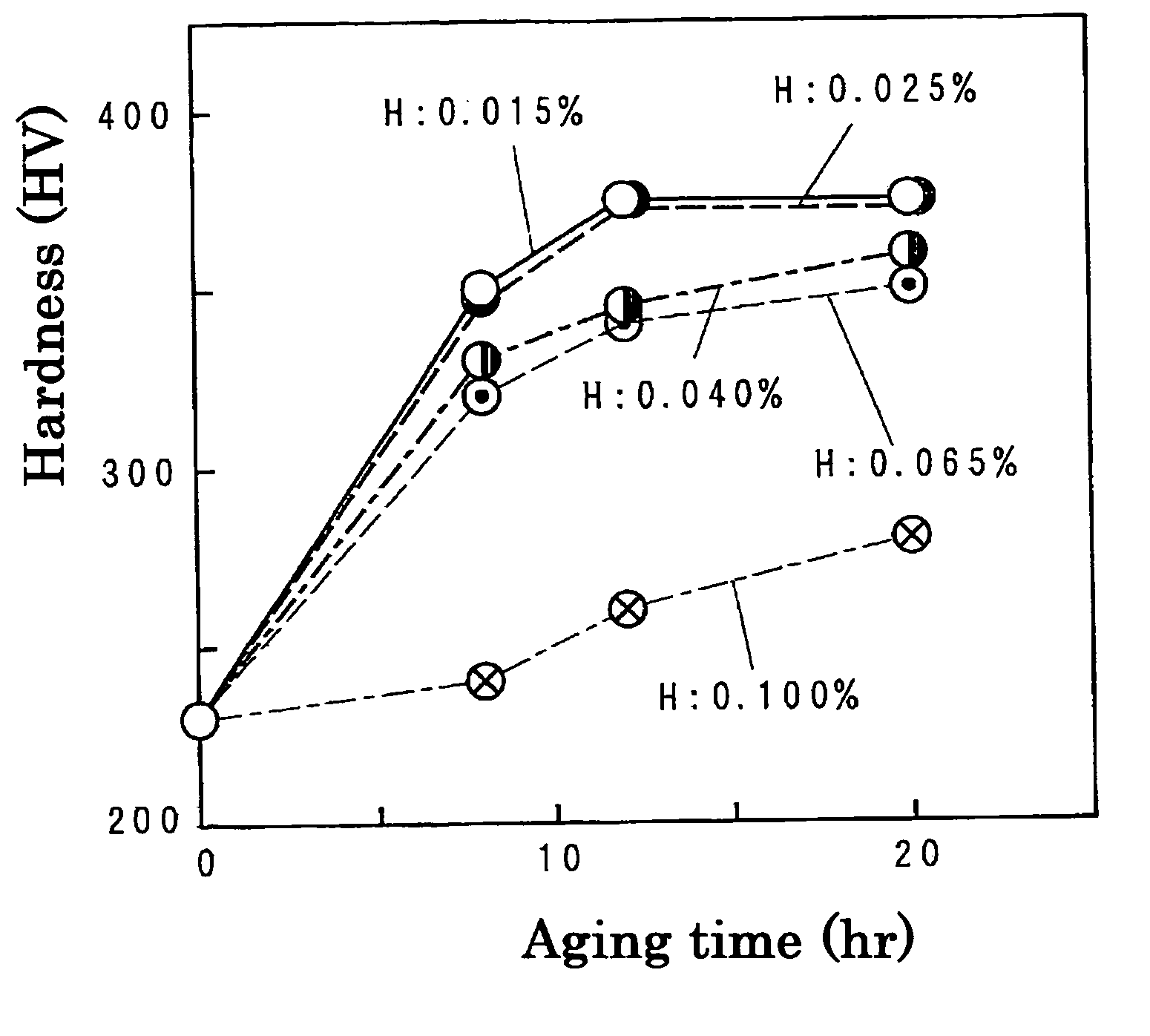

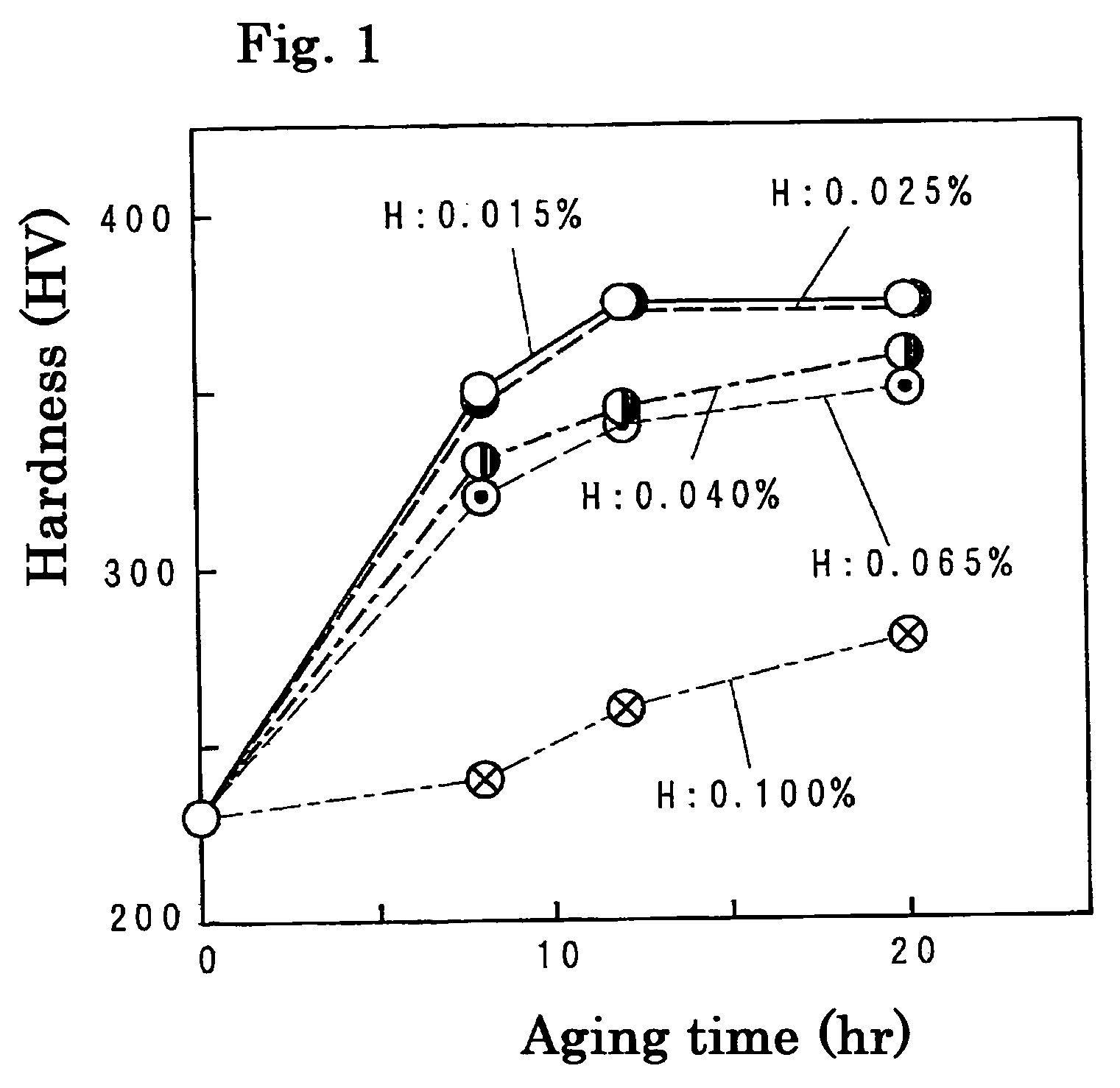

[0081] Titanium alloys which have compositions shown in Tables 1 and 2 were melted in a vacuum arc melting furnace with a water-cooled copper crucible consumable-electrode, and produced ingots which are 140 mm in diameter. The ingots were heated to 1000° C. followed by hot forging to form hot rolled materials 50 mm in thickness and 150 mm in width. These materials were heated to 950° C. followed by hot rolling, and the rolling ended at 800° C. They were immediately cooled to 300° C. at an average cooling rate of 200° C. / min by a water spray cooling method, and allowed to stand cool. The resulting hot rolled plates were subjected to a solution treatment of “heating at 880° C. for 10 minutes followed by water cooling”.

[0082] After the solution treatment, the plates were shot blasted, dipped for 4 minutes in an aqueous solution of 30° C. fluoric acid including 4 mass % of HF, and successively dipped for 10 minutes in an aqueous solution of 30° C. of nitric fluoric acid including 10 ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com