Excellent Cold-Workability Exhibiting High-Strength Steel Wire or Steel Bar or High-Strength Shaped Article, and Process for Producing Them

a high-strength steel wire or steel bar technology, applied in the field of excellent cold workability exhibiting high-strength steel wire or steel bar or high-strength shaped articles, can solve the problems of large loss of heat energy, long time, and the shape of the article is subject to thermal refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1 and example 2

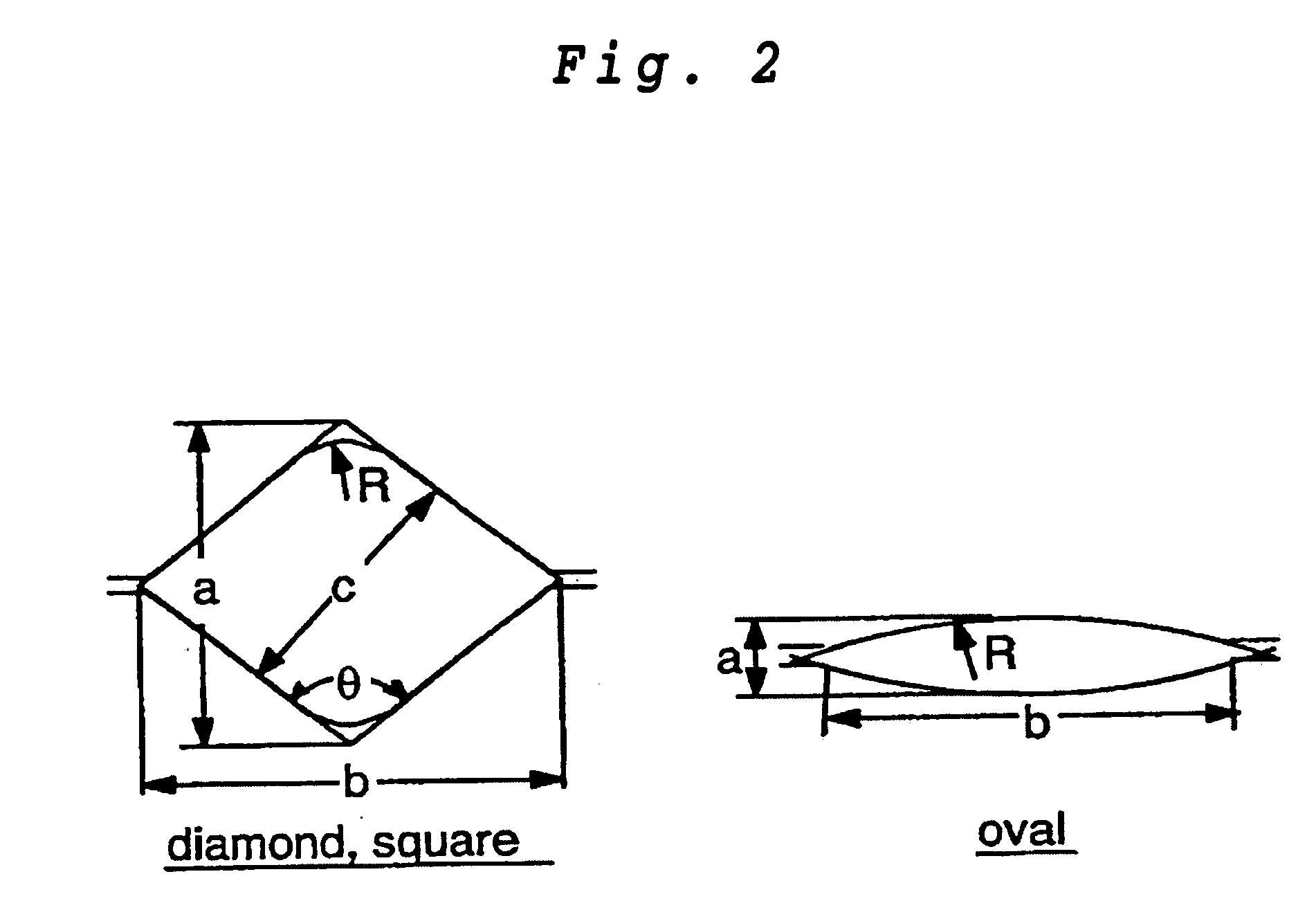

[II] (1)-1) Common Test Between Example 1 and Example 2 (Warm Rolling Step and Characterization Test of Test Material Obtained)

[0087]Example 1 and Example 2 were tested as follows. A steel having the chemical component composition shown in Table 1 was melted using a vacuum melting furnace, and cast into a steel ingot. This chemical component composition is, for example, that, in the chemical component composition defined by SWRCH5A belonging to the carbon steel wire rod for cold heading according to JIS G 3507, having Si content of 0.10 mass % or less, Si contains 0.30 mass % exceeding the Si content. However, there is the characteristic in the point that C content is low 0.0245 mass %.

TABLE 1Chemical component composition (mass %)SuppliedCSiMnPSNsol. AlExample 10.02450.300.200.0100.0010.00180.032Example 2

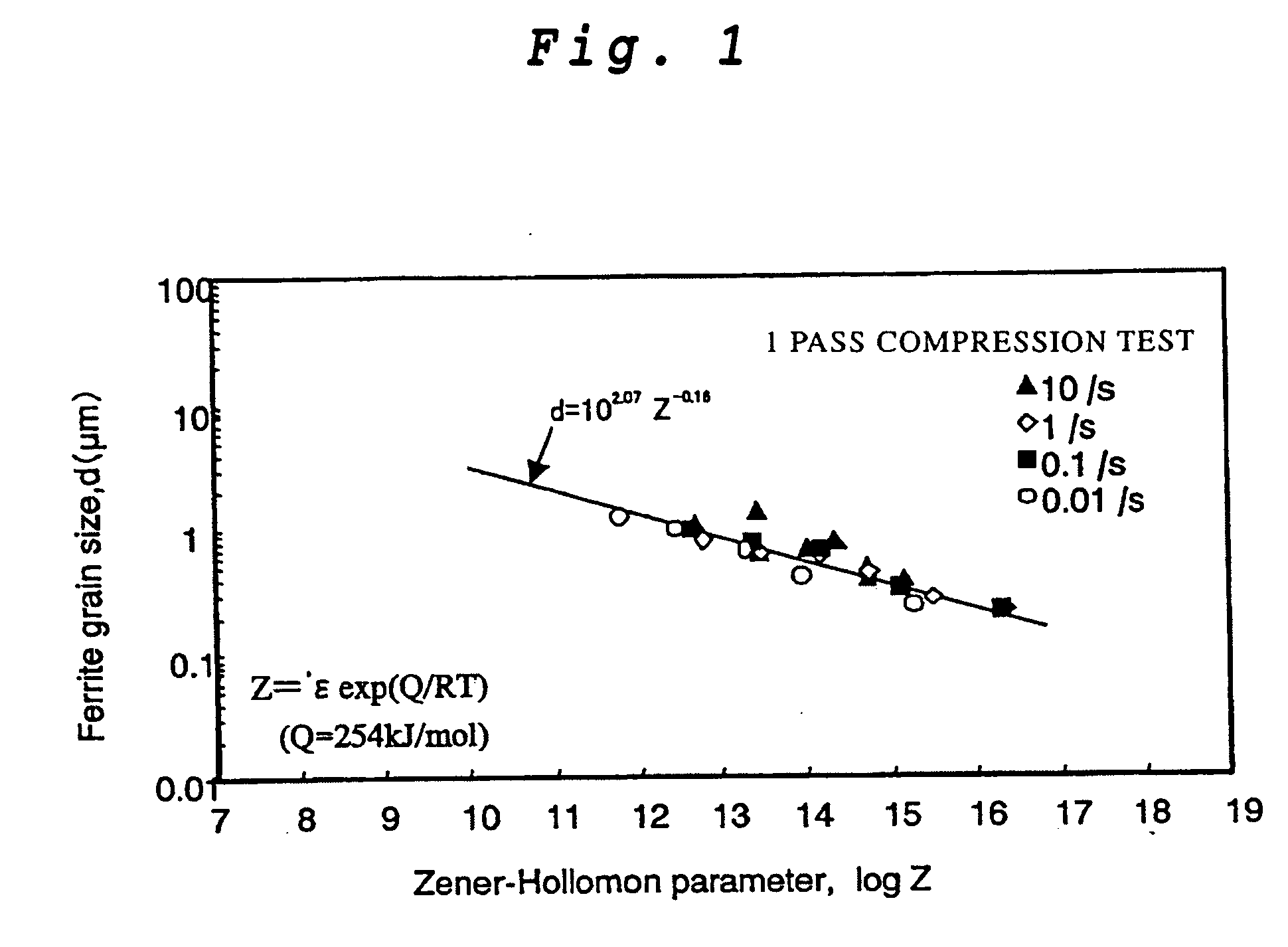

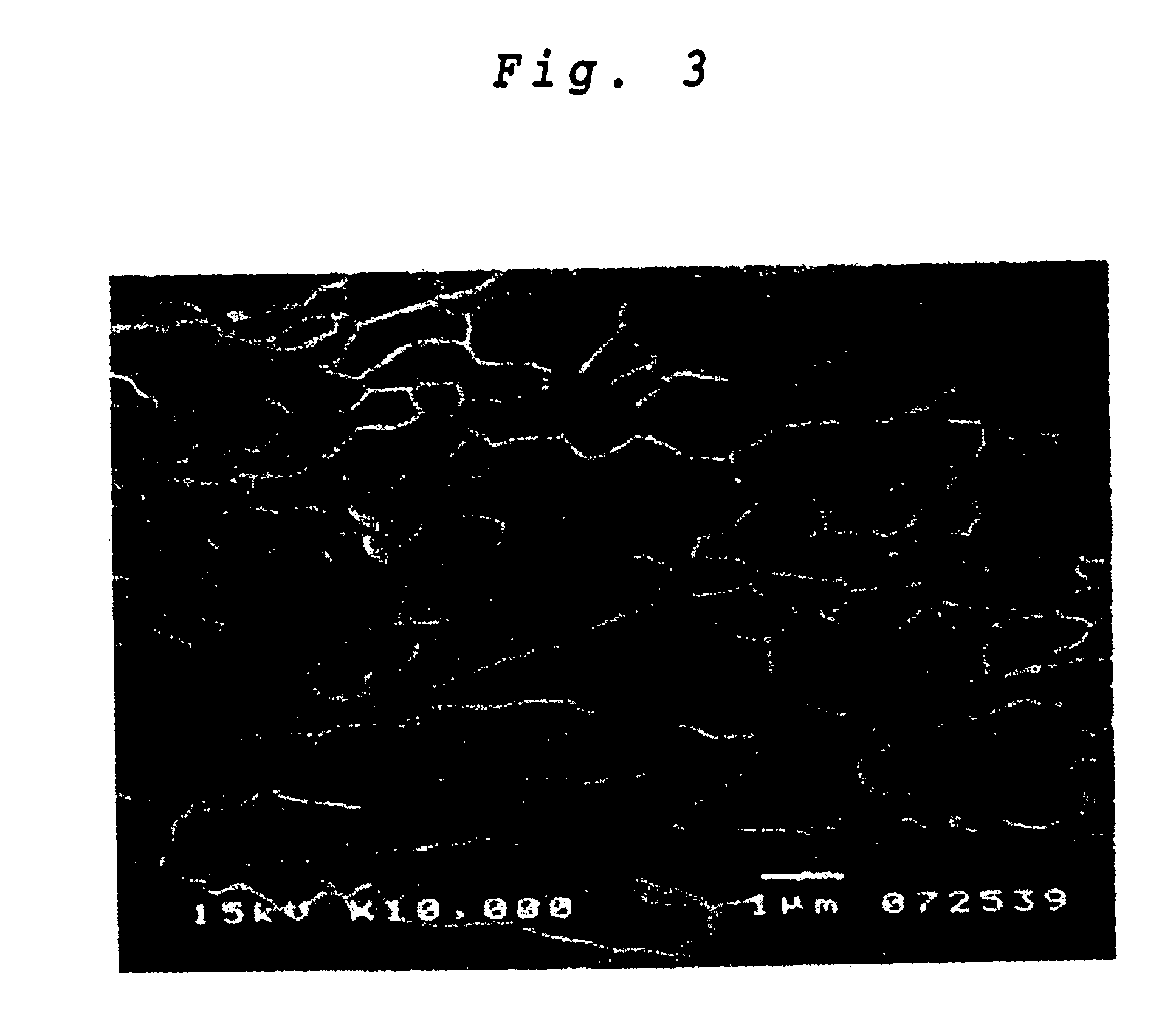

[0088]The steel ingot obtained above was shaped into a steel bar of 80 mm square by hot forging. Metal structure of those steel bars was ferrite main phase, and the average grain s...

example 3

[0123]As Example 3 within the scope of the invention of this application, the following test was conducted. A commercially available steel wire rod of 13 mm diameter belonging to SWRCH5A of the carbon steel wire rods for cold heading defined in JIS G 3507, having the chemical component composition shown in Table 8, and produced by hot rolling was used. The component of this steel wire rod has carbon C of 0.03 mass %, and is similar to the component composition of the steels used in Example 1 and Example 2. However, Si content of the steel used in Example 3 is 0.03 mass %, differing from Si=0.30 mass % in Examples 1 and 2, and satisfies the Si content provision (Si≦0.10 mass %) of SWRCH5A.

TABLE 8JISChemical component composition (mass %)correspondingsol.Suppliedto componentCSiMnPSAlExample 3SWRCH5A0.030.030.200.0160.0100.035

[0124]The above hot rolled steel wire of 13 mm diameter was worked into a steel wire rod of 6.0 mm diameter by multidirection and multipass warm rolling with cali...

examples 1 to 9

being fallen within the scope of the invention of this application were tested as follows.

[0164]Each of steels having the chemical component composition of component Nos. 1 to 5 shown in Table 16 was melted using a vacuum melting furnace, and cast into a steel ingot. The compositional characteristics here are that it is an ultra-low carbon steel in which carbon C is changed within a range of C content of from 0.0014 to 0.0109 mass %, component No. 4 has high level of Si=1.01 mass % as compared with others, and component No. 5 has N=0.0080 mass % which is relatively high as compared with others.

TABLE 16Chemical componentComponentcomposition (mass %)No.SuppliedCSiMnPSNSol. Al1Examples0.00140.300.200.0090.0010.00310.0281 and 62Examples0.00470.300.200.0090.0010.00240.0262 and 73Examples0.00980.300.200.0090.0010.00250.0283 and 84Examples0.01091.010.190.0100.0010.00200.0334 and 95Example 50.00950.300.190.0090.0010.00800.029

[0165]The steel ingots obtained were shaped into a steel bar of 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com