Patents

Literature

81 results about "Characterization test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In computer programming, a characterization test (also known as Golden Master Testing) is a means to describe (characterize) the actual behavior of an existing piece of software, and therefore protect existing behavior of legacy code against unintended changes via automated testing. This term was coined by Michael Feathers.

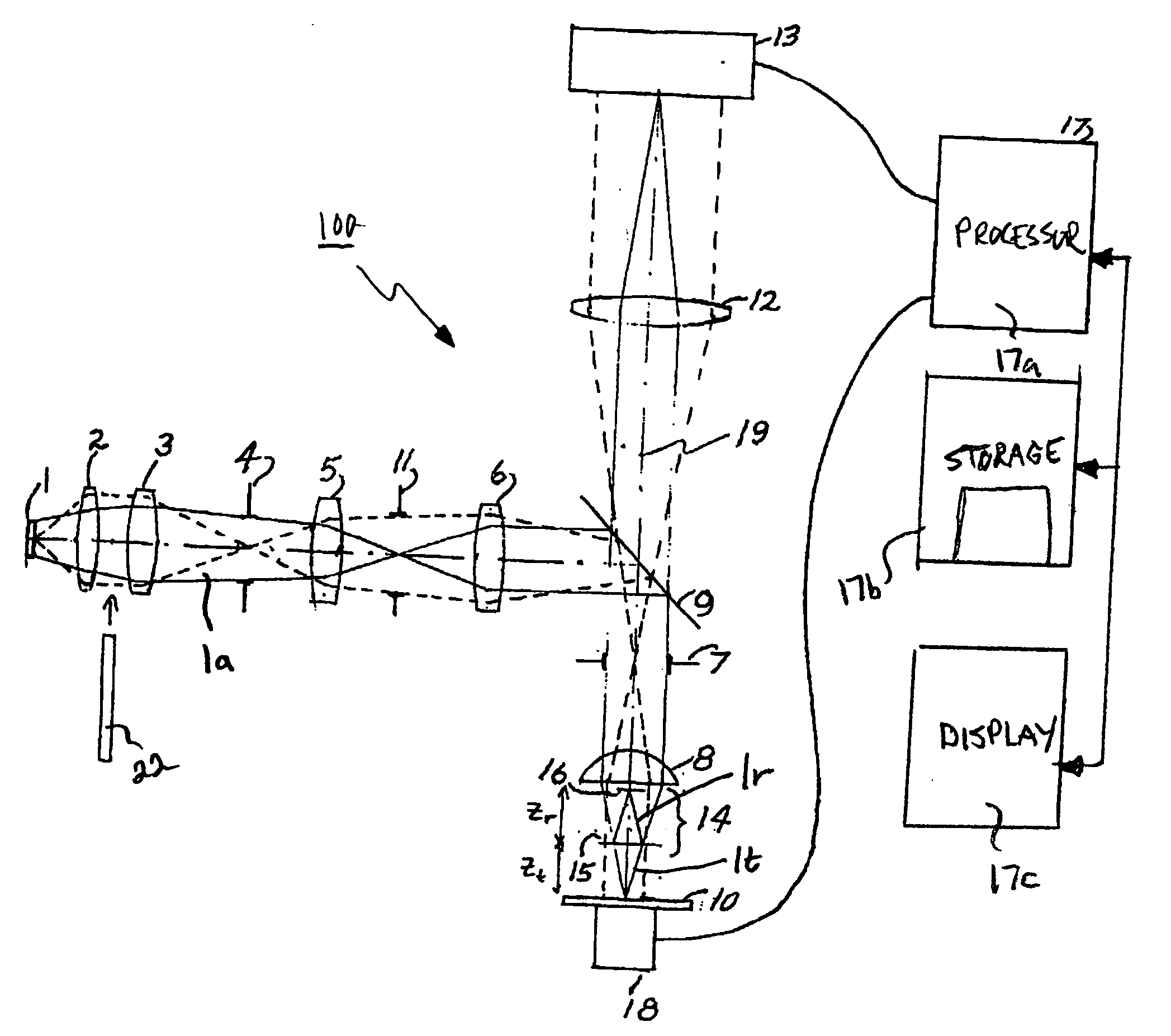

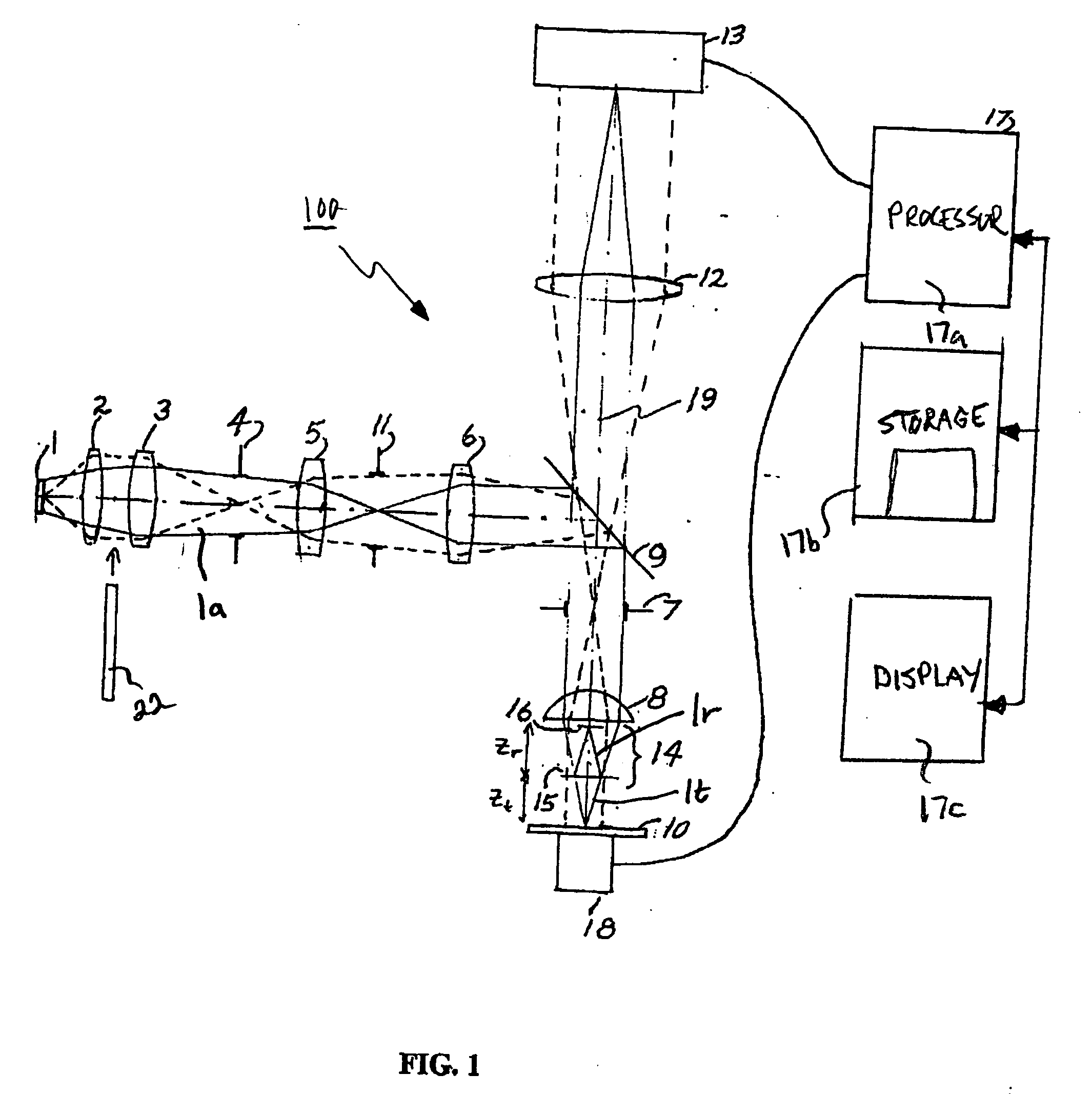

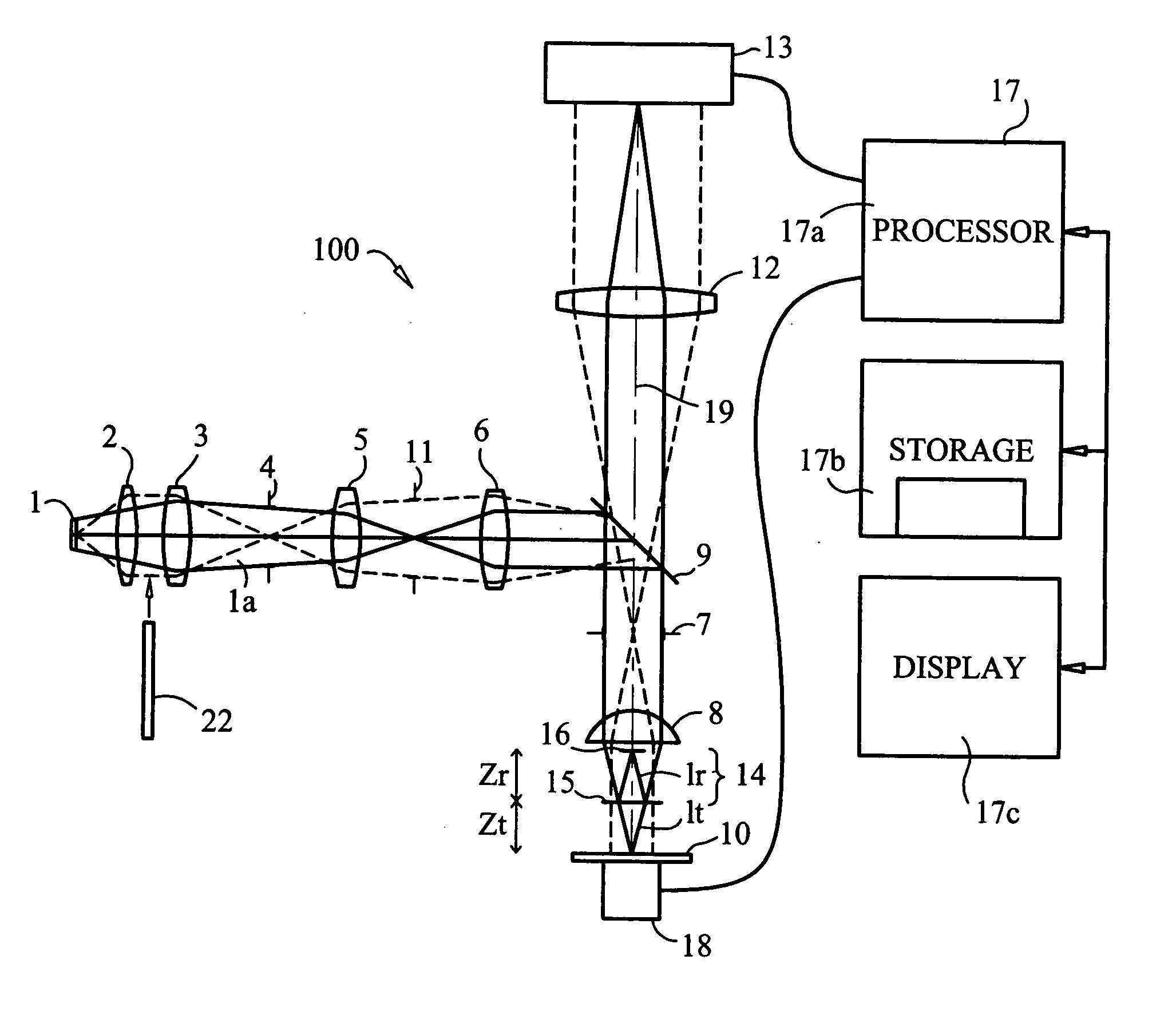

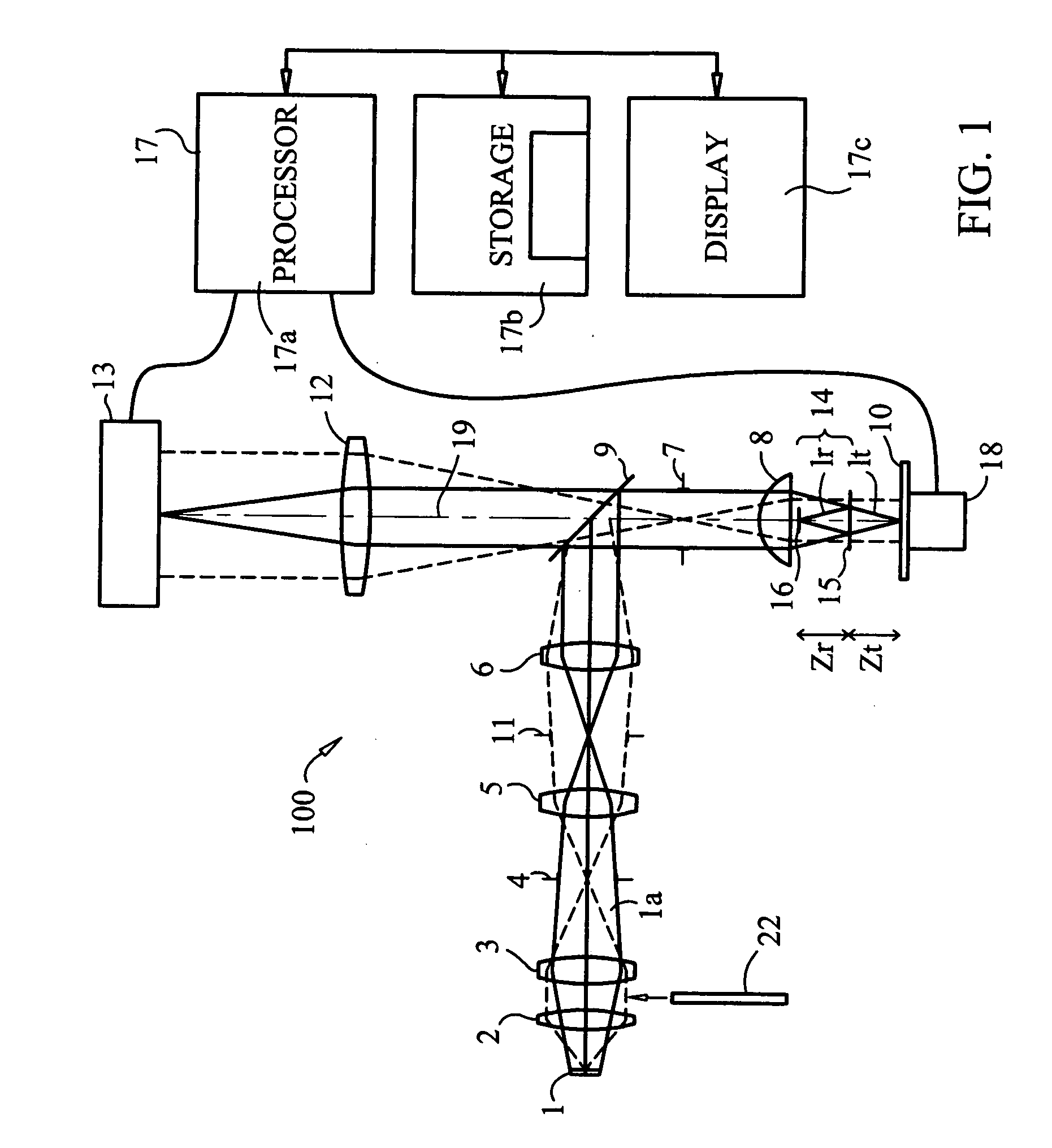

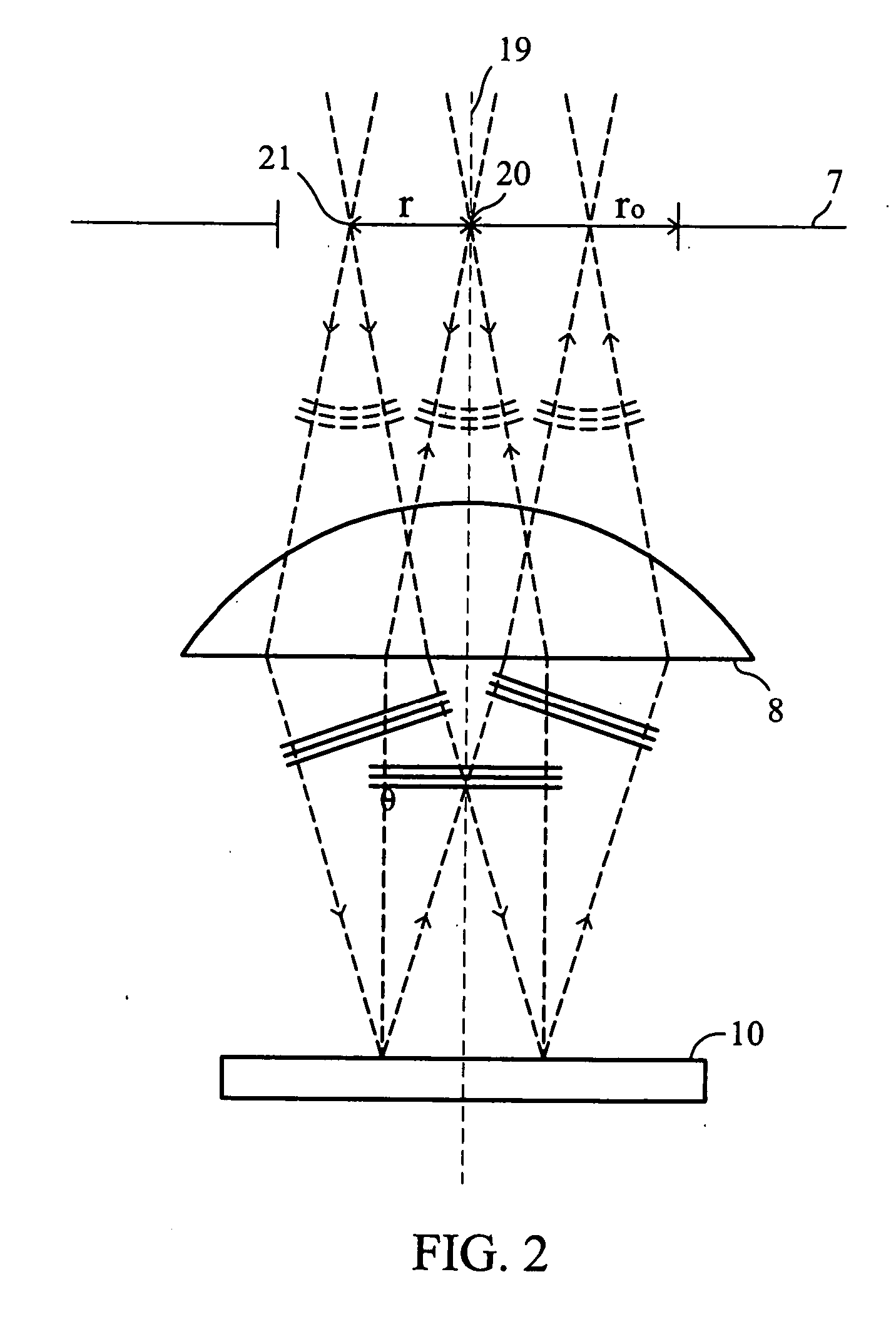

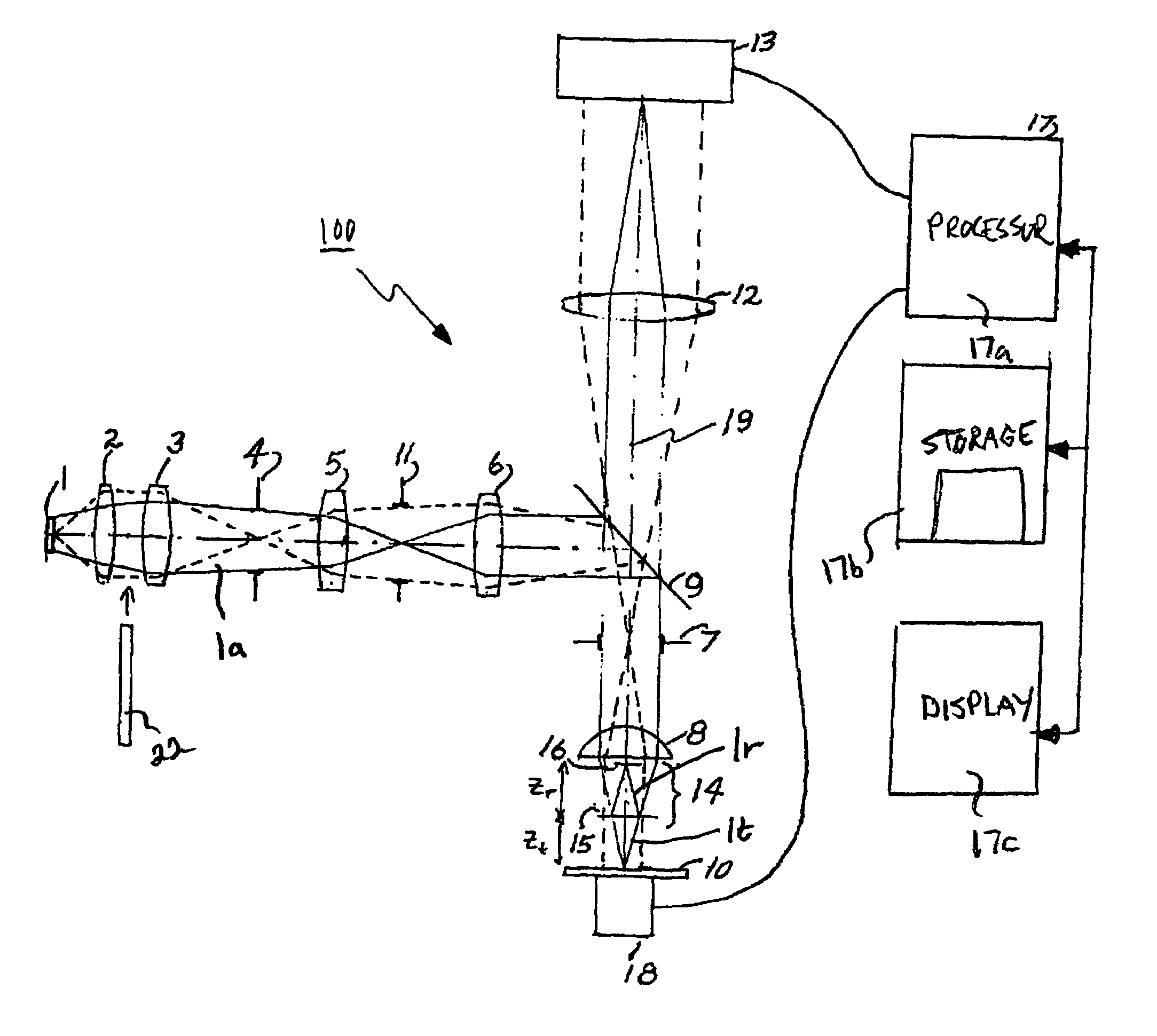

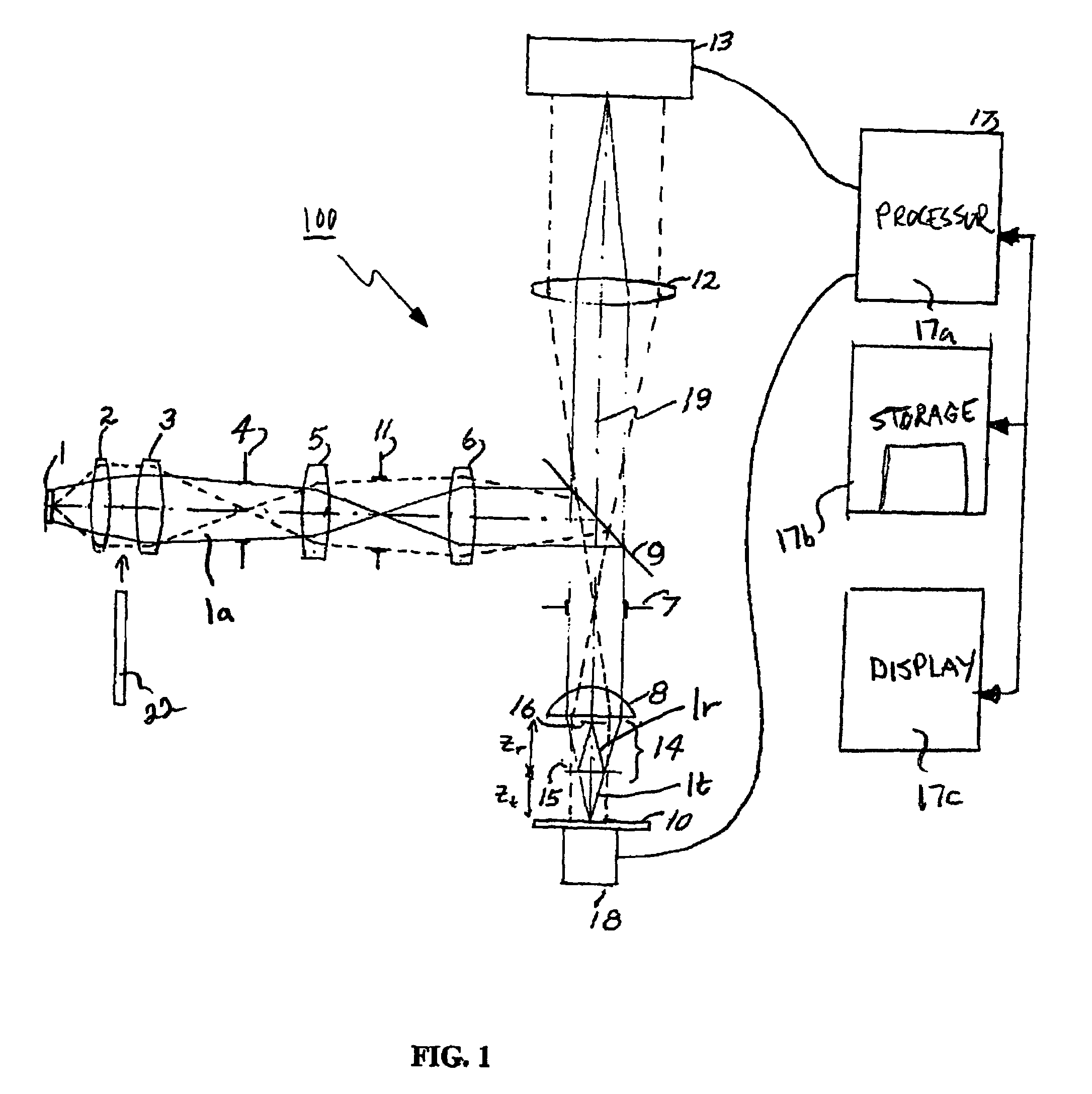

Method and apparatus for optically analyzing a surface

InactiveUS20070091317A1Quick and efficient analysisEffectively and accurately characteristicRadiation pyrometryInterferometric spectrometryCharacterization testBroadband

Apparatus and methods are provided for analyzing surface characteristics of a test object using broadband scanning interferometry. Test objects amenable to these apparatus and methods include but are not limited to semiconductor wafers, semiconductor devices, metallic surfaces, and the like. An interferometry system is used to obtain an interferometry signal and related to data embodied in the signal representative of the test object surface. This signal and / or data is used to construct an n-dimensional function that includes an independent frequency variable and an independent time variable, and / or an n-dimensional function that includes an independent scale variable and an independent time variable, and / or a multi-domain function. These functions are compared with various models to obtain a best match that is then used to characterize the test object surface.

Owner:PHASE SHIFT TECH

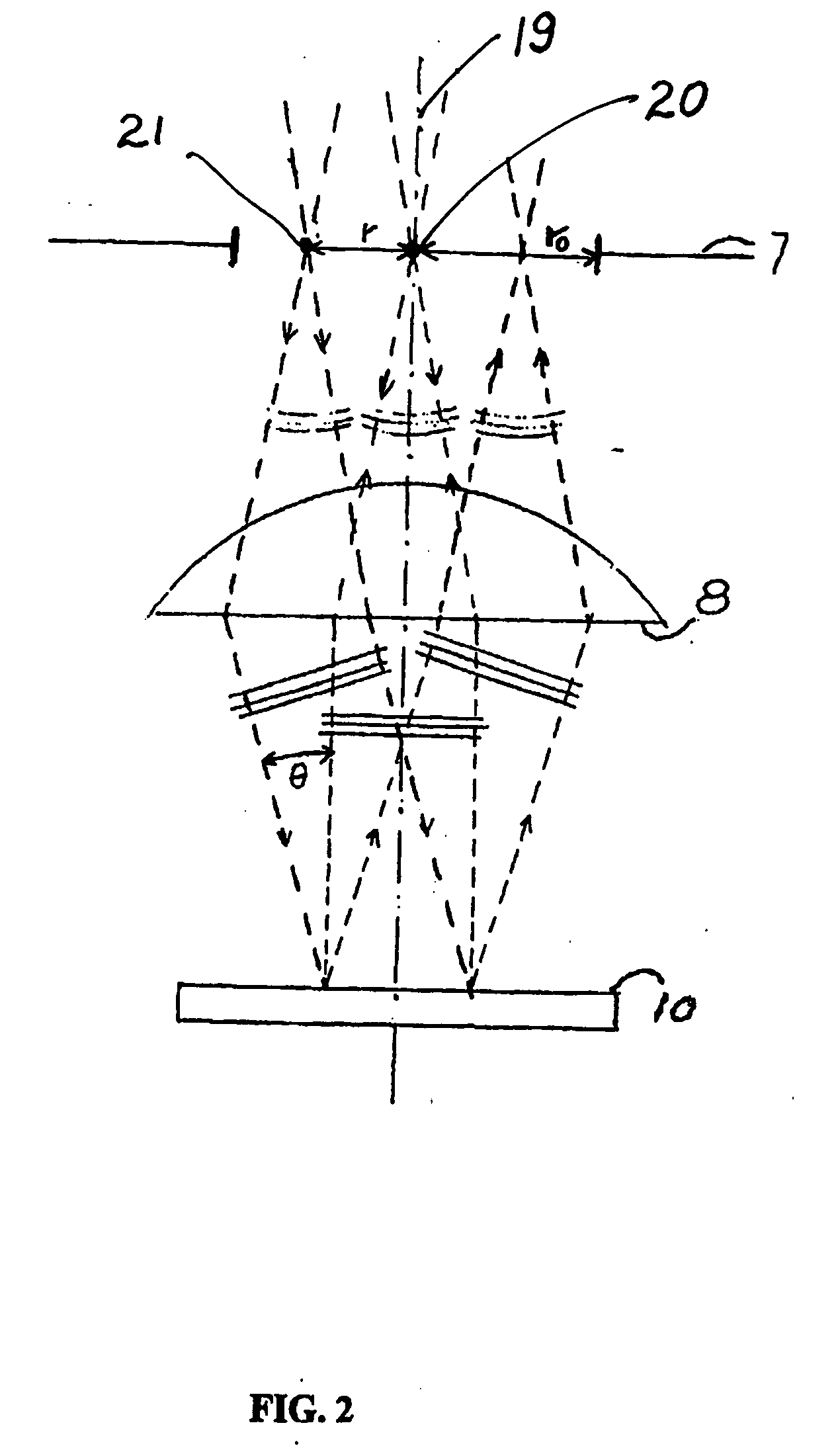

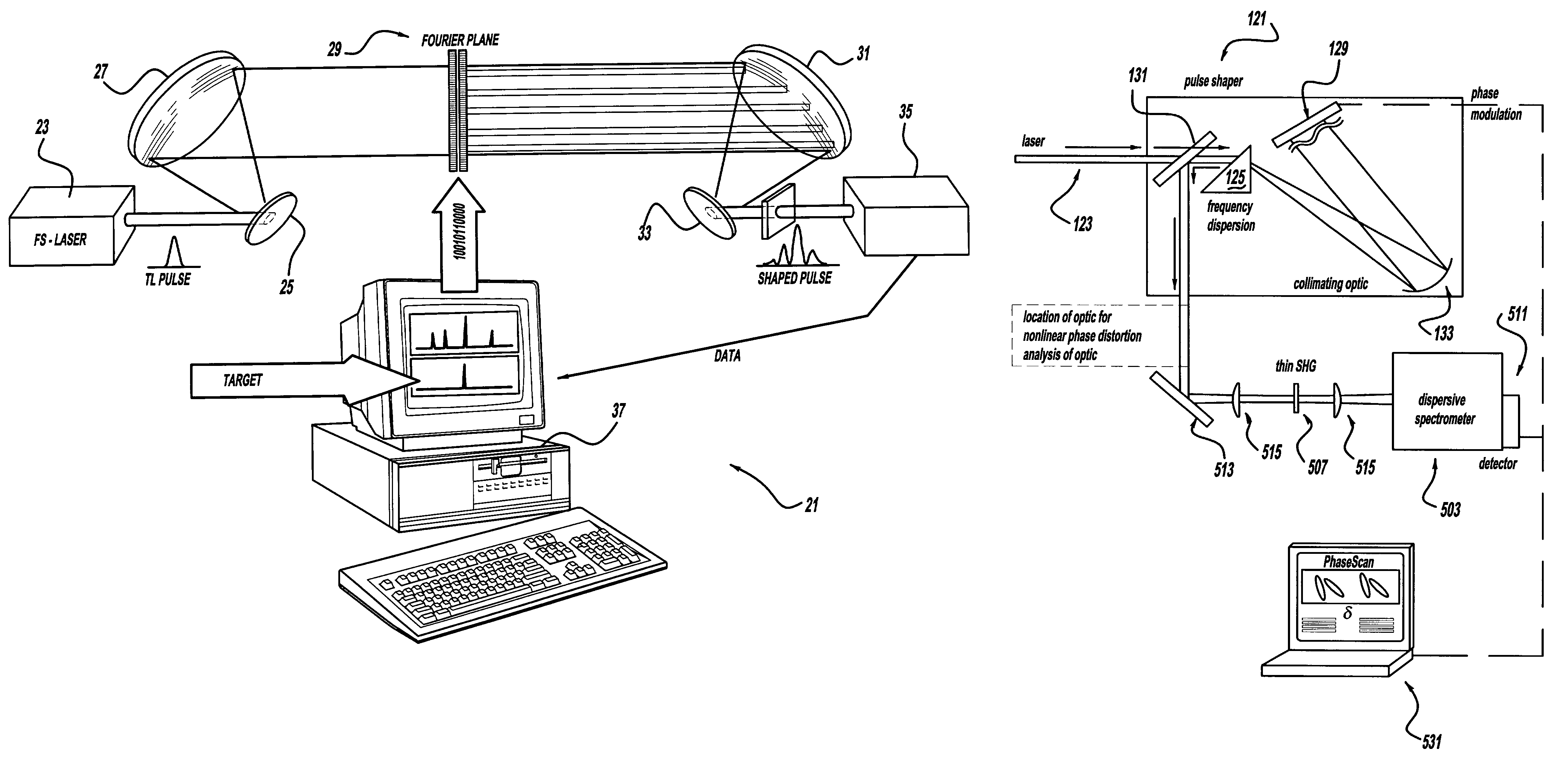

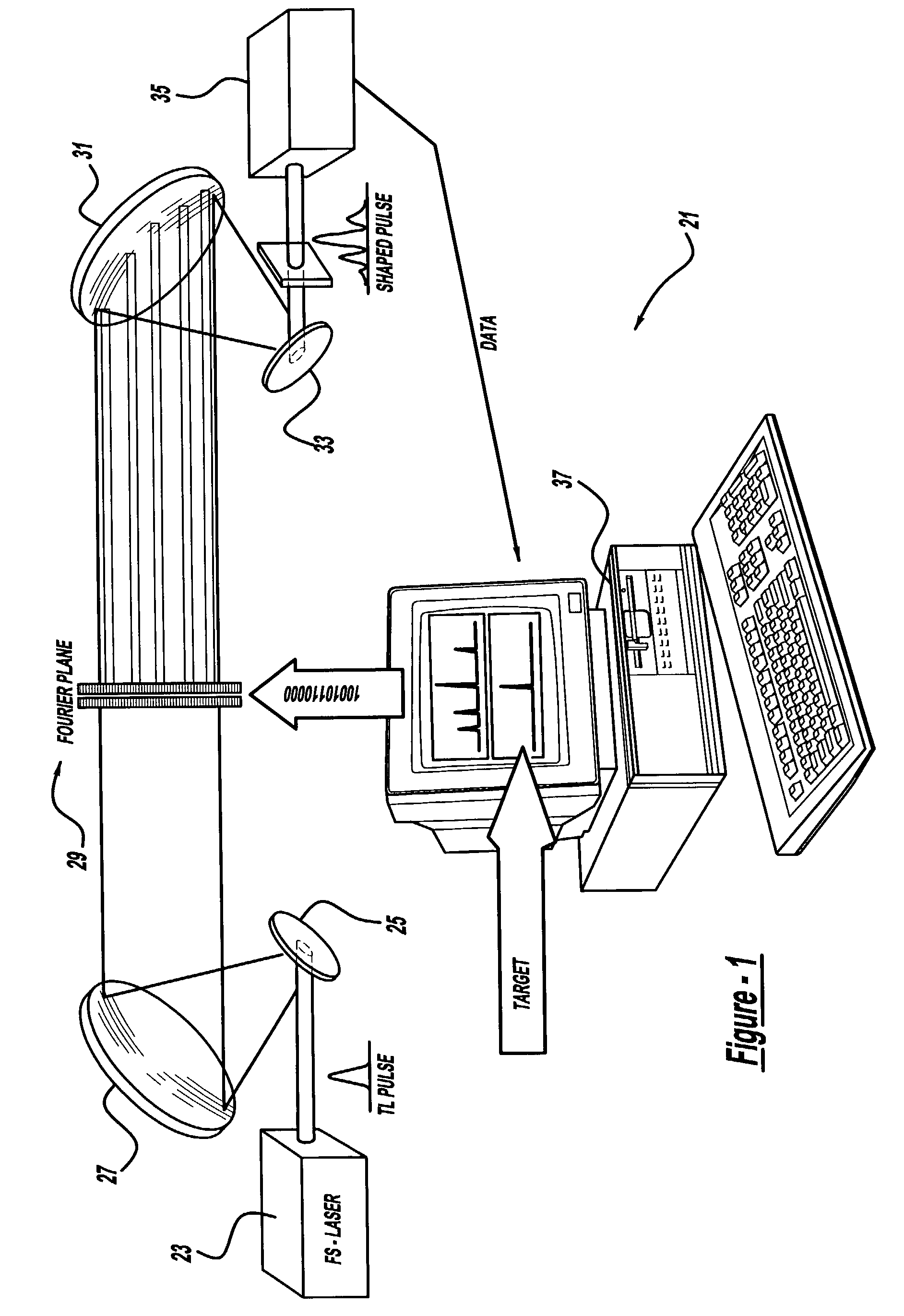

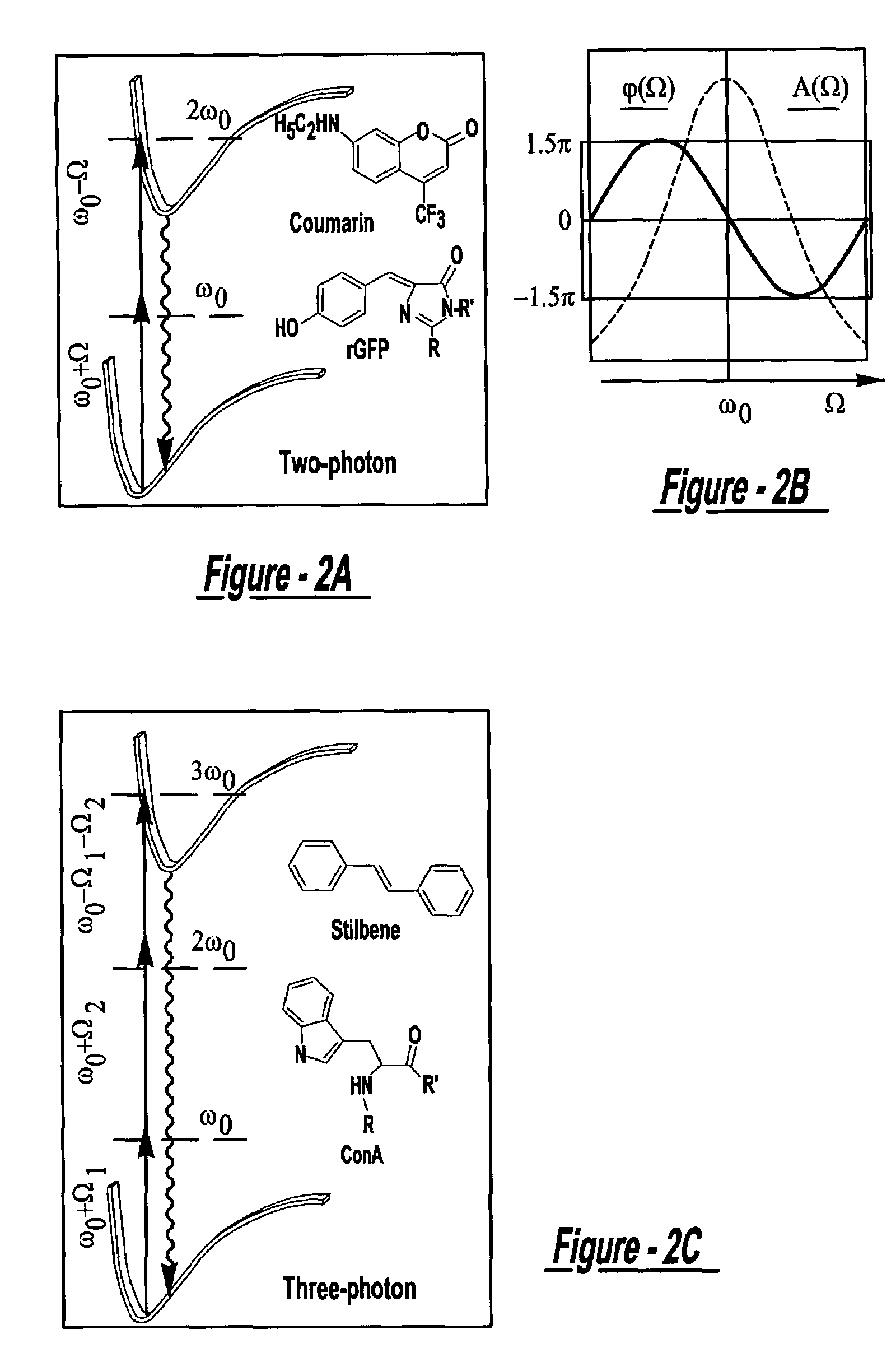

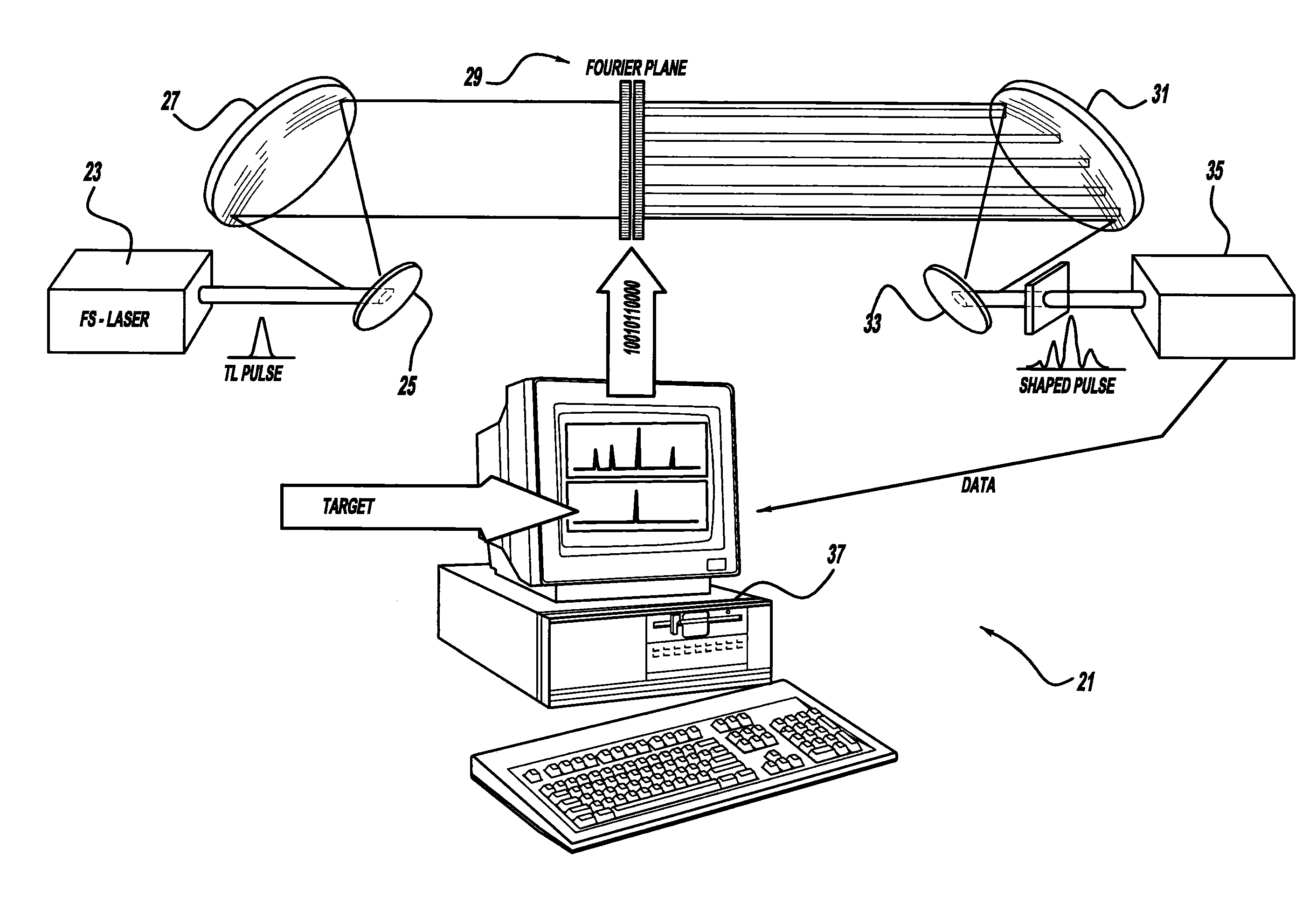

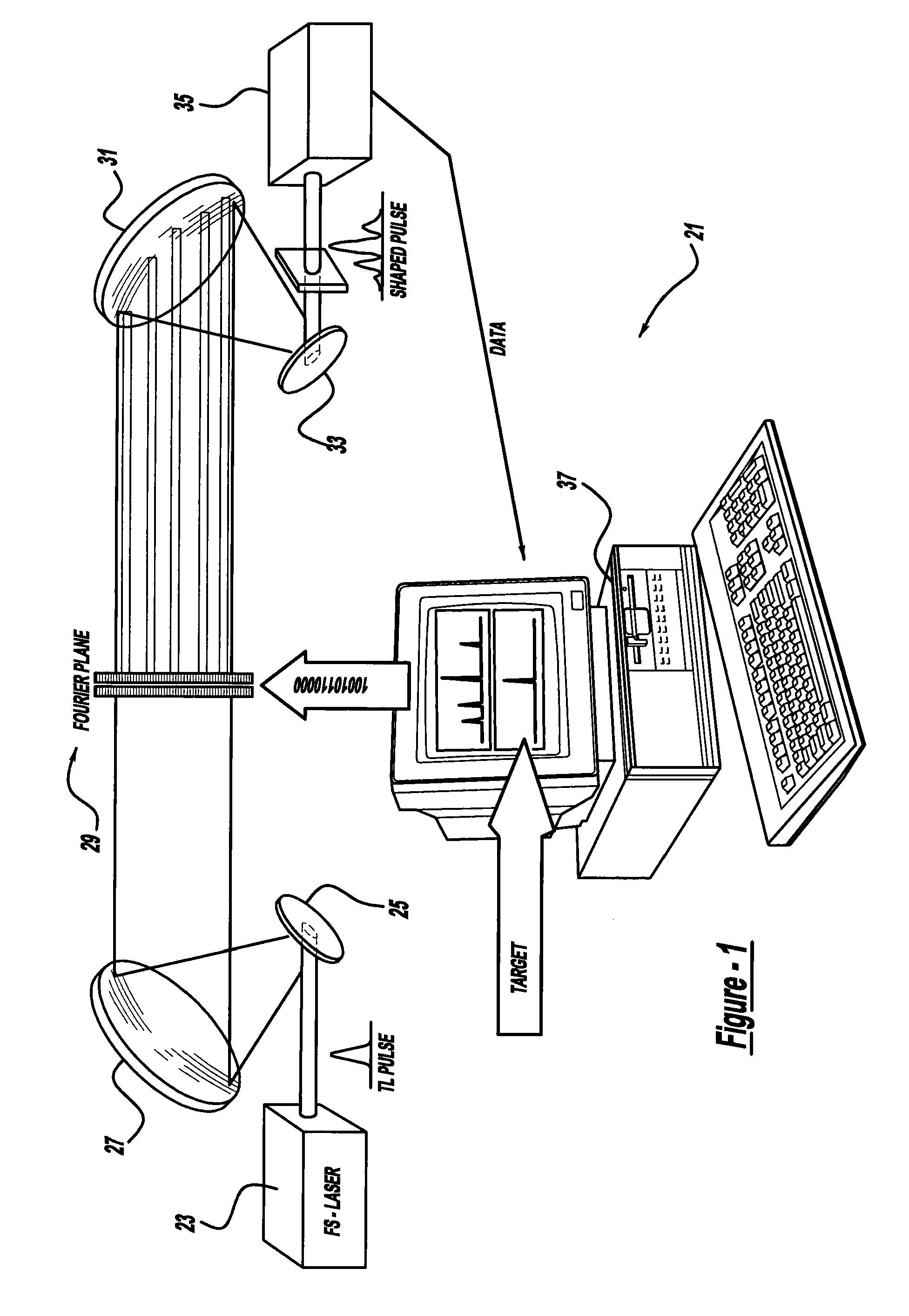

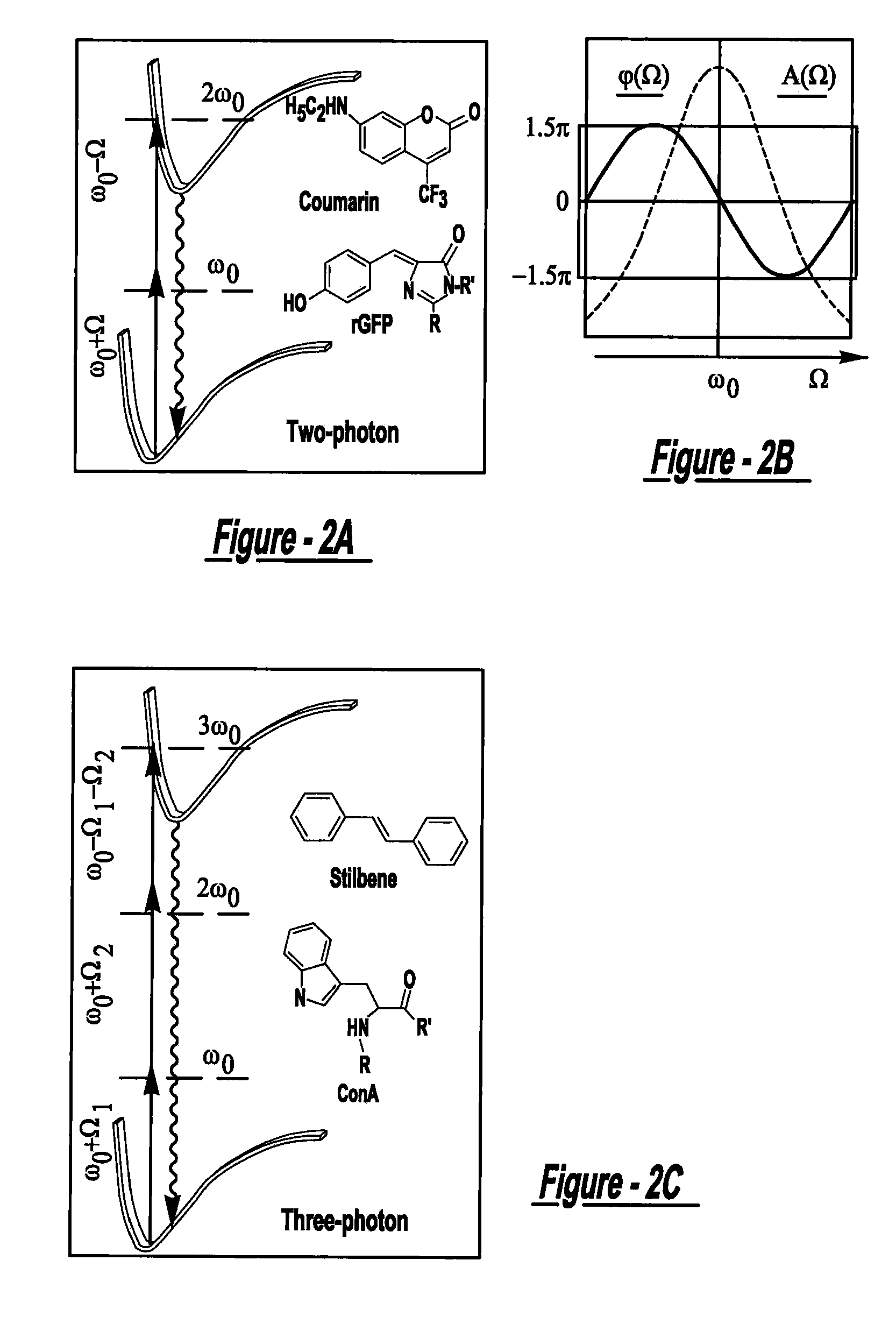

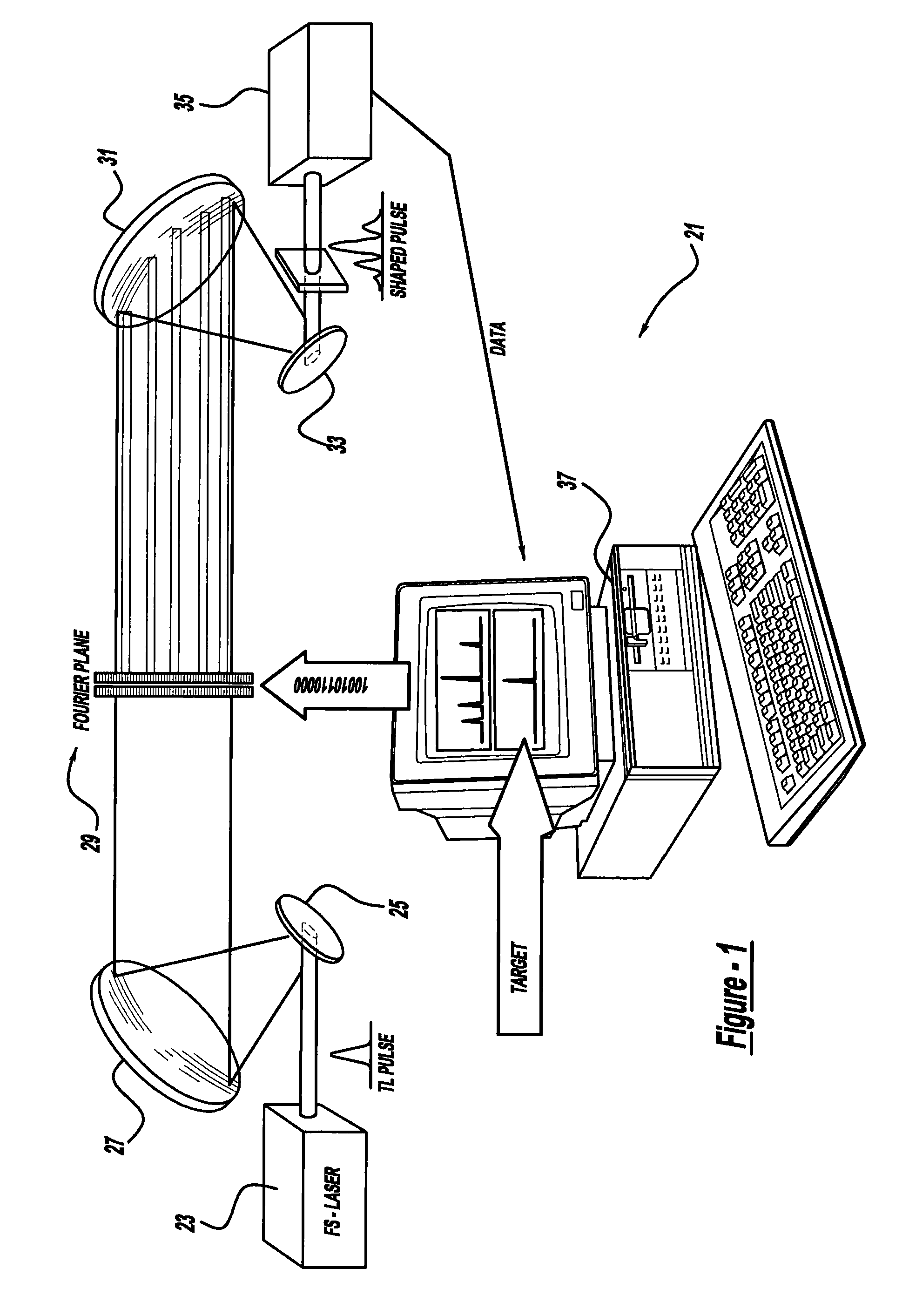

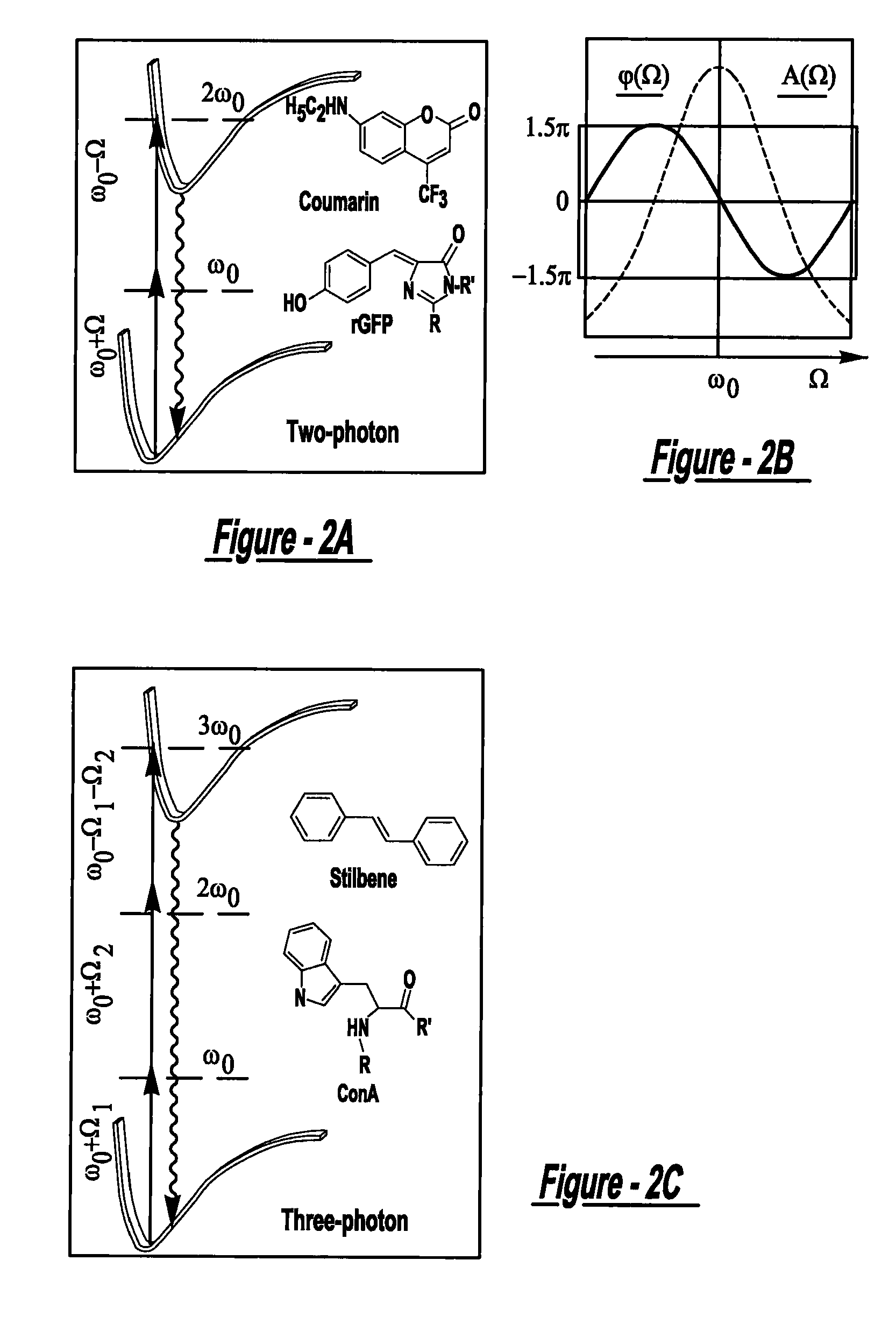

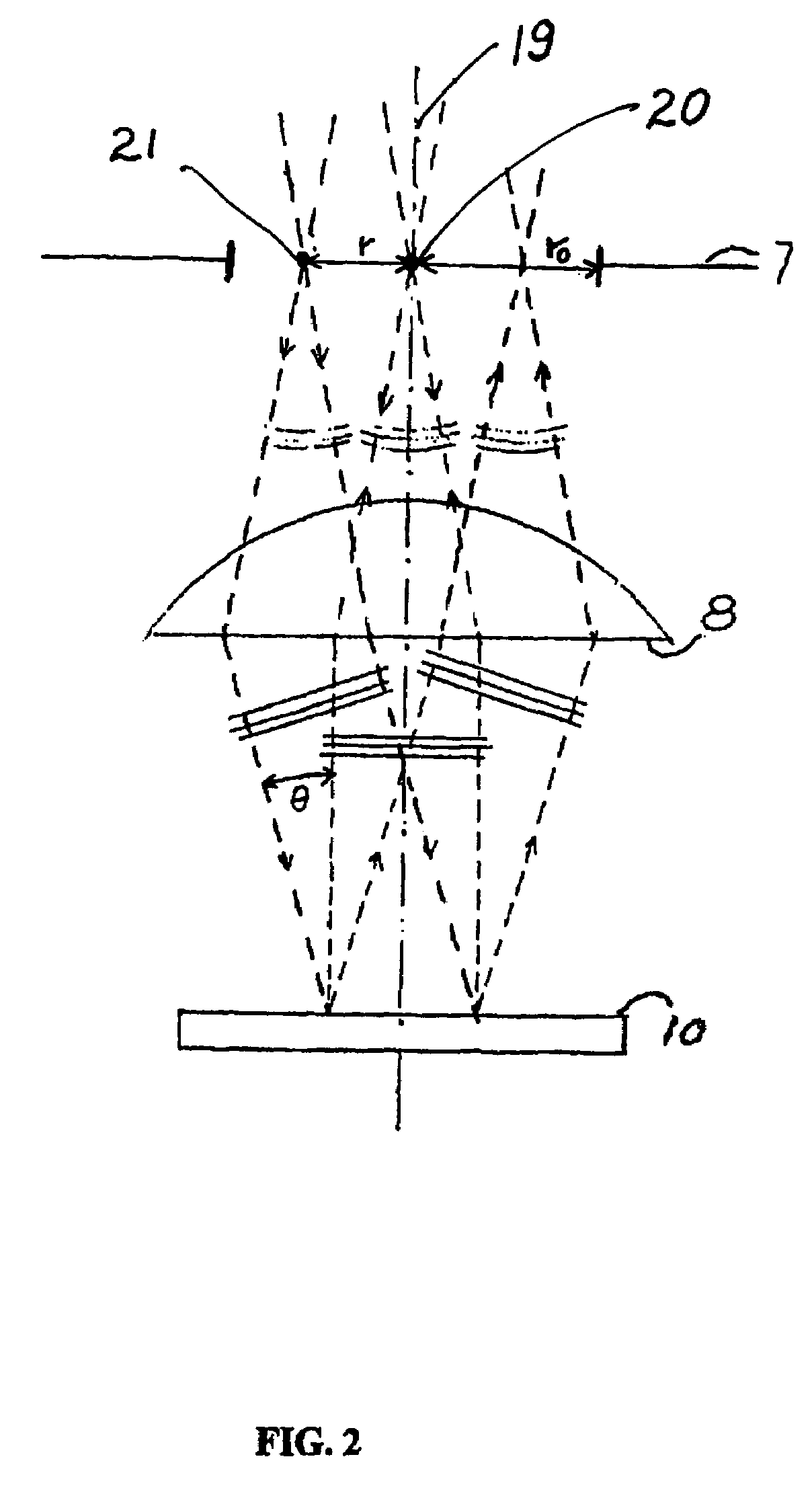

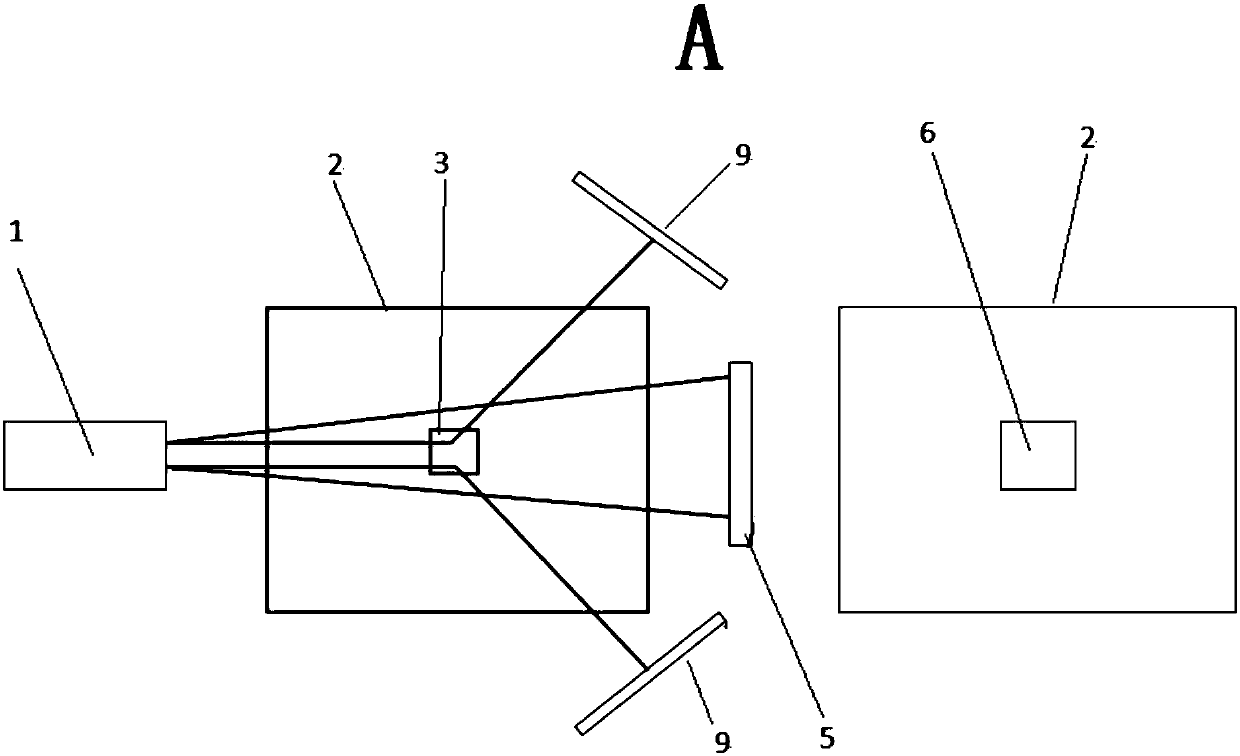

Laser system using ultrashort laser pulses

ActiveUS7450618B2Easy to set upEasy to useLaser detailsMaterial analysis by optical meansFemto second laserCharacterization test

A laser system using ultrashort laser pulses is provided. In another aspect of the present invention, the system includes a laser, pulse shaper and detection device. A further aspect of the present invention employs a femtosecond laser and a spectrometer. Still another aspect of the present invention uses a laser beam pulse, a pulse shaper and a SHG crystal. In yet another aspect of the present invention, a multiphoton intrapulse interference phase scan system and method characterize the spectral phase of femtosecond laser pulses. Fiber optic communication systems, photodynamic therapy and pulse characterization tests use the laser system with additional aspects of the present invention.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Method & apparatus for optically analyzing a surface

InactiveUS20070091318A1Quick and efficient analysisEffectively and accurately characteristicRadiation pyrometryInterferometric spectrometryCharacterization testTest object

A method and apparatus for analyzing a surface of a test object employs apparatus with a scanning interferometry system which generates a windowed interferometric signal from the surface of a test object to characterize the surface of the test object.

Owner:KLA TENCOR TECH CORP

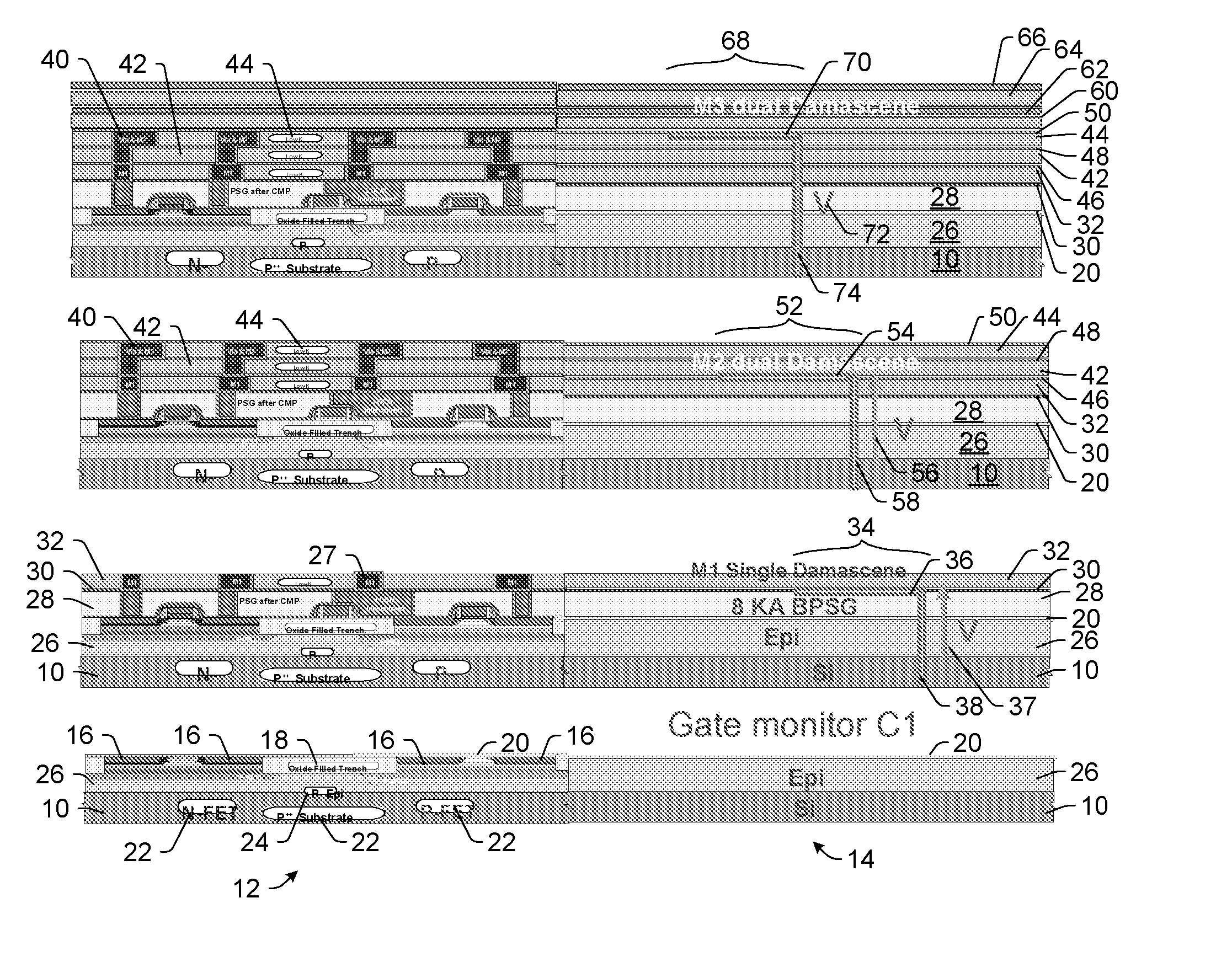

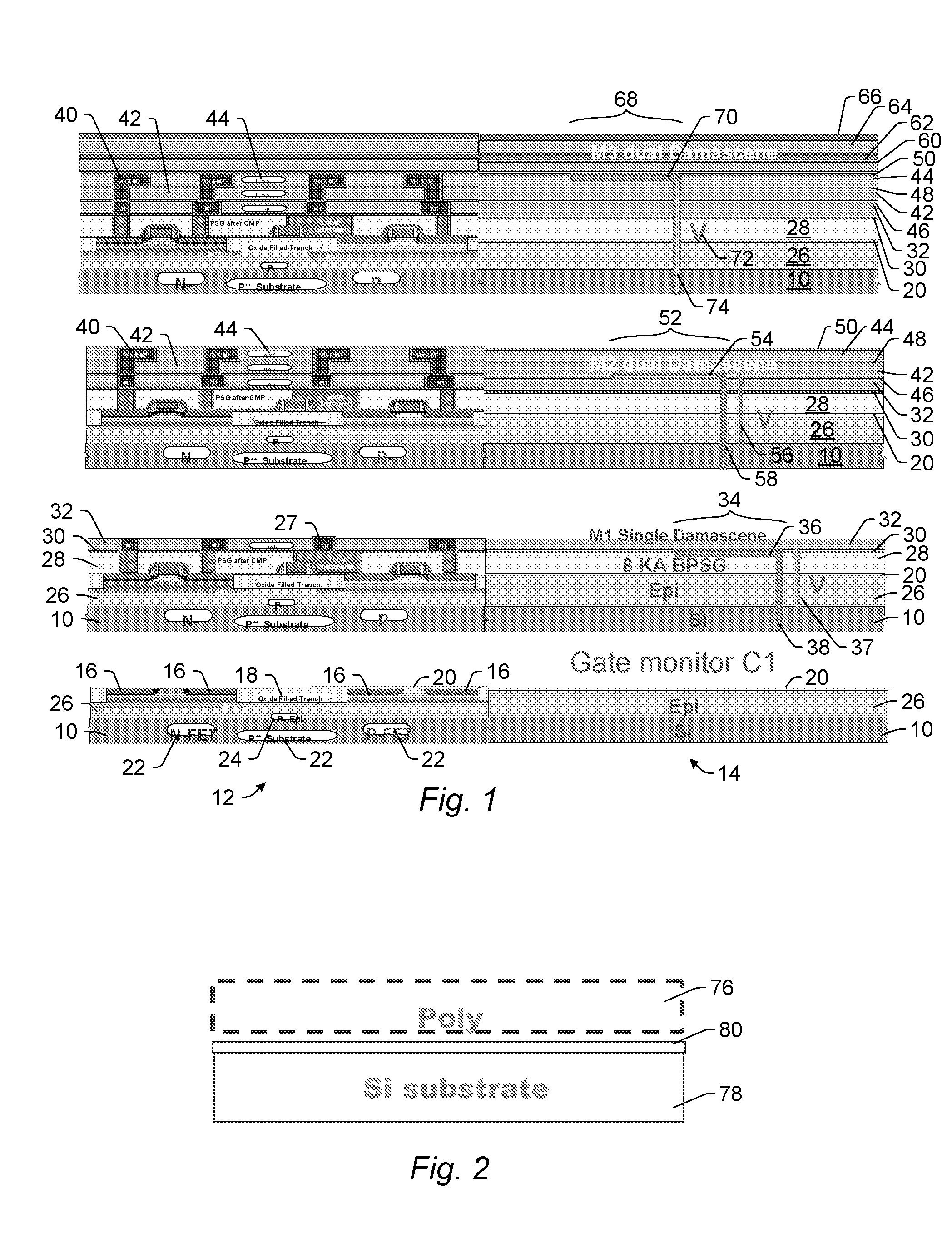

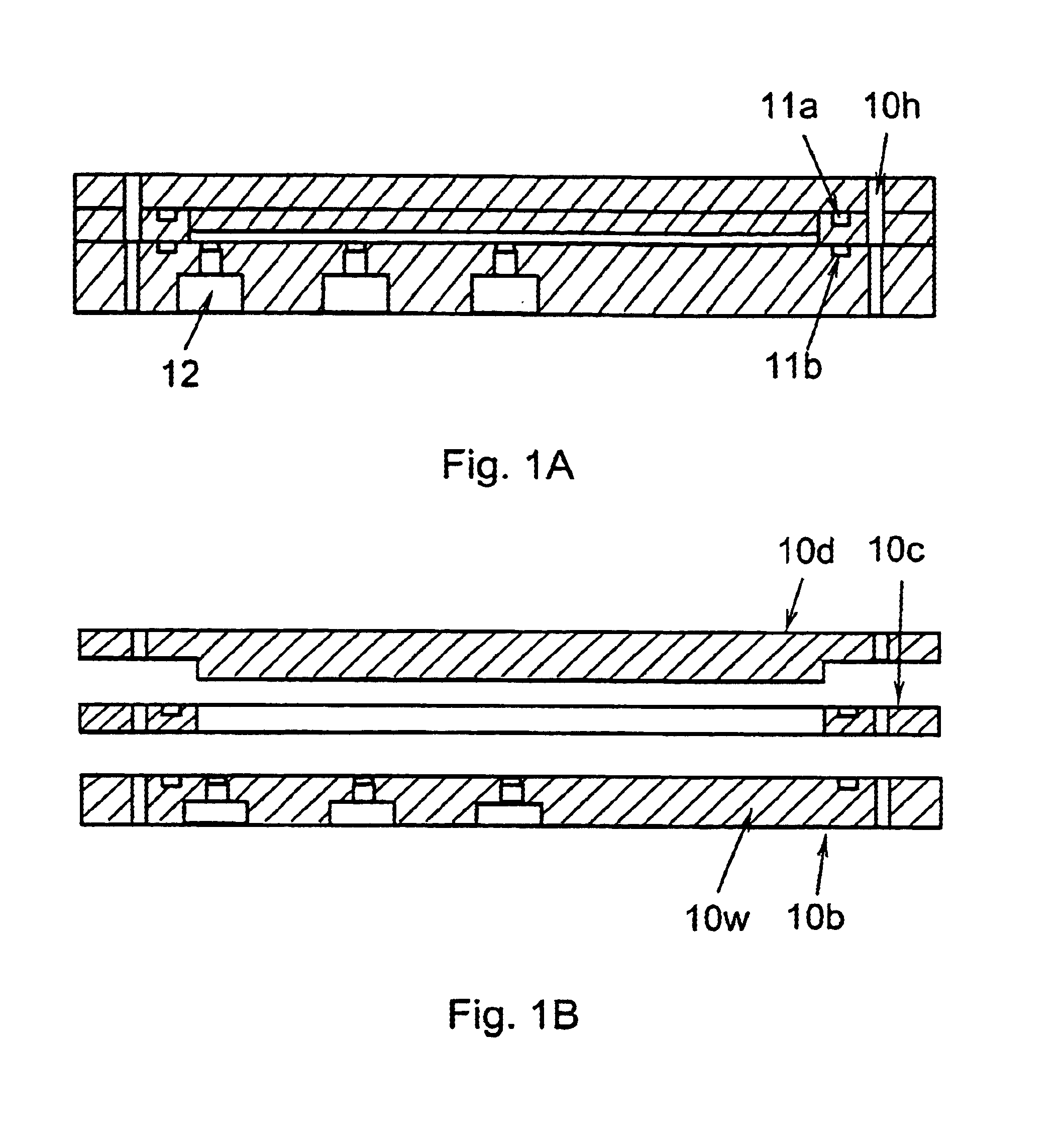

Test Pads, Methods and Systems for Measuring Properties of a Wafer

InactiveUS20070109003A1Semiconductor/solid-state device testing/measurementSolid-state devicesMeasurement testingCharacterization test

Test pads, methods, and systems for measuring properties of a wafer are provided. One test pad formed on a wafer includes a test structure configured such that one or more electrical properties of the test structure can be measured. The test pad also includes a conductive layer formed between the test structure and the wafer. The conductive layer prevents structures located under the test structure between the conductive layer and the wafer from affecting the one or more electrical properties of the test structure during measurement. One method for assessing plasma damage of a wafer includes measuring one or more electrical properties of a test structure formed on the wafer and determining an index characterizing the plasma damage of the test structure using the one or more electrical properties.

Owner:KLA TENCOR TECH CORP

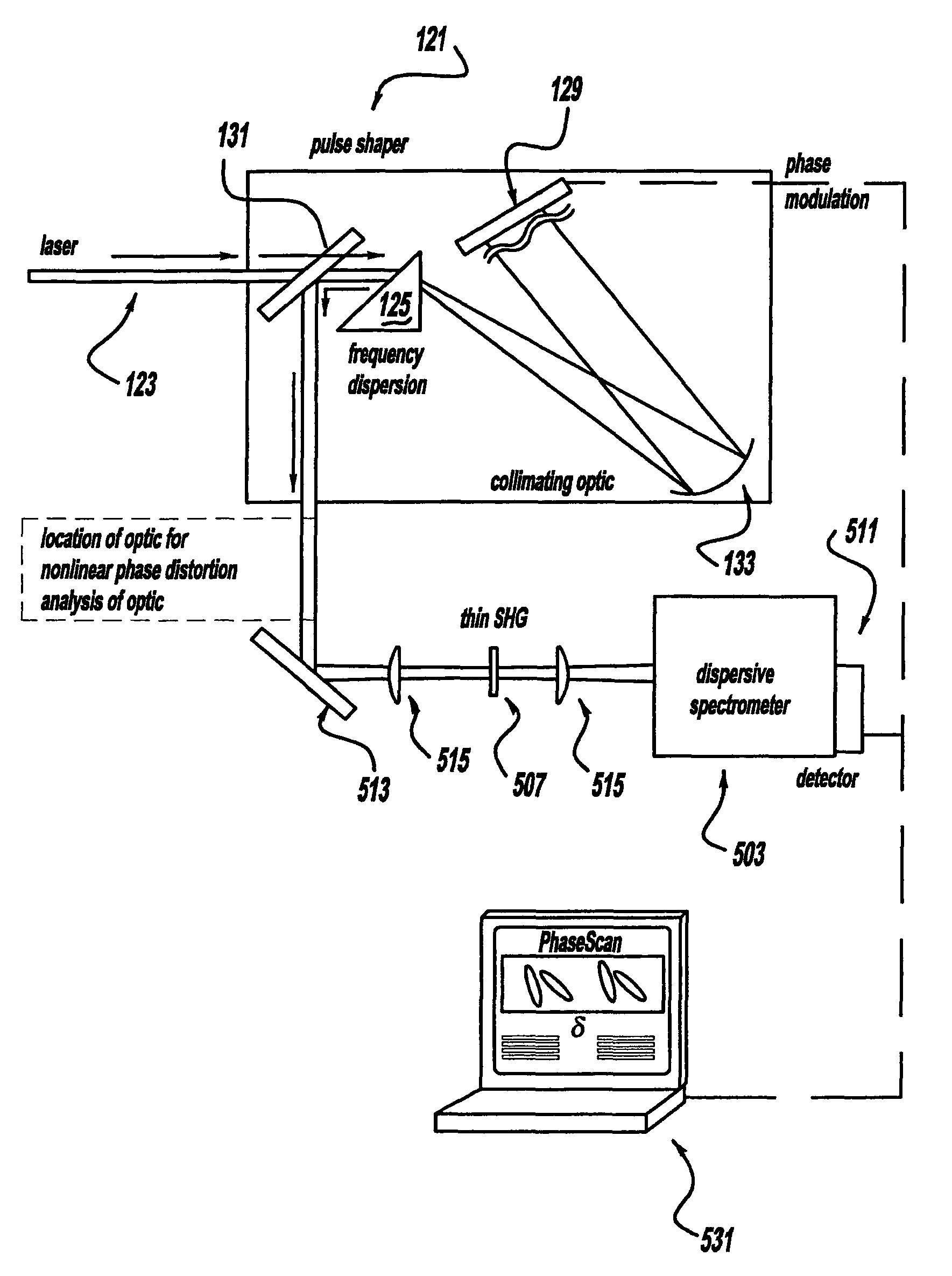

Laser Pulse Shaping System

ActiveUS20090122819A1Increase productionWide bandwidthLaser detailsMaterial analysis by optical meansCharacterization testUltrashort laser

A laser system using ultrashort laser pulses is provided. In another aspect of the present invention, the system includes a laser, pulse shaper and detection device. A further aspect of the present invention employs a femtosecond laser and a spectrometer. Still another aspect of the present invention uses a laser beam pulse, a pulse shaper and a SHG crystal. In yet another aspect of the present invention, a multiphoton intrapulse interference phase scan system and method characterize the spectral phase of femtosecond laser pulses. Fiber optic communication systems, photodynamic therapy and pulse characterization tests use the laser system with additional aspects of the present invention.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Laser pulse shaping system

InactiveUS8208504B2Increase productionWide bandwidthLaser detailsMaterial analysis by optical meansCharacterization testUltrashort laser

A laser system using ultrashort laser pulses is provided. In another aspect of the present invention, the system includes a laser, pulse shaper and detection device. A further aspect of the present invention employs a femtosecond laser and a spectrometer. Still another aspect of the present invention uses a laser beam pulse, a pulse shaper and a SHG crystal. In yet another aspect of the present invention, a multiphoton intrapulse interference phase scan system and method characterize the spectral phase of femtosecond laser pulses. Fiber optic communication systems, photodynamic therapy and pulse characterization tests use the laser system with additional aspects of the present invention.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

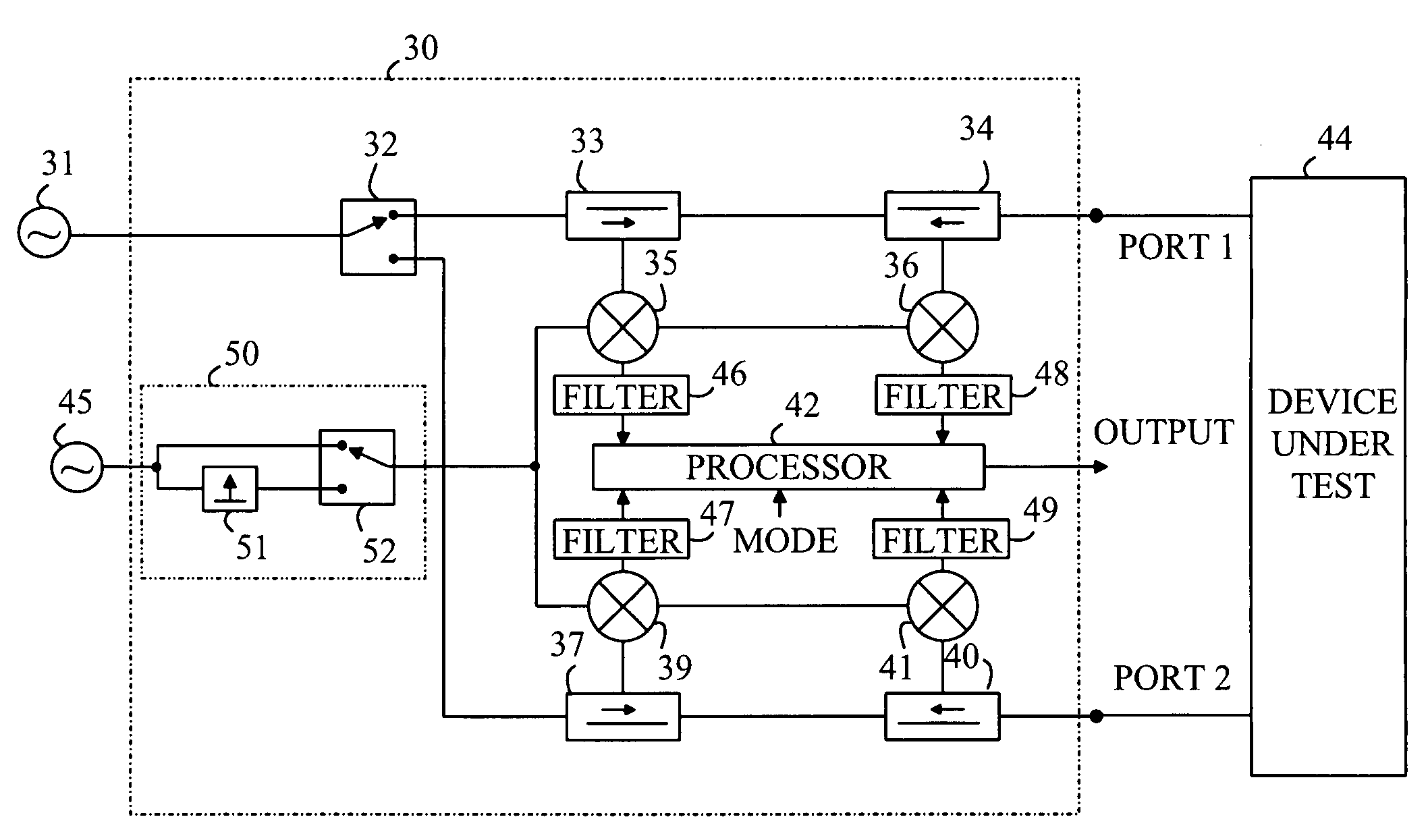

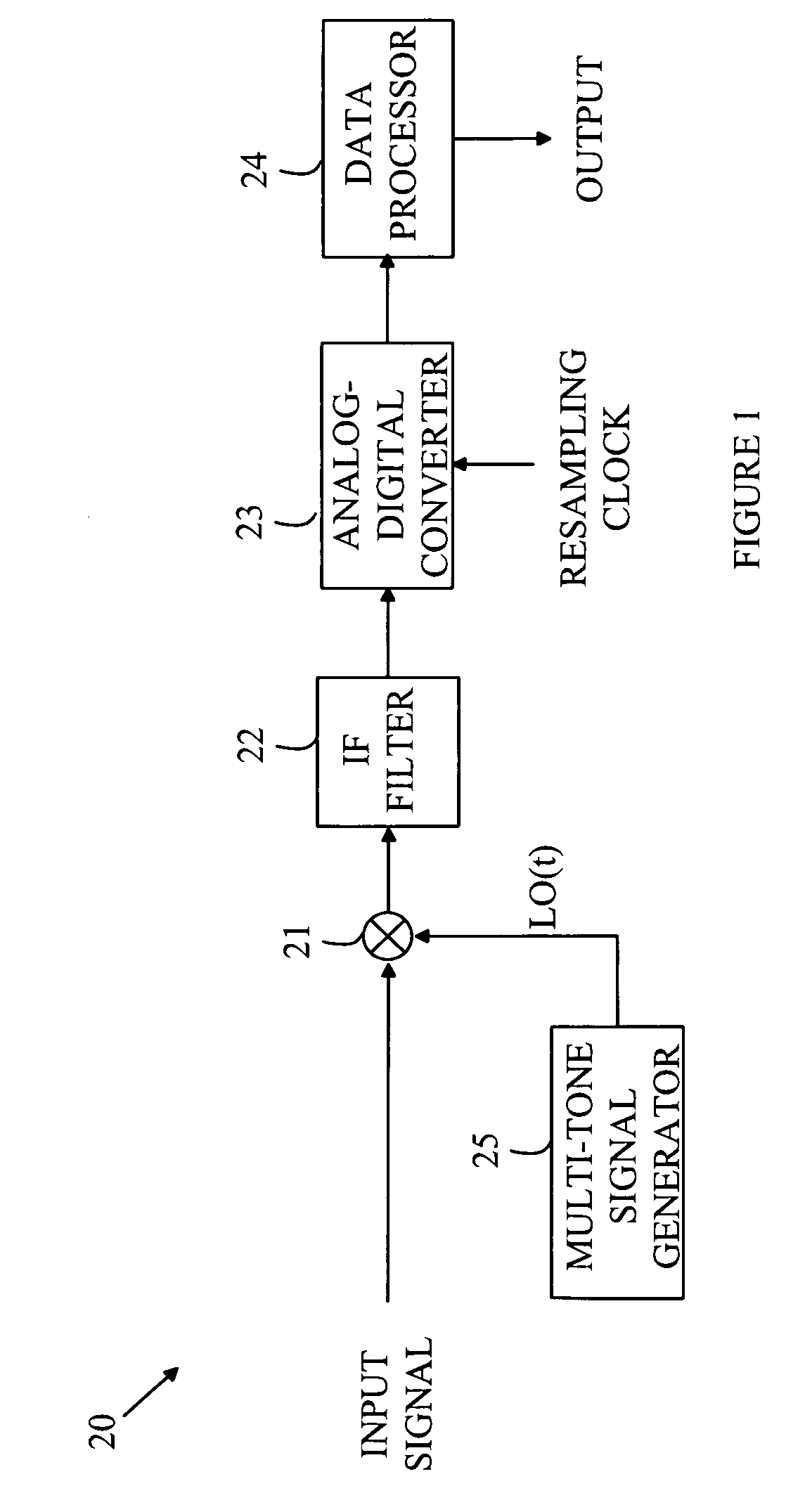

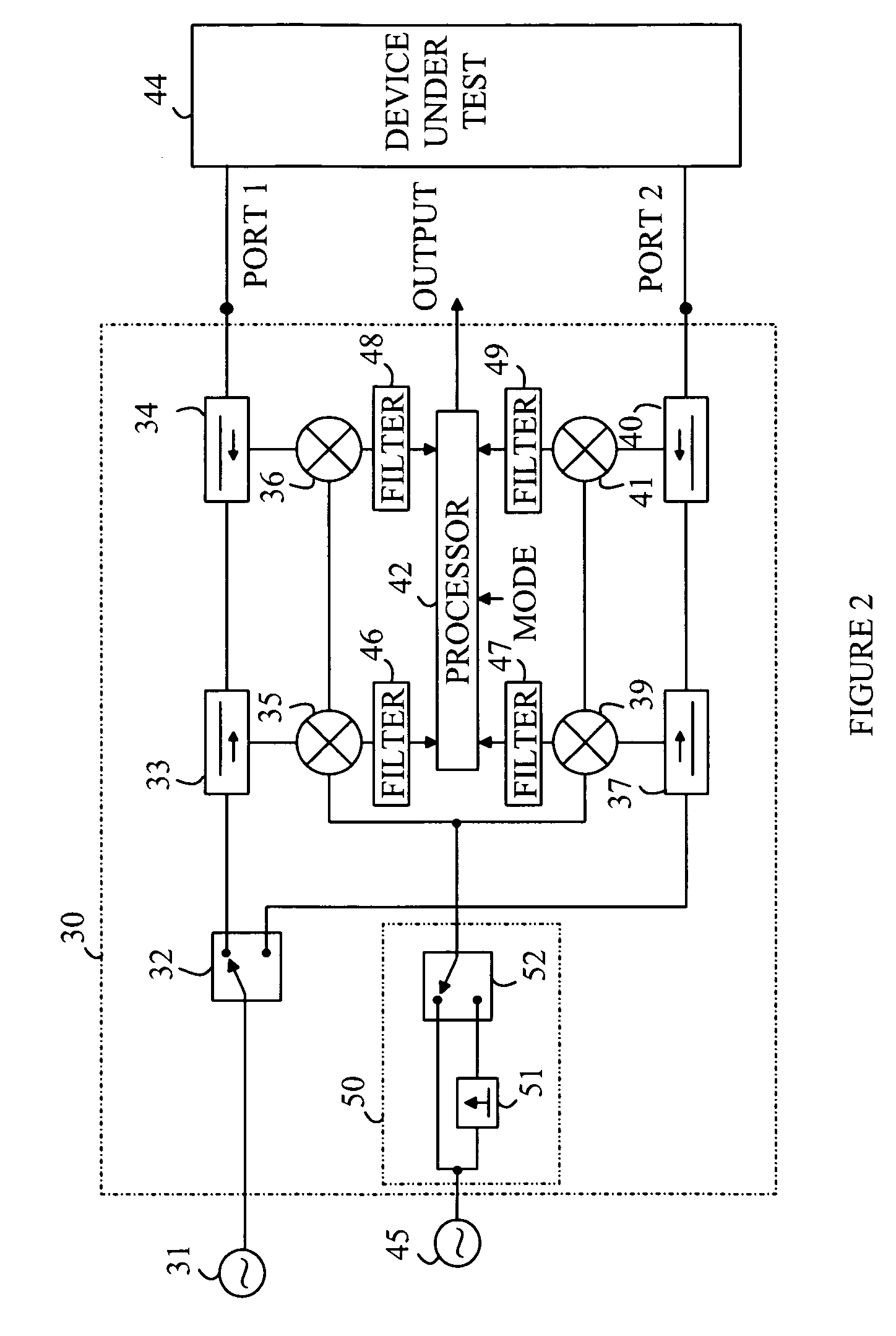

Dual Mode Vector Network Analyzer

A multimode network analyzer (VNA) and the method of using the same are disclosed. The VNA includes a signal input port that receives a test signal, an LO signal generator, a mixer, an IF filter and a processor. The LO signal generator generates a mixer LO signal from a mixer input test signal, the LO signal generator having first and second modes. The mixer LO signal is substantially a first periodic signal in the first mode and a second periodic signal having a plurality of harmonically related tones in the second mode. The mode that is currently operative is determined by a mixer control signal. The mixer is driven by the LO signal and has an output that is filtered by the IF filter to generate an IF signal. The processor analyzes the IF signal to determine a parameter characterizing the test signal and outputs that parameter.

Owner:AGILENT TECH INC

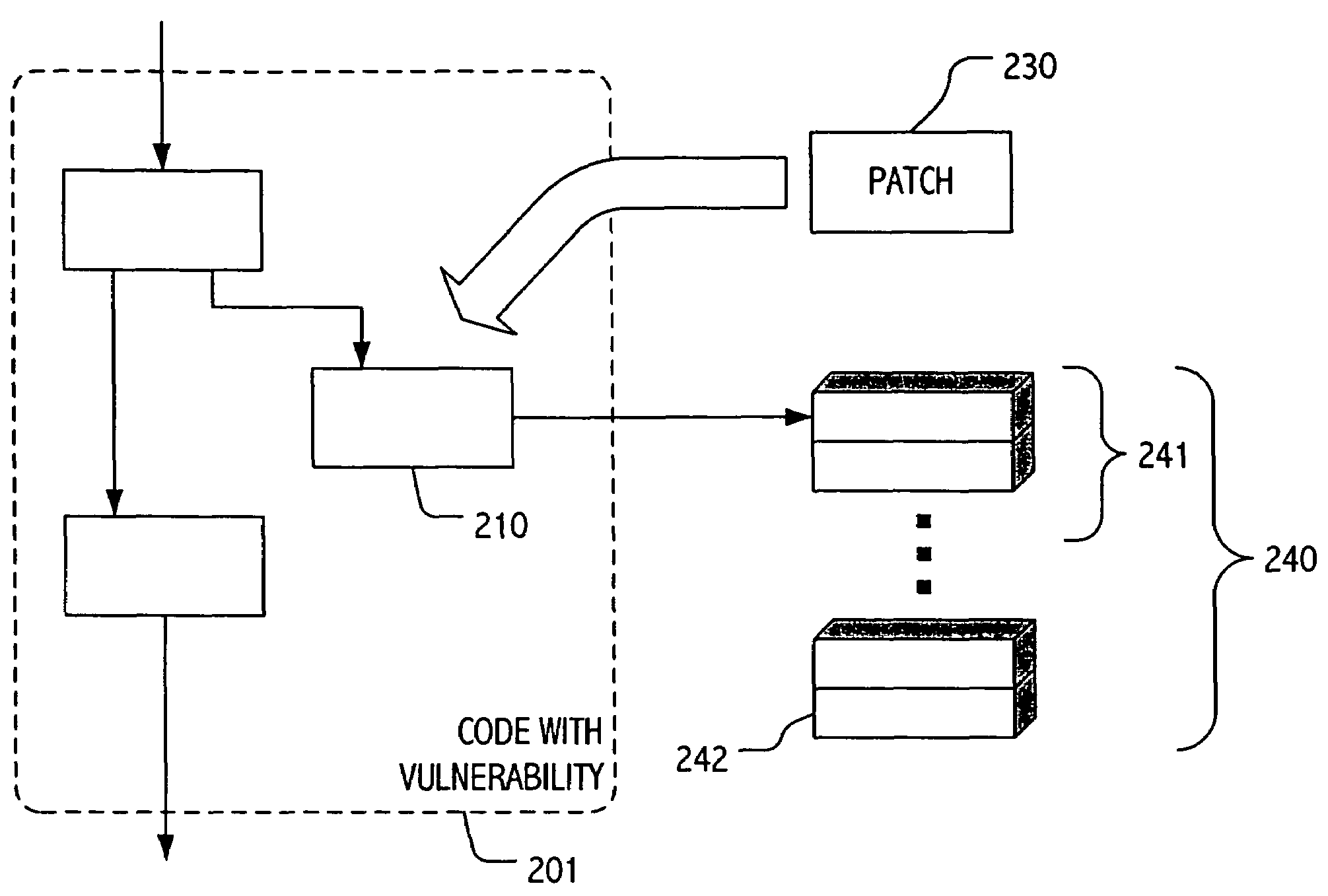

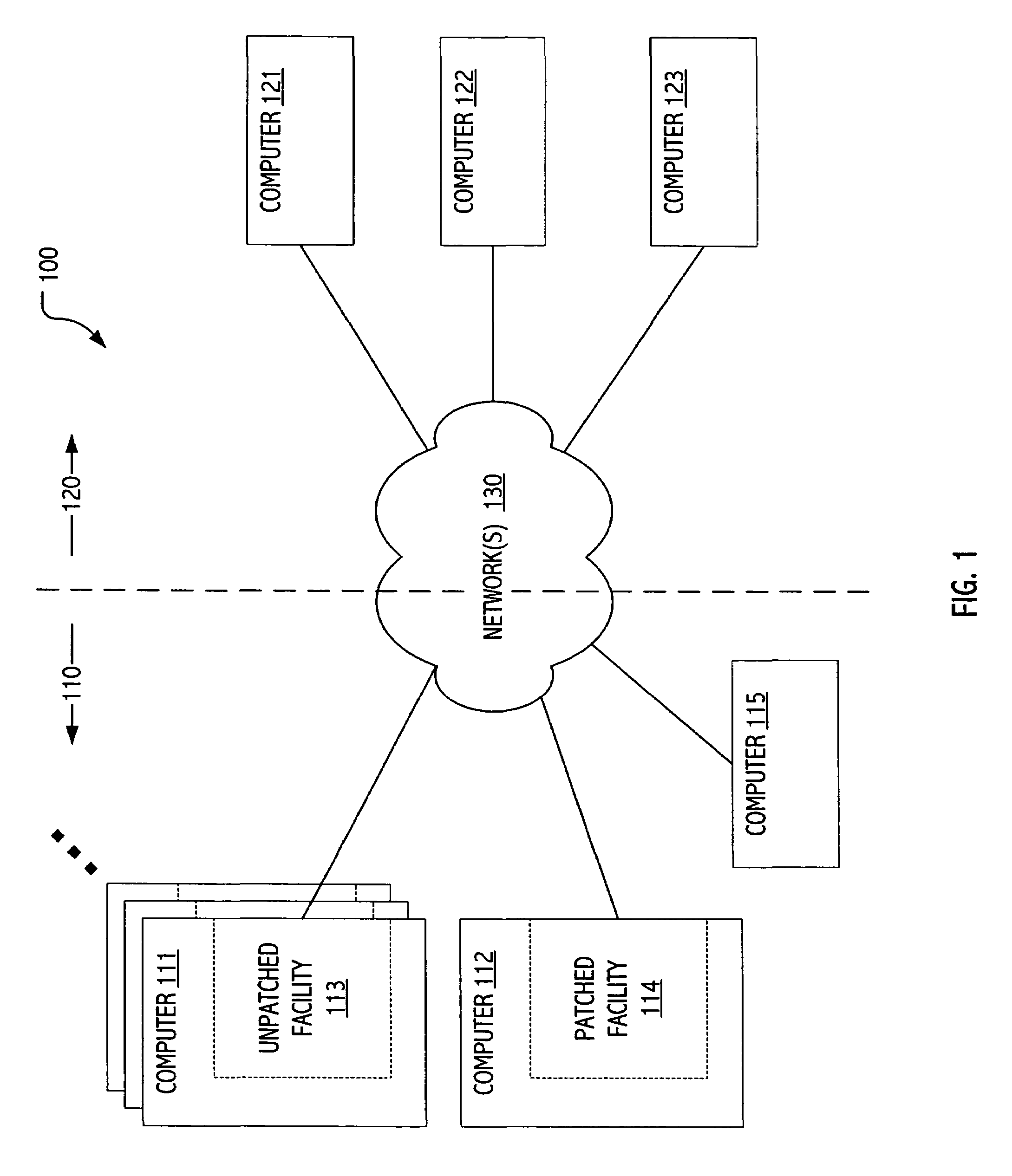

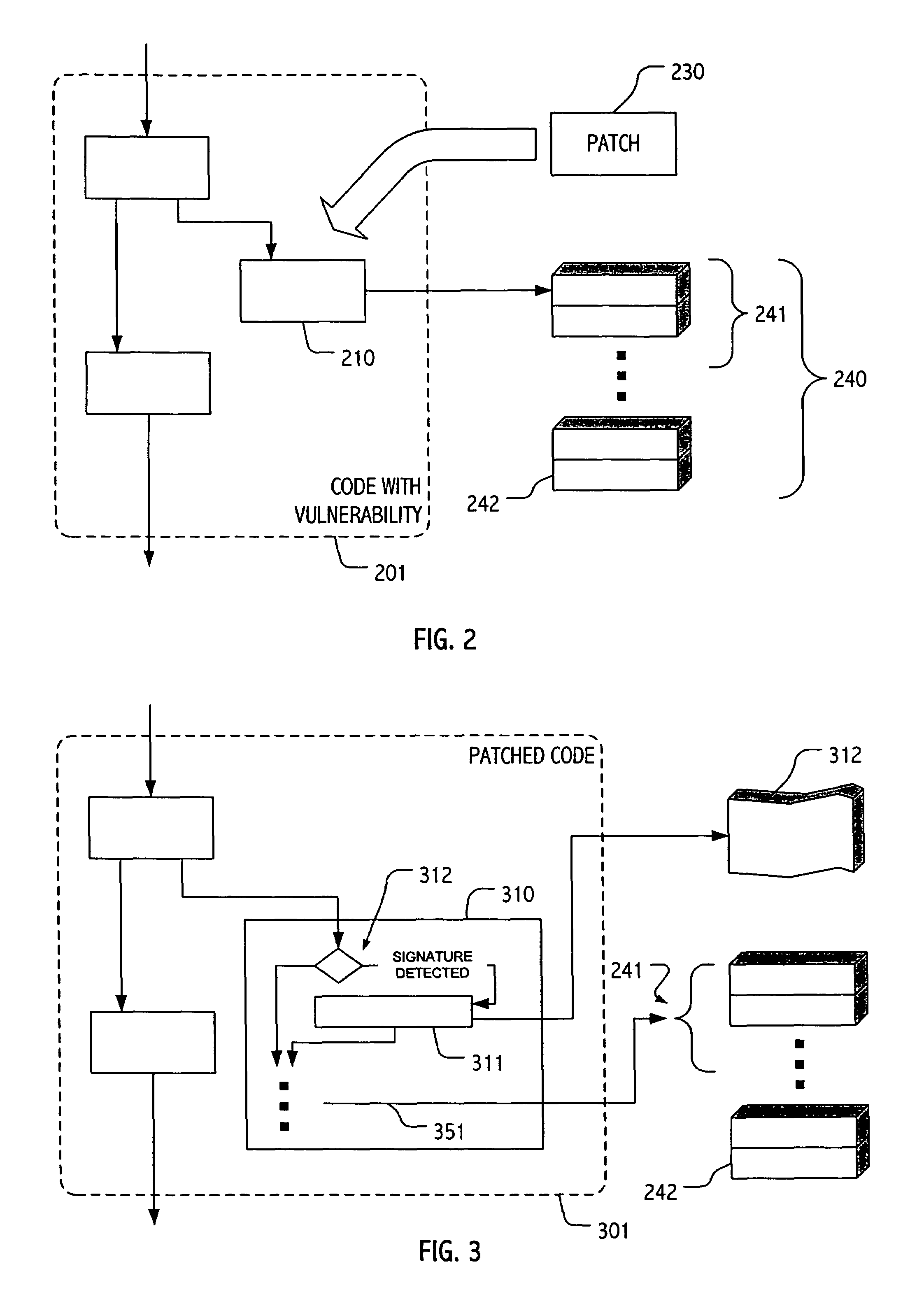

Computer security technique employing patch with detection and/or characterization mechanism for exploit of patched vulnerability

ActiveUS7647637B2Memory loss protectionUnauthorized memory use protectionCharacterization testProtection domain

A patch or set of patches may be deployed, often to a subset of potentially vulnerable systems, to address a particular vulnerability while providing a facility to monitor and, in some cases, characterize post-patch exploit attempts. Often, such a patch will check for an exploit signature and, if an exploit attempt is detected or suspected, take an appropriate action. For example, the patch may include code to log indicative data or trigger such logging. In some exploitations, the patch may generate or contribute to a warning or advisory regarding an additional target (or targets) of the exploit and, if appropriate, initiate a patch or protective measure for the additional target(s). In some exploitations, the patch may simulate responses or behaviors suggestive (to an attacker) of unpatched code. In some exploitations, the patch may direct an exploit attempt to a service (or simulated service) hosted or executing in an isolated protection domain.

Owner:ORACLE INT CORP

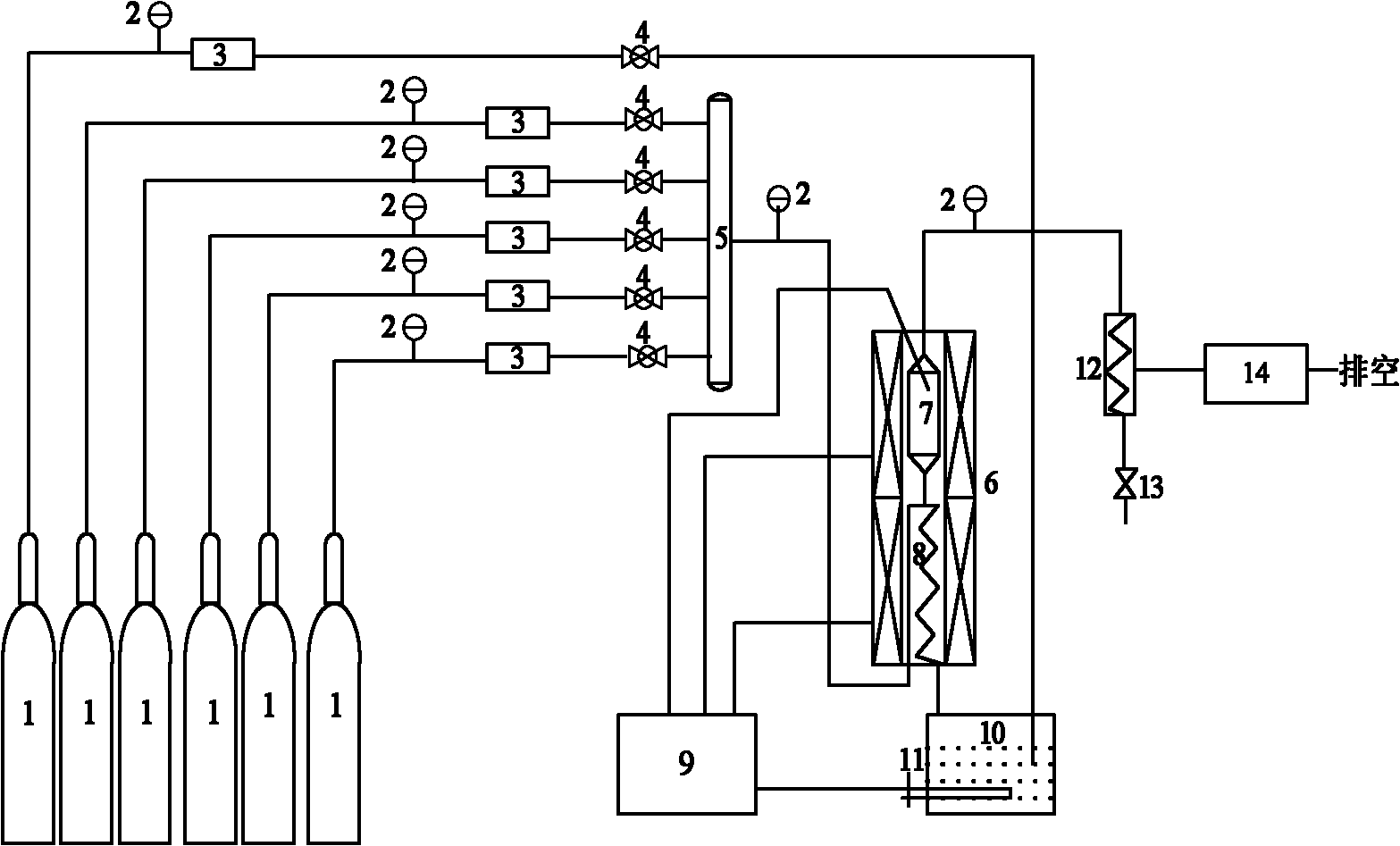

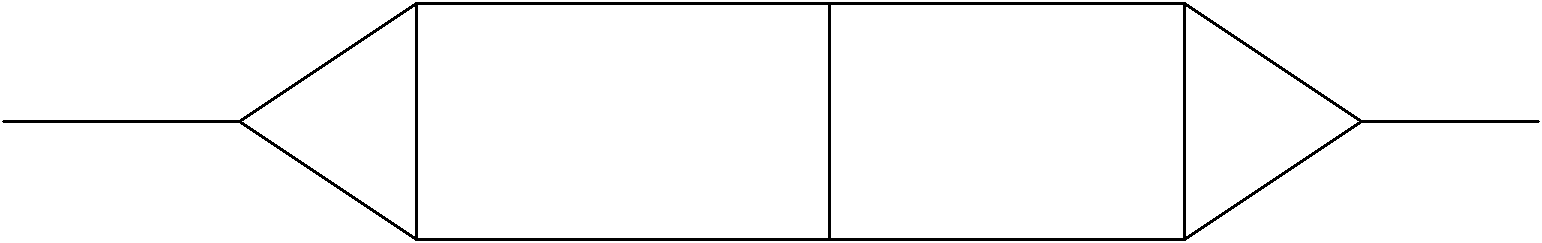

System and method for testing activity of vehicle exhaust purification catalytic material

ActiveCN101858901AGood repeatabilityAchieve light-off temperature characteristicsChemical analysis using catalysisPreparing sample for investigationCharacterization testVapor generator

The invention discloses a system and a method for testing activity of a vehicle exhaust purification catalytic material. The method comprises the following steps of: filling and fixing the vehicle exhaust purification catalytic material into a reactor, wherein the reactor is axially arranged into a heating furnace; setting the temperature of a vapor generator in order to lead vapor in the vapor generator to achieve set volume concentration; preheating simulative vehicle exhaust and vapor transmitted by the vapor generator in a preheating pipe arranged in the heating furnace; transmitting the simulative vehicle exhaust and the vapor which are preheated by the preheating pipe into the reactor for reaction by a catalyst, and then, collecting data by an analyzer; and taking out the catalytic material which completes evaluation treatment along the axial direction of the reactor for a subsequent characteristic test. The evaluation method has simple process, low cost, good repeatability of an experimental result and wide application and can evaluate the initiation temperature characteristic and the air-fuel delivery ratio characteristic of a three-way catalyst of a gasoline car and the temperature window characteristic of a selective catalytic reduction catalyst of a diesel engine car.

Owner:CATARC AUTOMOTIVE TEST CENT TIANJIN CO LTD +1

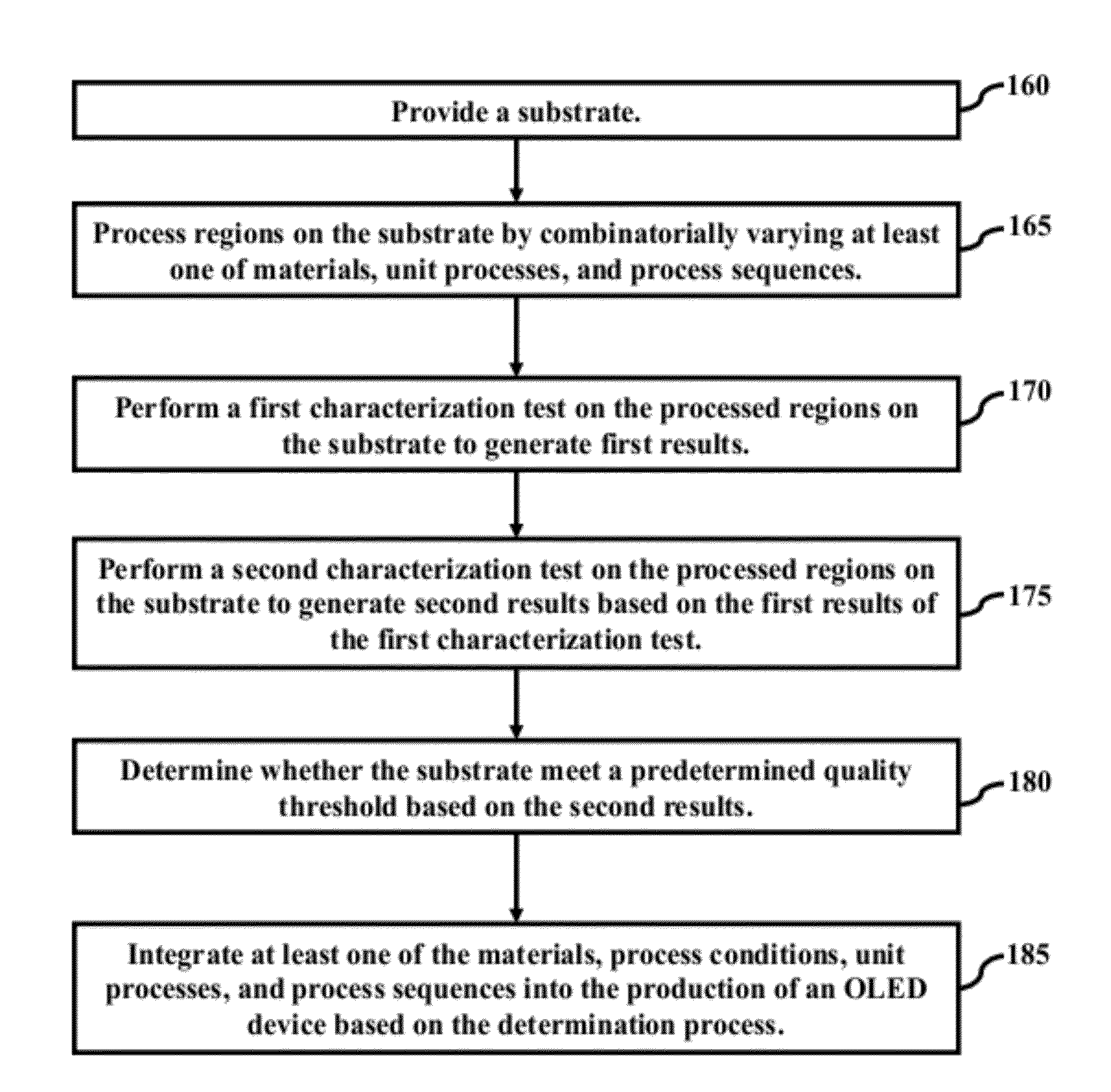

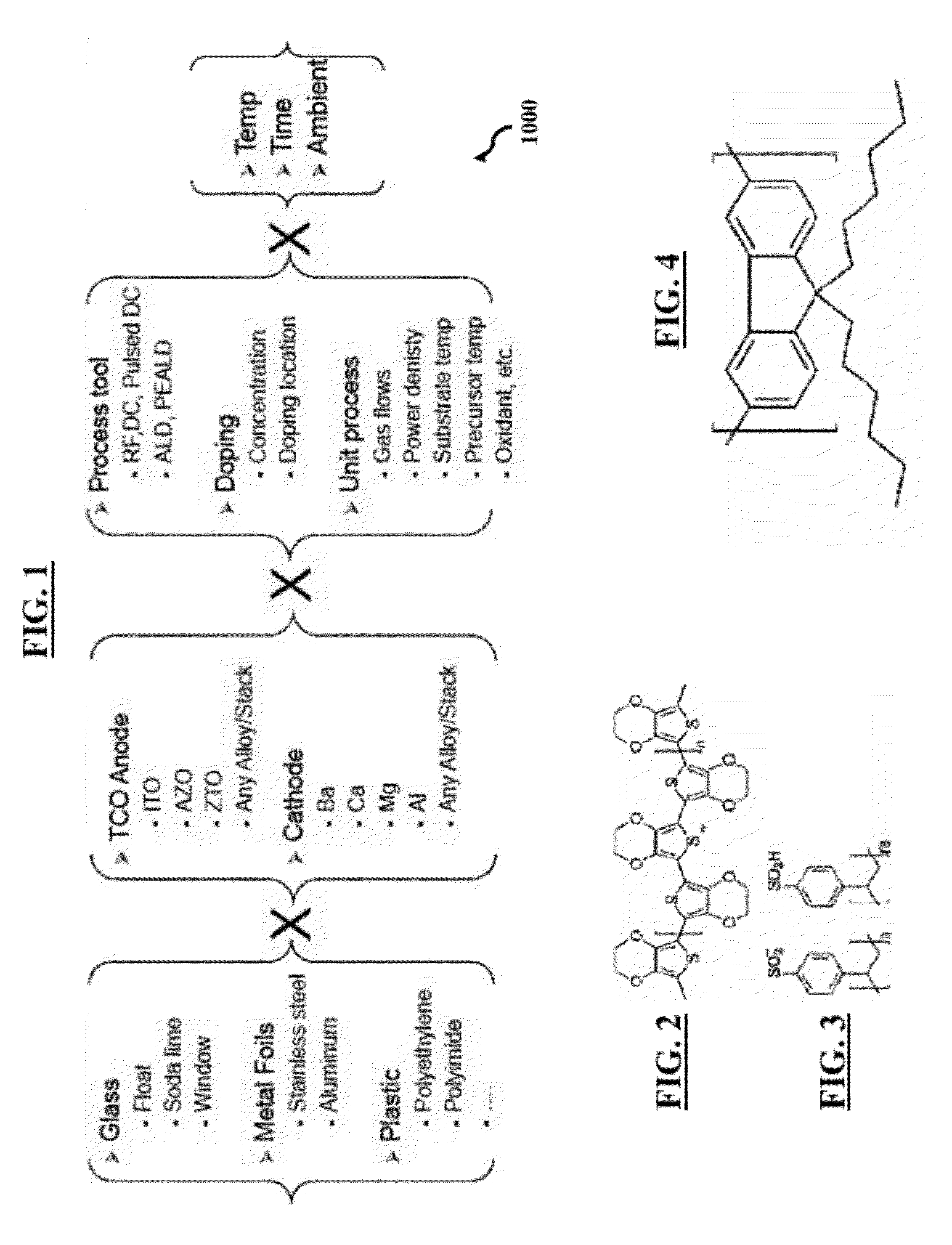

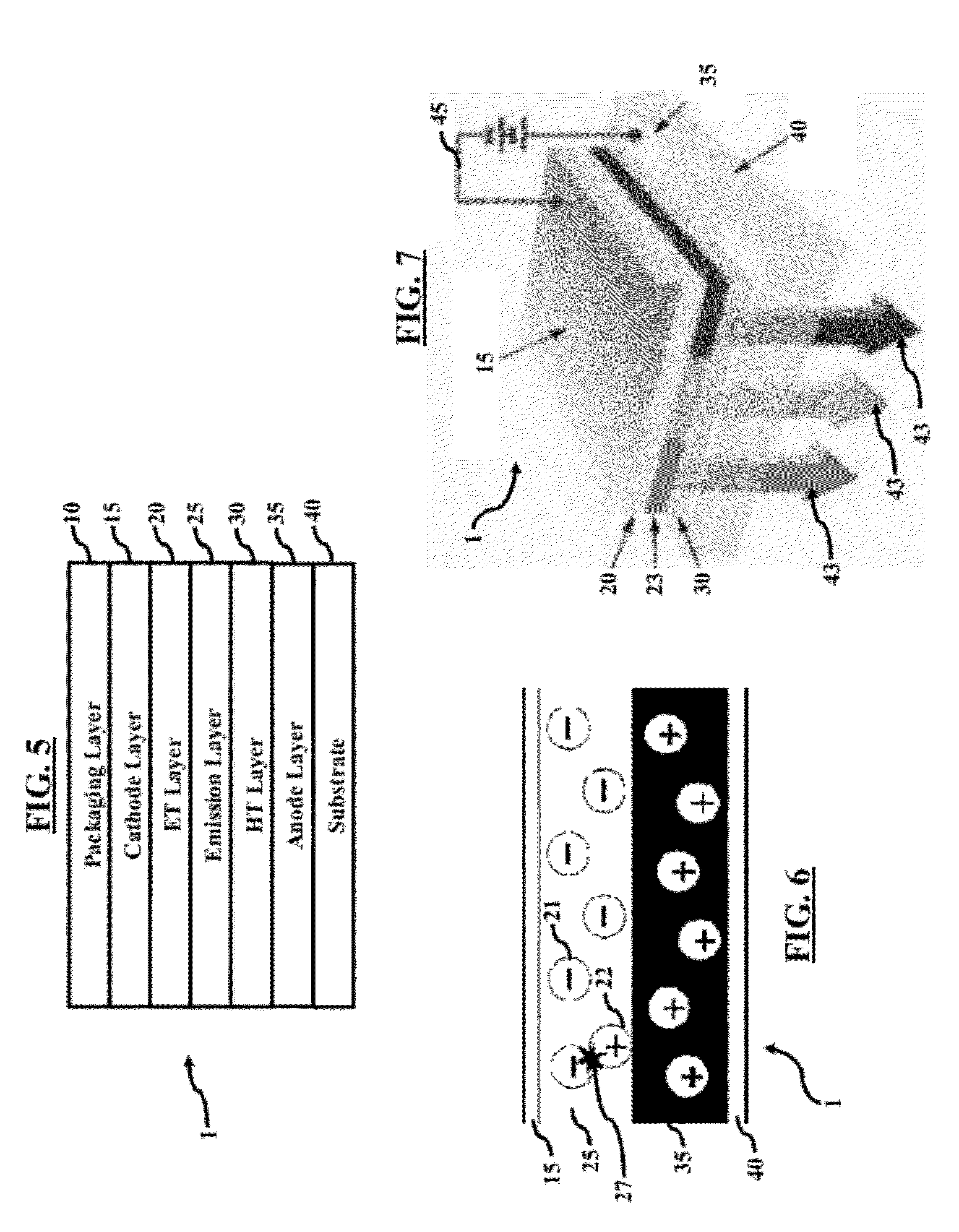

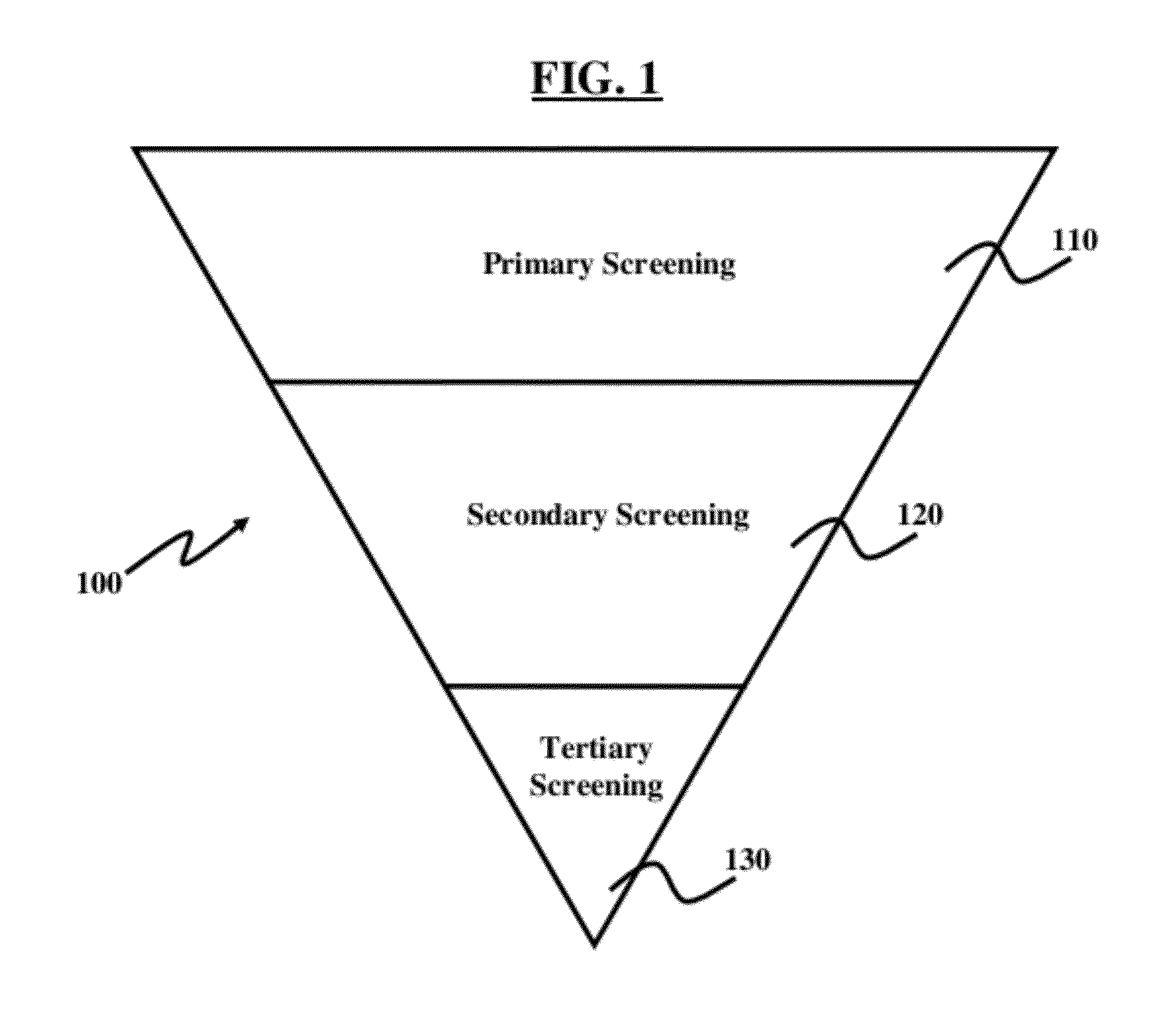

System and Method for Increasing Productivity of Organic Light Emitting Diode Material Screening

ActiveUS20120244644A1Semiconductor/solid-state device testing/measurementSolid-state devicesProduction rateCharacterization test

A system and method of increasing productivity of OLED material screening includes providing a substrate that includes an organic semiconductor, processing regions on the substrate by combinatorially varying parameters associated with the OLED device production on the substrate, performing a first characterization test on the processed regions on the substrate to generate first results, processing regions on the substrate in a combinatorial manner by varying parameters associated with the OLED device production on the substrate based on the first results of the first characterization test, performing a second characterization test on the processed regions on the substrate to generate second results, and determining whether the substrate meets a predetermined quality threshold based on the second results.

Owner:INTERMOLECULAR

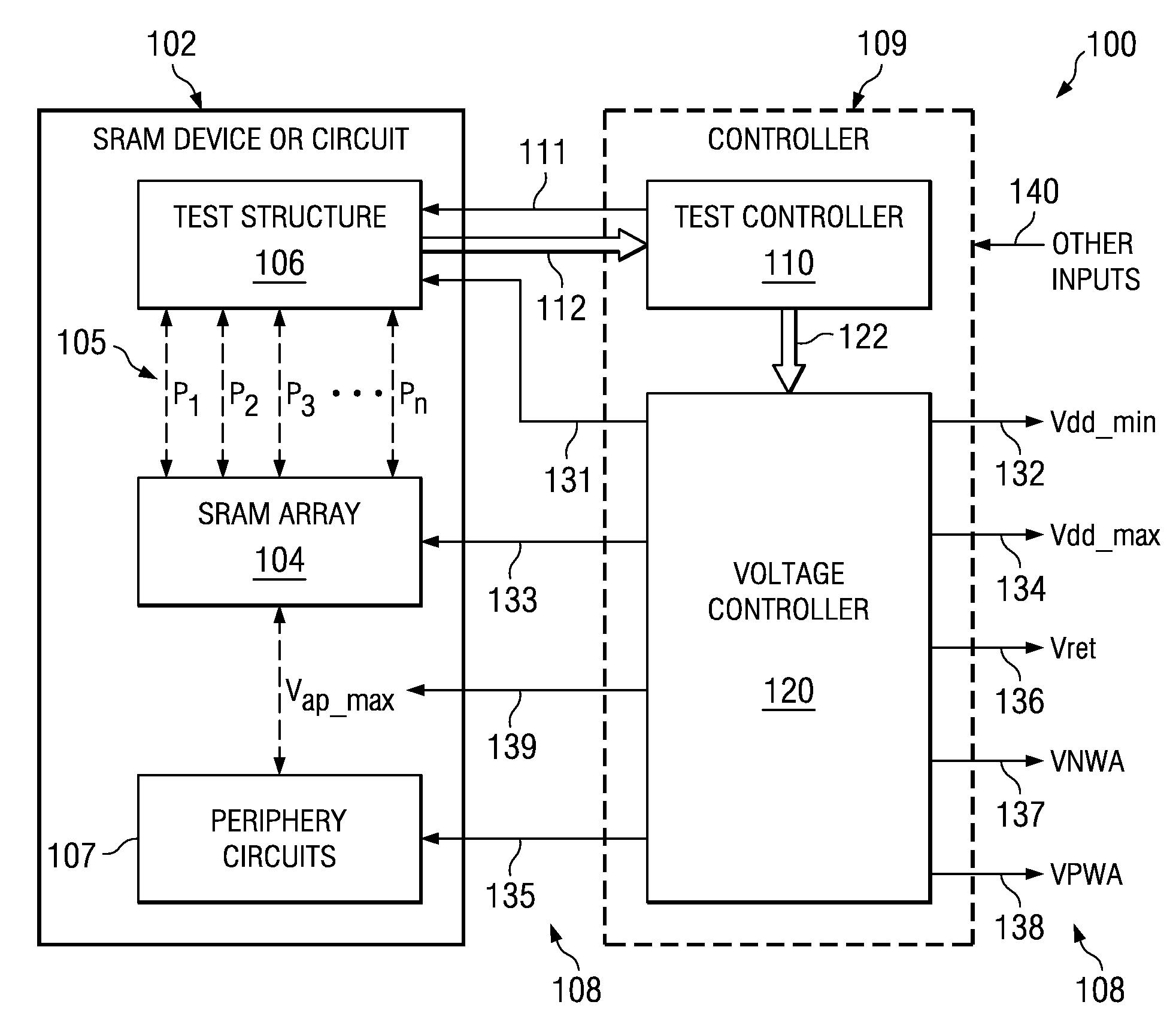

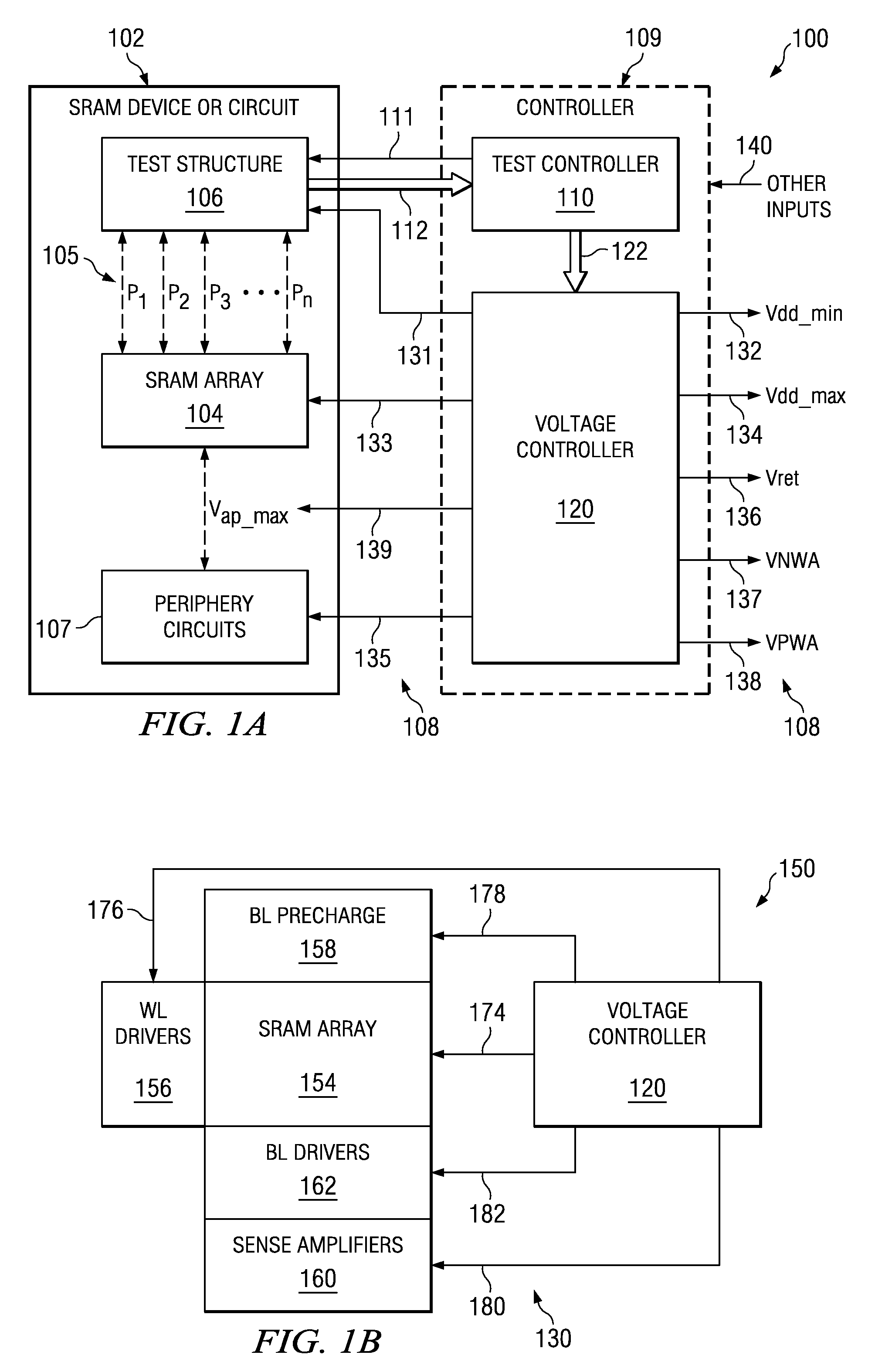

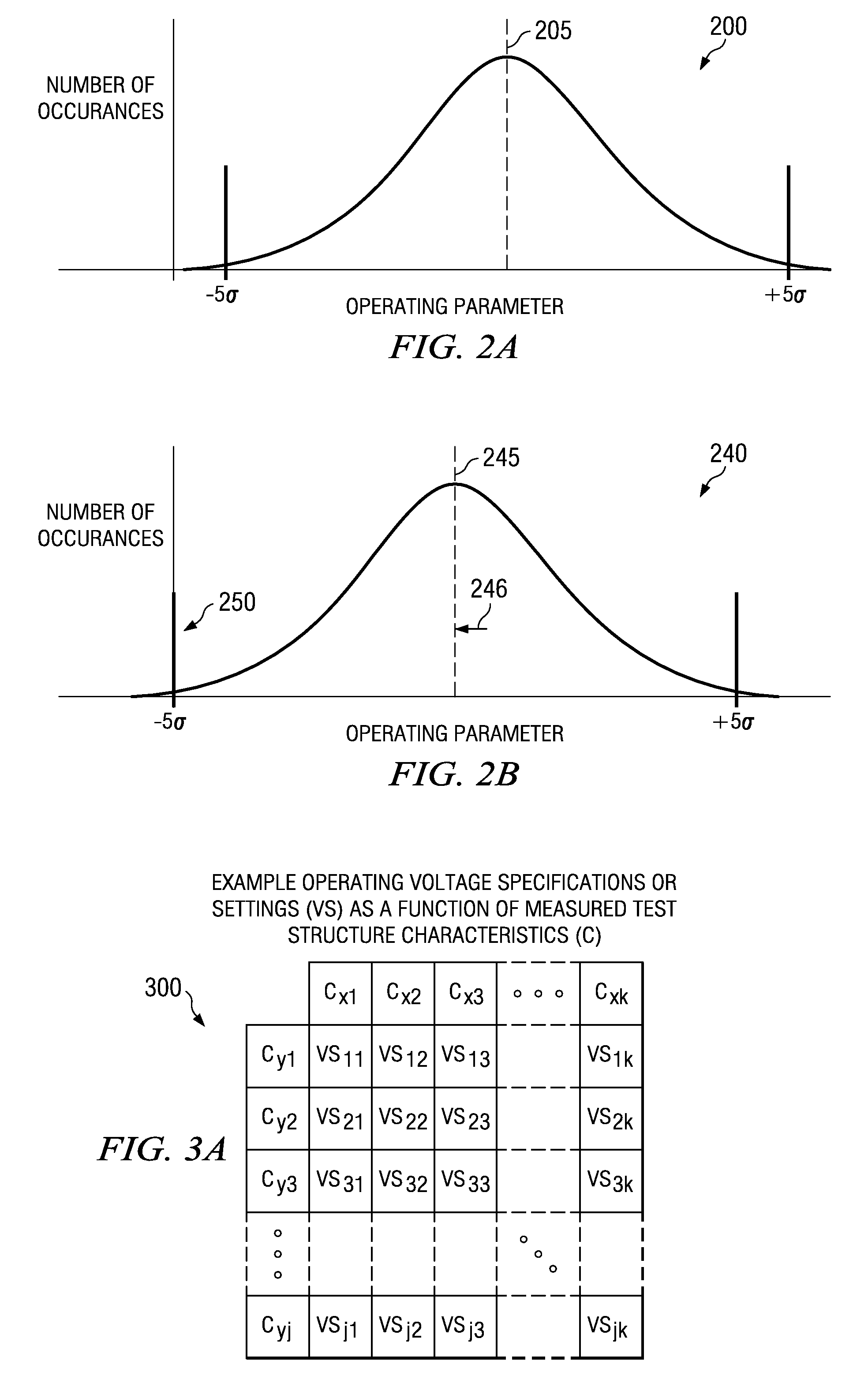

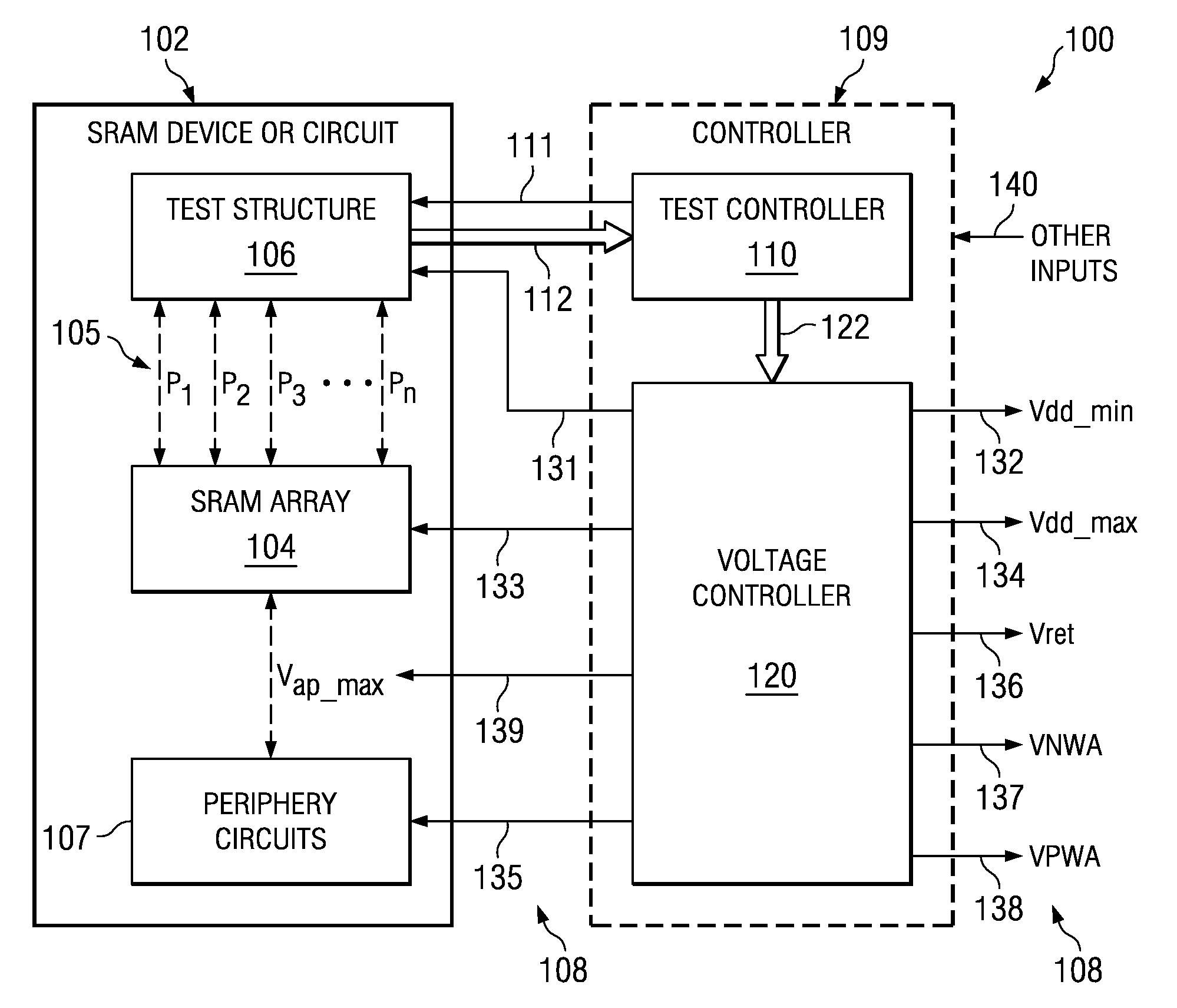

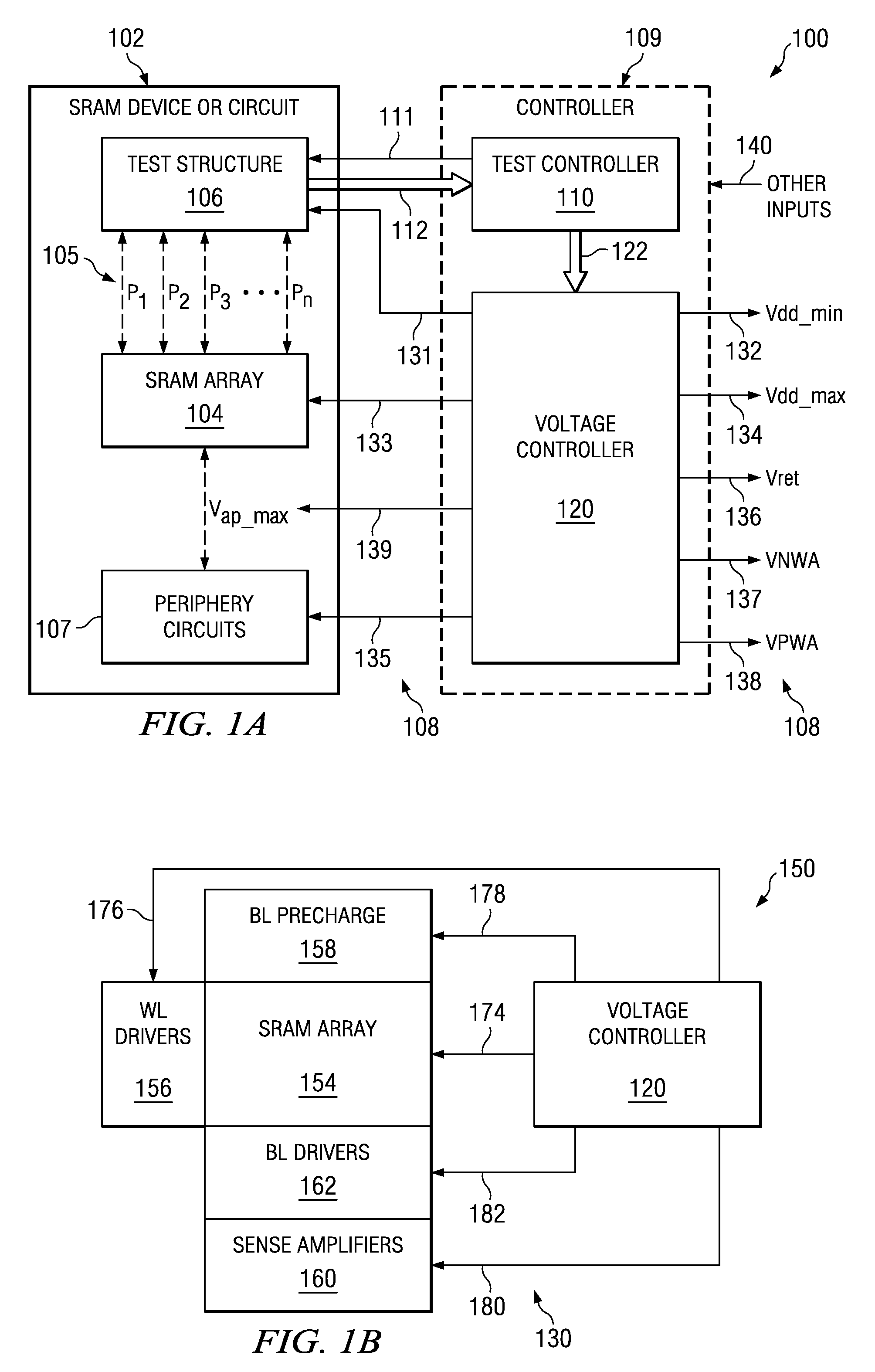

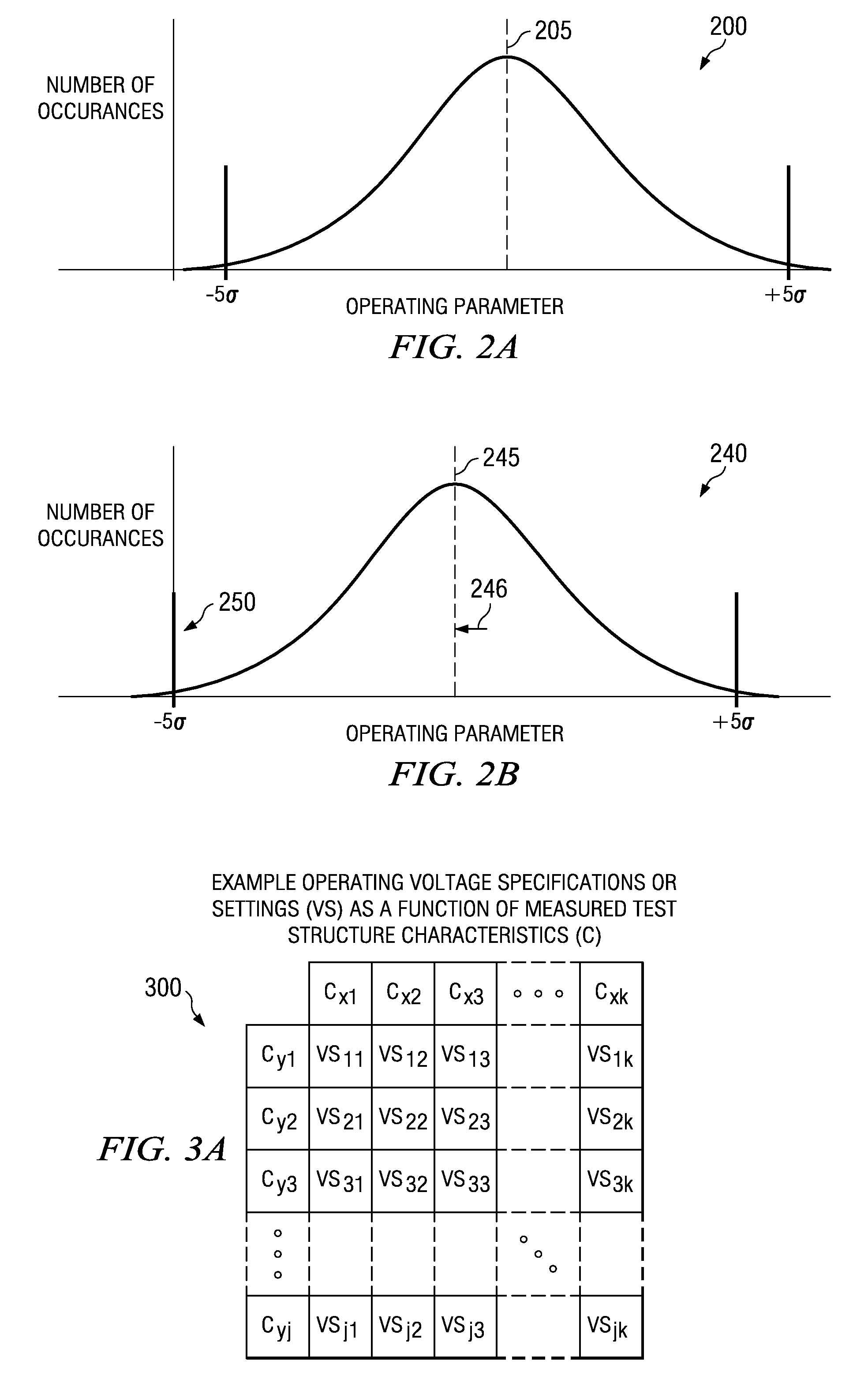

Adaptive voltage control for SRAM

The present invention pertains to semiconductor memory devices, and particularly to a system and method for adaptively setting the operating voltages for SRAM for both Vtrip and SNM to reduce power while maintaining functionality and performance, based on modeling and characterizing a test structure. One embodiment comprises an SRAM array, a test structure that characterizes one or more parameters that are predictive of the SRAM functionality and outputs data of the parameters, a test controller that reads the parameters and identifies an operating voltage that satisfies predetermined yield criteria, and a voltage controller to set an operating voltage for the SRAM array based on the identified operating voltage. One method sets an operating voltage for an SRAM by reading test structure data of the parameters, analyzing the data to identify an operating voltage that satisfies predetermined yield criteria, and setting the operating voltage for the SRAM based on the identified operating voltage.

Owner:TEXAS INSTR INC

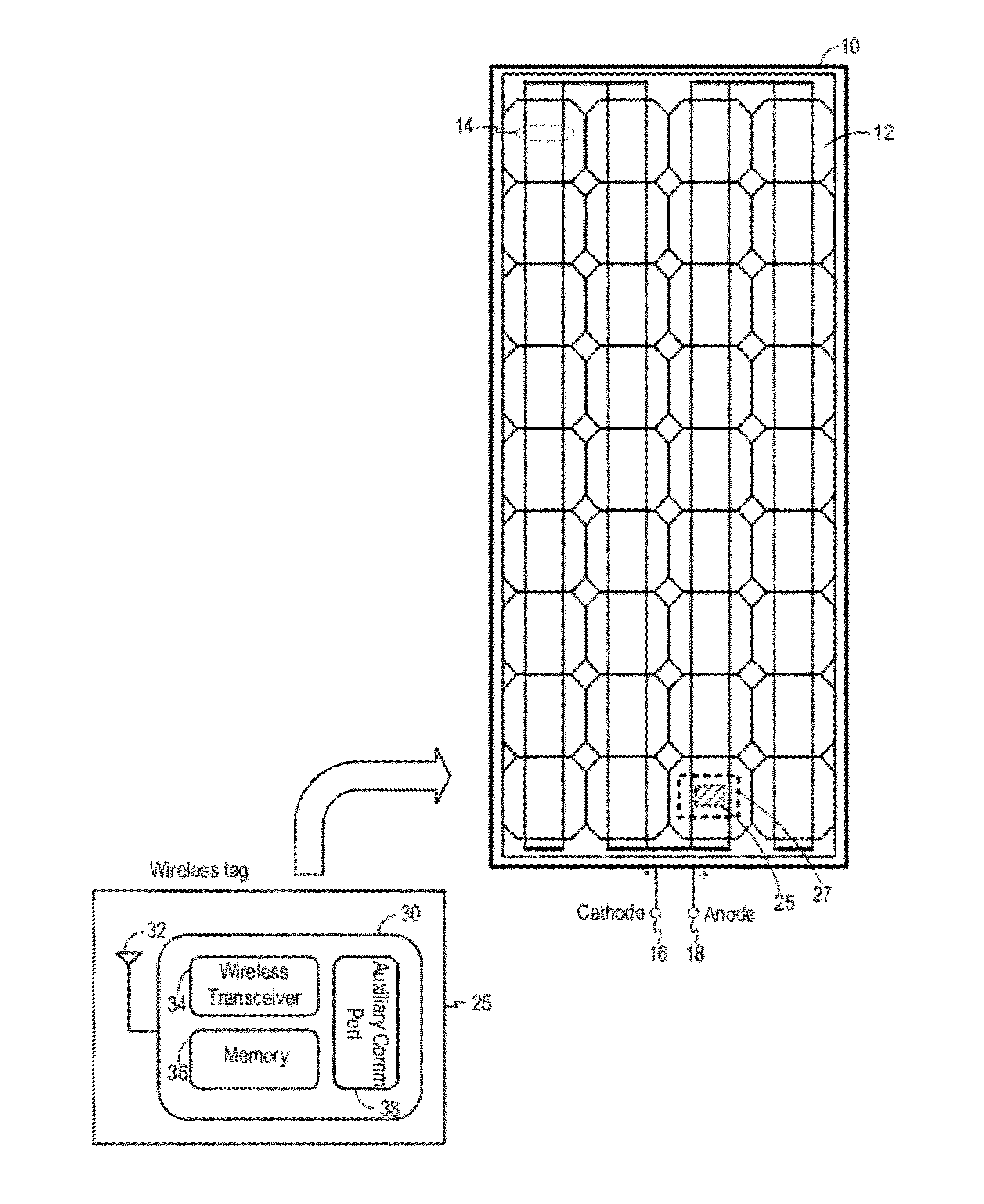

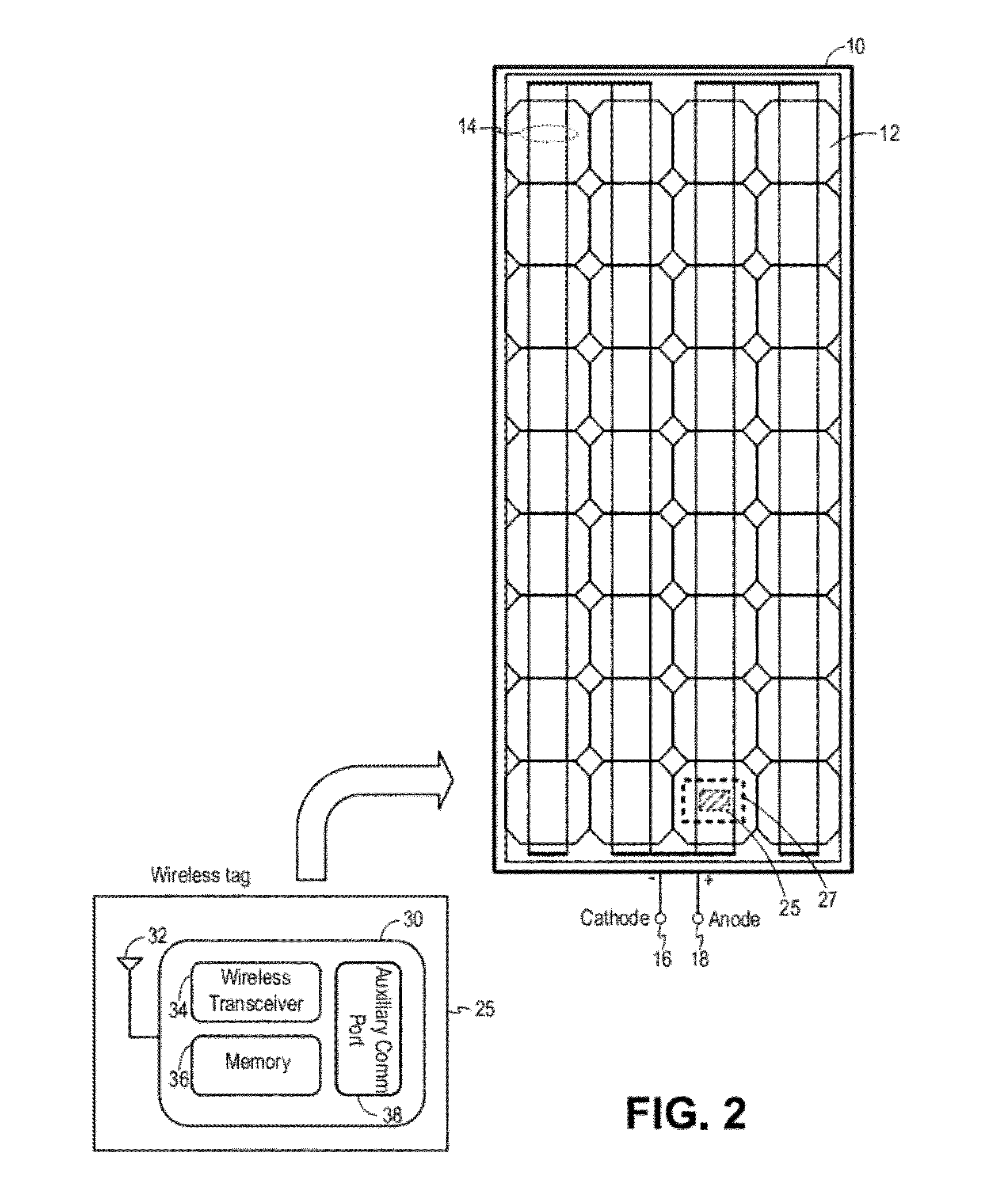

System and Method For Storing Panel-Specific Data onto a Wireless Tag Affixed to a Solar Panel

InactiveUS20120227792A1Photovoltaic monitoringPV power plantsCommunication interfaceCharacterization test

A solar panel includes a wireless tag affixed to the solar panel where the wireless tag includes a wireless communication interface, a memory, and an auxiliary communication port. The memory of the wireless tag is configured to store at least panel-specific data of the solar panel where the panel-specific data includes at least current-voltage characteristics of the solar panel. The data is stored onto the memory of the wireless tag through the auxiliary communication port and the stored data is accessible through the wireless communication interface of the wireless tag. In another embodiment, a method for storing panel-specific data in a solar panel includes placing the solar panel with a wireless tag affixed thereto in a solar panel characterization chamber to perform characterization test and storing panel-specific data of the solar panel, including at least current-voltage characteristics of the solar panel, in the memory of the wireless tag.

Owner:E LIGHTRIC

Adaptive voltage control for SRAM

Owner:TEXAS INSTR INC

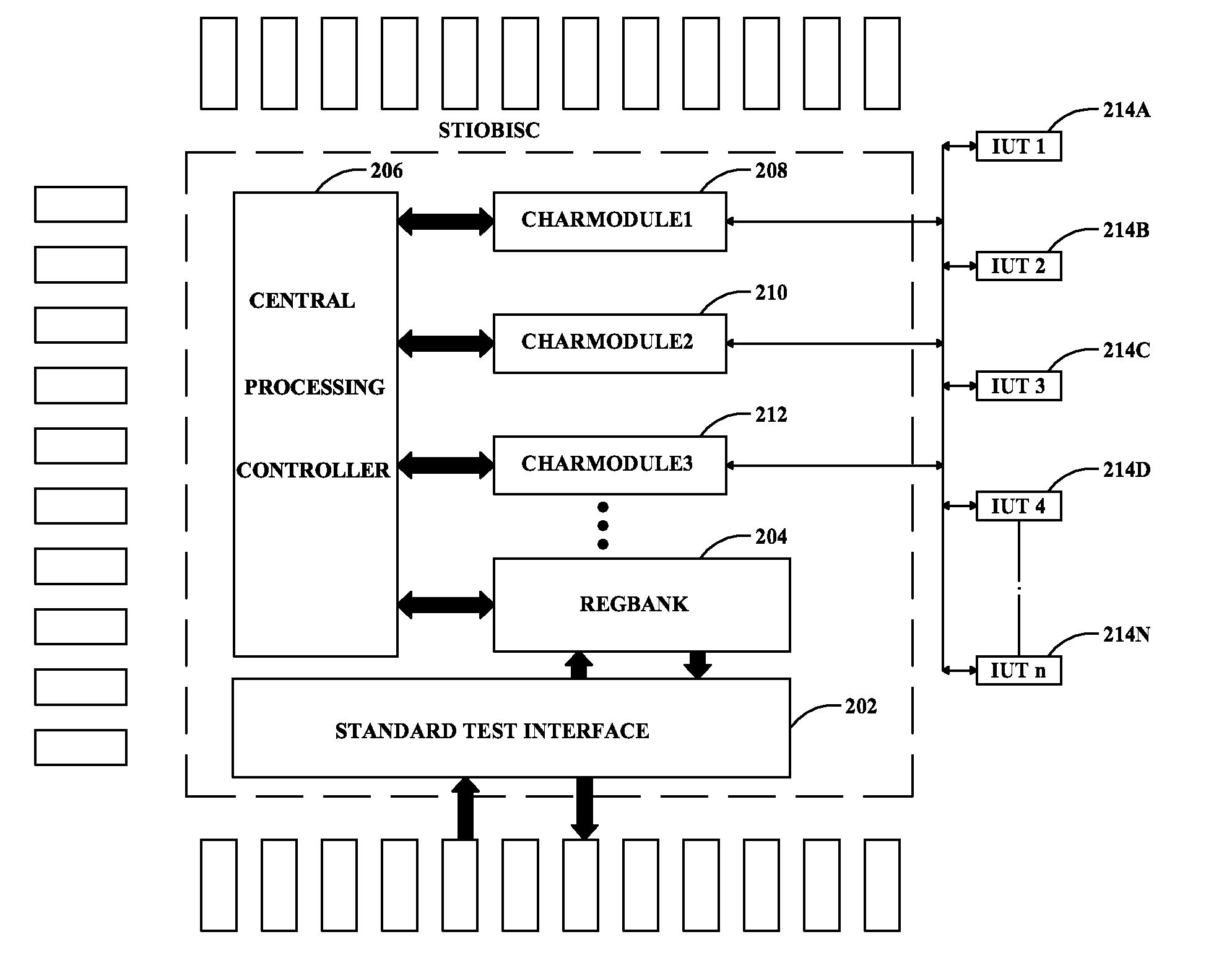

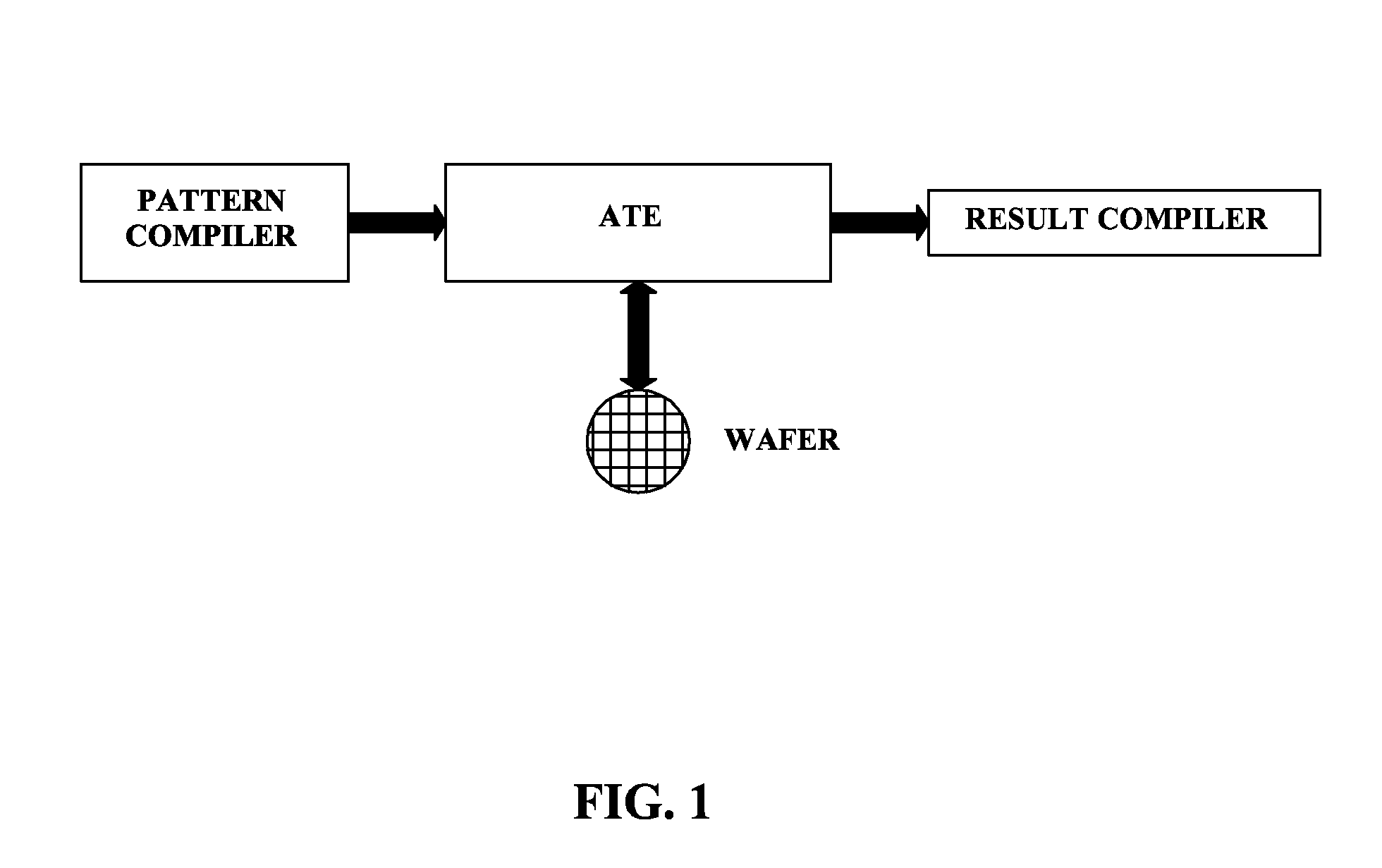

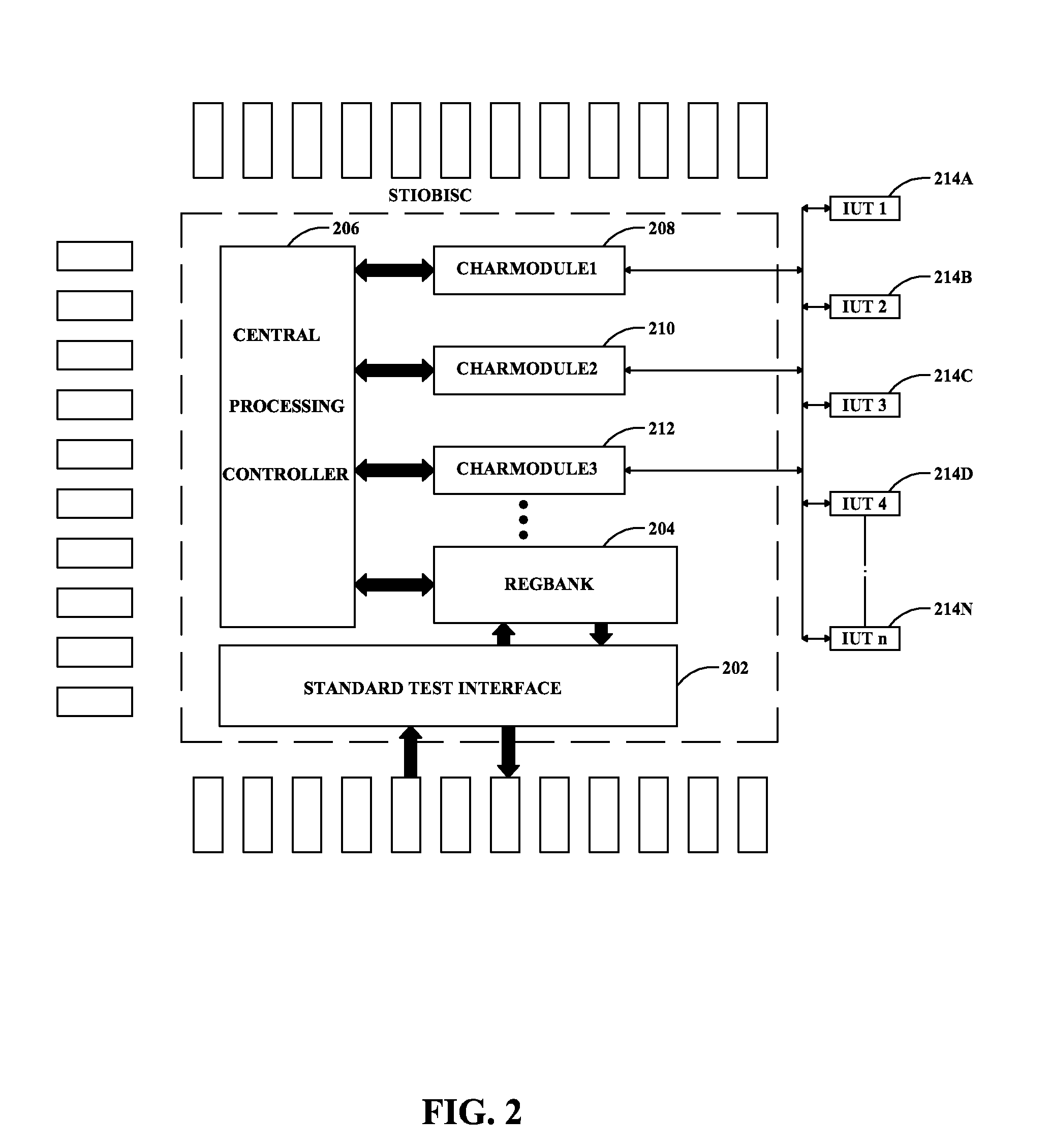

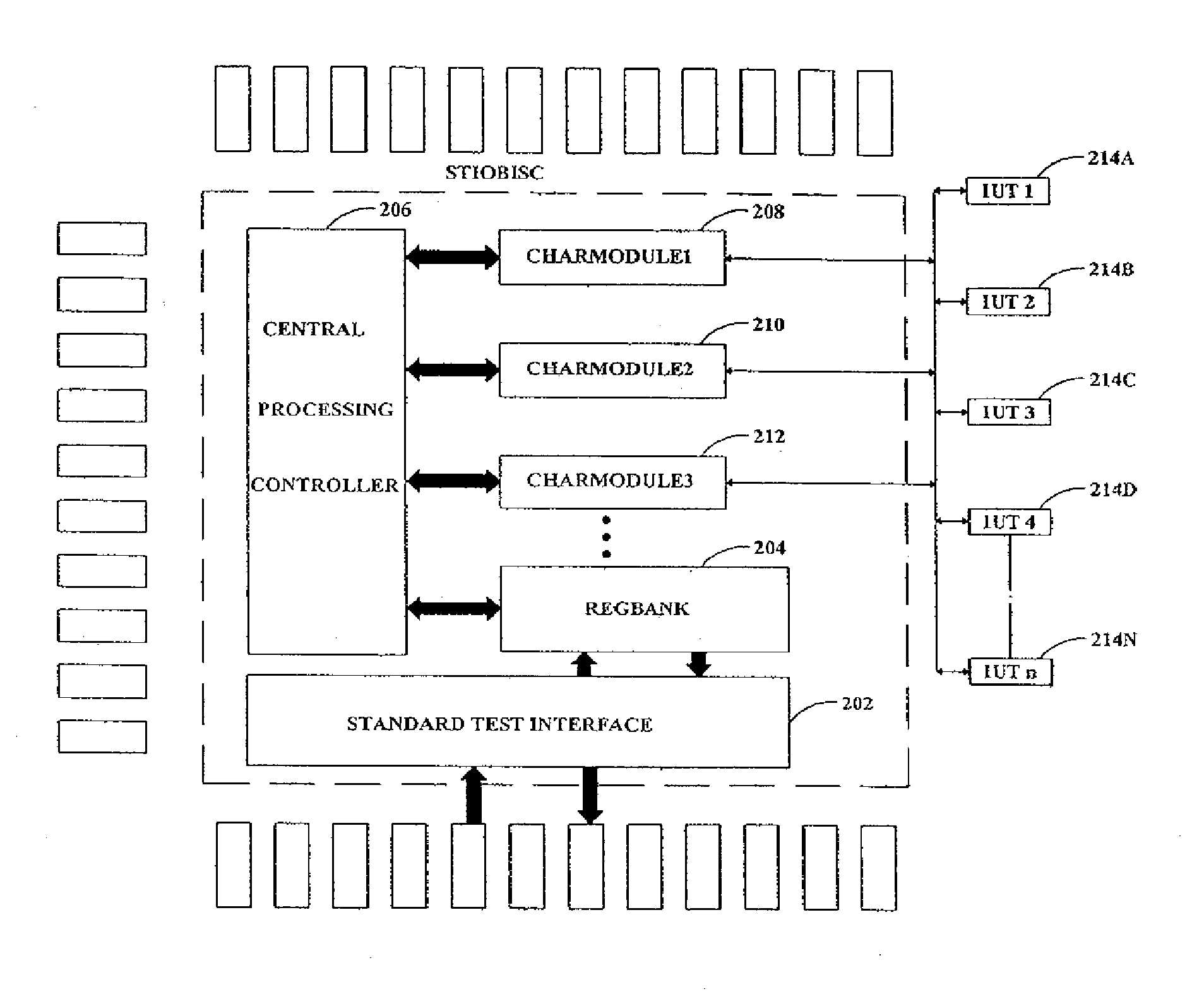

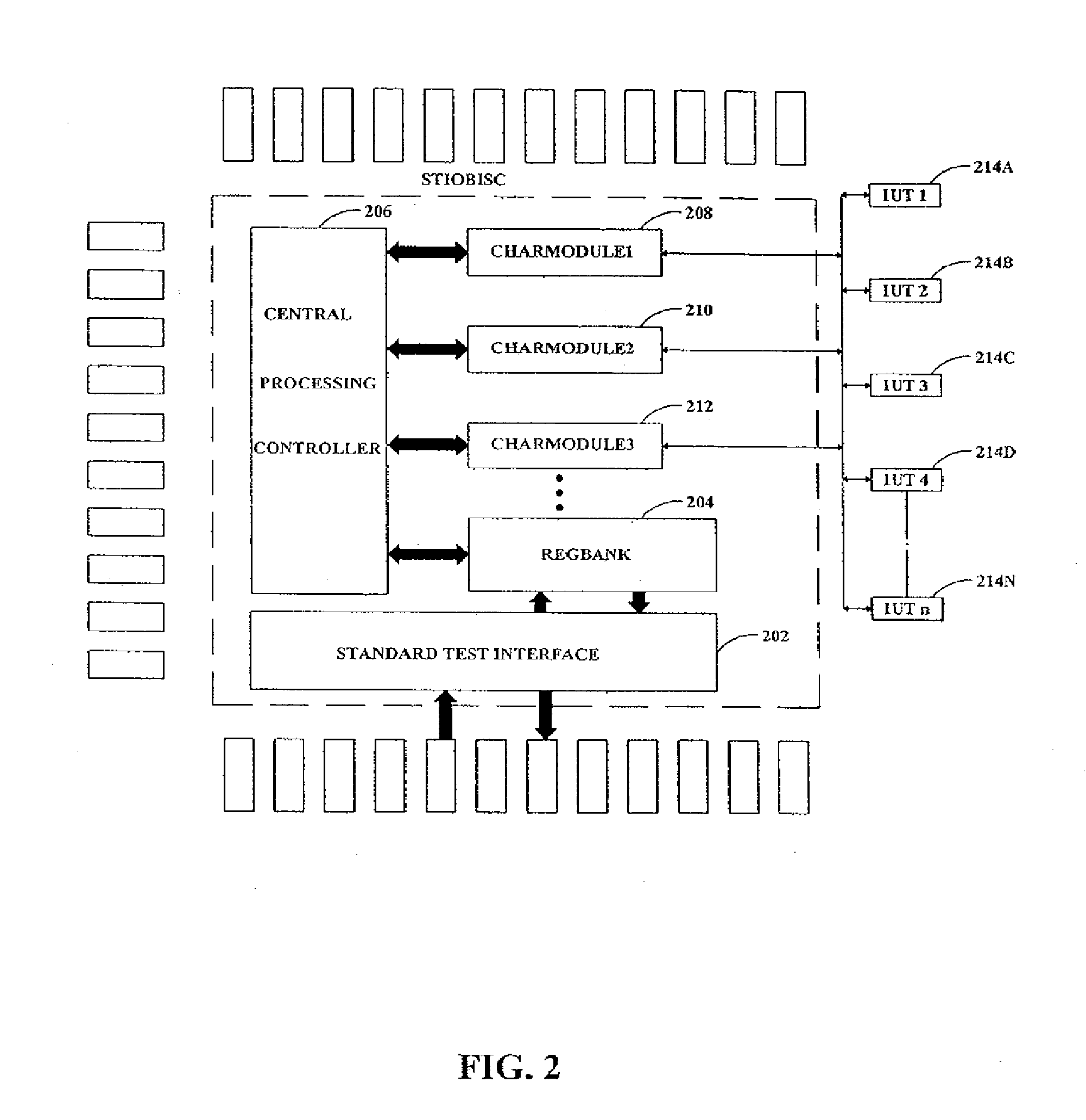

Flexible on chip testing circuit for i/o's characterization

The present invention provides a flexible on-chip testing circuit and methodology for measuring I / O characterization of multiple I / O structures. The testing circuit includes a register bank, a central processing controller (CPC), a character slew module, a delay characterization module, and a character frequency module. The register bank stores multiple instructions, and measurement results. The CPC fetches the instructions from the register bank. The CPC includes various primary and secondary state machines for interpreting the fetched instructions for execution. Depending on the input instruction the CPC applies stimulus to the IUT and the output of the IUT is used by the Local characterization modules (CHARMODULE) to extract the desired characterization parameters such as the character slew module which measures a voltage rise / fall time either for a single voltage IUT or a multi-voltage IUT. The Test Methodology for STIOBISC consists of an automated ATE pattern generation from verification test benches and automated result processing by converting the ATE data logs into the final readable format, thereby considerably reducing the test setup and output processing time. The testing circuit can operate in multiple modes for selecting one of these modules.

Owner:STMICROELECTRONICS PVT LTD

Flexible on chip testing circuit for i/o's characterization

ActiveUS20090076753A1Digital circuit testingVoltage-current phase angleFall timeCharacterization test

The present invention provides a flexible on-chip testing circuit and methodology for measuring I / O characterization of multiple I / O structures. The testing circuit includes a register bank, a central processing controller (CPC), a character slew module, a delay characterization module, and a character frequency module. The register bank stores multiple instructions, and measurement results. The CPC fetches the instructions from the register bank. The CPC includes various primary and secondary state machines for interpreting the fetched instructions for execution. Depending on the input instruction the CPC applies stimulus to the IUT and the output of the IUT is used by the Local characterization modules (CHARMODULE) to extract the desired characterization parameters such as the character slew module which measures a voltage rise / fall time either for a single voltage IUT or a multi-voltage IUT. The Test Methodology for STIOBISC consists of an automated ATE pattern generation from verification test benches and automated result processing by converting the ATE data logs into the final readable format, thereby considerably reducing the test setup and output processing time. The testing circuit can operate in multiple modes for selecting one of these modules.

Owner:STMICROELECTRONICS PVT LTD

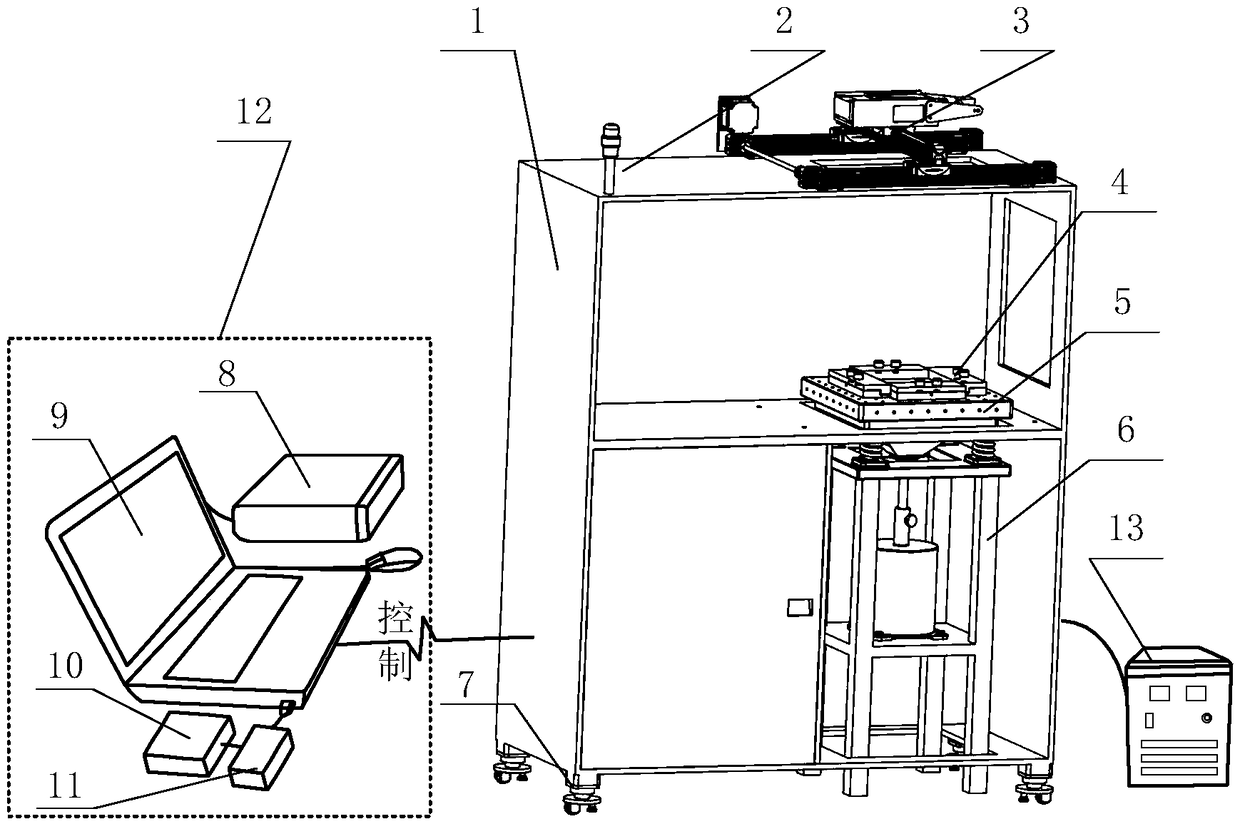

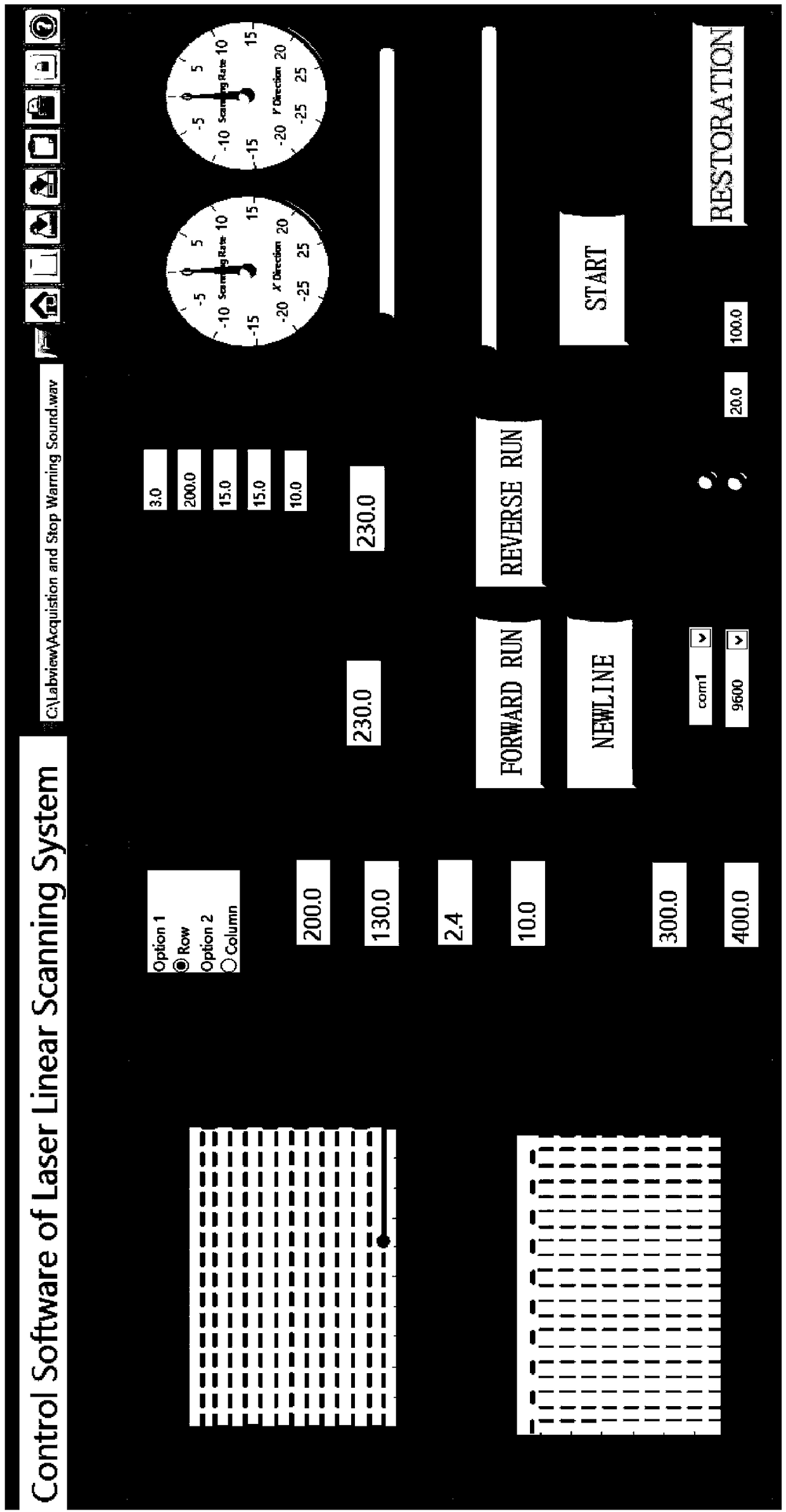

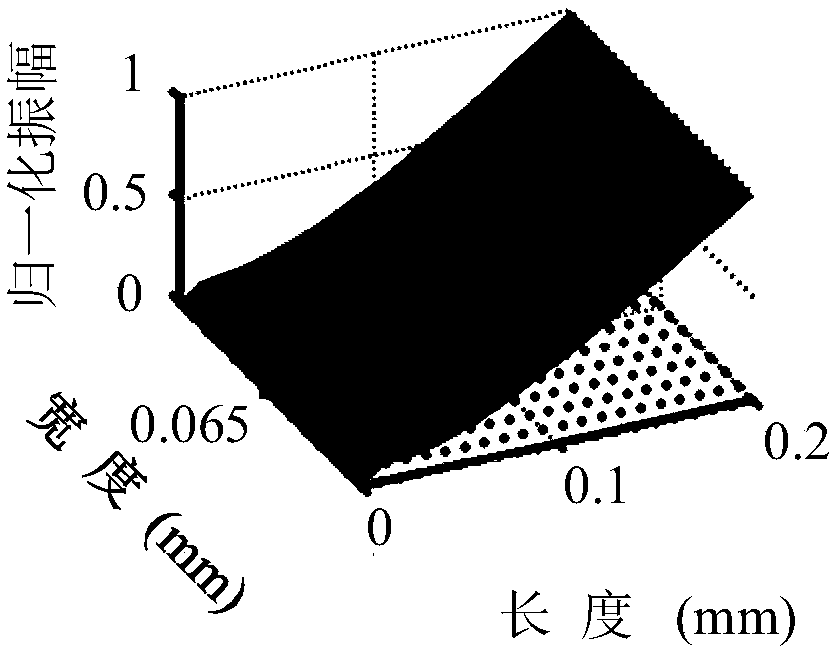

Fiber composite thin plate nonlinear vibration characterization test method based on vibration measurement with laser

InactiveCN108760020AImprove test efficiencyTest accurateSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFiberCharacterization test

The invention relates to a fiber composite thin plate nonlinear vibration characterization test method based on vibration measurement with laser, First, the inherent frequency and modal shape of a fiber composite thin plate needs to be obtained accurately. Then, a nonlinear vibration characterization test is carried out according to a test idea of from a time domain to a frequency domain and thento a time-frequency domain. The specific steps are as follows: testing inherent frequency of each order of the fiber composite thin plate; testing the modal shape of each order of the fiber compositethin plate according to the inherent frequency; carrying out a harmonic distortion nonlinear characterization test; carrying out a nonlinear time-varying damping characterization test; carrying out ahard / soft rigidity nonlinear characterization test; carrying out a characterization test of amplitude dependent on nonlinear damping; carrying out a nonlinear jump characterization test; carrying outan ultraharmonic / subharmonic resonance nonlinear characterization test; and carrying out an internal resonance nonlinear characterization test. The method provided by the invention can obtain variousnonlinear vibration characterization of the fiber composite thin plate through one-time testing, a test result is relatively accurate, the test efficiency is improved, and an important reference is provided for establishing a method system for a nonlinear vibration test of a composite structure of this type.

Owner:NORTHEASTERN UNIV

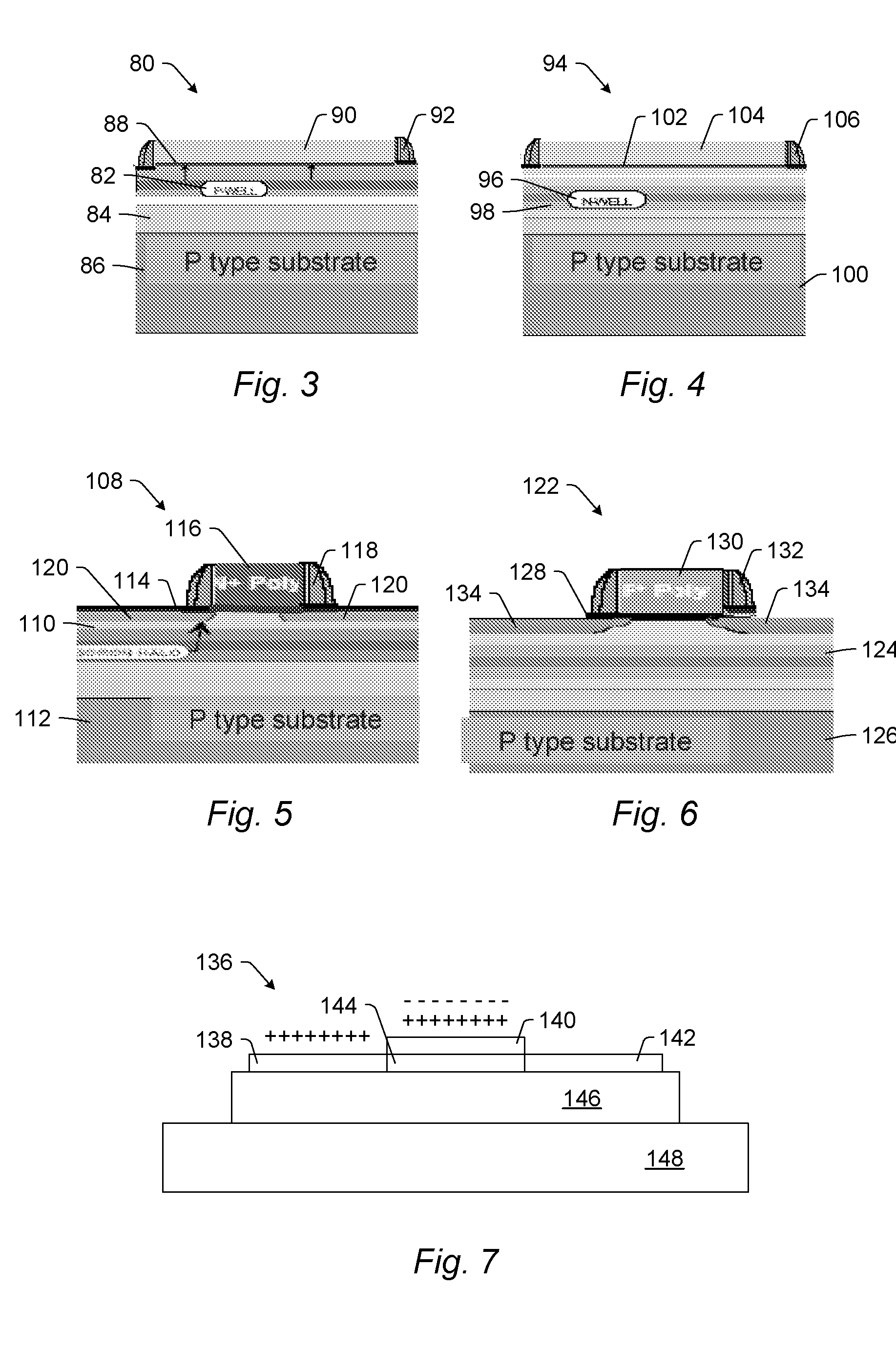

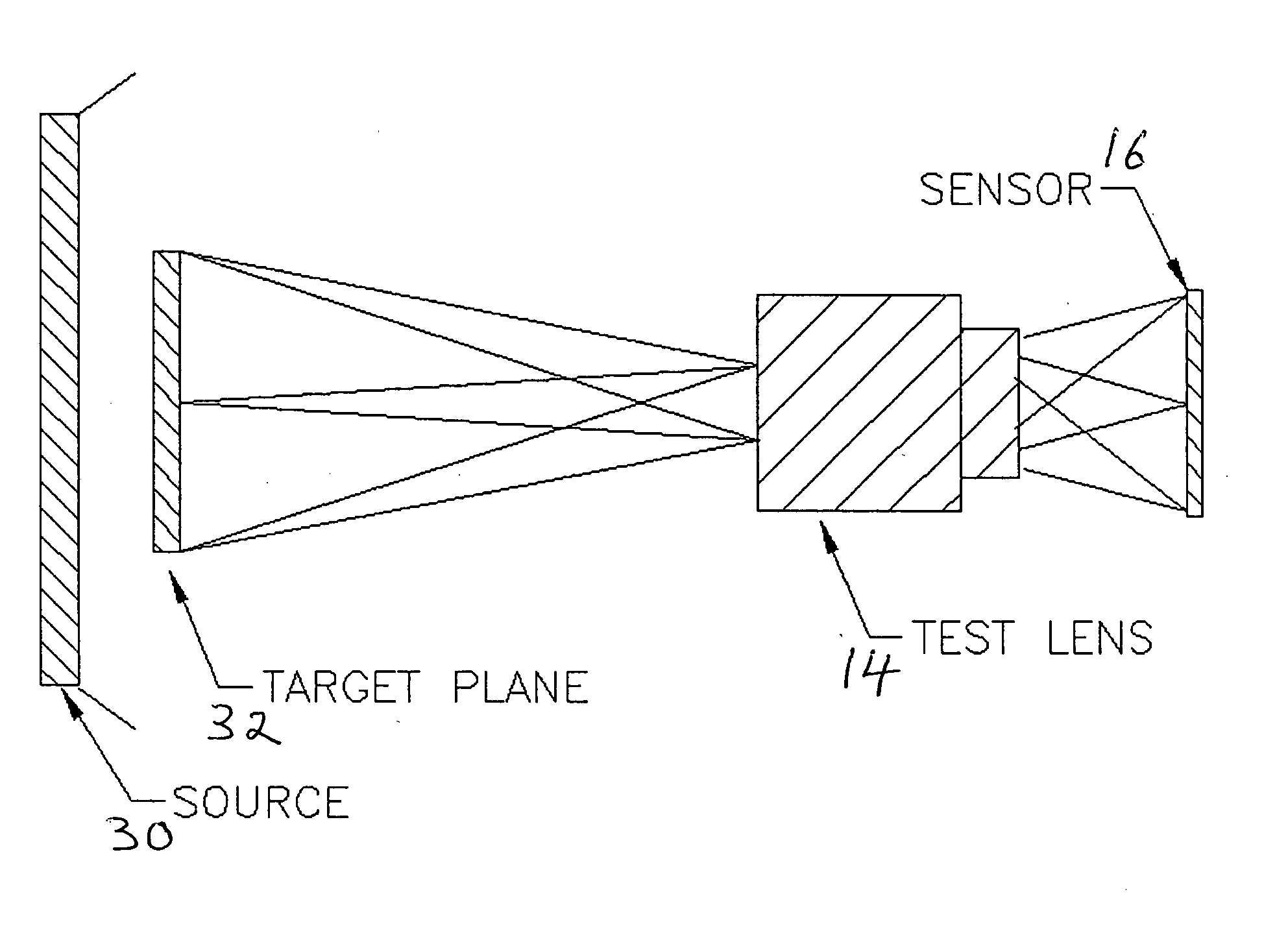

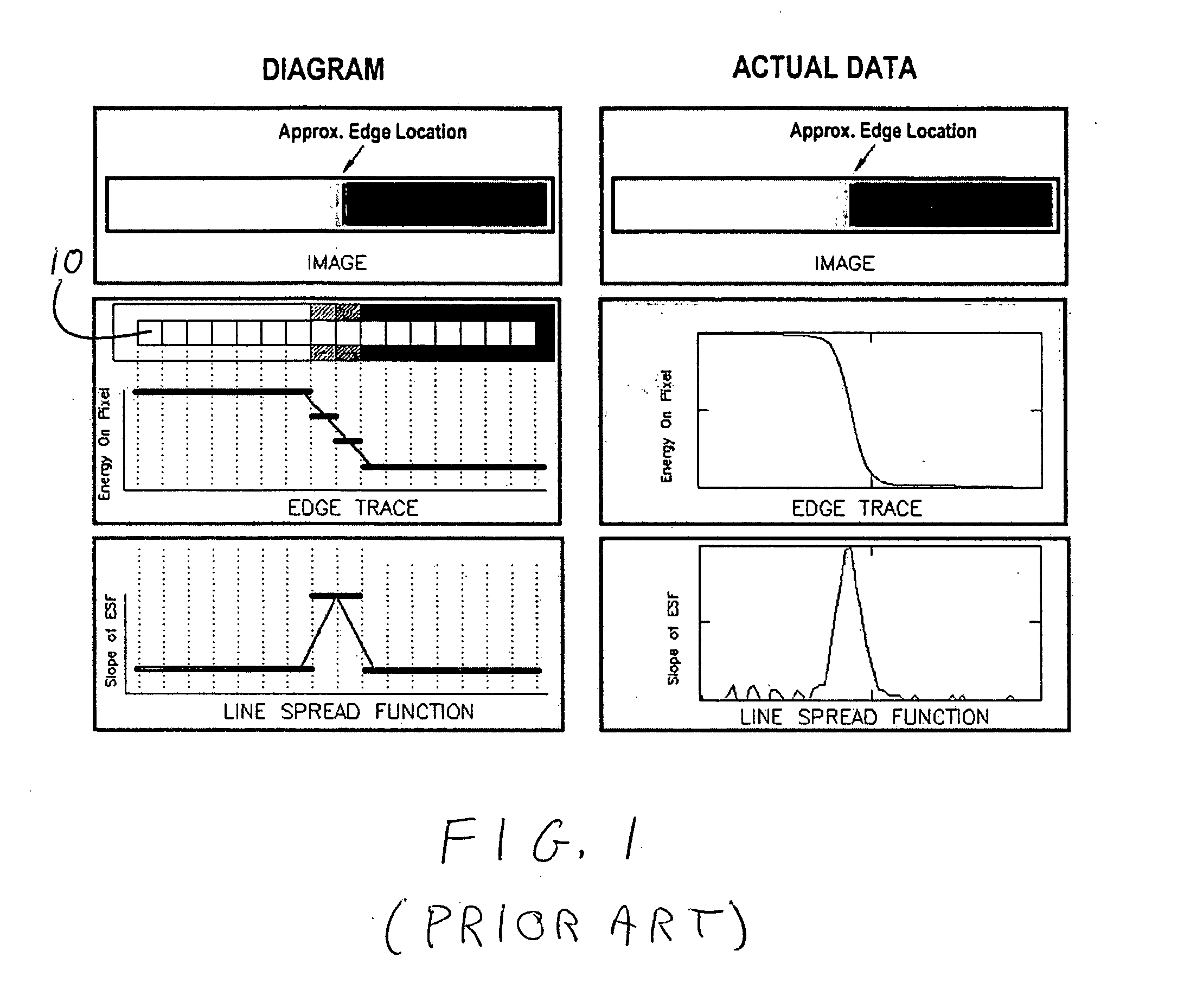

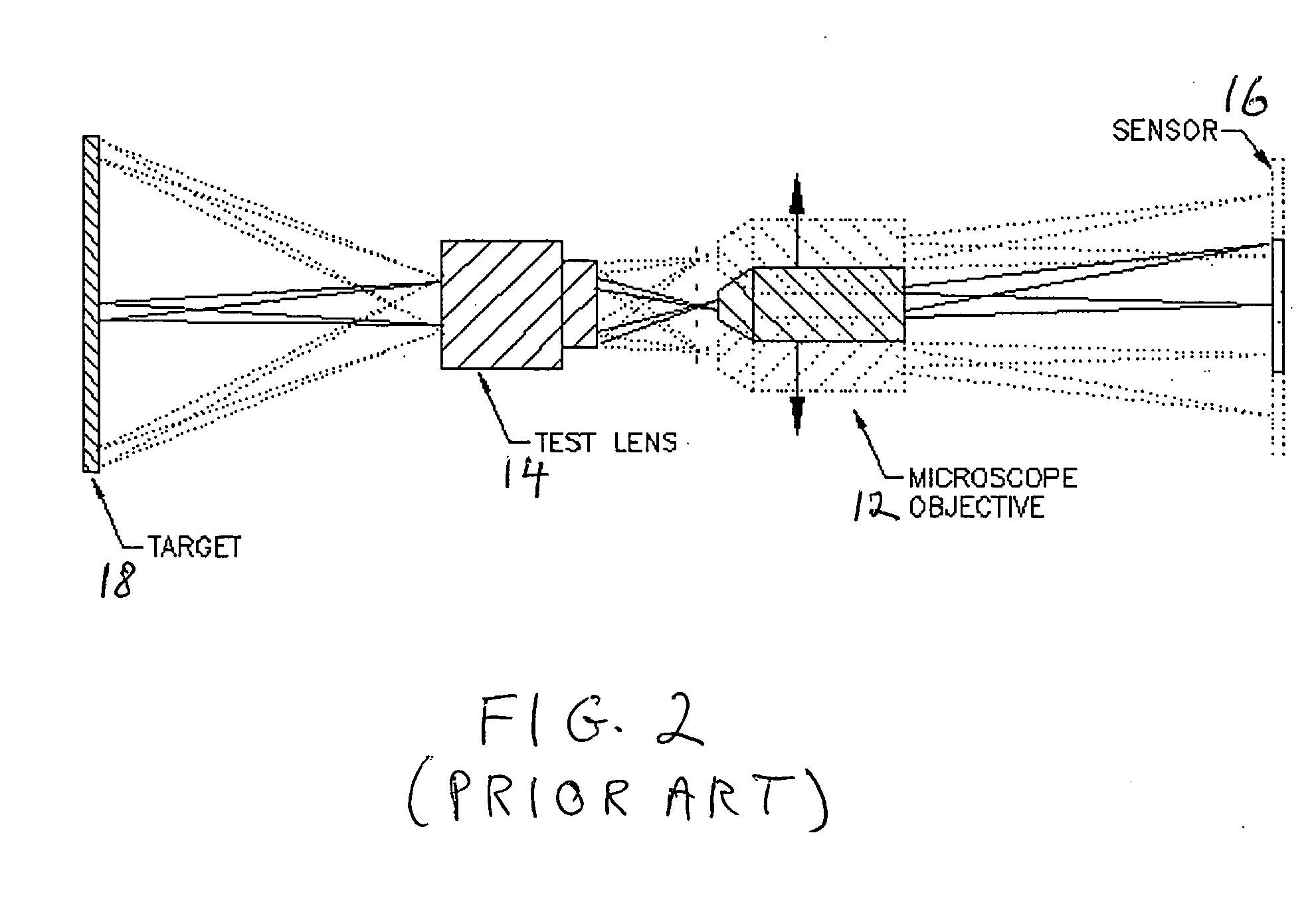

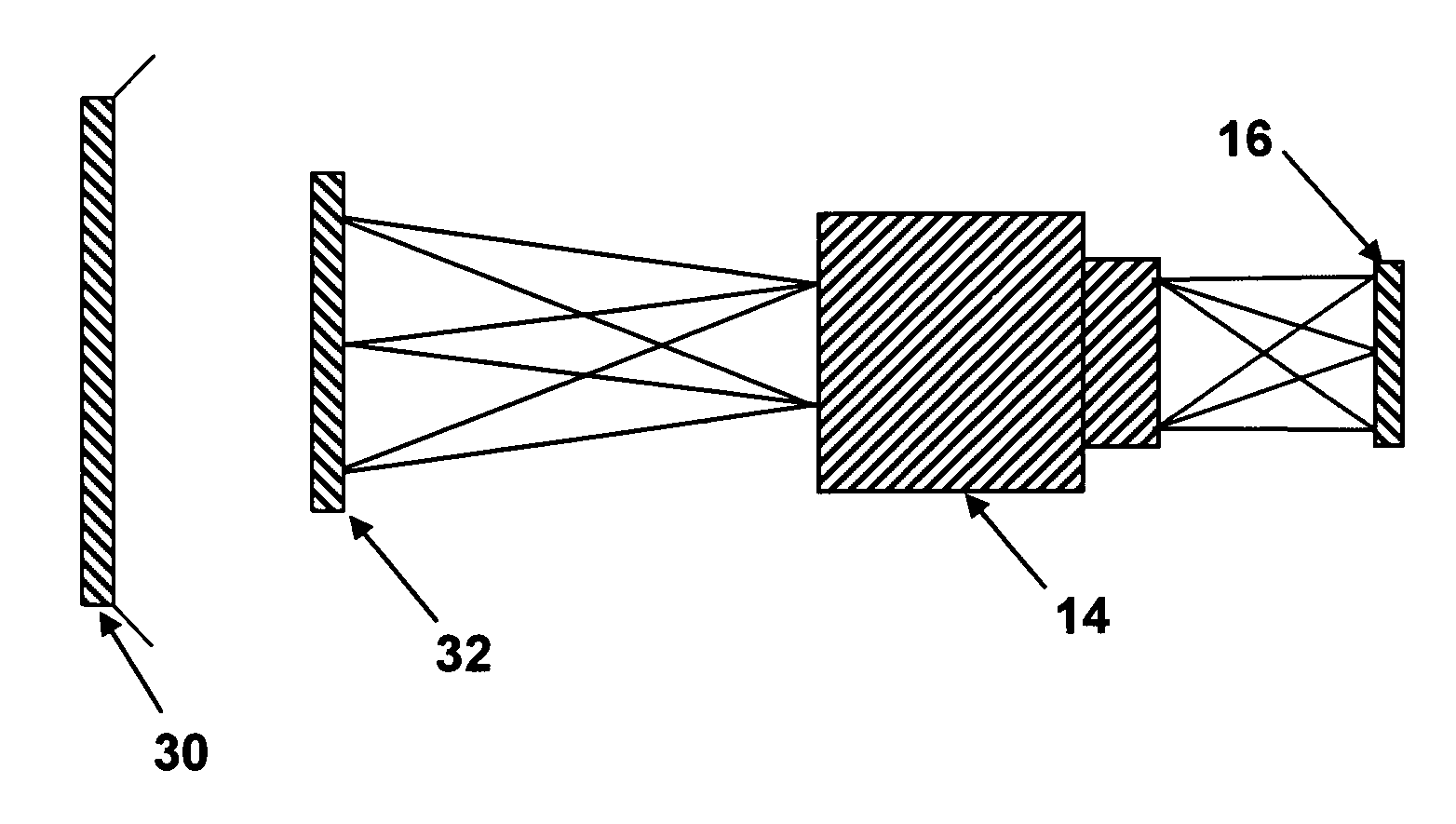

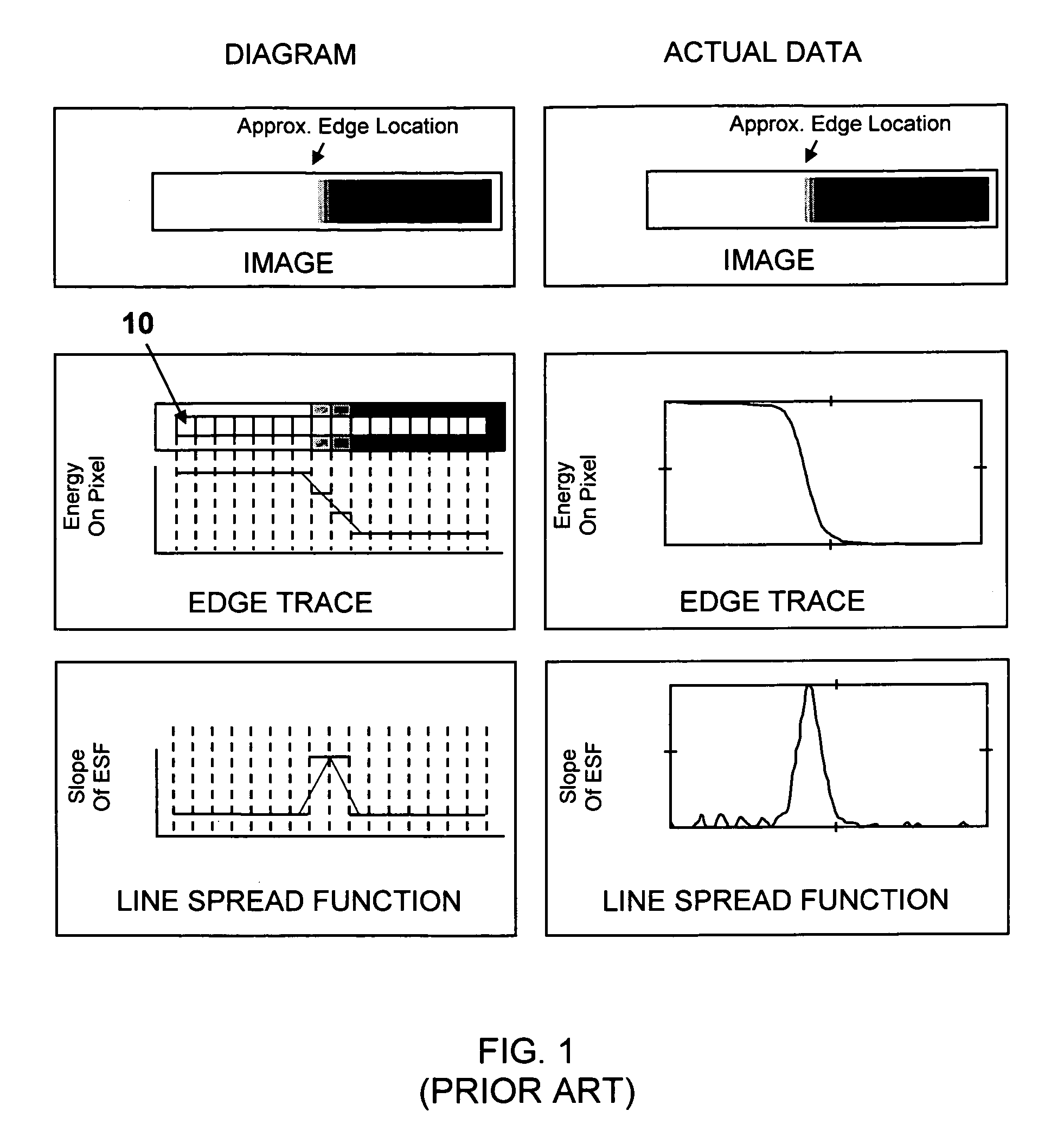

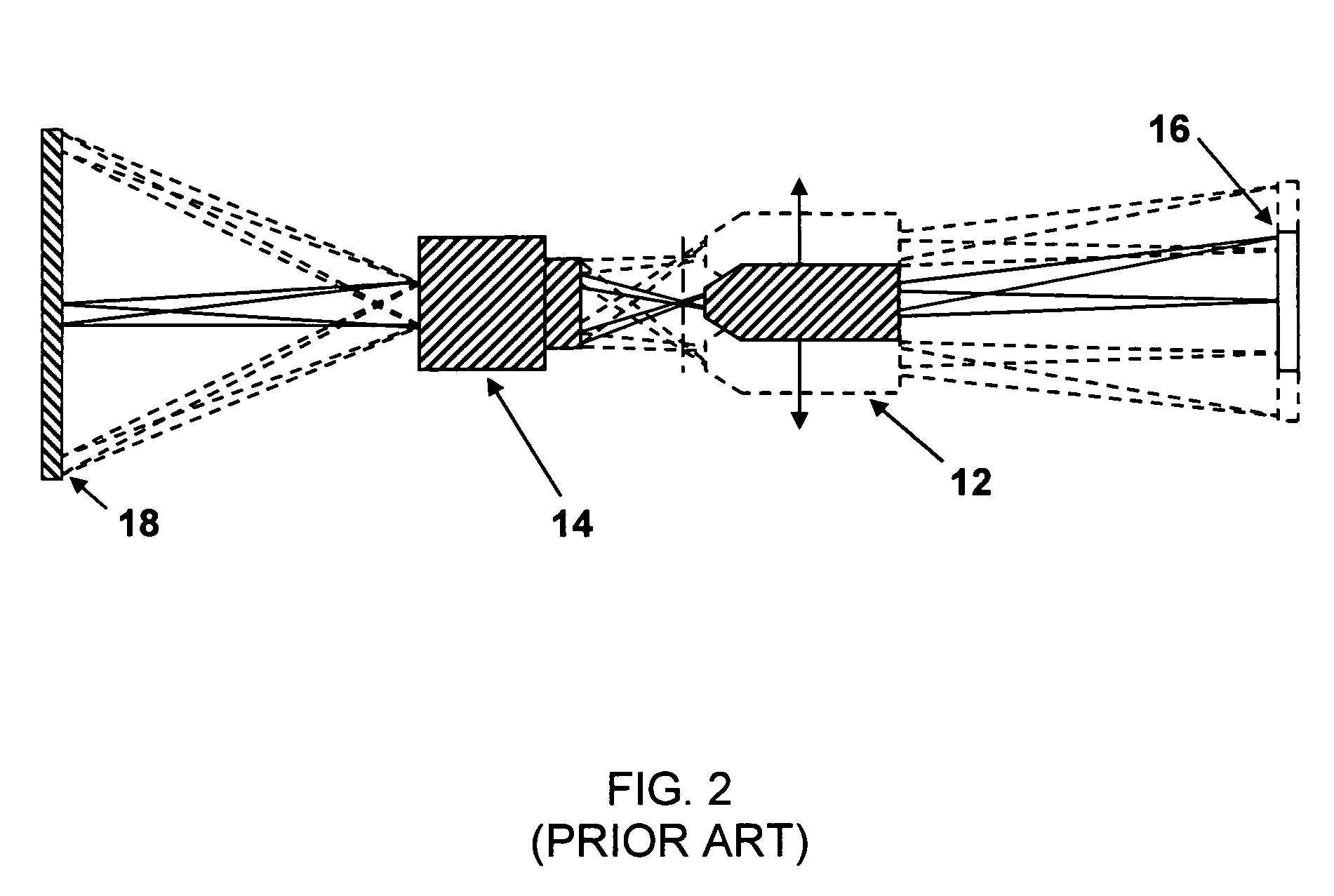

Tilted edge for optical-transfer-function measurement

InactiveUS20050254041A1Quick calculationAvoid aliasingUsing optical meansTesting optical propertiesFast measurementCharacterization test

The optical transfer function of imaging optics is carried out with a plurality of tilted edges with respect to the edge-response detection line. The effect of the tilt is to stretch out the edge response so that fine details can be detected even operating at a spatial frequency below the Nyquist limit of the detector. The use of multiple targets, each corresponding to a sub-region of the field of view of the optics being tested, enables the simultaneous characterization of the full field of view of the test optics with a single measurement without the use of a magnifying objective. The result is a rapid measurement and a simpler apparatus suitable for high-throughput testing. A pair of tilted edges can be used in a target to also determine the sagittal and tangential OTFs (as well as that of any other arbitrary cross-section). All of these data are acquired with a single measurement.

Owner:EDMUND OPTICS

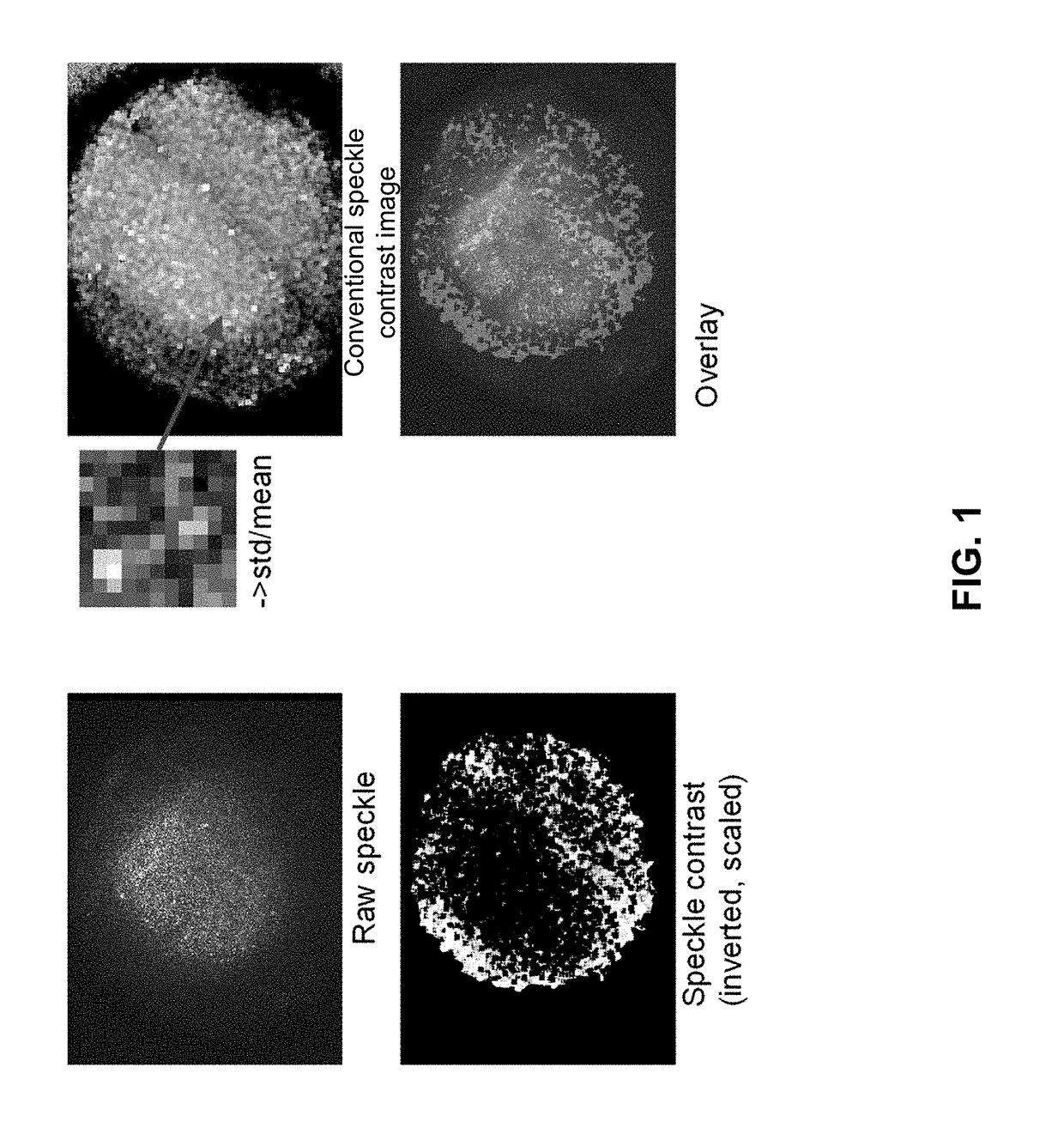

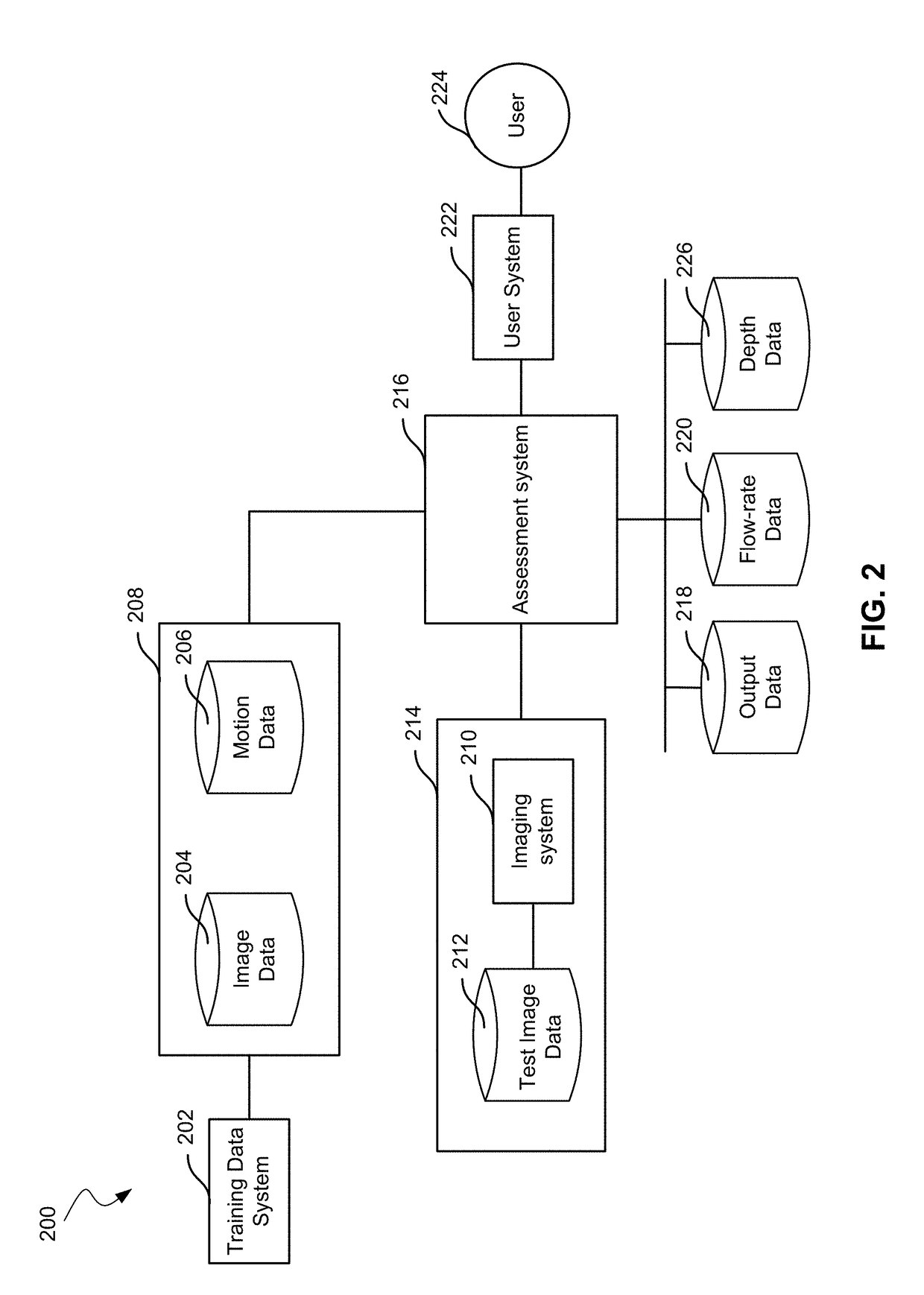

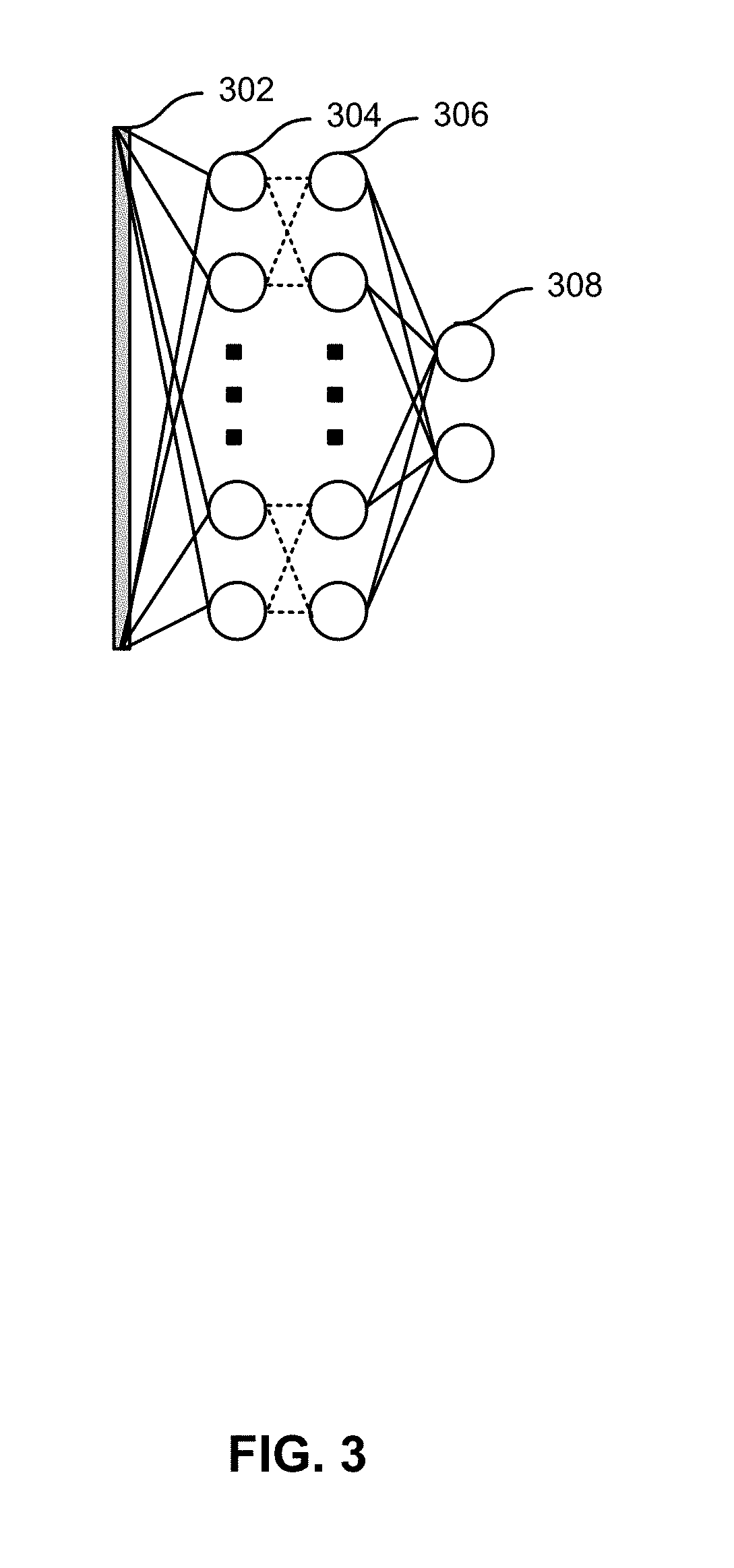

Speckle contrast analysis using machine learning for visualizing flow

Embodiments may include a method to estimate motion data based on test image data sets. The method may include receiving a training data set comprising a plurality of training data elements. Each element may include an image data set and a motion data set. The method may include training a machine learning model using the training data set, resulting in identifying one or more parameters of a function in the machine learning model based on correspondences between the image data sets and the motion data sets. The method may further include receiving a test image data set. The test image data set may include intensities of pixels in a deep-tissue image. The method may include using the trained machine learning model and the test image data set to generate output data for the test image data set. The output data may characterize motion represented in the test image data set.

Owner:VERILY LIFE SCI LLC

Method and apparatus for optically analyzing a surface

InactiveUS7408649B2Quick and efficient analysisEffectively and accurately characteristicRadiation pyrometryInterferometric spectrometryDevice materialCharacterization test

Apparatus and methods are provided for analyzing surface characteristics of a test object using broadband scanning interferometry. Test objects amenable to these apparatus and methods include but are not limited to semiconductor wafers, semiconductor devices, metallic surfaces, and the like. An interferometry system is used to obtain an interferometry signal and related to data embodied in the signal representative of the test object surface. This signal and / or data is used to construct an n-dimensional function that includes an independent frequency variable and an independent time variable, and / or an n-dimensional function that includes an independent scale variable and an independent time variable, and / or a multi-domain function. These functions are compared with various models to obtain a best match that is then used to characterize the test object surface.

Owner:PHASE SHIFT TECH

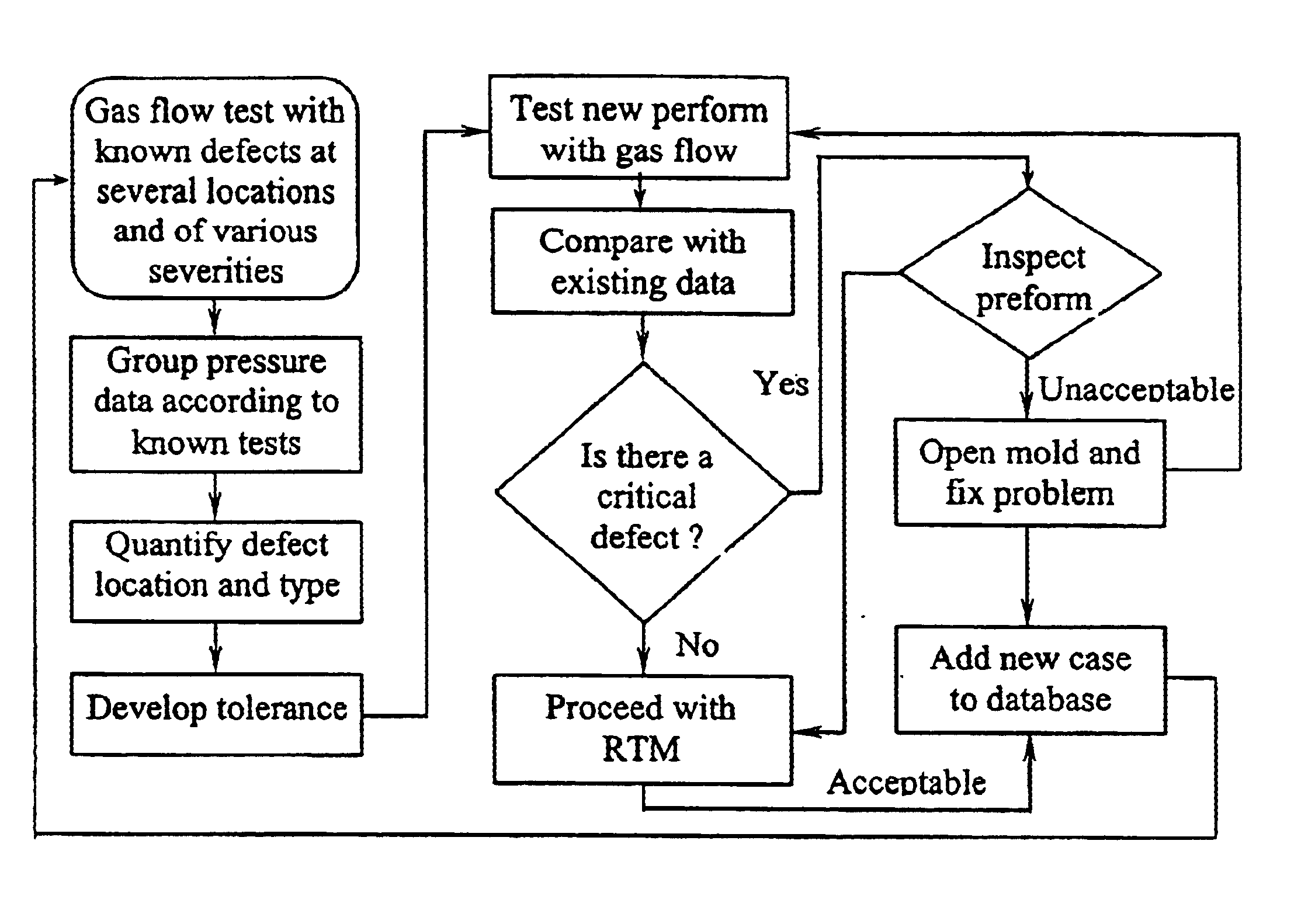

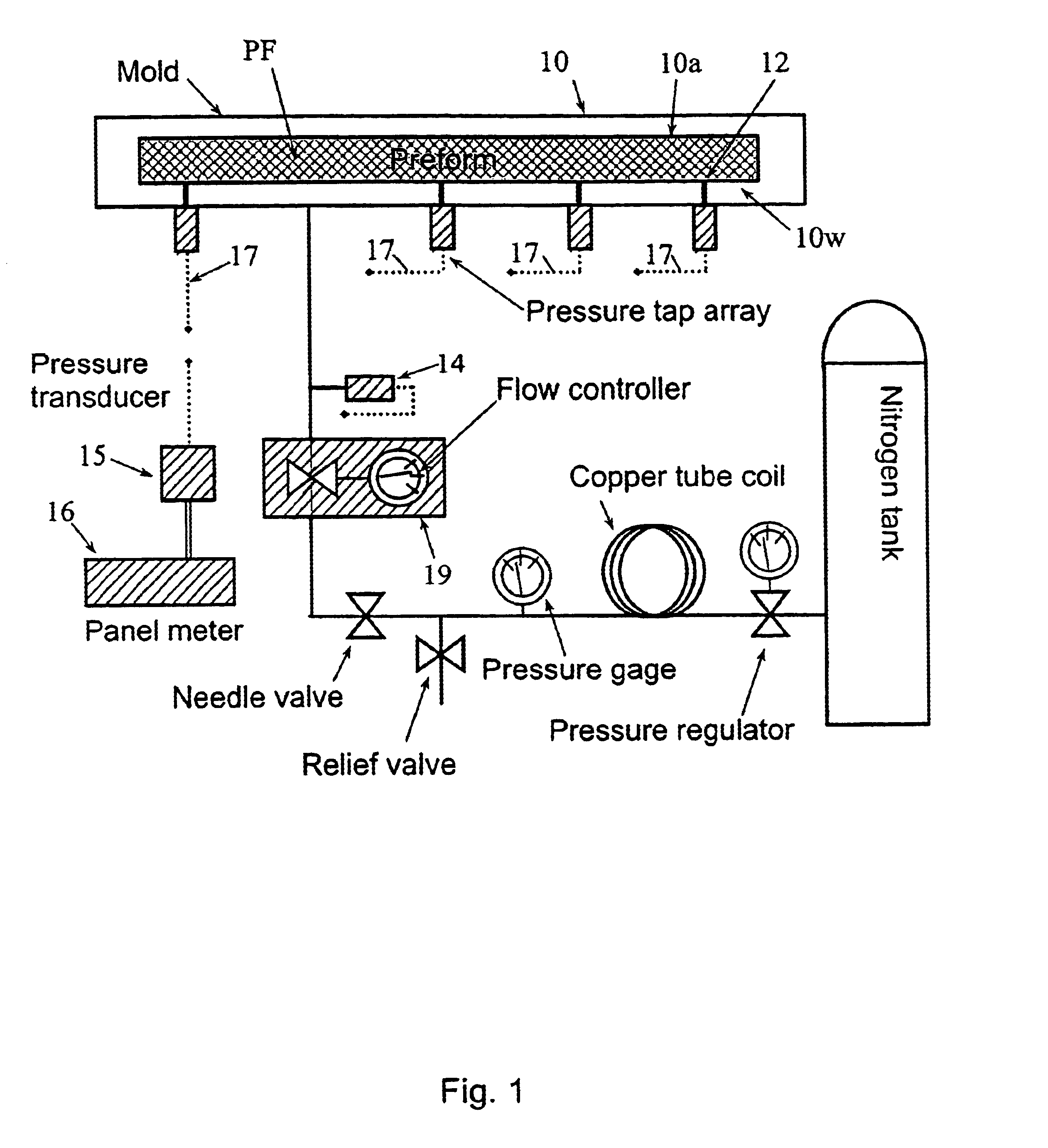

Gas flow method for detection of local preform defects based on statistical analysis

InactiveUS6853925B2Affect qualityStructural/machines measurementPermeability/surface area analysisFiberCharacterization test

Methods to detect and characterize a defect in a fiber preform residing in a molding cavity for liquid composite molding (e.g. resin transfer molding) to make a composite component or structure. The defect may result from fiber preform misplacement in the molding cavity, accidental inclusions, preform density variations, and / or distortion of the preform. Gas pressures at multiple locations on a mold wall are measured during gas flow through the mold cavity containing the fiber preform. Normalized or measured pressures are analyzed by discriminant analysis to detect and characterize any defect in the tested fiber preform.

Owner:NORTHWESTERN UNIV

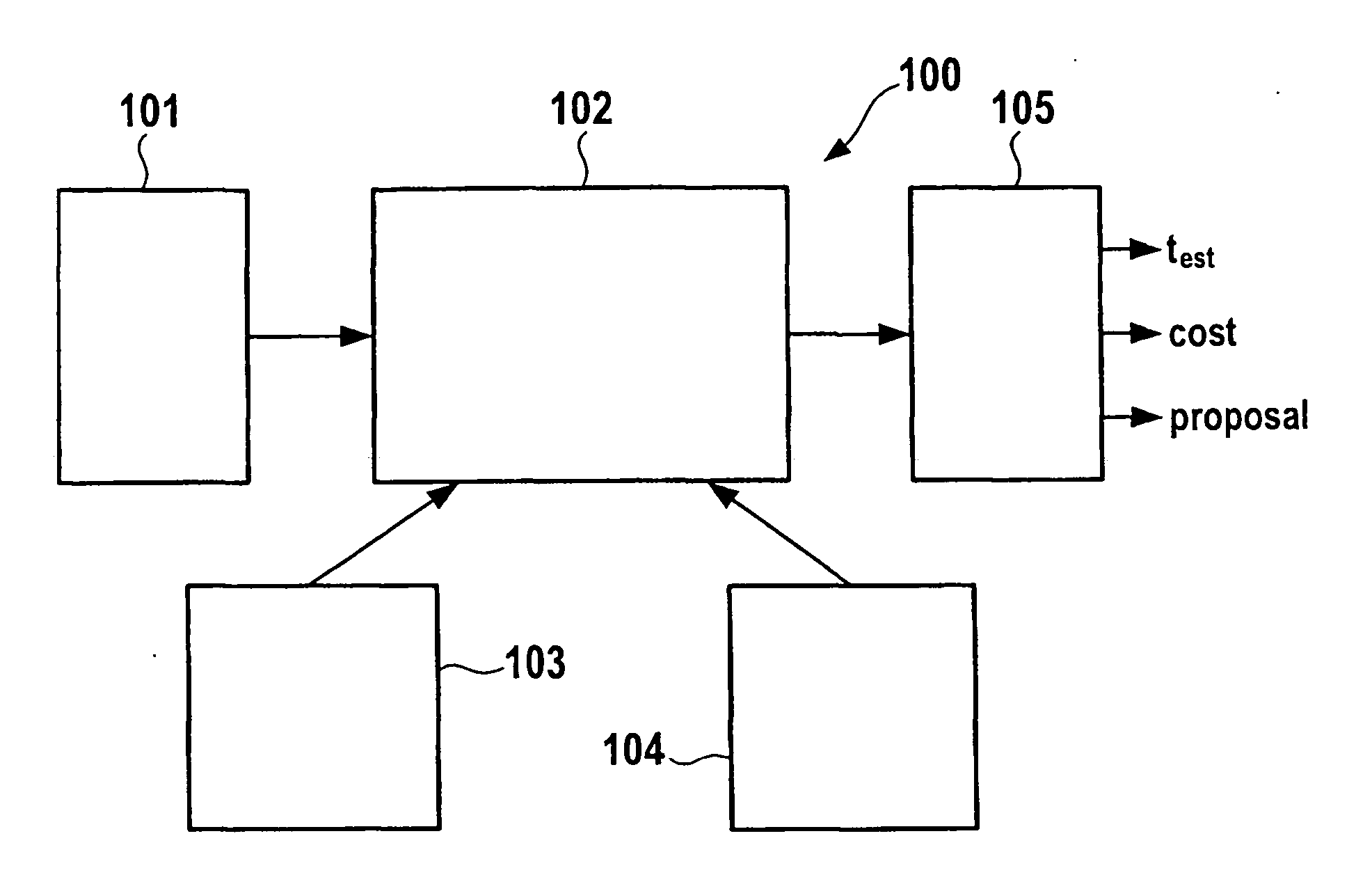

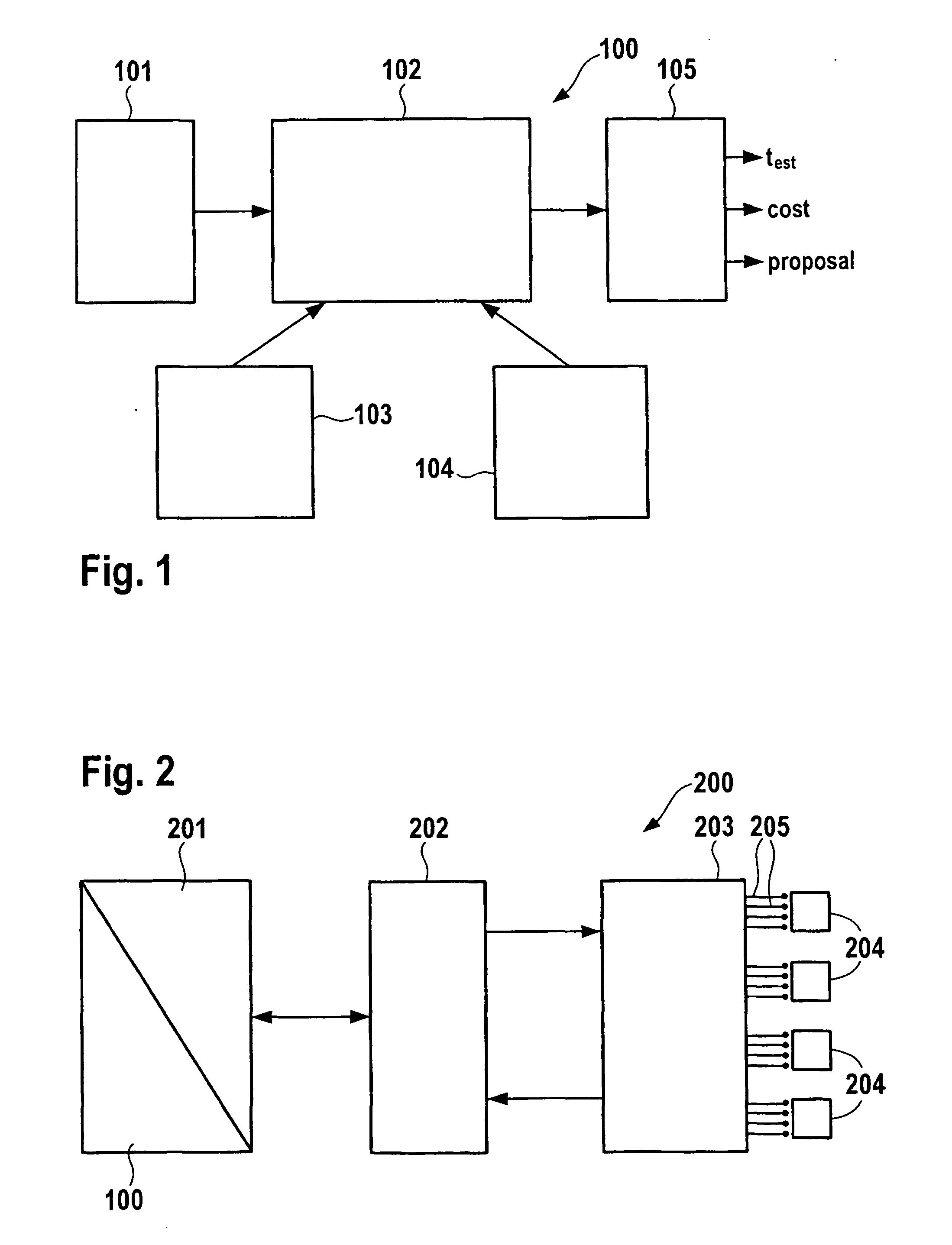

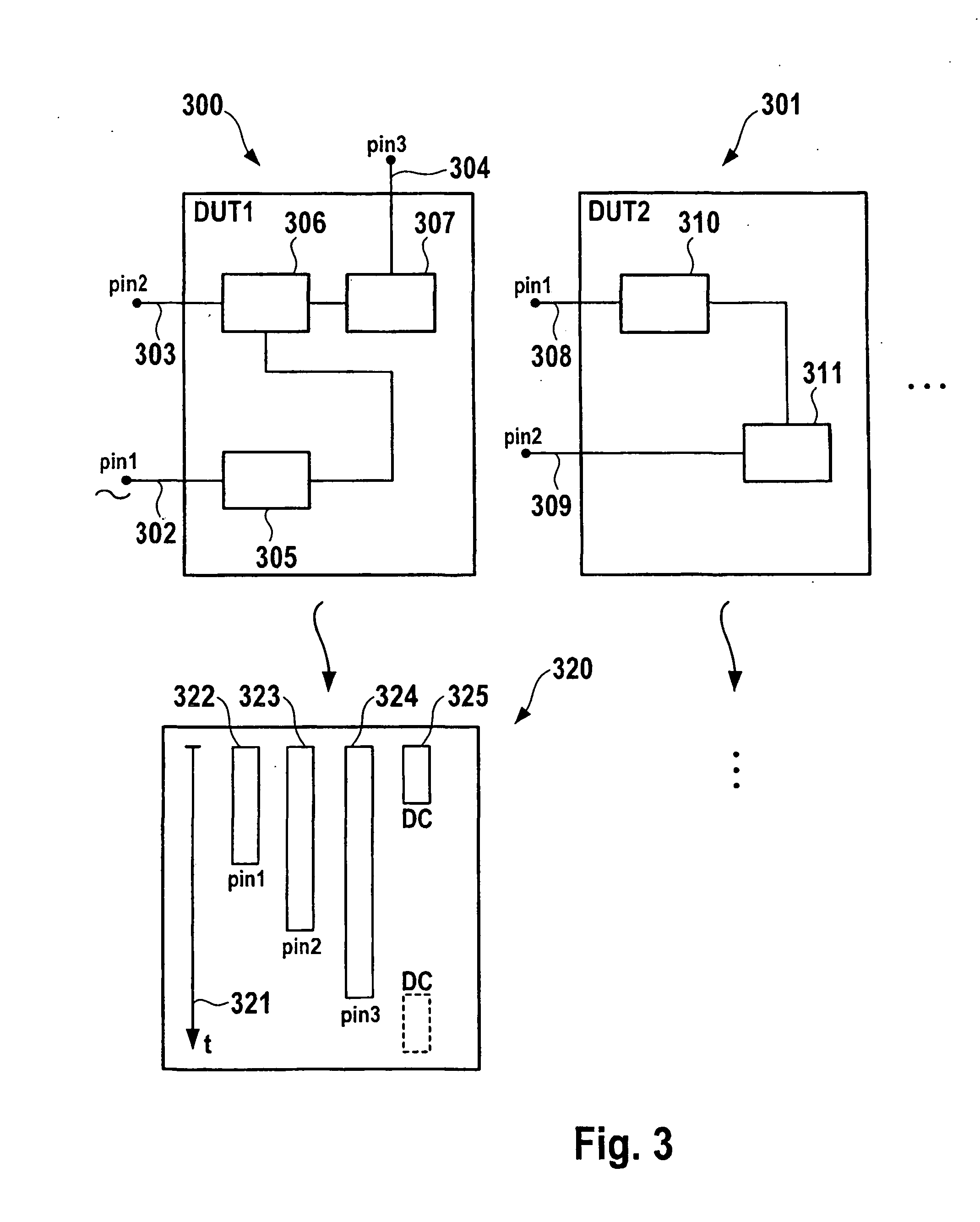

Test Time Calculator

InactiveUS20100223035A1Increase impressionShorten the construction periodAnalogue computers for electric apparatusElectrical testingComputer hardwareCharacterization test

An apparatus for estimating a duration of a test of a device under test to be performed by a test device, the apparatus including an input unit adapted for receiving test information indicative of the test to be performed, and a processing unit adapted to estimate the duration of the test of the device under test performed by the test device based on the received test information and based on a model characterizing the test.

Owner:ADVANTEST SINGAPORE PTE LTD

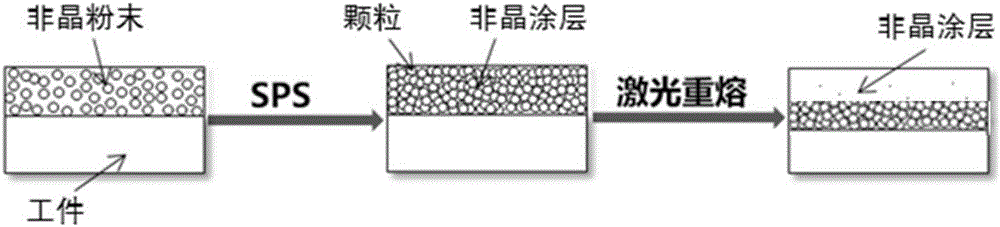

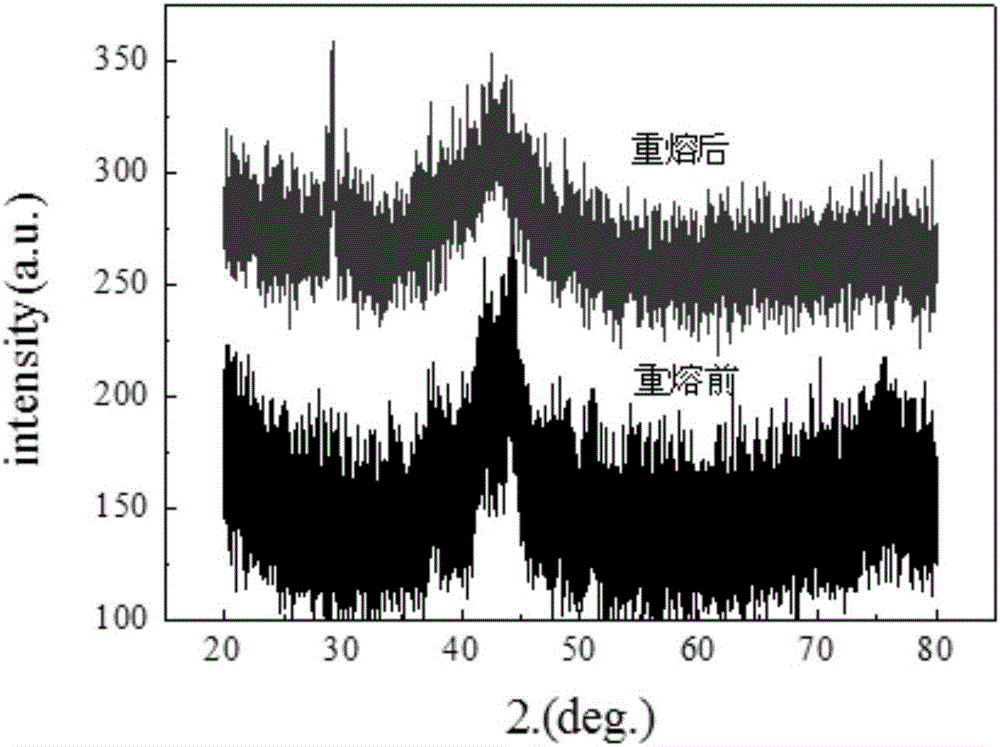

Surface modification method for spark plasma sintering type amorphous alloy coating

ActiveCN106141189AEliminate aggregated stateReduce holesCharacterization testScanning electron microscope

The invention discloses a surface modification method for a spark plasma sintering type amorphous alloy coating. The surface modification method includes the steps of S1, adopting a spark plasma sintering furnace and sintering amorphous powder through an instantaneous high-temperature field generated by the pulse energy, the discharge pulse pressure and the joule heat to obtain a sintered amorphous alloy coating sample; and S2, carrying out laser re-melting on the obtained amorphous alloy coating sample through a laser welding machine to obtain the final amorphous alloy coating. Characterization tests are carried out on the obtained sample and include the steps that XRD characterization is carried out on the sample before and after laser re-melting; the surface appearance of the re-molten sample is observed through a stereoscopic microscope; the surface hardness of the sample after re-melting is measured through a micro-hardness tester; and the microscopic structure of the cross section of the sample is observed through a scanning electron microscope. According to the method, the spark plasma sintering technology and the laser re-melting technology are combined, the amorphous alloy coating surface with higher hardness and strength and better abrasive resistance can be obtained, and therefore the service life of work-pieces can be prolonged.

Owner:HOHAI UNIV CHANGZHOU

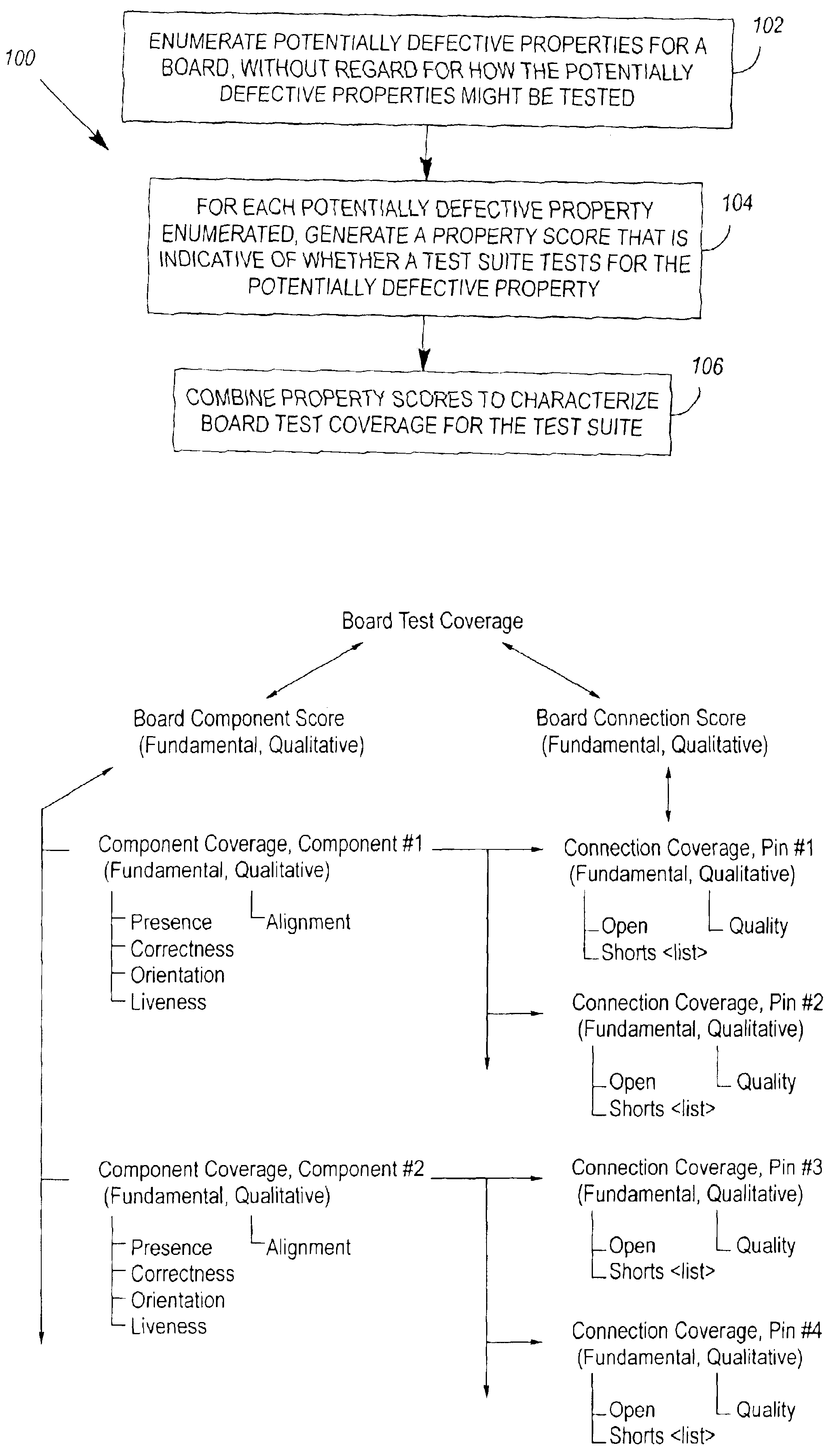

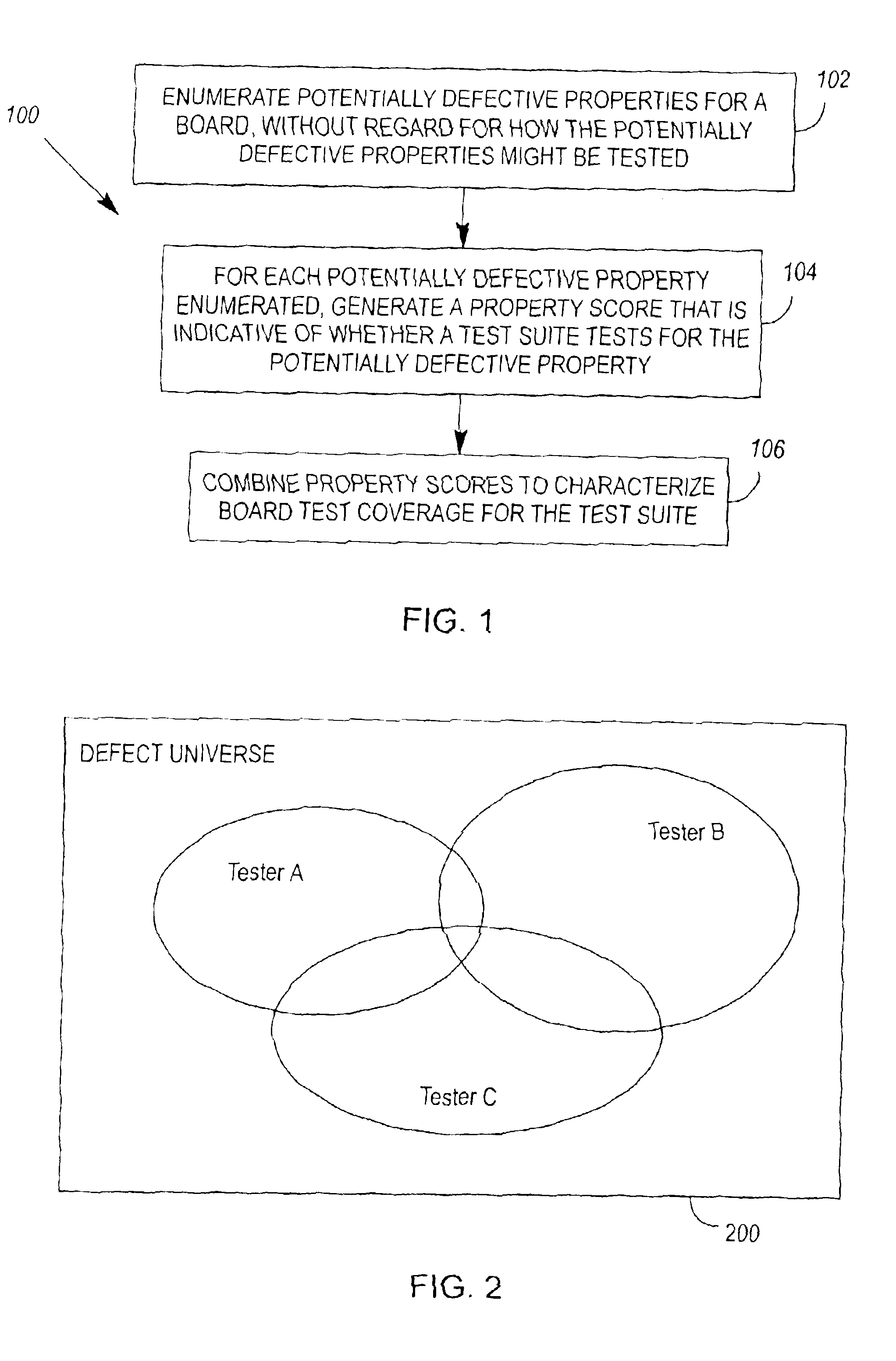

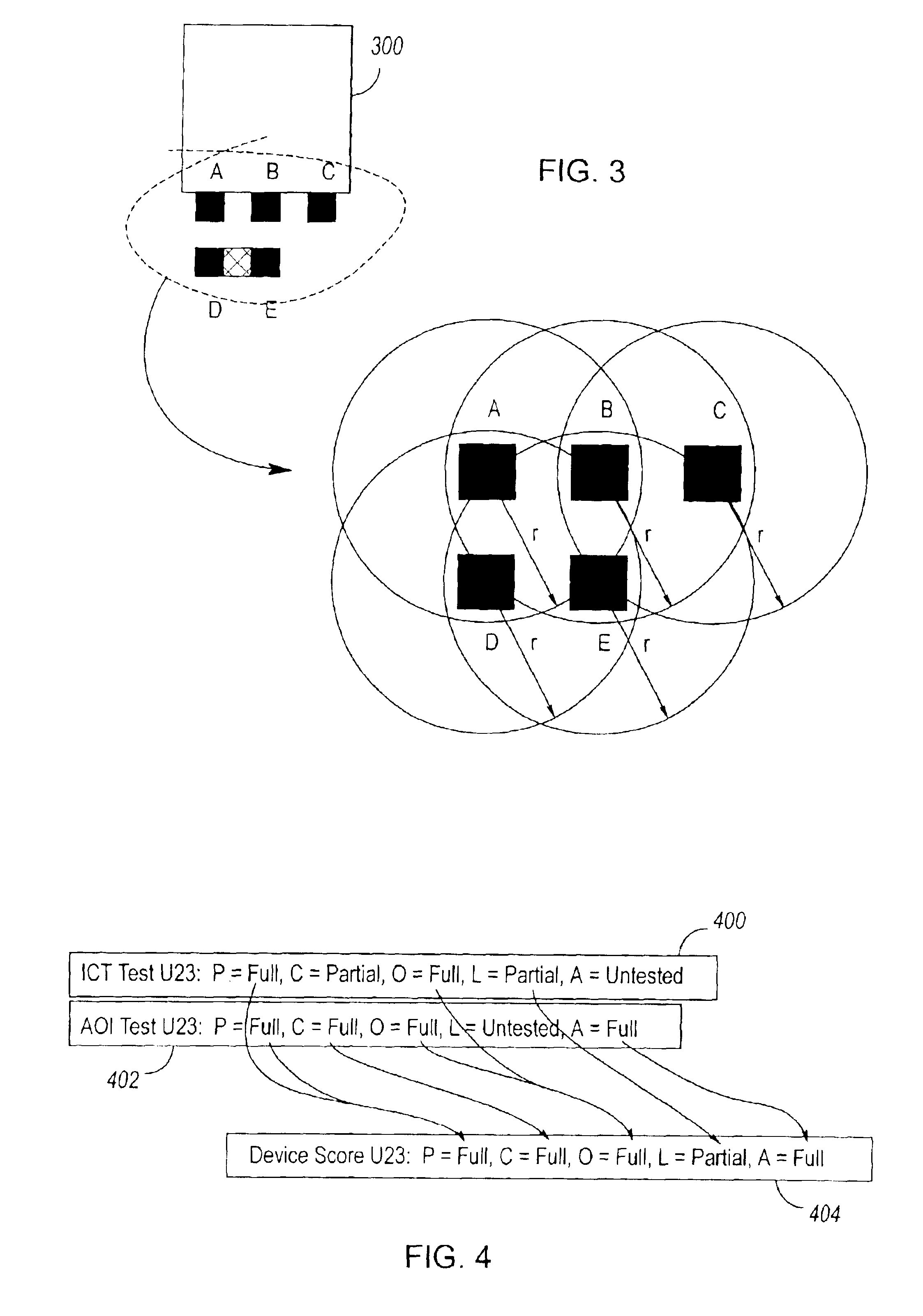

Methods and apparatus for characterizing board test coverage

InactiveUS6948140B2Software simulation/interpretation/emulationSpecial data processing applicationsTest suiteCharacterization test

Disclosed are methods and apparatus for characterizing board test coverage. In one method, potentially defective properties are enumerated for a board, without regard for how the potentially defective properties might be tested. For each potentially defective property enumerated, a property score is generated. Each property score is indicative of whether a test suite tests for a potentially defective property. Property scores are then combined to characterize board test coverage for the test suite.

Owner:AGILENT TECH INC

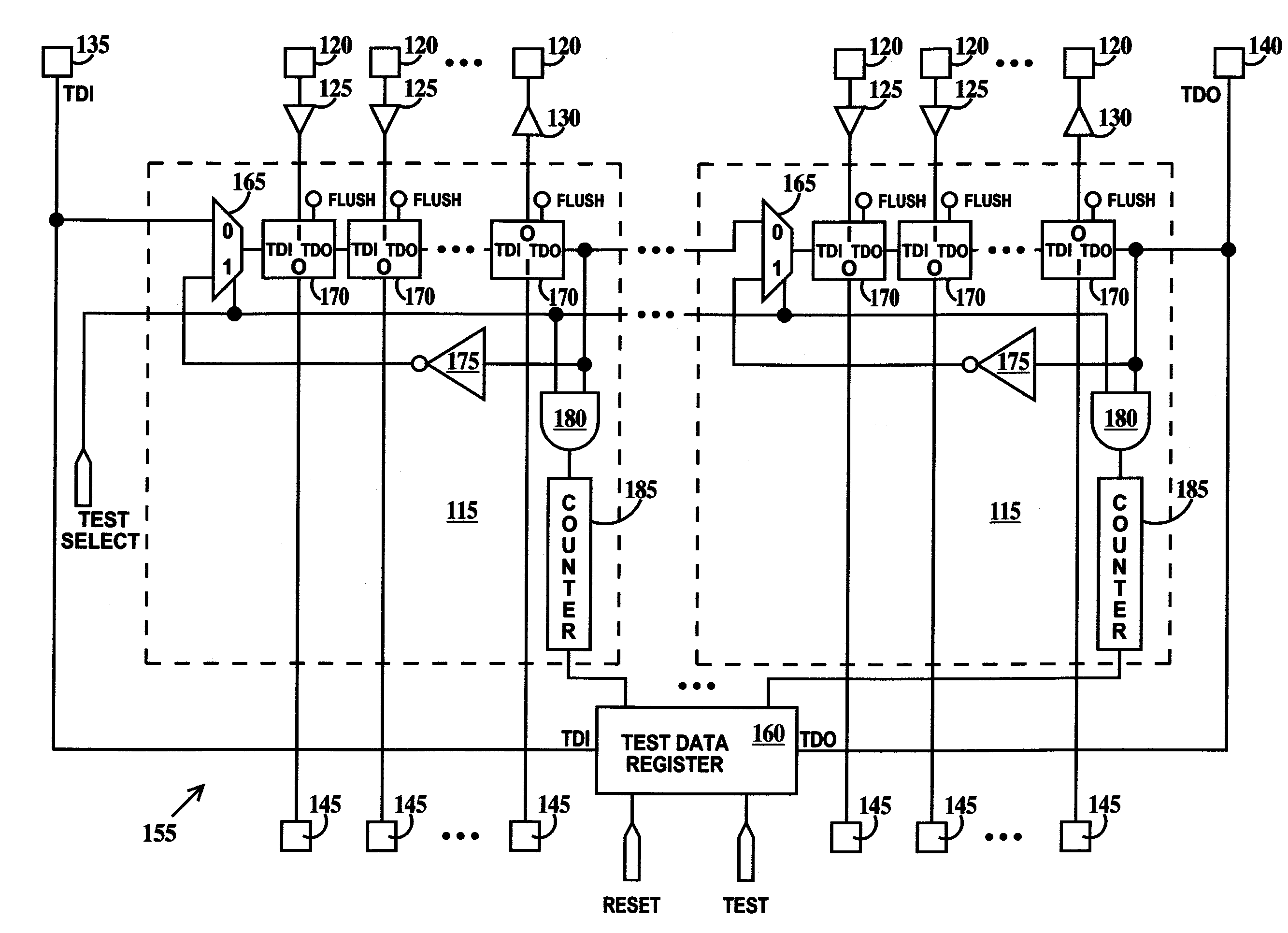

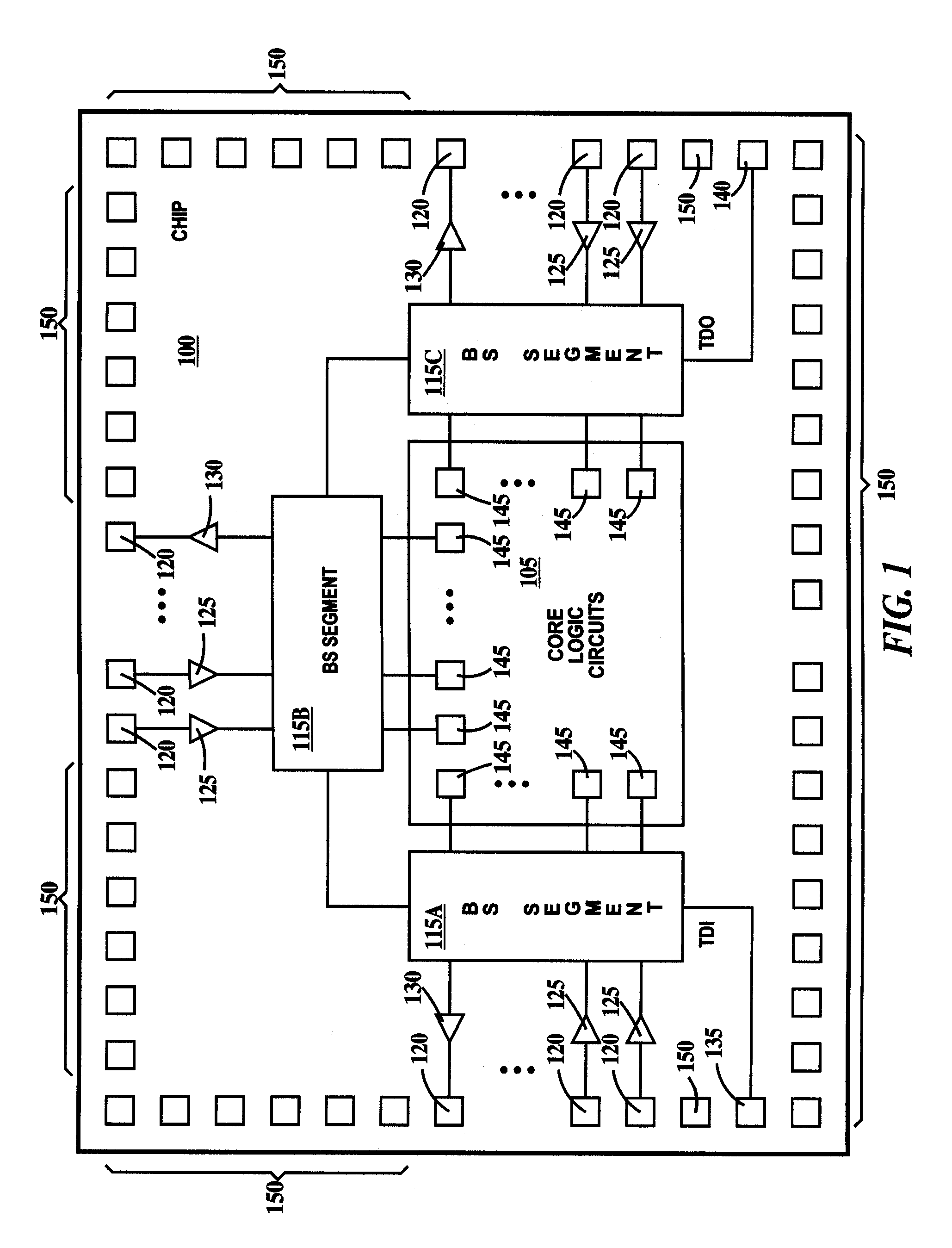

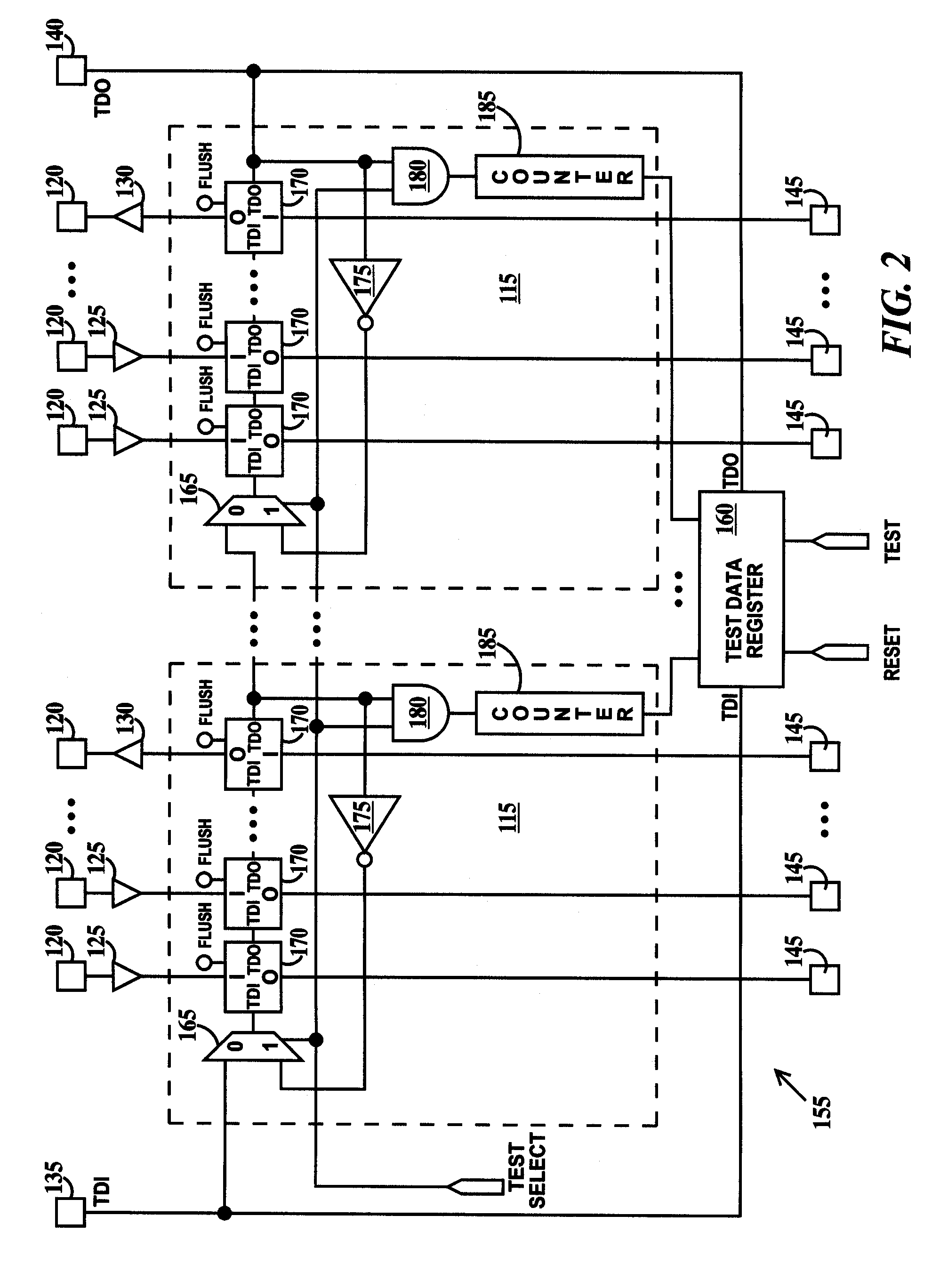

Method and circuit using boundary scan cells for design library analysis

ActiveUS7281182B2Electronic circuit testingDetecting faulty computer hardwareCharacterization testProcessor register

A boundary scan register circuit and a method of characterization testing. The boundary scan register circuit, including: a multiplicity of boundary scan cells connected in series, each boundary scan cell having a latch; means for isolating the boundary scan cells into one or more boundary scan segments, each boundary scan segment containing a different set of the boundary scan cells; and means for characterizing signal propagation through each boundary scan segment.

Owner:GOOGLE LLC

Method and device for high-throughput characterization of heat and structure in process of crystal material melting and solidification

ActiveCN107843614AAchieve heatRealize the structureMaterial analysis using wave/particle radiationMaterial heat developmentMicro structureReal time analysis

The invention discloses a method and device for high-throughput characterization of heat and a structure in the process of crystal material melting and solidification. The method comprises characterizing the change of heat in the process of crystal melting and solidification in real time through a differential scanning calorimetry method, simultaneously, analyzing the structural information of theprocess in real time through X-ray diffraction, and in the crystal growth process after nucleation, observing the micro-structure evolution in real time through X-ray imaging. In one experiment, heatinformation in the crystal material melting-solidification process, melt structure change information along with temperatures before solidification and solidification micro-structure evolution information such as a solid / liquid interface advancing speed and dendritic crystal morphology when solidification are obtained. The device greatly shortens the research cycle of the crystal material melting-solidification process, realizes high-throughput characterization test analysis of the process heat and structure information in the same experiment and is used for the regulation and control of crystal material properties.

Owner:SHANGHAI UNIV +1

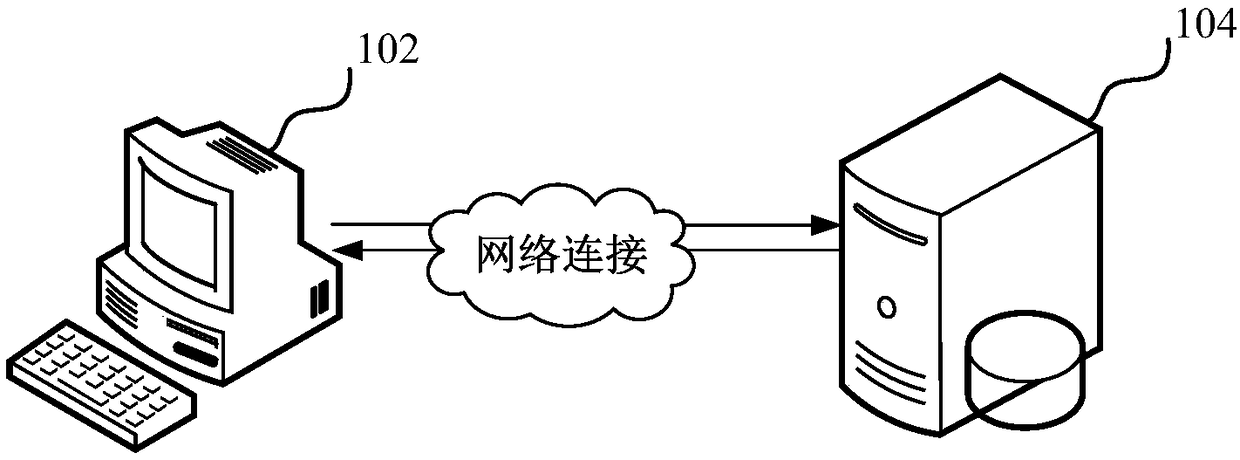

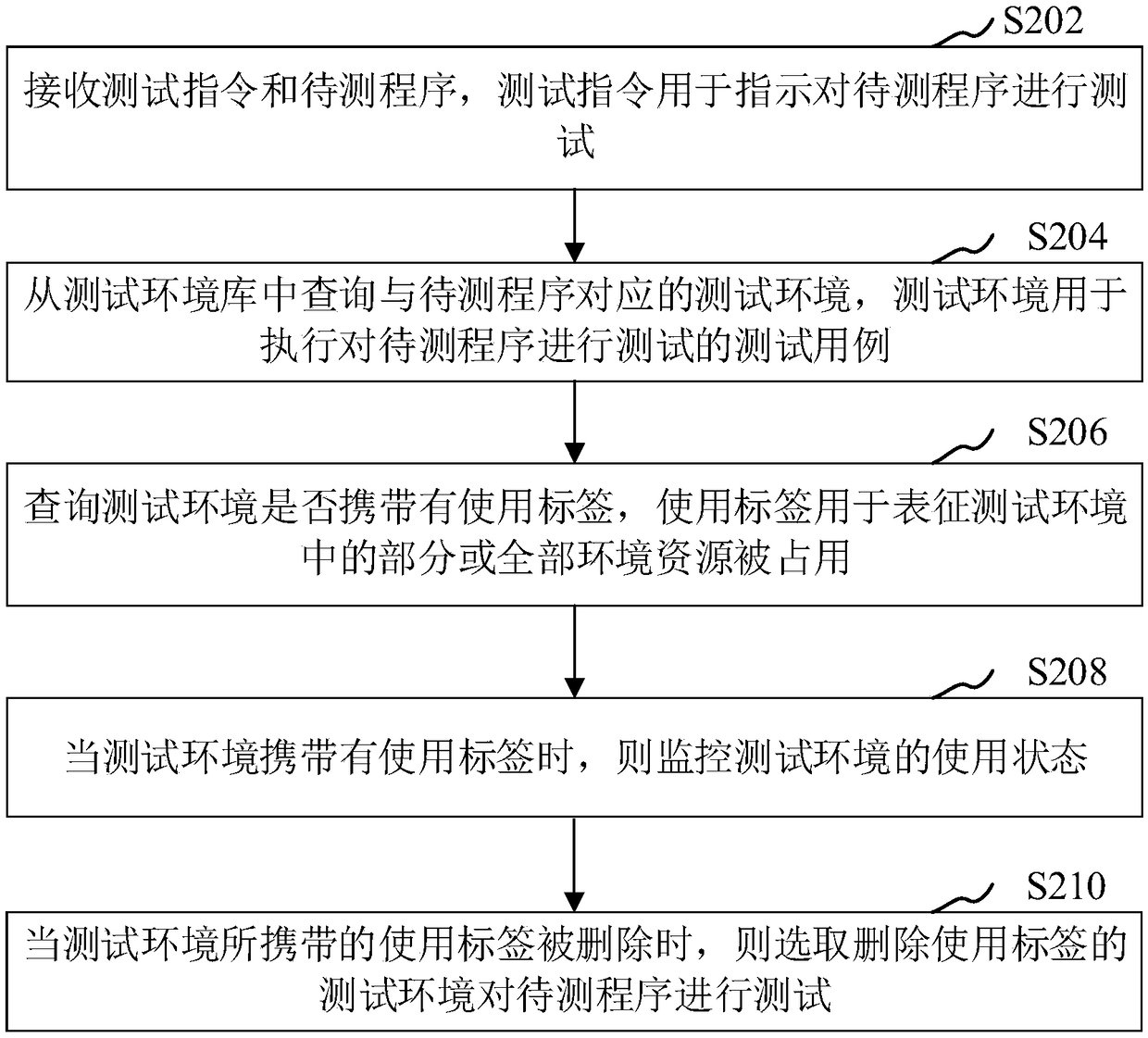

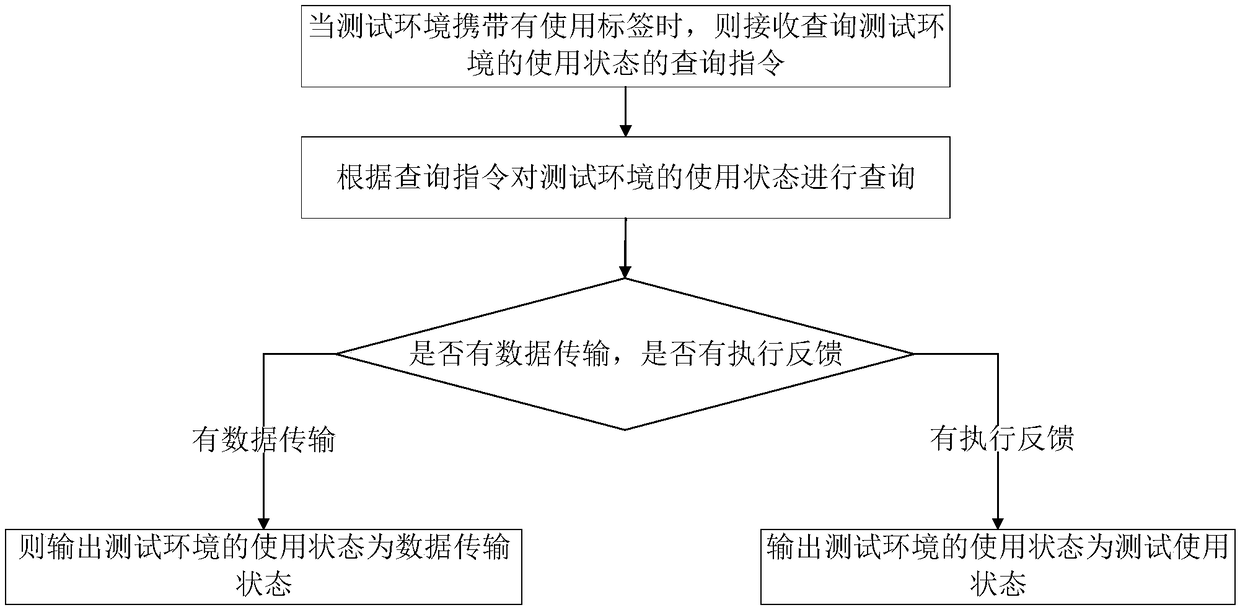

Test environment monitoring method and apparatus, computer device and storage medium

PendingCN108845937AImprove test efficiencySoftware testing/debuggingTest efficiencyCharacterization test

The invention relates to a test environment monitoring method and apparatus, a compute device and a storage medium. The method comprises: receiving a test instruction and a program to be tested, wherein the test instruction is used for instructing the program to be tested to be tested; querying a test environment corresponding to the program to be tested from a test environment library, wherein the test environment is used to execute test cases for testing the program to be tested; querying whether the test environment carries a use tag, wherein the use tag indicates that some or all of the environmental resources in the test environment are occupied; monitoring the usage status of the test environment when the test environment carries the use tag; and selecting a test environment in whichthe use label is deleted to test the program to be tested. The method can obtain the test environment corresponding to the program to be tested without manual monitoring of the test environment, thereby improving the test efficiency.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

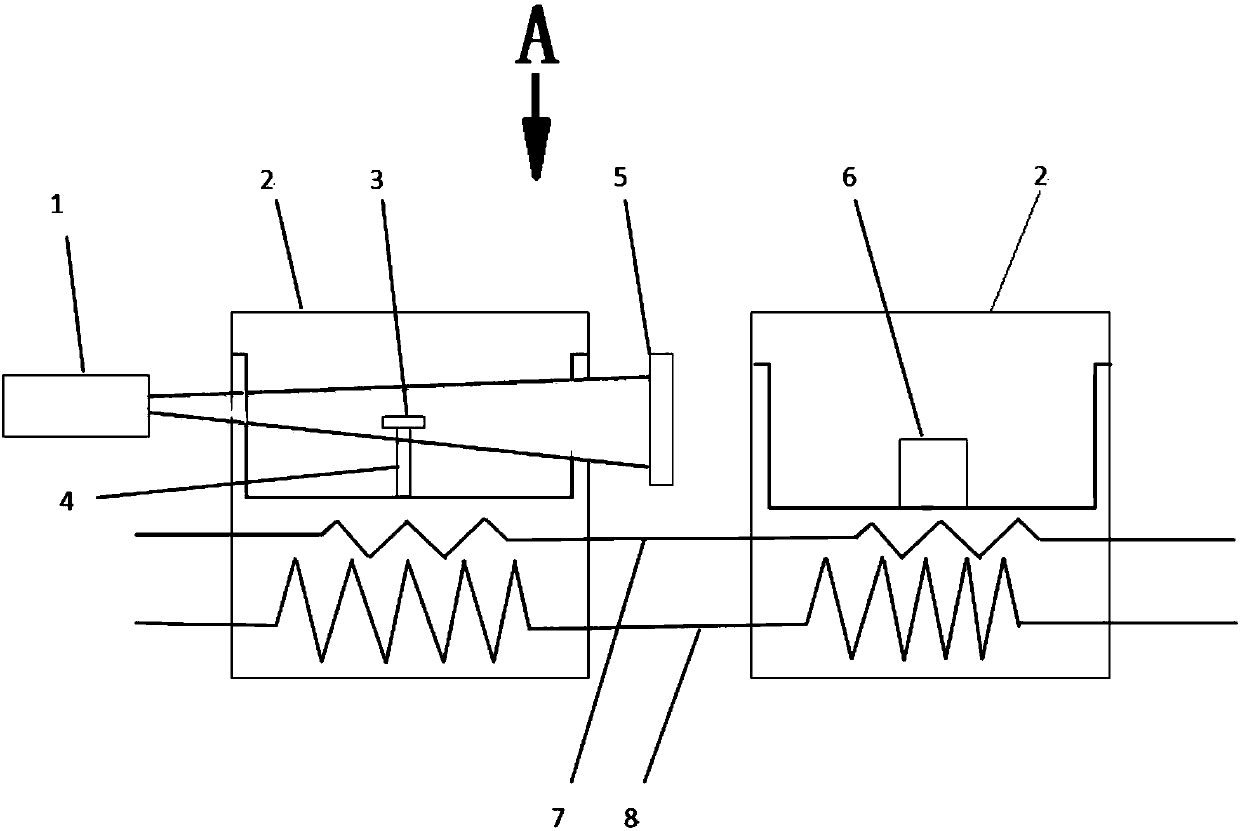

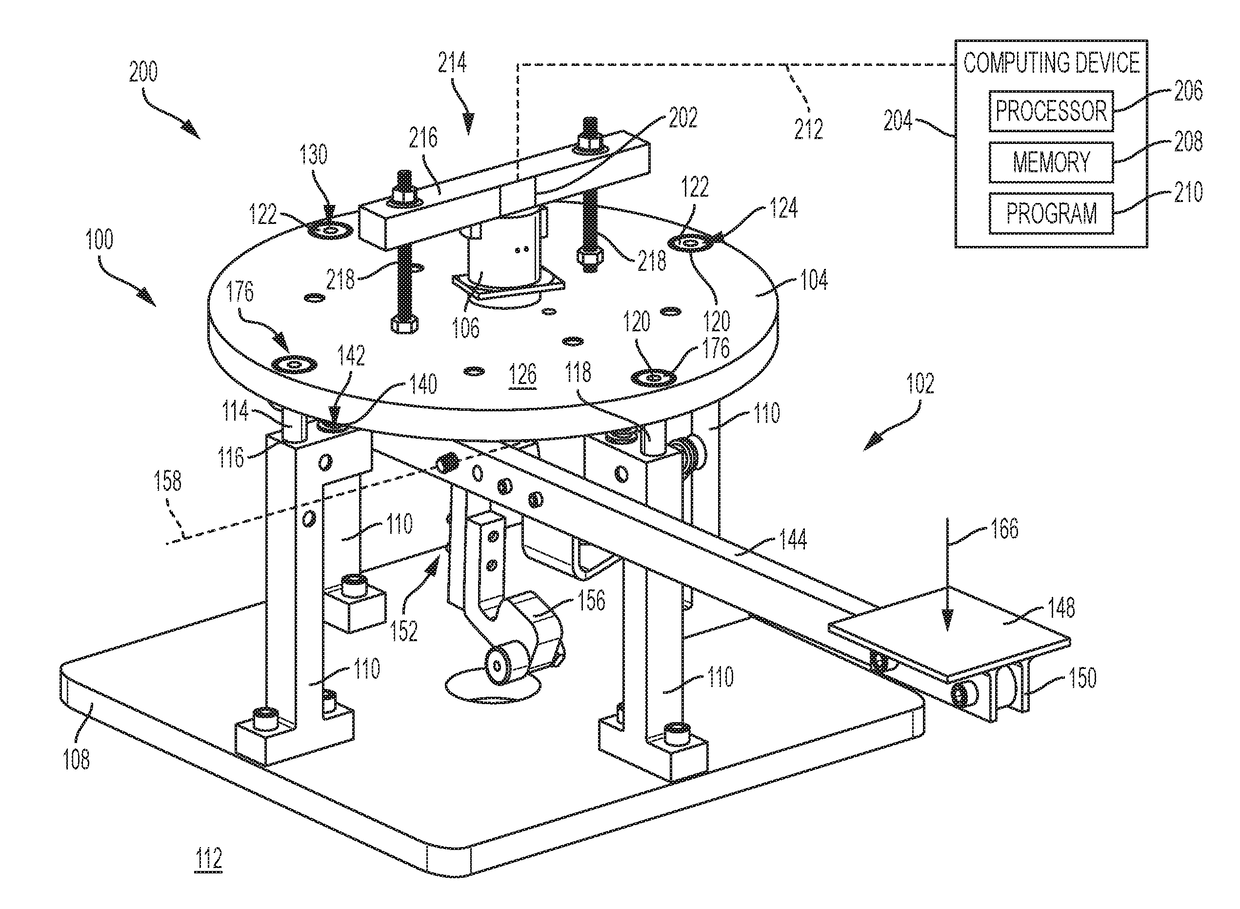

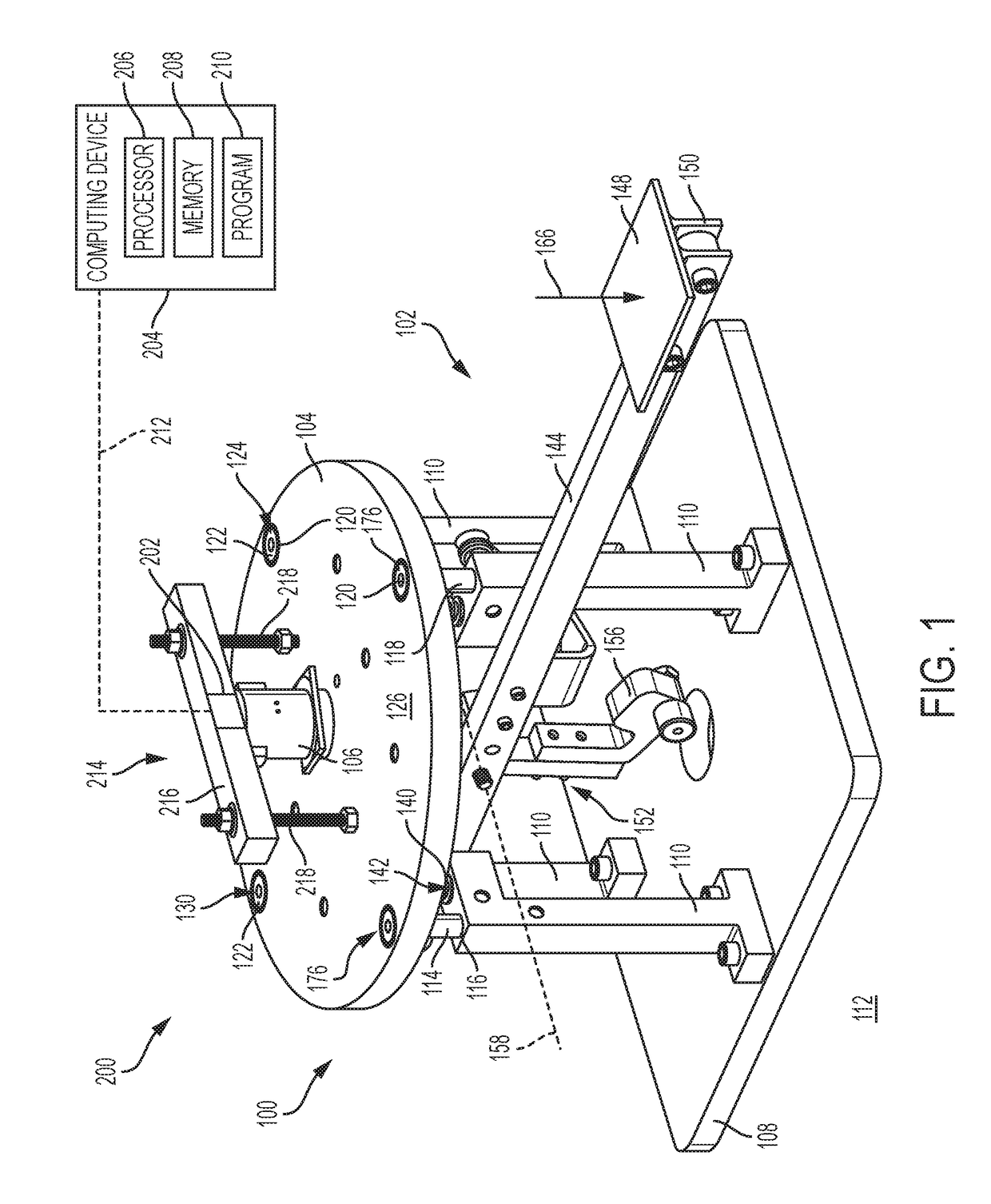

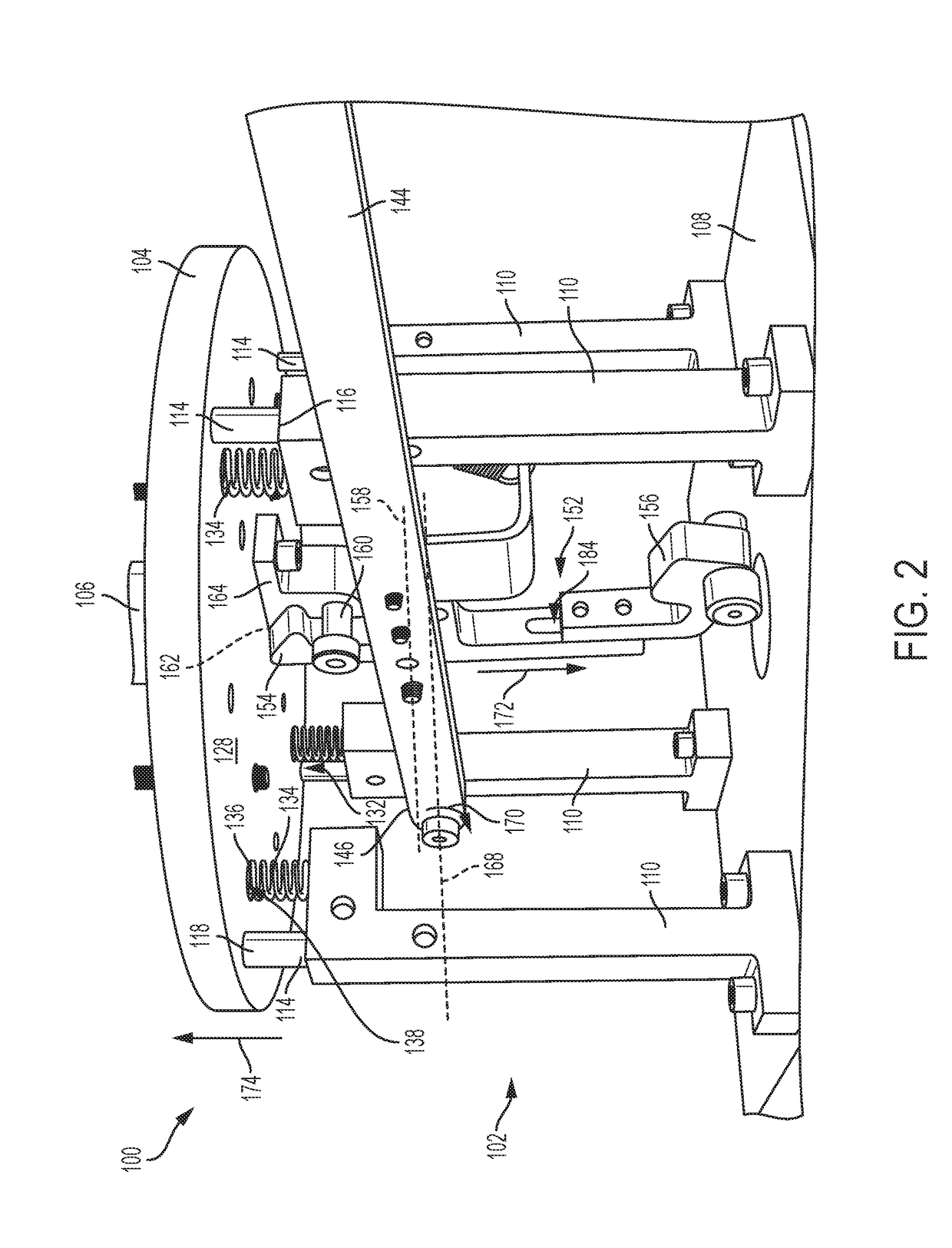

Tunable mass damper characterization test stand

A test stand for characterization of a tunable mass damper may include (a) a support base including a stop member, (b) a test plate coupled to the support base, with the test plate configured to move relative to the support base and to fixedly carry a tunable mass damper, (c) a spring coupled to the support base and the test plate, (d) a lever configured to be releasably coupled to the test plate and to move the test plate relative to the support base against the urging of the spring, and (e) a latch mechanism configured to release the test plate from the lever when the test plate is at a predetermined position relative to the support base. The motion of the test plate, after the test plate has been released by the latch mechanism, may be halted by the stop member of the support base.

Owner:THE BOEING CO

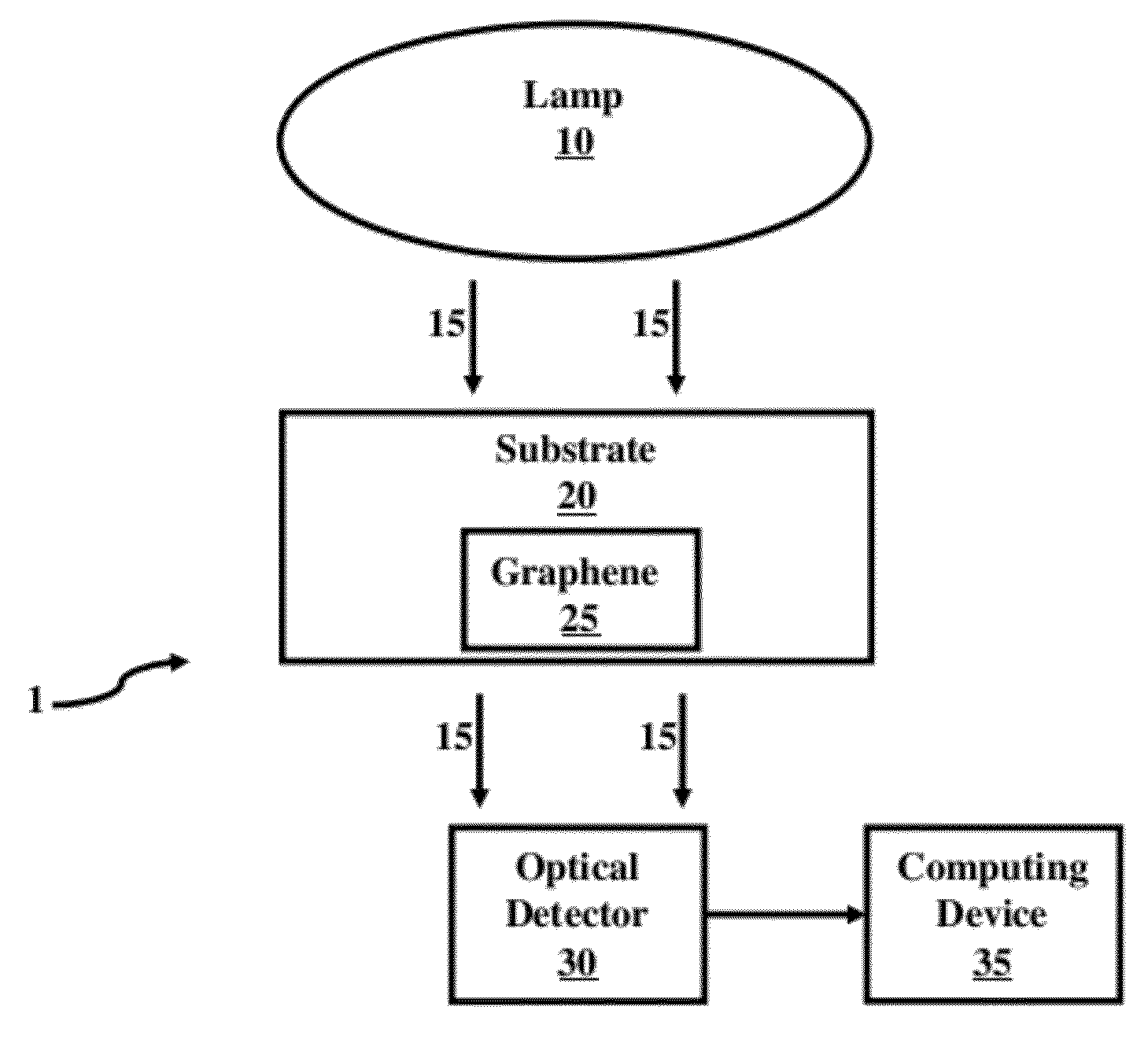

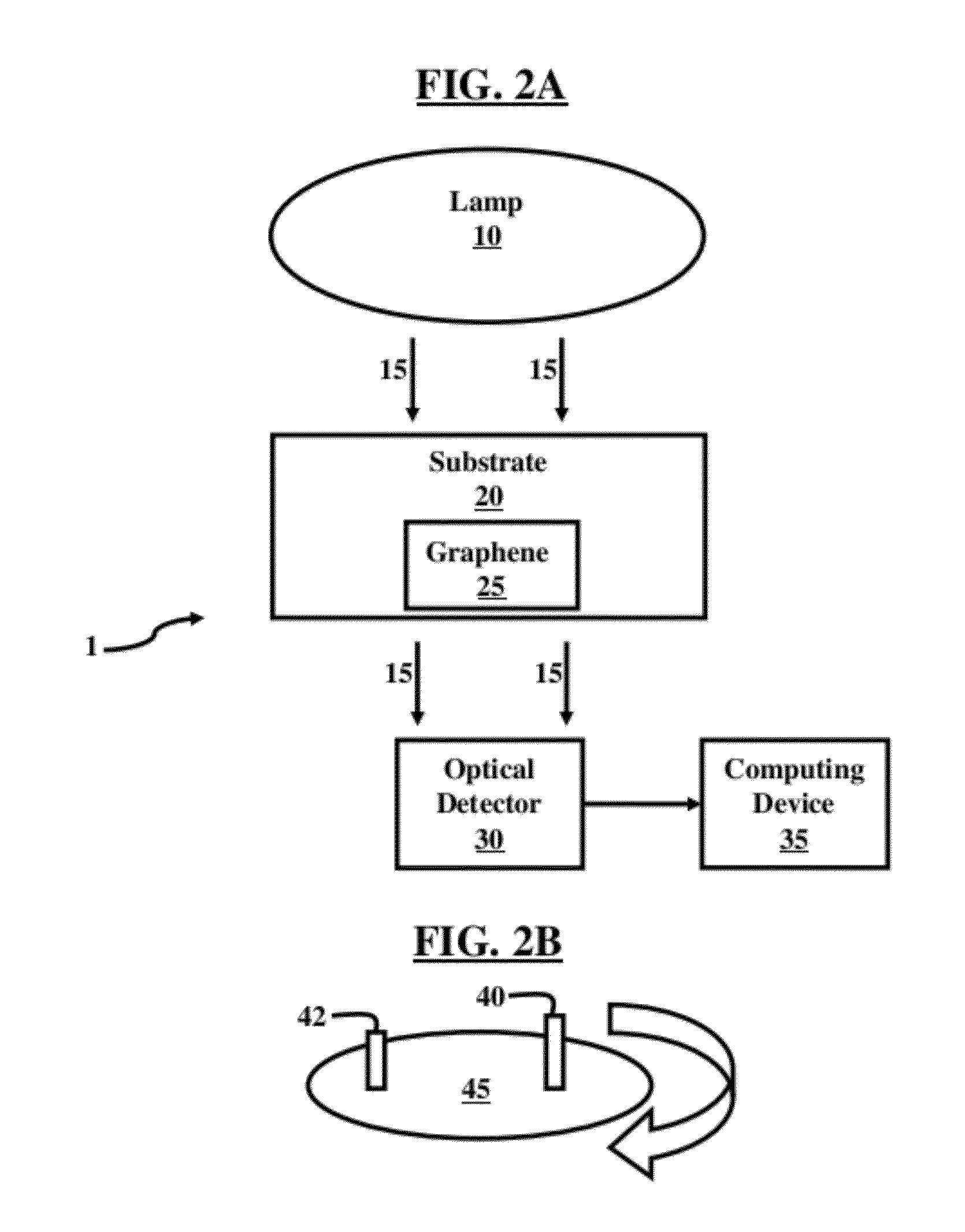

Method and System of Improved Uniformity Testing

InactiveUS20120136601A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingCharacterization testTransmittance

A method and system includes a first substrate and a second substrate, each substrate comprising a predetermined baseline transmittance value at a predetermine wavelength of light, processing regions on the first substrate by combinatorially varying at least one of materials, process conditions, unit processes, and process sequences associated with the graphene production, performing a first characterization test on the processed regions on the first substrate to generate first results, processing regions on a second substrate in a combinatorial manner by varying at least one of materials, process conditions, unit processes, and process sequences associated with the graphene production based on the first results of the first characterization test, performing a second characterization test on the processed regions on the second substrate to generate second results, and determining whether at least one of the first substrate and the second substrate meet a predetermined quality threshold based on the second results.

Owner:INTERMOLECULAR

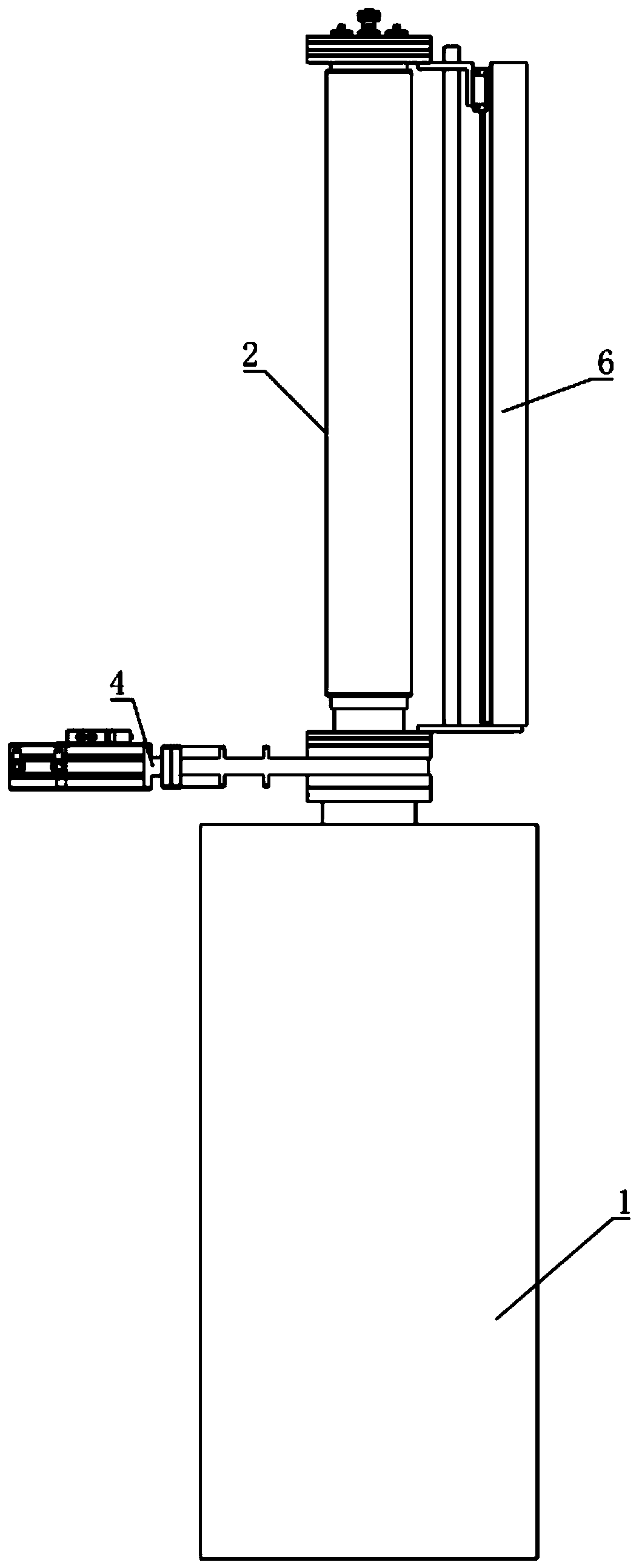

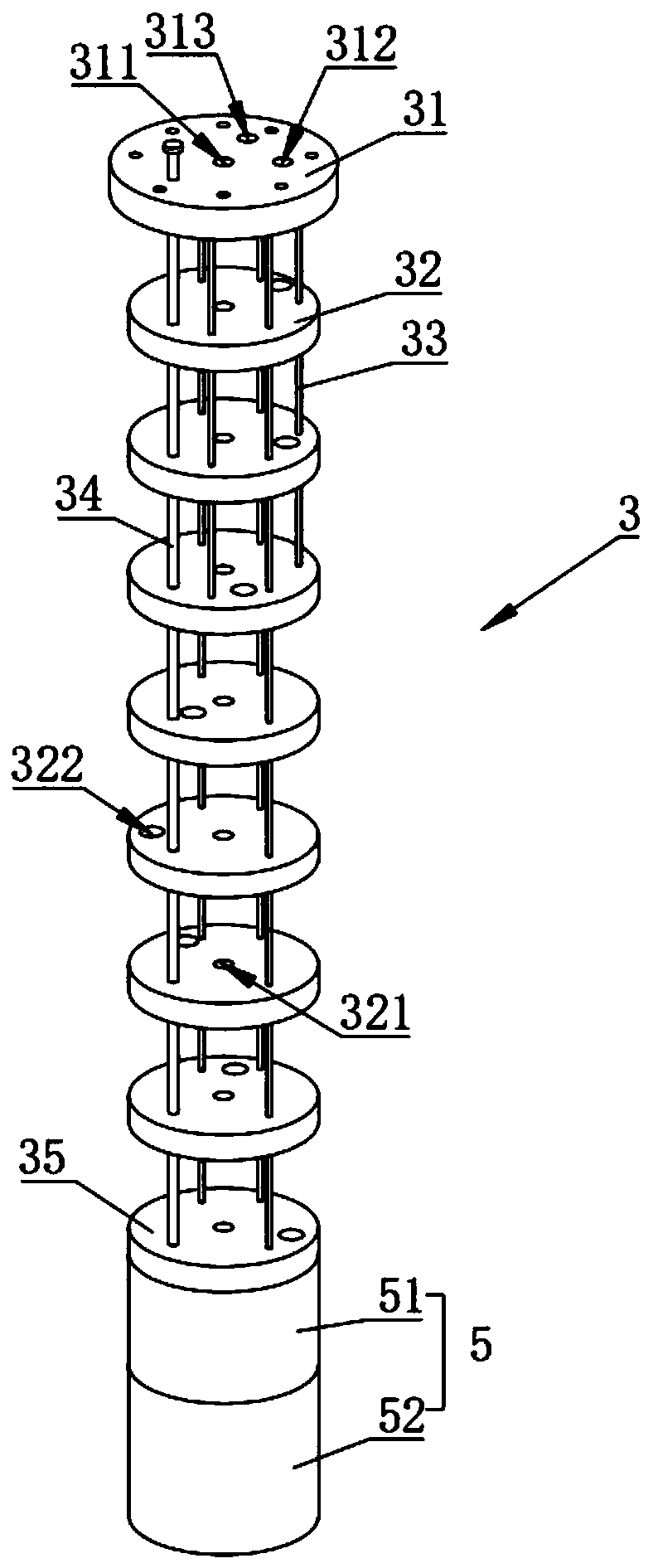

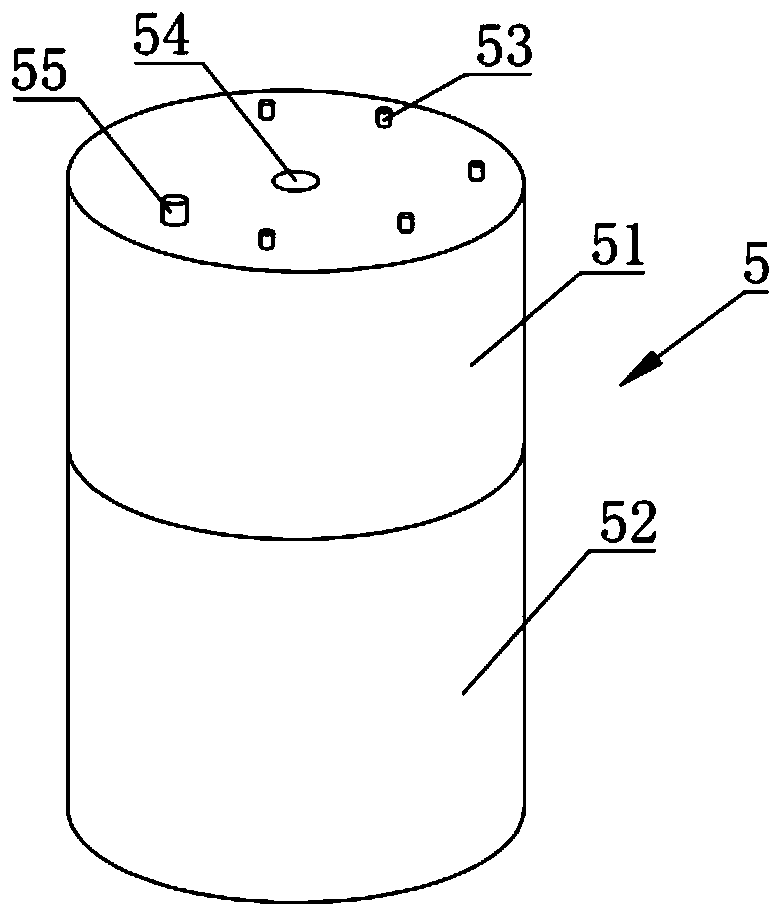

In-situ physical property test system and sample mounting method

PendingCN110320389ASolve loading and unloadingGuaranteed accuracyMaterial analysis by optical meansScanning probe microscopyAtmospheric airCharacterization test

The invention relates to the technical field of an in-situ physical property test and discloses an in-situ physical property test system and a sample mounting method. According to the in-situ physicalproperty test system provided by the invention, vacuum equipment is connected with vacuum sample preparation equipment; in the vacuum equipment, a sample is placed into a vacuum test cavity and the vacuum test cavity is sealed; a vacuum test part is connected with an insertion rod assembly; the insertion rod assembly is in sealed connection with a rapid sample injection chamber; the rapid sampleinjection chamber and a dilution refrigerator are communicated through adoption of an insertion plate valve; and the insertion rod assembly is controlled to act, thereby pushing the vacuum test part into the dilution refrigerator for a sample test. Accuracy when the in-situ physical property test system is used for characterizing a physical property is ensured. A physical property characterizationrequirement under all extreme conditions related to the dilution refrigerator are satisfied. The problem that according to a characterization test depending on the dilution refrigerator, a sample loading and unloading process is exposed to air is solved. An original high-intensity magnetic field and ultra low temperature environment of the dilution refrigerator is completely reserved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Tilted edge for optical-transfer-function measurement

InactiveUS7518712B2Avoid aliasingQuick measurementUsing optical meansTesting optical propertiesFast measurementCharacterization test

The optical transfer function of imaging optics is carried out with a plurality of tilted edges with respect to the edge-response detection line. The effect of the tilt is to stretch out the edge response so that fine details can be detected even operating at a spatial frequency below the Nyquist limit of the detector. The use of multiple targets, each corresponding to a sub-region of the field of view of the optics being tested, enables the simultaneous characterization of the full field of view of the test optics with a single measurement without the use of a magnifying objective. The result is a rapid measurement and a simpler apparatus suitable for high-throughput testing. A pair of tilted edges can be used in a target to also determine the sagittal and tangential OTFs (as well as that of any other arbitrary cross-section). All of these data are acquired with a single measurement.

Owner:EDMUND OPTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com