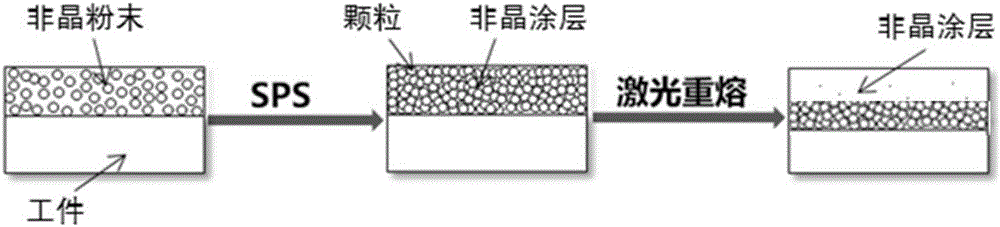

Surface modification method for spark plasma sintering type amorphous alloy coating

A discharge plasma and amorphous alloy technology, which is applied in the field of environmental protection, can solve problems affecting coating performance, etc., and achieve the effects of increasing life, reducing holes, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] S1, using commercially available Fe 48 Cr 15 Mo 14 Y 2 C 15 B 6 (purity 99.9%, particle size 10-30μm) amorphous powder is used as the experimental raw material, use spark plasma sintering equipment to prepare amorphous coating, keep the equipment under high vacuum pressure, set the pressure between 50-90MPa, and set the temperature to low The crystallization temperature of the amorphous coating is 575°C. A typical preparation cycle is divided into three parts: rapid heating to sintering temperature at a rate of 100°C / min, holding for a certain period of time, and finally using nitrogen purge to achieve rapid cooling. The cylindrical sample obtained by sintering has a height of 10 mm and a diameter of 15 mm.

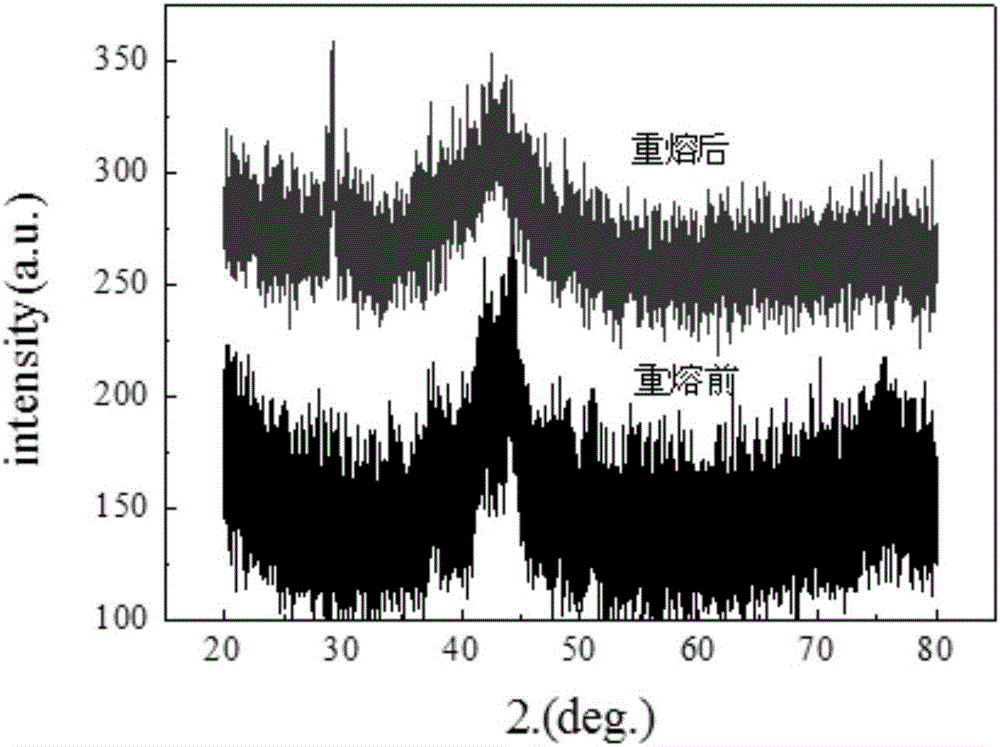

[0031] S2. Use the YAG energy feedback laser welding machine (model GD-YAG-W200 / W300) produced by Everbright Laser to remelt the sintered amorphous coating by laser; before remelting, use HP-05 ceramic closed constant temperature electric furnace to The samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com