Method for preparing particle-reinforced aluminum-based composite material adopting hot-pressing sintering under atmospheric atmosphere

A particle-reinforced aluminum, hot-pressing sintering technology, applied in the field of powder metallurgy, can solve the problems of low production efficiency, complex process, high cost, etc., and achieve the effect of low cost, simple process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

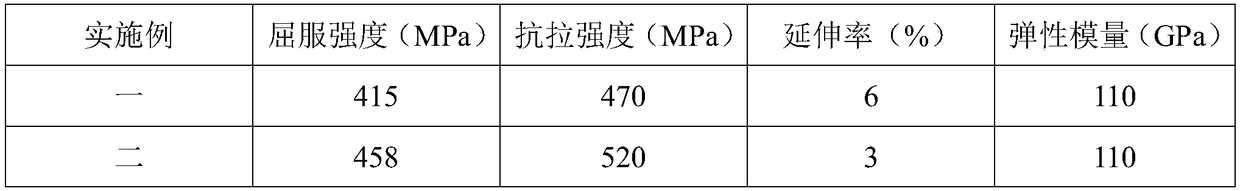

Examples

specific Embodiment approach 1

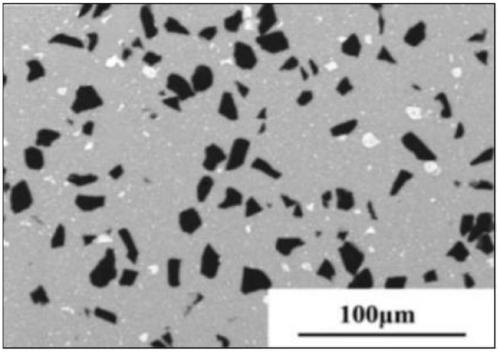

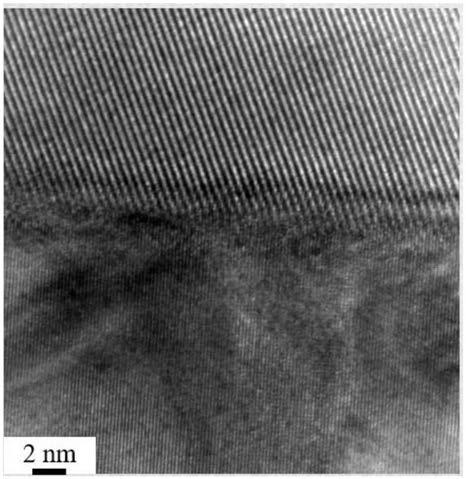

[0017] Specific implementation mode 1: In this implementation mode, a method for preparing particle-reinforced aluminum-based composite materials by hot pressing and sintering under atmospheric atmosphere is carried out according to the following steps:

[0018] 1. Ball milling and powder mixing: the ceramic particle reinforcement and the aluminum matrix are ball milled and mixed to obtain a mixed powder;

[0019] 2. Preparation of prefabricated body by cold pressing: use graphite mold to compact the mixed powder step by step to obtain a prefabricated body;

[0020] 3. Carry out hot-press sintering on the prefabricated body under atmospheric atmosphere. After the sintering is completed, the graphite mold is transferred to the air, naturally cooled to room temperature, and the particle-reinforced aluminum matrix composite is obtained by demoulding.

[0021] Washing and drying the reinforced body described in this embodiment is one of the factors affecting the quality of the mat...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment differs from Embodiment 1 in that: the ceramic particle reinforcement described in Step 1 is washed with water before ball milling. Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the water washing is specifically carried out in the following steps: wash the ceramic particle reinforcement in water at a temperature of 30-45°C for 3-5 times to obtain a paste Put the paste in a stainless steel tray, transfer it to a drying box for drying, the drying temperature is 60-90°C, and the drying time is greater than 48h; the volume ratio of the ceramic particle reinforcement to water is 1: (2~4). Others are the same as those in Embodiment 1 or 2.

[0026] In this embodiment, the volume ratio of water to ceramic particle reinforcement should be higher than 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com