Rapid preparation method of ceramic matrix composite material

A composite material and ceramic-based technology, which is applied in the field of rapid preparation of ceramic-based composite materials, can solve problems such as affecting the bearing capacity, prolonging the preparation period, affecting the self-healing effect, etc., and achieves the effect of improving the service life and improving the compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

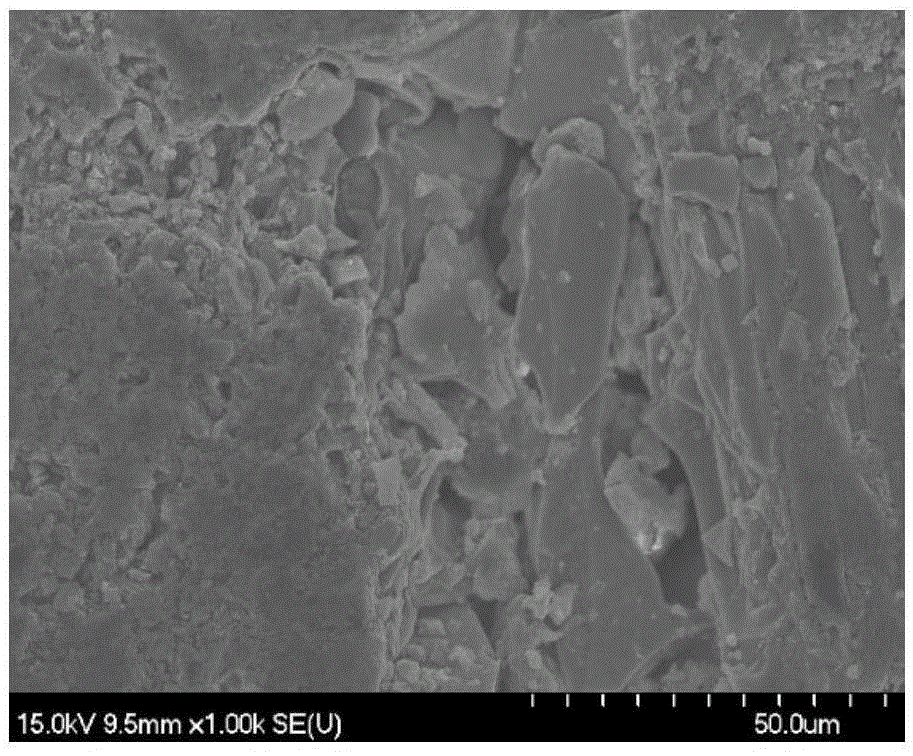

[0025] Step 1: The surface of the C / SiC composite material deposited by the CVI process for 4 furnaces was polished with sandpaper at room temperature, cleaned ultrasonically, and dried.

[0026] Step 2: The dried sample is impregnated with polysilaborazane (PSNB) at room temperature to fill the cavities and cracks inside the material. After impregnation, cure at 120-250°C for 2-5 hours to achieve preliminary sealing of micro-cracks in the SiC matrix;

[0027] Step 3: Put the cured sample in the CVI deposition furnace, so that the cracking of the SiBCN precursor is carried out during the heating process, and the additive cracking and ceramicization of the SiBCN precursor are completed during the substrate deposition process;

[0028] The process conditions of the CVI method are as follows: MTS is used as a precursor, hydrogen is used as a carrier gas and a dilution gas, and argon is used as a protective gas; the total pressure is 0.1-10kPa, the deposition temperature is 800-12...

Embodiment 2

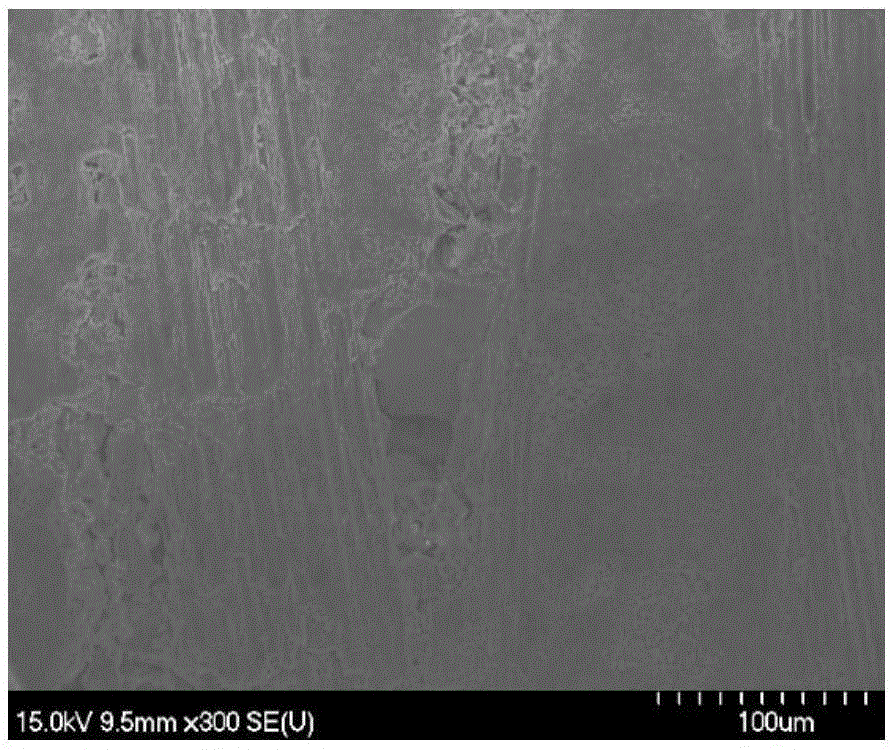

[0031] Step 1: The surface of the C / SiC composite material deposited by the CVI process for 4 furnaces was polished with sandpaper at room temperature, cleaned ultrasonically, and dried.

[0032] Step 2: The dried sample is impregnated with polyborosilazane (PBSZ) at room temperature to seal the cavities and cracks inside the material. After impregnation, cure at 120-250°C for 2-5 hours to achieve preliminary sealing of micro-cracks in the SiC matrix;

[0033] Step 3: Put the cured sample in the CVI deposition furnace, so that the cracking of the SiBCN precursor is carried out during the heating process, and the additive cracking and ceramicization of the SiBCN precursor are completed during the substrate deposition process;

[0034] The process conditions of the CVI method are as follows: MTS is used as a precursor, hydrogen is used as a carrier gas and a dilution gas, and argon is used as a protective gas; the total pressure is 0.1-10kPa, the deposition temperature is 800-12...

Embodiment 3

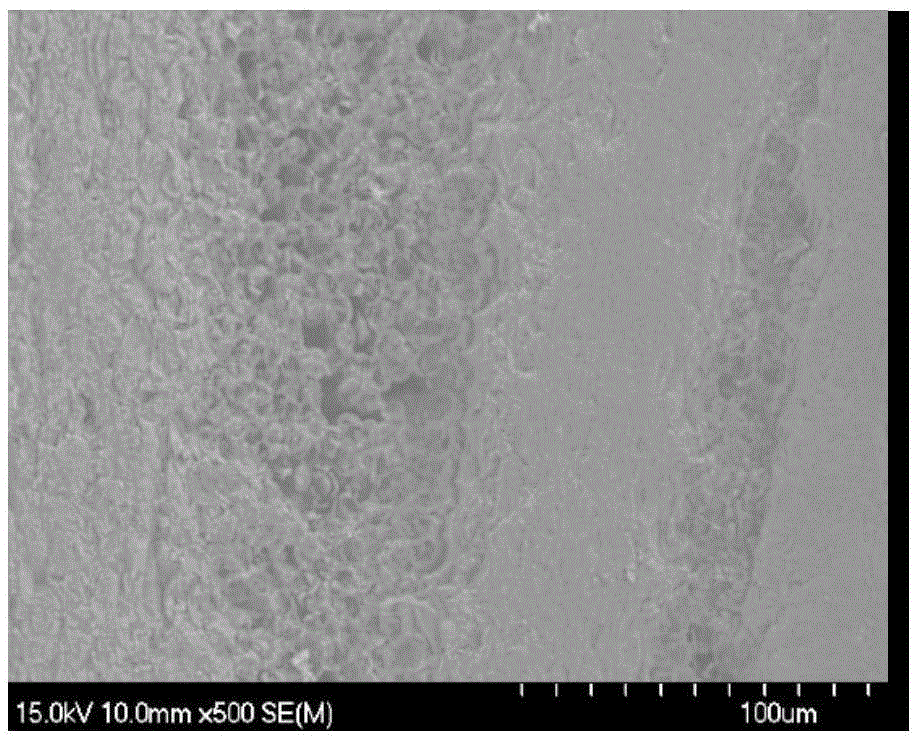

[0037] Step 1: Polish the surface of the C / SiC composite material deposited by the CVI process for 6 furnaces at room temperature with sandpaper, clean it ultrasonically, and dry it.

[0038]Step 2: The dried sample is impregnated with polysilaborazane (PSNB) at room temperature to fill the cavities and cracks inside the material. After impregnation, cure at 120-250°C for 2-5 hours to achieve preliminary sealing of micro-cracks in the SiC matrix;

[0039] Step 3: Put the cured sample in the CVI deposition furnace, so that the cracking of the SiBCN precursor is carried out during the heating process, and the additive cracking and ceramicization of the SiBCN precursor are completed during the substrate deposition process;

[0040] The process conditions of the CVI method are as follows: MTS is used as a precursor, hydrogen is used as a carrier gas and a dilution gas, and argon is used as a protective gas; the total pressure is 0.1-10kPa, the deposition temperature is 800-1200°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com