Patents

Literature

47results about How to "No anisotropy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of aluminum-alloy gas meter end cover

InactiveCN101598585AReduce weightImprove anti-corrosion performanceVolume meteringMechanical pressureAir tightness

The invention discloses a preparation method of an aluminum-alloy gas meter end cover, which is characterized by comprising the following steps: (1) respectively configurating aluminum alloy material and magnesium; (2) melting and refining; (3) pretreating and extruding cast mould; (4) extruding and moulding; (5) carrying out heat processing; and (6) carrying out post-processing. Compared with the prior art, the invention has the advantages that aluminum alloy material and advanced indirect extruding and casting process are adopted, so that the moulding material of the gas meter end cover is light in weight and good in corrosion resistance performance; the aluminum alloy melt solution is crystallized at a higher mechanical pressure, the crystal grain is refined, the organizational density is increased, and the defects of porosity, shrinkage, needle eye and the like inside the casting are eliminated, thereby significantly increasing the air tightness, hardness and tensile strength of the casting.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

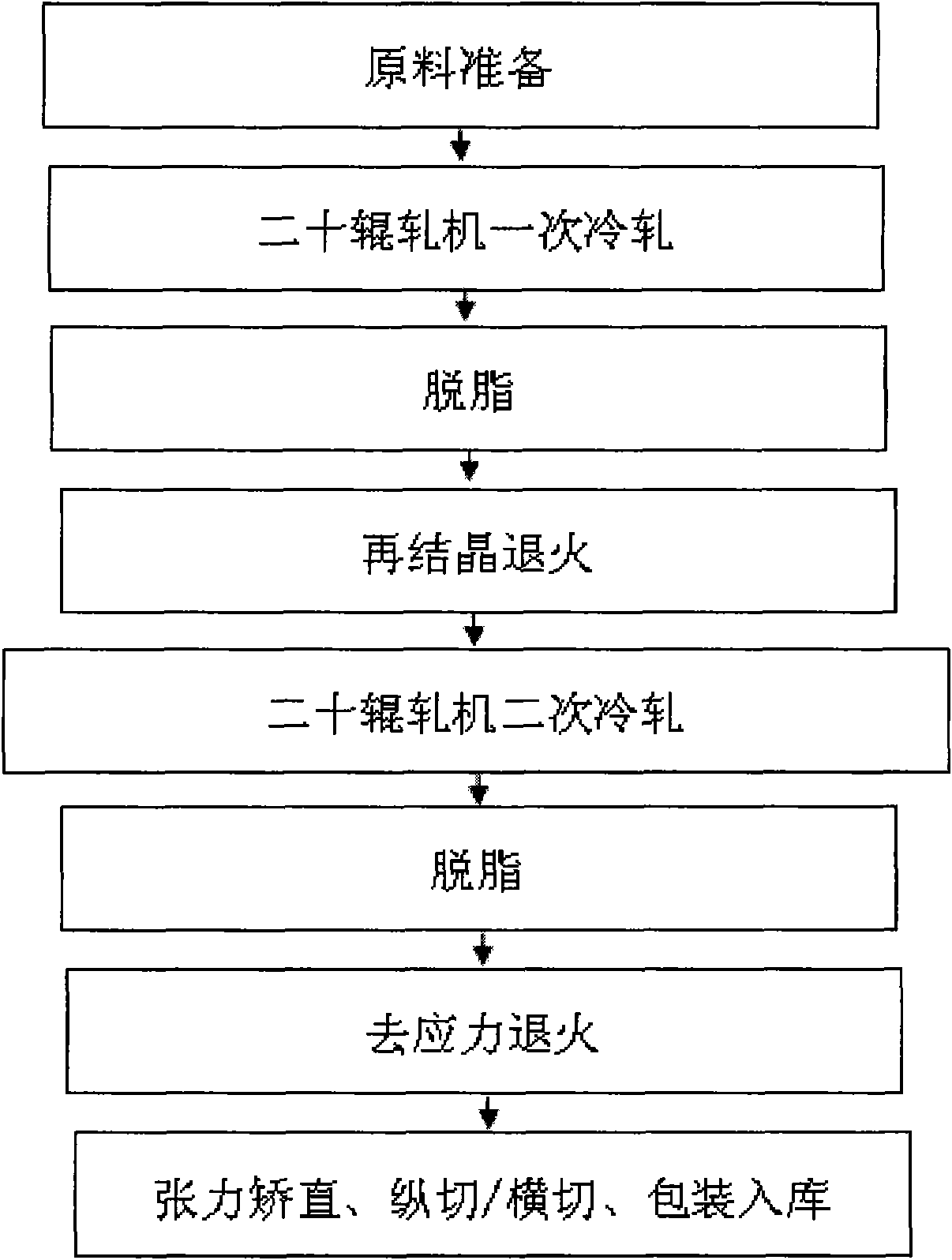

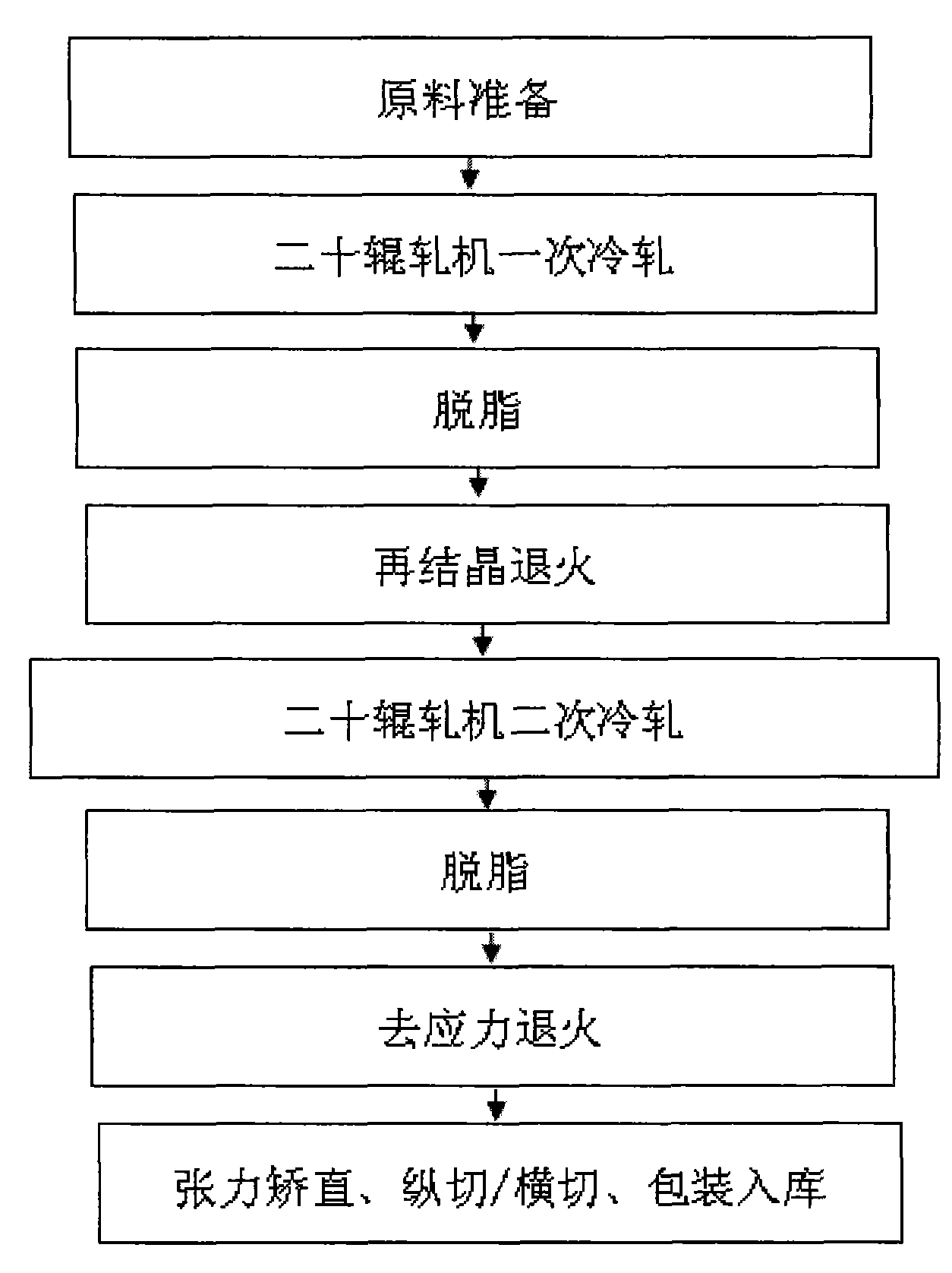

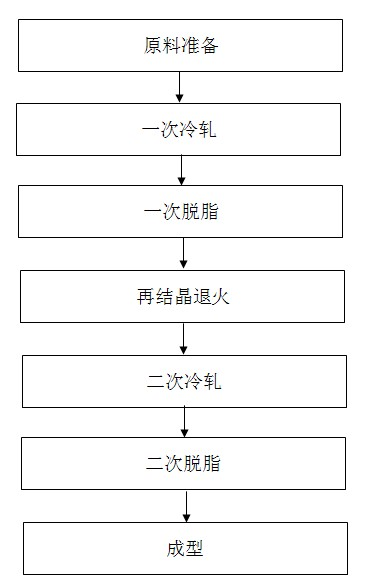

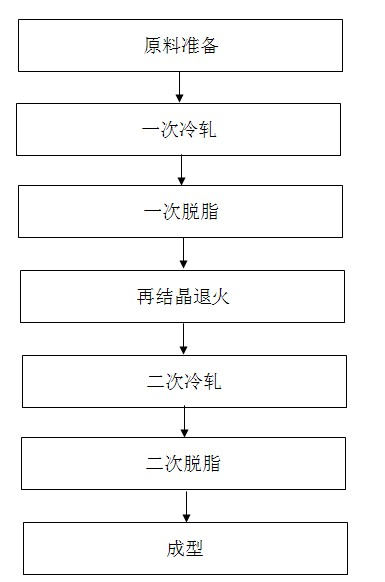

Method for rolling and molding low-oxygen content aero titanium alloy precision sheet

ActiveCN101817015AUniform distribution of internal stressNo anisotropyRoll mill control devicesFurnace typesDegreasingTitanium alloy

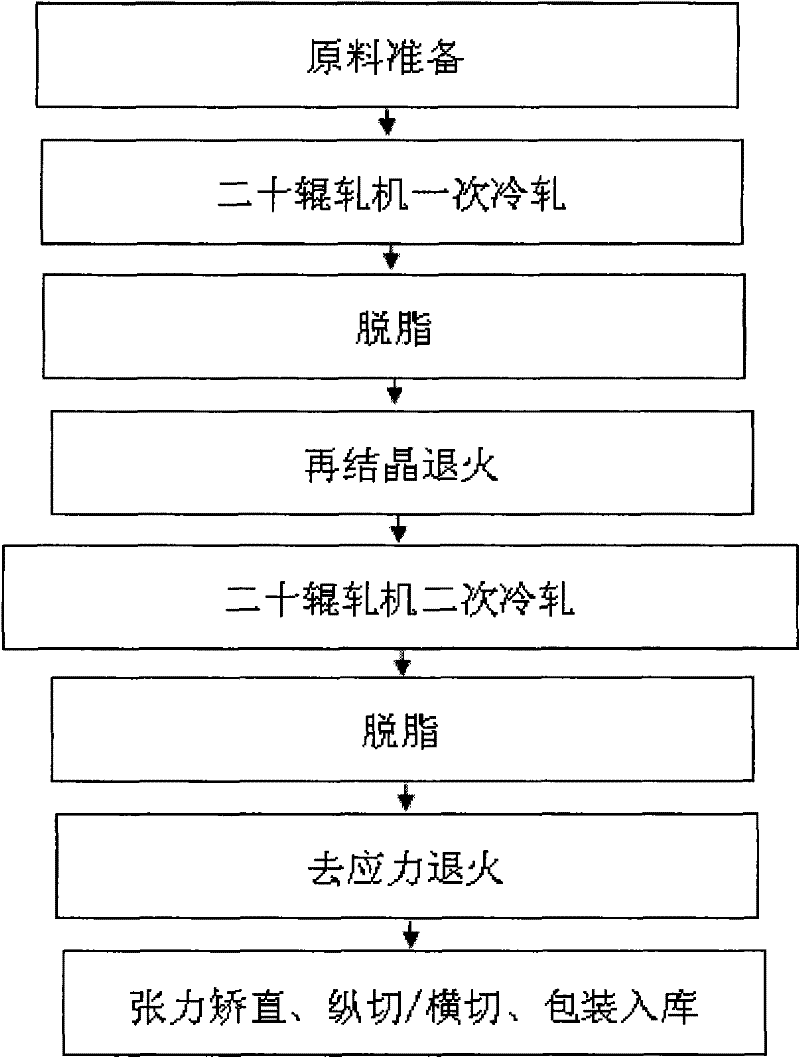

The invention discloses a method for rolling and molding a low-oxygen content aero titanium alloy precision sheet. Tthe low-oxygen content aero titanium alloy precision sheet is obtained by rolling twice by using a twenty high rolling mill. The method comprises the following steps of: rolling by using the twenty high rolling mill, degreasing, recrystallization annealing, cold rolling with the twenty high rolling mill again, degreasing, stress relief annealing, stretcher leveling, longitudinal cutting / transverse cutting, inspecting, packaging, and the like, wherein aero titanium alloy plates, such as TC4, TA15 and the like, with the thickness of 1-5 mm, are used as raw materials. The thickness tolerance of the titanium alloy precision sheet is + / -0.005 mm, the camber is 0.3-1 mm / 1m, the surface quality is No.2B, the surface smoothness is up to 1-2 I-Unit, the grain size is up to 5-6 grades, the surface has no surface contamination layer (such as an oxygen-enriched layer, an alpha layer and the like), the internal stress is distributed uniformly, no anisotropy exists, and the subsequent plastic forming feature is favorable. The invention has the advantages of easy production method, low cost, high product quality and high production efficiency.

Owner:江苏呈飞新材料科技有限公司

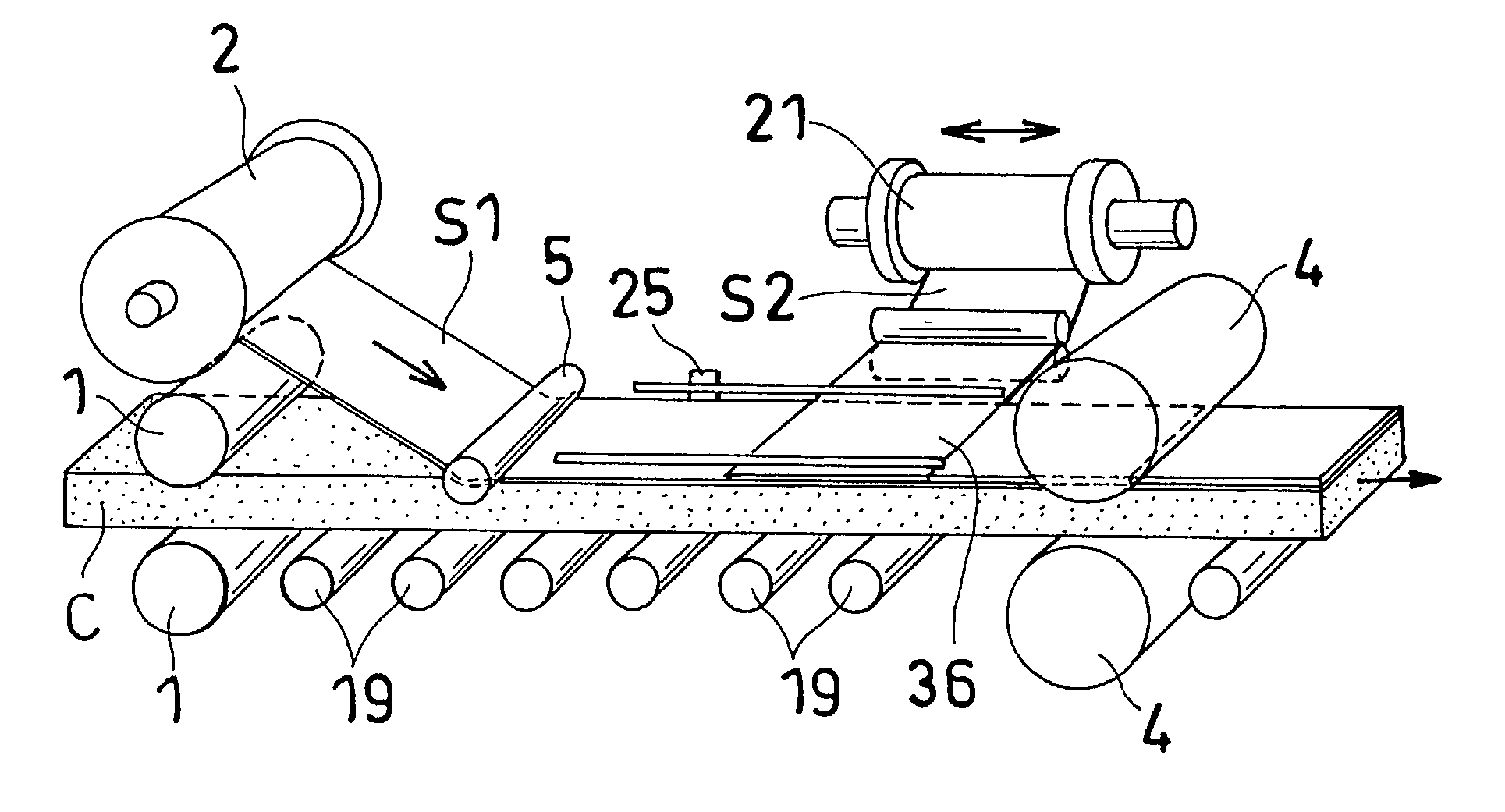

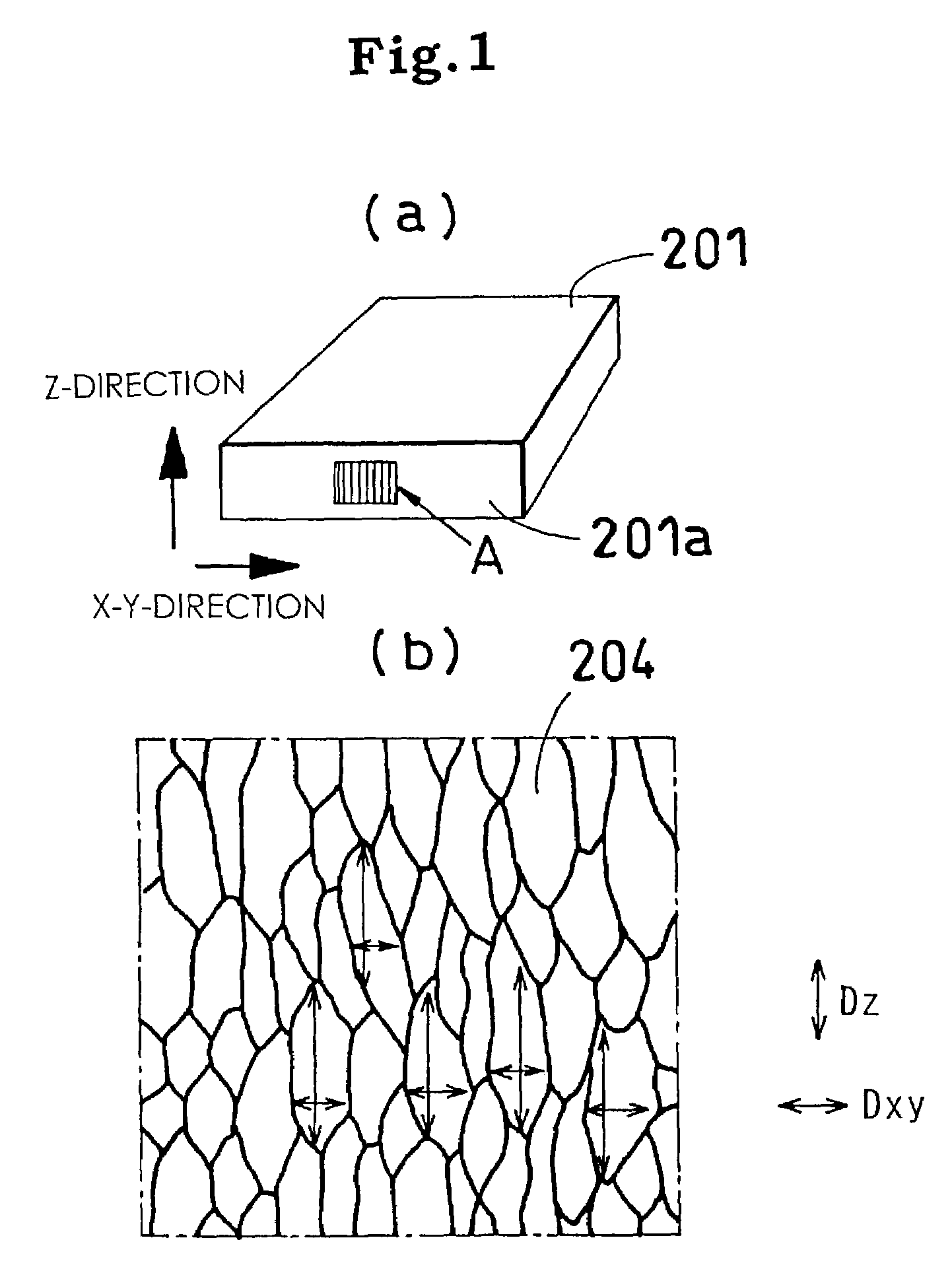

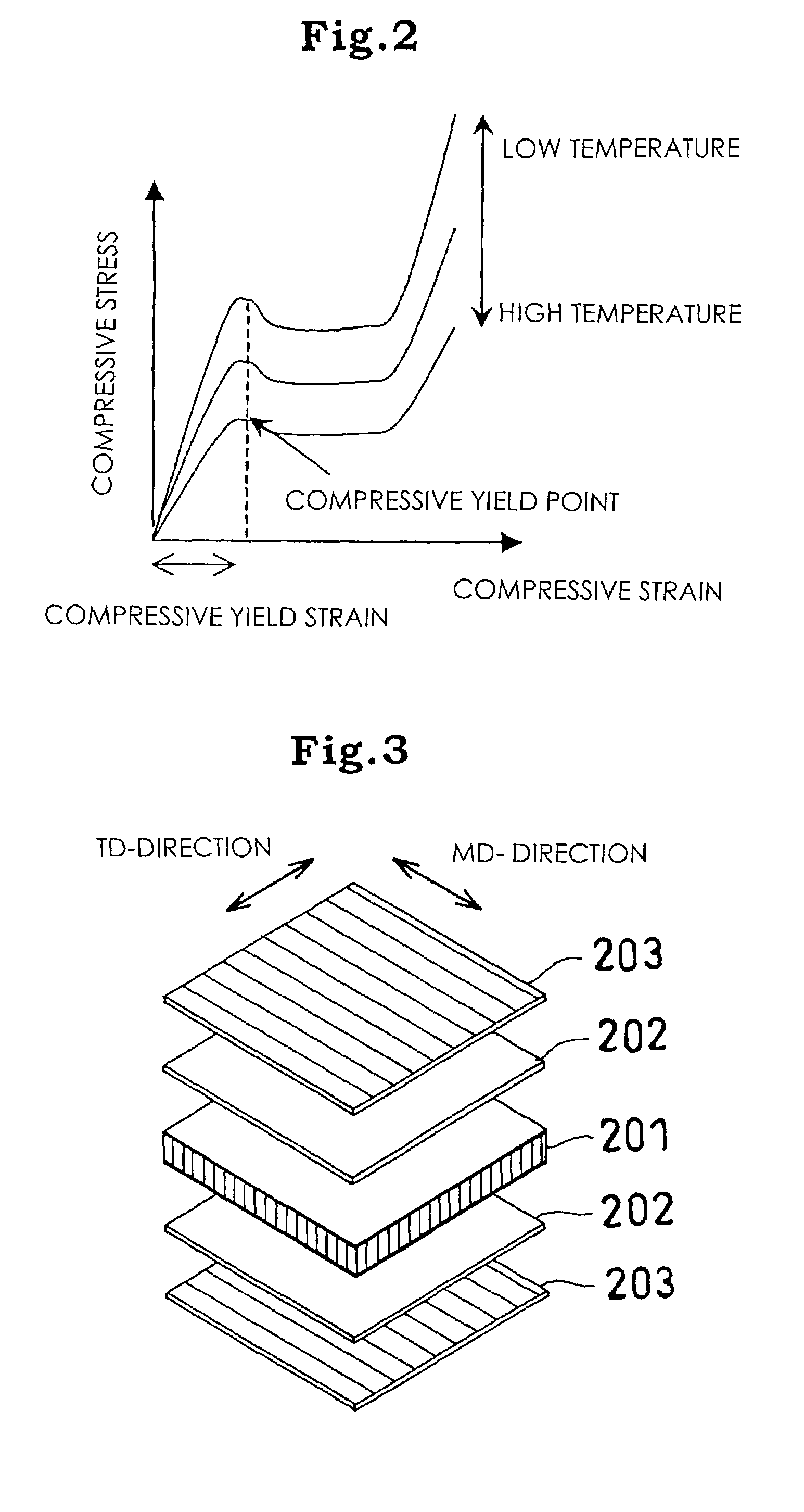

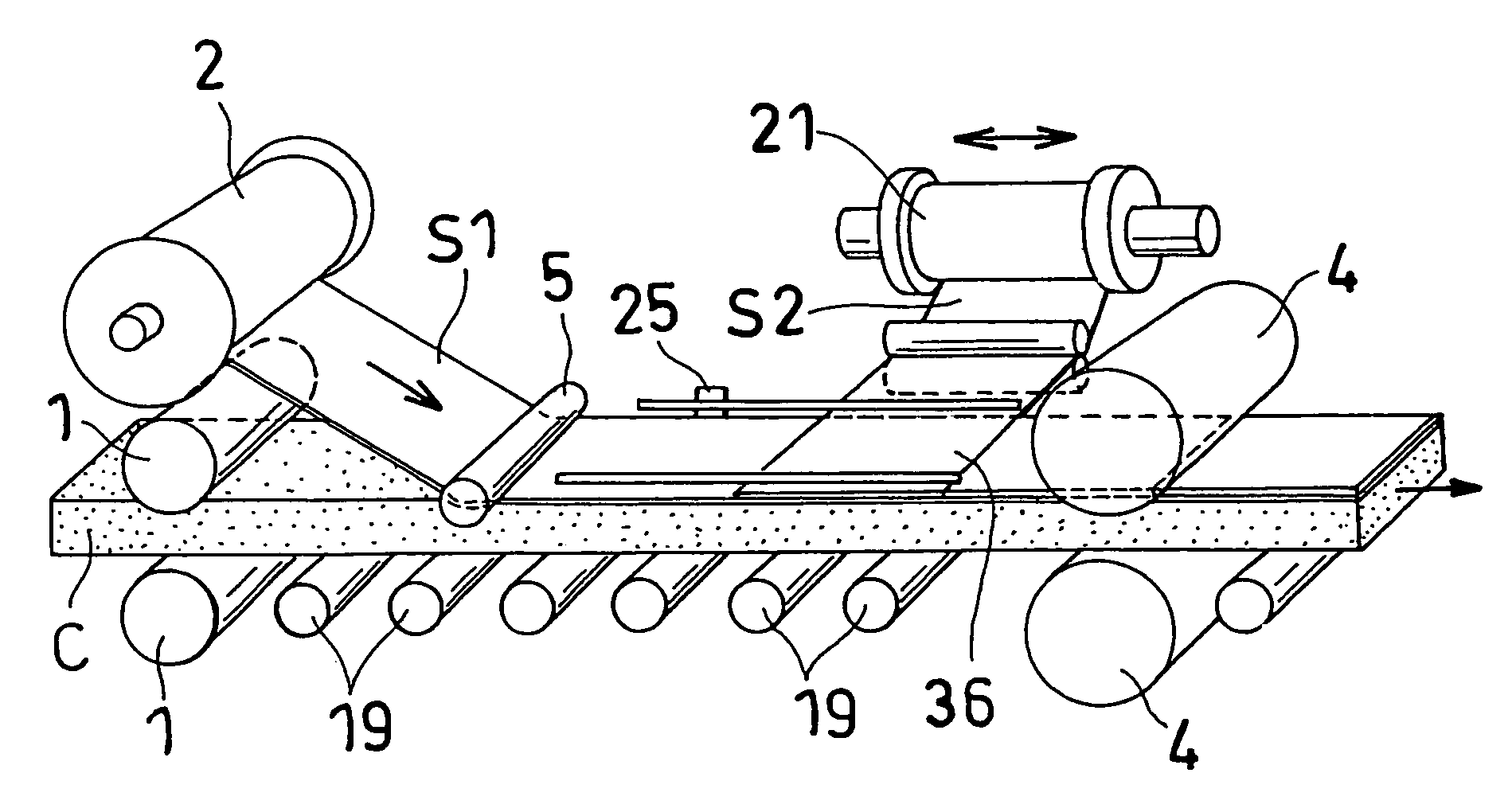

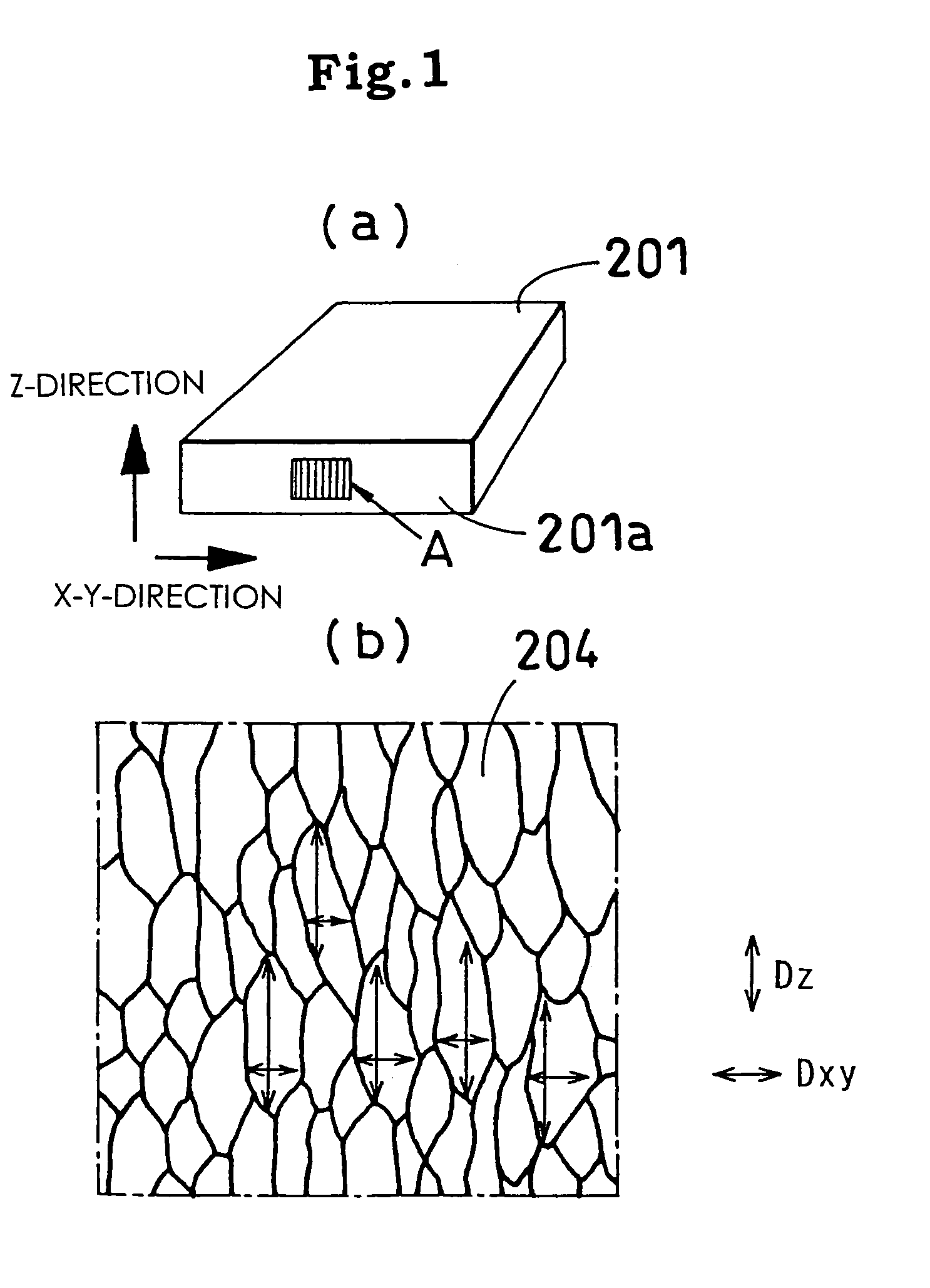

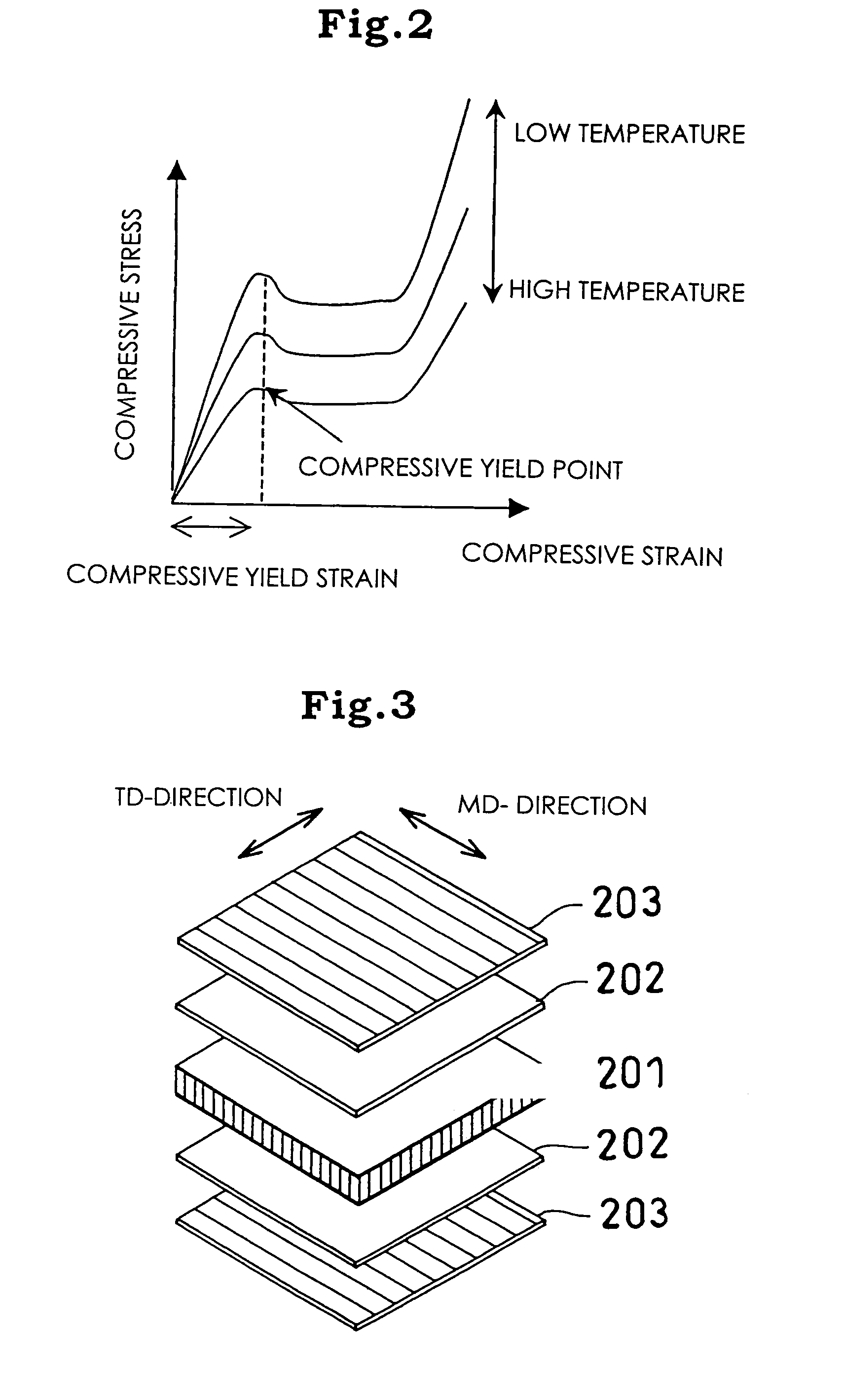

Method and device for producing laminated composite

InactiveUS7063768B2Easy to recycleImprove production efficiencyMechanical working/deformationLamination ancillary operationsHeat deflection temperaturePolyolefin

A polyolefin resin drawn sheet 4 is laminated on at least one face of a sheet-form core material 6 having a density of 30 to 300 kgf / m3. At this time, a sheet or film 5 made of a bonding synthetic resin or rubber having a flow starting temperature lower than the thermal deformation temperature of the core material 6 and the melting point of the drawn sheet 4 is interposed between the core material 6 and the drawn sheet 4. The resultant stack product is heated to not less than the flow starting temperature of the synthetic resin or the rubber and not more than the thermal deformation temperature of the core material 6 and the melting point of the drawn sheet 4. At the same time of or after the heating, the stack product is pressed to apply a compression strain of 0.01 to 10% to the core material 6.

Owner:SEKISUI CHEM CO LTD

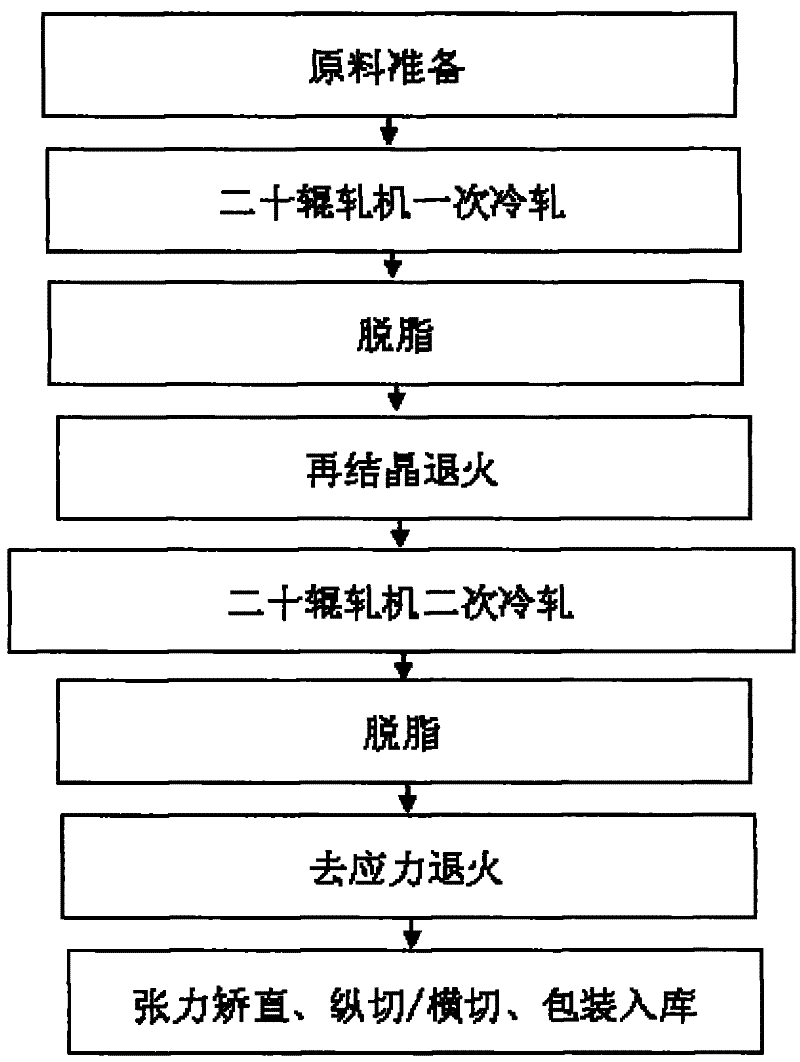

Method for rolling and forming low-oxygen-content pure-titanium precise thin strip coiled material

The invention discloses a method for rolling and forming a low-oxygen-content pure-titanium precise thin strip coiled material. The rolling and forming method is used for rolling the low-oxygen-content pure-titanium precise thin strip coiled material by using a multi-pass twenty high rolling mill and particularly comprises the following steps of: preparing raw materials; performing primary rolling; degreasing; performing recrystallizational annealing; performing secondary cold rolling; performing secondary degreasing; and forming. In the low-oxygen-content pure-titanium precise thin strip coiled material finished product obtained by the method, no surface pollution layers, such as an oxygen enriched layer and the like, are formed on the surface; internal stress is distributed uniformly; no anisotropism exists; the subsequent plastic forming property is high; thickness tolerance is + / - 2percent; camber is 0.3 to 1 millimeter per meter; the surface quality is TR; the surface flatness reaches 1-2I-Unit; and grain size reaches 5 to 6 levels. Compared with the prior art, the method has the advantages that: the low-oxygen-content pure-titanium precise thin strip coiled material obtained by the method has excellent comprehensive performance; and the production method is simple and practicable, low in cost and high in efficiency.

Owner:JIANGSU CHENGFEI PRECISION ALLOY

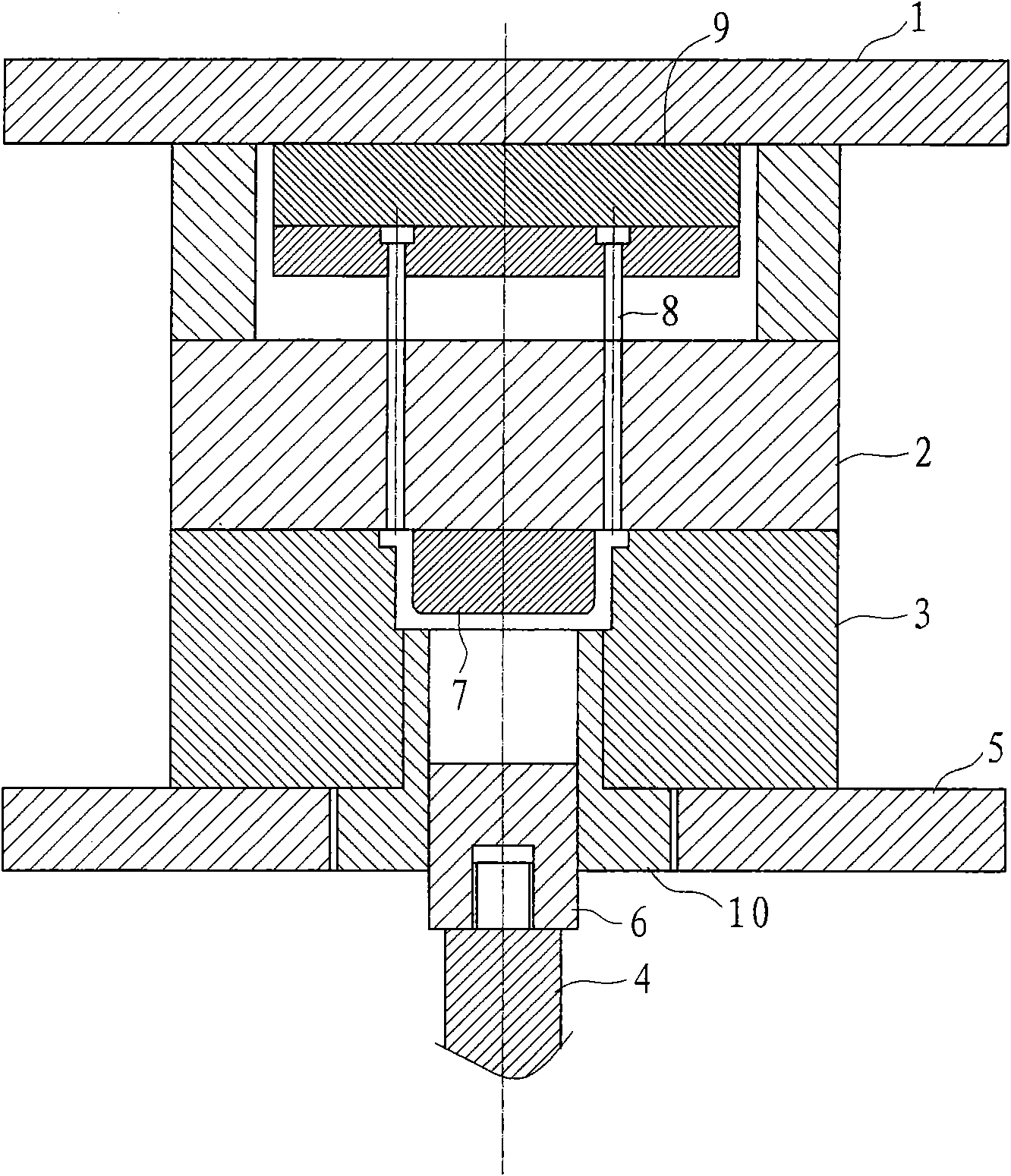

Preparation method of oblique oil cylinder body

The invention discloses a preparation method of an oblique oil cylinder body. The method comprises the following step of: a, preparing a metal solution which comprises the following chemical composition in percentage by weight: 0.18-0.27% of C, 1.1-2.0% of Mn, 0.6-1.25 of Si, 0.08-0.15% of V, 0.11-0.2% of Ti, 0.8-2.0% of Cr, 0.5-1.5% of Ni, trace amount-0.40% of Mo, 0.1-0.8% of WO, 0.05-0.07% of Nb, trace amount-0.23% of Al, trace amount-0.50% of Cu, no more than 0.030% of P, no more than 0.030% of S, and the balance of aluminum and inevitable foreign matters. Aiming at the defects of higher cost and low material utilization ratio, the invention provides preparation method of an aluminum alloy oil cylinder body cover which is simple in forming process, low in manufacturing cost, high in material utilization ratio, high in product strength and light in weight.

Owner:ANHUI ZHENYE MACHINERY

Method and device for producing laminated composite

InactiveUS7452440B1Easy to recycleImprove production efficiencyLamination ancillary operationsSynthetic resin layered productsHeat deflection temperaturePolyolefin

A polyolefin resin drawn sheet 4 is laminated on at least one face of a sheet-form core material 6 having a density of 30 to 300 kgf / m3. At this time, a sheet or film 5 made of a bonding synthetic resin or rubber having a flow starting temperature lower than the thermal deformation temperature of the core material 6 and the melting point of the drawn sheet 4 is interposed between the core material 6 and the drawn sheet 4. The resultant stack product is heated to not less than the flow starting temperature of the synthetic resin or the rubber and not more than the thermal deformation temperature of the core material 6 and the melting point of the drawn sheet 4. At the same time of or after the heating, the stack product is pressed to apply a compression strain of 0.01 to 10% to the core material 6.

Owner:SEKISUI CHEM CO LTD

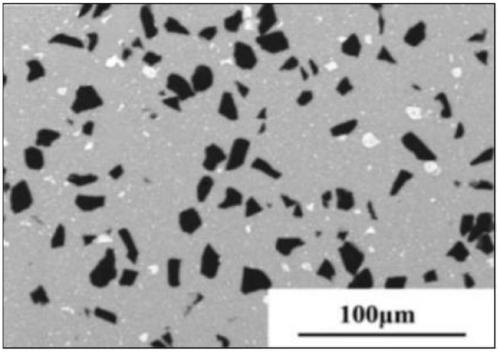

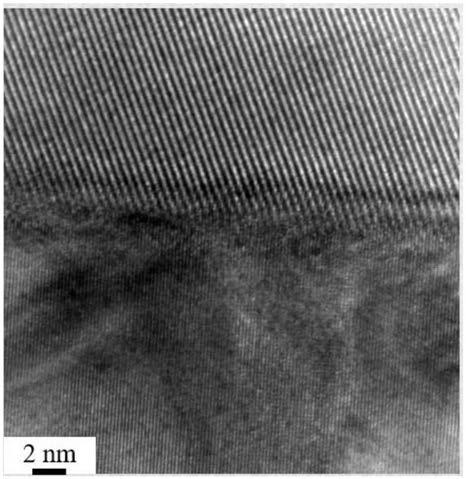

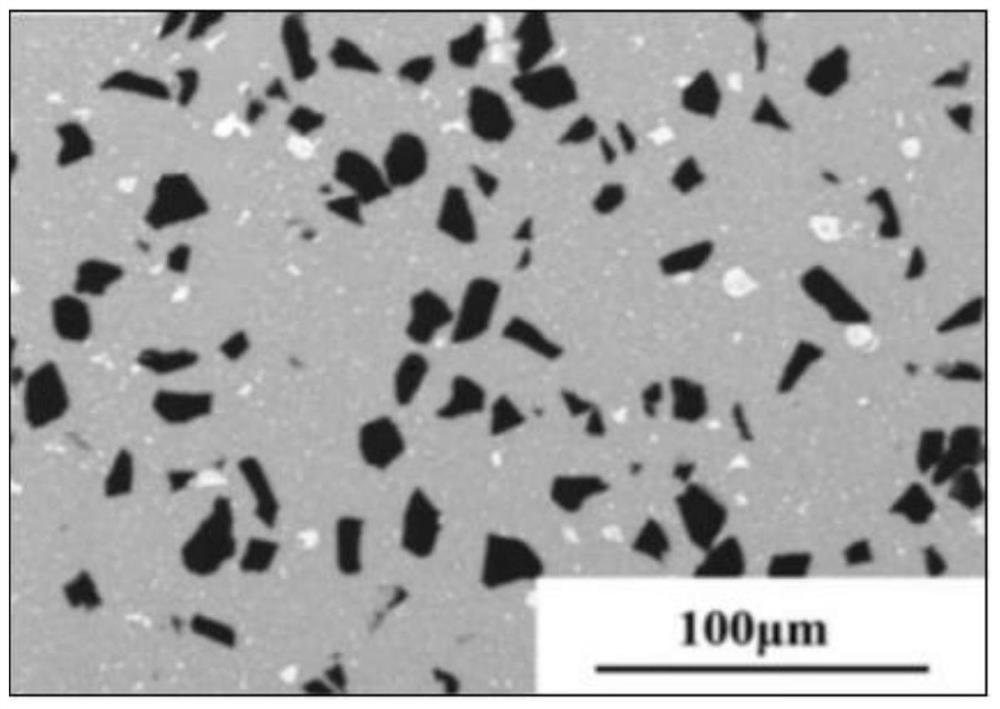

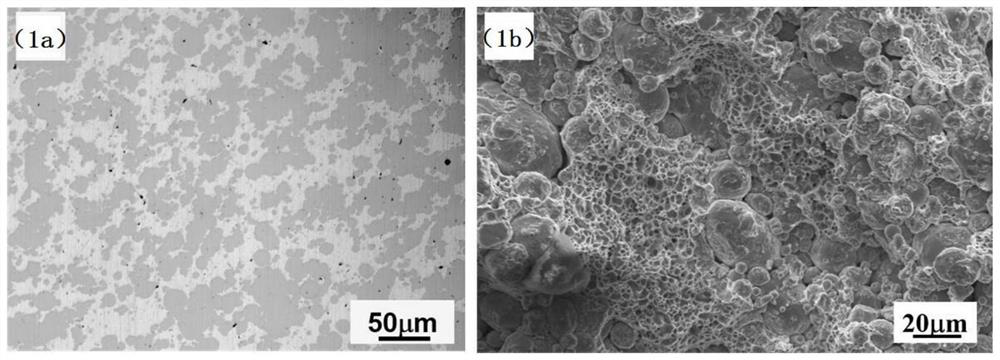

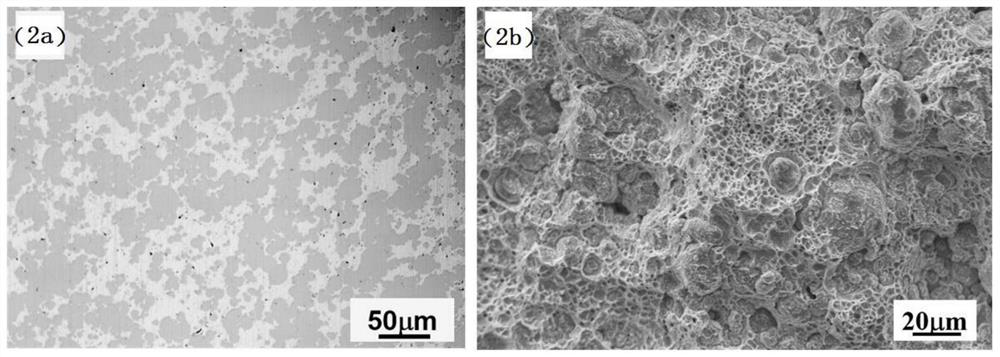

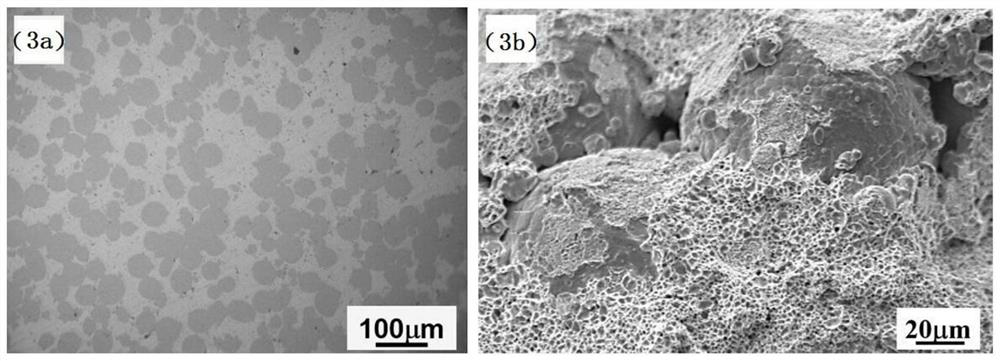

Method for preparing particle-reinforced aluminum-based composite material adopting hot-pressing sintering under atmospheric atmosphere

The invention relates to a method for preparing a particle-reinforced aluminum-based composite material adopting hot-pressing sintering under an atmospheric atmosphere. The invention belongs to the field of powder metallurgy, in particular to the method for preparing the particle-reinforced aluminum-based composite material adopting hot-pressing sintering under the atmospheric atmosphere. The method aims to overcome the defects of complex process, high cost and low production efficiency of an existing composite material preparation process adopting the hot-pressing sintering. The method comprises the following steps that 1, ball-milling is carried out to mix powder, specifically, the ball-milling is carried out on ceramic particle reinforcement and an aluminum-based body for mixing the powder to obtain the mixed powder; 2, cold pressing is carried out to prepare a prefabricated body, specifically, step-by-step compaction is carried out on the mixed powder by adopting a graphite die soas to obtain the prefabricated body; and 3, the hot-pressing sintering is carried out on the prefabricated body under the atmospheric atmosphere, the graphite die is transferred into the air after thesintering is completed till the die is naturally cooled to the room temperature, and the die is removed to obtain the particle-reinforced aluminum-based composite material. The method is used for preparing the particle-reinforced aluminum-based composite material.

Owner:QIQIHAR XIANGKE NEW MATERIAL CO LTD

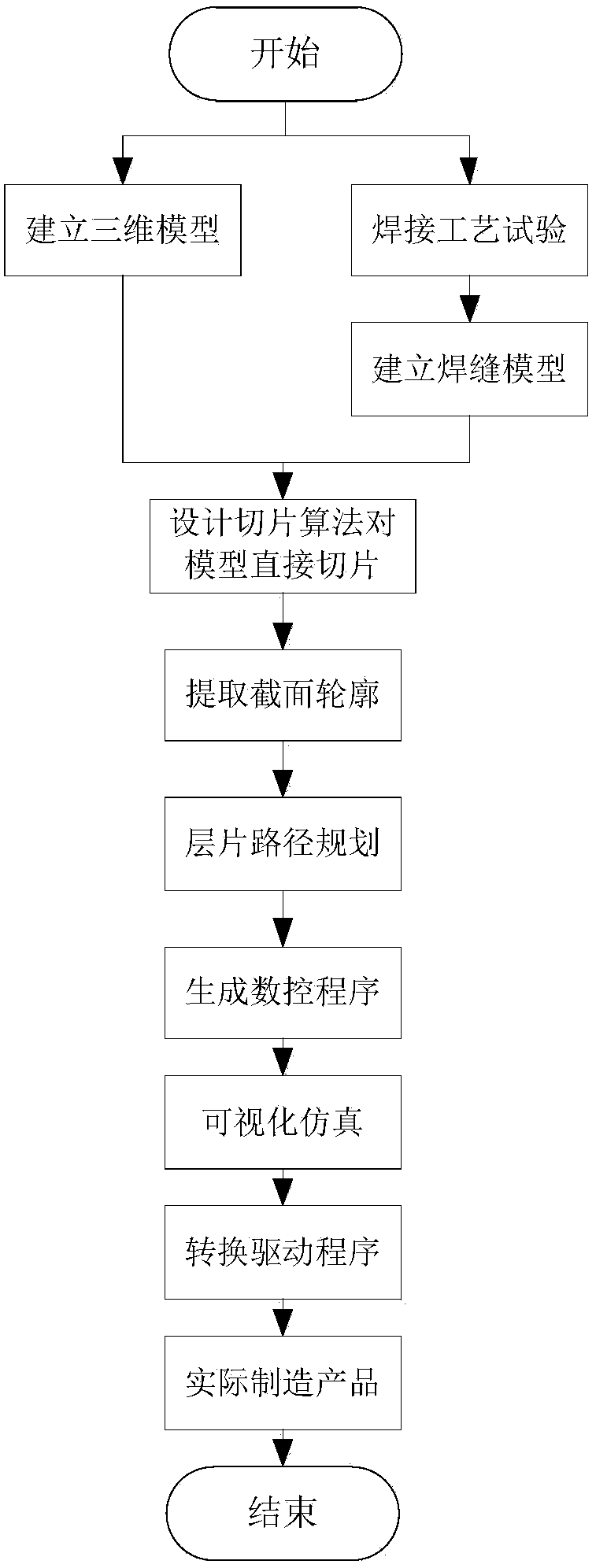

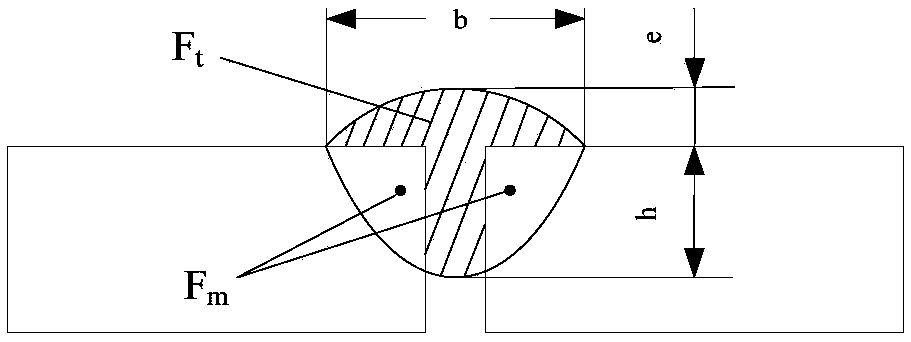

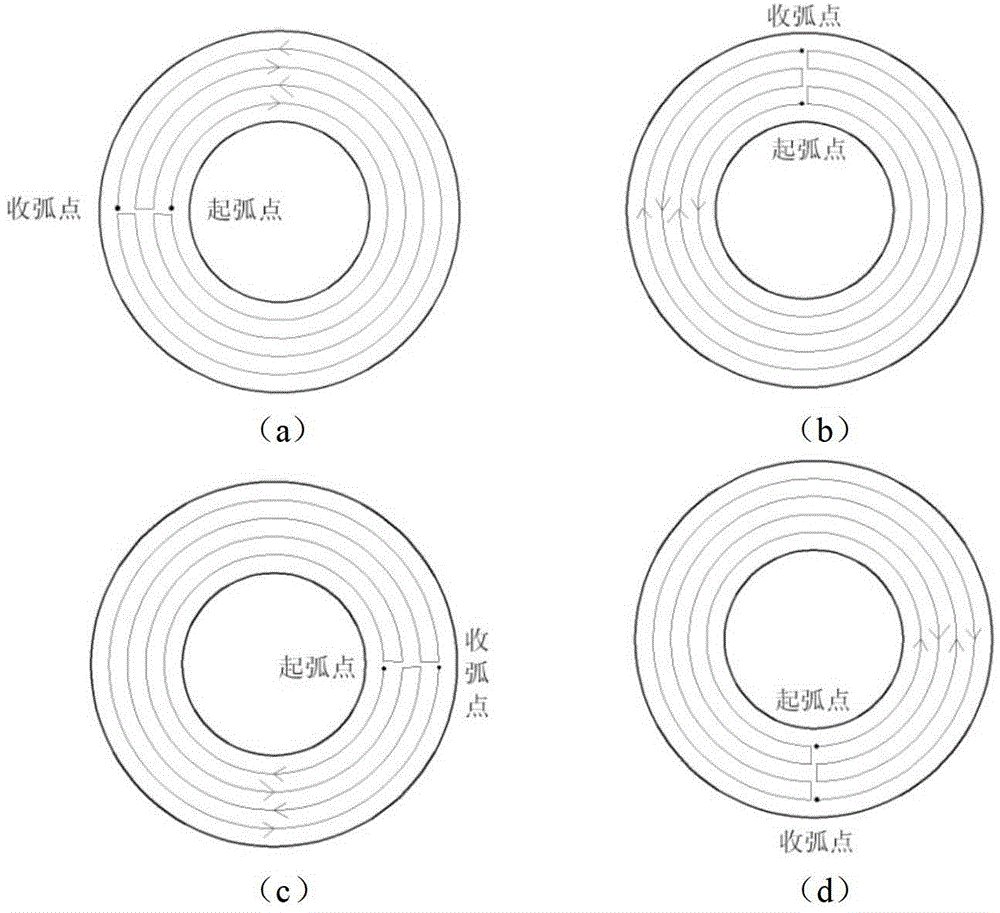

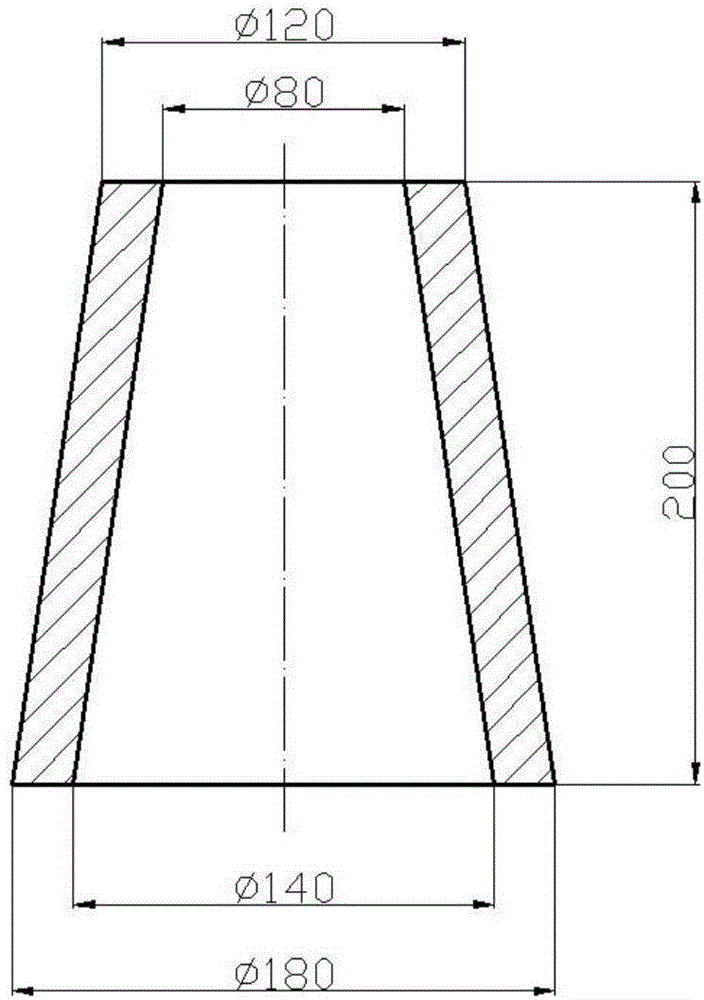

Robot additive manufacturing method based on MIG/MAG welding process

ActiveCN109420819AEasy to modifyReduce manufacturing costArc welding apparatusDesign optimisation/simulationNumerical controlProcess integration

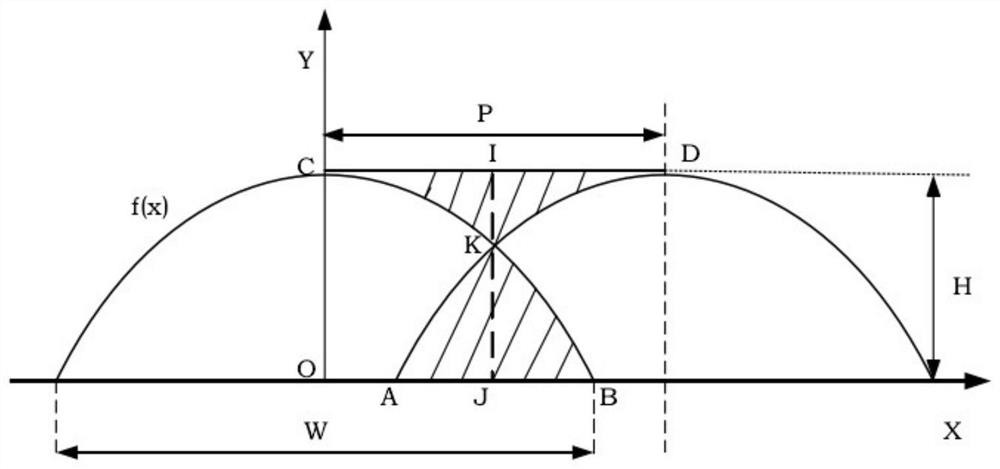

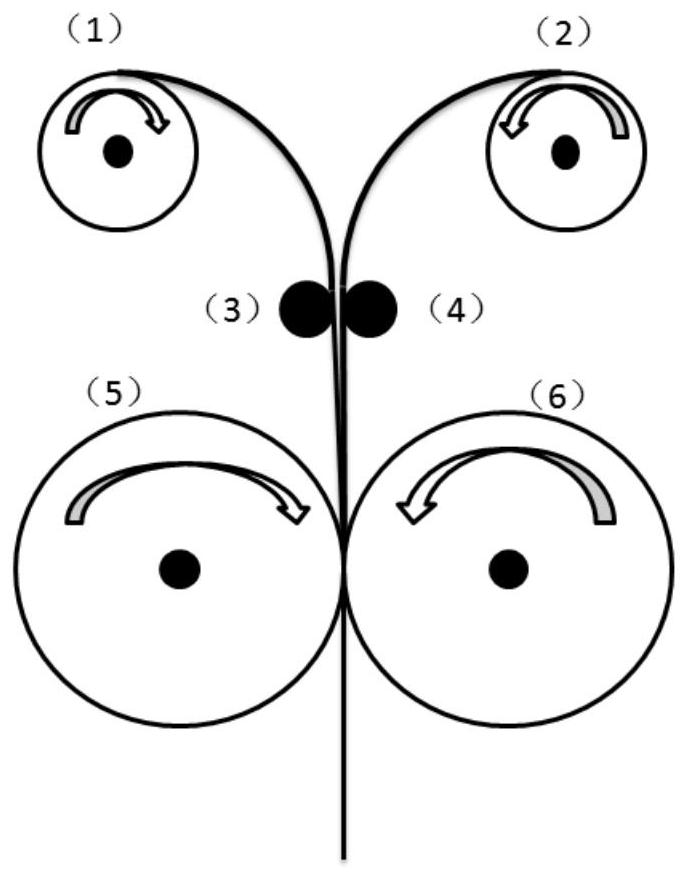

The invention discloses a robot additive manufacturing method based on a MIG / MAG welding process. The robot additive manufacturing method based on the MIG / MAG welding process comprises the following steps that (1) a CAD model of a metal part is established; (2) a welding process test is carried out to establish a mapping relation between welding process parameters and weld seam geometric characteristics; (3) modeling is carried out on a weld seam body and weld seam characteristic parameters; (4) the stacking direction is determined according to the shape of the metal part, the layering heightof overlaying welding is determined according to the established weld seam model, and secondary development is carried out on a three-dimensional model software to realize a slicing function to the model; (5) a section profile obtained in the slicing step is extracted, the row spacing of overlaying welding is determined according to the established weld seam model, an appropriate path planning algorithm is designed, and a numerical control program is generated; and (6) after the numerical control program is imported into a robot simulation software for testing, a robot drive program is exported to produce the metal part. The robot additive manufacturing method based on the MIG / MAG welding process has the advantages of high forming precision and quality, process integration and the like, and has low manufacturing costs and high market response speed.

Owner:NANJING UNIV OF SCI & TECH

Functional film prepared from functionalized organic powder, low-temperature damage-free manufacturing method and application

ActiveCN111004404AHigh strengthImprove toughnessOrganic-compounds/hydrides/coordination-complexes catalystsFinal product manufactureOrganic filmMicron scale

The invention provides a functional film prepared from functionalized organic powder, a low-temperature damage-free manufacturing method and application. The organic powder film material is composed of the functionalized organic powder and polytetrafluoroethylene (PTFE), polytetrafluoroethylene molecular chains are opened through preheated supersonic airflow, the functionalized organic powder is bonded, air in the powder is extruded to form a continuous cake shape, the powder forms a film through a low-temperature hot-pressing process, and then the film material with low porosity and uniform thickness is formed through a multi-layer film hot-pressing compounding process. According to the method, micron-sized organic films can be continuously prepared in a roll-to-roll mode, the physical and chemical properties of the organic powder can be brought into play to the maximum extent, and performance damage caused by high temperature or introduction of a solvent for film formation or anisotropy caused by recrystallization is prevented. No solvent is introduced in the manufacturing process, and the problems of environmental pollution, high energy consumption, uneven film material densityand the like caused in the solvent drying process are avoided.

Owner:东莞奥创能源科技有限公司

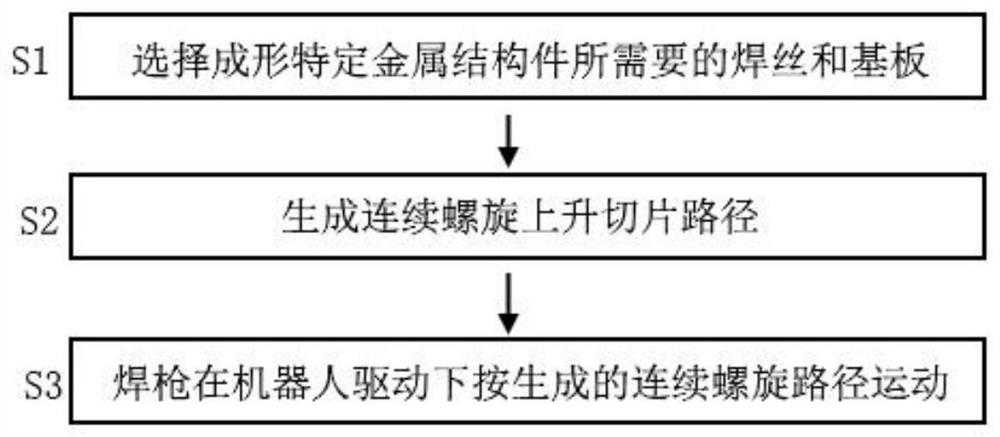

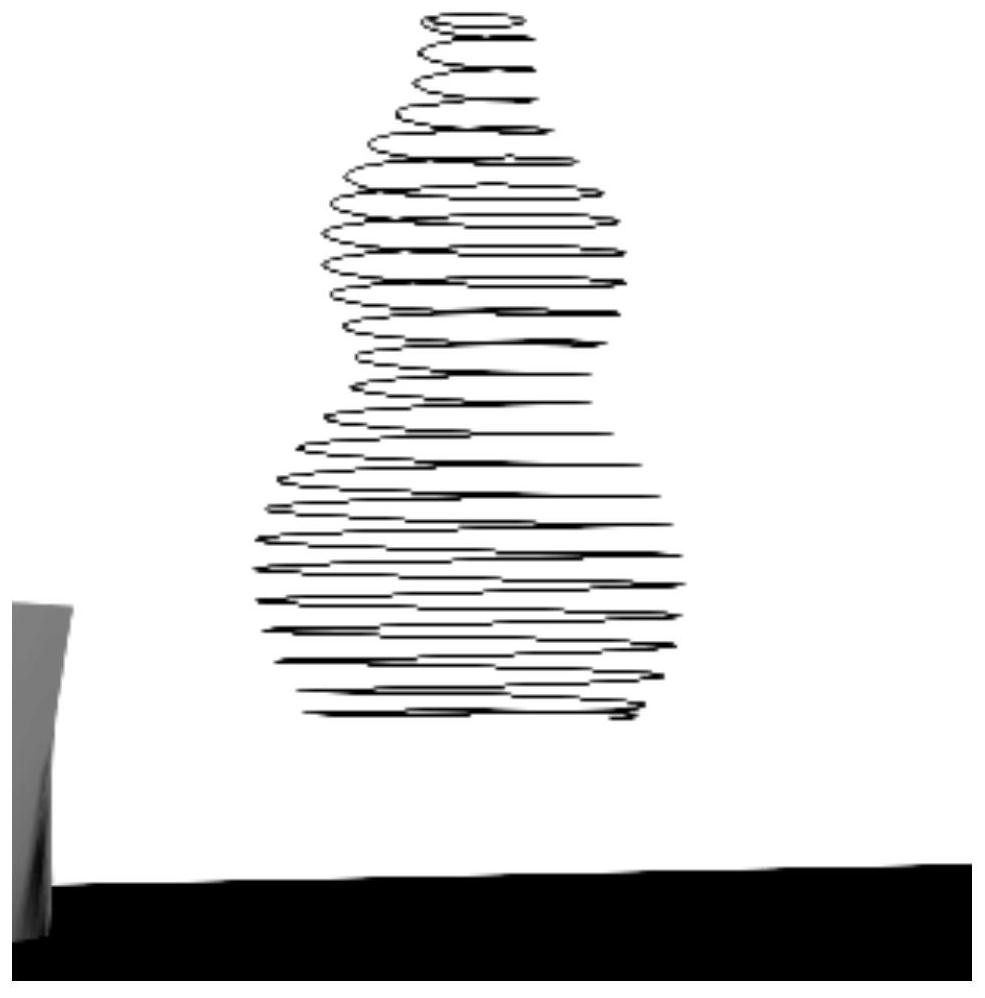

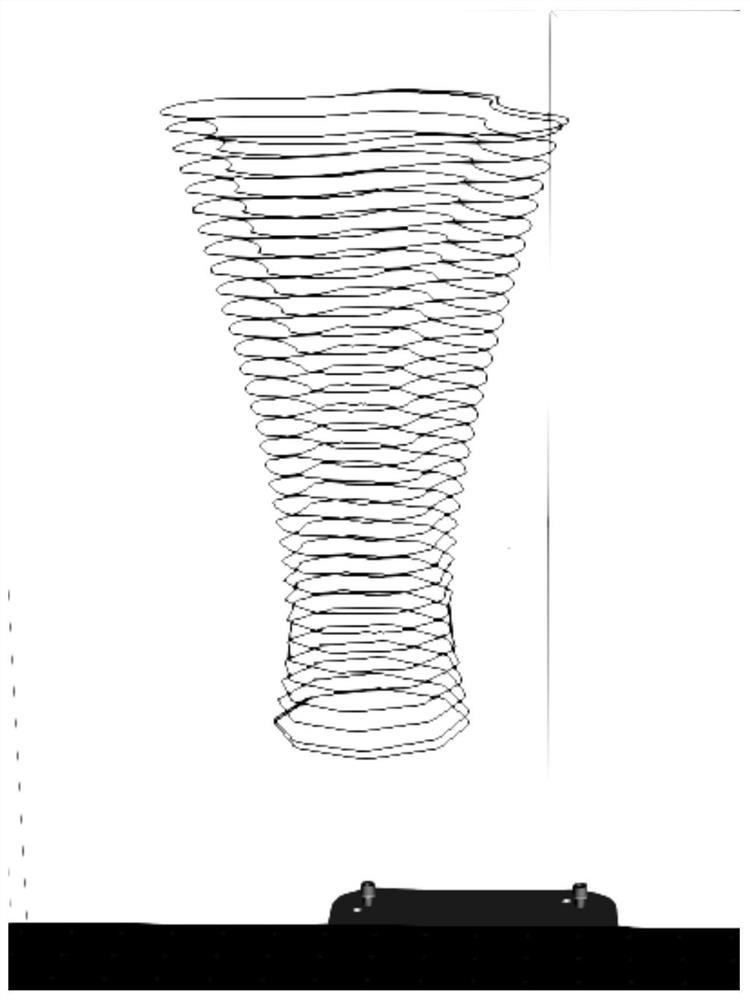

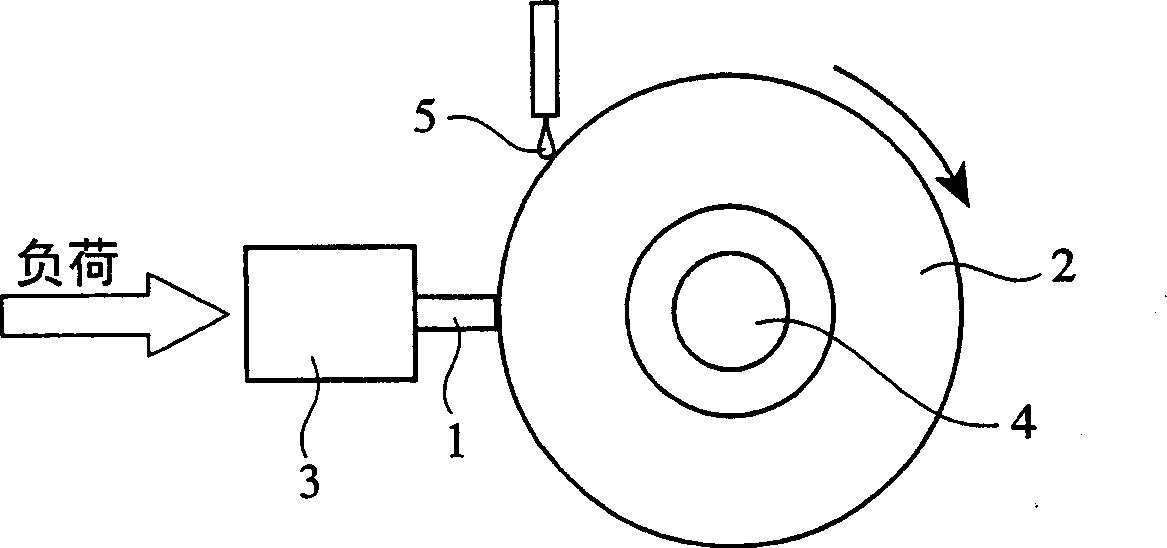

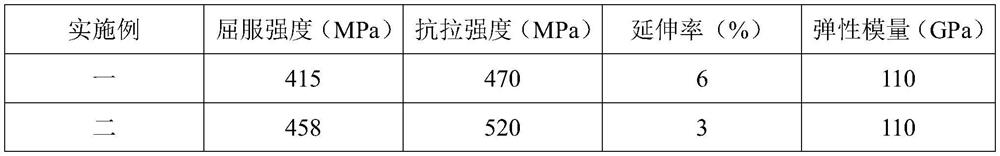

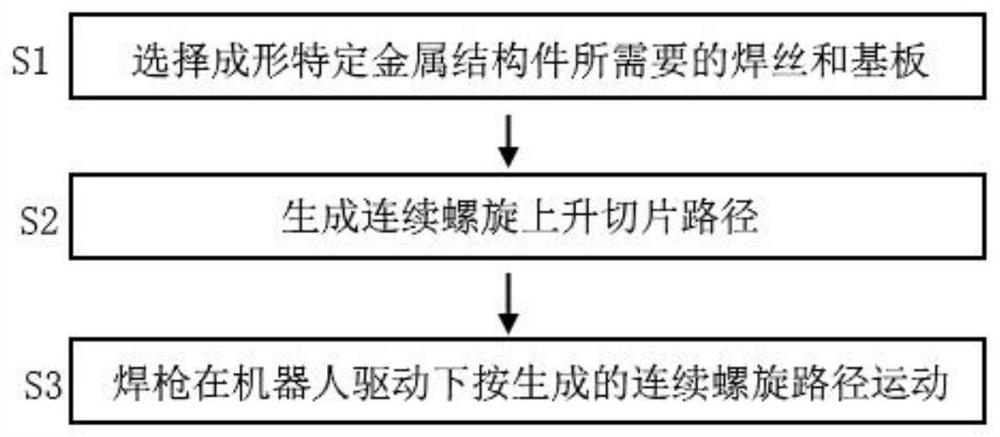

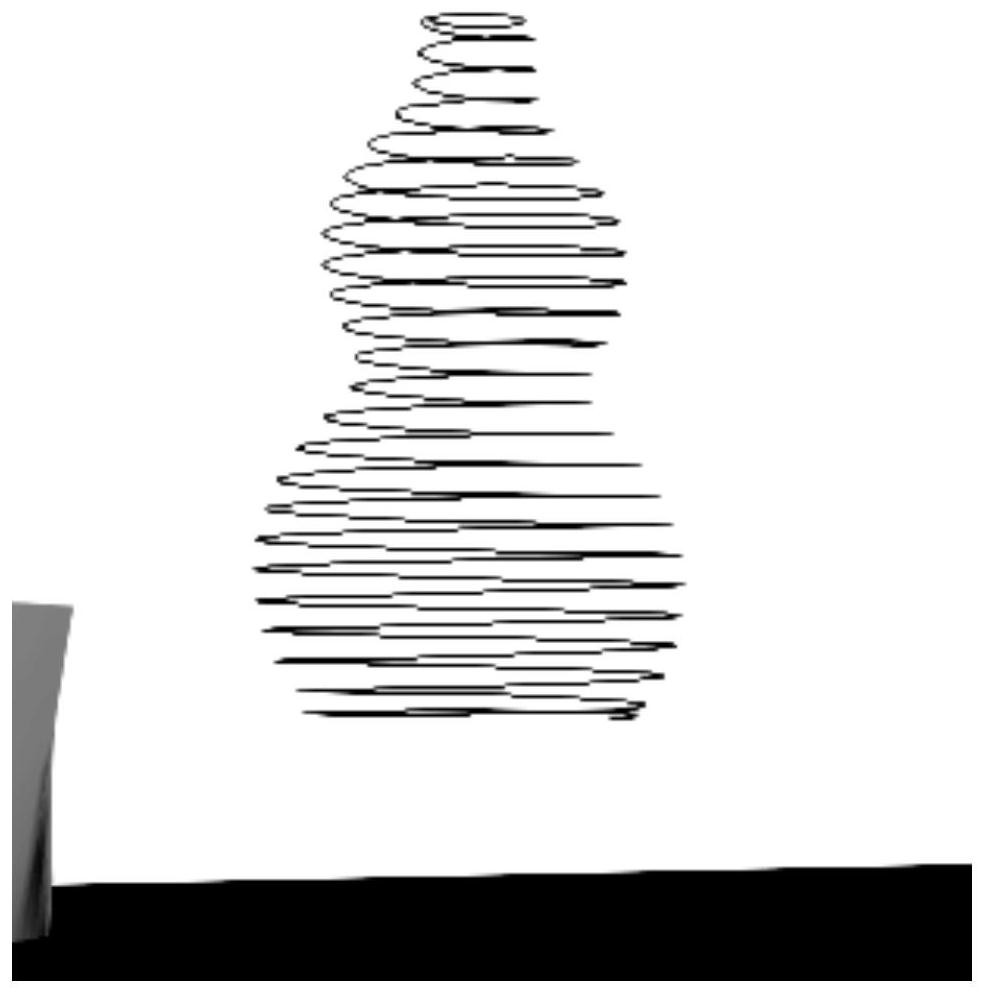

Metal structural part multi-layer single-pass continuous electric arc additive manufacturing method and system

ActiveCN111702292AGo digitalRealize intelligenceArc welding apparatusMaterials scienceIndustrial engineering

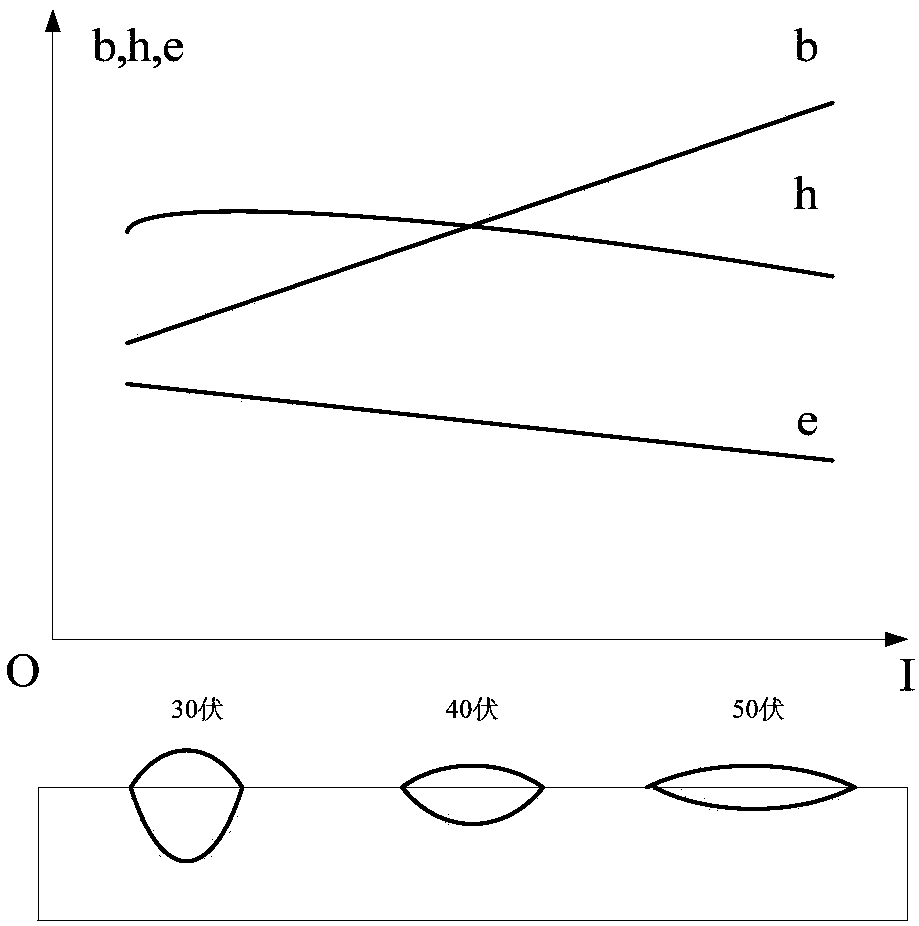

The invention discloses a metal structural part multi-layer single-pass continuous electric arc additive manufacturing method and system. The metal structural part multi-layer single-pass continuous electric arc additive manufacturing method adopts a welding machine as a heat source and a metal wire material as a molding material; and under the driving of a robot, a welding device moves on a substrate according to a planned continuous spiral rising slicing path to carry out electric arc additive manufacturing. Firstly, a welding wire and the substrate needed by molding a specific metal structural part are selected; secondly, the continuous spiral rising slicing path is generated; and thirdly, a welding gun moves according to the generated continuous spiral path under the driving of the robot, a servo system drives a welding gun mechanical arm according to a calculated spiral path, the welding gun mechanical arm drives the welding gun to print a single-pass welding seam along a desiredtrajectory, and the height of the welding gun from the substrate in the printing process is gradually increased according to the spiral path. The continuous spiral rising path enables the height of the welding gun from the substrate to be gradually increased in the whole 3D printing process; but the dry extension is kept invariable; arc quenching cannot be caused in the whole printing process; andfinally, the metal structural part with excellent performance is molded.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

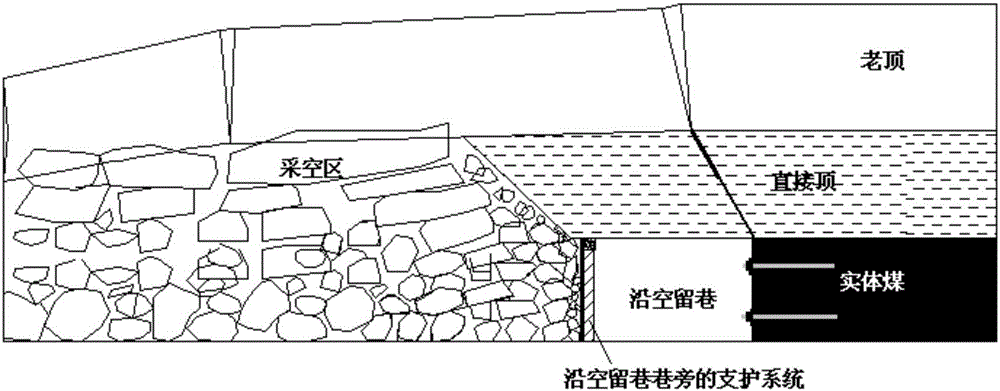

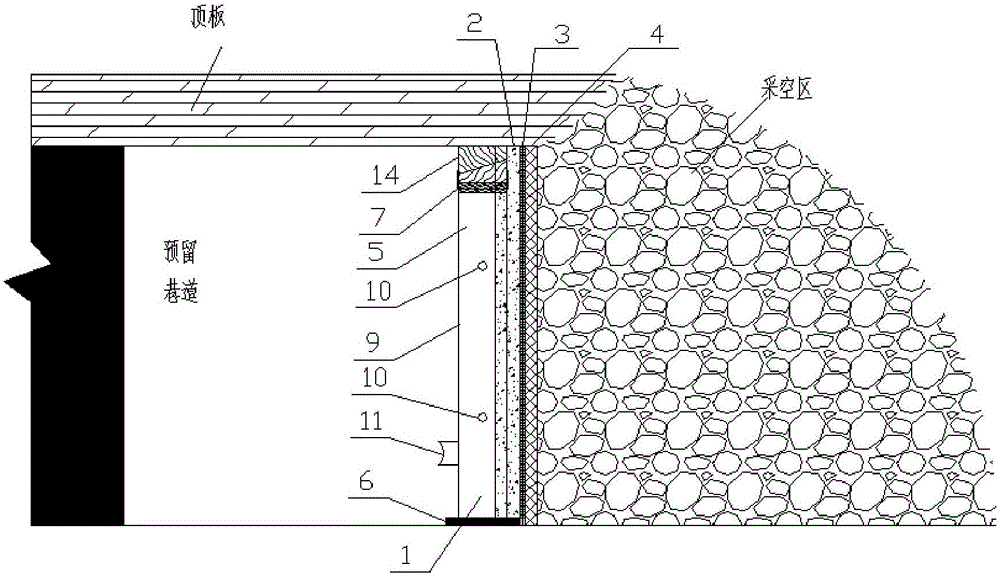

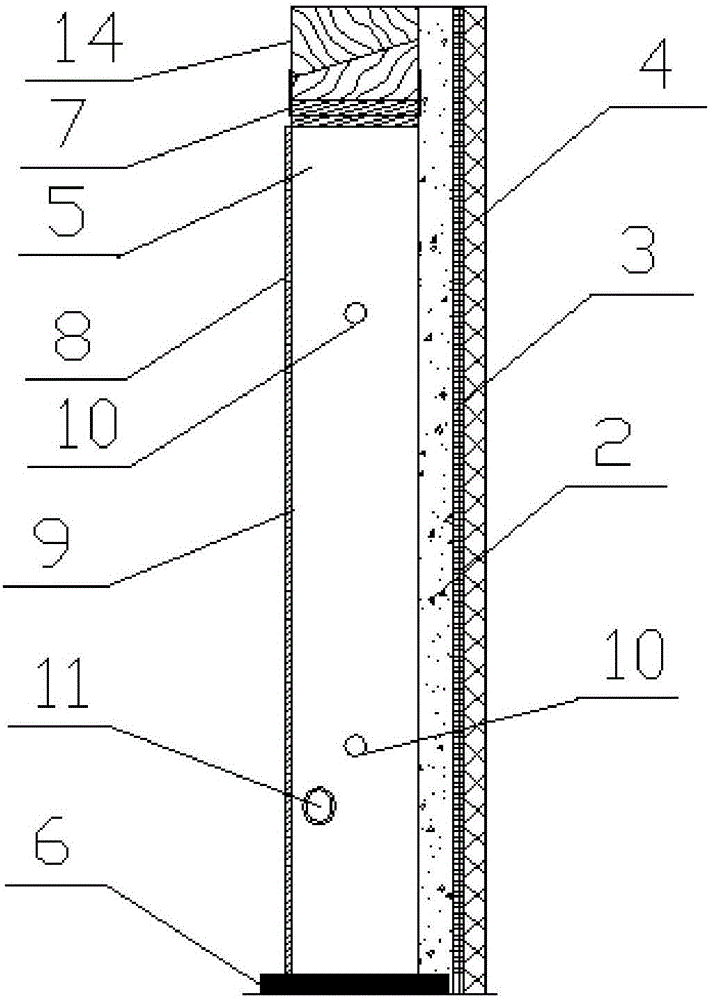

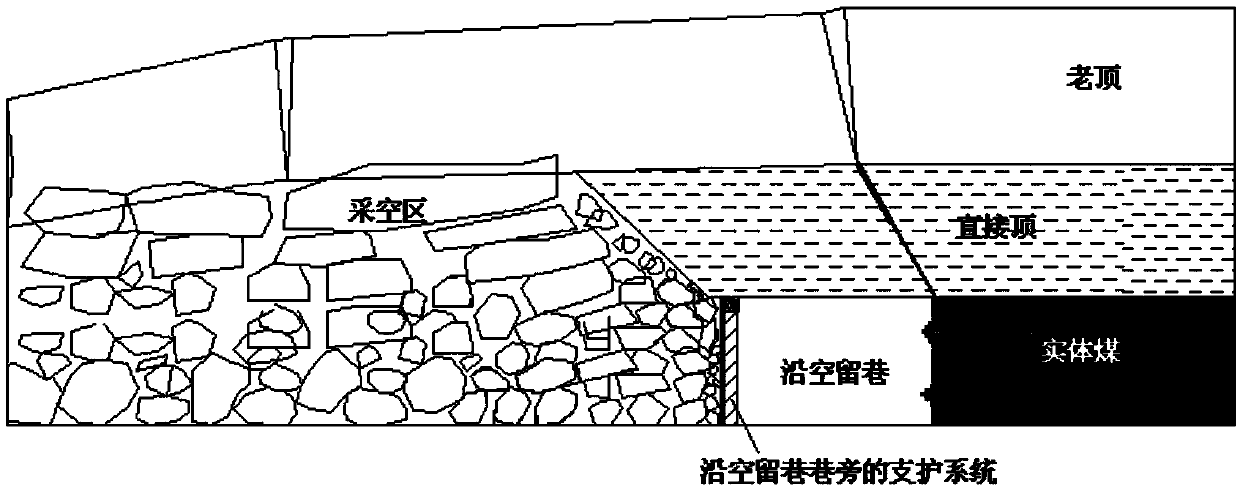

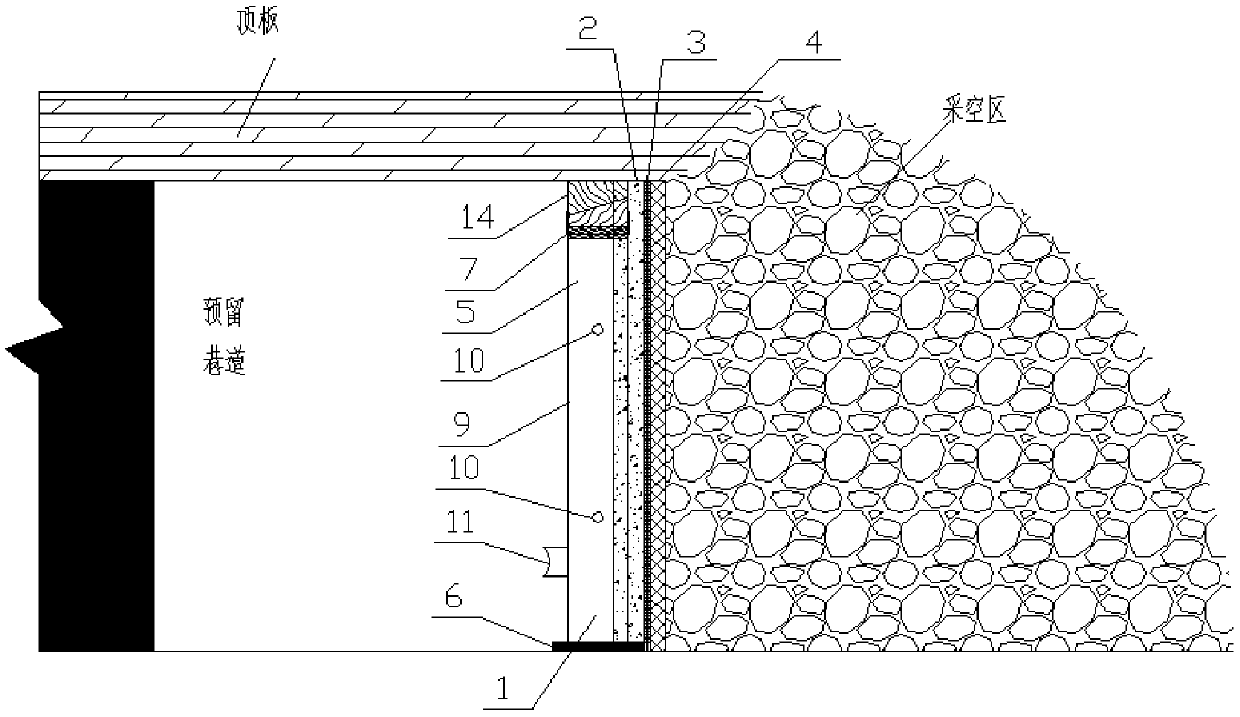

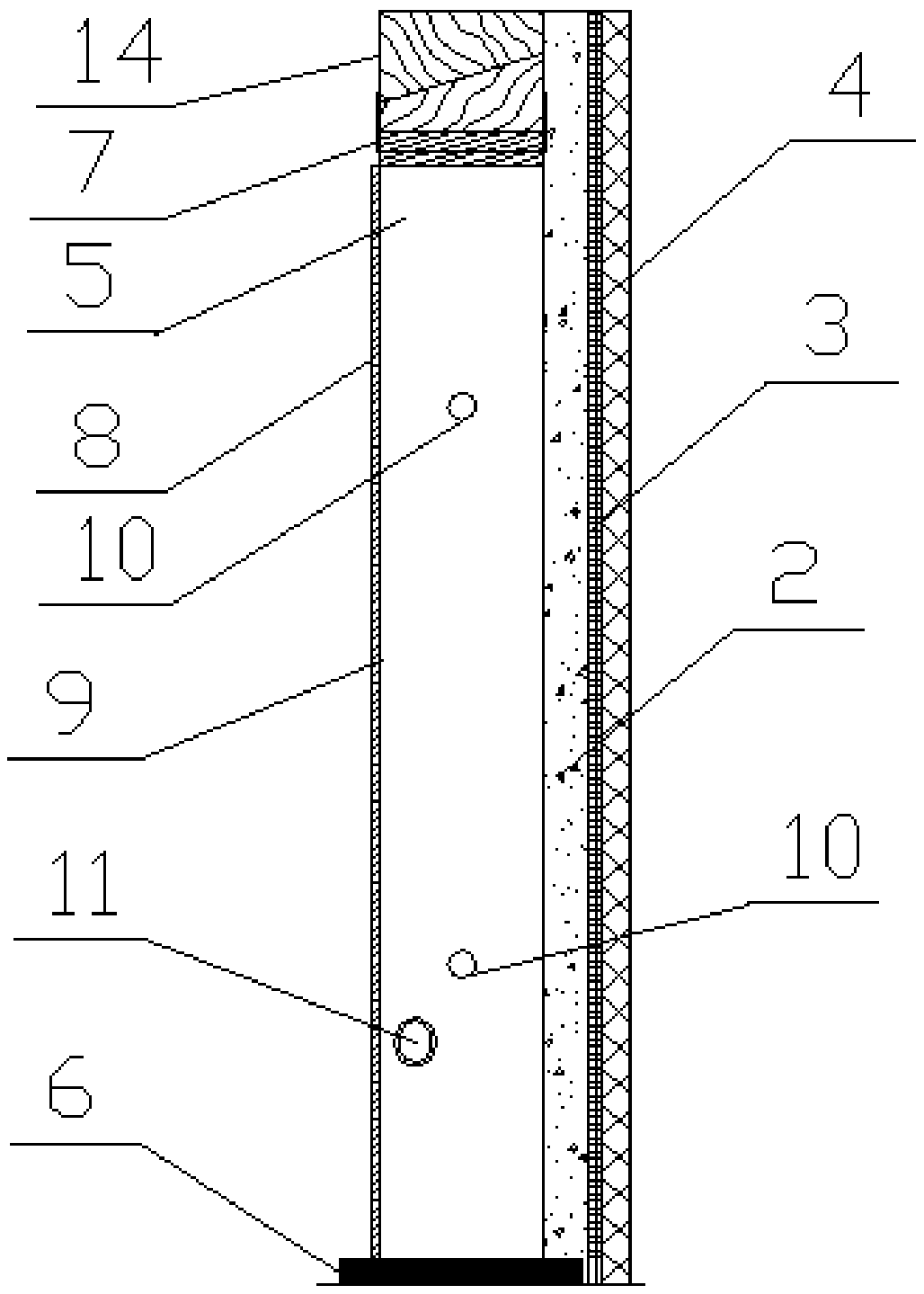

Gob-side entry retaining roadside support system and construction method thereof

ActiveCN106677804AAchieve recyclingGood removal effectUnderground chambersTunnel liningSupporting systemGeometric stability

The invention relates to a gob-side entry retaining roadside support system and a construction method thereof. A rhombic steel bar net is arranged on one side of a gob, an air drum cloth is laid on the inner side of the rhombic steel bar net, light aggregate concrete is adopted to perform guniting treatment on the air drum cloth and the rhombic steel bar net, a windtight light aggregate concrete spray layer is formed on the side of the gob, the thickness of the light aggregate concrete spray layer is 200-500 mm, and the other side of the light aggregate concrete spray layer is close to a steel tube concrete pier stud supporting device. A steel tube concrete pier stud is formed by filling an empty steel tube with concrete; through a restraint effect of a steel tube casing, internal concrete is in a three-dimensional stressed state, the geometrical stability of the steel tube wall is enhanced, and the bearing capacity of the steel tube concrete pier stud is improved. According to the gob-side entry retaining roadside support system, a top plate can be supported in high strength, coal mining efficiency is effectively improved, and an operation environment in a roadway is improved; the steel tube concrete pier stud can be recycled through a special thrust device, and the roadway retained cost is reduced.

Owner:SHANDONG JIANZHU UNIV

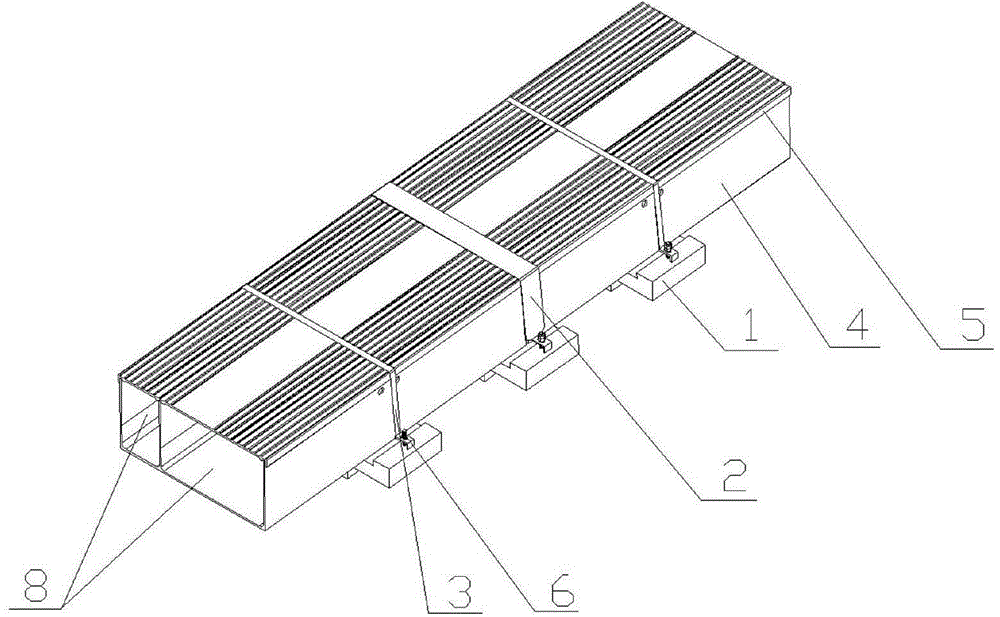

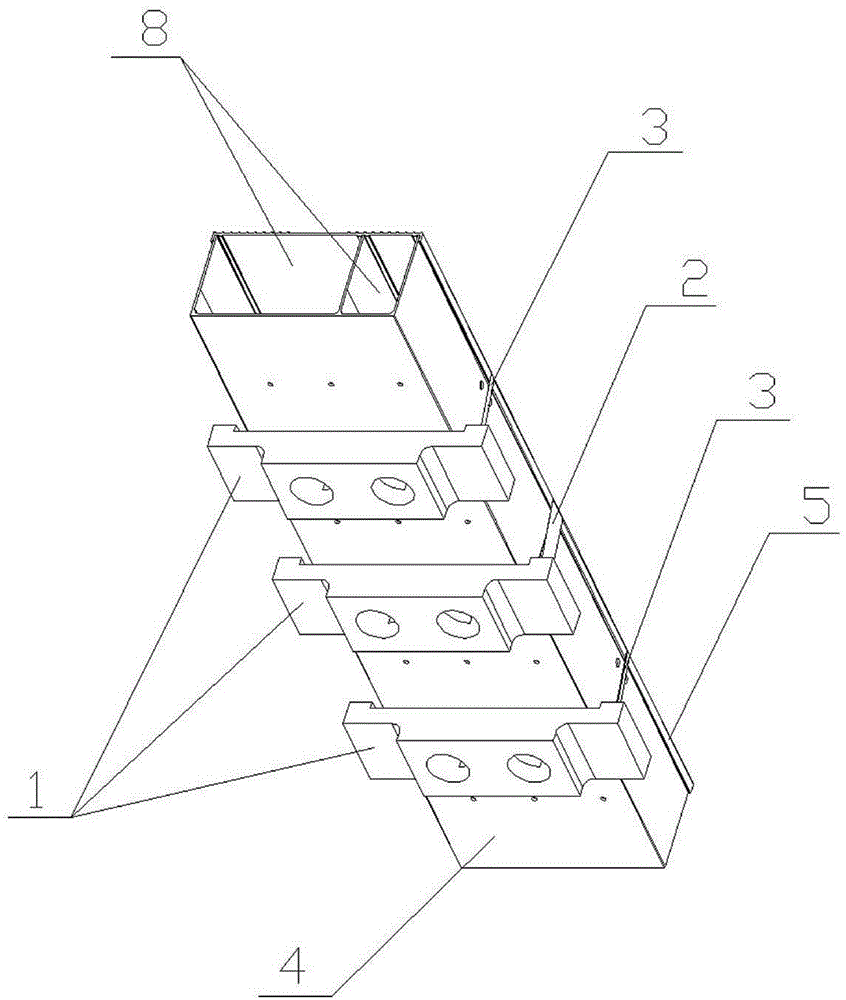

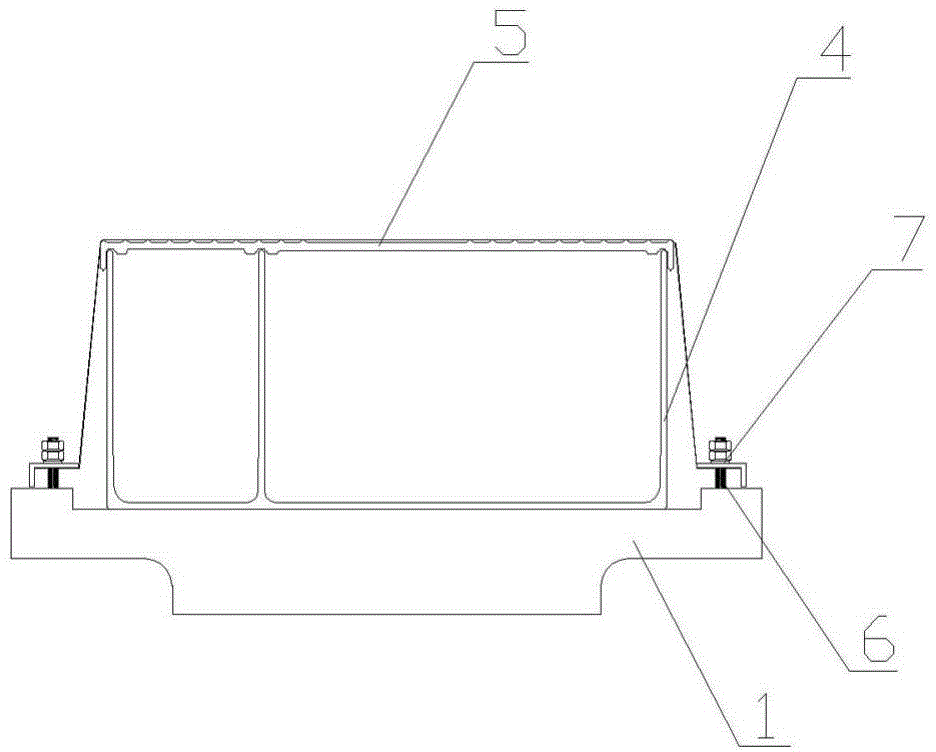

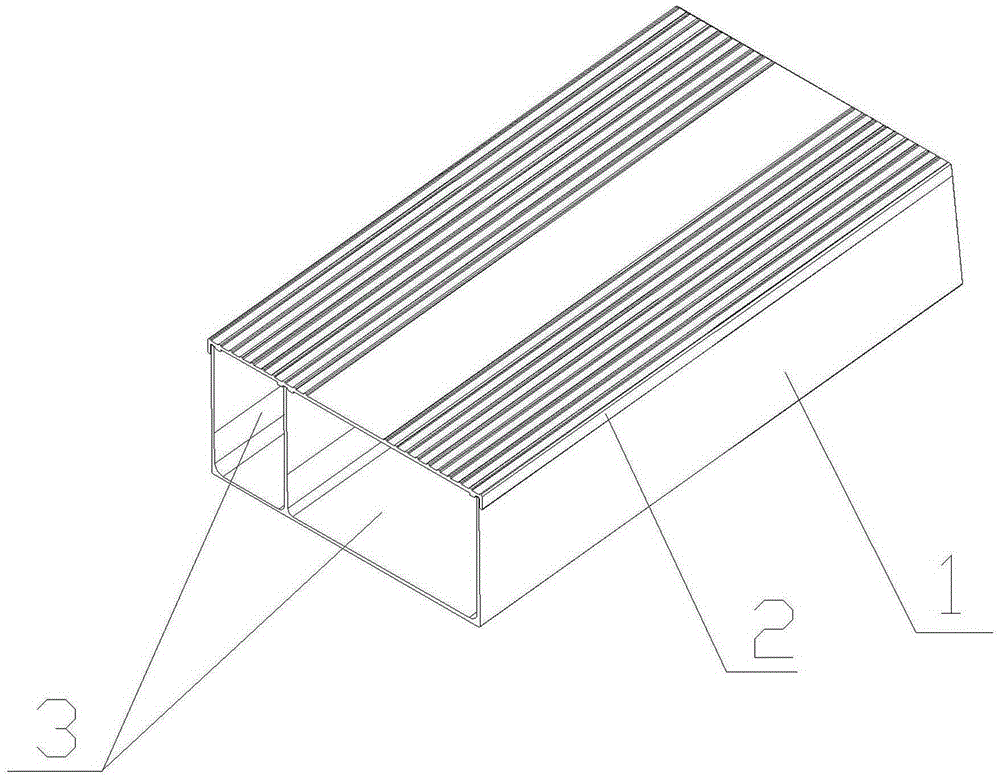

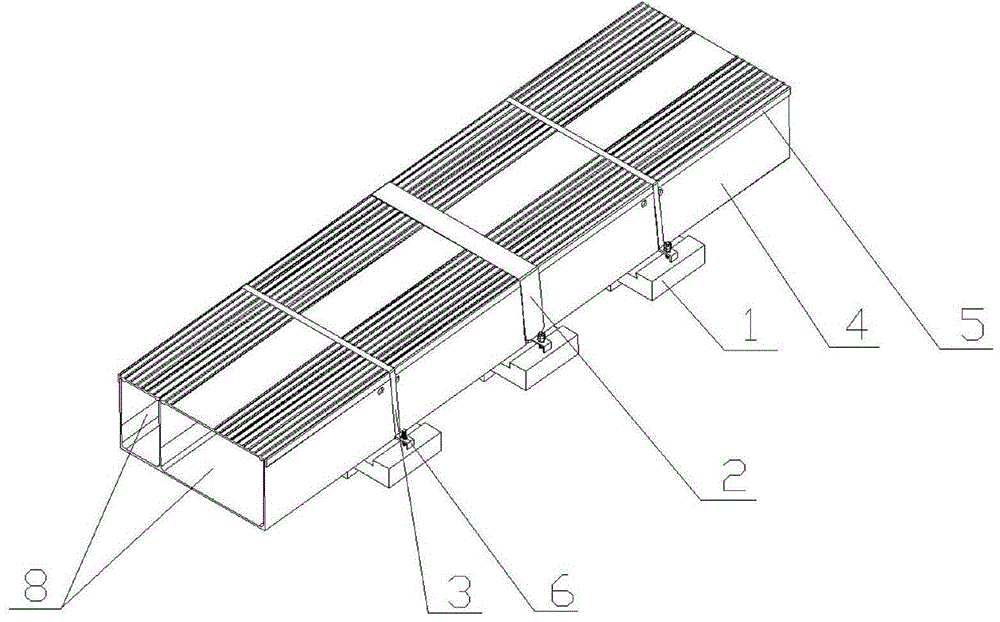

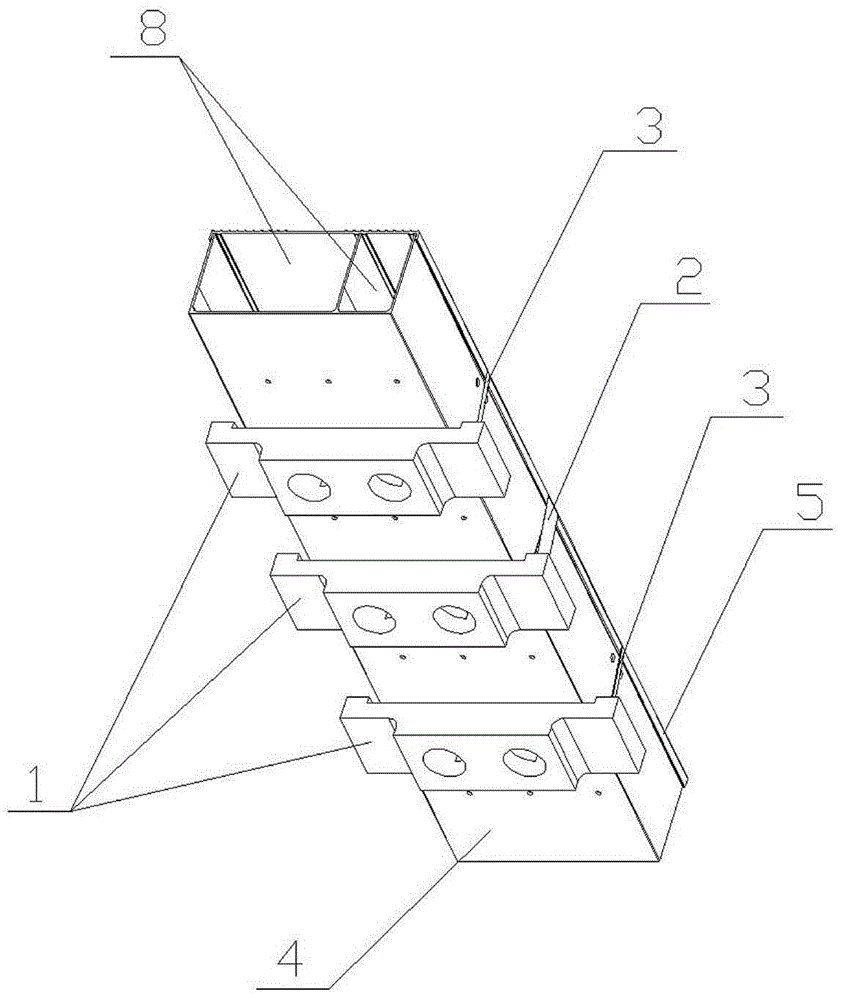

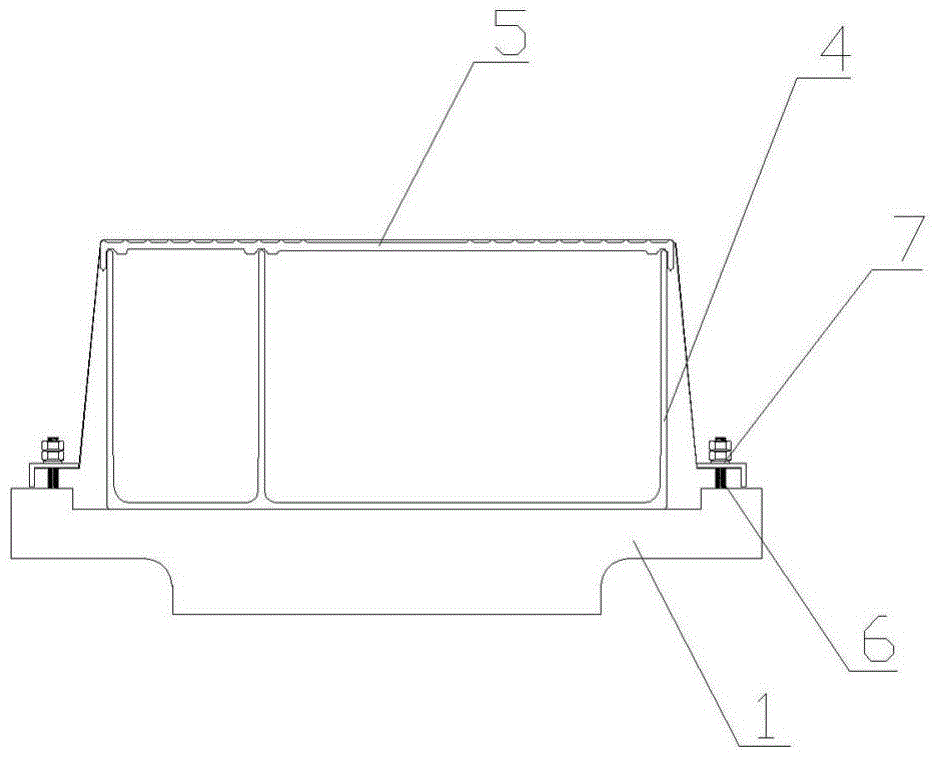

Cable duct box device for rail transportation

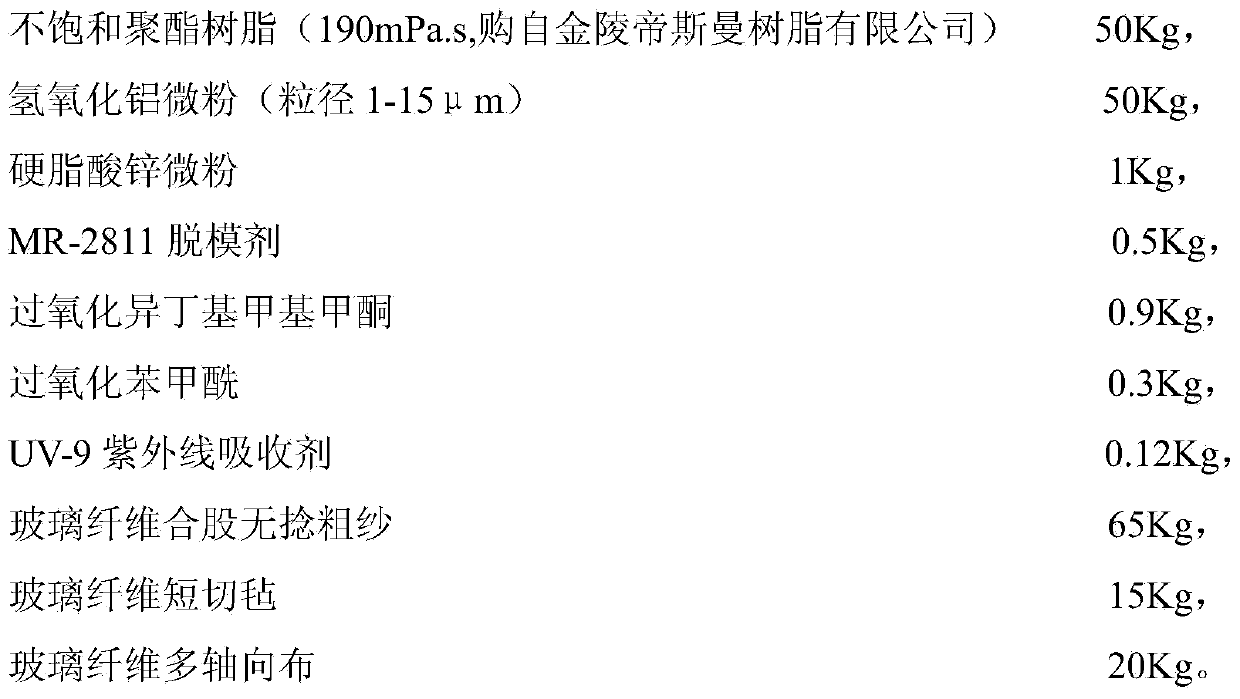

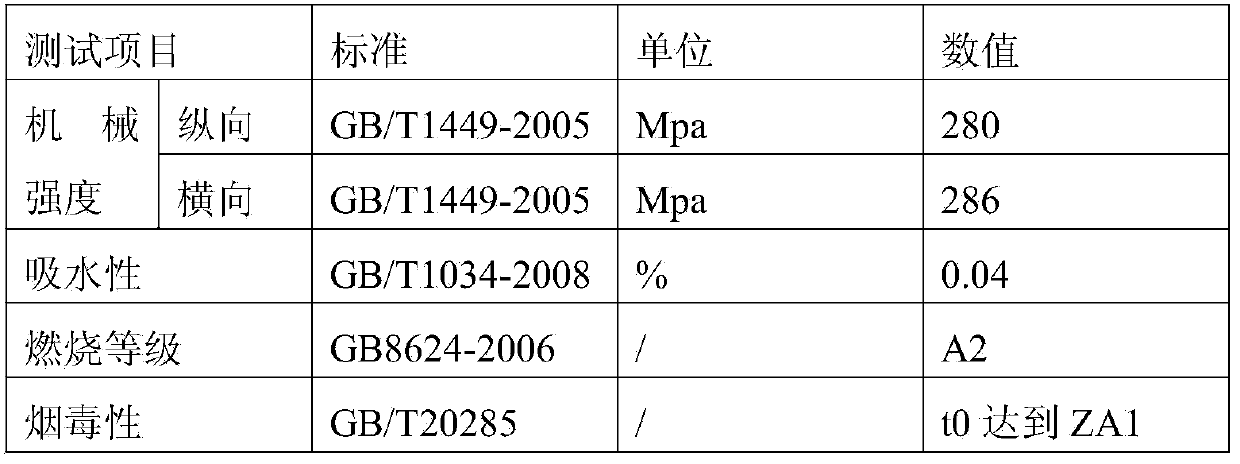

ActiveCN104158133AReduce combustion heatWon't happenElectrical apparatusLow densityUltimate tensile strength

The invention provides a cable duct box device for rail transportation. The cable duct box device comprises a plurality of cable duct box units sequentially connected end to end and made of composite material, and sealing assemblies arranged at the joints of the cable duct box units. Each sealing assembly includes a sealing pressing strip (2) and a cushion block (1). Each cushion block (1) is arranged at the bottom of the corresponding joint of the cable duct box units, each sealing pressing strip (2) seals and presses the upper surface and the side faces of the corresponding joint of the cable duct box units, and each sealing pressing strip (2) and the corresponding cushion block (1) are detachably connected. The cable duct box device for rail transportation has the advantages of high flame retardancy, low smoke toxicity, high strength, low density, good aging-resistant performance, convenient installation, low cost, short production cycle, and the like.

Owner:NINGBO HUAYUAN FRP ELECTRICAL APPLIANCE MFR

Composite chromium plating film and sliding member having the same and method for manufacture thereof

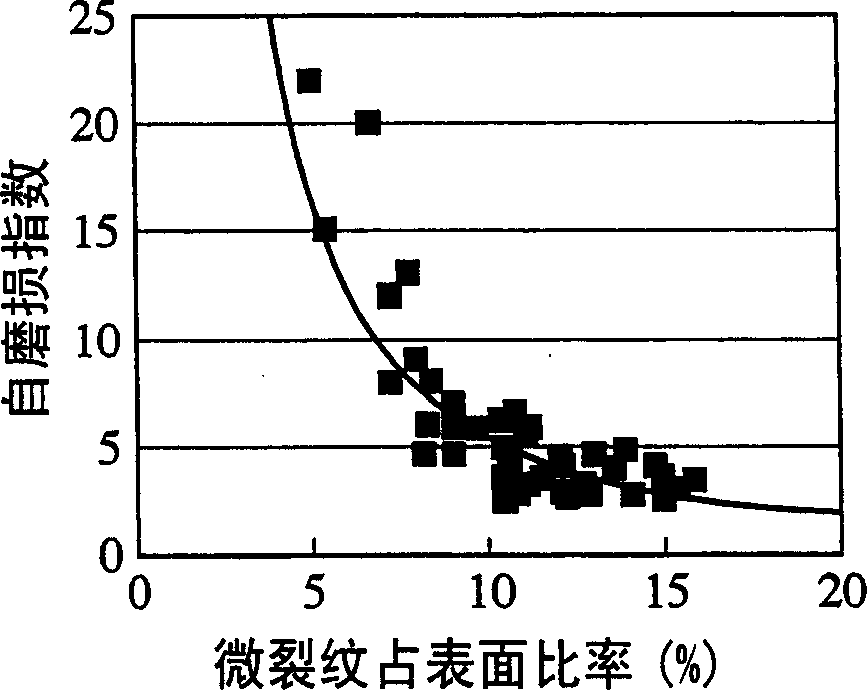

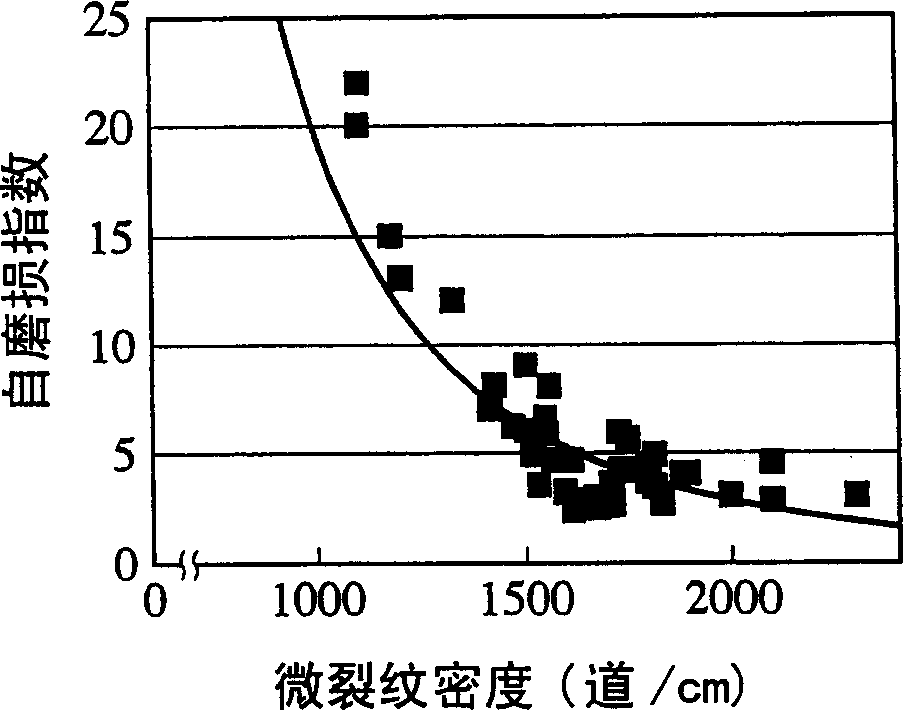

InactiveCN1764745AImprove retentionImprove scratch resistancePiston ringsElectrolytic coatingsVolumetric Mass DensityElectroplating

A composite chromium electroplated film containing hard particles in network microcracks, the microcracks account for 10 to 20 area % of the surface, the distribution density of microcracks is 1,200 to 2,500 lines / cm, and the amount of the above-mentioned hard particles 1 to 15% by mass / 100% by mass of the above-mentioned entire plating film. This composite chrome plating provides excellent wear and mar resistance and low impact to mating parts.

Owner:RIKEN CO LTD

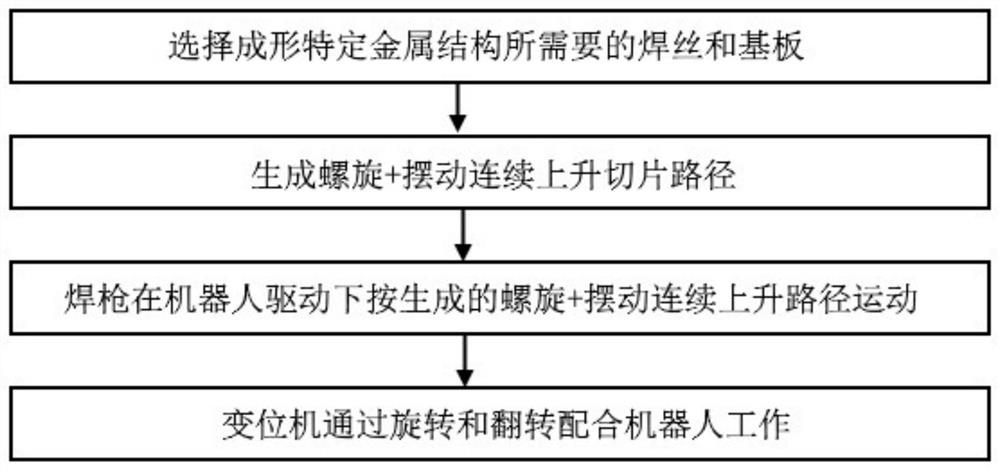

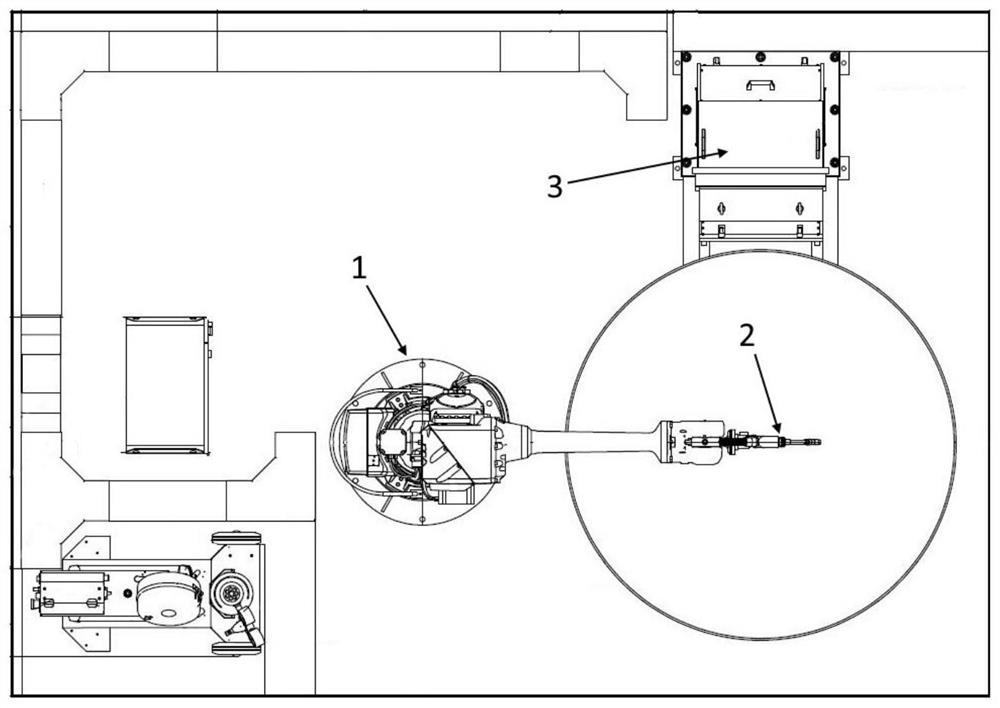

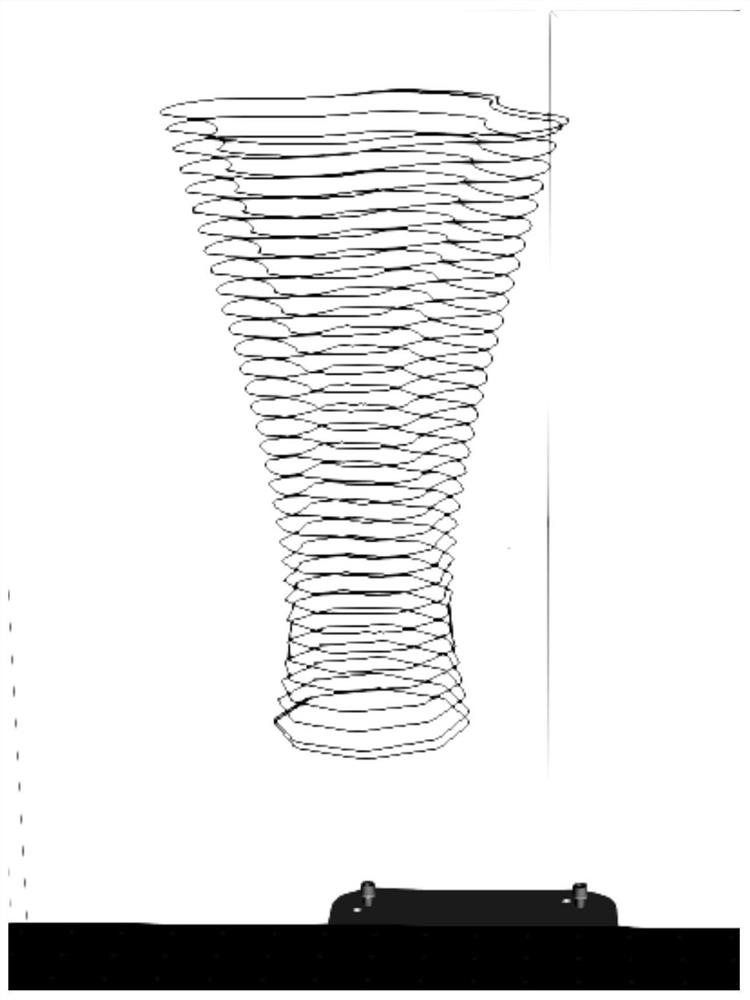

Wire arc additive manufacturing method, device and equipment for continuous growth of curved surface metal structure and computer storage medium

ActiveCN112846446ASolving the bottleneck of difficult continuous arc additive manufacturingContinuous ascending print pathAdditive manufacturing apparatusArc welding apparatusPath generationMechanical engineering

The invention provides a wire arc additive manufacturing method and system for continuous growth of a curved surface metal structure. The method comprises the following steps: selecting a welding wire and a base plate needed for forming a specific metal structure; generating a spiral and swinging continuous rising slice path; driving a welding gun by a robot to move according to the generated spiral and swinging continuous rising path; and enabling a positioner to cooperate with the robot to work through rotation and overturning. The system comprises a base assembly, a path generation module, an eight-axis linkage mechanism and a visual sensing module, wherein the base assembly is used for placing a specific metal structural member; the path generation module is used for generating the spiral and swinging continuous rising slice path; the eight-axis linkage mechanism (comprising a six-axis robot and a double-axis positioner) is used for tracking and printing according to the spiral and swinging continuous rising slice path generated by the path generation module; and the visual sensing module is used for monitoring a printed workpiece in real time. According to the method and system, the bottleneck that continuous wire arc additive manufacturing of an existing curved surface metal structural part is difficult is solved, the product development period is shortened, and the efficiency is improved.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

Liquid forging process for main reduction gear used for automobile transmission

InactiveCN106086619AImprove corrosion resistanceImprove forging efficiencyFoundry mouldsSolid state diffusion coatingHardnessAutomotive transmission

The invention provides a liquid forging process for a main reduction gear of an automobile transmission. The process comprises the steps of (1) smelting; (2) mould designing; (3) liquid forging; (4) normalizing; (5) turning; (6) carburizing and quenching; (7) tempering; (8) grinding; (9) shot blasting and flaw detecting; and (10) phosphorus saponification treatment, cleaning, polishing and anti-rust oil coating. According to the process, the liquid forging method is adopted for conducting gear machining and forging, labor and energy are saved, the material utilizing ratio is high, a blank is approximate to a final machined gear of the main reduction gear, the forging quality is high, the obtained gear hardness is high, the abrasion resistance is good, the corrosion resistance is high, the forging cost is low, and the forging process is environmentally friendly.

Owner:JIANGSU BAOJIE FORGING

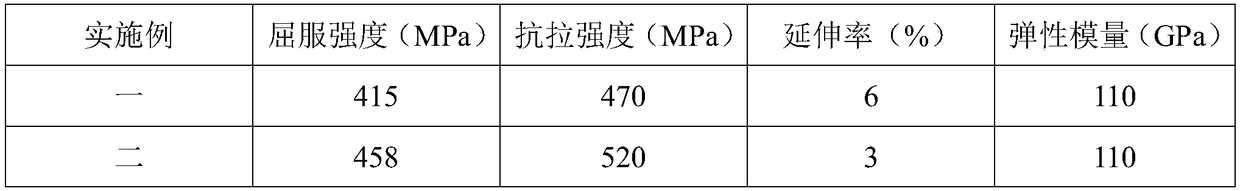

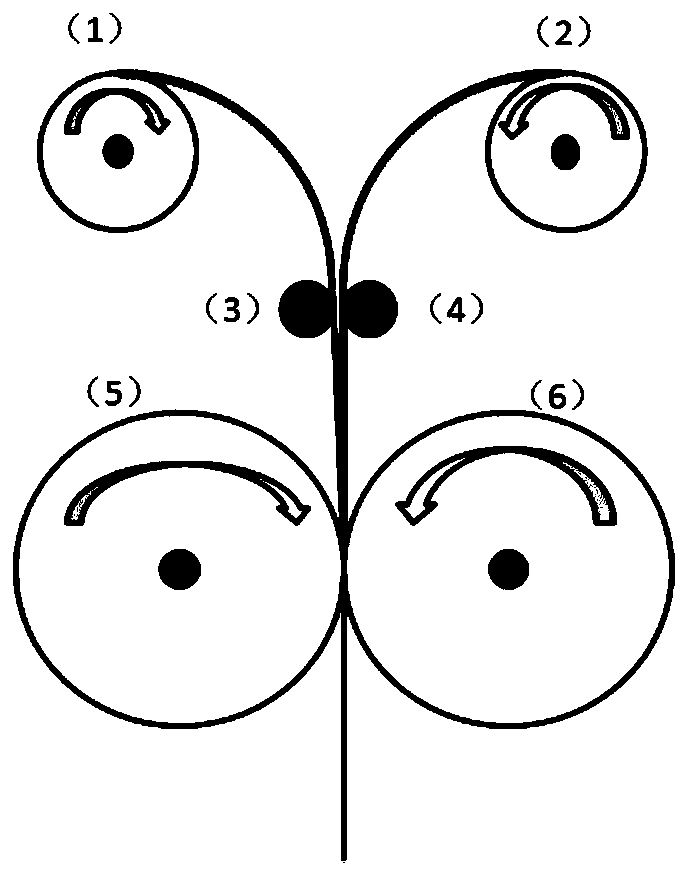

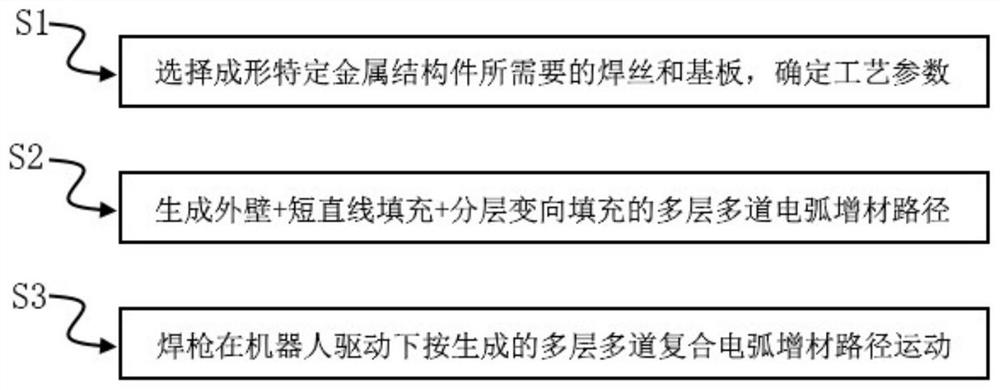

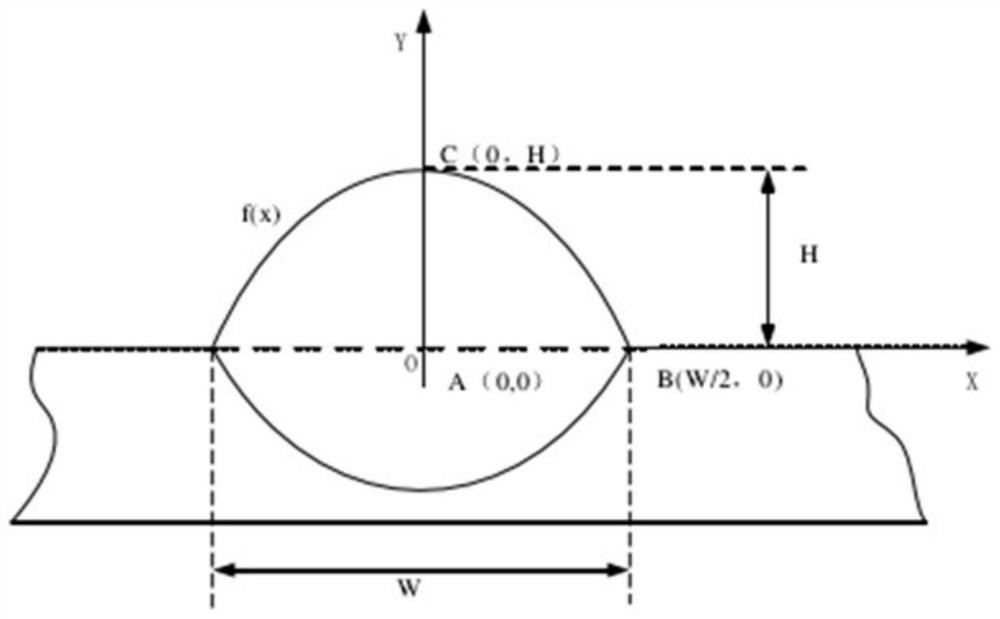

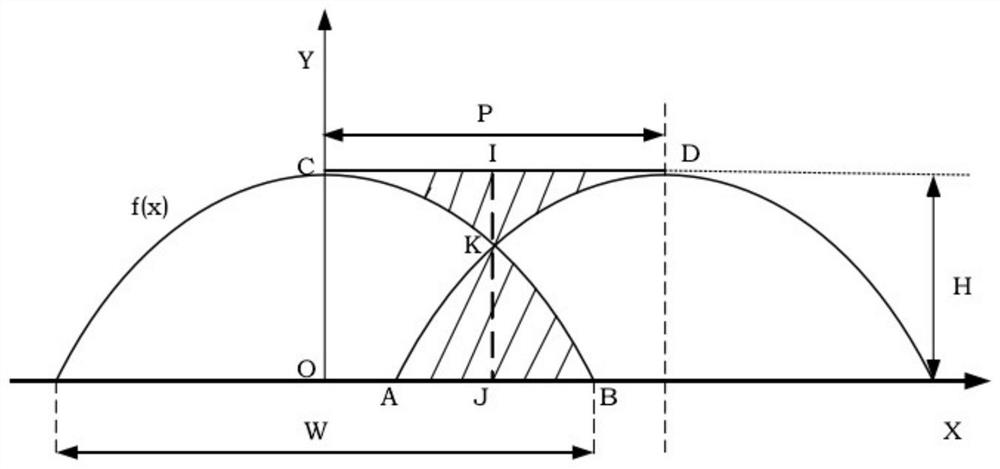

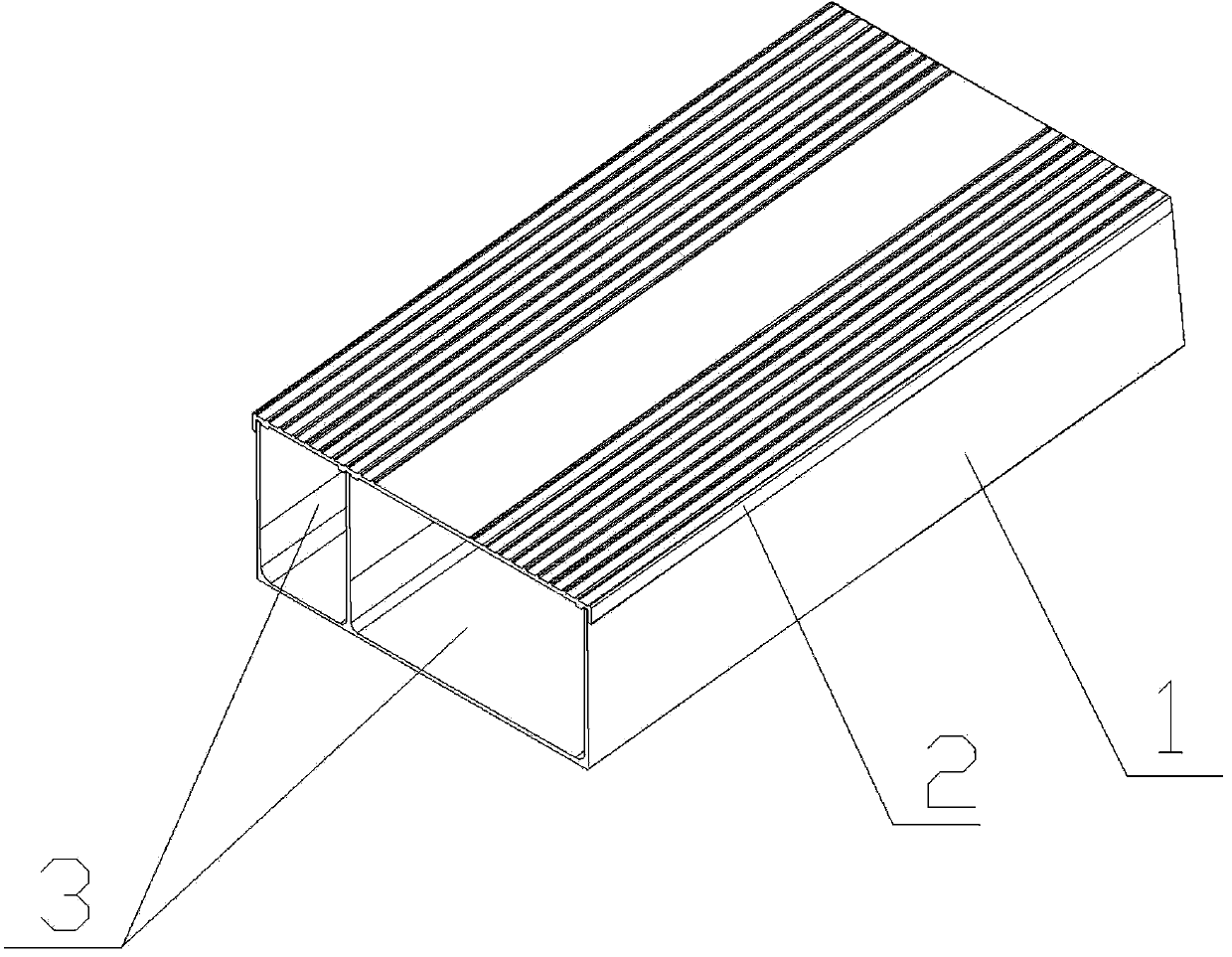

Multi-layer multi-pass composite wire arc additive manufacturing method and system for metal structure

ActiveCN112846445AHigh dimensional accuracyImprove mechanical propertiesAdditive manufacturing apparatusArc welding apparatusEngineeringMechanical property

The invention provides a multi-layer and multi-pass composite wire arc additive manufacturing method and system for a metal structure. The multi-layer and multi-pass composite wire arc additive manufacturing method for the metal structure comprises the following steps of: 1, selecting a welding wire and a substrate required for forming a specific metal structural part, and determining technological parameters; 2, generating a multi-layer and multi-pass wire arc additive path of outer wall, short straight line filling and layered turning filling; and 3, enabling a welding gun to move according to the generated multi-layer and multi-pass wire arc additive path under the driving of a robot. The welding gun is driven by the robot to conduct 3D printing according to the generated outer wall, short straight line filling and layered turning filling composite path; the outer wall path improves the size precision of a formed workpiece; the short straight line filling path solves the problem that the heights of complex structural parts are inconsistent in the printing process, and obvious macro buckling deformation is not prone to being formed; and through layered turning filling, interlayer defects are greatly reduced through, and the mechanical property of the workpiece is improved. Digitization, intellectualization and parallelization of part manufacturing are achieved.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

Flame retardant composition, flame-retardant resin composition and molded product and fiber made of flame-retardant resin composition

InactiveUS20100331467A1Harmful carbon monoxide to be restrained from occurringImprove flame retardant performanceFlame-proof filament manufactureOther chemical processesFiberCopolymer

To provide a halogen-free flame retardant composition containing no antimony, phosphorus and phosphorus compounds at all, a non-halogen flame-retardant resin composition of environmental type ideal for disaster prevention made of the flame retardant composition, which causes little carbon monoxide (CO) during combustion while having high flame retardance, and molded products, electric wires, cables, fiber or fiber post-processed products made of the resin composition. The flame retardant composition comprises a mixture of (A) a resin having an average particle diameter of not more than 1000 μm selected from wholly aromatic polyamide, polyimide, polyamideimide, a copolymer of the wholly aromatic polyamide, the polyimide or the polyamideimide or a mixture of the above mentioned polymers and (B) a metal hydrate. The flame-retardant resin composition contains 50 to 200 parts by mass of the flame retardant composition to 100 parts by mass of a thermoplastic resin or a thermosetting resin.

Owner:DUPONT TORAY CO LTD

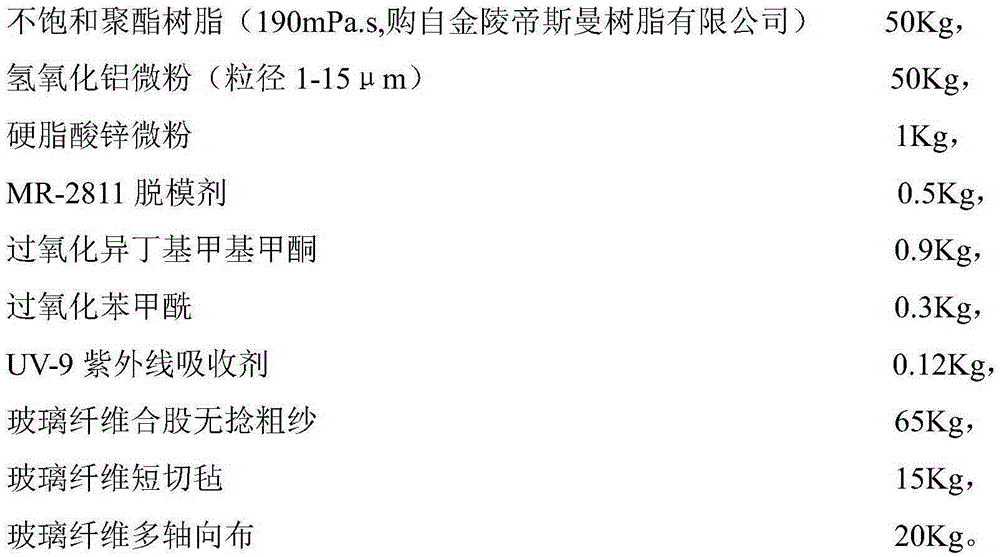

Novel composite material cable trough box for rail transit

The invention provides a novel composite material cable trough box for rail transit. The novel composite material cable trough box comprises a cable trough body (1) and a cable trough cover (2) which covers the upper surface of the cable trough body (1), wherein the cable trough box is prepared from the following components in parts by weight by virtue of a pultrusion process: 15-35 parts of unsaturated polyester resin, 15-35 parts of aluminum hydroxide micro powder, 40-70 parts of glass fiber, 0.5-1.5 parts of mold releasing agent, 0.1-0.2 part of ultraviolet absorbent and 3-10 parts of additives. The cable trough box provided by the invention has the advantages of high flame-retardant performance, low smoke toxicity, high strength, low density, good aging resistance, convenience in assembly, low cost, short production cycle and the like.

Owner:NINGBO HUAYUAN FRP ELECTRICAL APPLIANCE MFR

Flame retardant composition, flame-retardant resin composition and molded product and fiber made of flame-retardant resin composition

InactiveUS20090230366A1High in LOI valueSlight in occurrence amountFlame-proof filament manufactureOther chemical processesAntimonyPolyresin

To provide a halogen-free flame retardant composition containing no antimony, phosphorus and phosphorus compounds at all, a non-halogen flame-retardant resin composition of environmental type ideal for disaster prevention made of the flame retardant composition, which causes little carbon monoxide (CO) during combustion while having high flame retardance, and molded products, electric wires, cables, fiber or fiber post-processed products made of the resin composition. The flame retardant composition comprises a mixture of (A) a resin having an average particle diameter of not more than 1000 μm selected from wholly aromatic polyamide, polyimide, polyamideimide, a copolymer of the wholly aromatic polyamide, the polyimide or the polyamideimide or a mixture of the above mentioned polymers and (B) a metal hydrate. The flame-retardant resin composition contains 50 to 200 parts by mass of the flame retardant composition to 100 parts by mass of a thermoplastic resin or a thermosetting resin.

Owner:DUPONT TORAY

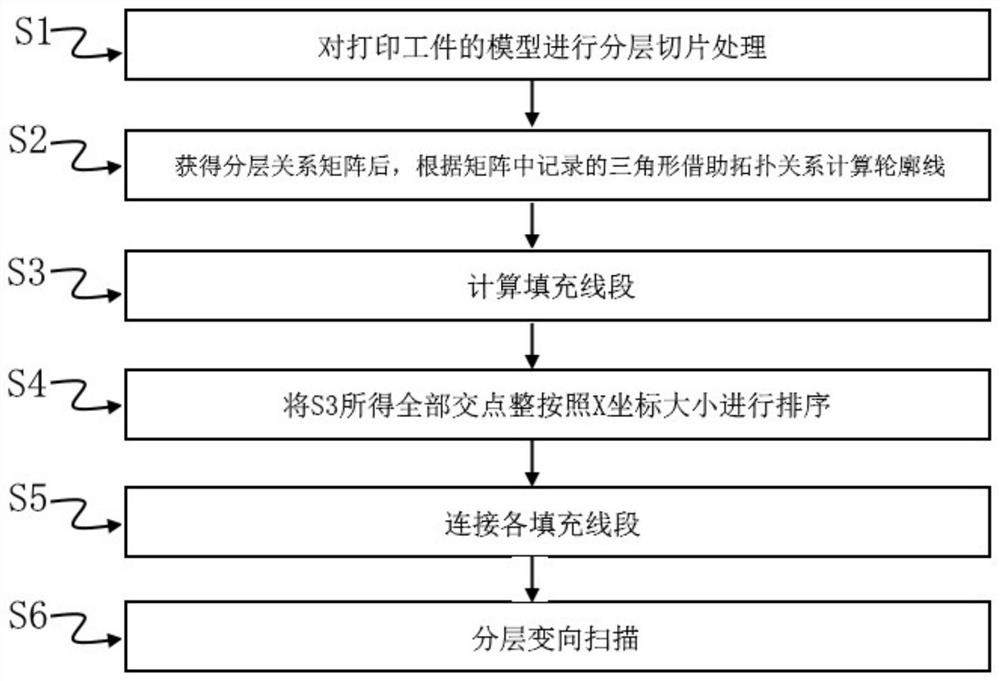

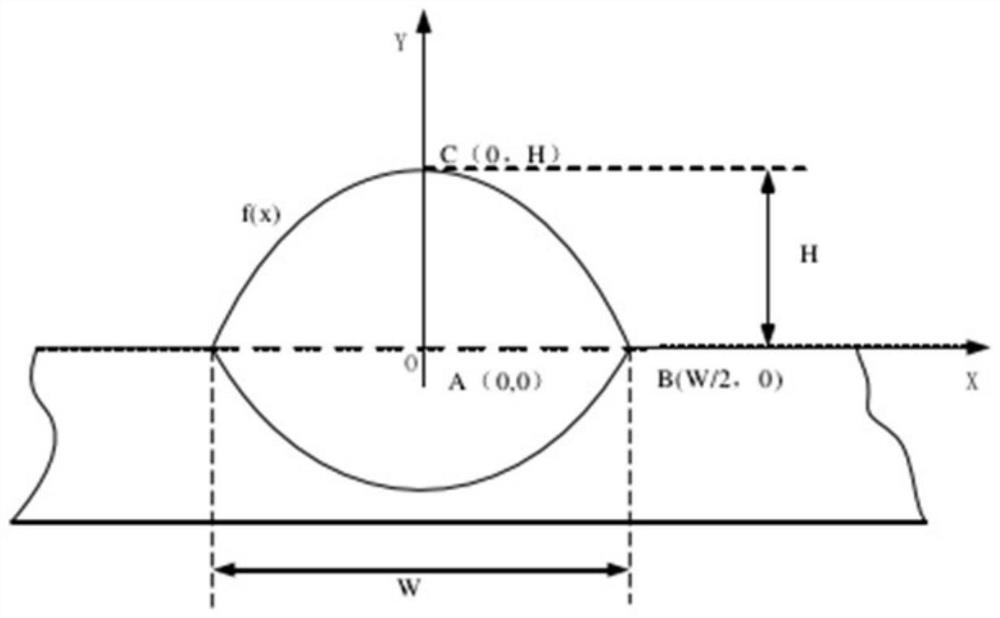

Automatic trajectory planning method and system for multi-layer and multi-channel wire arc additives of metal structure

ActiveCN112846232AHigh dimensional accuracyUniform grain sizeAdditive manufacturing apparatusIncreasing energy efficiencyTrajectory planningLine segment

The invention provides an automatic trajectory planning method and system for multi-layer and multi-channel wire arc additives of a metal structure. The automatic trajectory planning method comprises the following steps: Step 1, conducting layered slicing treatment on a model of a printed workpiece; Step 2, after obtaining a layered relation matrix, calculating a contour line according to triangles recorded in the matrix by means of a topological relation; Step 3, calculating filling line segments; Step 4, sorting all the intersection points obtained in the Step 3 according to the size of the X coordinate; Step 5, connecting the filling line segments; and Step 6, carrying out layered direction-changing scanning. Multi-layer and multi-channel 3D printing of a metal structural part is carried out according to the composite printing path of outer wall + short straight line filling + layered direction-changing filling, chemical components of a formed workpiece are uniform, the purity is high, and the structure is almost free of anisotropy. Multi-layer and multi-channel 3D printing of the metal structural part is carried out according to the composite printing path of outer wall + short straight line filling + layered direction-changing filling, the grain size of the formed workpiece is small and uniform, the mechanical performance is high, and the level of the formed workpiece can exceed that of a casting with the same component.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

Method for rolling and molding low-oxygen content aero titanium alloy precision sheet

ActiveCN101817015BUniform distribution of internal stressNo anisotropyRoll mill control devicesFurnace typesStress reliefTitanium alloy

The invention discloses a method for rolling and molding a low-oxygen content aero titanium alloy precision sheet. The low-oxygen content aero titanium alloy precision sheet is obtained by rolling twice by using a twenty high rolling mill. The method comprises the following steps of: rolling by using the twenty high rolling mill, degreasing, recrystallization annealing, cold rolling with the twenty high rolling mill again, degreasing, stress relief annealing, stretcher leveling, longitudinal cutting / transverse cutting, inspecting, packaging, and the like, wherein aero titanium alloy plates, such as TC4, TA15 and the like, with the thickness of 1-5 mm, are used as raw materials. The thickness tolerance of the titanium alloy precision sheet is + / -0.005 mm, the camber is 0.3-1 mm / 1m, the surface quality is No.2B, the surface smoothness is up to 1-2 I-Unit, the grain size is up to 5-6 grades, the surface has no surface contamination layer (such as an oxygen-enriched layer, an alpha layer and the like), the internal stress is distributed uniformly, no anisotropy exists, and the subsequent plastic forming feature is favorable. The invention has the advantages of easy production method, low cost, high product quality and high production efficiency.

Owner:江苏呈飞新材料科技有限公司

A roadside support system for gob-side entry retention and its construction method

ActiveCN106677804BHigh compressive strengthEnhanced geometric stabilityUnderground chambersTunnel liningSupporting systemGeometric stability

Owner:SHANDONG JIANZHU UNIV

Composite Cable Tray Box for Rail Transit

The invention provides a novel composite material cable trough box for rail transit. The novel composite material cable trough box comprises a cable trough body (1) and a cable trough cover (2) which covers the upper surface of the cable trough body (1), wherein the cable trough box is prepared from the following components in parts by weight by virtue of a pultrusion process: 15-35 parts of unsaturated polyester resin, 15-35 parts of aluminum hydroxide micro powder, 40-70 parts of glass fiber, 0.5-1.5 parts of mold releasing agent, 0.1-0.2 part of ultraviolet absorbent and 3-10 parts of additives. The cable trough box provided by the invention has the advantages of high flame-retardant performance, low smoke toxicity, high strength, low density, good aging resistance, convenience in assembly, low cost, short production cycle and the like.

Owner:NINGBO HUAYUAN FRP ELECTRICAL APPLIANCE MFR

High-plasticity dissolvable magnesium alloy as well as preparation method and application thereof

The invention discloses a high-plasticity dissolvable magnesium alloy as well as a preparation method and application thereof. The high-plasticity dissolvable magnesium alloy is composed of the following components of, in percentage by mass, 1%-3% of Zn, 0.1%-0.3% of Al, 0.1%-0.3% of Cu, 0.1%-1% of rare earth metal and the balance Mg, and the rare earth metal is at least one of Gd and Y. The preparation method comprises the following steps of casting to obtain a cast ingot, heating to 380-420 DEG C, processing the cast ingot into a bar under the conditions that the extrusion speed is 2-5mm / s and the extrusion ratio is not less than 16, and heating at 150-200 DEG C for 18-24 hours to perform heat treatment, thus obtaining the high-plasticity dissolvable magnesium alloy. The elongation of the dissolvable magnesium alloy at room temperature is greater than 25%, the dissolvable magnesium alloy has good plasticity and high strength in both the radial direction and the axial direction, the dissolution rate of the dissolvable magnesium alloy is adjustable, and the dissolvable magnesium alloy can be applied to packer tools or parts requiring large plasticity in oil and gas field fracturingtransformation construction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacturing method of arc additive of titanium alloy structural part

ActiveCN102962547BUniform chemical compositionHigh purityArc welding apparatusTitanium alloyFeed additive

Owner:CAPITAL AEROSPACE MACHINERY +1

A method for preparing particle-reinforced aluminum matrix composites by hot pressing and sintering in atmospheric atmosphere

The invention relates to a method for preparing a particle-reinforced aluminum-based composite material adopting hot-pressing sintering under an atmospheric atmosphere. The invention belongs to the field of powder metallurgy, in particular to the method for preparing the particle-reinforced aluminum-based composite material adopting hot-pressing sintering under the atmospheric atmosphere. The method aims to overcome the defects of complex process, high cost and low production efficiency of an existing composite material preparation process adopting the hot-pressing sintering. The method comprises the following steps that 1, ball-milling is carried out to mix powder, specifically, the ball-milling is carried out on ceramic particle reinforcement and an aluminum-based body for mixing the powder to obtain the mixed powder; 2, cold pressing is carried out to prepare a prefabricated body, specifically, step-by-step compaction is carried out on the mixed powder by adopting a graphite die soas to obtain the prefabricated body; and 3, the hot-pressing sintering is carried out on the prefabricated body under the atmospheric atmosphere, the graphite die is transferred into the air after thesintering is completed till the die is naturally cooled to the room temperature, and the die is removed to obtain the particle-reinforced aluminum-based composite material. The method is used for preparing the particle-reinforced aluminum-based composite material.

Owner:QIQIHAR XIANGKE NEW MATERIAL CO LTD

Method and system for multilayer single-channel continuous arc additive manufacturing of metal structural parts

The present invention proposes a multi-layer single-channel continuous arc additive manufacturing method and system for metal structural parts. The method adopts a welding machine as a heat source, a metal wire as a forming material, and the welding device is driven by a robot according to a planned continuous spiral. Slicing path motion for arc additive manufacturing on a substrate. First, select the welding wire and substrate needed to form a specific metal structure; then generate a continuous spiral slice path; finally, the welding gun moves according to the generated continuous spiral path under the drive of the robot, and the servo system drives the welding gun mechanical arm according to the calculated spiral path, The welding torch is driven by the welding torch manipulator to print a single-pass weld seam along a predetermined trajectory, and the height of the welding torch from the substrate is gradually increased during the printing process according to the helical path. The continuous spiral path makes the height of the welding torch from the substrate gradually increase during the entire 3D printing process, but keeps the dry elongation constant, and the arc will not be extinguished during the entire printing process, and finally a metal structure with excellent performance is formed.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

Functional film prepared by functionalized organic powder, low-temperature non-damaging manufacturing method and application

ActiveCN111004404BHigh molecular weightEfficient exclusionOrganic-compounds/hydrides/coordination-complexes catalystsFinal product manufactureOrganic filmHigh energy

The invention provides a functional membrane prepared by using functionalized organic powder, a low-temperature non-damaging manufacturing method and its application. The organic powder membrane material is composed of functionalized organic powder and polytetrafluoroethylene (PTFE). The heated supersonic airflow opens the polytetrafluoroethylene molecular chain, bonds the functionalized organic powder, and extrudes the air in the powder to form a continuous cake. Layer-film hot-pressing composite process forms a low-porosity, uniform-thickness film. This method can continuously roll-to-roll to produce micron-sized organic membranes, which can maximize the physical and chemical properties of organic powders and prevent performance damage or anisotropy caused by recrystallization due to high temperature or introduction of solvents into the film. . No solvent is introduced in the manufacturing process, which avoids the problems of environmental pollution, high energy consumption and uneven density of membrane materials caused by the solvent drying process.

Owner:东莞奥创能源科技有限公司

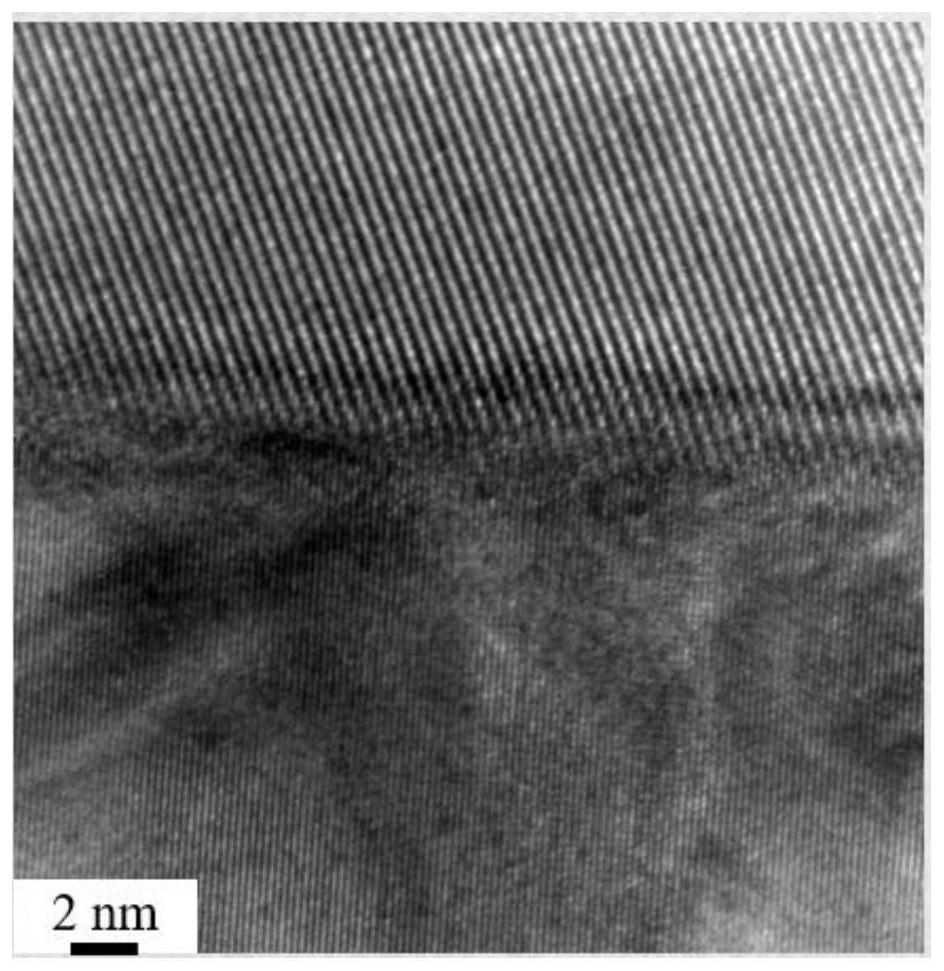

Powder metallurgy preparation method of high-thermal-conductivity Cu-Invar bimetal-based composite material

ActiveCN113667852ALower sintering temperatureShort residence time at high temperatureSemiconductor/solid-state device detailsSolid-state devicesPowder metallurgyHeat sink

The invention discloses a powder metallurgy preparation method of a high-thermal-conductivity Cu-Invar bimetal-based composite material. The powder metallurgy preparation method comprises the following preparation steps of (1) material selection, (2) screening, (3) material mixing, (4) reduction and (5) sintering. Compared with other preparation methods of Cu-Invar composite materials, the powder metallurgy preparation method has the advantages that Invar alloy powder with the large particle size is selected, a discharge plasma sintering process is adopted, the sintering temperature is reduced, the high-temperature retention time is shortened, Invar particles in the prepared Cu-Invar bimetal-based composite material are evenly distributed, the performance is free of anisotropy, interface diffusion is basically and completely inhibited, the comprehensive performance is excellent, and the Cu-Invar bimetal-based composite material can be used as a high-performance electronic packaging heat sink material.

Owner:HEFEI UNIV OF TECH

Cable trough box device for rail transit

Owner:NINGBO HUAYUAN FRP ELECTRICAL APPLIANCE MFR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com