Method for rolling and molding low-oxygen content aero titanium alloy precision sheet

A technology with low oxygen content and forming method, which is applied in the direction of metal rolling, metal rolling, rolling mill control device, etc., can solve the problems of rolling technology, backward equipment, large thickness deviation, poor superplastic formability, etc., and achieve the production method Simple and easy to implement, uniform internal stress distribution, and good plastic formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

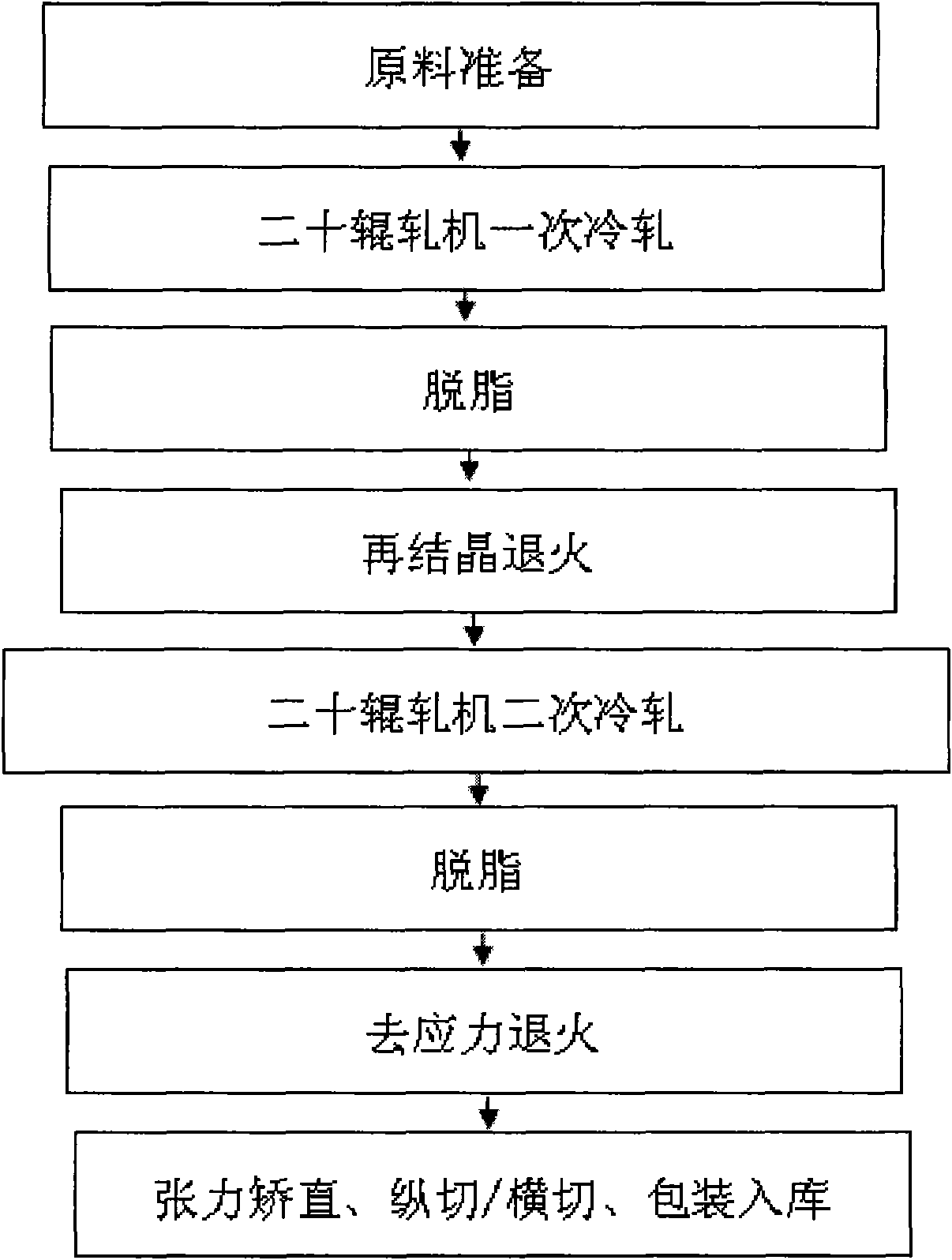

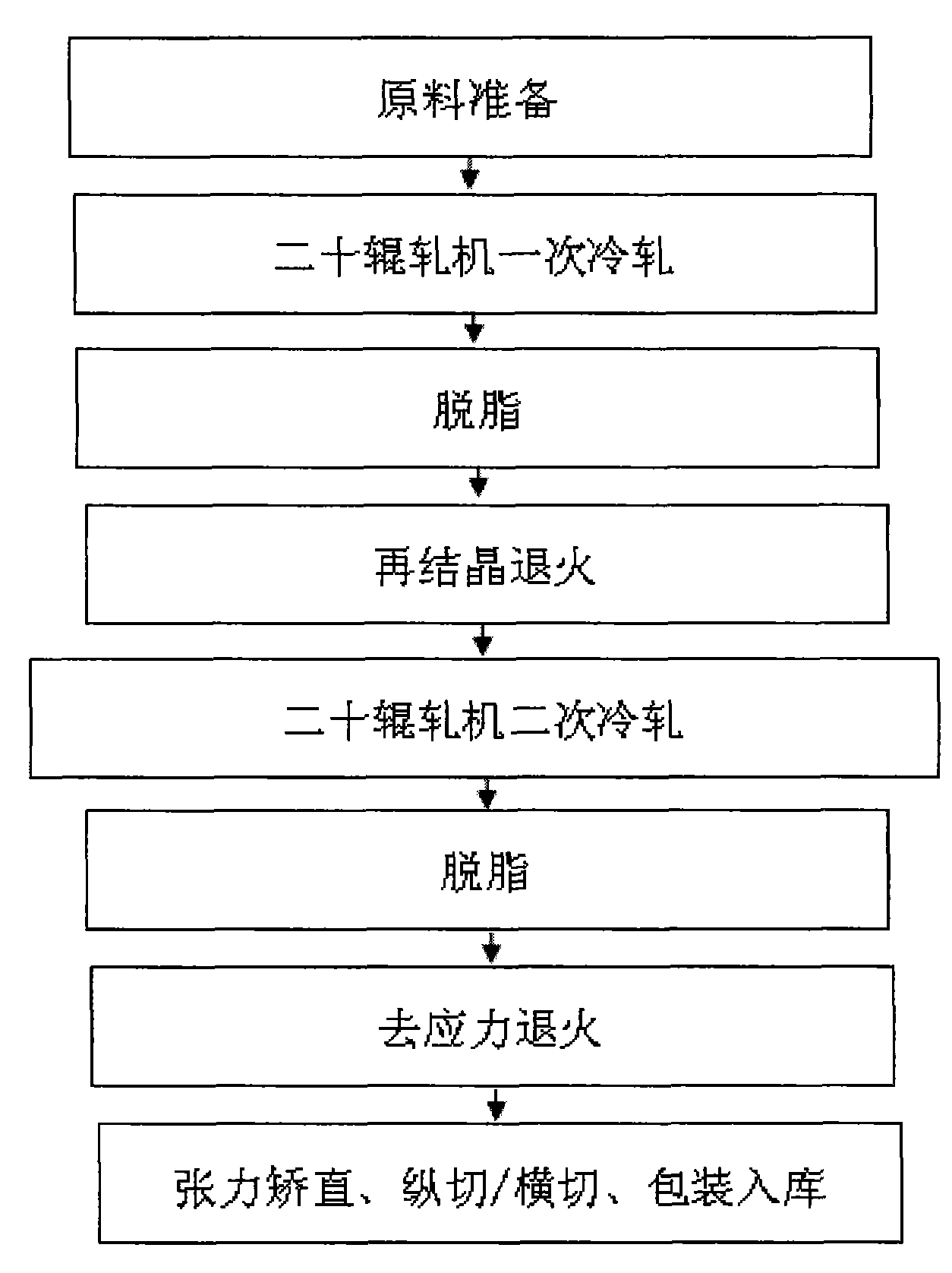

Method used

Image

Examples

Embodiment 1

[0024] The TC4 titanium alloy sheet with a thickness of 5mm is cold-rolled 2B surface as raw material, rolled by a 20-roll mill, degreased, bright annealed, secondary cold-rolled by a 20-roll mill, degreased, bright annealed, tension straightened, and slitting / Cross-cutting, inspection, packaging and warehousing and other processes are made. Among them, the surface roughness of the work rolls in the secondary cold rolling of the 20-high rolling mill is Ra0.50μm, and the pass deformation rate is 40%; the recrystallization annealing temperature is 850 ° C, the holding time is 15 minutes, the reducing atmosphere is protected, and the cooling is rapid; the stress is relieved The annealing temperature is 650°C, the holding time is 10 minutes, the reducing atmosphere is protected, and the cooling is rapid. The prepared low-oxygen aerospace titanium alloy precision thin sheet has no oxygen-enriched layer, α layer and other surface pollution layers on the surface, uniform internal st...

Embodiment 2

[0026] The TC4 titanium alloy sheet with a thickness of 3mm is cold-rolled 2B surface as raw material, rolled by a 20-roll mill, degreased, bright annealed, secondary cold-rolled by a 20-roll mill, degreased, bright annealed, tension straightened, and slitting / Cross-cutting, inspection, packaging and warehousing and other processes are made. Among them, the surface roughness of the work rolls in the secondary cold rolling of the 20-high rolling mill is Ra0.02μm, and the deformation rate of each pass is 50%; the recrystallization annealing temperature is 800 ° C, the holding time is 20 minutes, the reducing atmosphere is protected, and the cooling is rapid; the stress is relieved The annealing temperature is 550°C, the holding time is 15 minutes, protected by a reducing atmosphere, and cooled rapidly. The surface of the prepared low-oxygen aerospace titanium alloy precision sheet should not have any surface pollution layers such as oxygen-enriched layer and α layer, the intern...

Embodiment 3

[0028] The TA15 titanium alloy sheet with a thickness of 1mm is used as a raw material, and it is rolled by a 20-roller mill, degreased, bright annealed, twice cold-rolled by a 20-roller mill, degreased, bright annealed, tension straightened, and slitting / Cross-cutting, inspection, packaging and warehousing and other processes are made. Among them, the surface roughness of the work rolls in the secondary cold rolling of the 20-high rolling mill is Ra0.20μm, and the pass deformation rate is 65%; the recrystallization annealing temperature is 700 ° C, the holding time is 30 minutes, the reducing atmosphere is protected, and the cooling is rapid; the stress is relieved The annealing temperature is 500°C, the holding time is 20 minutes, the reducing atmosphere is protected, and the cooling is rapid. The surface of the prepared low-oxygen aerospace titanium alloy precision sheet should not have any surface pollution layers such as oxygen-enriched layer and α layer, the internal st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com