High-performance titanium connecting seal ring and processing method for deep-sea oil drilling and production equipment

一种石油钻采、密封环的技术,应用在机械设备、法兰连接、土方钻采等方向,能够解决组件内应力不均匀、耐海水腐蚀能力差、使用寿命短等问题,达到更换或维护简易、内应力分布均匀、提高开采效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the titanium connection sealing ring and its processing method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

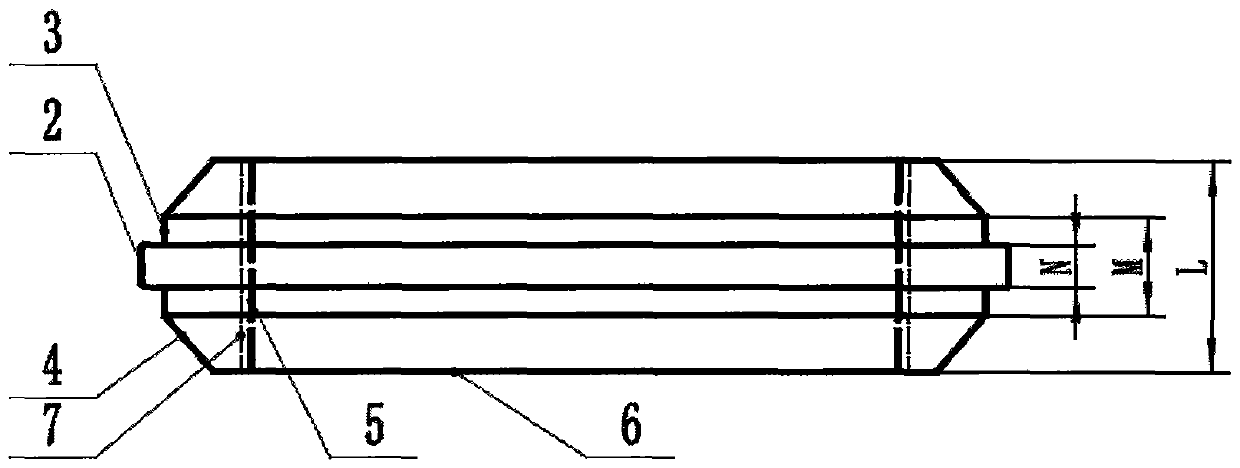

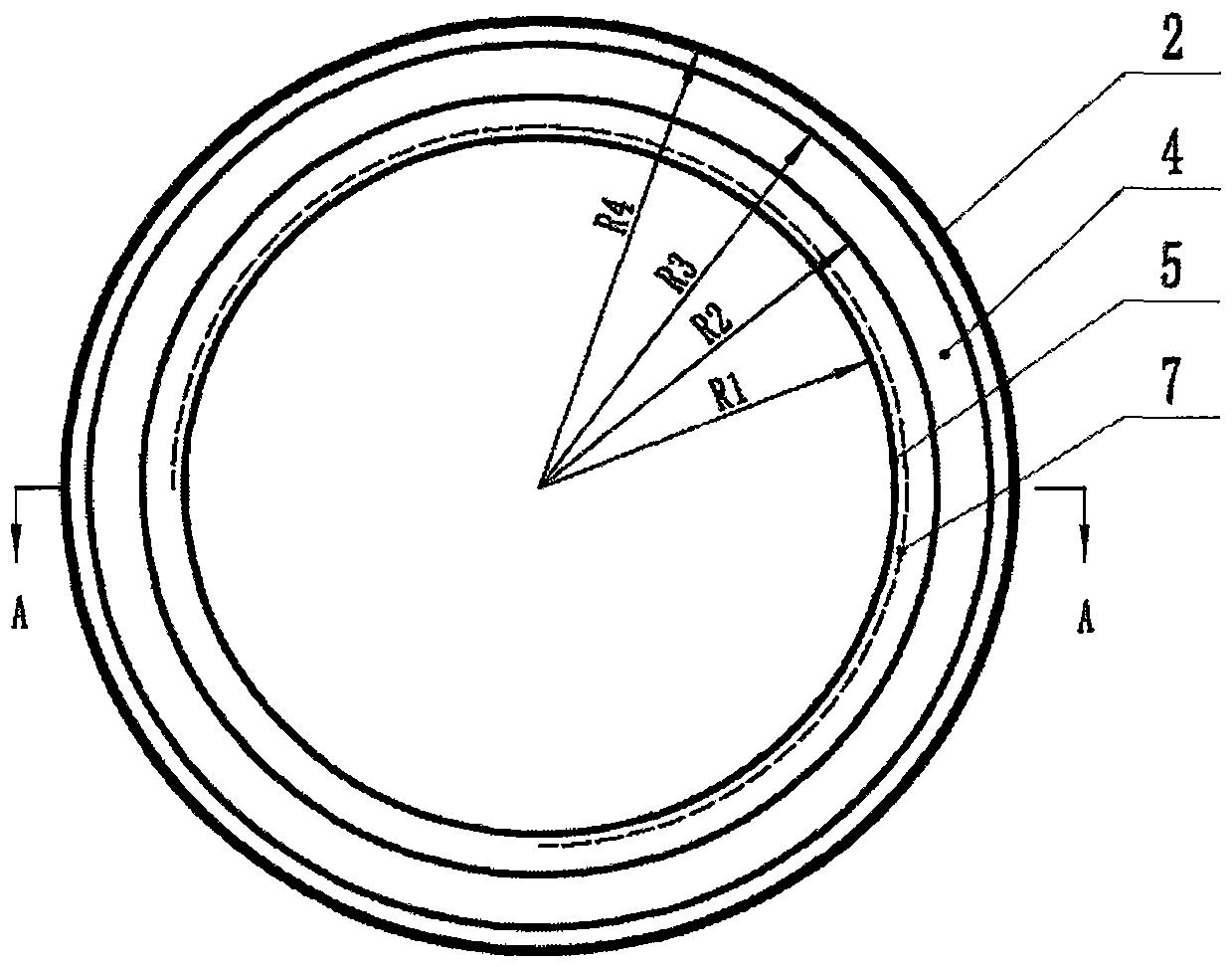

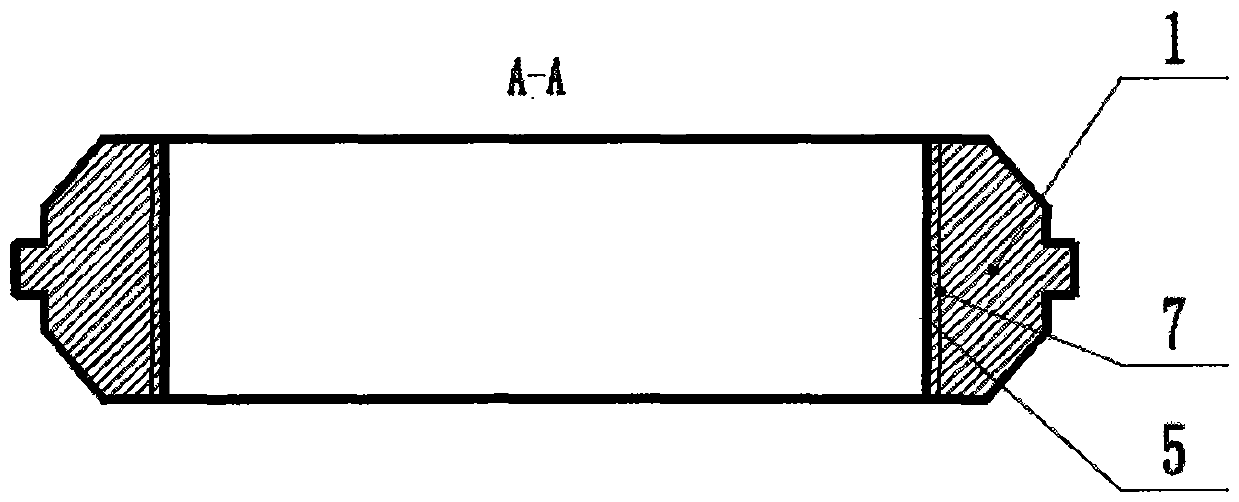

[0035] 1. First, if Figure 1 ~ Figure 3 Shown is the front view, top view and A-A sectional view of the top view of the high-performance titanium connection seal ring for deep-sea oil drilling equipment of the present invention. Among them, L—the axial width of the titanium connecting sealing ring, N—the axial width of the boss, M—the sum of the axial widths of the boss 2 and two adjacent platforms 3 . The ring body 1 of the present invention is a hollow cavity structure symmetrical to the boss 2 . The inner surface of the hollow body is an inner circumferential surface 5 , and its outer surface is also a circumferential surface, and has a boss 2 , a platform 3 , and an inclined end surface 4 . like figure 1 and image 3As shown, along the up or down direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com