Patents

Literature

30results about How to "Uniform distribution of internal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

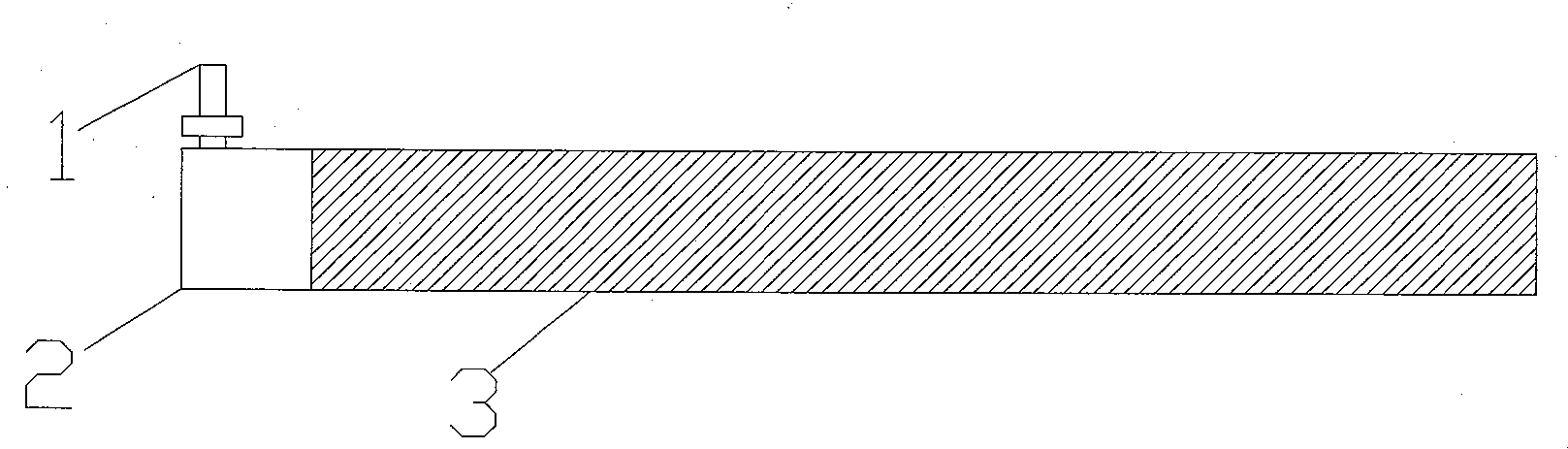

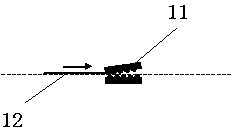

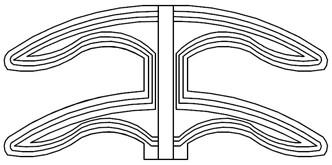

Lithium ion battery and combination method of pole pieces thereof

InactiveCN102664285AEnsure safetyReduce in quantityFinal product manufactureCell electrodesEngineeringPole piece

The invention relates to the technical field of lithium ion battery, in particular to a lithium ion battery, which comprises a battery cell, a packaging bag containing the battery cell, and an electrolyte filled in the battery cell and the packaging bag. The battery cell comprises positive pole pieces, negative pole pieces, and isolating films spaced between the positive pole pieces and the negative pole pieces, wherein head parts of the positive pole pieces and head parts of the negative pole pieces are mutually perpendicular and overlapping, and the positive pole pieces and the negative pole pieces are folded crosswise in a Z shape. Compared with the prior art, the lithium ion battery of the invention comprises a smaller amount of pole pieces, no multi-battery parallel structure with a lamination structure will be formed, and security performance of the battery is ensured; the positive pole pieces and the negative pole pieces are sequentially folded crosswise in a Z shape, layers of the pole pieces are arranged according to a feature which is similar to the lamination structure, same force is exerted on pole piece in each layer, internal stresses between the layers of the battery pole pieces are distributed uniformly, and the battery is not deformable. In addition, the invention further discloses a combination method of pole pieces of the lithium ion battery.

Owner:NINGDE AMPEREX TECH +1

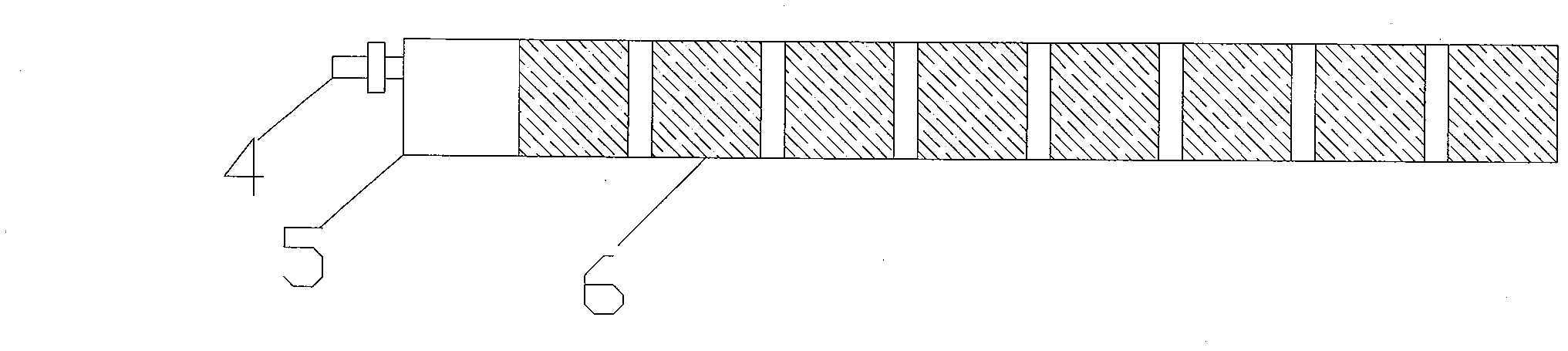

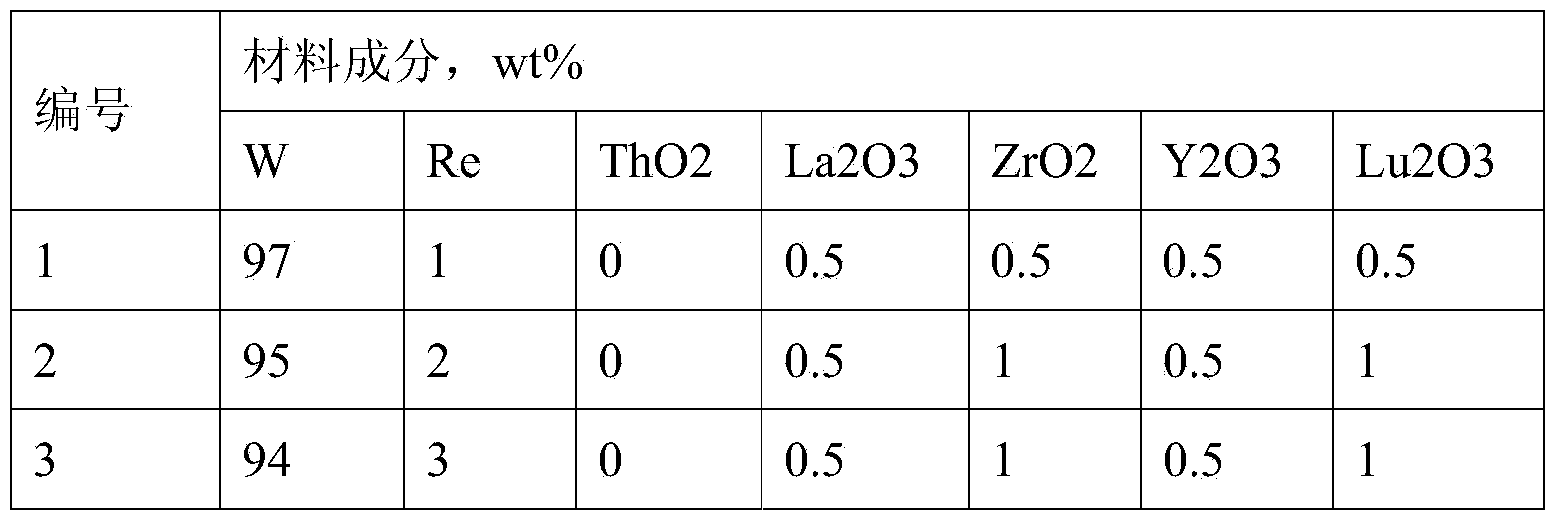

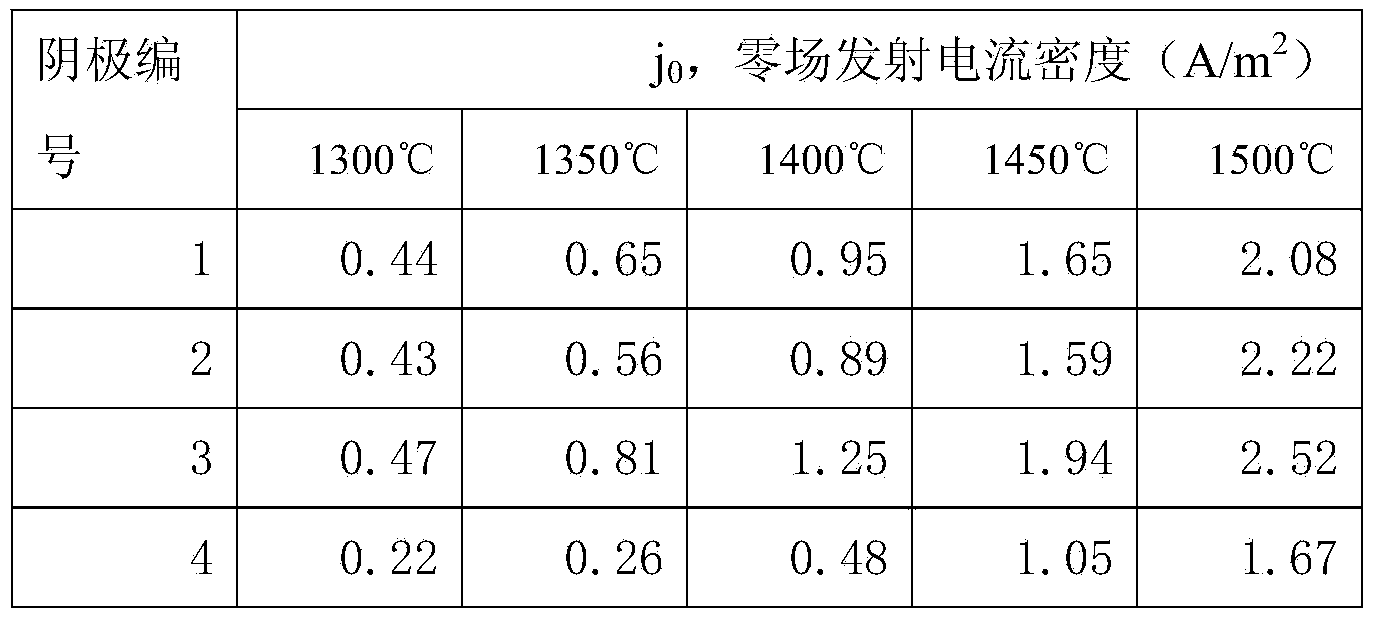

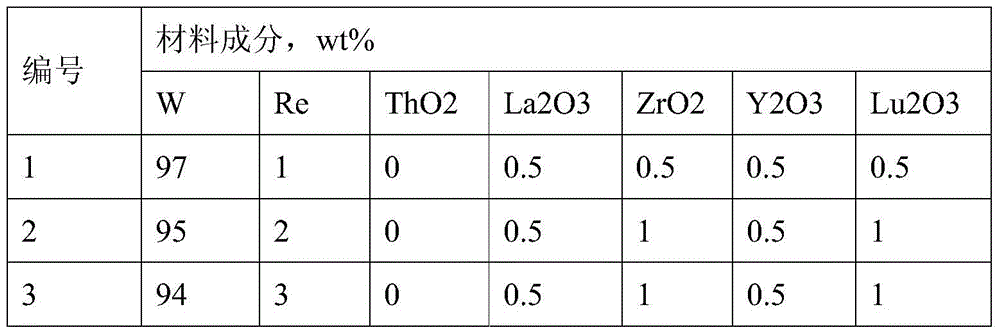

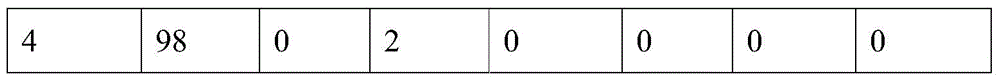

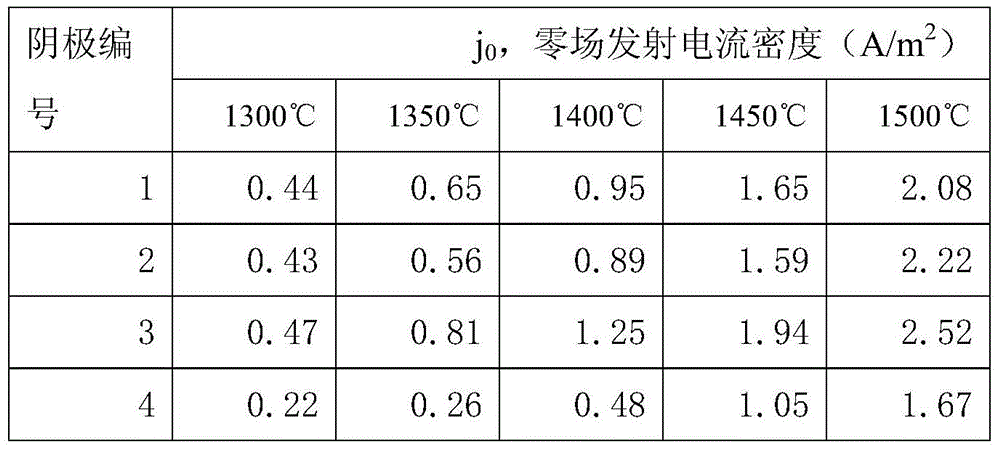

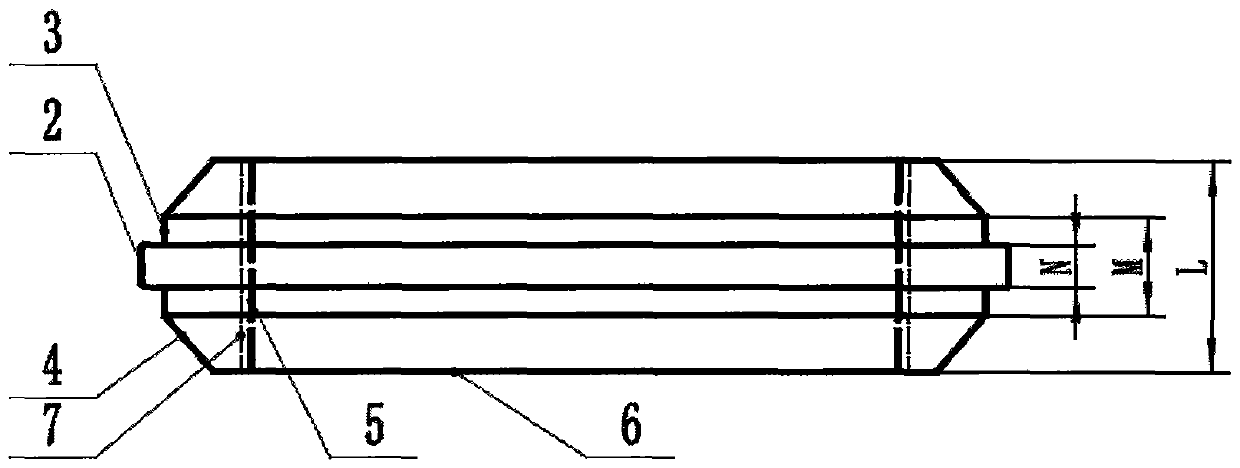

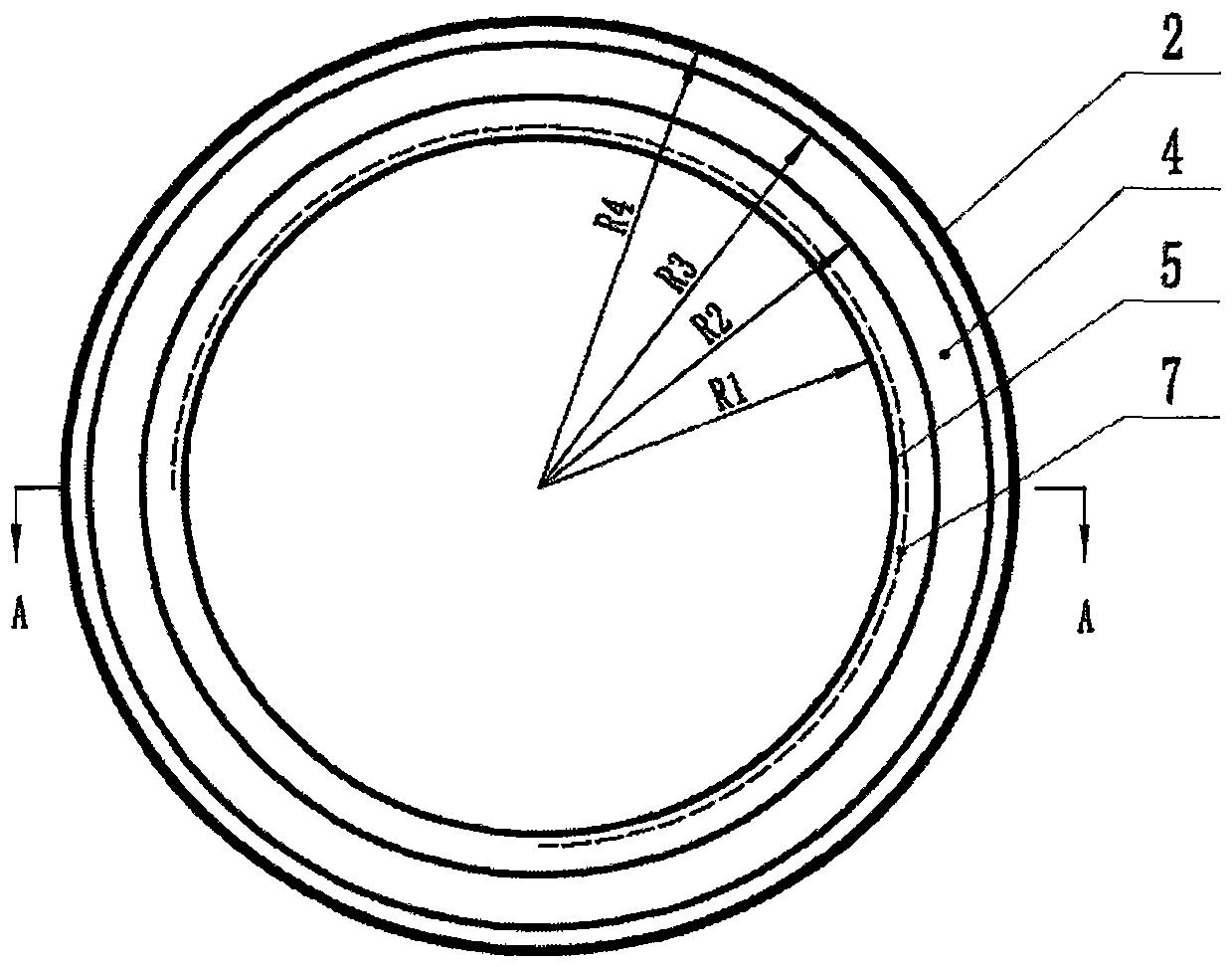

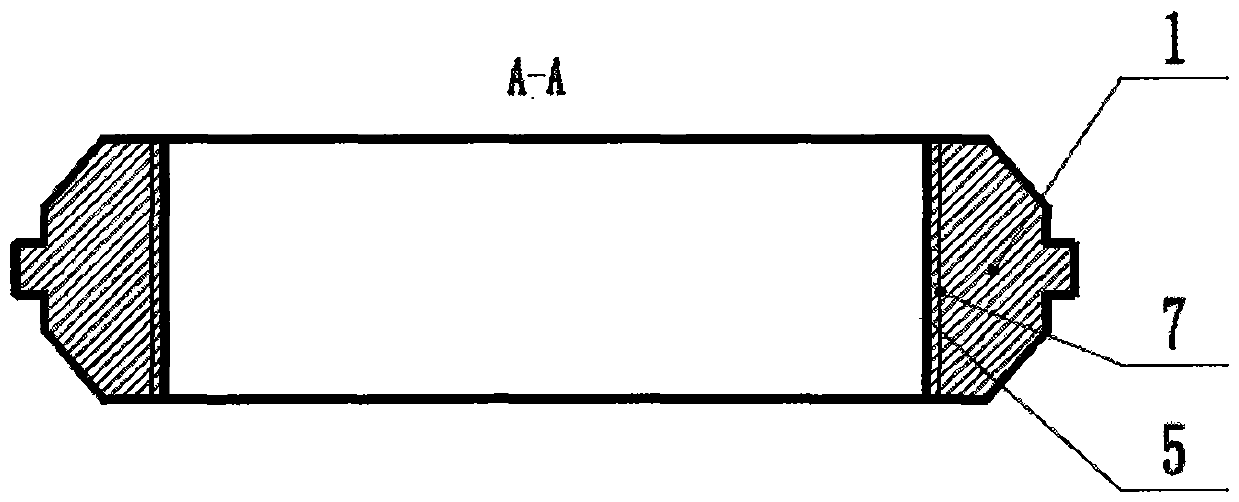

Non-radiative multi-component composite tungsten negative material for microwave oven magnetron and preparation process of negative material

InactiveCN103849804AImproved winding performanceWinding Performance GuaranteeTransit-tube cathodesRheniumLutetium

The invention discloses a non-radiative multi-component composite tungsten negative material for a microwave oven magnetron and a preparation process of the negative material. The tungsten cathode material comprises lanthanum oxide, zirconium oxide, yttrium oxide, lutetium oxide, rhenium and tungsten, wherein the mass percent of each rare-earth oxide in the tungsten electrode material is 0.5%-1.5%, the mass percent of the total rare-earth oxides in the tungsten electrode is 2%-3%, the mass percent of the alloy element rhenium in the tungsten electrode material is 1%-4%, and the tungsten accounts for the rest mass percent. The tungsten cathode material is non-radiative, excellent in thermal emission performance, excellent in high-temperature creep resistance, thermal shock resistance and sag resistance, and long in service life. The preparation method of the non-radiative multi-component composite tungsten cathode material for the microwave oven magnetron comprises the steps of solution preparation, drying, reducing, isostatic cool pressing, sintering, incipient fusion, medium-frequency induction annealing, press working, winding and mechanical straightening. The non-radiative multi-component composite tungsten negative material for the microwave oven magnetron is better in usability. When heated periodically for a long time at a high temperature, the multi-component composite tungsten wire produced by virtue of the process is capable of going through large deformational resistance, and has the sag resistance.

Owner:深圳市威勒科技股份有限公司

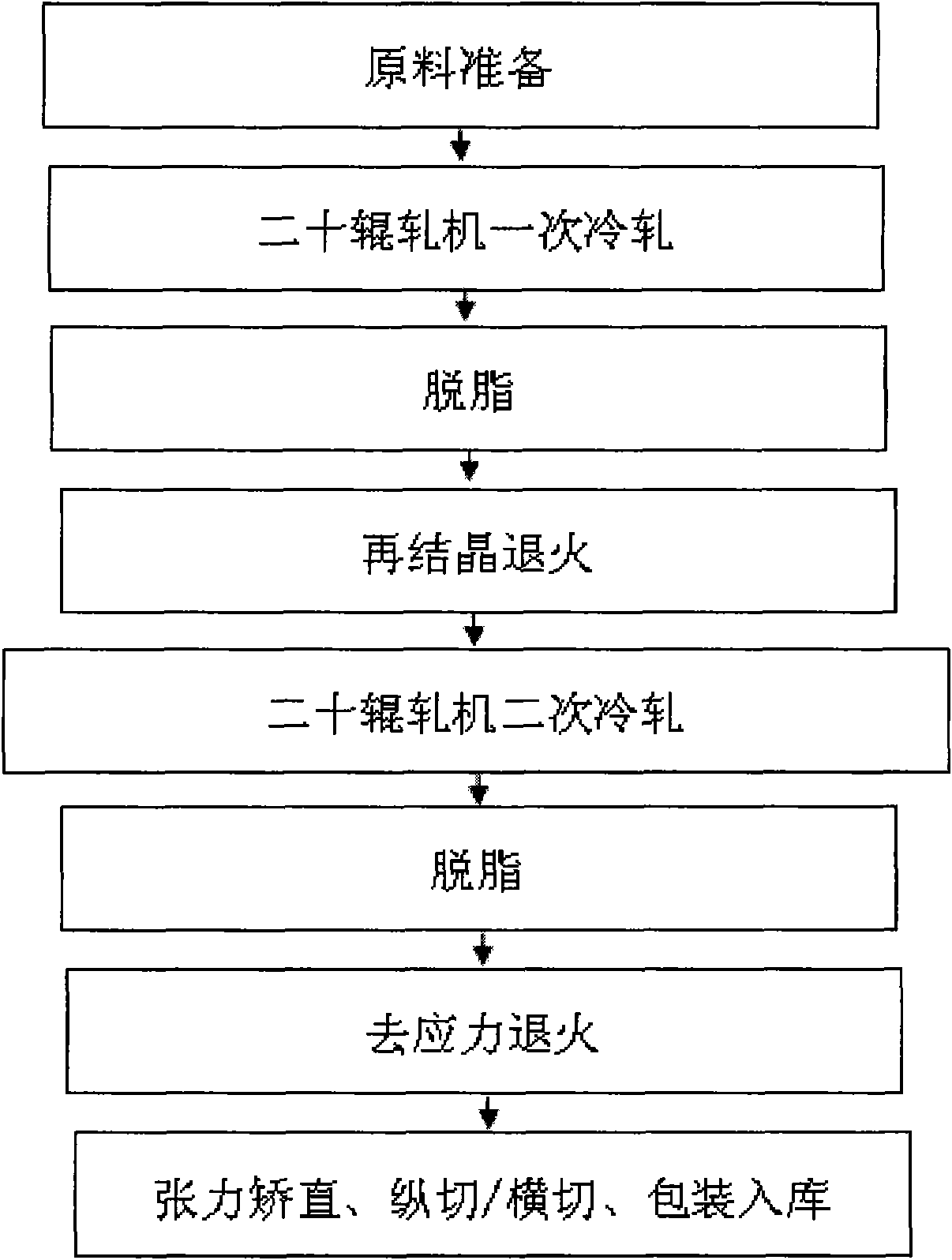

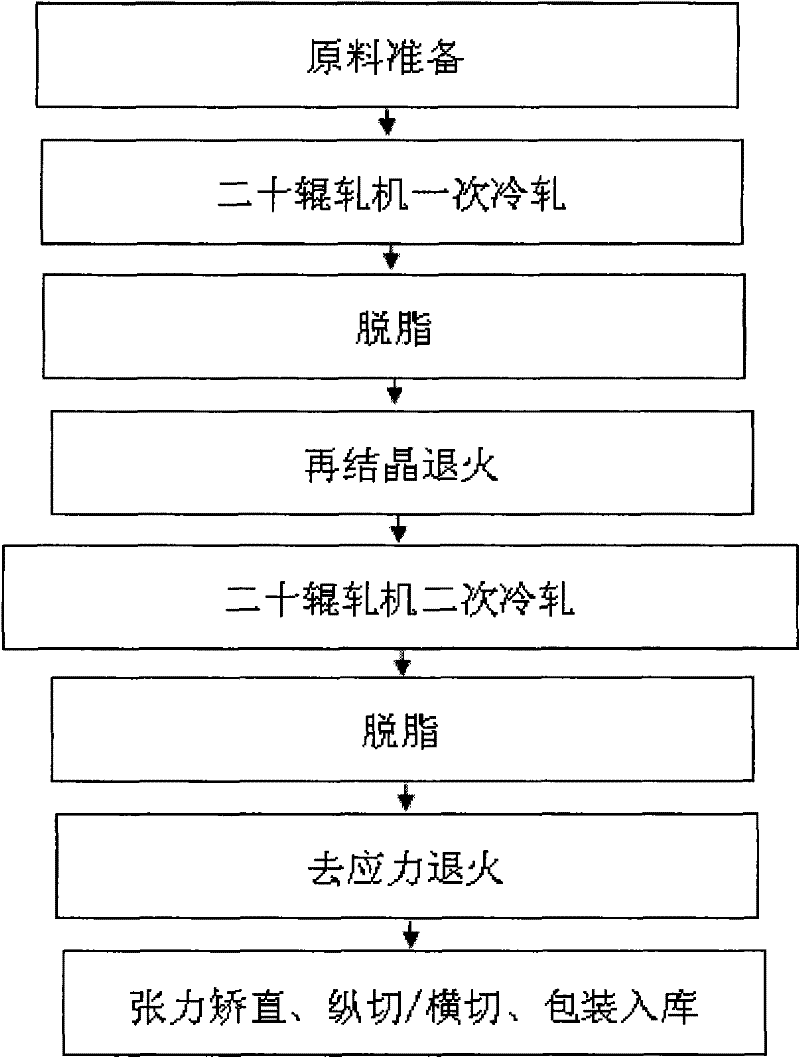

Method for rolling and molding low-oxygen content aero titanium alloy precision sheet

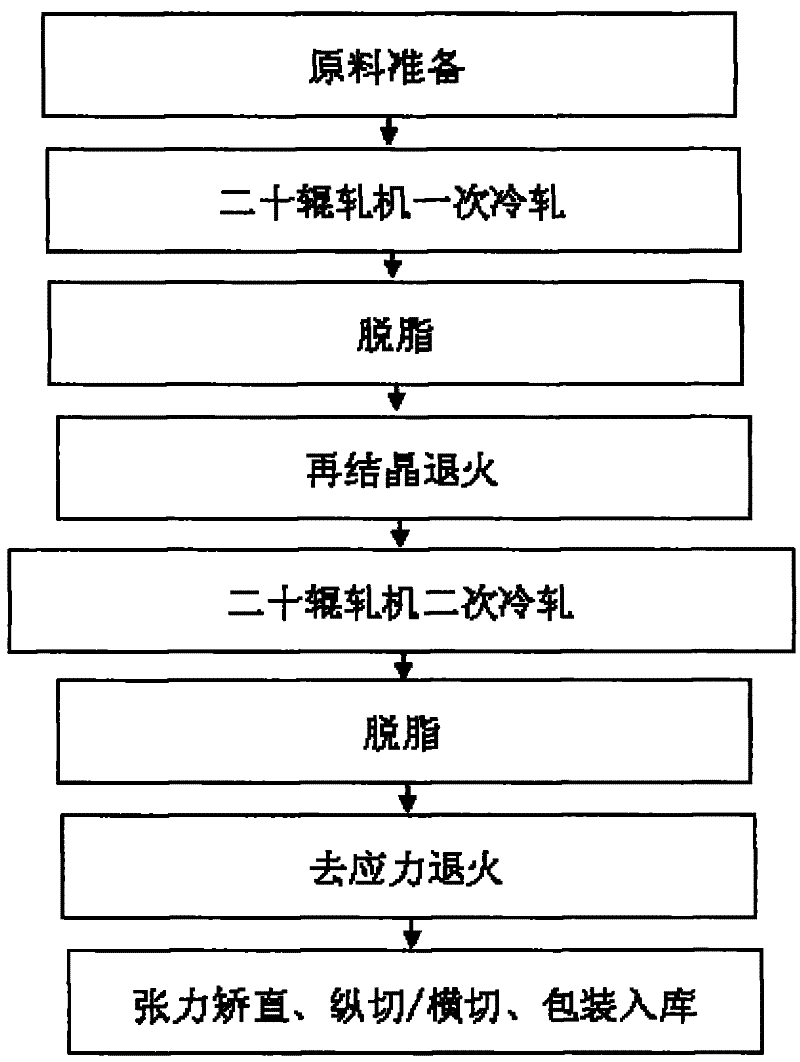

ActiveCN101817015AUniform distribution of internal stressNo anisotropyRoll mill control devicesFurnace typesDegreasingTitanium alloy

The invention discloses a method for rolling and molding a low-oxygen content aero titanium alloy precision sheet. Tthe low-oxygen content aero titanium alloy precision sheet is obtained by rolling twice by using a twenty high rolling mill. The method comprises the following steps of: rolling by using the twenty high rolling mill, degreasing, recrystallization annealing, cold rolling with the twenty high rolling mill again, degreasing, stress relief annealing, stretcher leveling, longitudinal cutting / transverse cutting, inspecting, packaging, and the like, wherein aero titanium alloy plates, such as TC4, TA15 and the like, with the thickness of 1-5 mm, are used as raw materials. The thickness tolerance of the titanium alloy precision sheet is + / -0.005 mm, the camber is 0.3-1 mm / 1m, the surface quality is No.2B, the surface smoothness is up to 1-2 I-Unit, the grain size is up to 5-6 grades, the surface has no surface contamination layer (such as an oxygen-enriched layer, an alpha layer and the like), the internal stress is distributed uniformly, no anisotropy exists, and the subsequent plastic forming feature is favorable. The invention has the advantages of easy production method, low cost, high product quality and high production efficiency.

Owner:江苏呈飞新材料科技有限公司

Method for producing thorium-tungsten wire

InactiveCN101004995AUniform distribution of internal stressImprove the winding effectCold cathode manufactureThorium nitrateTungsten filament

The method includes following steps: adding certain quantity of solution of thorium nitrate into tungsten oxide so as to prepare doped powder of tungsten oxide; deoxidizing the obtained doped powder of tungsten oxide to obtain powder of thorium - tungsten; acid cleaning powder of thorium - tungsten to remove impurity, and producing sintered body of powder of thorium - tungsten; using press work to obtain thorium -tungsten filament with needed diameter, and content of thorium dioxide being 0.7-1.1 wt%, and enwinding thorium -tungsten filament by using wire coil; Finally, straightening filament. The invention raises the rate of finished products, and optimizes working performance of tungsten winding.

Owner:兆恒威勒(石门)钨业有限公司

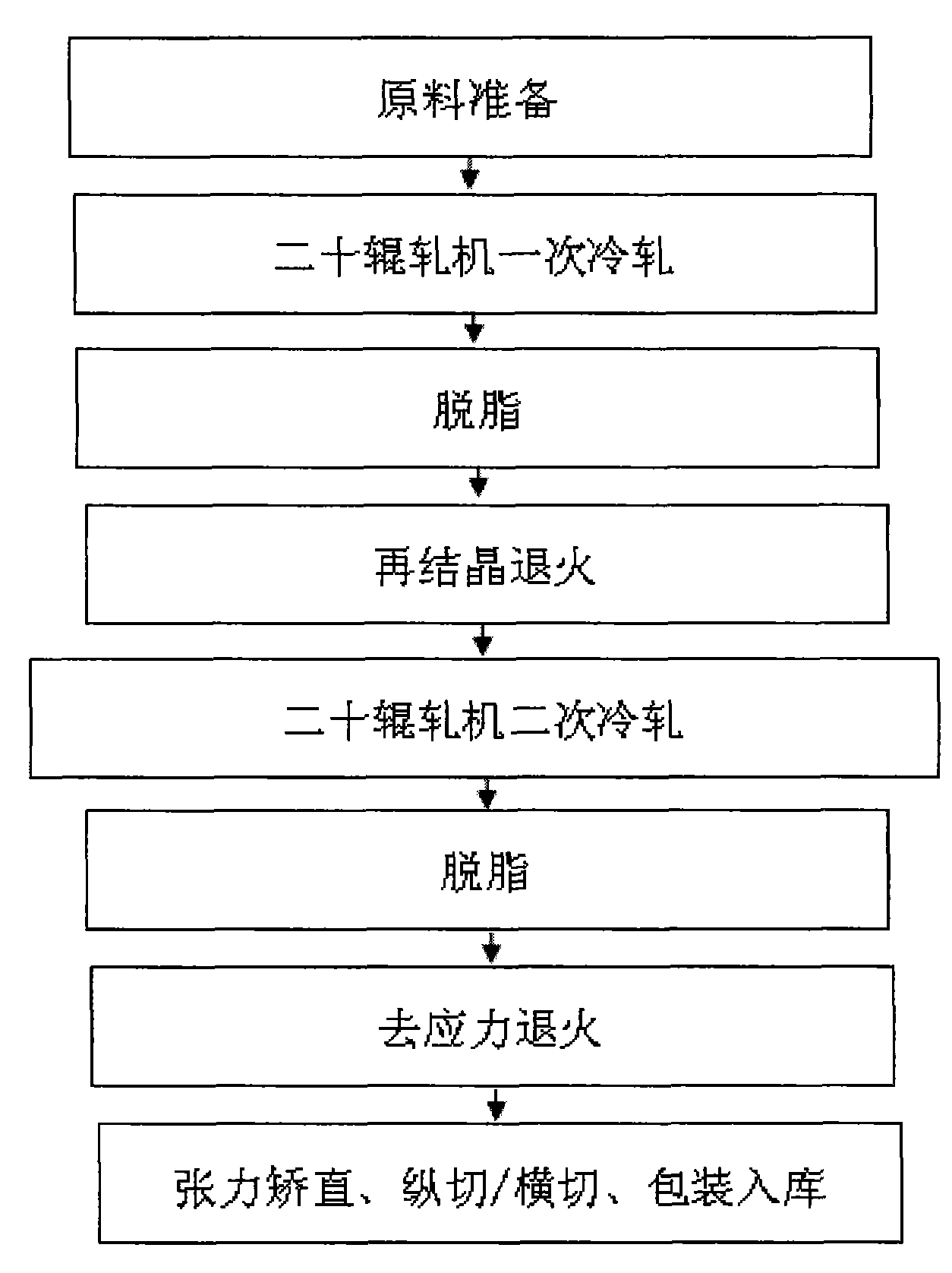

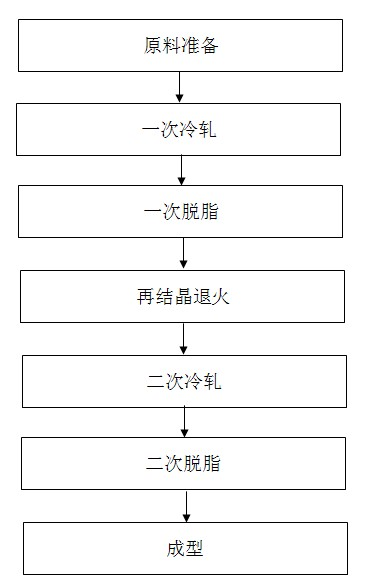

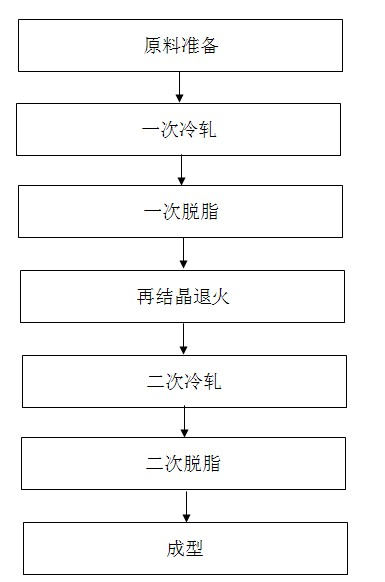

Method for rolling and forming low-oxygen-content pure-titanium precise thin strip coiled material

The invention discloses a method for rolling and forming a low-oxygen-content pure-titanium precise thin strip coiled material. The rolling and forming method is used for rolling the low-oxygen-content pure-titanium precise thin strip coiled material by using a multi-pass twenty high rolling mill and particularly comprises the following steps of: preparing raw materials; performing primary rolling; degreasing; performing recrystallizational annealing; performing secondary cold rolling; performing secondary degreasing; and forming. In the low-oxygen-content pure-titanium precise thin strip coiled material finished product obtained by the method, no surface pollution layers, such as an oxygen enriched layer and the like, are formed on the surface; internal stress is distributed uniformly; no anisotropism exists; the subsequent plastic forming property is high; thickness tolerance is + / - 2percent; camber is 0.3 to 1 millimeter per meter; the surface quality is TR; the surface flatness reaches 1-2I-Unit; and grain size reaches 5 to 6 levels. Compared with the prior art, the method has the advantages that: the low-oxygen-content pure-titanium precise thin strip coiled material obtained by the method has excellent comprehensive performance; and the production method is simple and practicable, low in cost and high in efficiency.

Owner:JIANGSU CHENGFEI PRECISION ALLOY

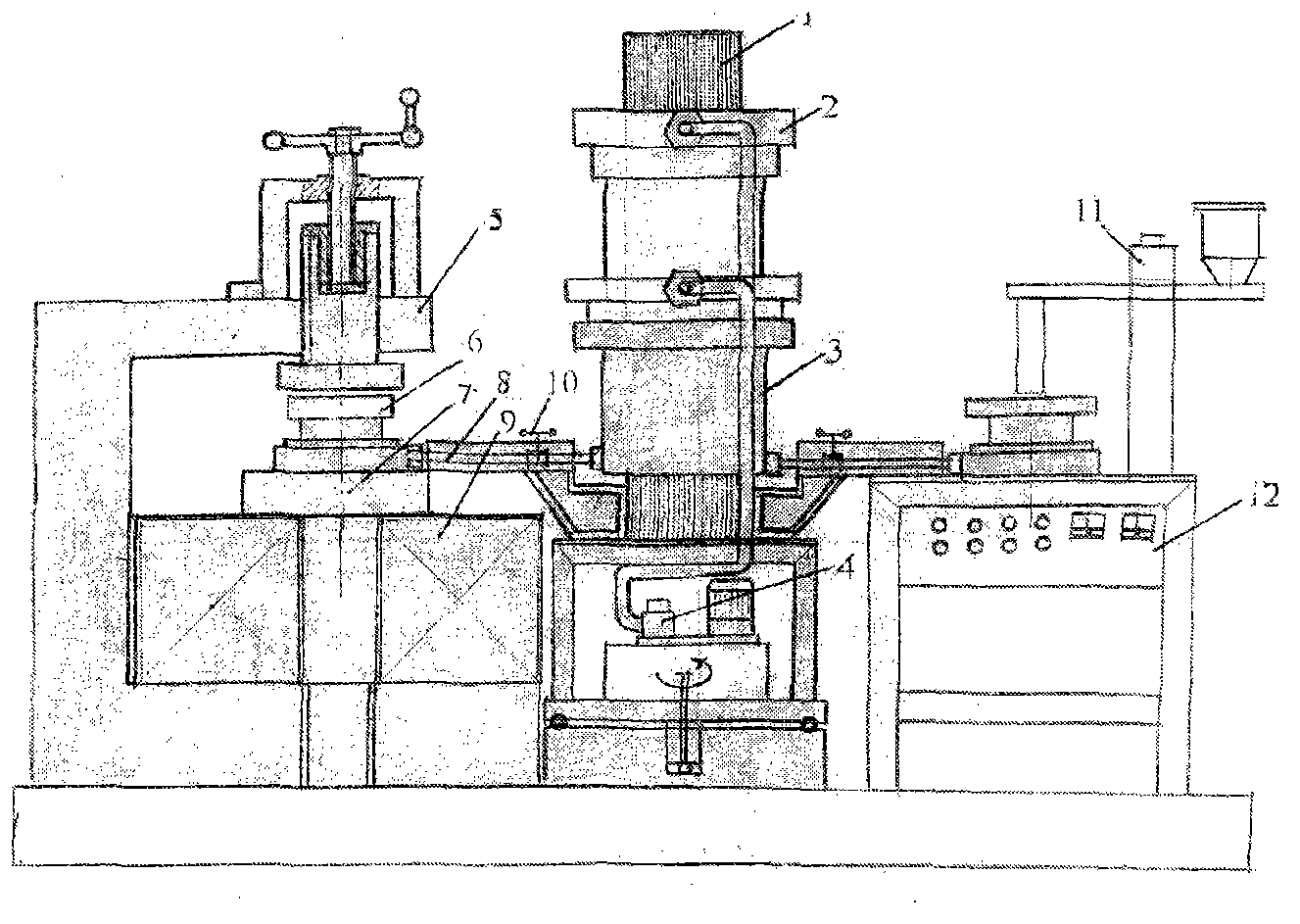

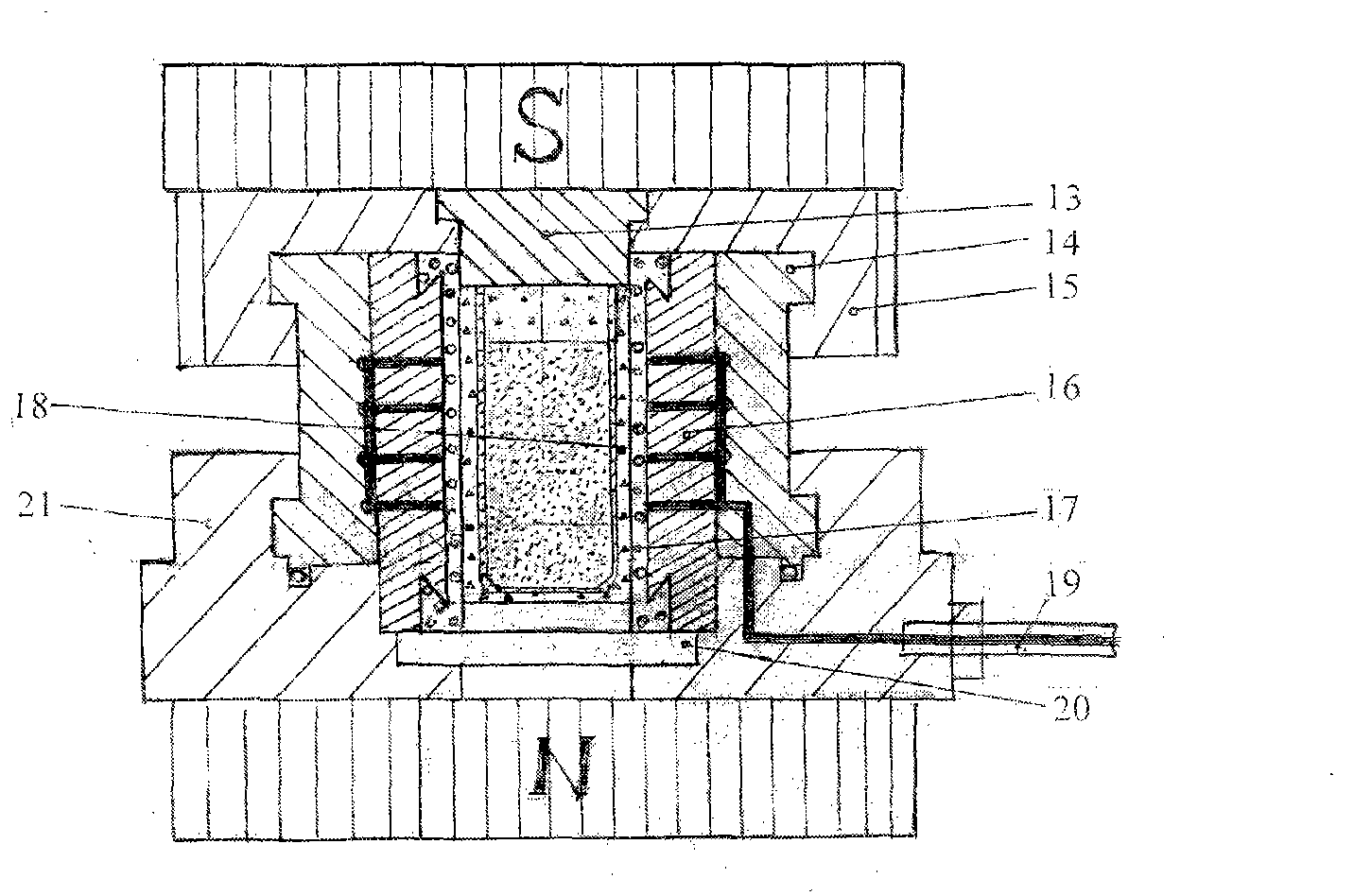

Technology and device for forming dry bag quick isostatic pressing in oriented magnetic fields

InactiveCN103878368AImprove automationIncrease the level of mechanizationInorganic material magnetismInductances/transformers/magnets manufactureResource utilizationMagnetic poles

The invention belongs to the field of technologies for manufacturing magnetic materials, and provides a technology and a device for forming dry bag quick isostatic pressing in oriented magnetic fields. The technology and the device have the advantages that an oriented magnetic field technology is ingeniously and organically combined with the technology and the device for forming dry bag isostatic pressing by the aid of a novel design concept, so that dry bag isostatic pressing can be formed in the oriented magnetic fields which have optional directions and optional magnetic field intensities by the aid of the novel technology and the novel device; orientation degrees of products can be obviously upgraded; two necessary working procedures in existing neodymium, iron and boron magnet production can be combined with each other to form one working procedure by the novel technology and the novel device, and the automation and mechanization levels are high; powder is not in contact with pressing blanks and oil in production procedures, and accordingly a latex sheath for binding the corresponding pressing blank can be omitted; the pressing blanks are quite uniform in density distribution and internal stress distribution; the pressing blanks can be machined, and original powder can be recycled; single-hole and multi-hole thin-walled pipes, sleeves and multi-magnetic-pole products which are heavy and are in complicated shapes or have large length-diameter (L / d) ratios can be produced by the aid of the technology and the device, the rare earth mineral resource utilization rate can be greatly increased, and the neodymium, iron and boron magnet industrial production level of China can be upgraded to the world leading level.

Owner:吴庆华 +2

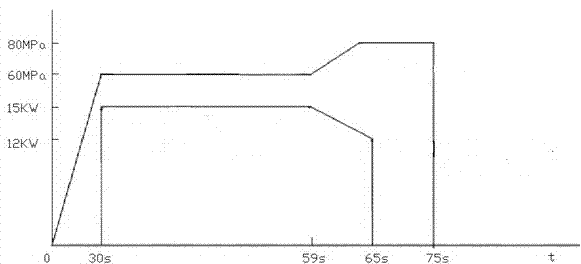

Cold straightening process for high-strength thin plate

InactiveCN104001757AImprove straightnessUniform distribution of internal stressSheet steelInternal stress

The invention discloses a straightening process for a high-strength thin plate. The problem that the head of a steel plate collides with a straightening roll when the steel plate is bit in the large-rolling-reduction straightening process is avoided by adopting the method of firstly biting steel plate and then arranging roll bites. The problem that the steel plate cannot come in due to overlarge head-tail warpage amount in the subsequent straightening process is solved by positioning the head and tail of the steel plate in the straightening process. The straightness of the steel plate is improved through the straightening process of arranging the multi-pass progressive-decreasing type roll bits, and meanwhile the distribution of the internal stress of the steel plate is more uniform.

Owner:NANJING IRON & STEEL CO LTD

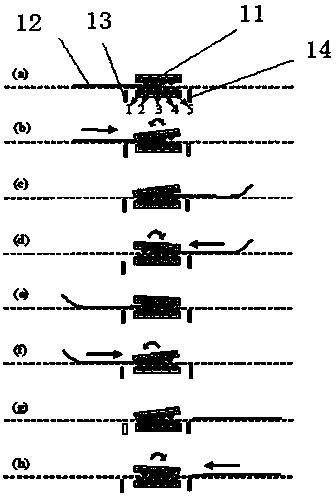

Mold system with high/low-temperature rapid conversion function

The invention discloses a mold system with a high / low-temperature fast conversion function. An upper mold plate and a lower mold plate of a mold are each internally provided with a snake-shaped pipe. The upper mold snake-shaped pipe and a high-temperature circulating system form an independent loop. The lower mold snake-shaped pipe and a cooling circulating system form an independent loop. A circulating fluid medium is adopted for the high-temperature circulating system for heating, a circulating fluid medium is adopted for the cooling circulating system for cooling, and the loop of the high-temperature circulating system and the loop of the low-temperature circulating system are each provided with a switching valve. According to the mold system with the high / low-temperature fast conversion function, the mold can be heated or cooled rapidly through high-temperature fluid or low-temperature fluid, high / low temperature rapid conversion of the mold is achieved, it is guaranteed that a material (or a component) is shaped under a uniform temperature field, internal stress distribution is uniform, and it is guaranteed that the performance of products is stable and deformation is prevented; and besides, rapid and safe demolding can be achieved.

Owner:CENT SOUTH UNIV

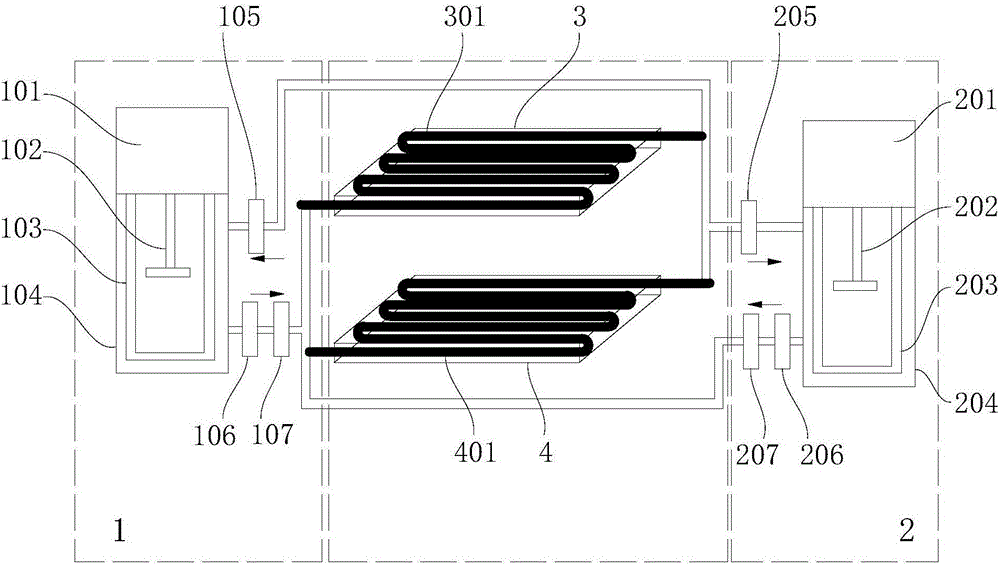

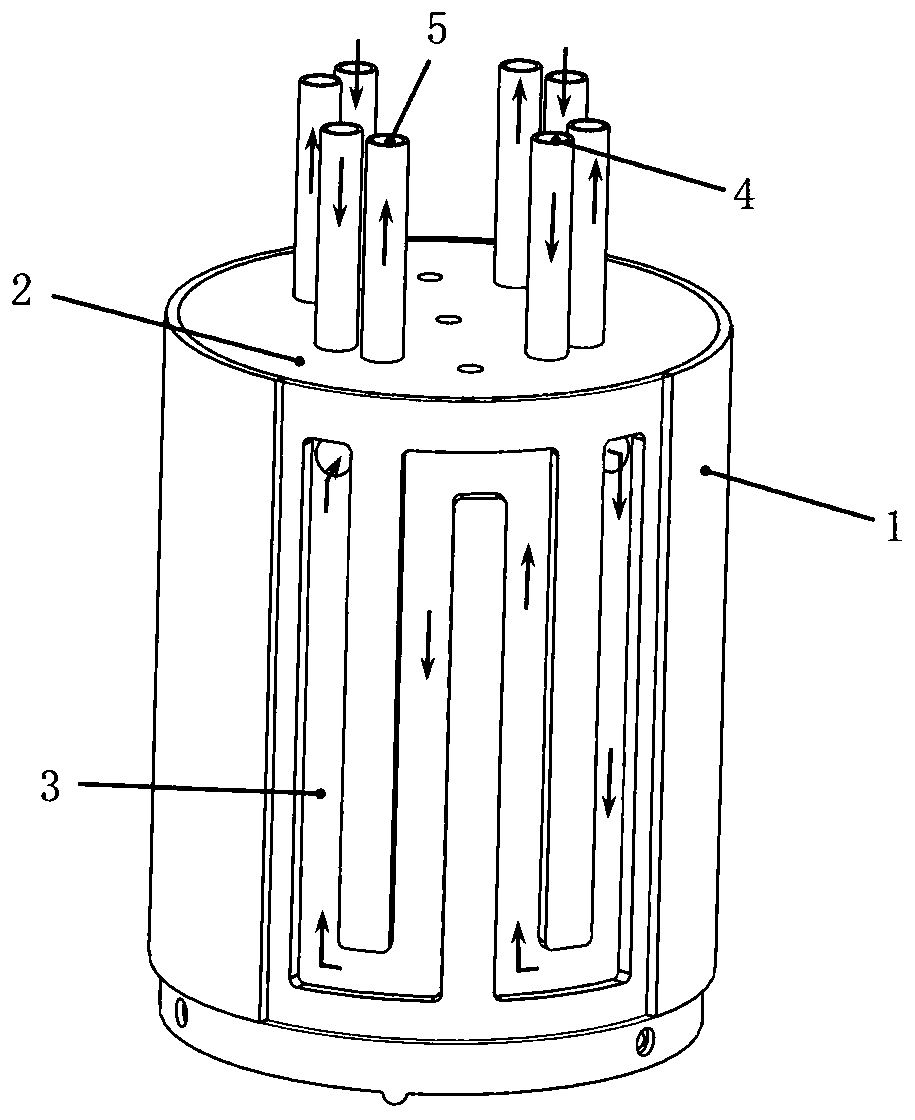

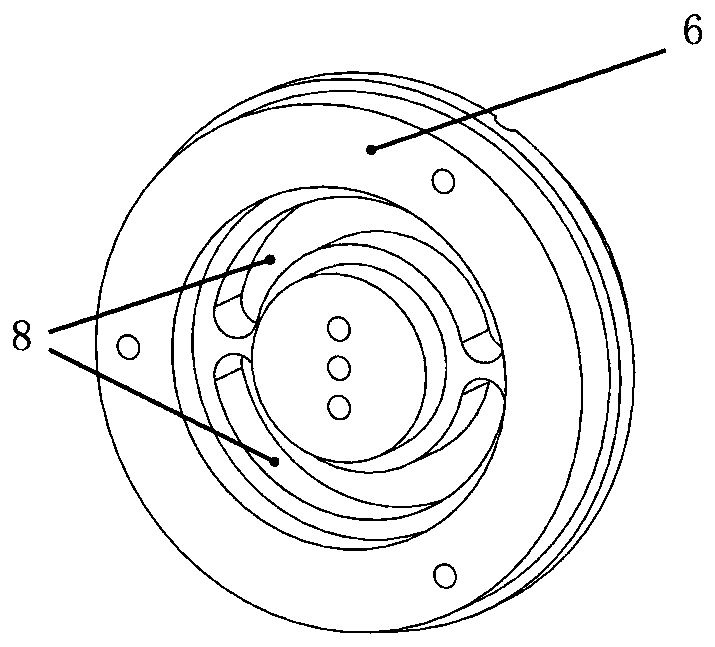

Cooling device for high-temperature magnetic resonance probe and application thereof

InactiveCN110161438AGuaranteed efficiencyImprove uniformityMeasurements using magnetic resonanceCooling channelCooling Units

The invention belongs to the technical field of high-temperature magnetic resonance probe cooling, and discloses a cooling device for a high-temperature magnetic resonance probe and application thereof. The cooling device comprises an upper cooling unit and a lower cooling unit, wherein the upper cooling unit comprises an outer barrel structure and an inner barrel structure; the inner barrel structure is sleeved with the outer barrel structure, and the two are in tight fit with each other; an inner surface of the outer barrel structure or an outer surface of the inner barrel structure is provided with a plurality of S-shaped channels which are uniformly distributed; the inner barrel structure is provided with a plurality of groups of water inlets and water outlets; the water inlets and thewater outlets are connected with two ends of the S-shaped channels; the lower cooling unit is arranged at the bottom of the upper cooling unit, and comprise an upper cover and a lower cover which arein tight fit with each other; a plurality of cooling channels are formed in the upper cover or the lower cover; and the lower cover is provided with a water inlet and a water outlet which are connected with the cooling channels. During application, the cooling device wraps the outside of the high-temperature magnetic resonance probe. Through adoption of the cooling device, omni-directional cooling can be realized for the high-temperature magnetic resonance probe, and the detection accuracy and the service life are ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

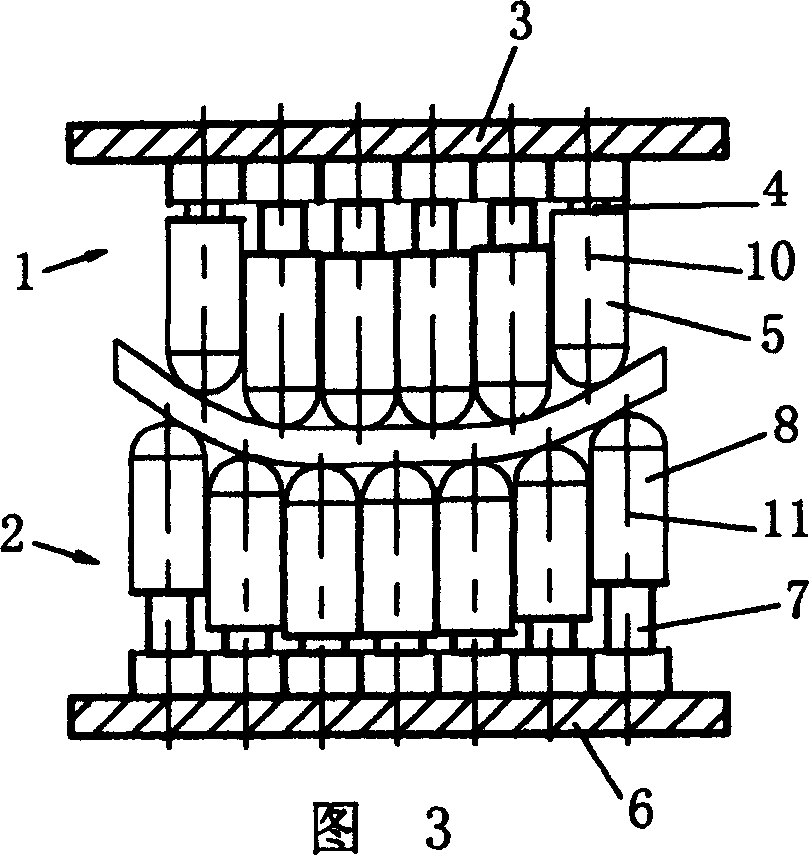

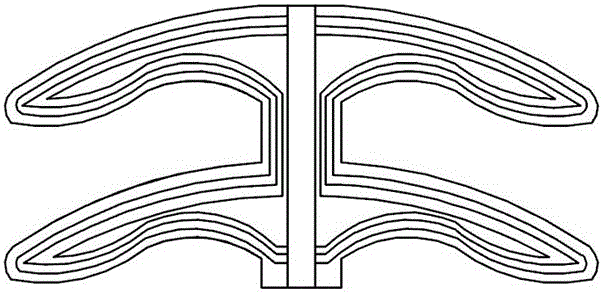

Discrete face mold device for plate material heat forming

Owner:HUNAN UNIV

Impact-resistant ceramic insulator and manufacturing method thereof

The invention discloses an impact-resistant ceramic insulator and a manufacturing method thereof. The impact-resistant ceramic insulator has impact strength of being not less than 1.5 J / cm<2>, volume resistivity of being not less than 1*10<14>Omega.cm, dielectric strength of being not less than 750 kV / cm, thermal conductivity of being not less than 20 W / m.K, bending strength of being not less than 600 Mpa, Young's modulus of being not less than 450 Gpa and fracture toughness of being not less than 55 Mpa. A one-stage multiple-sintering manner is adopted in every 4-5 mm, so that a finished insulator has a multi-layer buffer and support structure, can withstand multi-angle and high frequency impact energy; a micro-structure is formed on the surface of the insulator, so as to facilitate the use on one hand and also increase the impact resistance on the other hand; and the impact-resistant ceramic insulator provided by the invention has advantages of high economy, high impact resistance, high fracture toughness and high comprehensive mechanical properties.

Owner:郭思源

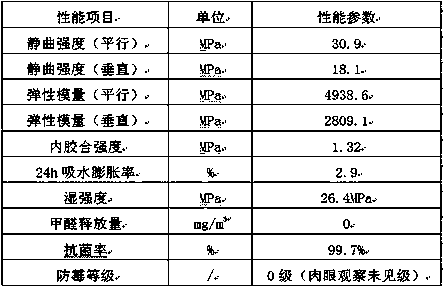

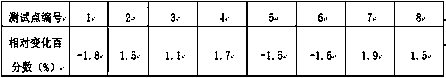

Waterproof antibacterial directional shaving board and preparation method thereof

InactiveCN110815485AThorough responseGood gluing propertiesFlat articlesDomestic articlesAnti bacterialFormaldehyde free

The invention provides a waterproof antibacterial directional shaving board. The waterproof antibacterial directional shaving board comprises an upper surface layer, a core layer and a lower surface layer, the mass ratio of the upper surface layer and the lower surface layer to the core layer is (60% to 75%):(25% to 40%), and the paving included angles between the upper surface layer and the corelayer as well as between the lower surface layer and the core layer are each 80-90 degrees. The invention further provides a preparation method of the waterproof antibacterial directional shaving board. The preparation method comprises the steps of shaving, drying, mixed spraying, drying, gluing, paving, liquid spraying and hot pressing, plate billet balancing, edge cutting, cooling, sanding and film forming. The waterproof antibacterial directional shaving board has the beneficial effects that a reaction between -NCO groups of isocyanate MDI glue in a board material of the waterproof antibacterial directional shaving board and -OH groups of shavings is complete, the gluing effect is good, and internal stress is uniformly distributed; the board material is good in overall stability, in thelong-term using or storage process, the phenomena of crack, layering, bulking and the like are avoided, and release of substances such as formaldehyde harmful to the human body is avoided; and bacterial resisting, mold preventing and insect preventing can be effectively achieved, and the antibacterial rate of the waterproof antibacterial directional shaving board reaches 99.1-99.7%.

Owner:寿光市鲁丽木业股份有限公司

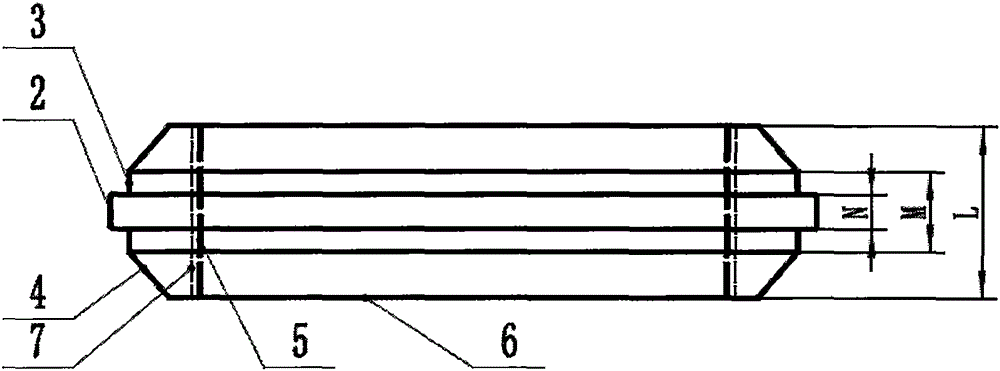

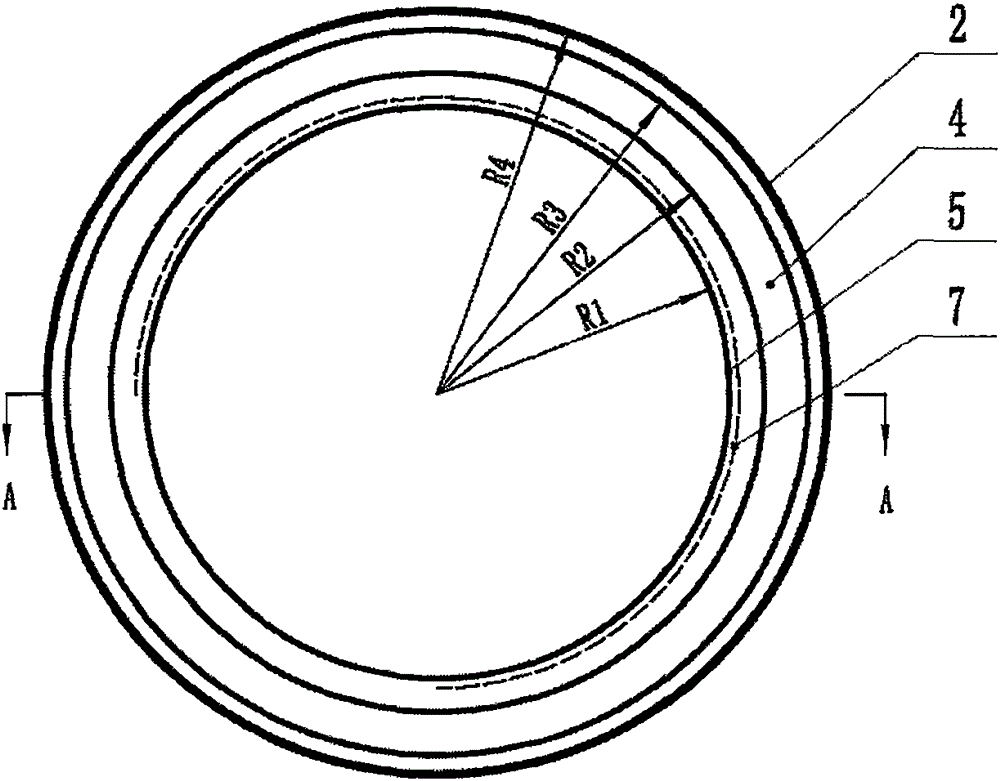

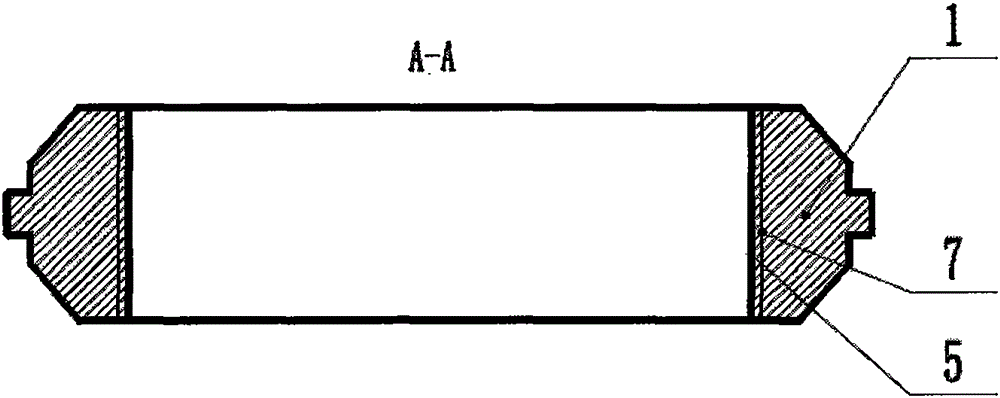

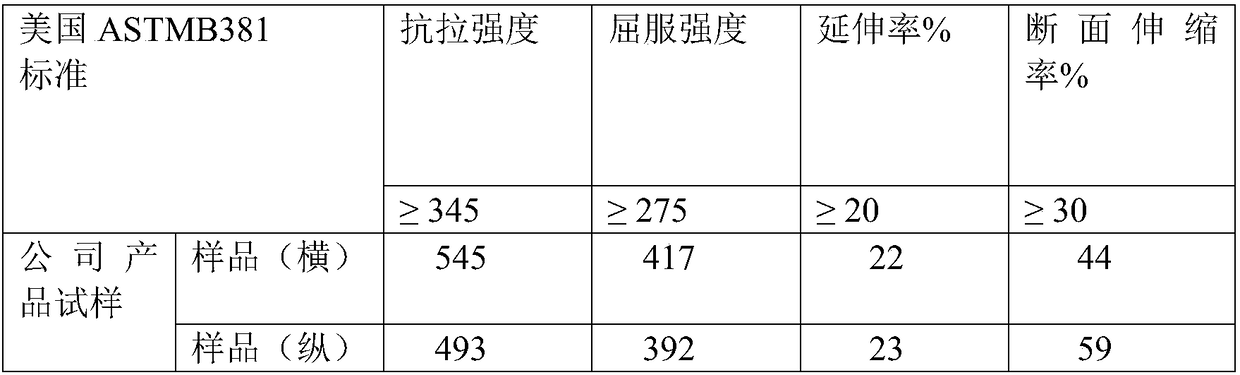

High-performance titanium joint seal ring for deep-sea oil drilling and production equipment and processing method thereof

ActiveCN105156672AHigh tensile strengthHigh yield strengthEngine sealsFlanged jointsCustomer requirementsOil drilling

The invention provides a titanium joint seal ring for deep-sea oil drilling and production equipment, which comprises an annular ring body, wherein the center hole of the ring body is provided with a circumferential surface; the outer circle surface of the ring body is sequentially provided with an annular lug boss, a platform, an oblique end surface and a horizontal end surface in the circumferential direction; and the inner circumferential surface can be provided with a thread according to the customer requirements, and thus, can be connected with an oil delivery pipe or used on other devices. The invention also provides a processing method of the titanium joint seal ring, which mainly comprises the following steps: sponge titanium preparation, vacuum smelting of titanium ingot, press forging for root extraction, forging by heating, heat treatment and machining. The actually measured tensile strength is 565 MPa, the yield strength is 460 MPa, the, elongation percentage is 25.2%, the percentage reduction in area is 44%, and thus, the technical properties are obviously enhanced. The titanium joint seal ring can be reliably used in deep sea with the depth of 1000-3000m or more, can bear the huge deep-sea pressure and satisfy the demand of the oil-gas delivery pressure, can enhance the service life and recovery efficiency of the drilling and production equipment, and can prevent the corroded and damaged leaking oil from polluting the sea environment.

Owner:BAOJI YIXIN METALS PROD WORKS

Method for rolling and molding low-oxygen content aero titanium alloy precision sheet

ActiveCN101817015BUniform distribution of internal stressNo anisotropyRoll mill control devicesFurnace typesStress reliefTitanium alloy

The invention discloses a method for rolling and molding a low-oxygen content aero titanium alloy precision sheet. The low-oxygen content aero titanium alloy precision sheet is obtained by rolling twice by using a twenty high rolling mill. The method comprises the following steps of: rolling by using the twenty high rolling mill, degreasing, recrystallization annealing, cold rolling with the twenty high rolling mill again, degreasing, stress relief annealing, stretcher leveling, longitudinal cutting / transverse cutting, inspecting, packaging, and the like, wherein aero titanium alloy plates, such as TC4, TA15 and the like, with the thickness of 1-5 mm, are used as raw materials. The thickness tolerance of the titanium alloy precision sheet is + / -0.005 mm, the camber is 0.3-1 mm / 1m, the surface quality is No.2B, the surface smoothness is up to 1-2 I-Unit, the grain size is up to 5-6 grades, the surface has no surface contamination layer (such as an oxygen-enriched layer, an alpha layer and the like), the internal stress is distributed uniformly, no anisotropy exists, and the subsequent plastic forming feature is favorable. The invention has the advantages of easy production method, low cost, high product quality and high production efficiency.

Owner:江苏呈飞新材料科技有限公司

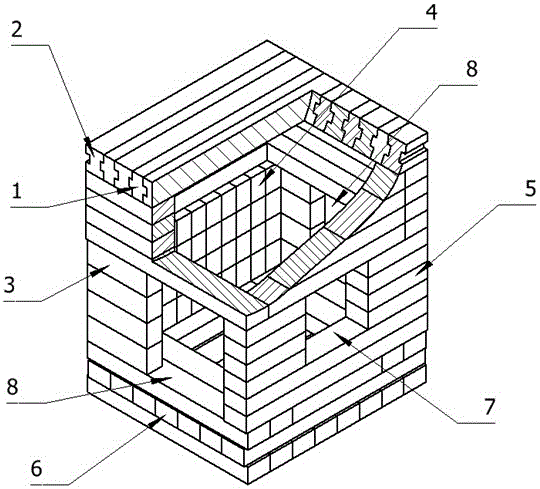

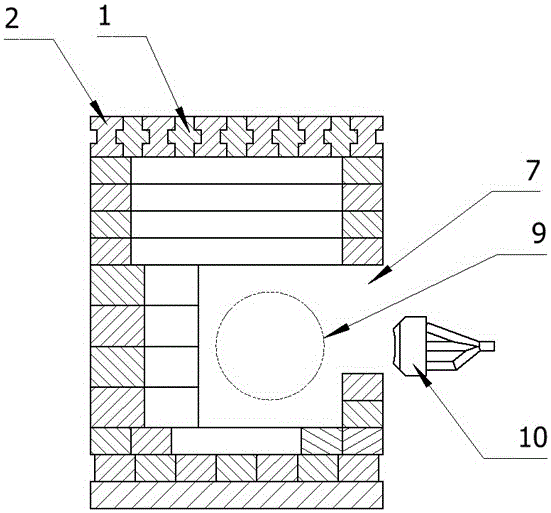

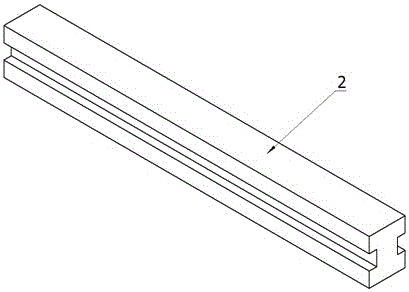

Glass rod sintering furnace used for making optical fiber preform

InactiveCN106587589APrevent fallingExtend the life of noodlesGlass making apparatusBrickCombustible gas

The invention relates to a glass rod sintering furnace used for making optical fiber preform. The furnace comprises a box-shaped furnace body, the furnace body comprises two side surfaces, a front surface, a back furnace, a bottom surface and a top surface, the two side surfaces are correspondingly provided with rod traversing windows, the front surface of the furnace body is provided with a combustible gas blast burner window, and the top surface is obtained through splicing and inserting quartz glass strip-shaped bricks laterally respectively provided with tenons and grooves. The furnace can prevent falling of fractured top bricks and avoid damages of processed pieces and interruption of processing, so the working reliability of the sintering furnace is enhanced, and the service life of the sintering furnace is prolonged; mutual embedded connection of the strip-shaped top bricks through the tenons and the grooves forms the seamless quartz glass top surface and improves the heat insulation performance of the sintering furnace; the top surface strip-shaped bricks adopt the grooves or the tenons with a symmetric equal section structure, so the fracture risk of the quartz glass strip-shaped top bricks is reduced, thereby further prolonging the service life of the glass rod sintering furnace; and the furnace has a reasonable structure, and is convenient to make and maintain.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

A method for manufacturing a composite sound-absorbing diamond saw blade matrix

ActiveCN102756177BLow costShorten the processing cycleMetal sawing tool makingFurnace typesPerformance indexQuenching

The invention provides a manufacturing method of a composite noise-reducing diamond saw blade base body. The manufacturing method comprises the process steps of: preparing a single-sheet saw blade base bodies, carrying out combined rolling welding, quenching and annealing, and carrying out finish machining. The manufacturing method is characterized in that after two single-sheet saw blade base bodies are wholly punched and baited and burrs are removed, a damping material is clamped between the two single-sheet saw blade base bodies; a composite noise-reducing diamond saw blade base body blank is formed by rolling welding and the composite noise-reducing diamond saw blade base body blank is subjected to continuous pressurizing, oil spraying and quenching, controllable temperature pressurizing, cooling and finish machining to form a composite noise-reducing diamond saw blade base body finished product. The manufacturing method disclosed by the invention has the advantages that the single work procedure efficiency in a product manufacturing process is improved and the secondary annealing do not need to be carried out, so that the machining cost of the product is effectively reduced and various performance indexes of the product are improved.

Owner:HEIXUANFENG SAW IND

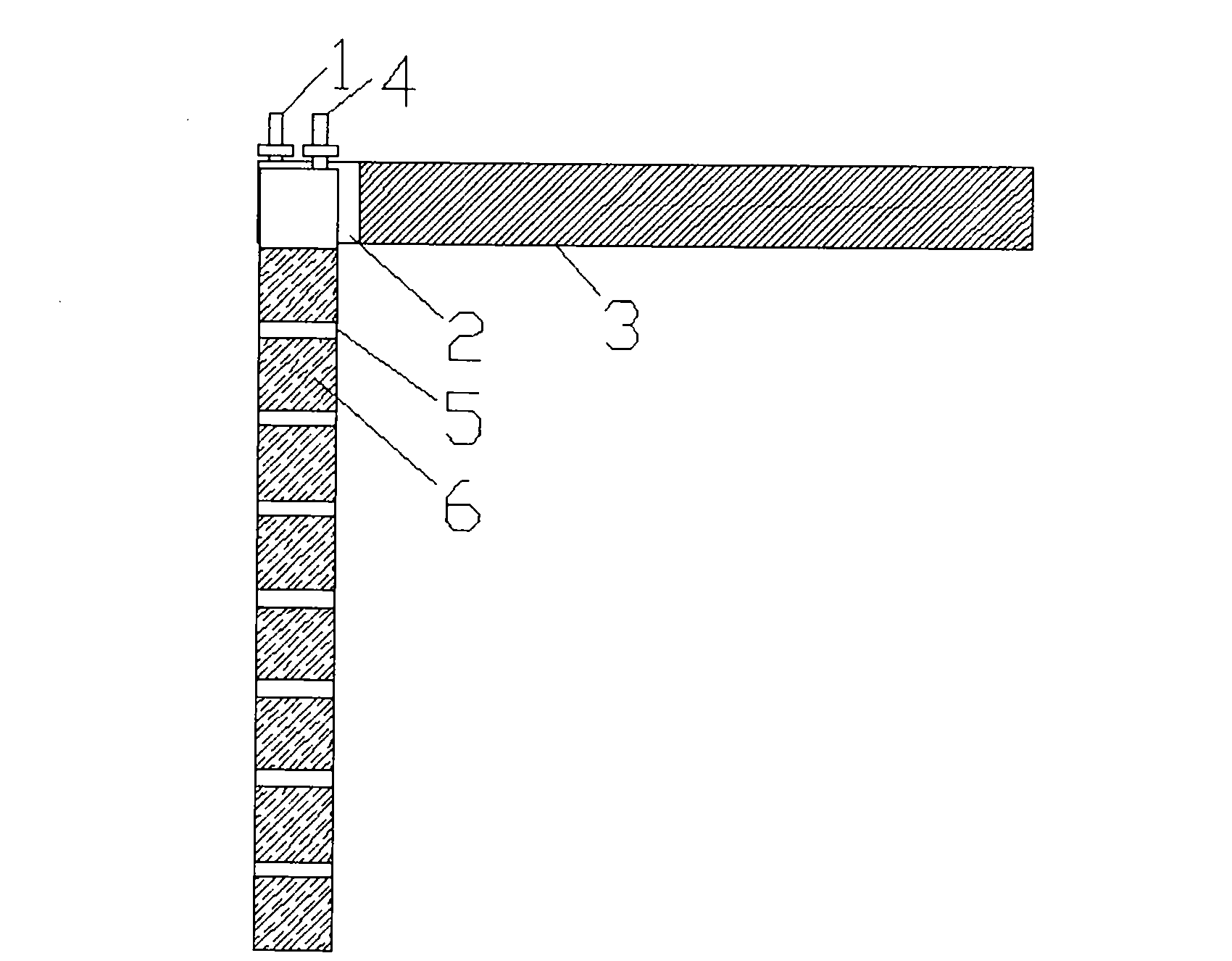

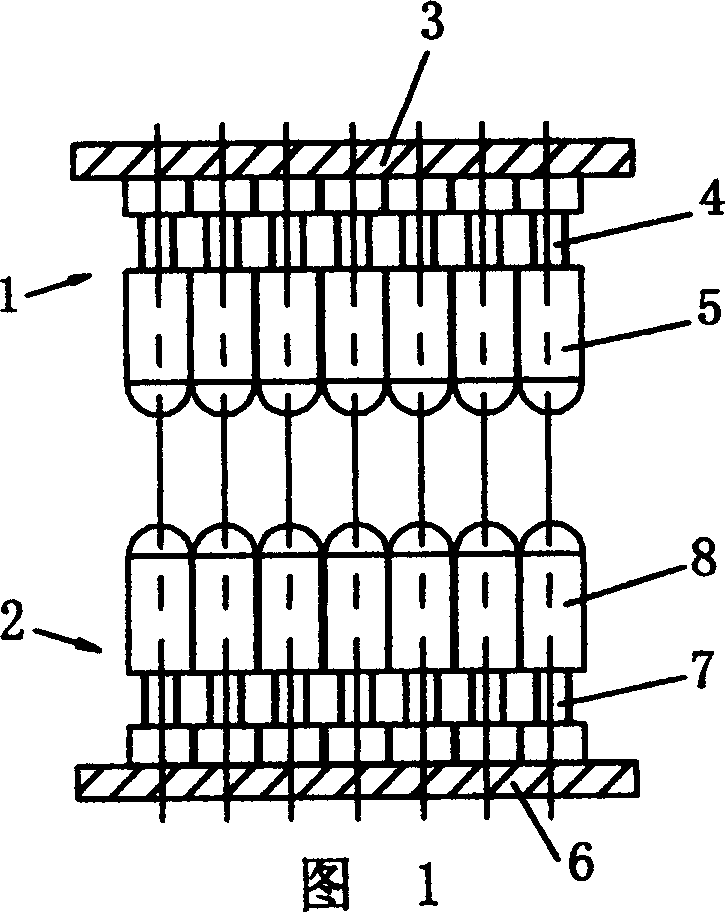

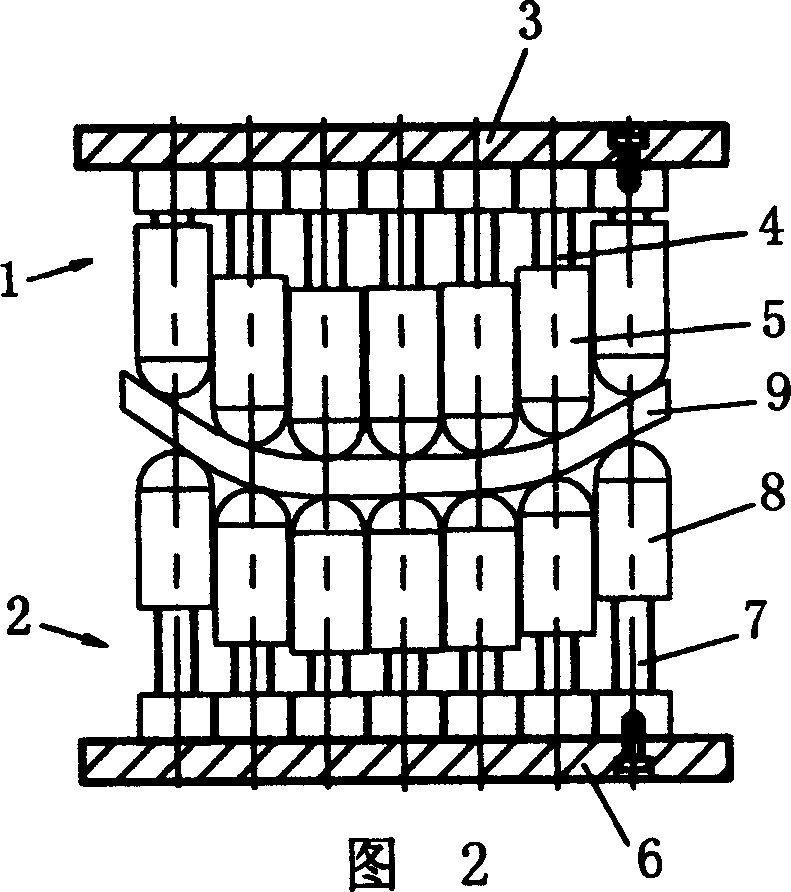

Discrete face mold device for plate material heat forming

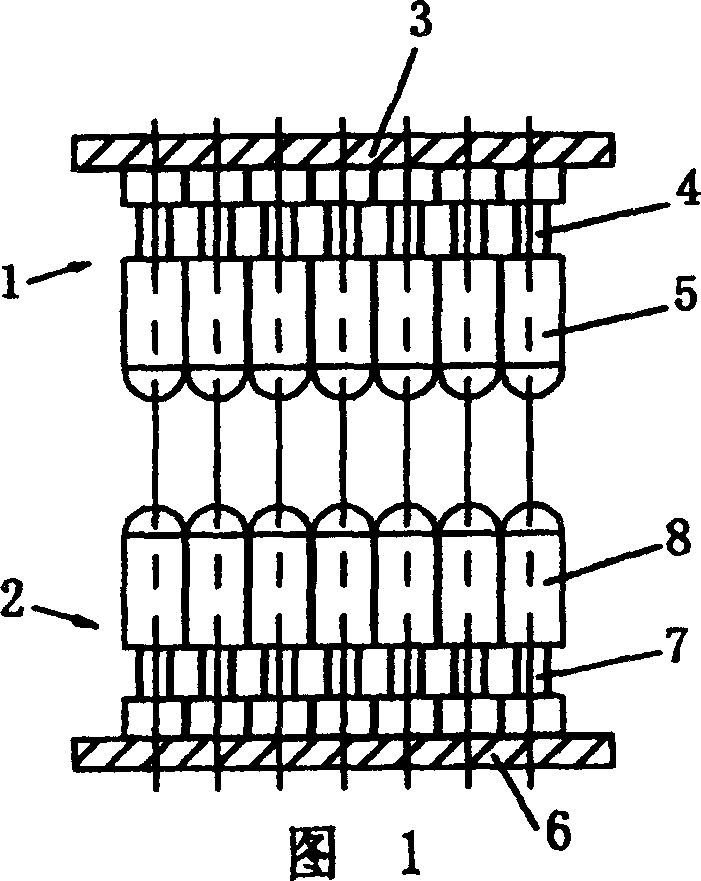

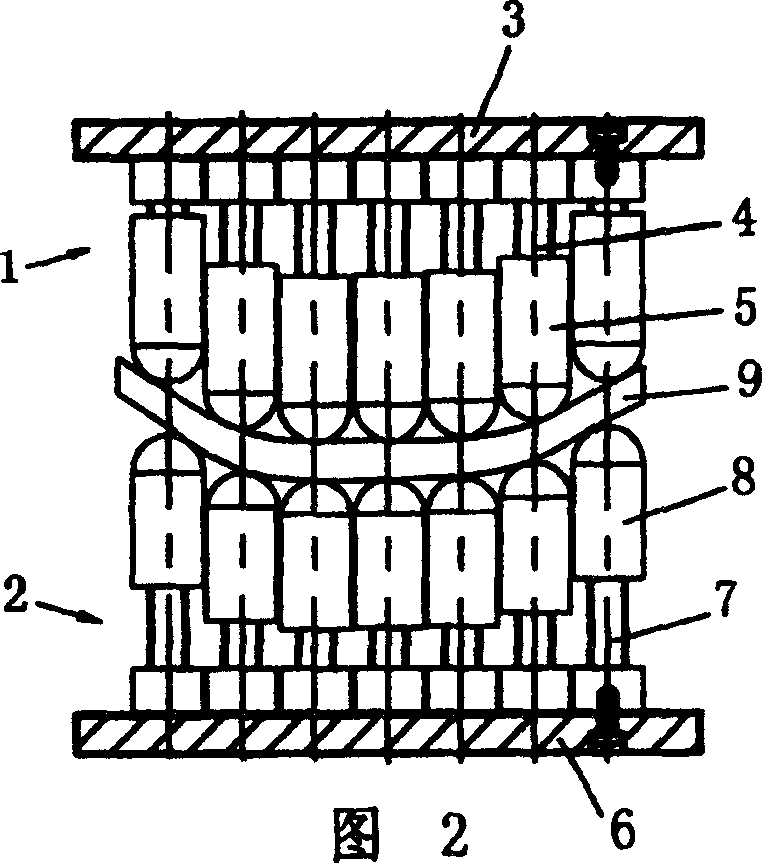

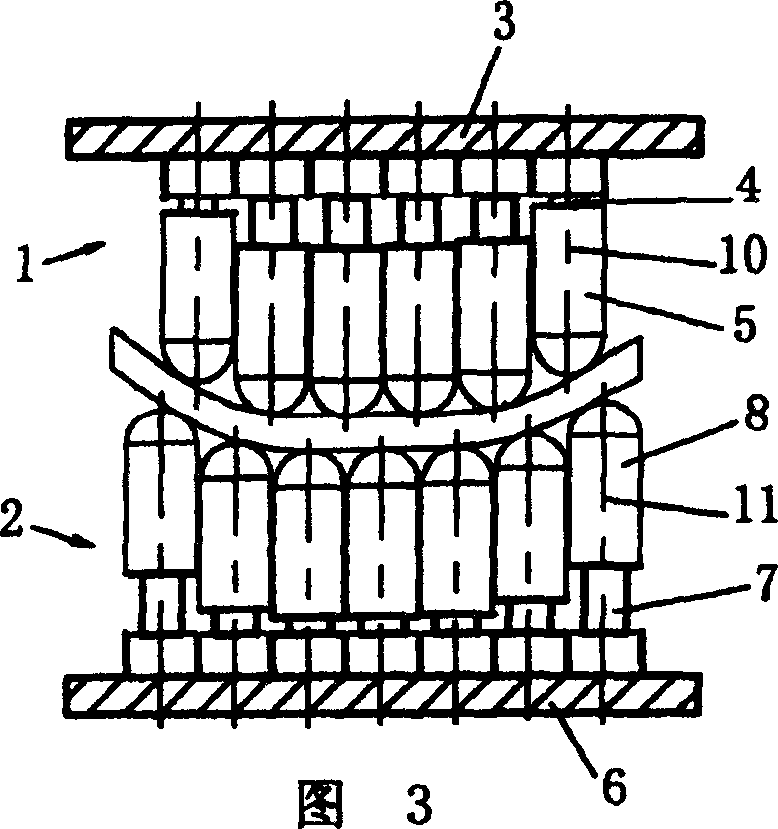

Discrete surface die device for sheet metal thermoforming. There are several closely arranged punches on the upper die (1). The punches are composed of a screw (4) connected to the template (3) and a head body (5) matched with the screw. The head body (5) can move along the screw ( 4) Displacement; there are several closely arranged punches on the lower mold (2), the punches are composed of a screw (7) connected to the template (6) and a head body (8) matched with the screw rod, the head body (8) It can be displaced along the screw rod (7); the punches on the upper and lower dies are corresponding, and the corresponding punches on the upper and lower dies can be on the same axis or staggered from each other. It has the characteristics of simple structure, low cost, convenient operation and maintenance, and the punches can be adjusted to meet various heights. The corresponding punches are misplaced, which can not only prevent some punches from being overstressed or dead, but also make the sheet metal The number of stress points on the projection surface is increased, which is conducive to the more uniform forming of the sheet and the uniform distribution of internal stress, reducing the amount of springback after forming.

Owner:HUNAN UNIV

A kind of manufacturing method of titanium forged flange tee

ActiveCN106475503BHigh tensile strengthHigh yield strengthMetal-working apparatusMaterials preparationElectric arc furnace

The invention discloses a method for manufacturing a titanium-forge flange tee joint. The method comprises the following steps that (1) material preparation is conducted through matching of O-grade titanium sponge and an oxygen bag; (2) firstly, the titanium sponge and the oxygen bag are subjected to piezoelectric electrode treatment, so that an electrode block is obtained, and then an electrode is formed by welding; (3) the obtained electrode is placed in a vacuum electric-arc furnace for secondary smelting treatment, so that a titanium ingot is obtained; (4) heat preservation is conducted on the titanium ingot; (5) the titanium ingot is subjected to upsetting-drawing forging through an oil press, and a titanium square block is obtained after four-time upsetting, four-time drawing are conducted and two-time repeated heating treatment ; (6) the titanium square block is ground and checked, and thus a finished square block is obtained; (7) the finished square block checked to be qualified is machined, and thus a primarily-machined titanium-forge flange tee joint is obtained; and (8) the primarily-machined titanium-forge flange tee joint is subjected to external dimension checking, the diameter of a flange and the wire interval of a hole are checked in sequence, surface polishing treatment is conducted if the primarily-machined titanium-forged flange tee joint is flawless, and thus the titanium-forge flange tee joint is obtained. According to the method for manufacturing the titanium-forge flange tee joint provided by the invention, the problem that the compressive properties of a titanium-cast tee joint and a titanium-welded tee joint are insufficient is solved.

Owner:BAOJI YONGSHENGTAI TITANIUM IND

Preparation method of alloy steel used for manufacturing flanged ball valve body

InactiveCN106967920AImprove high temperature resistanceThe internal atomic structure is stableThermal expansionManganese oxide

The invention discloses a preparation method of alloy steel used for manufacturing a flanged ball valve body. The alloy steel comprises, by weight, 1000-1200 parts of steel, 160-180 parts of copper, 1-10 parts of manganese oxide, 0.5-0.8 part of magnesium, 1-3 parts of aluminum, 0.06-0.25 part of zinc, 0.1-0.3 part of cobalt oxide, 0.4-0.8 part of strontium, 0.08-0.15 part of chromium, 0.5-0.7 part of nickel and 0.001-0.008 part of beryllium. The alloy steel prepared through the preparation method of the alloy steel has good high-temperature resistance. Even the alloy steel is in a high-temperature state for a long time, the internal atomic structure of the alloy steel is stable, and internal stress distribution is uniform. The flanged ball valve body made of the alloy steel is stable in mechanical property and small in thermal expansion coefficient, the valve body and a ball body make tight contact, the sealing property is high and the service life is long.

Owner:高金建

a welding rod

ActiveCN104002060BImprove crack resistanceWelds are strong and firmWelding/cutting media/materialsSoldering mediaNitrocelluloseEcological environment

The invention provides a welding electrode which comprises a welding wire and a coating. The coating comprises, by weight, the components of 34%-37% of nitrocellulose, 36%-38% of calcium carbonate, 7%-9% of ferromanganese, 17%-19% of sodium ferrite and 1%-3% of sodium chloride. The welding electrode has the advantages that nickel which is harmful to human bodies and fluorine which harms the atmospheric ozone layer are not contained, namely cancerogenic substances and harmful gas of fluoride slag are not generated during a welding process, non-toxic performance is achieved, dust is low, electricity is saved, harm and influence on ecological environment and the life of an electrowelding technician are avoided, all kinds of carbon steel, alloy steel and casting pieces can be directly subjected to cold welding without preheating, compared with a similar welding rod, anti-cracking performance is good, super toughness and super plasticity are achieved, different metal materials such as ferrite, pearlite, and austenite with different qualities can be subjected to overall combined welding, and welding seams are firm and solid.

Owner:营口公牛矿山机械设备有限公司

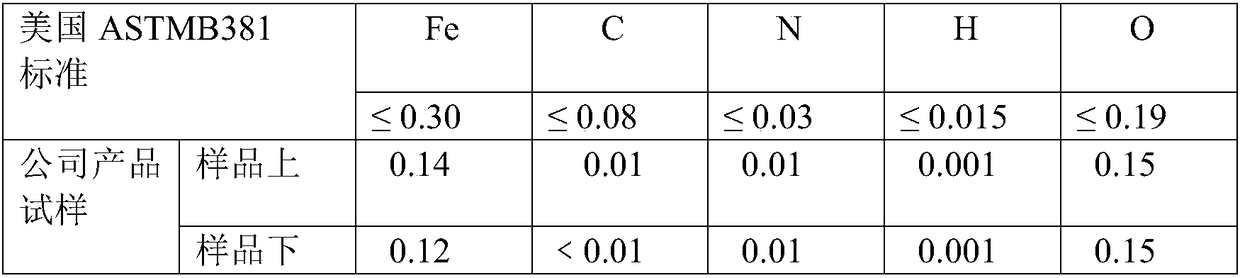

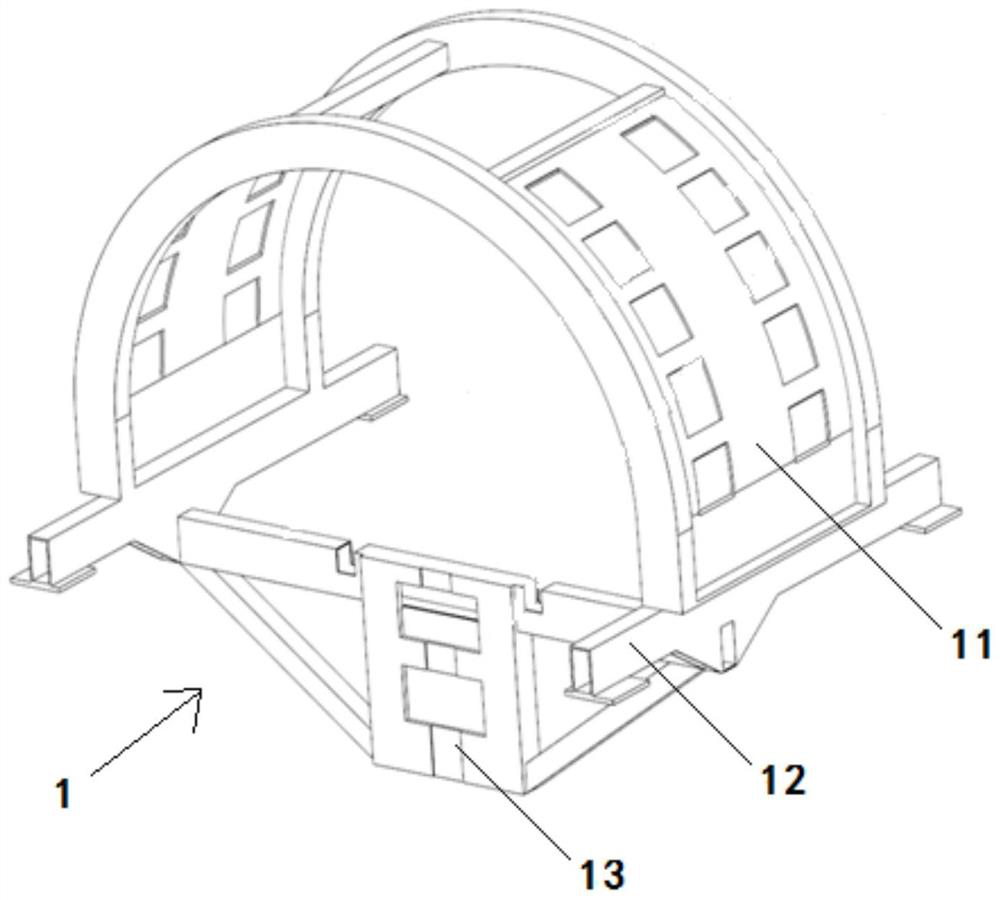

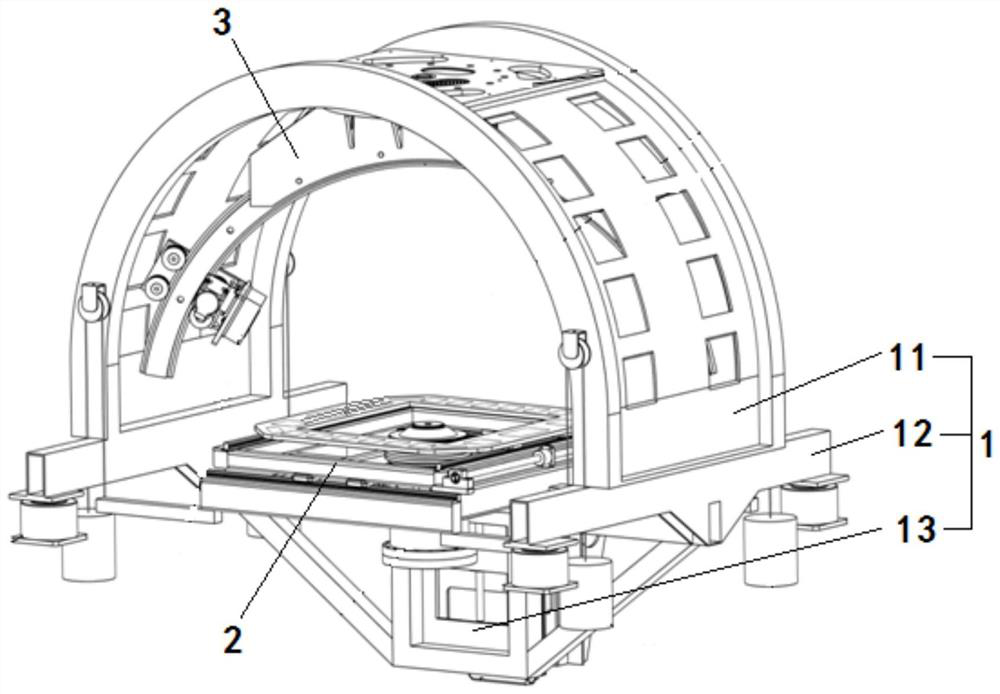

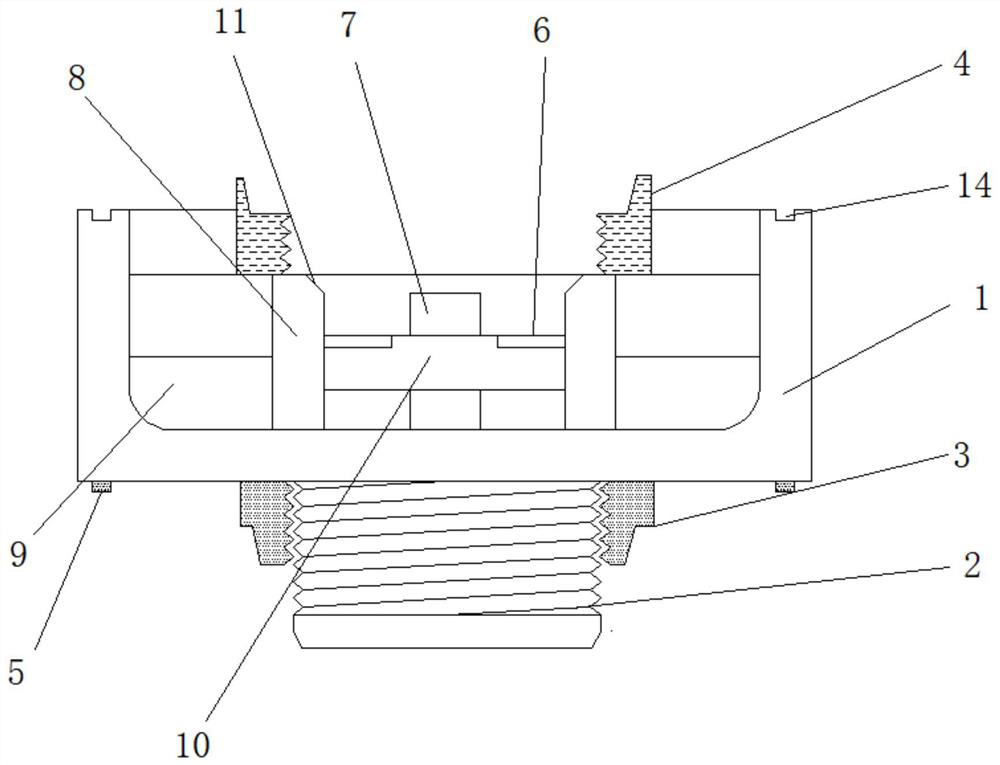

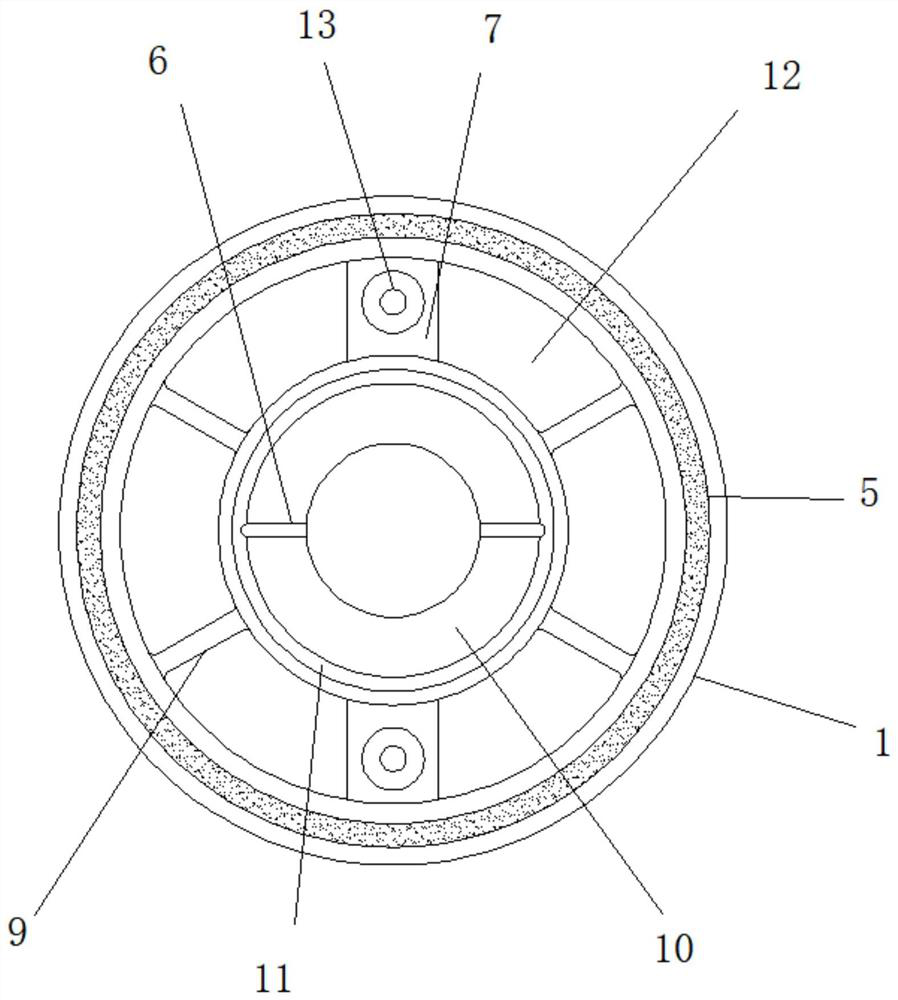

An arch bridge type motion platform for X-ray detection device

ActiveCN110530903BMode shape amplitude is smallRaise the resonant frequencyMaterial analysis by transmitting radiationVibration amplitudeLinear motion

The invention discloses an arch bridge type motion platform for an X-ray detection device, which comprises a platform support frame, a three-axis linear motion mechanism and a two-axis rotary motion mechanism; the platform support frame includes an arch bridge type frame, a horizontal support frame and a vertical support frame There are two horizontal support frames, the upper wall of the horizontal support frame is respectively fixed with the two ends of the arch bridge frame; the vertical support frame is arranged between the two side walls of the horizontal support frame and its side wall is fixed with the two ends of the vertical support frame The three-axis linear motion mechanism is fixedly arranged on the inner side of the vertical support frame; the two-axis rotary motion mechanism is fixedly arranged on the lower side of the arch bridge frame frame top. In the present invention, through the setting of the arch bridge frame, the arch bridge frame is relatively uniform in internal stress distribution compared with the square frame in the prior art, so that the amplitude of the frame mode vibration shape is small, thereby increasing the resonant frequency of the frame and reducing the The impact of environmental vibration on the motion platform keeps the three-axis linear motion mechanism and the two-axis rotary mechanism stable.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Method for producing thorium-tungsten wire

InactiveCN101004995BUniform distribution of internal stressImprove the winding effectCold cathode manufactureThorium nitrateWork Performances

The method includes following steps: adding certain quantity of solution of thorium nitrate into tungsten oxide so as to prepare doped powder of tungsten oxide; deoxidizing the obtained doped powder of tungsten oxide to obtain powder of thorium - tungsten; acid cleaning powder of thorium - tungsten to remove impurity, and producing sintered body of powder of thorium - tungsten; using press work toobtain thorium -tungsten filament with needed diameter, and content of thorium dioxide being 0.7-1.1 wt%, and enwinding thorium -tungsten filament by using wire coil; Finally, straightening filament.The invention raises the rate of finished products, and optimizes working performance of tungsten winding.

Owner:兆恒威勒(石门)钨业有限公司

Aluminum pressure casting with good pressure resistance

InactiveCN112412956AUniform distribution of internal stressImprove stress resistanceNutsBoltsPressure castingRubber ring

The invention discloses an aluminum pressure casting with good pressure resistance. The bottom end of an aluminum pressure casting body is fixedly connected with a threaded steel pipe, the surface ofthe threaded steel pipe is sleeved with a convex nut, the convex nut is of a convex structure, the horizontal section of the convex nut is of an eccentric circle structure, and the convex nut and thethreaded steel pipe are of a threaded connection structure; the inner wall of the aluminum pressure casting body is fixedly connected with fixed blocks, and each fixed block is of a fan-shaped structure, so that the internal stress of the casting can be evenly distributed; and the bottom end of the aluminum pressure casting body is fixedly connected with a rubber ring, and the cross section of therubber ring is of a rectangular structure. The aluminum pressure casting is provided with the convex nut and a concave nut, the left side of the bottom end of the convex nut can apply transverse acting force to the right side to prevent loosening, the interior of the aluminum pressure casting body is composed of the six fixed blocks, and a fixed plate is connected between every two fixed blocks,so that internal stress distribution of the casting is more uniform, and the pressure resistance of the casting is higher.

Owner:高邮市宜达机械配件有限公司

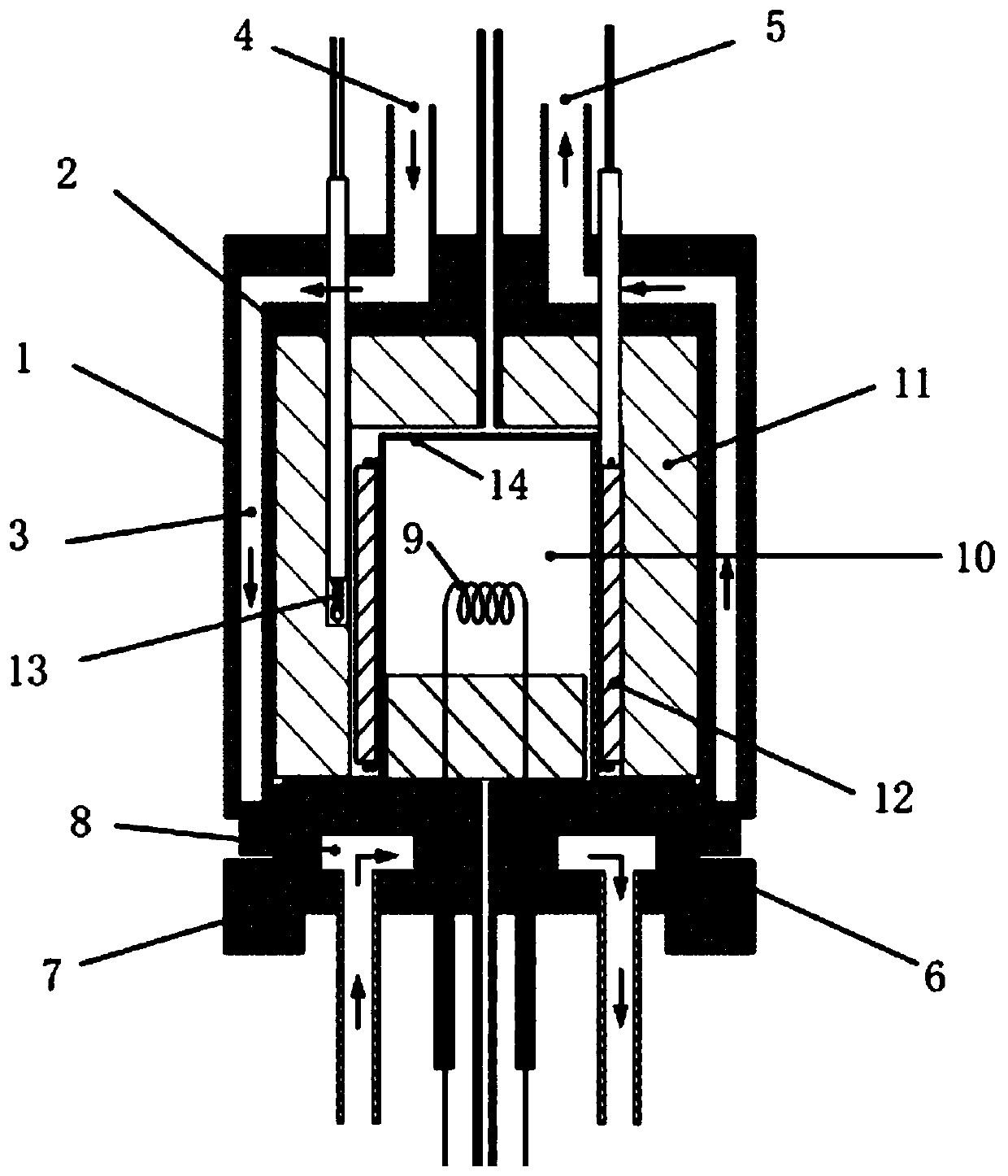

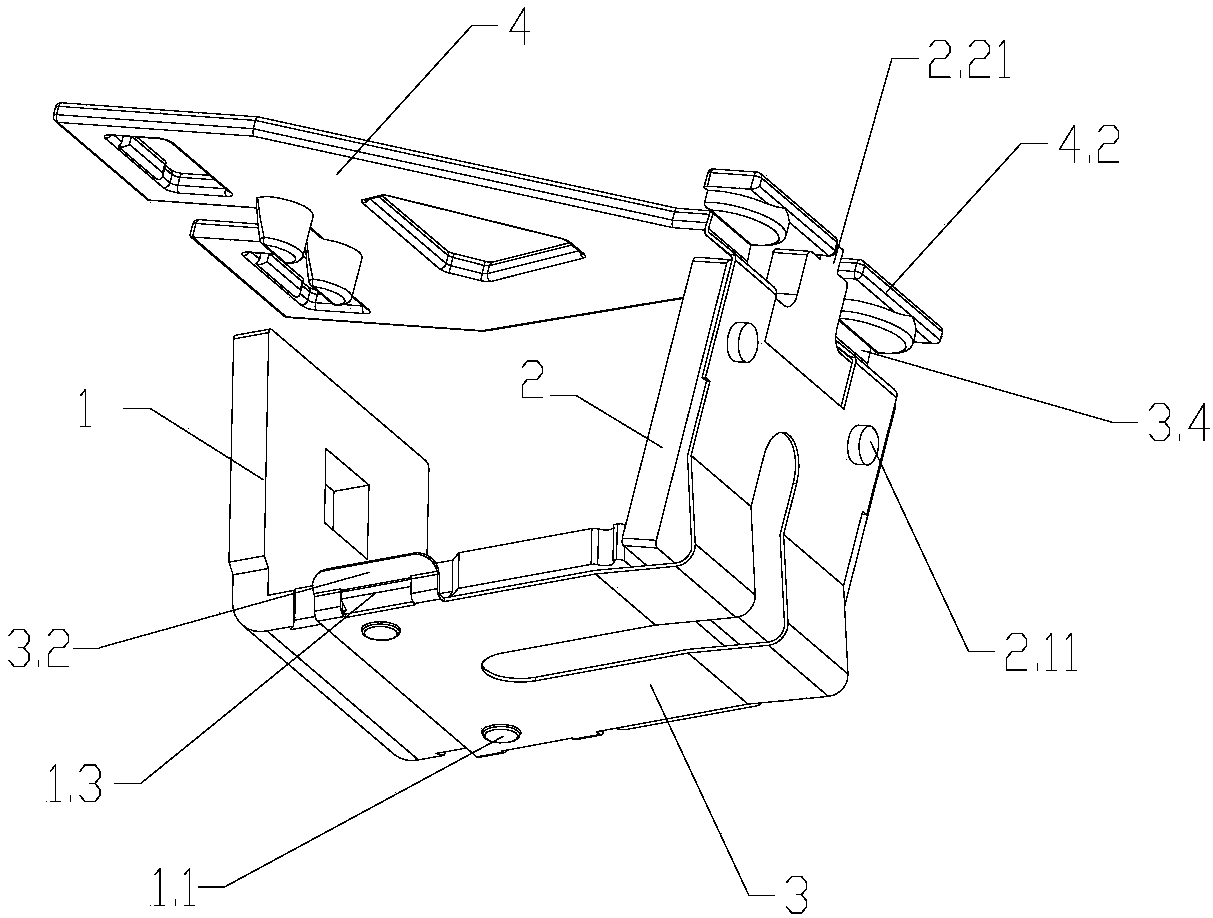

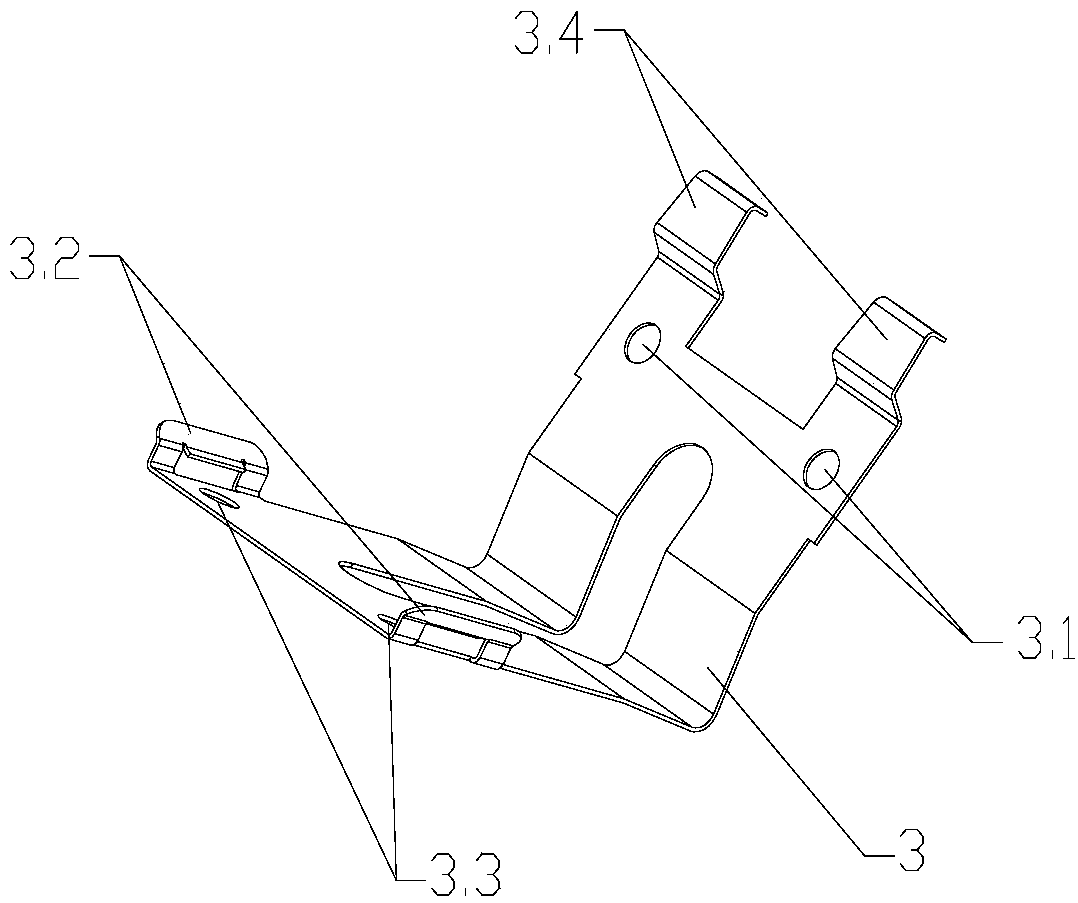

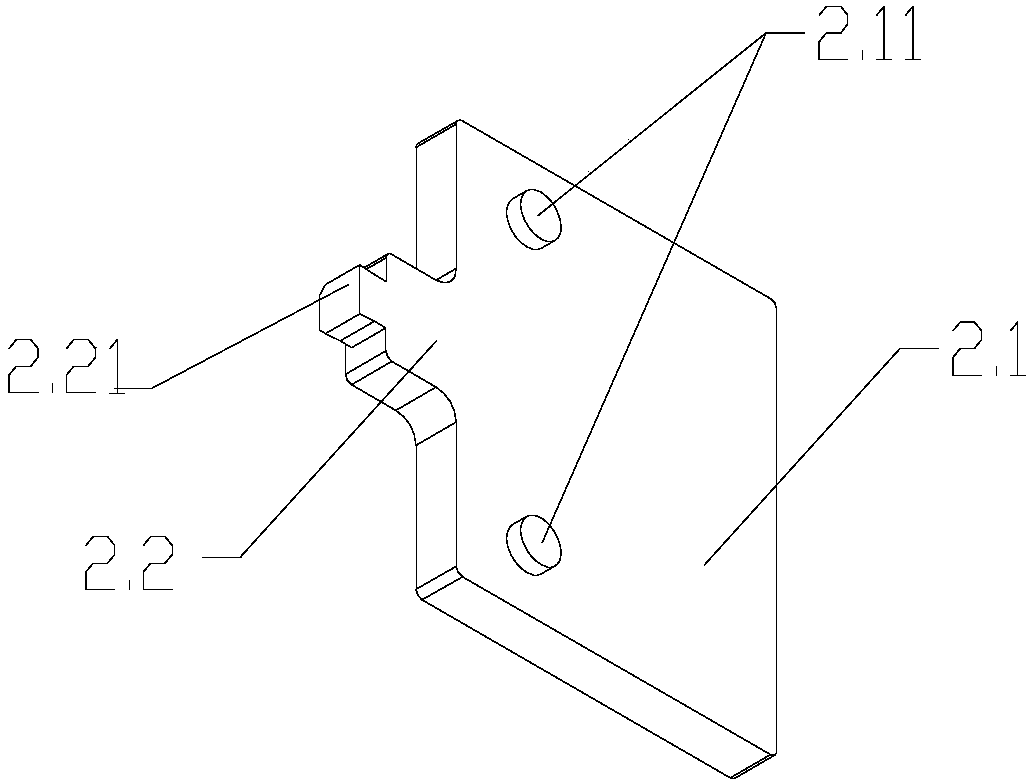

Shockproof relay

PendingCN108257821APrevent deviationImprove stabilityElectromagnetic relay detailsEngineeringElectrical equipment

The invention relates to an electromagnetic relay and particularly relates to a shockproof relay, which belongs to the technical field of electrical equipment. The shockproof relay comprises a yoke, an armature, an elastic piece and a push rod, wherein armature riveting holes in a reversed L-shaped elastic piece vertical section are in matched and fixed riveting with elastic piece riveting terminals of the armature; blocks at the tail part of the vertical section abut against block grooves at an elastic piece connection end of the push rod; clamping blocks of the armature terminal are clampedand inserted in clamping grooves in the push rod; the elastic piece horizontal section is fixed and matched with the L-shaped yoke horizontal section; an elastic piece mounting table of the yoke is nested in a yoke mounting hole in the elastic piece; elastic piece clamping blocks of the yoke are clamped and inserted in buckling loops of the elastic piece; and a pair of elastic piece supporting tables which abut against the surface of the elastic piece is arranged near the yoke blade and on the outer wall of the yoke. According to the shockproof relay in the invention, serial movement does nothappen to the yoke or the armature in a shock working condition, the yoke blade and the armature blade are constantly contacted together, the product stability is good, and automatic assembly can be realized easily.

Owner:YUEQING MEISHUO ELECTRIC

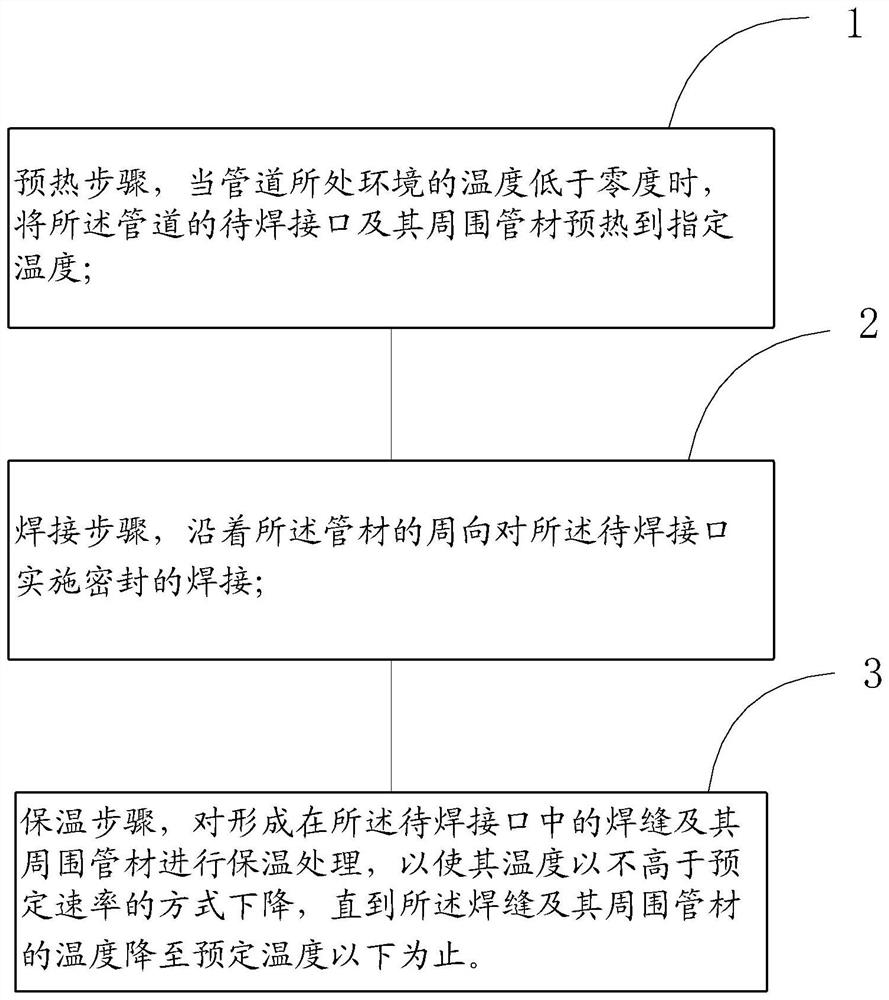

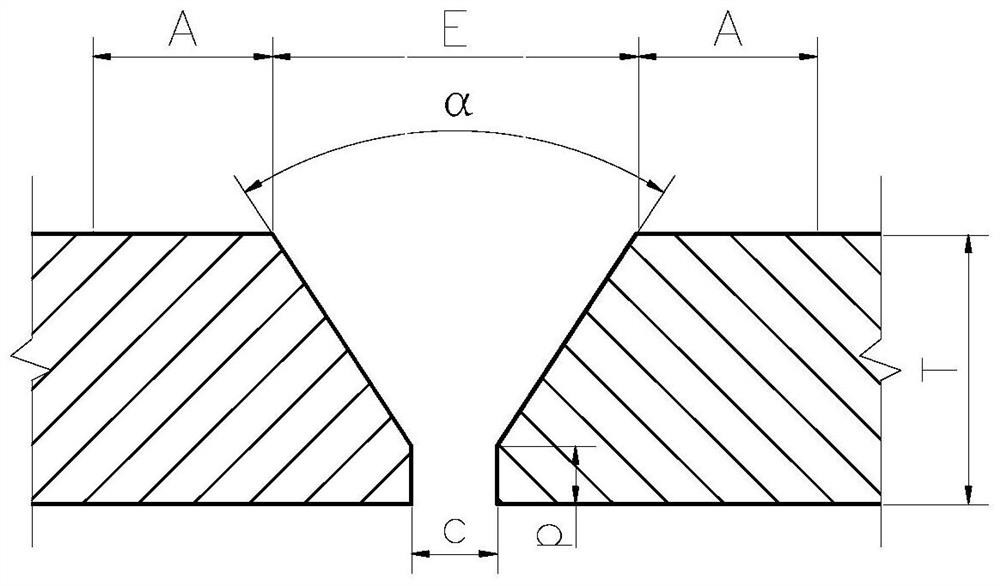

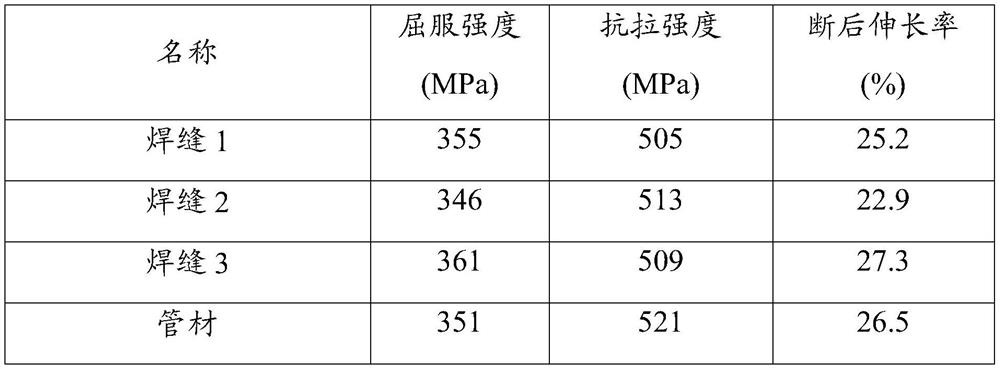

A pipe welding method

ActiveCN109514051BReduce temperature differenceCool evenlyArc welding apparatusThermal insulationEngineering

The invention relates to a pipeline welding method, which specifically includes: a preheating step, when the temperature of the environment where the pipeline is located is lower than zero, preheating the joint to be welded of the pipeline and the surrounding pipe materials to a specified temperature; the welding step, Carry out sealed welding on the joint to be welded along the circumference of the pipe material; heat preservation step, heat preservation treatment is carried out on the weld seam formed in the joint to be welded and its surrounding pipe materials, so that the temperature thereof is not higher than a predetermined The speed decreases until the temperature of the weld and its surrounding pipes drops below a predetermined temperature. The invention controls the temperature of the joint to be welded and its surrounding pipes through the early waste heat and post-insulation, and reduces the residual stress of the joint to be welded and its surrounding pipes, so that the tensile strength of the weld is equivalent to that of the pipe, and solves the problem of low temperature welding Cracks are prone to occur in the end, improve the safe service performance of heating pipes, and protect the work and life of urban residents.

Owner:BAOTOU ENG & RES CORP OF IRON & STEEL IND CHINA METALLURGY CONSTR GROUP BERIS

A non-radiative multi-component composite tungsten cathode material for microwave oven magnetron and its preparation process

InactiveCN103849804BImproved winding performanceWinding Performance GuaranteeTransit-tube cathodesRheniumMicrowave oven

The invention discloses a radiation-free multi-component composite tungsten cathode material for a microwave oven magnetron and a preparation process thereof. The mass percentage of the tungsten electrode material is 0.5%~1.5%, the total amount of rare earth oxides accounts for 2%~3% of the mass percentage of the tungsten electrode material, and the alloy element rhenium accounts for 1%~4% of the mass percentage of the tungsten electrode material, The rest is tungsten. The tungsten cathode material has no radiation, excellent thermal emission performance, high temperature creep resistance, thermal shock resistance, sagging resistance, and long service life. The preparation method of non-radiation multi-element composite rare earth tungsten alloy electrode material for microwave oven magnetron includes preparation solution, drying, reduction, acid washing, cold isostatic pressing, sintering, vertical melting, medium frequency induction annealing, pressure processing, winding and mechanical calibration straight. And the performance is better. The multi-component composite tungsten wire produced by this process can obtain large deformation resistance and anti-sagging performance when it is heated for a long period of time at high temperature.

Owner:深圳市威勒科技股份有限公司

High-performance titanium connecting seal ring and processing method for deep-sea oil drilling and production equipment

ActiveCN105156672BHigh tensile strengthHigh yield strengthEngine sealsFlanged jointsShrinkage rateIngot

Owner:BAOJI YIXIN METALS PROD WORKS

Method for eliminating annealing wrinkles of aluminum alloy strip

ActiveCN113151757AUniform distribution of internal stressAvoid extrusion deformationFurnace typesHeat treatment furnacesHeating timeAluminium alloy

The invention discloses a method for eliminating annealing wrinkles of an aluminum alloy strip, and belongs to the technical field of aluminum alloy production. Before complete annealing, the rolling reduction of the first pass of cold rolling of the aluminum alloy strip is controlled to be 25%-35%; the rolling reduction of the middle pass of the cold rolling of the aluminum alloy strip is controlled to be 25%-40%, and the rolling reduction is gradually reduced by 3%-5% one by one; the final pass rolling reduction of the cold rolling of the aluminum alloy strip is controlled to be 15%-20%; heating is started after the complete annealing, the temperature of furnace gas rises to 400-500 DEG C, and the heating time is longer than or equal to 8 hours; and the furnace gas is heated to a target temperature for the complete annealing, heat preservation is conducted, cooling is conducted to 200 DEG C or below along with a furnace after the heat preservation, and discharging is conducted from the furnace. The invention provides a production method for eliminating the annealing wrinkles of the aluminum alloy strip. The method can solve the problem that after an aluminum alloy cold-rolled strip is annealed, wrinkles appear in the middle of an inner ring of a coiled material in the width direction.

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND

Production technology for quickly synthesizing polycrystalline diamond

ActiveCN103316613BSmall internal stress on the surfaceUniform distribution of internal stressUltra-high pressure processesMetallurgyPolycrystalline diamond

The invention discloses a production technology for quickly synthesizing polycrystalline diamond. Graphite is transformed into polycrystalline diamond under the action of a catalyst through different ultrahigh temperatures and high pressures in a short time. The polycrystalline diamond produced by the production technology disclosed by the invention has small surface internal stress and uniform distribution of internal stress, and the service life of the polycrystalline diamond is greatly prolonged.

Owner:HENAN FAMOUS DIAMOND IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com